Abstract

Hydrothermal carbonization (HTC) has recently emerged as a promising technology for converting diverse forms of waste with a high moisture content into value-added products such as biofuel, biochar, and activated carbon. With an increasing demand for sustainable and carbon-neutral energy sources, HTC has attracted considerable attention in the literature. However, a successful transition from laboratory-scale to large-scale industrial applications entails notable challenges. This review critically assesses the upscaling of hydrothermal carbonization processes, emphasizing the challenges, innovations, and environmental implications associated with this transition. The challenges inherent in upscaling HTC are comprehensively discussed, including aspects such as reactor design, process optimization, and the current treatment technology for process water. This review presents recent innovations and technological advancements that address these challenges and explores integrated solutions to enhancing hydrothermal carbonization’s scalability. Additionally, this review highlights key companies that have developed and implemented HTC plants for commercial purposes. By overcoming the obstacles and achieving advancements in the upscaling of hydrothermal carbonization, this review contributes to the ongoing efforts to realize the full potential of HTC as a sustainable and scalable biomass conversion technology and proposes future directions.

1. Introduction

In the last four to five decades, researchers have conducted extensive studies to find innovative technologies with which to develop sustainable methods to mitigate the environmental pollution caused by organic waste and convert it into renewable energy and valuable products. Landfill and compost are two affordable technologies for treating waste in terms of the economic aspects [1]. However, compost has a large footprint and elicits a lot of complaints from neighbors due to odor issues, and it also generates greenhouse gases such as N2O and CH4. Landfills are also not a suitable solution for the future due to the lack of available land and the potential risk of second-hand contamination such as groundwater and soil pollution. The thermochemical carbonization of biomass has more benefits compared to biochemical treatment. Instead of taking days or moths by the biochemical treatment, this process generally takes only several hours. There are a variety of thermochemical processes for converting biomass into various products with higher carbon content, such as dry pyrolysis and wet pyrolysis which is called as hydrothermal carbonization. Pyrolysis can only be used to treat feedstock with a low moisture content (under 20%), at high temperatures, and with oxygen limitation [2]. However, most organic waste has a high water content and a high degree of heterogeneity in form and composition. To utilize this method, an additional pre-drying step is required, resulting in high energy consumption and increasing operating costs. Nevertheless, hydrothermal treatment can overcome these drawbacks. It enables the treatment of wet waste without pre-drying, saving up to 70% energy consumption via the recirculation of wasted heat [3]. As Kruse et al. [4] mentioned, subcritical water hydrothermal treatment can be “an excellent reaction environment, reactant, and solvent for a diverse range of reactions”. Hydrothermal processes include thermal hydrolysis (THP), hydrothermal carbonization (HTC), hydrothermal liquefaction (HTL), and hydrothermal gasification (HTG) under different operating conditions [5]. In Table 1, four different (dry) pyrolysis and four different wet pyrolysis methods are compared in terms of their operating conditions and final products.

Furthermore, thermal hydrolysis, an example of successful upscaling to industrial and commercial scales, has drawn significant attention for treating sewage sludge, which is not easily degradable because of its glue zone or sticky phase zone. The thermal hydrolysis treatment process (THP) breaks down the organic structure of feedstock through the process of cracking under high-pressure and high-temperature steam [6]. This process is known as the pre-treatment process of anaerobic digestion (AD) for producing biogas and fertilizer from sewage sludge, and it is applied in wastewater treatment plants. Meanwhile, there is always an argument for a clear cut between the THP and HTC, but the authors want to define the THP as an endothermic reaction that absorbs heat from its surroundings, while HTC is an exothermic reaction thanks to its decarboxylation reaction [7]. For its energy consumption efficiency and the high demand for renewable fuel, HTC stands out as a developing technology in contrast to the other thermochemical methods used for treating wet biomass. HTC was known to researchers over a century ago and was first discovered by Friedrich Bergius, who was awarded the Nobel Prize in 1913 for the transformation of cellulose, through wet thermochemical conversion, into different products with various applications [7,8]. HTC is a complicated simultaneous process involving hydrolysis, dehydration, decarboxylation, condensation, aromatization, and polymerization [9,10,11]. Zhung et al. [11] presented the details of the mechanisms of lignocellulose and non-lignocellulose biowastes during the HTC process. In this process, some organic compounds are present, such as acetic acid, alkenes, aldehydes, and aromatics like phenolic compounds and furan. The decarboxylation process inevitably produces CO2 gas. The major solid product of HTC, hydrochar, has an enriched carbon content with different characteristics, different yields and a wide range of HHVs, depending on the feedstock and process conditions, such as the temperature, residence time, catalyst, and pH [12,13,14,15]. A higher temperature and a longer residence time result in a decrease in the yield rate of hydrochar, while a higher carbon content in hydrochar with a higher heating value results in lower hydrogen and oxygen content [4,7,8,9,10,15]. In the HTC process, one type of feedstock is normally used as an input, but reliance on a single feedstock boosts the uncertainties regarding the sustainability of industrial production methods. Recently, co-hydrothermal carbonization has been identified as a promising method for treating two or more types of feedstock combinations such as biomass–biomass, biomass–PVC, and biomass–coal [16,17]. Most studies have reported that co-HTC treatment can enhance the carbon content of hydrochar, increase its solid yield, and yield higher heating values (HHVs), as well as provide higher dechlorination/desulfurization efficiency when compared to a single feedstock. HTC is an elaborate thermochemical process dealing with many reaction mechanisms and pathways that result in changes in the chemical and structural compositions of hydrochar, as reported by Xue Y. et al. and Fakudze S. et al. [18,19,20]. Microwave-assisted HTC is also a new way of addressing the limitations associated with the traditional HTC methods, such as heat loss, uncontrolled side reactions, and non-selective heating. This technology demonstrated the capability to generate hydrochar with characteristics comparable to those of solid fuel with energy efficiency [21,22]. To further develop this method, more large-scale trials need to be conducted.

Due to the demand for the upscaling of the HTC process to the pilot and industrial scales, it is necessary to review the current upscaling scenario, accounting for its challenges in terms of the technical aspects and environmental and economic effects. There are some review papers discussing the status of industrial-scale HTC by Romano et al. and Child, M. [8,14]. In these papers, the current trend of upscaling from the lab to the industrial scale and new approaches to designing and implementing an HTC plant at a large scale are reviewed to explore the potential of HTC technology’s expansion in this industry. Additionally, different combinations of HTC with other technologies and solutions for treating process water are presented, alongside the future direction of HTC technology.

Table 1.

Comparison of different thermal treatments.

Table 1.

Comparison of different thermal treatments.

| Process | Moisture of Feedstock | Process Conditions | Main Product/Purpose | Ref. |

|---|---|---|---|---|

|

Fast Pyrolysis | 10–20% |

800 °C or Higher, 0.5–10 s, Limited Oxygen Supply, 1 bar | Bio-oil (60–75%) | [23,24] |

| Intermediate Pyrolysis | <10% |

400–500 °C, 0.5–20 s, Absence of Air, 1 bar | Biochar (25–40%), Bio-oil (35–50%), Gas (20–30%) | [2,24] |

|

Slow Pyrolysis | 15–20% | 300–500 °C, 5 min–12 h, Absence of Air, 1 bar | Solid (25–35%), Liquid (20–30%), Gas (25–35%) | [23] |

| Torrefaction | <10% |

200–300 °C, 0.5–4 h, Absence of Air, 1 bar | Char (80–90%) | [25] |

| HTC | 70–85% |

180–260 °C, 0.5–8 h, Vacuum, 10–60 bar | Hydrochar (50–80%) | [4,5,9] |

| HTL | 70–85% |

260–375 °C, Vacuum, 50–220 bar | Bio-oil, Bio-crude (30–60%) | [5] |

| HTG | 70–85% |

375–800 °C, Vacuum, 220 bar or higher | Syngas (30–80%) | [5] |

| THP | 70–85% | 140 °C–170 °C, 20 min to Several Hours, 6–9 bar | Pre-treatment of AD, Fertilizer | [6] |

2. Upscaling Case of HTC and Challenges

Although HTC technology has attracted significant attention from numerous researchers on producing hydrochar with various applications, the corresponding approaches are mostly implemented in batch mode with a lab-scale autoclave, bench scales, and a few pilot scales. A review of the HTC process from the lab to pilot scale is presented in Table 2 below to reveal the challenges and perspectives at a large scale.

To obtain the intended physical-chemical characteristics of the HTC product, it is crucial to adjust the specific process conditions. These parameters typically include temperature, residence time, pressure, catalyst, biomass/water ratio (BWR), and other relevant factors.

The relations of process parameters at the lab and pilot scales are useful for obtaining more favorable working circumstances on an industrial scale. Areeprasert C. et al. used a pilot-scale cylindrical batch-type reactor with a capacity of 1 m3 to apply the optimal conditions, which can be determined from lab-scale experiments on a vertical reactor with a size of 500 mL [26]. The optimal process condition of the lab-scale process was 200 °C, whereas 197 °C with the same holding time of 30 min is optimal for the pilot scale. The fuel recovery of the pilot scale has a larger gap than that of the lab scale due to the mass loss. However, 15.4% of the required energy for the whole HTC process is reduced when scaling up due to the utilization of a part of the obtained hydrochar as boiler fuel. The heating value of hydrochar at the pilot scale was slightly higher than that at the lab scale; this result is in agreement with the findings of the study by Gusman, M. H. et al. [27]. Teribele, T. et al performed an experiment on a pilot plant involving the treatment of corn stover residues in a cylindrical reactor at 250 °C, employing a duration of 1–4 h with different BWRs [28]. Pre-treatment of some feedstock, such as corn stoves, wood waste, or green waste, before transferring it to the HTC reactor is sometimes required to ensure operating efficiency and stability. Reducing biomass size can enhance the reaction kinetics when the feedstock is milled or sieved to achieve a specific particle size. The results also demonstrated that a higher BWR resulted in a higher hydrochar yield, a result that is in agreement with other research [29,30,31], while a longer residence time reduced the solid yield but increased the carbon content in hydrochar [32,33]. The optimal conditions for decomposing corn stover in this study were achieving a BWR of 1:10 in 4 h. In many studies, the use of catalysts in the HTC process demonstrated the ability to increase the heating value (HHV) of hydrochar and decrease the reaction time and temperature [34,35,36,37,38]. Shin et al. [39] produced bio-coal products from wood waste and conducted a comparative study with and without catalysts in HTC process at lab and pilot scales. The pilot plant was a binary reactor system designed by Kinava Co. and presented in the previous research reported by Mackintosh et al. [40]. The hydrochar produced through the pilot-scale HTC process at a temperature of 220 °C with a 1.5 h residence time and a catalyst showed a high calorific value of over 27 MJ/kg, which is 18% higher than that of coal. It also satisfied the hazardous substances standard, similar to the lab experiment’s results, but required a 1.5-times higher catalyst concentration. This study indicated that the development of catalysts for each feedstock was crucial for industrial applications to increase the value of hydrochar. The mixture of different feedstocks to add in the HTC process called co-HTC is an innovative method for treating different wastes at the same time. A pilot-scale plant involving a reactor volume of 200 L was used to perform the co-HTC process of a 20kg mixture of paper waste and food waste according to the optimal condition at the lab scale [41]. The results indicated that the mixture ratio with the higher mixture ratio of paper waste significantly increased the carbon content and calorific value of hydrochar. This should be studied to attain the optimal ratio when upscaling, and the mixture of different types of biomass waste will contribute to not only reducing large amounts of waste but also enhancing the properties of HTC products.

Based on the above experiments, the optimal temperature and catalyst concentration could have a minor gap between the lab and pilot scales, and this discrepancy extends to the residence time and BWR as well. The mixture of two or more different feedstocks could affect upscaling in terms of hydrochar characteristics and yield rate. Determining the trend of temperature after conducting many trials at both the lab scale and pilot scale is important before designing a large plant. These determinants can predict the trend of the characteristics of final products and operating conditions and be used to propose the optimal design for upscaling HTC plant. Choosing between a batch reactor and a continuous reactor is a significant factor in large-scale hydrothermal carbonization. In small-scale experiments or some of the above pilot-scale trials, a batch reactor was mostly used due to its easy handling and ability to connect to various feeding systems. However, the drawback of a batch reactor is the interruption of the process required to fill an empty reactor [42]. Meanwhile, continuous reactors are more complex and require a special design to handle the flow stream of a feedstock [43].

