Recent Innovations in Computer and Automation Engineering for Performance Improvement in the Steel Industry Production Chain: A Review

Abstract

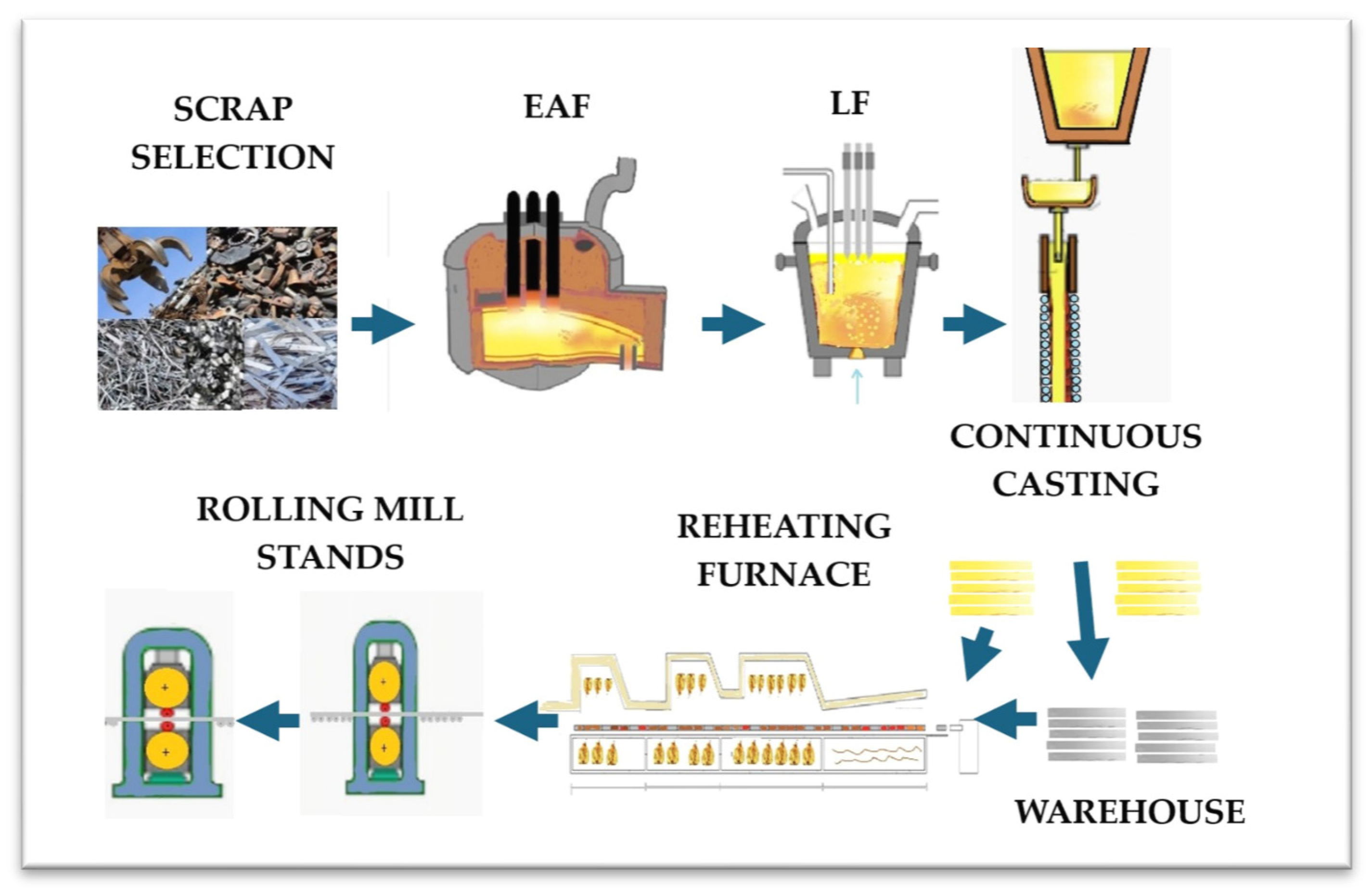

1. Introduction

- Assessment of the problems associated to the transition to Steelworks 4.0 and identification of technologies (e.g., artificial intelligence (AI) and virtual reality (VR)) that can enable digitalization [21];

- GHG control, with focus on emissions data [28];

- Supervisory Control and Data Acquisition (SCADA) systems [37];

- Instrumentation technology for automation [38];

- Production and operation decision optimization [36];