Hoekman S. et al. [44] reported the fabrication of a larger-scale process development unit (PDU) with a V-shaped tubular design in order to carry out a semi-continuous HTC process for bio-fuel production from 3 kg of wood chips. The hydrochar properties in this system were aligned with the results obtained in a batch reactor. A twin-screw extrusion system (TSE) developed by Hoekman S.’s group was used to perform a fast HTC to treat loblolly pine feedstock in continuous mode [45]. The biomass was fed and then carbonized and cooled in one direct flow. This approach allowed for a slight reduction in reaction time, but the reaction temperature of this system is higher, amounting to 290 °C, compared to the batch process’ reaction temperature of 230 °C in 30 min. Its hydrochar, however, was produced in a higher yield than the batch process with similar process conditions (54.2–69.7% vs. 50.9–63.7%). In another study, Ipiales, R.P. et al. performed a swine manure treatment (TS 5%) experiment to compare batch and continuous operation [46]. HTC in batch mode was carried out in a cylinder-type Zipper Claver pressure vessel with a volume of 4L at the temperature in range of 180 to 250 °C for 45 min, while other reactors were used in continuous mode. The continuous-type pilot reactor comprises a feeding tank with stirring capacity and employs a screw pump to convey the feedstock to the reactor. The reactor, made of stainless steel, is a tube equipped with a mixing system designed to prevent the settling and buildup of solids on its walls. The tube reactor is divided into five zones, namely, two for pre-heating and three for the reaction, which allows the process to run continuously and be more complex than the batch system. The hydrochar characteristics that were obtained at similar operating conditions from batch and continuous reactors were compared. The HHV and carbon content were similar in both modes, but continuous operation provided a much higher yield of hydrochar than that of the batch process (22.7–71.8% vs. 19.9–42.9%). The process water of the continuous reactor was also more biodegradable than that of the batch reactor. These results indicated that the HTC process induced using a continuous reactor provides higher quality in terms of both solid and liquid products than batch reactors. However, a continuous reactor has a more complex system to deal with inputting the feedstock with a high-pressure pump working against the inner pressure of the reactor. Therefore, continuous reactors are not profitable because of high CAFEX when upscaling in a large plant for commercial/industrial purposes. On top of this, the pipe-type continuous processes inevitably have inherent limitations regarding capacity. The various solutions to treat biomass waste through HTC process using batch reactor and continuous/semi-continuous reactor are presented in Section 3.

For the post-process of HTC, the solid phase and liquid phase are separated for further treatment. The final solid product, hydrochar, can usually be used as solid fuel. For other applications, hydrochar should be treated in more steps so that it can be utilized in different applications. Ketwong, T. et al. [47] produced activated carbon in a pilot-scale reactor through the activation process adding to the HTC of an empty fruit bunch. Moreover, hydrochar could be used as fertilizer [48,49] and biochar [50,51,52], which should be more readily implemented in upscaling projects. Process water is one of the drawbacks of HTC and is hard to manage on a large scale, so the valorization of process water (PW) is critical. The main characteristic of PW is that it is highly acidic, with a pH in the range of 2.7–4.5, and contains toxins with high COD and TOC, alongside complex recalcitrant organic compounds [53,54,55,56]. Anaerobic digestion (AD) is a possible method for treating PW to produce biogas for energy applications [57,58,59,60]. This combination was demonstrated in a 25 L reactor by Oliveria, L. et al. [61] for producing biogas, although it eslimits the biogas generation due to recalcitrant chemicals. The recirculation of PW into the HTC process is applied to mostly reduce the amount of fresh water, increase the hydrochar yield, improve the energy efficiency, and make the HTC process more environment-friendly [62,63,64,65,66]. HTC PW can be used for nutrient recovery [67,68], liquid fertilizer [69], bio-chemical production [70], and algae cultivation [71,72]. Wet oxidation has recently become well-known as an advanced technology for treating HTC process water in order to decompose the organic compounds, offering the ability to reduce COD by 50–70% and allowing for the recovery of energy or valuable byproducts from the treated water [73,74,75]. In fact, the use of HTC PW reformation to produce hydrogen and clean water may play a promising role in the future [76,77].

Table 2.

The upscaling of HTC from the lab to bench and pilot scales.

Table 2.

The upscaling of HTC from the lab to bench and pilot scales.

| Feedstock | Reactor | Process Conditions | Final Products | Ref. |

|---|---|---|---|---|

| Paper Sludge |

Lab: 0.5 L Pilot: 1000 L Batch |

Lab: 180–240 °C, 2.8–2.4 MPa, 0.5 h Pilot: 197 °C, 1.9 MPa, 0.5 h |

Solid Fuel Lab: Up to 13.6 MJ/kg Pilot: 14.1–14.7 MJ/kg | [26] |

| EFB |

Lab: 2.5 L Pilot: 250 L Batch | 175 °C, 0.5 h, BWR: 1:3 |

Solid Fuel, Lab: 18.5 MJ/kg; Pilot: 18.56 MJ/kg | [27] |

| Corn Stover |

Pilot: 18.75 L Cylindrical Batch | 250 °C, 1–4 h, BWR: 1:10, 1:15, 1:20 |

Biochar Surface Area: 4.35 m2/g, Solid Yield: 31.08–35.82%, | [28] |

| Wood Chips |

Lab: 2 L Pilot: 40 L Semi-continuous |

235–275 °C, 0.5 h |

Solid Fuel HHV: 22–28 MJ/kg | [44] |

|

Swine Manure |

Lab: 4 L (Batch) Pilot: Screw Continuous |

180–250 °C, 0.75 h |

Solid Fuel HHV: 19–21 MJ/kg, FC: 22–24% | [46] |

|

Wood Waste |

Lab: 0.2 L Pilot: 500 L Batch |

220 °C, 1.5 h Catalyst |

Solid Fuel, HHV: 27 MJ/kg | [39] |

| Food Waste and Paper Waste |

Lab: 0.5 L Pilot: 200 L Batch |

Lab: 150–280 °C, 1.3–5.5 Mpa, 0.5 h Pilot: 200 °C, 1.6 MPa, 1 h |

Solid fuel, HHV up to 17.2 MJ/kg | [41] |

| EFB |

Pilot: 1000 L Batch | 200 °C, 20 bar, 0.5 h + Activation (KOH, 800 °C, 1 h, Ar, Air) |

Activated Carbon SSA: 810 m2/g Vpore: 511 cm3/g | [47] |

| Agriculture Residue |

25 L, Autoclave Batch | 180–220 °C, 4 h |

Solid Fuel, Yield of 52.5%, HHV: 26.6 MJ/kg, Biogas: 16.3 L CH4/kg | [61] |

To improve energy recovery, it is essential to combine HTC with other methods in a process and then perform different technical experiments with mass and energy balance analysis to support commercialization. Attasophonwattana, P. et al. [78] integrated a HTC pilot-scale involving 1 m3 reactor with gasification of AD system to process the oil palm fruit bunch (EFB) based on a circular-economy. This pilot-scale project showed a potential for energy recovery, a positive environmental influence, and economic efficiency when combining these technologies in one process to treat waste.

One essential method for upscaling from the small scale to the large scale is simulation. After obtaining data from numerous experiments on a small scale, the results can be used to predict the trend of operation for the HTC process on a large scale. The simulation of the HTC process represents an innovative approach that consolidates findings from extensive experimental HTC investigations involving diverse feedstocks. Using Comsol and Multiphysics for the reactor design allows for the evaluation of the reaction kinetics, mass, and heat transfer and the prediction of the optimal reaction conditions [79,80]. Modeling the whole HTC process or its combination with other technologies has been attempted using Aspen simulation (Aspen Plus V11.1) [81,82] or artificial neural networks [83,84]. Ismail et al. [85] conducted a numerical evaluation of HTC process parameters to evaluate the efficiency of HTC in converting municipal waste into hydrochar on a commercial scale. The benefit of such simulations is their ability to reduce experiment fees by estimating mass and energy balance, reaction conditions, solid yield, and even the properties of products. The simulations can be integrated with life cycle assessment (LCA) and techno-economic analysis to evaluate environmental and economic implications in a general way [86,87,88]. Mohammadi, A. et al. [89] performed an LCA analysis on two different scenarios for a combination of HTC on a large scale and combined heat and power systems (CHP), which can offer a synergistic approach to sustainable energy production and waste management. Further research is required to enhance the reliability of the models, ensuring their accuracy through comparisons with real-world applications.

An overview of upscaling challenges has been presented, revealing that the challenges to upscaling are the optimal operating conditions for the process, the reactor type or process type, the post-treatment of process water from the HTC reactor, and the method used to efficiently enhance the HTC process using other facilities. To provide a more comprehensive viewpoint, Section 3 explores commercial HTC companies and their technologies to resolve the aforementioned challenges when operating at an industrial scale.

3. Industrial-Scale Review

The commercialization of hydrothermal carbonization involves addressing technical, economic, and regulatory challenges. By strategically navigating these factors, businesses can unlock the full potential of HTC technologies and contribute to sustainable and environment-friendly solutions. After conducting numerous trial tests, several companies have developed processes for creating commercial HTC technologies on a large scale. An overview of recent commercial HTC technology is shown in Table 3.

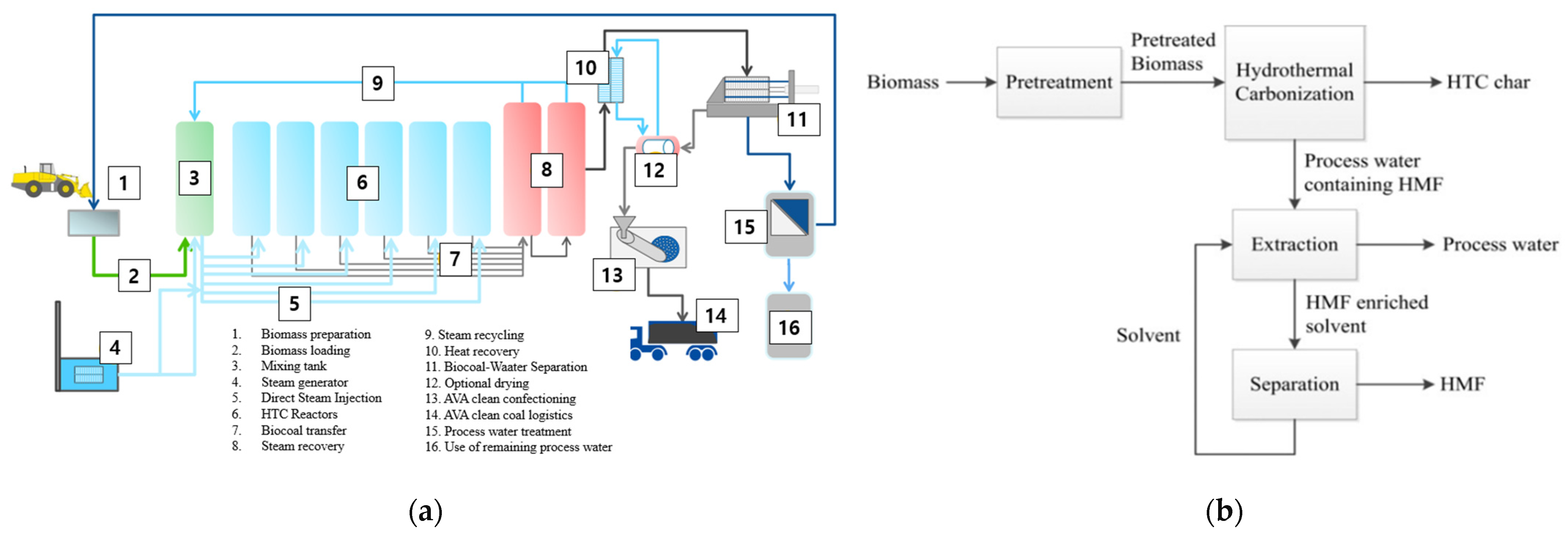

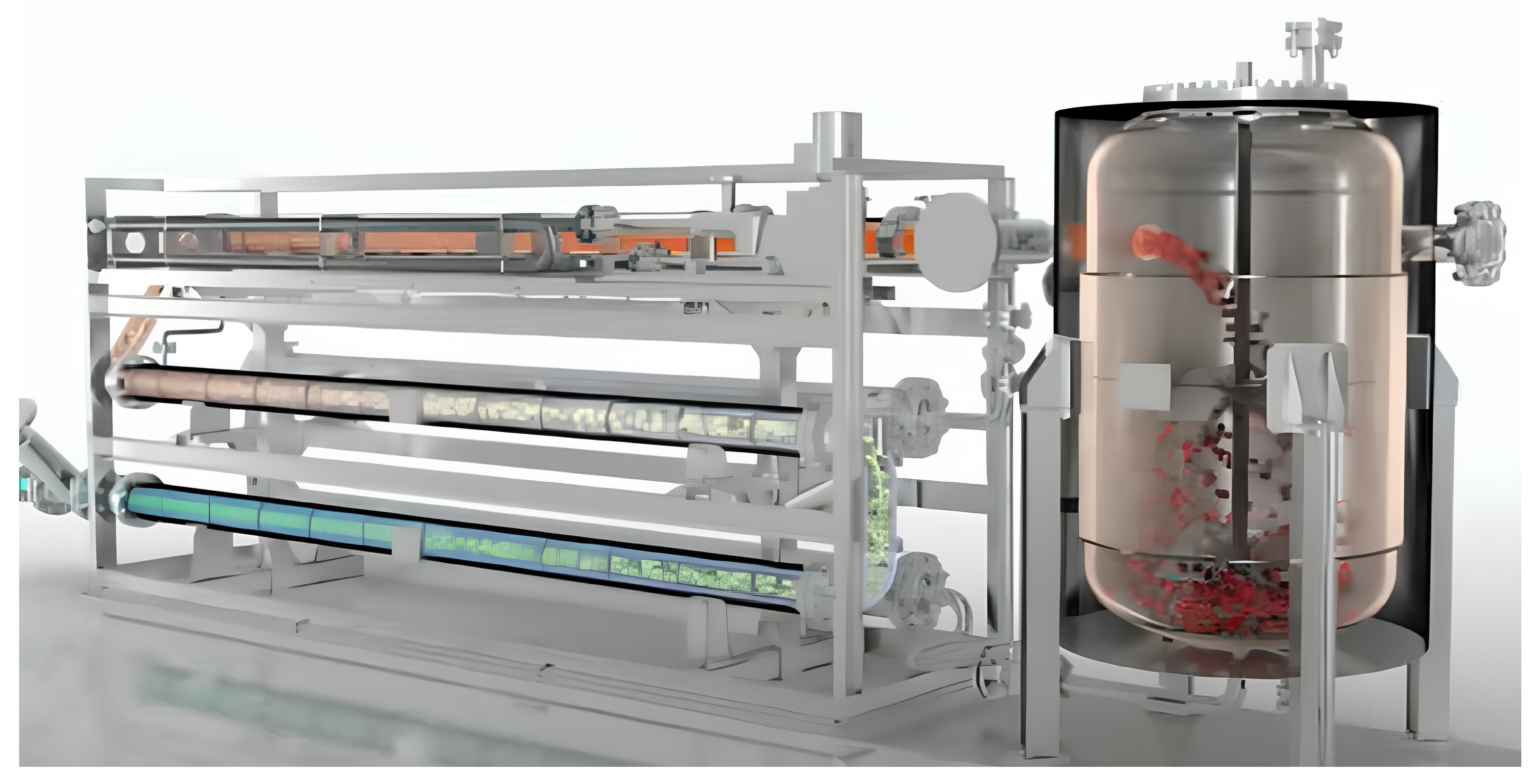

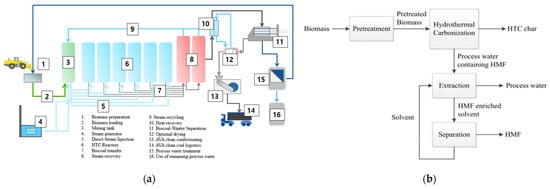

As mentioned in Section 2, the drawback of the batch reactor during a scale-up is the interruption of the process required to fulfill an empty reactor, so the multi-batch concept is the practical solution to this problem in terms of heat and water recovery ability. The industrial plant of AVA-CO2 operates HTC process parallel reactors as a multi-batch system and can treat different types of feedstock together in the range of 25–70 wt%. A modular design with a multi-batch concept is the key feature of AVA-CO2, which can scale up based on the desired capacity. A process diagram for AVA-CO2 is presented in Figure 1a. The feedstock is mixed with water and then pumped into the mixing tank to preheat at 160 °C and 10 bar. Then, the preheated mixed feedstock is pumped into the HTC reactor for carbonization. After reaction, the HTC slurry enters the cooling tank, then heat and steam are recovered to preheat the next batch. The cooled slurry is filtered to separate into the solid and liquid fractions for hydrochar production and wastewater treatment. A part of the process water is recirculated to mix in the input feedstock, contributing to reducing freshwater consumption. The heat recovery and steam-recycling system utilized make the whole process of the AVA-CO2 plant more efficient in terms of energy consumption [90]. The commercial HTC plant of AVA in Relzow, Germany, has a plant size of two reactors for 8000 T/year of biomass feedstock and 2664 T/year of biocoal production, which can be scaled up to six reactors [91]. Another process developed by AVA-CO2 called “AVA Cleanphos” enables the recovery of phosphorus from the hydrochar of HTC sewage sludge, achieving yields of up to 80% and lowering energy cost [92]. Moreover, HTC process water is exploited to produce bio-based chemical products. AVA Biochem is one of the plants of AVA-CO2, producing 5-HMF at purity levels up to 99.9% [93,94] thanks to the extraction and purification steps that make the process more effective, as shown in Figure 1b. The main challenges in HMF production are the formation of side-products, especially solid humins, and the separation of HMF from the reaction media, as well as its subsequent purification. These side products not only affect the purification but also the economic feasibility of the HMF production [94].

Figure 1.

(a) AVA-CO2 HTC process design for one unit [92]; (b) AVA Biochem HTC method for hydrochar and HMF production [94].

Table 3.

Global HTC commercialization businesses.

Table 3.

Global HTC commercialization businesses.

| Company | Feedstock | Process Type and Capacity | Heating System and Process Conditions | Final Products | Ref |

|---|---|---|---|---|---|

| AVA-CO2 | Biowaste |

Multi-batch 40,000–50,000 T/year | Steam 220–230 °C, 2.2–2.6 MPa, 5–10 h, Catalyst |

Biocoal, 5-HMF, P Recovery | [90,91,92,93,94] |

| CarboRem | Agro-industrial Digested Sludge |

Semi-continuous 5000 T/year |

Diathermic Oil 190 °C, 1.5 MPa, 1 h |

Biocoal, P Recovery | [95,96] |

| C-Green | Biowaste |

Semi-continuous 33,000 T/year | Steam 200 °C, 2 MPa, 1–4 h | Biocoal, P recovery and Nitrogen Recovery | [97,98,99] |

| TerraNova Energy | Biowaste or Sewage Sludge |

Semi-continuous 14,000 T/year |

Diathermic Oil 180–200 °C, 2–3.5 MPa, 4 h, Catalyst |

Biocoal, P recovery | [8,100,101,102] |

| Ingelia S.L. |

Agricultural Waste, Residential Green Waste |

Semi-continuous 78,000 T/year | Steam 180–220 °C, 1.7–2.4 MPa, 4–8 h |

Biocoal, Biochemical, Fertilizers | [3,8,103,104,105,106,107] |

| HTCycle | Sewage Sludge and Agricultural Waste |

Multi-batch 8000–16,000 T/year | Steam 200–220 °C, 2–2.5 MPa, 4 h |

Biocoal, P recovery, Activated Carbon | [108,109,110] |

| Antaco | Sludge and Paper Mill |

Continuous 31,000–150,000 T/year | Steam 180–250 °C, 1.5–2 MPa, 4–10 h |

Biocoal, Activated Carbon, Biogas | [111,112] |

|

Suncoal Industries | Biowaste |

Semi-continuous

50,000 T/year | Steam 200 °C, 2 MPa, 6–12 h | Biocoal | [8,113,114] |

|

Carbon Solutions | Sewage Sludge |

Semi-continuous 10,000 T/year | 160–250 °C, 1–6 MPa, 1.5 h | Biocoal, Activated Carbon | [115,116] |