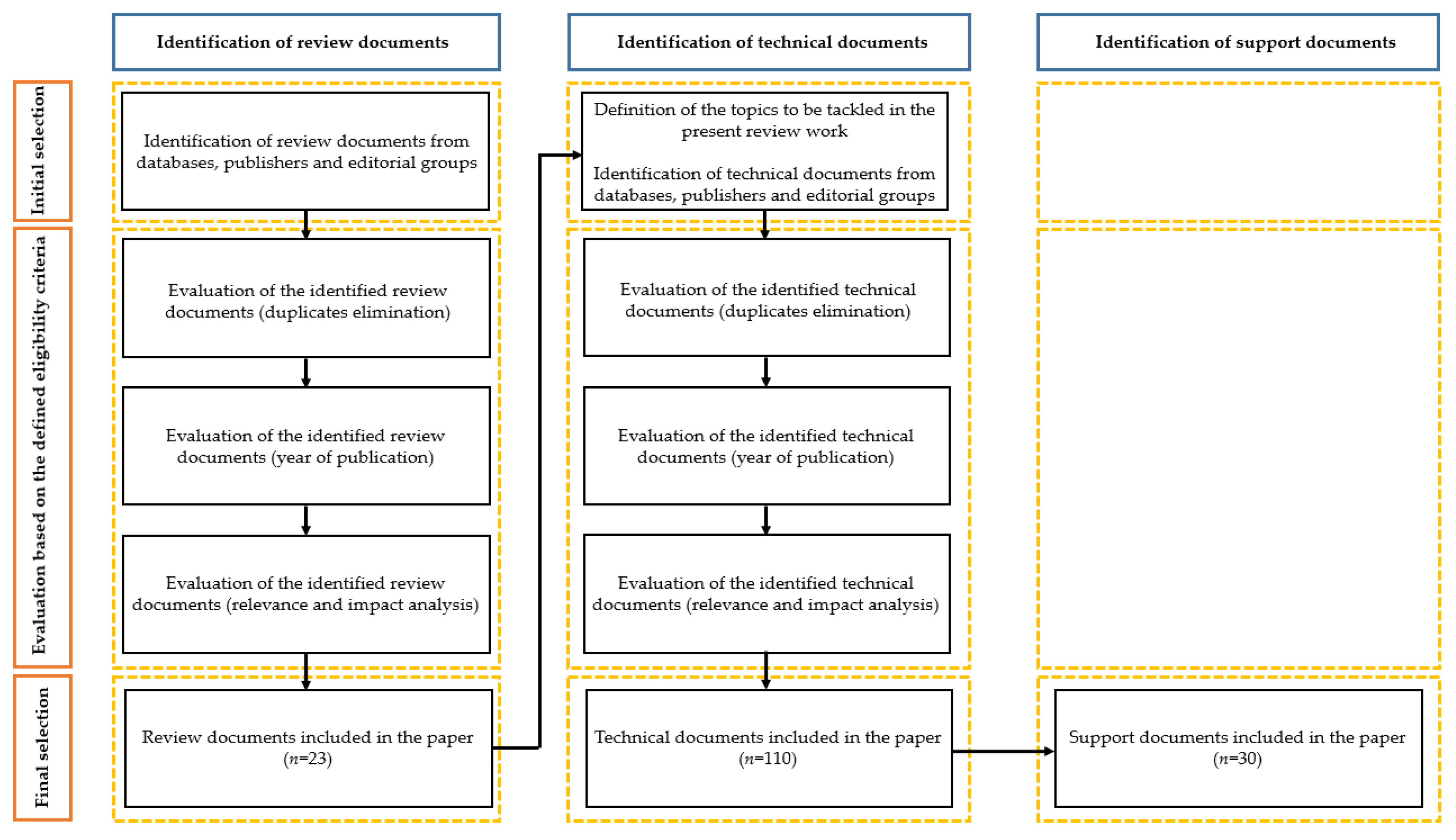

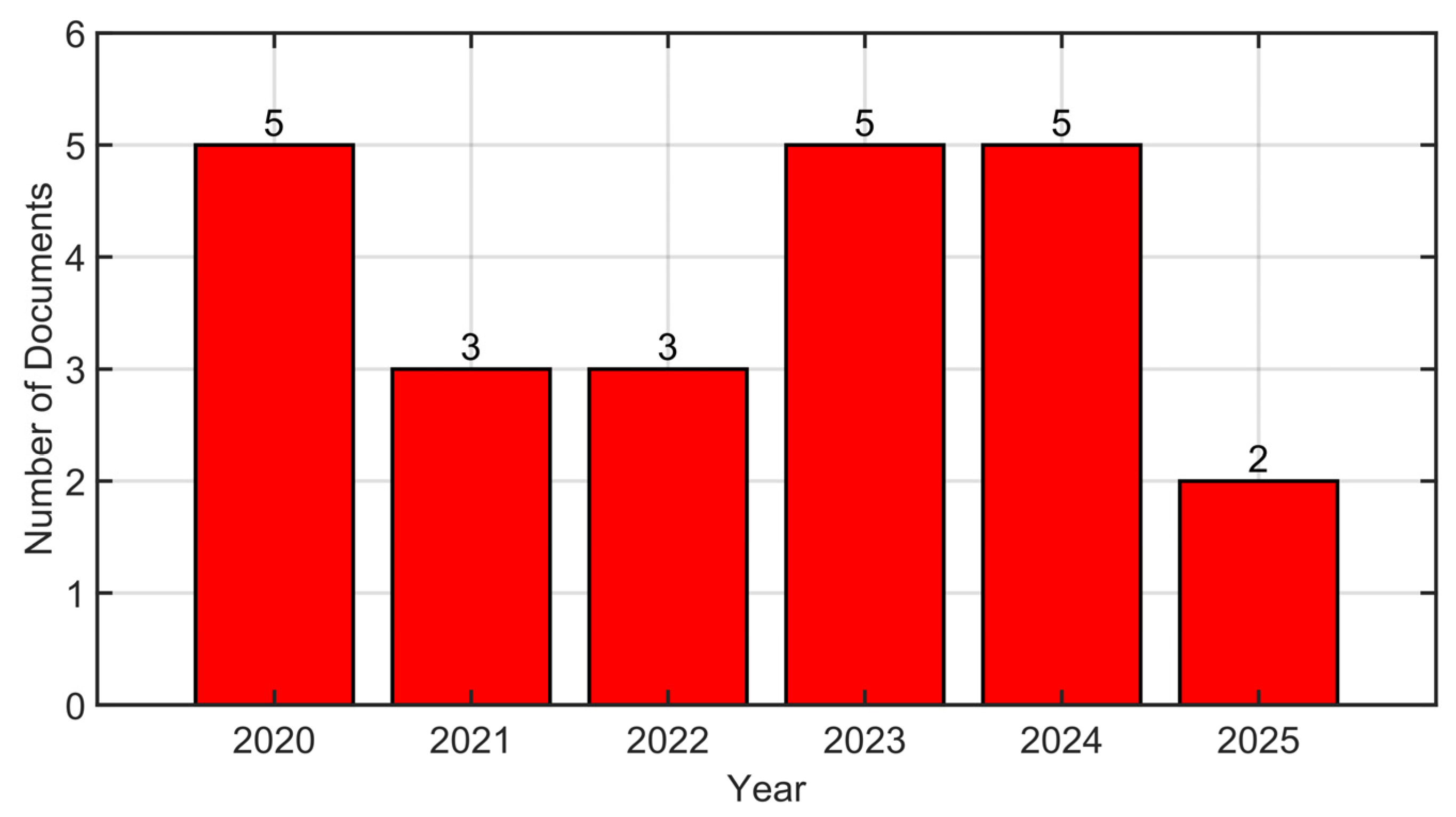

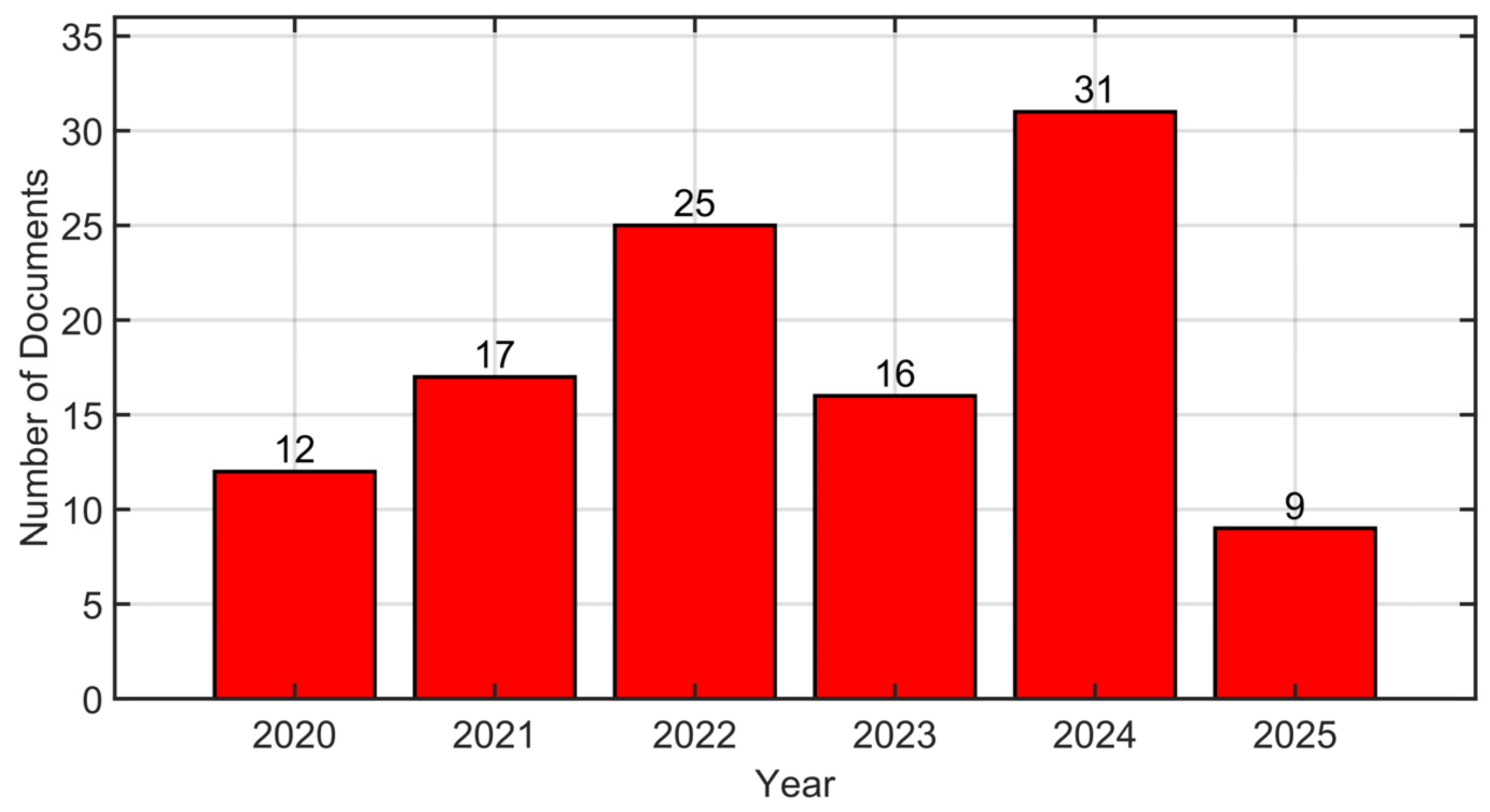

2. Methodology for the Literature Analysis

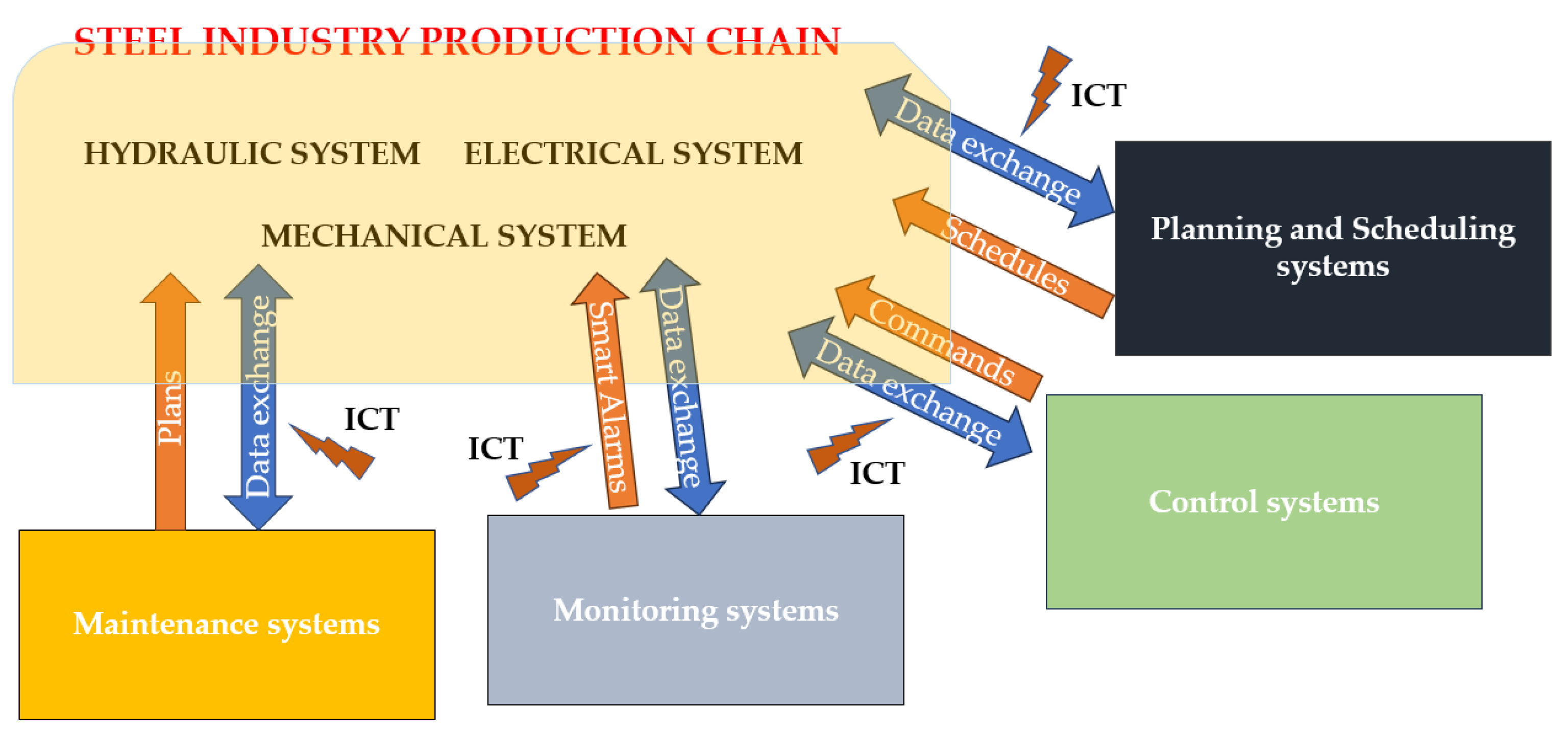

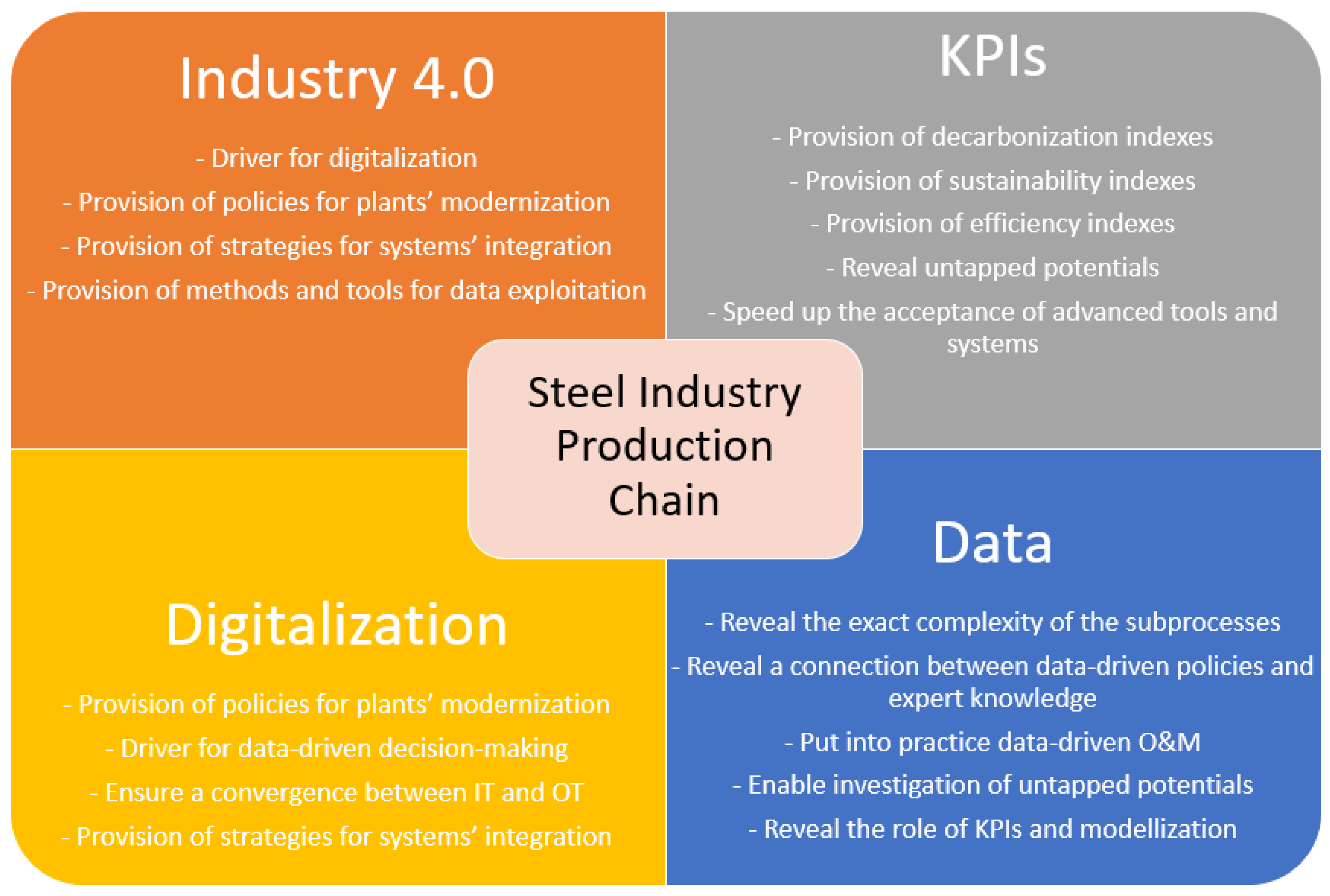

3. Industry 4.0 and Digitalization in the Steel Industry Production Chain

4. Data and KPIs in the Steel Industry Production Chain

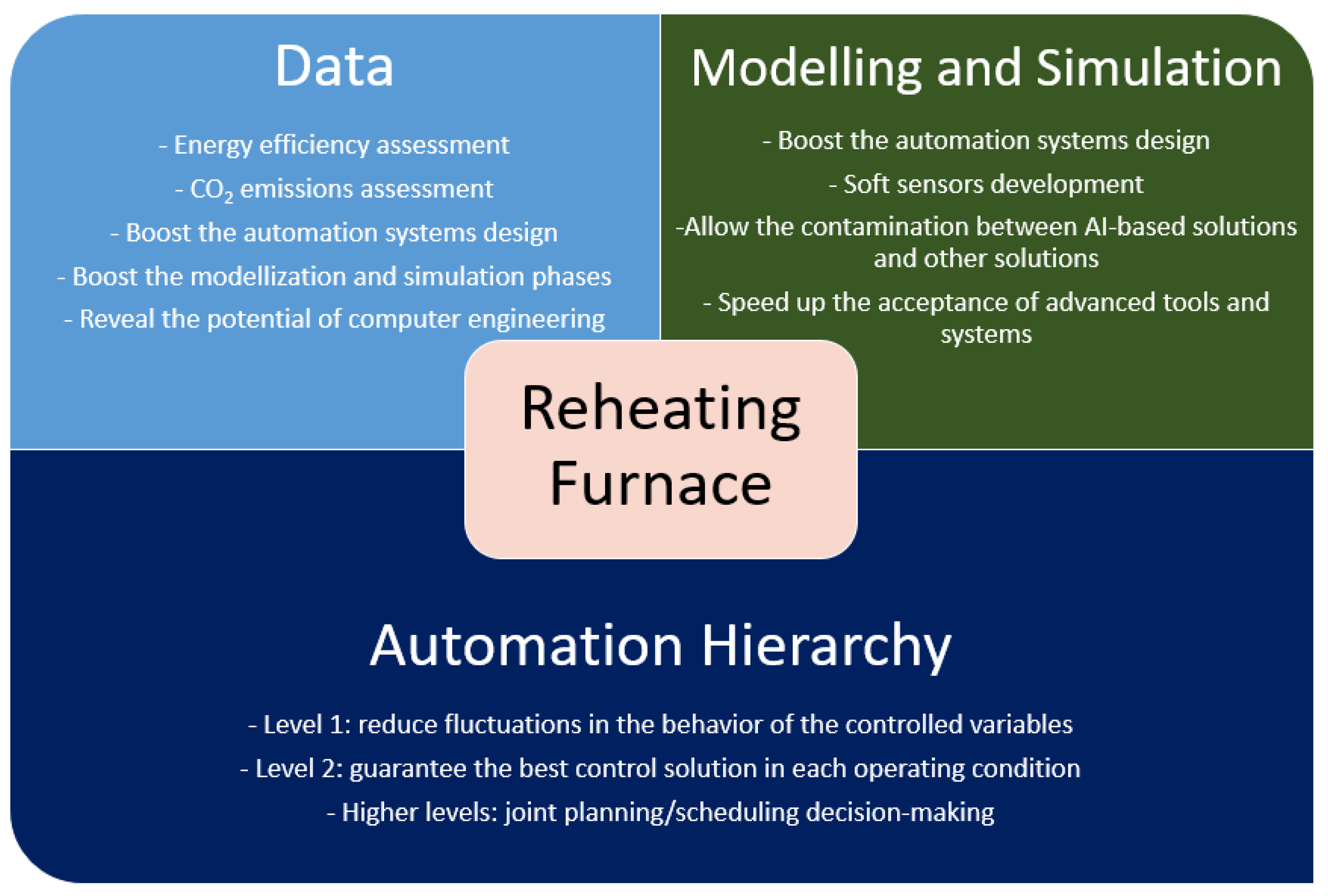

5. Focus on Steel Industry Reheating Furnaces in Hot Rolling Mills

5.1. Reheating Furnaces Description

5.2. Research Works on Selected Reheating Furnaces

6. Discussion

- Keep creating teams with computer and automation skills combined with other skills, e.g., energetics, for the development of tailored projects. The steel industry production chain involves very complex processes that are interconnected; knowledge fusion and skill sharing are fundamental requirements in order to evaluate significant variables the right way and at the right time.