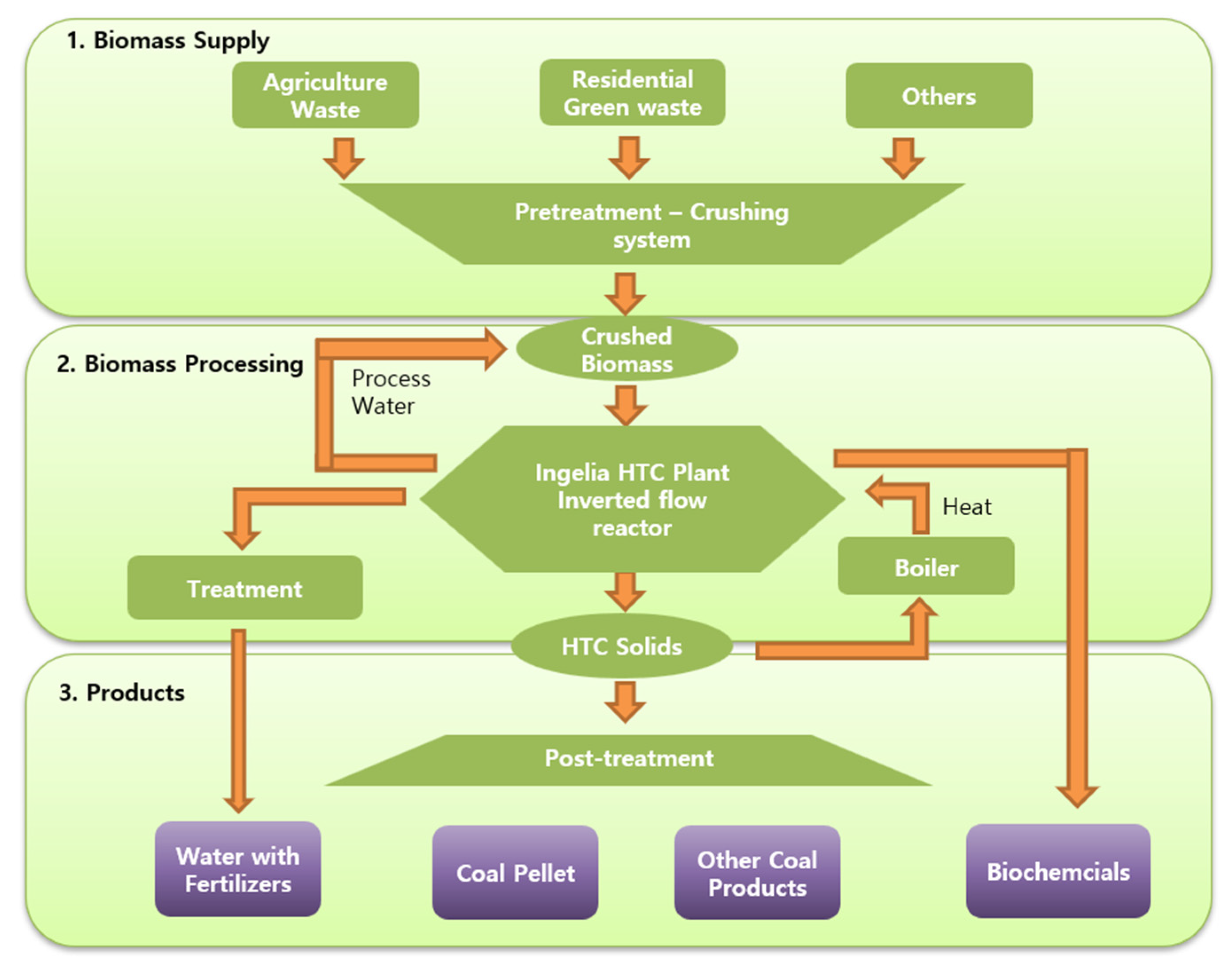

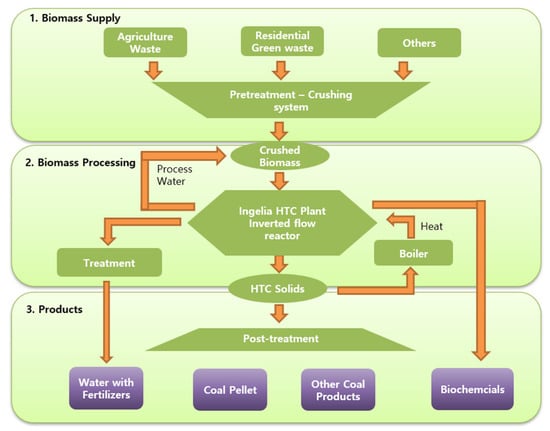

Like AVA-CO2, the Ingelia plant also increased the number of reactors to increase the treatment capacity, which reduces the scalability risk. Each modular unit has a capacity of 6000 T/year of wet biomass. Ingelia’s HTC process can also treat different feedstocks with a moisture content in the range of 30–90% inside inverted flow reactors for a continuous process and generate biocoal and liquid fertilizer [103,104,105]. Different from the AVA-CO2 plant, a pretreatment process is employed in the Ingelia HTC plant to mill the input feedstock into a particle size of below 8mm and then pump it into the reactor through a long pre-heating tube. The pre-treatment process makes the feedstock transfer to the HTC reactor more stable and increases the carbonization efficiency. This pre-heated feedstock is fed from the bottom of the cylindrical vertical reactor like in the AVA-CO2 process. Hydrochar slurry is also removed from the bottom, and the gases are collected from the top [3,106]. The Ingelia HTC process is shown in Figure 2. Like in AVA-CO2, the process water is recycled to mix the input feedstock and used to produce bio-based chemicals or throughout some treatments for liquid fertilizer application. Ingelia S.L. ran many trial plants in different countries, especially in the UK. They installed the first HTC commercial-scale plant in collaboration with CPL industries and subsequently installed a 78,000 T/year biomass plant in Italy for the life cycle assessment. In terms of environmental impact, the number of reactors is greater due to the modular nature of this plant, which is located near waste sources, and it does not cause any odor issues. The total CO2 emissions of green waste is 0.0624 T CO2 equivalent, which is very low. Moreover, carbon recovery from the waste is high, amounting to around 64.04%, which makes Ingelia technology very impactful [103]. As a promising technology, Ingelia S.L. was entered into the NEWAPP European project for converting biomass residues into high-quality carbonaceous products with an HHV of 24 MJ/kg and an over-58% carbon content [107].

Figure 2.

HTC process of Ingelia [8,103].

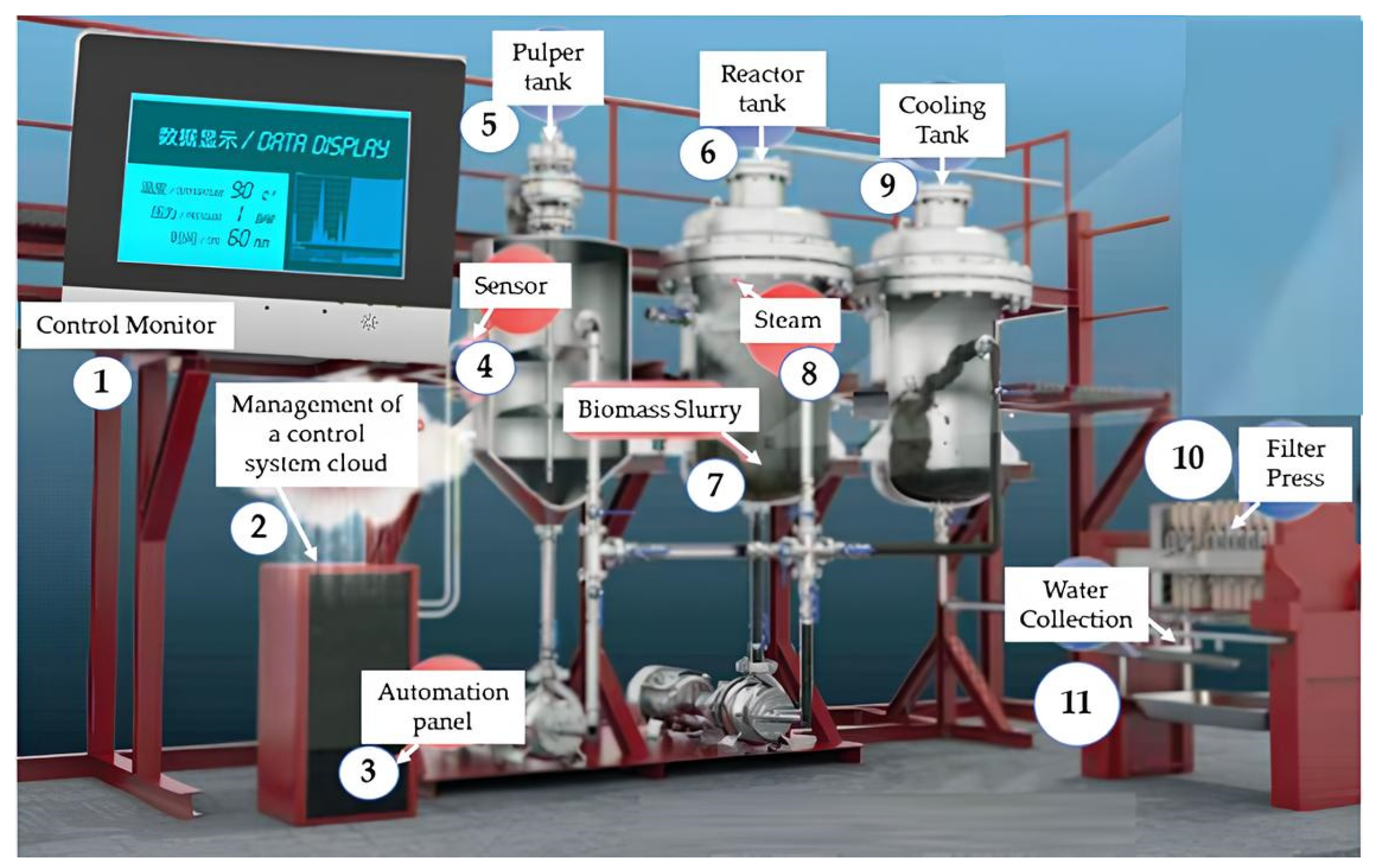

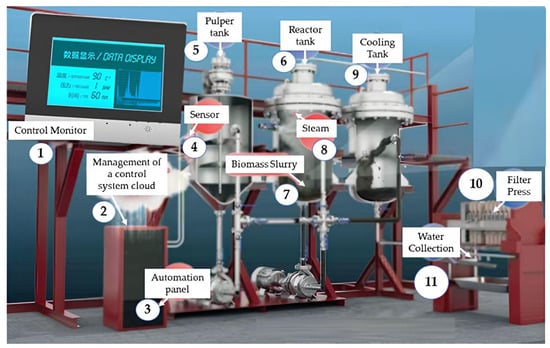

HTCycle also has modular units of multi-batch systems akin to AVA-CO2 and Ingelia L.S. HTCycle provides plants with two kinds of capacity: 8000 T/year and 16,000 T/year [108,109]. Figure 3 illustrates the HTCycle process. The mixture feedstock is pumped into the pulper tank to preheat at 90 °C for 1 h and then transferred to the reactor tank. Steam is injected directly into the reactor to increase the mixing capacity until it reaches the reaction temperature. A part of the process water is recycled for mixing with the input feedstock, or it can be used as liquid fertilizer. One of the main advantages of the HTCycle process is phosphorus extraction via leaching HTCycle coal with sulfuric acid. Process water can be used as liquid fertilizer, but there is no reported data from HTCycle about its toxicity and nutrient content which was suitable for fertilizer applications. According to the report titled “Sewage Sludge Reuse Phosphate Recovery with an Innovative HTC Technology”, the project of HTCycle for 50,000 tons of biomass, including sewage sludge, can generate up to 11,000 tons of HTC coal, up to 1750 tons of activated carbon, 1200 tons of phosphorus recovery, or 2000 tons of sulfur [110].

Figure 3.

HTCycle AG technology process [8,108].

Like AVA-CO2, Ingelia, and HTCycle, the SunCoal HTC plant has a batch-reactor modular design with a capacity of producing 50,000 T/year of raw material in a semi-continuous process [113]. This HTC process can transform green or organic waste into a solid biofuel called SunCoal. This biofuel exhibits characteristics comparable to dry brown coal [8]. Moreover, upgraded hydrochar can be used to produce bio-based chemicals, biochar, or activated carbon. The pre-processing of feedstock by crushing to achieve a uniform size of 60 mm and removing impurities, is required in the SunCoal HTC process. The low- and high-pressure steam used for heating is recycled, along with the process water. For other applications, to attain bio-based filler for rubber compounds, CarboREN technology is used to convert hydrothermally treated lignin biomass into functional bio-based filler for rubber compounds via the addition of silane coupling agents [114].

Another technology from Carbon Solutions (CS-HTC90) in Germany provides a semi-continuous HTC process [115]. The biomass is mixed with a part of the process water and preheated before entering from the top of the HTC reactor. This process can convert 10,000 tons of biomass into biocoke. In comparison with other company processes, the Carbon Solutions process uniquely involves the use of CarbonPure, their proprietary technology, to treat process water after filter pressing. CarbonPure converts the chemical oxygen demand (COD) of the process water from 50–80 g/L to less than 2 g/L, recovers energy in a steam generator, and produces liquid fertilizer [116].

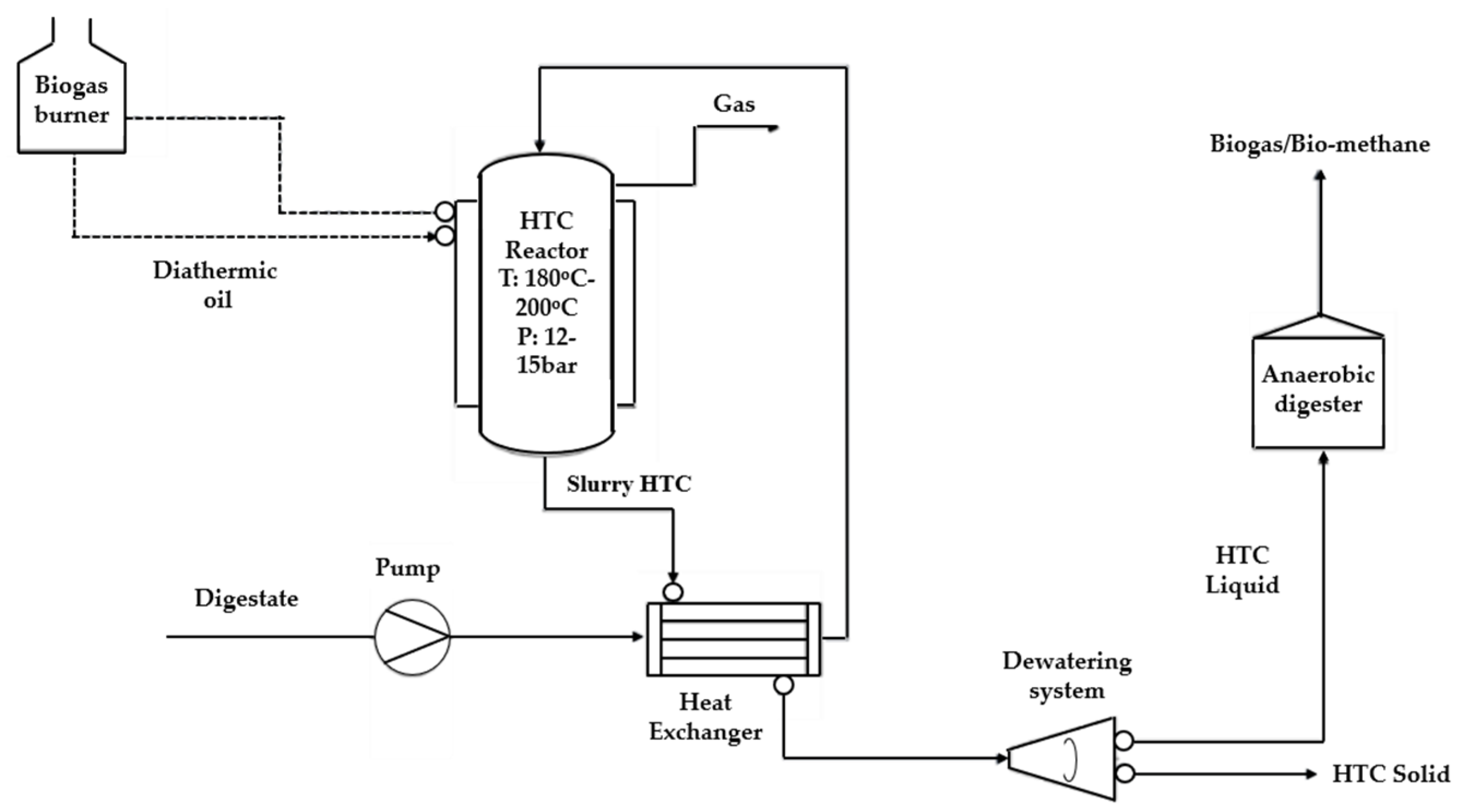

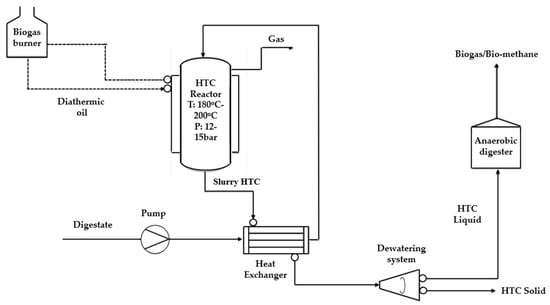

The C-700 HTC plant process is another industrial-scale semi-continuous HTC technology of CarboRem. It can treat 5000 T/year of sludge with a solid content in the range of 2–10 wt% [95]. This containerized plant comprises a stainless-steel HTC plug flow reactor, a diathermic oil boiler for supplying thermal energy, a heat exchanger, a PLC, and two storage tanks. The HTC process of the C-700 plant is illustrated in Figure 4. The digestate sludge is fed by a pump against the pressure inside the HTC reactor. The heat exchanger placed before the reactor is used to recover heat from the hot HTC slurry after the reaction; it then preheats the input flow pumped into the reactor. This HTC process is conducted at 190 °C for 1 h. The HTC slurry of the digestate is then treated by using different acids like HCl, H2SO4, or citric acid to remove the heavy metal content, releasing phosphorus into the liquid phase upto 97% and enhancing dewaterability. The separated solid hydrochar with a high solid yield of 80–89 wt%, showing potential for application in soil fertilizer, has a high carbon concentration, consisting of up to 16.8% fixed carbon, and low heavy metal content. The struvite precipitation technology is applied for the recovery of P in the liquid phase at up to 91 wt% when compared to the digestate sludge [96]. The HTC liquid can be transferred to the AD system for waste management to increase biogas production and generate energy for heating the diathermic oil in the HTC system. This combination of AD and HTC enhances the process efficiency.

Figure 4.

Schematic of diagram of the C-700 HTC plant [96].

Like CarboRem, TerraNova in Germany also serves as an example of a semi-continuous HTC plant that has a similar process with some different parts [100]. This entails a clever integration of high-pressure pumps, a continuous stirred-tank reactor that employs heat exchanger tubes and acts as a tubular reactor, dewatering, and drying equipment. In this semi-continuous system, a heat exchanger used to recover heat from HTC slurry plays an important role in improving the efficiency of HTC production, as shown for both the CarboRem and TerraNova systems. Note that the heating systems of the two technologies use diathermic oil. Compared to steam, diathermic oil is safe and simple for operations and can reach up to 350 °C while the pressure remains low. However, it requires a more complex and expensive heat regulation system. Notably, a catalyst such as H2SO4 is added into the HTC reactor to accelerate the process. An HTC process flow diagram is presented in Figure 5. A commercial HTC plant produced by TerraNova Energy was introduced in 2016 and installed in Jining, China for sewage sludge treatment. A total of 14,000 tons/year of dewatered sewage sludge with 68% dry matter content was treated to generate solid fuel or up to 80% of phosphorous recovered by adding calcium silicate hydrate to the filtrate or via acid leaching [101,102]. It also contributed to reducing the mass of sewage sludge by 75%, which is typically disposed of, providing a new approach for efficient P recovery.

Figure 5.

An illustration of TerraNova HTC technology process [8,100].

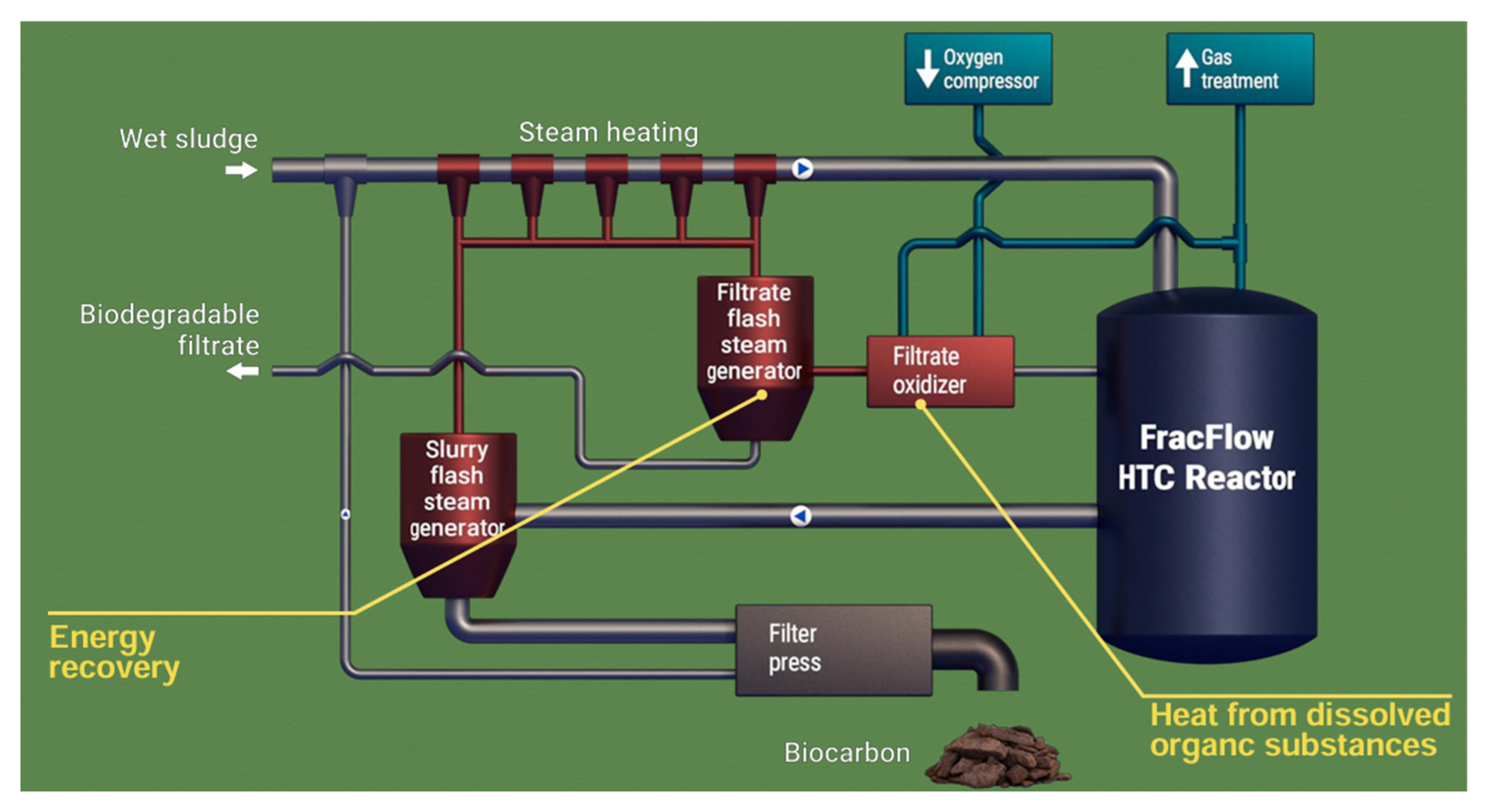

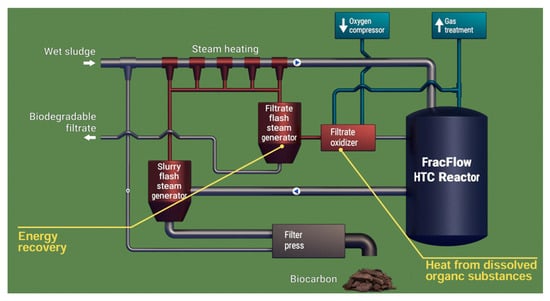

Different from other technologies, the OxyPower HTC, C-Green, provides an innovative process by uniquely integrating a semi-continuous HTC reactor with wet oxidation (WO) technology in a semi-continuous process to convert sludge from wastewater treatment into valuable products such as nitrogen fertilizer, solid fuel, or hydrochar for soil improvement. The sludge is heated two times with the steam fraction before entering the HTC reactor and reacted at 180–250 °C. Then, the obtained HTC slurry is mixed with an oxidizing agent such as oxygen gas, which may be added directly into the reactor, and the gas goes towards the gas treatement chamber. The oxygen is provided through an oxygen compressor to the filtrate oxidizer. A wet oxidation reaction occurs preferably at 220–260 °C, and the energy can be self sustained. The wet oxidized slurry is subjected to flashing to recover the steam for preheating the input sludge and then cooled; then, it is separated into solid and liquid phases [97]. Applying the wet oxidation method not only results in a lower COD of 15 g/L [102] in HTC process water but also decreases the volume of the solid fraction and enriches the nitrogen and phosphorous. The first HTC plant of C-Green was erected in Finland in 2020 and can treat pulp and paper sludge at a capacity of 18,000 T/year, which can reduce greenhouse gas emissions by up to 77% [98]. Wet oxidation contributes to reducing wastewater generation and improving energy efficiency. The innovative combination of HTC and wet oxidation with other methods such as AD should be further investigated. The process of OxyPower HTC technology is shown in Figure 6.

Figure 6.

Schematic diagram of the OxyPower HTCTM process [99].

A study comparing the efficiency in energy recovery and economic performance obtained by integrating HTC utilizing TerraNova and C-Green with other technology was presented by Bagheri, M. et al. [102], involving the combination of AD and CHP; AD, CHP and WO of C-Green or AD, CHP and HTC of TerraNova (using H2SO4 as a catalyst) for the wastewater treatment process. Overall, adding WO can balance the investment costs, self-heating ability, and power output, but it is still not attractive for profitable investments. However, the combination of HTC and AD, when HTC process water is directly added in AD, can improve biogas production and reduce the disposal cost of sewage sludge, resulting in a significant investment opportunity.

The technology produced by Antaco uses continuous processes with a tube-type reactor, which makes their process different from other companies’ approaches. It can deal with 30,000 to 150,000 T/year of feedstock on a dry and wet base, respectively. The distinct aspect of this process is that after the completion of the reaction, the energy present within the slurry is efficiently recycled to facilitate the processing of incoming biomass. Following this, the HTC slurry is subjected to a series of steps, including dewatering, drying, and pelletization, ultimately yielding biocoal. The biocoal has a heat value of 23 MJ/kg, like fossil coal [111]. Just like CarboRem, Antaco also applies an anaerobic digestion system to process the wastewater. Campbell, B. S., et al. reported on the HTC of spent coffee grounds integrated with an Antaco anaerobic digestion plant to investigate the stability of an AD system. Process water resulted in a higher yield of methane and higher COD degradation throughout the 190 days of operation [112]. The main issue with the Antaco AD system is that it is only 25% efficient in biogas production, which falls significantly short of industry standards.

Yoshikawa, K. et al. [117] implemented a commercial demonstration plant in Indonesia. The plant produced biocoal from municipal solid waste using HTC in a single year. The treatment capacity of this plant was 50 T/day. The procedure utilizing the steam generator was completed in a 10 m3 batch-type reactor. The hydrochar that was obtained had an HHV greater than 17 MJ/kg. Using 15% of the obtained biocoal was sufficient for providing the necessary steam during the HTC process, making the overall process more energy efficient.