- Keep reducing the gap between public and private entities in order to implement policy support, technological innovation, and collaborative efforts. In this way, roadmaps toward energy-efficiency and environmental sustainability can be enhanced and accelerated.

- Keep reducing the gap between facilities and universities with regard to computer and automation engineering. Facilities can provide expert knowledge on different aspects, e.g., current O&M procedures and critical issues to be addressed. Universities can provide state-of-the-art scientific and theoretical approaches.

- Increase the number of small-scale laboratories. Small-scale laboratories can support and speed up the development of optimized O&M practices through the small-scale implementation of parts of real plants.

- Increase the amount of open access information. Open access data can trigger the cross-fertilization of existent algorithms (e.g., those implemented in other sectors) within the steel industry production chain at all process and system levels, further speeding up performance improvement processes.

- Effectively apply scientific results associated to the steel industry production chain, and, in particular, with computer and automation engineering. The present paper highlights the huge benefits that can be obtained by properly applying the potential of data, KPIs, Industry 4.0, and digitalization in the steel industry production chain. In addition, the focus of this paper on reheating furnaces in hot rolling mills provides a zoomed-in view of a critical process which has crucial implications for emissions, energy consumption, and product quality.

- Keep exploring the connections among different processes in order to provide high-level analyses that consider all possible interconnections among different production chain stages.

- Use the mentioned trends in order to enhance the effectiveness of the monitoring/control (remote and onsite) of the different processes of the steel industry production chain.

- Keep customizing computer and automation solutions based on the target to be reached at each level.

- Keep sharing expert and data-driven knowledge in order to design computer and automation solutions which are able to untap hidden performance improvement margins.

7. Conclusions and Future Research Directions

- An overall assessment of Industry 5.0 for the steel industry production chain. In this context, a thorough shift to a “value-driven” approach (Industry 5.0, 2017) is required, starting from the Industry 4.0 “technology-driven” concept (born in 2011). Investigations into the coexistence of Industry 4.0 and Industry 5.0 and of the benefits that could be obtained thereof should be performed [158,159,160]. Industry 5.0 is based on sustainability, resiliency, and human-centricity. As mentioned in this paper, sustainability pathways are being proposed and tracked; on the other hand, additional efforts are required to achieve resilience and human-centricity. For example, with regard to human-centricity, operators of monitoring/control rooms (remote and onsite) could be placed out of the lower-level loops in order to gain crucial supervisory roles. In this context, XAI could support Industry 5.0 pathways [159,161,162]. The same rationale could be extended to higher levels of the automation hierarchy, where engineers could apply advanced decision making technologies.

- Industry 6.0 overall assessment for the steel industry production chains. Digital Twins must continue to show their potential and be implemented within industrial plants, while AR/VR concepts must acquire major diffusion [163].

- Overall assessment of opportunities to obtain challenging and strategic certifications (e.g., for Industry 5.0).

- Continue to shrink the gap between field implementation and simulation. Computer and automation engineering projects that are tailored to steel industry production chains, characterized by lasting field implementation, could be used to effectively highlight the potential of these disciplines in the field. The real implementation of a system requires in-depth evaluation of its robustness and reliability against the requirements of a system, as tested through simulations in a virtual environment.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| APC | Advanced Process Control |

| AR | Augmented Reality |

| BOF | Basic Oxygen Furnace |

| CCUS | Carbon Capture, Utilization, and Storage |

| CFD | Computational Fluid Dynamics |

| CNN | Convolutional Neural Network |

| CO2 | Carbon Dioxide |

| CPS | Cyber Physical System |

| DEA | Data Envelopment Analysis |

| DL | Deep Learning |

| DS | Digital Shadow |

| DSS | Decision Support System |

| DT | Digital Twin |

| EAF | Electric Arc Furnace |

| ERP | Enterprise Resource Planning |

| GAN | Generative Adversarial Network |

| GHG | Greenhouse Gas |

| GPC | Generalized Predictive Control |

| GRU | Gated Recurrent Unit |

| ICT | Information and Communication Technology |

| I&I | Immersion and Invariance |

| IIoT | Industrial Internet of Things |

| IoT | Internet of Things |

| IT | Information Technology |

| KPI | Key Performance Indicator |

| LCA | Life Cycle Assessment |

| LF | Ladle Furnace |

| LSTM | Long Short-Term Memory |

| MES | Manufacturing Execution System |

| ML | Machine Learning |

| MPC | Model Predictive Control |

| O&M | Operation and Maintenance |

| OT | Operation Technology |

| PLC | Programmable Logic Controller |

| PSO | Particle Swarm Optimization |

| RES | Renewable Energy Source |

| RL | Reinforcement Learning |

| RNN | Recurrent Neural Network |

| SCADA | Supervisory Control And Data Acquisition |

| SF-AHP | Spherical Fuzzy Analytic Hierarchy Process |

| SF-WASPAS | Spherical Fuzzy Weighted Aggregated Sum Product Assessment |

| SME | Small- and Medium-sized Enterprise |

| TCN | Temporal Convolutional Network |

| VHCA-DBSCAN | Varying-scale Hypercube Accelerated Density Based Spatial Clustering for Applications with Noise |

| VR | Virtual Reality |

| XAI | Explainable Artificial Intelligence |

References

- Griffin, P.W.; Hammond, G.P.; Norman, J.B. Industrial energy use and carbon emissions reduction: A UK perspective. Wiley Interdiscip. Rev. Energy Environ. 2016, 5, 684–714. [Google Scholar] [CrossRef]

- Sharmina, M.; Edelenbosch, O.Y.; Wilson, C.; Freeman, R.; Gernaat, D.E.H.J.; Gilbert, P.; Larkin, A.; Littleton, E.W.; Traut, M.; van Vuuren, D.P.; et al. Decarbonising the critical sectors of aviation, shipping, road freight and industry to limit warming to 1.5–2 °C. Clim. Policy 2020, 21, 455–474. [Google Scholar] [CrossRef]

- Kumar, A.; Tiwari, A.K.; Milani, D. Decarbonizing hard-to-abate heavy industries: Current status and pathways towards net-zero future. Process Saf. Environ. Prot. 2024, 187, 408–430. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Orlietti, L.; Cocchioni, F.; Astolfi, G.; Pepe, C. Optimization of the Clinker Production Phase in a Cement Plant. In CONTROLO 2020; Gonçalves, J.A., Braz-César, M., Coelho, J.P., Eds.; Lecture Notes in Electrical Engineering; Springer: Cham, Switzerland, 2021; Volume 695. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Astolfi, G. Advanced Process Control for Clinker Rotary Kiln and Grate Cooler. Sensors 2023, 23, 2805. [Google Scholar] [CrossRef] [PubMed]

- Gajdzik, B.; Wolniak, R.; Grebski, W.; Szymszal, J.; Grebski, M.E. Sustainability and Smart Manufacturing: The Transformation of the Steelwork Industry; Routledge: London, UK, 2024. [Google Scholar] [CrossRef]

- Holappa, L. Challenges and Prospects of Steelmaking towards the Year 2050. Metals 2021, 11, 1978. [Google Scholar] [CrossRef]

- Cavaliere, P. Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions Abatement; Springer: Cham, Switzerland, 2019; Available online: https://link.springer.com/book/10.1007/978-3-030-21209-4 (accessed on 31 October 2024).

- Steinböck, A. Model-Based Control and Optimization of a Continuous Slab Reheating Furnace; Shaker Verlag GmbH: Aachen, Germany, 2011. [Google Scholar]

- Nguyen, X.M.; Rodriguez-Ayerbe, P.; Lawayeb, F.; Dumur, D.; Mouchette, A. Temperature control of reheating furnace based on distributed model predictive control. In Proceedings of the 2014 18th International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 17–19 October 2014. [Google Scholar] [CrossRef]

- Liu, Z.; He, G.; Wang, L. Optimization of Furnace Combustion Control System Based on Double Cross-Limiting Strategy. In Proceedings of the 2010 International Conference on Intelligent Computation Technology and Automation, Changsha, China, 11–12 May 2010. [Google Scholar] [CrossRef]

- Trinks, W.; Mawhinney, M.H.; Shannon, R.A.; Reed, R.J.; Garvey, J.R. Industrial Furnaces; Wiley Online Library: New York, NY, USA, 2003. [Google Scholar]

- Mullinger, P.; Jenkins, B. Industrial and Process Furnaces. Principles, Design and Operation; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Bundesministerium für Wirtschaft und Klimaschutz. Available online: https://www.plattform-i40.de/ (accessed on 31 October 2024).

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Erro-Garcés, A. Industry 4.0: Defining the research agenda. Benchmarking Int. J. 2021, 28, 1858–1882. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Hancha, M.S. Predictive Maintenance in Twin Screw Air Compressors: A Case Study. In Proceedings of the 2023 24th International Carpathian Control Conference (ICCC), Miskolc-Szilvásvárad, Hungary, 12–14 June 2023. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Hancha, M.S. A Comparison Between Supervised Learning Techniques for Predictive Maintenance in Twin Screw Air Compressors. In Proceedings of the 2023 15th IEEE International Conference on Industry Applications (INDUSCON), São Bernardo do Campo, Brazil, 22–24 November 2023. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Transitioning of Steel Producers to the Steelworks 4.0—Literature Review with Case Studies. Energies 2021, 14, 4109. [Google Scholar] [CrossRef]

- Branca, T.A.; Fornai, B.; Colla, V.; Murri, M.M.; Streppa, E.; Schröder, A.J. Current and future aspects of the digital transformation in the European Steel Industry. Matériaux Tech. 2020, 108, 508. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Digitalisation and Innovation in the Steel Industry in Poland—Selected Tools of ICT in an Analysis of Statistical Data and a Case Study. Energies 2021, 14, 3034. [Google Scholar] [CrossRef]

- Götting, A.; Behrend, C.; Kohlgrüber, M. Identifying Future Skills for the Digital Transformation in the Steel Industry: An Ecosystem Analysis in the German Rhein/Ruhr Area. In Industry 4.0 and the Road to Sustainable Steelmaking in Europe; Topics in Mining, Metallurgy and Materials Engineering; Stroud, D., Schröder, A.J., Antonazzo, L., Behrend, C., Colla, V., Goti, A., Weinel, M., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Branca, T.A.; Fornai, B.; Colla, V.; Murri, M.M.; Streppa, E.; Schröder, A.J. The Challenge of Digitalization in the Steel Sector. Metals 2020, 10, 288. [Google Scholar] [CrossRef]

- Qi, F.; Xu, J.; Hou, Y.; Li, B. Digitization and greening of industrial reheating furnaces: A review of mathematical model, heating pattern, control system and energy analysis in the reheating furnace. Appl. Therm. Eng. 2025, 263, 125320. [Google Scholar] [CrossRef]

- Stroud, D.; Antonazzo, L.; Weinel, M. The Technological and Social Transformation of the European Steel Industry: Towards Decarbonisation and Digitalisation. In Industry 4.0 and the Road to Sustainable Steelmaking in Europe; Topics in Mining, Metallurgy and Materials Engineering; Stroud, D., Schröder, A.J., Antonazzo, L., Behrend, C., Colla, V., Goti, A., Weinel, M., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Qian, Y.; Li, Y.; Hao, Y.; Yu, T.; Hu, H. Greenhouse gas control in steel manufacturing: Inventory, assurance, and strategic reduction review. Carbon Res. 2024, 3, 27. [Google Scholar] [CrossRef]