By reviewing the HTC processes employed by different commercial companies, one may conclude that HTC on a large scale brings many advantages to the environment and economy by reducing the amount of biomass waste, reducing wastewater treatment costs, and producing valuable end products like fertilizer, biofuel, biochar, biogas, and bio-chemicals. A number of factors need to be considered when operating a plant on a large scale: the selection of a suitable HTC reactor, either batch or continuous; the number of cycles per day or the capacity of treatment; the necessity of pretreatment for feedstock; the heating system, i.e., steam- or diathermal-oil-based; an efficient waste-heat recovery system; proper control of odor during the process; and the optimal operation conditions, such as temperature, residence time, and catalyst. Combining HTC and other technologies like AD and WO to treat process water not only creates a new energy source but also reduces wastewater treatment costs and makes the HTC process more eco-friendly with higher performance efficiency. However, a number of non-technical issues should be addressed and assessed in a systematic way, such as life cycle assessment or techno-economic analysis.

4. Conclusions

Based on recent studies about upscaling from the lab scale to pilot scale, it is evident that reaction temperature, pressure, residence time, type of feedstock, reactor type, energy recovery, mass balance, and energy balance are the crucial process parameters for designing an industrial scale HTC plant. Determining the optimal process parameters related to a cost–benefit analysis is also necessary when carrying out the HTC process on a large scale. Many companies like Ingelia, AVA-CO2, CarboRem, SunCoal, Antaco, Carbon Solution, TerrNova, HTCycle, and C-Green have successfully developed industrial-level plants, but they still face several challenges, particularly in terms of plant design and in the sector of wastewater treatment plant. Innovative reactor designs intended to improve productivity, such as continuous systems and multi-batch reactors, should be carefully chosen for suitable processes to accommodate different purposes of production. Upscaling is necessary because it can optimize resource utilization through increasing process efficiency, leading to reduced cost and labor requirements. Moreover, larger-scale HTC operations should meet the demands of industries and markets for commercialization. When upscaling HTC technology, a significant quantity of organic waste from landfills can be diverted to valuable products, reducing greenhouse gas emissions and mitigating the environmental impact. However, the challenges and caveats to upscaling should be recognized. The treatment of process water will need more research to address valorization and reducing wastewater treatment costs on an industrial scale. By integrating HTC (Hydrothermal Carbonization) with other waste treatment methods like anaerobic digestion, combustion, and wet oxidation can indeed offer several potential benefits in terms of energy efficiency and sustainability.

Author Contributions

Data collection, T.T.-T.H.; Conceptualization, T.T.-T.H. and K.C.; Design of the work, T.T.-T.H. and A.N.; Writing and draft preparation, T.T.-T.H. and A.N.; writing, review, and editing, T.T.-T.H., A.N. and K.C.; Critical revision of the article, K.C.; Final approval of the version to be published, K.C.; supervision, K.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry and Energy (MOTIE) of the Republic of Korea (Project No: 20228520090010 Project Title: “Development of Integrated System for Biofuel Production from Tapioca Starch Wastes by Anaerobic Digestion and Hybrid Hydrothermal Carbonization”).

Data Availability Statement

The authors confirm that all data used in this study are openly available within the article.

Conflicts of Interest

Authors Thi. Thu-Trang Ho, Ahmad Nadeem were employed by the company Bioenergy Center, Kinava Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yaashikaa, P.R.; Kumar, P.S.; Nhung, T.C.; Hemavathy, R.V.; Jawahar, M.J.; Neshaanthini, J.P.; Rangasamy, G. A review on landfill system for municipal solid wastes: Insight into leachate, gas emissions, environmental and economic analysis. Chemosphere 2022, 309, 136627. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, M.; Sahu, J.N.; Ganesan, P. Effect of process parameters on production of biochar from biomass waste through pyrolysis: A review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Hitzl, M.; Corma, A.; Pomares, F.; Renz, M. The hydrothermal carbonization (HTC) plant as a decentral biorefinery for wet biomass. Catal. Today 2015, 257, 154–159. [Google Scholar] [CrossRef]

- Kruse, A.; Funke, A.; Titirici, M.M. Hydrothermal conversion of biomass to fuels and energetic materials. Curr. Opin. Chem. Biol. 2013, 17, 515–521. [Google Scholar] [CrossRef] [PubMed]

- Hrnčič, M.K.; Kravanja, G.; Knez, Ž. Hydrothermal treatment of biomass for energy and chemicals. Energy 2016, 116, 1312–1322. [Google Scholar] [CrossRef]

- Ngo, P.L.; Udugama, I.A.; Gernaey, K.V.; Young, B.R.; Baroutian, S. Mechanisms, status, and challenges of thermal hydrolysis and advanced thermal hydrolysis processes in sewage sludge treatment. Chemosphere 2021, 281, 130890. [Google Scholar] [CrossRef] [PubMed]

- Ischia, G.; Cazzanelli, M.; Fiori, L.; Orlandi, M.; Miotello, A. Exothermicity of hydrothermal carbonization: Determination of heat profile and enthalpy of reaction via high-pressure differential scanning calorimetry. Fuel 2022, 310, 122312. [Google Scholar] [CrossRef]

- Child, M. Industrial-Scale Hydrothermal Carbonization of Waste Sludge Materials for Fuel Production. Master’s Thesis, Faculty of Technology, Lappeenranta University of Technology, Lappeenranta, Finland, 2014. [Google Scholar]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Pauline, A.L.; Joseph, K. Hydrothermal carbonization of organic wastes to carbonaceous solid fuel—A review of mechanisms and process parameters. Fuel 2020, 279, 118472. [Google Scholar] [CrossRef]

- Zhuang, X.; Zhan, H.; Song, Y.; He, C.; Huang, Y.; Yin, X.; Wu, C. Insights into the evolution of chemical structures in lignocellulose and non-lignocellulose biowastes during hydrothermal carbonization (HTC). Fuel 2019, 236, 960–974. [Google Scholar] [CrossRef]

- Islam, M.T.; Sultana, A.I.; Chambers, C.; Saha, S.; Saha, N.; Kirtania, K.; Reza, M.T. Recent Progress on Emerging Applications of Hydrochar. Energies 2022, 15, 9340. [Google Scholar] [CrossRef]

- Cavali, M.; Junior, N.L.; de Sena, J.D.; Woiciechowski, A.L.; Soccol, C.R.; Belli Filho, P.; Bayard, R.; Benbelkacem, H.; de Castilhos Junior, A.B. A review on hydrothermal carbonization of potential biomass wastes, characterization and environmental applications of hydrochar, and biorefinery perspectives of the process. Sci. Total Environ. 2023, 857, 159627. [Google Scholar] [CrossRef] [PubMed]

- Romano, P.; Stampone, N.; Di Giacomo, G. Evolution and Prospects of Hydrothermal Carbonization. Energies 2023, 16, 3125. [Google Scholar] [CrossRef]

- Sharma, R.; Jasrotia, K.; Singh, N.; Ghosh, P.; Srivastava, S.; Sharma, N.R.; Singh, J.; Kanwar, R.; Kumar, A. A comprehensive review on hydrothermal carbonization of biomass and its applications. Chem. Afr. 2020, 3, 1–19. [Google Scholar] [CrossRef]

- Saba, A.; Saha, P.; Reza, M.T. Co-Hydrothermal Carbonization of coal-biomass blend: Influence of temperature on solid fuel properties. Fuel Process. Technol. 2017, 167, 711–720. [Google Scholar] [CrossRef]

- Lin, Y.; Ge, Y.; Xiao, H.; He, Q.; Wang, W.; Chen, B. Investigation of hydrothermal co-carbonization of waste textile with waste wood, waste-paper, and waste food from typical municipal solid wastes. Energy 2020, 210, 118606. [Google Scholar] [CrossRef]

- Bardhan, M.; Novera, T.M.; Tabassum, M.; Islam, M.A.; Islam, M.A.; Hameed, B.H. Co-hydrothermal carbonization of different feedstocks to hydrochar as potential energy for the future world: A review. J. Clean. Prod. 2021, 298, 126734. [Google Scholar] [CrossRef]

- Fakudze, S.; Chen, J. A critical review on co-hydrothermal carbonization of biomass and fossil-based feedstocks for cleaner solid fuel production: Synergistic effects and environmental benefits. Chem. Eng. J. 2023, 457, 141004. [Google Scholar] [CrossRef]

- Xue, Y.; Bai, L.; Chi, M.; Xu, X.; Chen, Z.; Yu, K.; Liu, Z. Co-hydrothermal carbonization of pretreatment lignocellulose biomass and polyvinyl chloride for clean solid fuel production: Hydrochar properties and its formation mechanism. J. Environ. Chem. Eng. 2022, 10, 106975. [Google Scholar] [CrossRef]

- Wang, Y.J.; Yu, Y.; Huang, H.J.; Yu, C.L.; Fang, H.S.; Zhou, C.H.; Yin, X.; Chen, W.H.; Guo, X.C. Efficient conversion of sewage sludge into hydrochar by microwave-assisted hydrothermal carbonization. Sci. Total Environ. 2022, 803, 149874. [Google Scholar] [CrossRef]

- Holliday, M.C.; Parsons, D.R.; Zein, S.H. Microwave-assisted hydrothermal carbonisation of waste biomass: The effect of process conditions on hydrochar properties. Processes 2022, 10, 1756. [Google Scholar] [CrossRef]

- Li, L.; Rowbotham, J.S.; Greenwell, C.H.; Dyer, P.W. An introduction to pyrolysis and catalytic pyrolysis: Versatile techniques for biomass conversion. In New and Future Developments in Catalysis: Catalytic Biomass Conversion; Suib, S.L., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 173–208. [Google Scholar]

- Kazawadi, D.; Ntalikwa, J.; Kombe, G. A review of intermediate pyrolysis as a technology of biomass conversion for coproduction of bio-oil and adsorption biochar. J. Renew. Energy 2021, 2021, 5533780. [Google Scholar]

- Shankar Tumuluru, J.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Areeprasert, C.; Zhao, P.; Ma, D.; Shen, Y.; Yoshikawa, K. Alternative solid fuel production from paper sludge employing hydrothermal treatment. Energy Fuels 2014, 28, 1198–1206. [Google Scholar] [CrossRef]

- Gusman, M.H.; Sastroredjo, P.N.E.; Prawisudha, P.; Hardianto, T.; Pasek, A.D. A pilot-scale study of wet torrefaction treatment for upgrading palm oil empty fruit bunches as clean solid fuel. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 012003. [Google Scholar] [CrossRef]

- Teribele, T.; Costa, M.E.G.; Sales da Silva, C.D.M.; Pereira, L.M.; Bernar, L.P.; de Castro, D.A.R.; da Costa Assunção, F.P.; Santos, M.C.; de Sousa Brandão, I.W.; Fonseca, C.J.N.; et al. Hydrothermal Carbonization of Corn Stover: Structural Evolution of Hydro-Char and Degradation Kinetics. Energies 2023, 16, 3217. [Google Scholar] [CrossRef]

- Kang, K.; Sonil, N.; Guotao, S.; Ling, Q.; Yongqing, G.; Tianle, Z.; Mingqiang, Z.; Runcang, S. Microwave-assisted hydrothermal carbonization of corn stalk for solid biofuel production: Optimization of process parameters and characterization of hydrochar. Energy 2019, 186, 115–125. [Google Scholar] [CrossRef]

- Sabio, E.; Álvarez-Murillo, A.; Román, S.; Ledesma, B. Conversion of tomato-peel waste into solid fuel by hydrothermal carbonization: Influence of the processing variables. Waste Manag. 2016, 47, 122–132. [Google Scholar] [CrossRef] [PubMed]

- Sales da Silva, C.D.M.; Rocha de Castro, D.A.; Santos, M.C.; Almeida, H.D.S.; Schultze, M.; Lueder, U.; Hoffmann, T.; Machado, N.T. Process Analysis of Main Organic Compounds Dissolved in Aqueous Phase by Hydrothermal Processing of Açaí (Euterpe Oleracea, Mart.) Seeds: Influence of Process Temperature, Biomass-to-Water Ratio, and Production Scales. Cellulose 2021, 40, 15–6124. [Google Scholar]