- Depczyński, R.; Secka, J.; Cheba, K.; D’Alessandro, C.; Szopik-Depczyńska, K. Decision-Making Approach in Sustainability Assessment in Steel Manufacturing Companies—Systematic Literature Review. Sustainability 2023, 15, 11614. [Google Scholar] [CrossRef]

- Rodríguez Diez, J.; Tomé-Torquemada, S.; Vicente, A.; Reyes, J.; Orcajo, G.A. Decarbonization Pathways, Strategies, and Use Cases to Achieve Net-Zero CO2 Emissions in the Steelmaking Industry. Energies 2023, 16, 7360. [Google Scholar] [CrossRef]

- John, N.; Wesseling, J.H.; Worrell, E.; Hekkert, M. How key-enabling technologies’ regimes influence sociotechnical transitions: The impact of artificial intelligence on decarbonization in the steel industry. J. Clean. Prod. 2022, 370, 133624. [Google Scholar] [CrossRef]

- Mishra, R.; Singh, R.K.; Gunasekaran, A. Adoption of industry 4.0 technologies for decarbonisation in the steel industry: Self-assessment framework with case illustration. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- Wolniak, R.; Saniuk, S.; Grabowska, S.; Gajdzik, B. Identification of Energy Efficiency Trends in the Context of the Development of Industry 4.0 Using the Polish Steel Sector as an Example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- Shabur, M.A.; Rahman, K.A.; Siddiki, M.R. Evaluating the difficulties and potential responses to implement Industry 4.0 in Bangladesh’s steel sector. J. Eng. Appl. Sci. 2023, 70, 158. [Google Scholar] [CrossRef]

- Motallebi, S.; Zandieh, M.; Tabriz, A.A.; Tirkolaee, E.B. Assessing the industry 4.0 strategies for a steel supply chain: SWOT, game theory, and gap analysis. Heliyon 2025, 11, e41374. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Zhang, K.; Gao, X. Human-cyber-physical system for production and operation decision optimization in smart steel plants. Sci. China Technol. Sci. 2022, 65, 247–260. [Google Scholar] [CrossRef]

- Sverko, M.; Grbac, T.G.; Mikuc, M. SCADA Systems with Focus on Continuous Manufacturing and Steel Industry: A Survey on Architectures, Standards, Challenges and Industry 5.0. IEEE Access 2022, 10, 109395–109430. [Google Scholar] [CrossRef]

- Isei, Y. Recent progress of instrumentation technology for process automation in steel industry. Tetsu-Hagane/J. Iron Steel Inst. Jpn. 2020, 106, 591–601. [Google Scholar] [CrossRef]

- Colla, V.; Pietrosanti, C.; Malfa, E.; Peters, K. Environment 4.0: How digitalization and machine learning can improve the environmental footprint of the steel production processes. Matériaux Tech. 2020, 108, 507. [Google Scholar] [CrossRef]

- Tsutsui, K.; Namba, T.; Kihara, K.; Hirata, J.; Matsuo, S.; Ito, K. Current Trends on Deep Learning Techniques Applied in Iron and Steel Making Field: A Review. ISIJ Int. 2024, 64, 1619–1640. [Google Scholar] [CrossRef]

- Fang, W.; Huang, J.; Peng, T.; Long, Y.; Yin, F. Machine learning-based performance predictions for steels considering manufacturing process parameters: A review. J. Iron Steel Res. Int. 2024, 31, 1555–1581. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, J. State of the art in applications of machine learning in steelmaking process modeling. Int. J. Miner. Metall. Mater. 2023, 30, 2055–2075. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, L.; Zayed, M.E.; Elsheikh, A.H.; Li, W.; Yan, Q.; Wang, J. Industrial reheating furnaces: A review of energy efficiency assessments, waste heat recovery potentials, heating process characteristics and perspectives for steel industry. Process Saf. Environ. Prot. 2021, 147, 1209–1228. [Google Scholar] [CrossRef]

- Khalid, R.; Ahmed, N.; Anglani, N. Predictive Model for High Energy Consumption Processes in the Steel Manufacturing Industry Using Machine Learning Tools: Industry 4.0 Pathway. In Proceedings of the 2024 IEEE International Conference on Artificial Intelligence & Green Energy (ICAIGE), Yasmine Hammamet, Tunisia, 10–12 October 2024. [Google Scholar] [CrossRef]

- Ilmola, J.; Paananen, J.; Larkiola, J. Effect of Work Roll Surface Warming on Hot Strip Temperature Development in Industrial Scale Virtual Rolling Model. In Numerical Methods in Industrial Forming Processes, Proceedings of the NUMIFORM 2023, Kraków, Poland, 25–29 June 2023; Lecture Notes in Mechanical Engineering; Kusiak, J., Rauch, Ł., Regulski, K., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Wang, J.; Naber, H.; Ackermann, M.; Brasche, F.; Gramlich, A.; Krupp, U. Concept for databased material property description along the process chain press hardening: Implementing the Digital Material Twin and the Digital Material Shadow. Comput. Mater. Sci. 2025, 249, 113666. [Google Scholar] [CrossRef]

- Zhukov, P.; Fomin, A.; Glushchenko, A.; Podvalnyi, E. Comparison of Finite-difference and Data-based Models of Temperature Transfer Process in Heating Furnaces for Cast Billet Temperature Prediction. In Proceedings of the 2021 3rd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA), Lipetsk, Russian, 10–12 November 2021. [Google Scholar] [CrossRef]

- Kasper, L.; Schwarzmayr, P.; Birkelbach, F.; Javernik, F.; Schwaiger, M.; Hofmann, R. A digital twin-based adaptive optimization approach applied to waste heat recovery in green steel production: Development and experimental investigation. Appl. Energy 2024, 353, 122192. [Google Scholar] [CrossRef]

- Ma, Y.; Younis, K.; Ahmed, B.S.; Kassler, A.; Krakhmalev, P.; Thore, A.; Lindbäck, H. Automated and Systematic Digital Twins Testing for Industrial Processes. In Proceedings of the 2023 IEEE International Conference on Software Testing, Verification and Validation Workshops (ICSTW), Dublin, Ireland, 16–20 April 2023. [Google Scholar] [CrossRef]

- Cimino, A.; Longo, F.; Mirabelli, G.; Solina, V.; Verteramo, S. An ontology-based, general-purpose and Industry 4.0-ready architecture for supporting the smart operator (Part II—Virtual Reality case). J. Manuf. Syst. 2024, 73, 52–64. [Google Scholar] [CrossRef]

- Ma, Y.; Kassler, A.; Ahmed, B.S.; Krakhmalev, P.; Thore, A.; Toyser, A.; Lindbäck, H. Using Deep Reinforcement Learning for Zero Defect Smart Forging. In Proceedings of the 10th Swedish Production Symposium 2022 (SPS2022), Skövde, Sweden, 26–29 April 2022. [Google Scholar] [CrossRef]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction, 2nd ed.; The MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Nath, V.; Chattopadhyay, C. S2D2Net: An Improved Approach for Robust Steel Surface Defects Diagnosis with Small Sample Learning. In Proceedings of the 2021 IEEE International Conference on Image Processing (ICIP), Anchorage, AK, USA, 19–22 September 2021. [Google Scholar] [CrossRef]

- Gligoric, N.; Krco, S.; Drajic, D. Digital transformation in Industry 4.0 Using Vibration Sensors and Machine Learning. In Proceedings of the 2021 International Balkan Conference on Communications and Networking (BalkanCom), Novi Sad, Serbia, 20–22 September 2021. [Google Scholar] [CrossRef]

- Chen, X.; Van Hillegersberg, J.; Topan, E.; Smith, S.; Roberts, M. Application of data-driven models to predictive maintenance: Bearing wear prediction at TATA steel. Expert Syst. Appl. 2021, 186, 115699. [Google Scholar] [CrossRef]

- Ruiz-Sarmiento, J.-R.; Monroy, J.; Moreno, F.-A.; Galindo, C.; Bonelo, J.-M.; Gonzalez-Jimenez, J. A predictive model for the maintenance of industrial machinery in the context of industry 4.0. Eng. Appl. Artif. Intell. 2020, 87, 103289. [Google Scholar] [CrossRef]

- Raducan, E.; Nicolau, V.; Andrei, M.; Petrea, G.; Vlej, G.M. Prediction algorithms using specialized software tools for steel industry equipment. In Proceedings of the 2020 IEEE 26th International Symposium for Design and Technology in Electronic Packaging (SIITME), Pitesti, Romania, 21–24 October 2020. [Google Scholar] [CrossRef]

- Lou, S.; Yang, C.; Zhang, X.; Zhang, H.; Wu, P. From Complexity to Clarity: M2KCSVA’s Nonlinear Temporal Correlation Analysis and Stationary Estimation Pave the Way for Fault Diagnosis in Ironmaking Processes. IEEE Trans. Ind. Inform. 2024, 20, 5469–5481. [Google Scholar] [CrossRef]

- Mazzoleni, M.; Sarda, K.; Acernese, A.; Russo, L.; Manfredi, L.; Glielmo, L.; Del Vecchio, C. A fuzzy logic-based approach for fault diagnosis and condition monitoring of industry 4.0 manufacturing processes. Eng. Appl. Artif. Intell. 2022, 115, 105317. [Google Scholar] [CrossRef]

- Fei, J.; Ren, F.; Xu, L.; Doma, B.T.; Li, H. Comprehensive Computational Framework for Intelligent Steel Surface Defect Management and Prediction: A Synergy of Front end Interactivity, Back-end Robustness, and Predictive Modeling. IEEE Access 2024. [Google Scholar] [CrossRef]

- Hussain, T.; Seok, J. Steel Surface Defect Recognition in Smart Manufacturing Using Deep Ensemble Transfer Learning-Based Techniques. Comput. Model. Eng. Sci. 2025, 142, 231–250. [Google Scholar] [CrossRef]

- Aboulhosn, Z.; Musamih, A.; Salah, K.; Jayaraman, R.; Omar, M.; Aung, Z. Detection of Manufacturing Defects in Steel Using Deep Learning with Explainable Artificial Intelligence. IEEE Access 2024, 12, 99240–99257. [Google Scholar] [CrossRef]

- Miśkiewicz, R.; Wolniak, R. Practical Application of the Industry 4.0 Concept in a Steel Company. Sustainability 2020, 12, 5776. [Google Scholar] [CrossRef]

- Burresi, G.; Ermini, S.; Bernabini, D.; Lorusso, M.; Gelli, F.; Frustace, D.; Rizzo, A. Smart Retrofitting by Design Thinking Applied to an Industry 4.0 Migration Process in a Steel Mill Plant. In Proceedings of the 2020 9th Mediterranean Conference on Embedded Computing (MECO), Budva, Montenegro, 8–11 June 2020. [Google Scholar] [CrossRef]

- Chirumalla, K. Building digitally-enabled process innovation in the process industries: A dynamic capabilities approach. Technovation 2021, 105, 102256. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, D.; Ramtiyal, B.; Vijayvargy, L.; Bisht, S. Assessing feasibility of design constraints for mills in planning and scheduling of cold rolling: A case of steel industry. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 1519–1535. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Lan, S.-H.; Lee, H.-L. Applying ERP and MES to Implement the IFRS 8 Operating Segments: A Steel Group’s Activity-Based Standard Costing Production Decision Model. Sustainability 2020, 12, 4303. [Google Scholar] [CrossRef]

- Marinela, D.C.; Diana, S.; Gabriela, T.; Rodica, V.; Laura, C.; Dragos, S. Project Management in Steel Manufacturing. In Proceedings of the 2021 16th International Conference on Engineering of Modern Electric Systems (EMES), Oradea, Romania, 10–11 June 2021. [Google Scholar] [CrossRef]

- Kannisto, P.; Hästbacka, D.; Gutiérrez, T.; Suominen, O.; Vilkko, M.; Craamer, P. Plant-wide interoperability and decoupled, data-driven process control with message bus communication. J. Ind. Inf. Integr. 2022, 26, 100253. [Google Scholar] [CrossRef]

- Tang, J.; Liu, F.; Ma, X.; Lei, B.; Xie, Y. Integrated solution for industrial Internet based on edge computing. In Proceedings of the 2023 IEEE International Symposium on Broadband Multimedia Systems and Broadcasting (BMSB), Beijing, China, 14–16 June 2023. [Google Scholar] [CrossRef]

- Kasych, A.; Cherniavska, O.; Bondarenko, S.; Ievseitseva, O.; Glukhova, V. Industry 4.0 Technologies in Ensuring Environmental Friendliness of Production and Product Quality. In Proceedings of the 2022 IEEE 4th International Conference on Modern Electrical and Energy System (MEES), Kremenchuk, Ukraine, 20–23 October 2022. [Google Scholar] [CrossRef]

- Zsifkovits, H.; Kapeller, J.; Reiter, H.; Weichbold, C.; Woschank, M. Consistent Identification and Traceability of Objects as an Enabler for Automation in the Steel Processing Industry. In Industry 4.0 for SMEs; Matt, D., Modrák, V., Zsifkovits, H., Eds.; Palgrave Macmillan: Cham, Switerland, 2020. [Google Scholar] [CrossRef]

- Astudillo, M.F.; Krämer, K.; Arteaga, A. Using dynamic life cycle assessment to evaluate the effects of industry digitalization: A steel case study. J. Ind. Ecol. 2024, 28, 942–952. [Google Scholar] [CrossRef]

- Schulte, M. Steel Production Efficiency Improvements by Digitalization. In REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I); The Minerals, Metals & Materials Series; Lazou, A., Daehn, K., Fleuriault, C., Gökelma, M., Olivetti, E., Meskers, C., Eds.; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Maslak, O.; Maslak, M.; Grishko, N.; Yakovenko, Y.; Savielova, A. Formation of Metallurgy Industry Development Scenarios Based on Energy Efficiency and Digitalization of Production. In Proceedings of the 2023 IEEE 4th KhPI Week on Advanced Technology (KhPIWeek), Kharkiv, Ukraine, 2–6 October 2023. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Panagiotopoulou, V.C.; Papacharalampopoulos, A.; Aivaliotis, P.; Georgopoulos, D.; Smyrniotakis, K. A Framework for CO2 Emission Reduction in Manufacturing Industries: A Steel Industry Case. Designs 2022, 6, 22. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W.W. An Econometric Model of the Operation of the Steel Industry in POLAND in the Context of Process Heat and Energy Consumption. Energies 2022, 15, 7909. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W.W. Electricity and Heat Demand in Steel Industry Technological Processes in Industry 4.0 Conditions. Energies 2023, 16, 787. [Google Scholar] [CrossRef]

- Akyazi, T.; Goti, A.; Báyon, F. The Effects of Industry 4.0 on Steel Workforce: Identifying the Current and Future Skills Requirements of the Steel Sector and Developing a Sectorial Database. In Industry 4.0 and the Road to Sustainable Steelmaking in Europe; Topics in Mining, Metallurgy and Materials Engineering; Stroud, D., Schröder, A.J., Antonazzo, L., Behrend, C., Colla, V., Goti, A., Weinel, M., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Iannino, V.; Colla, V.; Mocci, C.; Matino, I.; Dettori, S.; Kolb, S.; Plankenbühler, T.; Karl, J. Multi-agent systems to improve efficiency in steelworks. Matériaux Tech. 2021, 109, 502. [Google Scholar] [CrossRef]

- Nayeri, S.; Vamarzani, M.Z.; Asadi, Z.; Sazvar, Z.; Javadian, N. Raw Material Provider Selection Problem Considering the Digitalization, Circular Economy and Resilience Dimensions: A Case Study. Int. J. Ind. Eng. Prod. Res. 2024, 35, 1–20. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Patra, P.K.; Jha, R. AHSS applications in Industry 4.0: Determination of optimum processing parameters during coiling process through unsupervised machine learning approach. Mater. Today Commun. 2022, 31, 103625. [Google Scholar] [CrossRef]

- Zhang, C.-J.; Zhang, Y.-C.; Han, Y. Industrial cyber-physical system driven intelligent prediction model for converter end carbon content in steelmaking plants. J. Ind. Inf. Integr. 2022, 28, 100356. [Google Scholar] [CrossRef]

- Yan, S.; Xu, D.; Yan, H.; Wang, Z.; He, H.; Wang, X.; Yang, Q. Measurement Method of Bar Unmanned Warehouse Area Based on Binocular Vision. Processes 2024, 12, 466. [Google Scholar] [CrossRef]

- Nenchev, B.; Panwisawas, C.; Yang, X.; Fu, J.; Dong, Z.; Tao, Q.; Gebelin, J.-C.; Dunsmore, A.; Dong, H.; Li, M. Metallurgical data science for steel industry: A case study on basic oxygen furnace. Steel Res. Int. 2022, 93, 2100813. [Google Scholar] [CrossRef]

- Yang, W.; Yi, G.; Zhiyu, Z.; Yue, C.; Wang, X.; Shuai, L.; Ning, L.; Jin, Z.; Dawei, Y. Correlation Analysis and Monitoring Method of Carbon Emissions in the Steel Industry Based on Big Data. Strateg. Plan. Energy Environ. 2023, 43, 27–54. [Google Scholar] [CrossRef]

- Buczaj, M.; Sumorek, A. A Computer system for acquisition and analysis of measurement data for a skew rolling mill in manufacturing steel balls. Inform. Autom. Pomiary Gospod. Ochr. Sr. 2020, 10, 47–50. [Google Scholar] [CrossRef]

- Bechny, M.; Sobieczky, F.; Zeindl, J.; Ehrlinger, L. Missing Data Patterns: From Theory to an Application in the Steel Industry. In Proceedings of the 33rd International Conference on Scientific and Statistical Database Management, Tampa, FL, USA, 6–7 July 2021. [Google Scholar] [CrossRef]

- Sarda, K.; Yerudkar, A.; Vecchio, C.D. Missing Data Imputation for Real Time-series Data in a Steel Industry using Generative Adversarial Networks. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021. [Google Scholar] [CrossRef]

- Yang, C.; Jin, F.; Zhao, J.; Wang, W. A Deep-Convolution-Generative-Adversarial-Networks-based Missing Data Filling Method for Blast Furnace Gas System in Steel Industry. In Proceedings of the 2022 IEEE 11th Data Driven Control and Learning Systems Conference (DDCLS), Chengdu, China, 3–5 August 2022. [Google Scholar] [CrossRef]

- He, H.; Pan, Y.; Tao, Y.; Li, Z.; Li, G. Research on Data-Driven Carbon Emission Prediction Method for the Steel Industry. In Proceedings of the 2024 Second International Conference on Cyber-Energy Systems and Intelligent Energy (ICCSIE), Shenyang, China, 17–19 May 2024. [Google Scholar] [CrossRef]

- Karthick, K.; Dharmaprakash, R.; Sathya, S. Predictive Modeling of Energy Consumption in the Steel Industry Using CatBoost Regression: A Data-Driven Approach for Sustainable Energy Management. Int. J. Robot. Control Syst. 2024, 4, 33–49. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Cao, Z.; Zhang, R.; Zhang, L. Daily Load Forecasting and Data-Driven Strategies for Steel Industry Based on Random Forest Modeling. Appl. Math. Nonlinear Sci. 2024, 9, 1–18. [Google Scholar] [CrossRef]

- Khalili-Fard, A.; Sabouhi, F.; Bozorgi-Amiri, A. Data-driven robust optimization for a sustainable steel supply chain network design: Toward the circular economy. Comput. Ind. Eng. 2024, 195, 110408. [Google Scholar] [CrossRef]

- Nguyen, T.-L.; Nguyen, P.-H.; Pham, H.-A.; Nguyen, T.-G.; Nguyen, D.-T.; Tran, T.-H.; Le, H.-C.; Phung, H.-T. A Novel Integrating Data Envelopment Analysis and Spherical Fuzzy MCDM Approach for Sustainable Supplier Selection in Steel Industry. Mathematics 2022, 10, 1897. [Google Scholar] [CrossRef]

- Backes, J.G.; Suer, J.; Pauliks, N.; Neugebauer, S.; Traverso, M. Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability 2021, 13, 3443. [Google Scholar] [CrossRef]

- Zhao, F.; Yin, C.; Huo, X.; Xu, Y. Research on Quality Control Application of Whole Process Intelligent Manufacturing in Steel Industry 4.0 Based on Big Data Analysis. J. Netw. Intell. 2022, 7, 685–703. [Google Scholar]

- Straat, M.; Koster, K.; Goet, N.; Bunte, K. An Industry 4.0 example: Real-time quality control for steel-based mass production using Machine Learning on non-invasive sensor data. In Proceedings of the 2022 International Joint Conference on Neural Networks (IJCNN), Padua, Italy, 18–23 July 2022. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Tang, L.; Zhang, Q. Multiobjective Ensemble Learning with Multiscale Data for Product Quality Prediction in Iron and Steel Industry. IEEE Trans. Evol. Comput. 2024, 28, 1099–1113. [Google Scholar] [CrossRef]

- Szelążek, M.; Bobek, S.; Nalepa, G.J. Semantic data mining-based decision support for quality assessment in steel industry. Expert Syst. 2024, 41, e13319. [Google Scholar] [CrossRef]

- Wang, A. Manufacturing Data Fusion: A Case Study with Steel Rolling Processes. In Multimodal and Tensor Data Analytics for Industrial Systems Improvement; Springer Optimization and Its Applications; Gaw, N., Pardalos, P.M., Gahrooei, M.R., Eds.; Springer: Cham, Switzerland, 2024; Volume 211. [Google Scholar] [CrossRef]

- Sarda, K.; Del Vecchio, C.; Fruggiero, F.; Mancusi, F.; Menchetti, F.; Natale, R. Physics-Enhanced Digital Twin based solution to control process state in a Steel Manufacturing plant. IFAC-PapersOnLine 2024, 58, 31–36. [Google Scholar] [CrossRef]

- Jin, F.; Wu, H.; Liu, Y.; Zhao, J.; Wang, W. Varying-scale HCA-DBSCAN-based anomaly detection method for multi-dimensional energy data in steel industry. Inf. Sci. 2023, 647, 119479. [Google Scholar] [CrossRef]

- Kaçar, S.; Balli, T.; Yetkin, E.F. Automatic Segmentation of Time Series Data with PELT Algorithm for Predictive Maintenance in the Flat Steel Industry. In Proceedings of the 2024 9th International Conference on Computer Science and Engineering (UBMK), Antalya, Turkiye, 26–28 October 2024. [Google Scholar] [CrossRef]

- Chavosh Nejad, M.; Hadavandi, E.; Nakhostin, M.M.; Mehmanpazir, F. A data-driven model for energy consumption analysis along with sustainable production: A case study in the steel industry. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 3360–3380. [Google Scholar] [CrossRef]

- Cho, S.; Jung, Y.; Seo, Y.; Jung, K.; Choi, S. Optimization Analysis and Standardization of Rolling Process with Machine Learning. In Proceedings of the 2022 IEEE International Conference on Big Data (Big Data), Osaka, Japan, 17–20 December 2022. [Google Scholar] [CrossRef]

- Ruiz, E.; Ferreño, D.; Cuartas, M.; López, A.; Arroyo, V.; Gutiérrez-Solana, F. Machine learning algorithms for the prediction of the strength of steel rods: An example of data-driven manufacturing in steelmaking. Int. J. Comput. Integr. Manuf. 2020, 33, 880–894. [Google Scholar] [CrossRef]

- Park, C.Y.; Kim, J.W.; Kim, B.; Lee, J. Prediction for Manufacturing Factors in a Steel Plate Rolling Smart Factory Using Data Clustering-Based Machine Learning. IEEE Access 2020, 8, 60890–60905. [Google Scholar] [CrossRef]

- Kim, S.-i.; Joo, Y. Energy-based key performance indicator for energy-intensive manufacturing processes: Application to steel casting. Energy 2025, 317, 134543. [Google Scholar] [CrossRef]

- Sampaio Brasil, J.E.; Piran, F.A.S.; Lacerda, D.P.; Morandi, M.I.W.; Oliveira da Silva, D.; Sellitto, M.A. Enhancing the efficiency of a gas-fueled reheating furnace of the steelmaking industry: Assessment and improvement. Manag. Environ. Qual. 2024, 35, 1254–1273. [Google Scholar] [CrossRef]

- Fărcean, I.; Proştean, G.; Socalici, A. Sustainable development indicators in the steel industry. J. Phys. Conf. Ser. 2023, 2540, 012045. [Google Scholar] [CrossRef]

- Tolettini, L.; Di Maria, E. Structuring and Measuring Environmental Sustainability in the Steel Sector: A Single Case Study. Sustainability 2023, 15, 6272. [Google Scholar] [CrossRef]

- Jiao, Y.; Chen, Q.; Wu, Y.; Ji, C.; Zhang, N.; Luo, H.; Zhang, K. Designing new environmental policy instruments to promote the sustainable development of iron and steel production in China: A comparative analysis of cleaner production assessment indicator systems and the assessment principles of the green factory. Resour. Policy 2024, 96, 105244. [Google Scholar] [CrossRef]

- Wurster, L.; Koval, V. Evaluating Waste Heat Recovery Potentials and Key Performance Indicators in Energy-Intensive Sectors. In Renewables in the Circular Economy and Business; SpringerBriefs in Applied Sciences and Technology; Koval, V., Ed.; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Branca, T.A.; Matino, I.; Colla, V.; Petrucciani, A.; Singh, A.K.M.; Zaccara, A.; Beone, T.; De Cecco, L.; Hakala, V.; Lorito, D.; et al. Paving the way for the optimization of water consumption in the steelmaking processes: Barriers, analysis and KPIs definition. Matériaux Tech. 2020, 108, 510. [Google Scholar] [CrossRef]