- Atallah, E.; Kwapinski, W.; Ahmad, M.N.; Leahy, J.J.; Zeaiter, J. Effect of water-sludge ratio and reaction time on the hydrothermal carbonization of olive oil mill wastewater treatment: Hydrochar characterization. J. Water Process Eng. 2019, 31, 100813. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, X.; Wang, J.; Li, X.; Cheng, J.; Yang, H.; Chen, H. Effect of residence time on chemical and structural properties of hydrochar obtained by hydrothermal carbonization of water hyacinth. Energy 2013, 58, 376–383. [Google Scholar] [CrossRef]

- Wang, G.; Li, D.; Xiong, L.; Dan, J.; Xu, K.; Yuan, X.; Kan, G.; Ning, X.; Wang, C. Application of catalysts in biomass hydrothermal carbonization for the preparation of high-quality blast furnace injection fuel. Energy 2023, 283, 129147. [Google Scholar] [CrossRef]

- Djandja, O.S.; Liew, R.K.; Liu, C.; Liang, J.; Yuan, H.; He, W.; Feng, Y.; Lougou, B.G.; Duan, P.G.; Lu, X.; et al. Catalytic hydrothermal carbonization of wet organic solid waste: A review. Sci. Total Environ. 2023, 873, 162119. [Google Scholar] [CrossRef] [PubMed]

- Nizamuddin, S.; Baloch, H.A.; Griffin, G.J.; Mubarak, N.M.; Bhutto, A.W.; Abro, R.; Mazari, S.A.; Ali, B.S. An overview of effect of process parameters on hydrothermal carbonization of biomass. Renew. Sustain. Energy Rev. 2017, 73, 1289–1299. [Google Scholar] [CrossRef]

- Ameen, M.; Zamri, N.M.; May, S.T.; Azizan, M.T.; Aqsha, A.; Sabzoi, N.; Sher, F. Effect of acid catalysts on hydrothermal carbonization of Malaysian oil palm residues (leaves, fronds, and shells) for hydrochar production. Biomass Convers. Biorefinery 2022, 12, 103–114. [Google Scholar] [CrossRef]

- John, K.I.; Omorogie, M.O. Biomass-based hydrothermal carbons for catalysis and environmental cleanup: A review. Green Chem. Lett. Rev. 2022, 15, 162–186. [Google Scholar] [CrossRef]

- Shin, T.-S.; Yoo, S.-Y.; Kang, I.-K.; Kim, N.; Kim, S.; Lim, H.-B.; Choe, K.; Lee, J.-C.; Yang, H.-I. Analysis of Hydrothermal Solid Fuel Characteristics Using Waste Wood and Verification of Scalability through a Pilot Plant. Processes 2022, 10, 2315. [Google Scholar] [CrossRef]

- Mackintosh, A.F.; Jung, H.; Kang, I.K.; Yoo, S.; Kim, S.; Choe, K. Experimental Study on Hydrothermal Polymerization Catalytic Process Effect of Various Biomass through a Pilot Plant. Processes 2021, 9, 758. [Google Scholar] [CrossRef]

- Kim, D.; Park, K.Y.; Yoshikawa, K. Conversion of municipal solid wastes into biochar through hydrothermal carbonization. Eng. Appl. Biochar 2017, 31, 31–46. [Google Scholar]

- Kruse, A.; Baris, D.; Tröger, N.; Wieczorek, P. Scale-Up in Hydrothermal Carbonization. In Sustainable Carbon Materials from Hydrothermal Processes; Titririci, M.M., Ed.; Wiley: Hoboken, NJ, USA, 2013; pp. 341–353. [Google Scholar]

- Ischia, G.; Fiori, L. Hydrothermal carbonization of organic waste and biomass: A review on process, reactor, and plant modeling. Waste Biomass Valorization 2021, 12, 2797–2824. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Purcell, R.; Zielinska, B.; Felix, L.; Irvin, J. Process development unit (PDU) for hydrothermal carbonization (HTC) of lignocellulosic biomass. Waste Biomass Valorization 2014, 5, 669–678. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Felix, L.; Farthing, W. Hydrothermal carbonization (HTC) of loblolly pine using a continuous, reactive twin-screw extruder. Energy Convers. Manag. 2017, 134, 247–259. [Google Scholar] [CrossRef]

- Ipiales, R.P.; Sarrion, A.; Diaz, E.; de la Rubia, M.A.; Diaz-Portuondo, E.; Coronella, C.J.; Mohedano, A.F. Swine manure management by hydrothermal carbonization: Comparative study of batch and continuous operation. Environ. Res. 2024, 245, 118062. [Google Scholar] [CrossRef] [PubMed]

- Ketwong, T.; Halabaso, E.R.; Nguyen, T.K.A.; Areeprasert, C.; Doong, R.A. Comparative study on pilot-scale production of CuO-loaded activated biochar and hydrochar from oil-palm empty fruit bunches for high-performance symmetric supercapacitor application. J. Electroanal. Chem. 2022, 905, 115970. [Google Scholar] [CrossRef]

- Zhao, X.; Becker, G.C.; Faweya, N.; Rodriguez Correa, C.; Yang, S.; Xie, X.; Kruse, A. Fertilizer and activated carbon production by hydrothermal carbonization of digestate. Biomass Convers. Biorefinery 2018, 8, 423–436. [Google Scholar] [CrossRef]

- Wang, L.; Chi, Y.; Du, K.; Zhou, Z.; Wang, F.; Huang, Q. Hydrothermal Treatment of Food Waste for Bio-fertilizer Production: Regulation of Humus Substances and Nutrient (N and P) in Hydrochar by Feedwater pH. Waste Biomass Valorization 2023, 14, 2767–2781. [Google Scholar] [CrossRef]

- Li, J.; Li, L.; Suvarna, M.; Pan, L.; Tabatabaei, M.; Ok, Y.S.; Wang, X. Wet wastes to bioenergy and biochar: A critical review with future perspectives. Sci. Total Environ. 2022, 817, 152921. [Google Scholar] [CrossRef]

- Wang, B.; Ran, M.; Fang, G.; Wu, T.; Ni, Y. Biochars from lignin-rich residue of furfural manufacturing process for heavy metal ions remediation. Materials 2020, 13, 1037. [Google Scholar] [CrossRef]

- Miliotti, E.; Casini, D.; Rosi, L.; Lotti, G.; Rizzo, A.M.; Chiaramonti, D. Lab-scale pyrolysis and hydrothermal carbonization of biomass digestate: Characterization of solid products and compliance with biochar standards. Biomass Bioenergy 2020, 139, 105593. [Google Scholar] [CrossRef]

- Langone, M.; Basso, D. Process waters from hydrothermal carbonization of sludge: Characteristics and possible valorization pathways. Int. J. Environ. Res. Public Health 2020, 17, 6618. [Google Scholar] [CrossRef]

- Nobre, C.; Alves, O.; Durão, L.; Şen, A.; Vilarinho, C.; Gonçalves, M. Characterization of hydrochar and process water from the hydrothermal carbonization of Refuse Derived Fuel. Waste Manag. 2021, 120, 303–313. [Google Scholar] [CrossRef] [PubMed]

- Mäkelä, M.; Forsberg, J.; Söderberg, C.; Larsson, S.H.; Dahl, O. Process water properties from hydrothermal carbonization of chemical sludge from a pulp and board mill. Bioresour. Technol. 2018, 263, 654–659. [Google Scholar] [CrossRef] [PubMed]

- Aragón-Briceño, C.I.; Grasham, O.; Ross, A.B.; Dupont, V.; Camargo-Valero, M.A. Hydrothermal carbonization of sewage digestate at wastewater treatment works: Influence of solid loading on characteristics of hydrochar, process water and plant energetics. Renew. Energy 2020, 157, 959–973. [Google Scholar] [CrossRef]

- Brown, A.E.; Finnerty, G.L.; Camargo-Valero, M.A.; Ross, A.B. Valorisation of macroalgae via the integration of hydrothermal carbonisation and anaerobic digestion. Bioresour. Technol. 2020, 312, 123539. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Ren, S.; Ji, M.; Sompong, O.; Qian, Y.; Luo, G.; Zhang, S. Characterization and biogas production potentials of aqueous phase produced from hydrothermal carbonization of biomass–Major components and their binary mixtures. Chem. Eng. J. 2020, 388, 124201. [Google Scholar] [CrossRef]

- Merzari, F.; Langone, M.; Andreottola, G.; Fiori, L. Methane production from process water of sewage sludge hydrothermal carbonization. A review. Valorising sludge through hydrothermal carbonization. Crit. Rev. Environ. Sci. Technol. 2019, 49, 947–988. [Google Scholar] [CrossRef]

- Brown, A.E.; Adams, J.M.; Grasham, O.R.; Camargo-Valero, M.A.; Ross, A.B. An assessment of different integration strategies of hydrothermal carbonisation and anaerobic digestion of water hyacinth. Energies 2020, 13, 5983. [Google Scholar] [CrossRef]

- Oliveira, I.; Blöhse, D.; Ramke, H.G. Hydrothermal carbonization of agricultural residues. Bioresour. Technol. 2013, 142, 138–146. [Google Scholar] [CrossRef] [PubMed]

- Kambo, H.S.; Minaret, J.; Dutta, A. Process Water from the Hydrothermal Carbonization of Biomass: A Waste or a Valuable Product? Waste Biomass 2018, 9, 1181–1189. [Google Scholar] [CrossRef]

- Stemann, J.; Putschew, A.; Ziegler, F. Hydrothermal carbonization: Process water characterization and effects of water recirculation. Bioresour. Technol. 2013, 143, 139–146. [Google Scholar] [CrossRef]

- Catalkopru, A.K.; Kantarli, I.C.; Yanik, J. Effects of spent liquor recirculation in hydrothermal carbonization. Bioresour. Technol. 2017, 226, 89–93. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Li, D.; Lv, M.; Yuan, L.; Zhang, J.; Qin, S.; Wang, B.; Cui, X.; Guo, C.; Zhao, P. Influence of process water recirculation on hydrothermal carbonization of rice husk at different temperatures. J. Environ. Chem. Eng. 2023, 11, 109364. [Google Scholar] [CrossRef]

- Sharma, H.B.; Panigrahi, S.; Vanapalli, K.R.; Cheela, V.S.; Venna, S.; Dubey, B. Study on the process wastewater reuse and valorisation during hydrothermal co-carbonization of food and yard waste. Sci. Total Environ. 2022, 806, 150748. [Google Scholar] [CrossRef] [PubMed]

- Stutzenstein, P.; Bacher, M.; Rosenau, T.; Pfeifer, C. Optimization of Nutrient and Carbon Recovery from Anaerobic Digestate via Hydrothermal Carbonization and Investigation of the Influence of the Process Parameters. Waste Biomass Valorization 2018, 9, 1303–1318. [Google Scholar] [CrossRef]

- Dai, L.; Yang, B.; Li, H.; Tan, F.; Zhu, N.; Zhu, Q.; He, M.; Ran, Y.; Hu, G. A synergistic combination of nutrient reclamation from manure and resultant hydrochar upgradation by acid-supported hydrothermal carbonization. Bioresour. Technol. 2017, 243, 860–866. [Google Scholar] [CrossRef] [PubMed]

- Jamal-Uddin, A.T.; Reza, M.T.; Norouzi, O.; Salaudeen, S.A.; Dutta, A.; Zytner, R.G. Recovery and Reuse of Valuable Chemicals Derived from Hydrothermal Carbonization Process Liquid. Energies 2023, 16, 732. [Google Scholar] [CrossRef]

- Koçer, A.T.; İnan, B.; Özçimen, D.; Gökalp, İ. A study of microalgae cultivation in hydrothermal carbonization process water: Nutrient recycling, characterization and process design. Environ. Technol. Innov. 2023, 30, 103048. [Google Scholar] [CrossRef]

- Tsarpali, M.; Arora, N.; Kuhn, J.N.; Philippidis, G.P. Beneficial use of the aqueous phase generated during hydrothermal carbonization of algae as nutrient source for algae cultivation. Algal Res. 2021, 60, 102485. [Google Scholar] [CrossRef]