- Hajoary, P.K.; Amrita, M.A.; Garza-Reyes, J.A. Industry 4.0 maturity assessment: A multi-dimensional indicator approach. Int. J. Product. Perform. Manag. 2024, 73, 981–1004. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Astolfi, G.; Di Carlo, A.; Mathis, R. Data Analysis and Predictive Control for a Pusher-Type Billets’ Reheating Furnace. In Proceedings of the 10th International Conference on Mechatronics and Control Engineering, ICMCE 2021, Online, 26–28 July 2021; Lecture Notes in Mechanical Engineering. Conte, G., Sename, O., Eds.; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Astolfi, G.; Moscoloni, E. Analysis and Modeling of Steel Industry Reheating Furnace Billets Temperature. In Proceedings of the 2022 23rd International Carpathian Control Conference (ICCC), Sinaia, Romania, 29 May–1 June 2022. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Cocchioni, F.; Valzecchi, C.; Pepe, C. Model Predictive Control of a Pusher Type Reheating Furnace. In CONTROLO 2020; Lecture Notes in Electrical Engineering; Gonçalves, J.A., Braz-César, M., Coelho, J.P., Eds.; Springer: Cham, Switzerland, 2021; Volume 695. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Moscoloni, E.; Astolfi, G. Data Analysis and Modelling of Billets Features in Steel Industry. Sensors 2022, 22, 7333. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Orlietti, L. Multi-Mode Model Predictive Control Approach for Steel Billets Reheating Furnaces. Sensors 2023, 23, 3966. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Orlietti, L. Synergic Combination of Hardware and Software Innovations for Energy Efficiency and Process Control Improvement: A Steel Industry Application. Energies 2023, 16, 4183. [Google Scholar] [CrossRef]

- Joo, Y.; Oh, S.H.; Cho, M.; Kim, S.-i. Manufacturing information-based energy usage simulation for energy-intensive steel casting process. J. Clean. Prod. 2022, 379, 134731. [Google Scholar] [CrossRef]

- Maciejowski, J.M. Predictive Control with Constraints; Prentice-Hall, Pearson Education Ltd.: Harlow, UK, 2002. [Google Scholar]

- Bemporad, A.; Morari, M.; Ricker, N.L. Model Predictive Control Toolbox User’s Guide; MathWorks: Natick, MA, USA, 2015. [Google Scholar]

- Seo, M.; Ban, J.; Koo, B.Y.; Kim, S.W. Static Model Identification for Sendzimir Rolling Mill Using Noise Corrupted Operation Data. IEEE Access 2020, 8, 150685–150695. [Google Scholar] [CrossRef]

- Kang, Y.; Zhao, J.-X.; Li, B.; Ren, M.-M.; Cao, G.; Yue, S.; An, B.-Q. End-point prediction of converter steelmaking based on main process data. Steel Res. Int. 2024, 95, 2400151. [Google Scholar] [CrossRef]

- ISA. ISA-95.00. 01-2000: Enterprise-Control System Integration Part 1: Models and Terminology; Technical Report; ISA, The Instrumentation, Systems, and Automation Society: Pittsburgh, PA, USA, 2000. [Google Scholar]

- Schmitz, N.; Sankowski, L.; Kaiser, F.; Schwotzer, C.; Echterhof, T.; Pfeifer, H. Towards CO2-neutral process heat generation for continuous reheating furnaces in steel hot rolling mills—A case study. Energy 2021, 224, 120155. [Google Scholar] [CrossRef]

- Niekurzak, M.; Mikulik, J. Modeling of Energy Consumption and Reduction of Pollutant Emissions in a Walking Beam Furnace Using the Expert Method—Case Study. Energies 2021, 14, 8099. [Google Scholar] [CrossRef]

- Lu, B.; Wang, X.; Chen, D.; Wang, H.; Hu, Q.; Chen, Y.; Huang, M. Energy saving study of reheating furnace from structure and oxygen-enriched combustion. Appl. Therm. Eng. 2025, 263, 125337. [Google Scholar] [CrossRef]

- Karambelkar, A.; Uzor, C.; Walla, N.; Silaen, A.; Johnson, K.; Zhou, C. Hydrogen-Fueled Regenerative Burners in a Reheating Furnace. In Proceedings of the ASME 2023 Heat Transfer Summer Conference collocated with the ASME 2023 17th International Conference on Energy Sustainability, Washington, DC, USA, 10–12 July 2023. [Google Scholar] [CrossRef]

- Lemus-Ávalos, L.; Ramos-Banderas, J.Á.; Hernández-Bocanegra, C.A.; Calderón-Rojas, M.U.; Solorio-Díaz, G. Energy optimization of a steel slab reheating furnace through the use of swirl and diffusion burners using a new mathematical simulation methodology. Numer. Heat Transf. Part B Fundam. 2024, 1–18. [Google Scholar] [CrossRef]

- Yang, K.; Yu, B.; Wang, M.; Rao, W.; Xiao, Q.; Wang, H. Quantitative Uniformity Evaluation of Steel Slab Heating Temperature by Non-contact Measuring Approach. Metall. Mater. Trans. 2024, 55, 4890–4905. [Google Scholar] [CrossRef]

- Ji, W.; Li, G.; Wei, L.; Yi, Z. Modeling and determination of total heat exchange factor of regenerative reheating furnace based on instrumented slab trials. Case Stud. Therm. Eng. 2021, 24, 100838. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Hou, Y.; Zhang, Y. Influence mechanism of flow parameters on temperature field in the regenerative reheating furnace. Int. J. Thermofluids 2022, 15, 100160. [Google Scholar] [CrossRef]

- Kavak, D.; Yalçın, Y. The modeling and identification of walking beam type slab reheating furnace based on immersion and invariance disturbance estimation. Control. Eng. Pract. 2023, 139, 105611. [Google Scholar] [CrossRef]

- de Souza Lima, R.; Scardua, L.A.; de Almeida, G.M. Predicting Temperatures Inside a Steel Slab Reheating Furnace Using Neural Networks. IEEE Trans. Ind. Appl. 2025, 1–10. [Google Scholar] [CrossRef]

- de Souza Lima, R.; Scardua, L.A.; de Almeida, G.M. Predicting Temperatures Inside a Steel Slab Reheating Furnace Using Deep Learning. In Proceedings of the 2023 15th IEEE International Conference on Industry Applications (INDUSCON), São Bernardo do Campo, Brazil, 22–24 November 2023. [Google Scholar] [CrossRef]

- Zhukov, P.; Glushchenko, A.; Fomin, A. On Adaptation of Third Kind Boundary Conditions for Grid Models of Nonstationary Heat Exchange. In Proceedings of the 2022 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 16–20 May 2022. [Google Scholar] [CrossRef]

- Skopec, P.; Vyhlídal, T.; Knobloch, J. Development of a continuous reheating furnace state-space model based on the finite volume method. Appl. Therm. Eng. 2024, 246, 122888. [Google Scholar] [CrossRef]

- Gao, Q.; Pang, Y.; Sun, Q.; Liu, D.; Zhang, Z. Modeling approach and numerical analysis of a roller-hearth reheating furnace with radiant tubes and heating process optimization. Case Stud. Therm. Eng. 2021, 28, 101618. [Google Scholar] [CrossRef]

- Liu, Q.; Hanoglu, U.; Rek, Z.; Šarler, B. Simulation of Temperature Field in Steel Billets during Reheating in Pusher-Type Furnace by Meshless Method. Math. Comput. Appl. 2024, 29, 30. [Google Scholar] [CrossRef]

- Xu, J.; Li, B.; Qi, F. Effect assessment of charging conditions on energy consumption and slab heating quality in an industrial-scale reheating furnace. Appl. Therm. Eng. 2025, 265, 125565. [Google Scholar] [CrossRef]

- Zhai, N.; Zhou, X.; Li, S.; Shi, H. Soft Sensor Model for Billet Temperature in Multiple Heating Furnaces Based on Transfer Learning. IEEE Trans. Instrum. Meas. 2023, 72, 3513613. [Google Scholar] [CrossRef]

- Yu, H.; Gong, J.; Wang, G.; Chen, X. A Hybrid Model for Billet Tapping Temperature Prediction and Optimization in Reheating Furnace. IEEE Trans. Ind. Inform. 2023, 19, 8703–8712. [Google Scholar] [CrossRef]

- Chaudhari, T.S.; Pise, A.S.; Mahato, A.K.; Satyam, K. Study on the scale formation of AISI–1018 carbon steel in walking beam steel reheat furnace. Mater. Today Proc. 2022, 62, 3916–3921. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, M.; Chen, L.; Chen, X.; Cao, W.; Du, S.; Pedrycz, W. Hybrid Intelligent Control Based on Condition Identification for Combustion Process in Heating Furnace of Compact Strip Production. IEEE Trans. Ind. Electron. 2022, 69, 2790–2800. [Google Scholar] [CrossRef]

- Chen, C.-J.; Liao, Y.-C.; Chou, F.-I. Optimal Design of the Cascade Controller for Reheating Furnace by Taguchi Method. IEEE Access 2024, 12, 39728–39736. [Google Scholar] [CrossRef]

- Guo, C. A Study of Optimization Strategy for Furnace Temperature Control System Based on Particle Swarm Optimization (PSO). In Proceedings of the 2024 IEEE 4th International Conference on Electronic Technology, Communication and Information (ICETCI), Changchun, China, 24–26 May 2024. [Google Scholar] [CrossRef]

- Carhuavilca, L.A.; Castro, E.N.; Rodriguez, A.L.; Esparta, D.B. A Comparison of GPC and Fuzzy Smith Predictor for Temperature Control of Steel Slab Reheating Furnace. In Proceedings of the 2021 IEEE XXVIII International Conference on Electronics, Electrical Engineering and Computing (INTERCON), Lima, Peru, 5–7 August 2021. [Google Scholar] [CrossRef]

- Chen, C.-J.; Chou, F.-I.; Chou, J.-H. Temperature Prediction for Reheating Furnace by Gated Recurrent Unit Approach. IEEE Access 2022, 10, 33362–33369. [Google Scholar] [CrossRef]

- Yang, Z.; Luo, X.; Qiao, J. A combined adaptive entropy-TOPSIS and model predictive control strategy for mixed loading and delay operations in the reheating furnace. Optim. Control Appl. Meth. 2023, 44, 2775–2795. [Google Scholar] [CrossRef]

- Zhang, T.; Li, M.-J.; Bi, L.-S. The study of heat transfer characteristics and a real-time synergistic control method on reheating furnace based on physical field regulation. Energy 2025, 317, 134694. [Google Scholar] [CrossRef]

- Ding, J.G.; Kong, L.P.; Guo, J.H.; Song, M.X.; Jiao, Z.J. Multi-Objective Optimization of Slab Heating Process in Walking Beam Reheating Furnace Based on Particle Swarm Optimization Algorithm. Steel Res. Int. 2020, 92, 2000382. [Google Scholar] [CrossRef]

- Wang, Q.; Han, Z.; Zhao, J.; Wang, W. Integrated Multi-Objective Optimization for Reheating Furnace Scheduling and Rolling Plan in Hot Rolling Process of Steel Industry. In Proceedings of the 2022 34th Chinese Control and Decision Conference (CCDC), Hefei, China, 15–17 August 2022. [Google Scholar] [CrossRef]

- Jiang, S.-L.; He, L.; Cao, L.; Sun, L.; Peng, G. A learning-enhanced ant colony optimization algorithm for integrated planning and scheduling in hot rolling production lines under uncertainty. Swarm Evol. Comput. 2025, 93, 101851. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Rame, R.; Purwanto, P.; Sudarno, S. Industry 5.0 and sustainability: An overview of emerging trends and challenges for a green future. Innov. Green Dev. 2024, 3, 100173. [Google Scholar] [CrossRef]

- Sarkar, B.D.; Shardeo, V.; Dwivedi, A.; Pamucar, D. Digital transition from industry 4.0 to industry 5.0 in smart manufacturing: A framework for sustainable future. Technol. Soc. 2024, 78, 102649. [Google Scholar] [CrossRef]

- Bobek, S.; Nowaczyk, S.; Gama, J.; Pashami, S.; Ribeiro, R.P.; Taghiyarrenani, Z.; Veloso, B.; Rajaoarisoa, L.; Szelazėk, M.; Nalepa, G.J. Why Industry 5.0 Needs XAI 2.0? In Proceedings of the xAI-2023 Late-Breaking Work, Demos and Doctoral Consortium Co-Located with the 1st World Conference on eXplainable Artificial Intelligence (xAI-2023), Lisbon, Portugal, 26–28 July 2023; Available online: https://ceur-ws.org/Vol-3554/paper1.pdf (accessed on 23 February 2025).

- Vlacic, L.; Huang, H.; Dotoli, M.; Wang, Y.; Ioannou, P.A.; Fan, L. Automation 5.0: The Key to Systems Intelligence and Industry 5.0. IEEE/CAA J. Autom. Sin. 2024, 11, 1723–1727. [Google Scholar] [CrossRef]

- Das, S.; Tanushree, P. A Strategic Outline of Industry 6.0: Exploring the Future (9 May 2022). Available online: https://ssrn.com/abstract=4104696 (accessed on 22 February 2025).

| Topic | Topic Description | Main Findings | Ref. |

|---|---|---|---|

| Digitalization | Transition to Steelworks 4.0 | Analysis of the main problems associated with the transition to Steelworks 4.0 (e.g., digitalization). Identification of the technologies and the methods that can enable digitalization (e.g., drones, AI, VR, industrial robots, full automatization). | [21] |

| Digitalization and digital transformation | Digital transformation in the European steel industry | Description of the current state of technological transformation in the steel sector. Provision and discussion of the results of a questionnaire tailored to European steel companies. | [22] |

| Digitalization and digital transformation Industry 4.0 | Digitalization and innovation in the steel industry in Poland | Presentation of the tools used in the steel industry in Poland to achieve adequate digitalization for Industry 4.0. | [23] |

| Digitalization and digital transformation | Digital transformation in the steel industry | Ecosystem analysis in the German Rhein/Ruhr Area. Investigation on the skills required to enable the digital transformation (e.g., digital skills and soft skills). | [24] |

| Digitalization and digital transformation | Digitalization in the steel sector | Introduction of the digitalization context. Description of the current technological transformation. Analysis of the main developments funded by European Research Programs. Analysis of the impact of the digitalization on the steel industry workforce and on economic developments. | [25] |

| Digitalization and digital transformation Sustainability Reheating furnaces | Digitization and greening of the industrial reheating furnaces | Review on mathematical models, heating patterns, control systems, and energy analyses. | [26] |

| Digitalization and digital transformation Decarbonization | Decarbonization and digitalization in the European steel industry | Discussion on social and technological innovations associated to the steel sector in Europe. Analysis of the “twin challenges” of digitalization (Industry 4.0) and decarbonization. | [27] |

| GHG control | GHG control in the steel manufacturing | Review on the current methodologies for GHG accounting in the steel sector, focusing on the critical role of emissions data. | [28] |

| Sustainability | Sustainability assessment of steel manufacturing companies | Review on decision-making methods for sustainability assessments in steel manufacturing companies. | [29] |

| Decarbonization | Decarbonization pathways in steelmaking industries | Review on current steel production processes, assessing their environmental impact in terms of the CO2 emissions at a global level. | [30] |

| Decarbonization | Steel industry decarbonization transition | Analysis of the socio-technical impact of Key Enabling Technologies for the transition to decarbonization in the steel industry. Assessment of the impact of AI on decarbonization in the steel industry. | [31] |

| Decarbonization Industry 4.0 | Adoption of Industry 4.0 technologies for steel industry decarbonization | Identification of barriers to Industry 4.0 technologies based on technological, organizational, and environmental theory. | [32] |

| Industry 4.0 | Energy efficiency trends for the Polish steel industry in the context of Industry 4.0 | Analysis of the issues associated to the energy efficiency and Industry 4.0 in the Polish steel sector. Provision of an econometric model to highlight the relationship between investment in new technologies and energy efficiency in steel production. | [33] |

| Industry 4.0 | Implementation of Industry 4.0 in Bangladesh’s steel sector | Identification of the current state of the affairs and barriers (e.g., high capital investment and a lack of government support) associated to the implementation of Industry 4.0. | [34] |

| Industry 4.0 | Industry 4.0 strategies in the steel supply chain | Identification and evaluation of the most effective policies to implement Industry 4.0 strategies. Analysis of the gap based on the current condition in Iran (e.g., associated to the infrastructure and to the supply chain balancing). | [35] |

| Industry 4.0 Production and operation | Production and operation decision optimization in smart steel plants under Industry 4.0 and human-CPS (Cyber Physical System) | Analysis of crucial features of the steel manufacturing process and related implications for the optimization of decisions about production and operations. | [36] |

| SCADA systems | SCADA systems in the steel industry | Survey on architectures, standards, challenges, and Industry 5.0 with a focus on interoperability and interconnectivity. | [37] |

| Instrumentation technology | Instrumentation technology for automation in the steel industry | Review on development trends and future prospects, focusing on the main challenges associated to the sustainability (e.g., GHG emission reduction and fulfilment of the required quality specifications). | [38] |

| AI | Implementation of digitalization and ML in the steel industry | Provision of a vision from the steel industry on how environmental DSSs can be defined and developed in order to improve the environmental footprint of production processes while preserving specifications regarding product quality and process operation. | [39] |

| AI | DL for the iron and steel making field | Review on the current trends associated to the application of DL techniques in the iron and steel making field, with a focus on the type of processes and analytical methodologies. | [40] |

| AI | ML application in steel manufacturing processes | Review on ML methods for the steel industry, focusing on methodologies that are able to establish complex relationships between manufacturing processes and steel industry performance. | [41] |

| AI | ML in steelmaking process modelling | Overview of applications of ML in steelmaking process modeling for hot metal pretreatment, primary steelmaking, and secondary refining. | [42] |

| Reheating furnaces | Assessment and perspectives for steel industry reheating furnaces | Review on energy efficiency assessments, waste heat recovery potential, heating process characteristics, and new perspectives. | [43] |

| Topic | Associated References |

|---|---|

| Digitalization and Industry 4.0 | [14,15,16,17,20,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84] |

| Data and KPIs | [44,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127] |

| Reheating Furnaces in Hot Rolling Mills | [9,10,11,12,13,110,117,119,121,122,124,125,128,129,130,131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Predictive modelling for steel manufacturing industry high energy consumption processes within an Industry 4.0 context | Use of ML to achieve relevant energy efficiency benchmarks | Identification of the gaps in steel mills (e.g., data to be collected for each energy intensive process) | [44] |

| Digitalization in the steel industry | Develop an industrial scale virtual rolling model for the hot rolling industry | Virtual models can be used to identify the crucial parameters that affect the warming of a work roll surface | [45] |

| Description of the material properties along the process chain based on databases | Provide a concept based on Material DT and Material DS. | Two concepts are applied for the implementation of materials into digital representations of production processes: an integrated digital description of the materials and their properties and an extended Material DT for material information retrieval. | [46] |

| DT for steel industry processes | Develop a DT on a heating furnace for cast billet temperature prediction | Pros and cons associated to the application of first principles and ML methods to process modelling | [47] |

| Waste heat recovery in green steel production | Application of DT for operation optimization | DT approaches can be used to model and optimize the involved energy systems (e.g., in the production operation planning) in an adaptive way | [48] |

| DT for steel industry processes | Design of an architecture for DT testing on a production line in the forging industry | Snapshot creation methods and testing agent architecture can be applied to quickly test DT, improving its reliability | [49] |

| Support the steel industry smart operator in Industry 4.0 | Propose an architecture that is able to support a smart operator | Development of an ontology-based, general-purpose, and Industry 4.0-ready architecture for a smart operator, based on VR (KNOW4I) and DT | [50] |

| Zero defect production | Exploitation of a DT-based optimization strategy for the heating process in a forging line | Deep RL can be used to automate the traditional heating process | [51] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Surface defect recognition of products in the steel manufacturing industry | To improve defect recognition | Application of a hybrid model for efficient and robust inspections of the steel surface during the manufacturing process | [53] |

| Digital transformation through Industry 4.0 for the steel industry | To design predictive maintenance algorithms through the use of vibration sensors and ML | The travel distance can be detected by vibration sensors | [54] |

| Predictive bearing wear maintenance in the steel industry | To show the potential of using incomplete sensor data to improve predictive maintenance algorithm performance | Comparison of data-driven methods for predictive maintenance and proofing of techniques for data cleaning in large and complex datasets in the real world | [55] |

| Maintenance of steel industry machinery in the context of Industry 4.0 | Proposes an Industry 4.0-based approach aimed at health assessment of critical assets | Development of a model based on expert knowledge and real time data | [56] |

| Predictive maintenance in the steel industry | To sustain turbo blower equipment prognostics | Application of a multi-step time prediction process using software analytics algorithms | [57] |

| Fault diagnosis in the steel industry | To overcome the limitations of data-driven multivariate statistical analyses due to complex dynamics, nonlinearities, and nonstationary characteristics | A mixed kernel-aided canonical stationary variate analysis method is proposed and tested on a blast furnace process | [58] |

| Fault diagnosis and condition monitoring of Industry 4.0 manufacturing processes, considering steelmaking plants | Classification of machine status through unsupervised approaches (e.g., anomaly detection and signal processing) | Application of diagnostic algorithms together with operator experience (qualitative information) to identify abnormal behaviors | [59] |

| Intelligent manufacturing in the steel industry | Intelligent steel surface defect management and prediction | Provision and implementation of a framework/ecosystem based on microservice architecture concepts that exploit ML and DL | [60] |

| Smart manufacturing and Industry 4.0 in the steel industry | Identification of hot rolled steel surface defects | Development of an ensemble methodology based on different CNN-based architectures | [61] |

| Guaranteeing quality in the steel manufacturing process | Implementation of automated defect detection systems for product quality enhancement | Evaluation and use of different semantic segmentation approaches based on XAI | [62] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Industry 4.0 in the steel industry | Practical application of the Industry 4.0 paradigm in a steel company | Investigation into the changes to be implemented in organizational structures in order to allow an Industry 4.0-based digitization process aimed at improving efficiency | [63] |

| Smart retrofitting in the steel industry | Industry 4.0 migration process in a steel mill plant | Application of a retrofitting methodology based on Design Thinking aimed at Industry 4.0 migration | [64] |

| Digital transformation, digitalization, and Industry 4.0 in the steel industry | Achieving digitally enabled process innovation | Contributions to the theory of process innovation in steel industries and to strategic management through the development of a specific framework | [65] |

| Industry 4.0 and automation in the steel industry | Use of automated models for the digitization of continuous planning and scheduling | Multi-criteria decision-making techniques can be used based on economic, environmental and social factors | [66] |

| Planning and control of a steel group in an Industry 4.0 environment | Creation of a smart operating roadmap and integration of ERP and MES under an Industry 4.0 environment | A strategic business plan can be obtained integrating functions, methods, and tools | [67] |

| Project management for steel manufacturing in the digitalization era | Provide guidelines for the generation of project plans | Reporting and communications rules are crucial to devise a good project plan in order to improve profitability and productivity | [68] |

| System integration for steel plants in the context of Industry 4.0 | Provide a solution to rigidness, inflexibility and lack of scalability associated to conventional industrial communication systems | Development of a message-bus-based communication architecture that does not depend on its position in the functional hierarchy of the plant | [69] |

| Current industrial internet considering steel manufacturing scenarios | Analysis of the problems associated to the current industrial internet (e.g., uncertainty of network performance and increase of AI computing demand) | Provision of integrated services aimed at the high-quality development of industrial internet | [70] |

| Industry 4.0 in the steel industry | Reveals prospects and potential associated to the use of Industry 4.0 technologies in the steel industry (e.g., AI and robotics) | Recommendations for the implementation of Industry 4.0 technologies in enterprises with limited financial means | [71] |

| Automation and digitalization of the steel industry | Investigates potential technologies for product identification and traceability over the supply chain | Evaluation criteria and methodology related to ICT approaches for small and medium-sized enterprises (SMEs) | [72] |

| Evaluation of the effects of steel industry digitalization | Use dynamic LCA for evaluations, minimizing losses during casting | Quantifications of economic costs and global warming impact using LCA | [73] |

| Digitalization in the steel industry | Pathways for efficiency improvement in the steel industry through digitalization | Investigation into the background required for energy efficiency improvement (equipment availability improvement, yield increase, optimized production schedules) | [74] |

| Energy efficiency and digitalization of production in the steel industry | Creation of industry development scenarios | Proposal of integrated solutions to optimize energy consumption in the steel industry (e.g., high-efficiency furnaces, waste heat recovery systems, and advanced control systems) | [75] |

| CO2 emission reduction in the steel industry | Presentation of a framework for energy intensive industries based on the introduction of digitalization and energy efficient equipment in the production line | Combine digital tools and energy efficient equipment through innovation absorption and digitalization | [76] |

| Process heat and energy consumption in the Polish steel industry within an Industry 4.0 context | Establish a relationship between heat and energy management in the steel production process | Development of an econometric model for the Polish steel industry based on data (e.g., electricity prices and intensity of heat consumption) | [77] |

| Electricity and heat demand in the steel industry within an Industry 4.0 context | Characterization of electricity and heat demand for EAFs and BOFs | Trends associated to electricity and heat consumption in EAFs and BOFs | [78] |