- Riedel, G.; Koehler, R.; Poerschmann, J.; Kopinke, F.D.; Weiner, B. Combination of hydrothermal carbonization and wet oxidation of various biomasses. Chem. Eng. J. 2015, 279, 715–724. [Google Scholar] [CrossRef]

- Reza, M.T.; Freitas, A.; Yang, X.; Coronella, C.J. Wet air oxidation of hydrothermal carbonization (HTC) process liquid. ACS Sustain. Chem. Eng. 2016, 4, 3250–3254. [Google Scholar] [CrossRef]

- Thomsen, L.B.S.; Anastasakis, K.; Biller, P. Wet oxidation of aqueous phase from hydrothermal liquefaction of sewage sludge. Water Res. 2022, 209, 117863. [Google Scholar] [CrossRef] [PubMed]

- Wilk, M.; Czerwińska, K.; Śliz, M.; Imbierowicz, M. Hydrothermal carbonization of sewage sludge: Hydrochar properties and processing water treatment by distillation and wet oxidation. Energy Rep. 2023, 9, 39–58. [Google Scholar] [CrossRef]

- Oliveira, A.S.; Sarrión, A.; Baeza, J.A.; Diaz, E.; Calvo, L.; Mohedano, A.F.; Gilarranz, M.A. Integration of hydrothermal carbonization and aqueous phase reforming for energy recovery from sewage sludge. Chem. Eng. J. 2022, 442, 136301. [Google Scholar] [CrossRef]

- Zoppi, G.; Pipitone, G.; Pirone, R.; Bensaid, S. Aqueous phase reforming process for the valorization of wastewater streams: Application to different industrial scenarios. Catal. Today 2022, 387, 224–236. [Google Scholar] [CrossRef]

- Attasophonwattana, P.; Sitthichirachat, P.; Siripaiboon, C.; Ketwong, T.; Khaobang, C.; Panichnumsin, P.; Ding, L.; Areeprasert, C. Evolving circular economy in a palm oil factory: Integration of pilot-scale hydrothermal carbonization, gasification, and anaerobic digestion for valorization of empty fruit bunch. Appl. Energy 2022, 324, 119766. [Google Scholar] [CrossRef]

- Brown, A.B.; Tompsett, G.A.; Partopour, B.; Deskins, N.A.; Timko, M.T. Hydrochar structural determination from artifact-free Raman analysis. Carbon 2020, 167, 378–387. [Google Scholar] [CrossRef]

- Chater, H.; Asbik, M.; Koukouch, A.; Mouaky, A.; Bostyn, S.; Sarh, B.; Tabet, F. Analysis of fluid flow and heat transfer inside a batch reactor for hydrothermal carbonization process of a biomass. Energies 2022, 15, 818. [Google Scholar] [CrossRef]

- Ghavami, N.; Özdenkçi, K.; Chianese, S.; Musmarra, D.; De Blasio, C. Process simulation of hydrothermal carbonization of digestate from energetic perspectives in Aspen Plus. Energy Convers. Manag. 2022, 270, 116215. [Google Scholar] [CrossRef]

- Sangaré, D.; Moscosa-Santillan, M.; Aragón Piña, A.; Bostyn, S.; Belandria, V.; Gökalp, I. Hydrothermal carbonization of biomass: Experimental study, energy balance, process simulation, design, and techno-economic analysis. Biomass Convers. Biorefinery 2022, 14, 2561–2576. [Google Scholar] [CrossRef]

- Vardiambasis, I.O.; Kapetanakis, T.N.; Nikolopoulos, C.D.; Trang, T.K.; Tsubota, T.; Keyikoglu, R.; Khataee, A.; Kalderis, D. Hydrochars as emerging biofuels: Recent advances and application of artificial neural networks for the prediction of heating values. Energies 2020, 13, 4572. [Google Scholar] [CrossRef]

- Kardani, N.; Hedayati Marzbali, M.; Shah, K.; Zhou, A. Machine learning prediction of the conversion of lignocellulosic biomass during hydrothermal carbonization. Biofuels 2022, 13, 703–715. [Google Scholar] [CrossRef]

- Ismail, T.M.; Yoshikawa, K.; Sherif, H.; El-Salam, M.A. Hydrothermal treatment of municipal solid waste into coal in a commercial Plant: Numerical assessment of process parameters. Appl. Energy 2019, 250, 653–664. [Google Scholar] [CrossRef]

- Knötig, P.; Etzold, H.; Wirth, B. Model-based evaluation of hydrothermal treatment for the energy efficient dewatering and drying of sewage sludge. Processes 2021, 9, 1346. [Google Scholar] [CrossRef]

- Heidari, M.; Salaudeen, S.; Norouzi, O.; Acharya, B.; Dutta, A. Numerical comparison of a combined hydrothermal carbonization and anaerobic digestion system with direct combustion of biomass for power production. Processes 2020, 8, 43. [Google Scholar] [CrossRef]

- López, R.; González-Arias, J.; Pereira, F.J.; Fernández, C.; Cara-Jiménez, J. A techno-economic study of HTC processes coupled with power facilities and oxy-combustion systems. Energy 2021, 219, 119651. [Google Scholar] [CrossRef]

- Mohammadi, A.; Venkatesh, G.; Sandberg, M.; Eskandari, S.; Joseph, S.; Granström, K. A comprehensive environmental life cycle assessment of the use of hydrochar pellets in combined heat and power plants. Sustainability 2020, 12, 9026. [Google Scholar] [CrossRef]

- Stucki, M.; Eymann, L.; Gerner, G.; Hartmann, F.; Wanner, R.; Krebs, R. Hydrothermal carbonization of sewage sludge on industrial scale: Energy efficiency, environmental effects and combustion. J. Energy Chall. Mech. 2015, 2, 38–44. [Google Scholar]

- Energy of the Future. Available online: https://www.google.com/search?q=ava+co2&oq=ava+co2 (accessed on 5 October 2023).

- Schweiz, Ag. AVA-CO2 develops phosphorus recovery process. Membr. Technol. 2015, 2015, 6. [Google Scholar]

- Kläusli, T. AVA Biochem: Commercialising renewable platform chemical 5-HMF. Green Process. Synth. 2014, 3, 235–236. [Google Scholar] [CrossRef]

- Rosenfeld, C.; Konnerth, J.; Sailer-Kronlachner, W.; Solt, P.; Rosenau, T.; van Herwijnen, H.W. Current situation of the challenging scale-up development of hydroxymethylfurfural production. ChemSusChem 2020, 13, 3544–3564. [Google Scholar] [CrossRef]

- Lucian, M.; Merzari, F.; Messineo, A.; Volpe, M. Hydrothermal Carbonization of Sludge Residues via Carborem C700 Industrial Scale Continuous Operating Plant. Chem. Eng. Trans. 2022, 92, 19–24. [Google Scholar]

- Lucian, M.; Merzari, F.; Gubert, M.; Messineo, A.; Volpe, M. Industrial-scale hydrothermal carbonization of agro-industrial digested sludge: Filterability enhancement and phosphorus recovery. Sustainability 2021, 13, 9343. [Google Scholar] [CrossRef]

- Lundqvist, F.; Oden, E.; Ohman, F.; C Green Technology AB. Method and System for Hydrothermal Carbonization and Wet Oxidation of Sludge. U.S. Patent 11,724,952, 15 August 2023. [Google Scholar]

- Mäki, E.; Saastamoinen, H.; Melin, K.; Matschegg, D.; Davidis, B.; Spekreijse, J.; Tselepi, V.; Kourkoumpas, D.S.; Axegård, P. Innovative hydrothermal carbonization (HTC) process for a Nordic pulp and paper mill. In Proceedings of the 29th European Biomass Conference and Exhibition, Online, 26–29 April 2021. [Google Scholar]

- Axegård, P. Towards Industrial Implementation of HTC Treatment of Biosludge. In Proceedings of the Green north HTC conference, Umeå, Sweden, 13–14 March 2019. [Google Scholar]

- TerraNova Energy GmbH. Available online: https://www.google.com/search?q=Hydrothermal+Carbonization+and+Thermal+Hydrolysis+-+TerraNova%C2%AEultra+%28terranova-energy.com%29&sca_esv=594172598 (accessed on 2 November 2023).

- Buttmann, M. Industrial scale plant for sewage sludge treatment by hydrothermal carbonization in Jining/China and phosphate recovery by terranova® ultra-htc process. In Proceedings of the European Biosolids and Organic Resources Conference, Leeds, UK, 20–21 November 2017. [Google Scholar]

- Bagheri, M.; Wetterlund, E. Introducing hydrothermal carbonization to sewage sludge treatment systems—A way of improving energy recovery and economic performance. Waste Manag. 2023, 170, 131–143. [Google Scholar] [CrossRef]

- Edo, M. Hydrothermal Carbonization (HTC): Valorisation of Organic Waste and Sludges for Hydrochar Production of Biofertilizers; IEA Bioenergy: Paris, France, 2021. [Google Scholar]

- Jarnerud, T.; Karasev, A.V.; Wang, C.; Bäck, F.; Jönsson, P.G. Utilization of Organic Mixed Biosludge from Pulp and Paper Industries and Green Waste as Carbon Sources in Blast Furnace Hot Metal Production. Sustainability 2021, 13, 7706. [Google Scholar] [CrossRef]

- Burguete, P.; Corma, A.; Hitzl, M.; Modrego, R.; Ponce, E.; Renz, M. Fuel and chemicals from wet lignocellulosic biomass waste streams by hydrothermal carbonization. Green Chem. 2016, 18, 1051–1060. [Google Scholar] [CrossRef]

- Owsianiak, M.; Ryberg, M.W.; Renz, M.; Hitzl, M.; Hauschild, M.Z. Environmental performance of hydrothermal carbonization of four wet biomass waste streams at industry-relevant scales. ACS Sustain. Chem. Eng. 2016, 4, 6783–6791. [Google Scholar] [CrossRef]

- De Mena Pardo, B.; Doyle, L.; Renz, M.; Salimbeni, A. Industrial Scale Hydrothermal Carbonization: New Applications for Wet Biomass Waste; Ttz Bremerhaven: Bremerhaven, Germany, 2016; pp. 1–71. [Google Scholar]

- HTCycle. Available online: https://www.google.com/search?q=HTCycle&oq=HTCycle (accessed on 25 November 2023).

- HTCycle AG. Europeon Sustainable Phosphorous Platform eNews; HTCycle AG: Murchin, Germany, 2021. [Google Scholar]

- HTCycle GmbH. Sewage Sludge Reuse Phosphate Recovery with an Innovative HTC Technology, SMEs; HTCycle GmbH: Murchin, Germany, 2019; p. 3726258. [Google Scholar]

- Antaco. Available online: https://www.google.com/search?q=antaco&sca_esv=594172598 (accessed on 30 November 2023).

- Campbell, B.S.; Thorpe, R.B.; Peus, D.; Lee, J. Anaerobic digestion of untreated and treated process water from the hydrothermal carbonisation of spent coffee grounds. Chemosphere 2022, 293, 133529. [Google Scholar] [CrossRef]

- Suncoal. Available online: https://www.google.com/search?q=Suncoal&sca_esv=594172598 (accessed on 10 December 2023).

- Sekar, P.; Noordermeer, J.W.; Anyszka, R.; Gojzewski, H.; Podschun, J.; Blume, A. Hydrothermally Treated Lignin as a Sustainable Biobased Filler for Rubber Compounds. ACS Appl. Polym. Mater. 2023, 5, 2501–2512. [Google Scholar] [CrossRef]

- Wiedner, K.; Rumpel, C.; Steiner, C.; Pozzi, A.; Maas, R.; Glaser, B. Chemical evaluation of chars produced by thermochemical conversion (gasification, pyrolysis and hydrothermal carbonization) of agro-industrial biomass on a commercial scale. Biomass Bioenergy 2013, 59, 264–278. [Google Scholar] [CrossRef]

- Wagner, J.; Richter, R.; Struck, K.; Dinslage, R. Sewage Sludge Disposal; Berlin Water Workshop: Berlin, Germany, 2013. [Google Scholar]

- Safril, T.; Safril, B.; Yoshikawa, K. Commercial Demonstration of Solid Fuel Production from Municipal Solid Waste Employing the Hydrothermal Treatment. Int. J. Environ. Sci. 2017, 2, 316–323. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).