| Effects of Industry 4.0 on the steel workforce | Identification of current and future skill requirements within the steel sector | Development of a sectorial occupational database that would serve the steel industry as a tool for all future technological and organizational changes | [79] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Multi-agent systems in a steelwork plant | Reports multi-agent system applications in the steel sector | Description of the benefits of agent-based technology to improve process efficiency and to valorize specific byproducts | [80] |

| Raw material provider selection in the steel industry | Evaluation of potential raw material providers | Digitalization, circular economy, and resilience dimensions represent important factors/indicators | [81] |

| Advanced high strength steel in an Industry 4.0 context | Determination of the optimum processing parameters for coiling process | Unsupervised ML approaches (e.g., self-organizing maps) can be applied to reveal correlations and patterns in production datasets | [82] |

| Converter intelligent steelmaking | Determination of molten steel carbon content | Development of a CPS framework for steelmaking plants in order to design a non-contact intelligent prediction model | [83] |

| Intelligent, efficient, and sustainable manufacturing in the steel industry | To improve the positioning accuracy requirement of bars | Application of machine vision technologies for unmanned warehouse areas used for bars, through the use of a binocular vision-based measurement method | [84] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Metallurgical data science for the steel industry | Provides a method for the prediction of final product composition and quality in a BOF | Combination of ML with fundamental knowledge and first-principal calculation | [85] |

| Carbon emissions in the steel industry | Provides a correlation analysis and a monitoring method based on big data | An entropy weight-grey correlation-TOPSIS analysis method is inferred to determine the correlation between carbon emissions and influencing factors | [86] |

| Acquisition and analysis of measurement data in the steel industry | Design of a computer system to analyze measurement data for a skew rolling mill used to produce steel balls | Enabling the configuration of measurement elements and technical parameters in order to customize the acquisition and storage of measurement data | [87] |

| Steel industry data analysis | Theory and application of missing data research in the steel industry | Identification of missing data patterns, understanding the causes thereof and the selection of an imputation technique | [88] |

| Steel industry data analysis | Management of missing values | Introduction of a GAN-based framework for the generation of synthetic data pertaining to data imputation | [89] |

| Steel industry data analysis | Management of missing values associated to datasets for a blast furnace | Introduction of a Deep-Convolution-GAN-based data filling method | [90] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Carbon emissions in the steel industry | Provides a correlation analysis and a monitoring method based on big data | An entropy weight-grey correlation-TOPSIS analysis method is inferred to assess the correlation between carbon emissions and influencing factors | [86] |

| Data-driven carbon emission prediction in the steel industry | Use of data-driven ensemble learning modelling | Data preprocessing and design of a stacking ensemble learning model | [91] |

| Predictive modelling of energy consumption in the steel industry | Proposes a data-driven approach to sustainable energy management | Highlights the potential of CatBoost regression as a valuable tool for energy management and conservation | [92] |

| Daily load forecasting in the steel industry | Designs a power demand management system for the iron and steel industry | Development of a module based on Random Forest Modeling | [93] |

| Design of a sustainable steel supply chain network to achieve a circular economy | Data-driven, robust optimization | Support vector-based clustering applied to historical data to address uncertainties and for the design of data-driven robust optimization models | [94] |

| Sustainable supplier selection in the steel industry | Provides an approach for multi-criteria decision-making problems associated to the supply chain sustainability | Integration of data envelopment analysis (DEA), spherical fuzzy analytic hierarchy process (SF-AHP), and spherical fuzzy weighted aggregated sum product assessment (SF-WASPAS) to identify a sustainable supplier for the steel manufacturing industry in Vietnam | [95] |

| LCA in the steel industry | Use of primary manufacturing data for LCA | Provision of an assessment of the emissions associated to blast furnaces, BOFs and casting rolling | [96] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Quality control in a steel Industry 4.0 context based on big data analysis | Upgrade to intelligent manufacturing in a steel plant | Big data can be exploited to migrate from univariate to multivariate monitoring in steel industry process operations, improving fault diagnosis accuracy and reducing manual work | [97] |

| Real-time quality control in the steel industry | Application of ML on non-invasive data | Development of a contactless, non-invasive, electromagnetic sensor to measure materials during production in real-time. The data provided by the sensor were used to design a ML-based model. | [98] |

| Product quality prediction in the iron and steel industry | Use of a multiobjective ensemble learning method | Development of multiobjective CNN-based ensemble learning methods with multiscale data fusion | [99] |

| DSSs for quality assessment in the steel industry | Evaluation of quality management practices in Industry 4.0 for steel manufacturing | Formulation of semantic data mining techniques | [100] |

| Manufacturing data fusion | Use of data fusion methods in steel rolling processes | Summary of case studies on steel rolling processes where valuable knowledge and quality improvement are obtained through data fusion | [101] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Process state control in a steel manufacturing plant | Use of physics-enhanced DTs | Data-driven modelling can be applied for correlation analyses among features in order to predict downtime and manage stoppages costs | [102] |

| Anomaly detection in the steel industry | Assessment of the quality of data from acquired energy systems for prediction analysis and operation scheduling | Development of a method based on varying-scale hypercube accelerated density-based spatial clustering for applications with noise (VHCA-DBSCAN) | [103] |

| Predictive maintenance in the steel industry | Tests the usability of change point detection algorithms to implement large data volumes | Design of a parameter selection method for defect diagnosis using time-series vibration data from critical assets | [104] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Metallurgical data science for the steel industry | Provides a method for the prediction of the final product composition and quality in a BOF | Combination of ML with fundamental knowledge and first-principal calculation | [85] |

| Energy consumption analysis in the steel industry production chain | Provide a data-driven model for energy consumption analysis along with sustainable production in the steel industry | Investigation into the electricity consumption of an EAF via data-driven models based on ML | [105] |

| Process optimization | Development of a ML-based model for the rolling mill process | Provision of an engineering strategy based on the collected data in order to obtain multiple models | [106] |

| Data-driven manufacturing in steelmaking | Application of ML algorithms for the prediction of the strength of steel rods manufactured in an EAF | Datasets provided from different stages (EAF, LF, continuous casting, hot rolling) can be used to design ML-based models | [107] |

| Prediction for manufacturing factors in a steel plate rolling smart factory | Use of data clustering-based ML in order to improve thickness estimation | Clustering algorithms and supervised learning algorithms can be combined to mitigate prediction problems in steel plate rolling processes | [108] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

| Inefficiency investigation in the steel industry | Quantitative assessment of machine- and line-level inefficiency in the steel industry | Formulation of an energy-based KPI | [109] |

| Enhancement of the efficiency of reheating furnaces in the steelmaking industry | Evaluation of the efficiency of a Brazilian steelmaking company’s hot rolling mill reheating process | Estimation of the efficiency, identification of the crucial variables to be considered, simulated analysis | [110] |

| Sustainable development in the steel industry | Presentation of an analysis of the indicators of steel companies based on data provided by the World Steel Association | Evaluation of the sustainability indicators associated to steel industry, taking into account social, economic, and environmental factors | [111] |

| Environmental sustainability in the steel sector | Structuring and measuring environmental sustainability | Exploration of the implications of strategic environmental sustainability indicators in order to assess company performance | [112] |

| Sustainable development in iron and steel production in China | Design of new environmental policy instruments to promote sustainable development | Investigation of indicators of cleaner production and a green factory | [113] |

| Evaluation of waste heat recovery potential in energy-intensive sectors (e.g., the steel industry) | Design of methodologies oriented toward the quantification of waste heat recovery potential, taking into account economic production conditions | Provision of different KPIs (e.g., specific heat input and heat utilization rate) | [114] |

| Optimization of water consumption in steelmaking processes | Investigation into barriers, with an analysis and KPI definition | Holistic combination of on-line monitoring and optimization and innovative water treatment technologies | [115] |

| Industry 4.0 maturity assessment in the steel industry | Development of a multi-dimensional analytical indicator methodology | Design of a weighted average method to assess Industry 4.0 readiness which applies a multi-dimensional analytical indicator | [116] |

| Main Topic | Scope | Main Findings | Ref. |

|---|---|---|---|

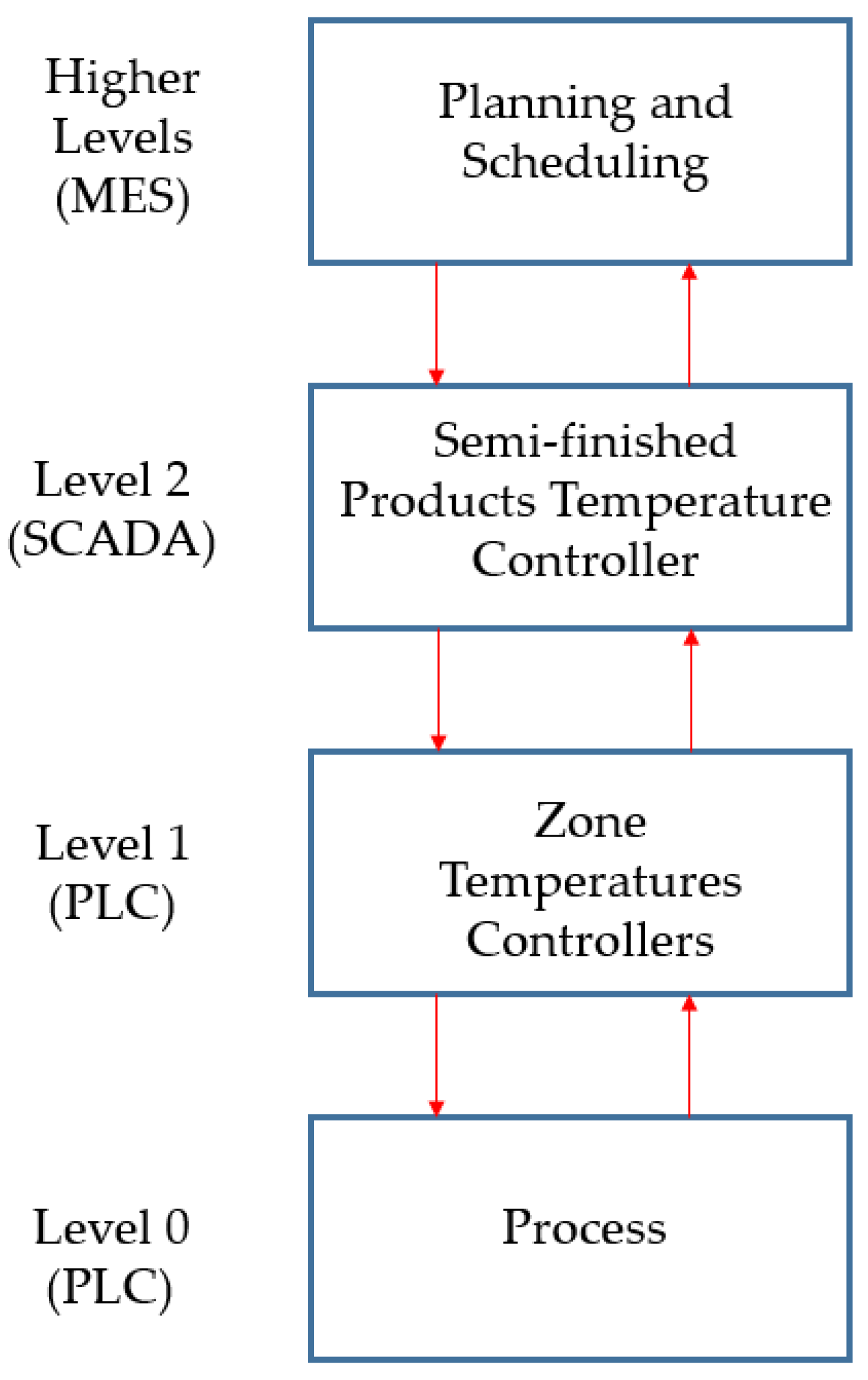

| Data analysis and control of a steel industry reheating furnace | Design of a control system for the considered reheating furnace, also applying data potential | By applying data analysis methodologies, crucial relationships among key process variables can be inferred | [117] |

| Data analysis and modelling for billet temperature in steel industry reheating furnaces | Design of temperature models based on data analysis | By applying data analysis techniques, key relationships can be inferred among crucial process variables, taking into account different plant configurations | [118] |

| Steel industry pusher type billet reheating furnace control | Design of an MPC system | KPIs, e.g., specific fuel consumption, are used to assess controller performance | [119] |

| Data analysis and modelling of billet features in the steel industry | Design of models associated to billet features based on data analysis | Data analysis can modify the plant hardware configuration in order to enhance the reliability of measurements | [120] |

| Level 2 control of steel industry reheating furnaces | Design of an APC system that is able to manage all process conditions | Use of data for the design and implementation of an APC system based on different control modes which is able to optimize all furnace conditions (production, planned/unplanned shutdowns/downtimes, and restarts) | [121] |

| Level 2 control of steel industry reheating furnaces | Design of an APC system that is able to manage all process conditions and different configurations of plant hardware | Application of data to obtain a synergic combination of hardware and software for energy efficiency and process control improvement | [122] |