A Coupled Finite Element and Crystal Plasticity Study of Friction Effect on Texture Evolution in Uniaxial Compression of NiTi Shape Memory Alloy

Abstract

:1. Introduction

2. Simulation Procedures

2.1. VPSC Modeling

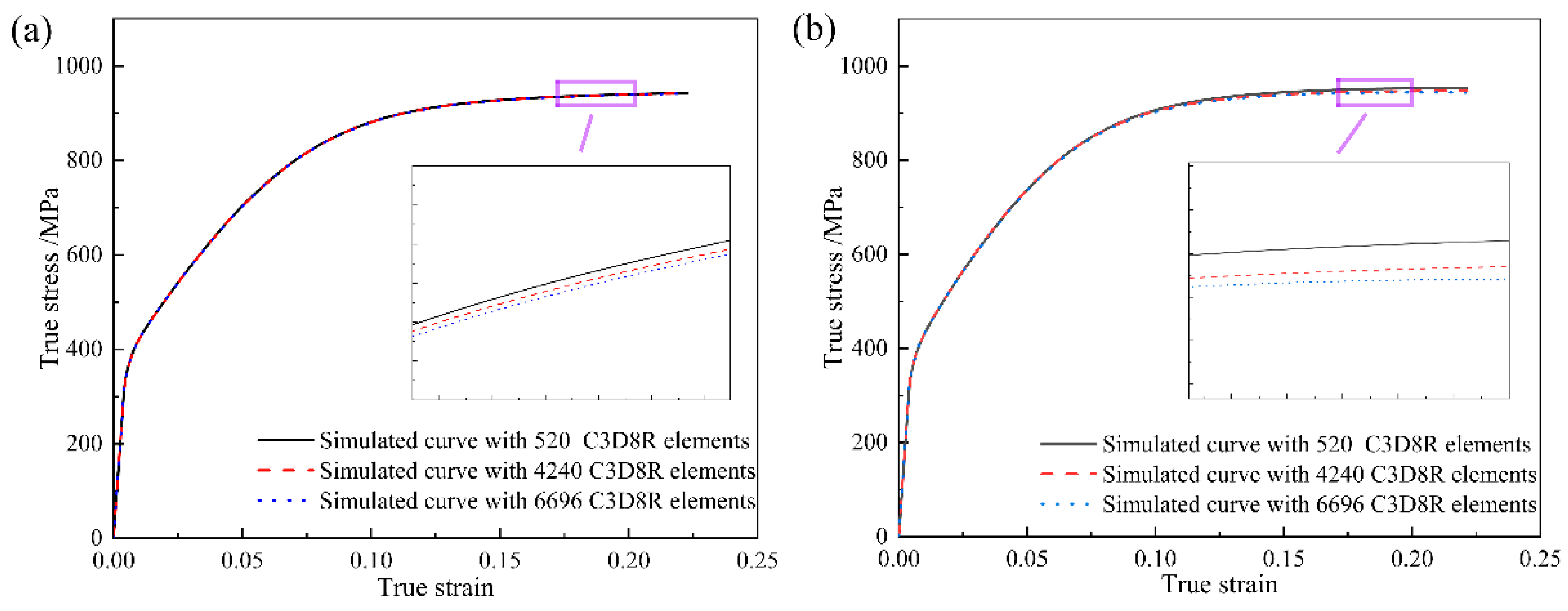

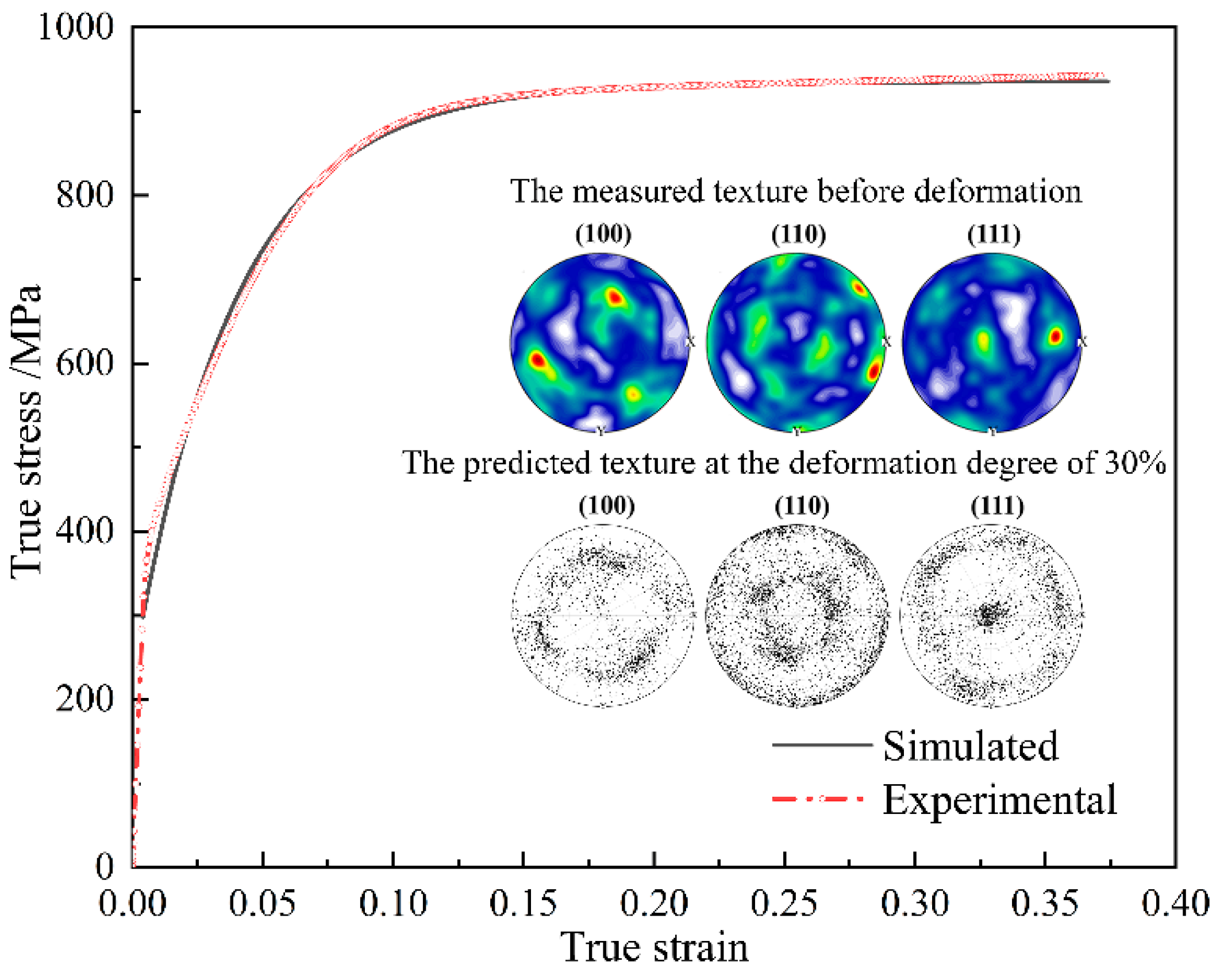

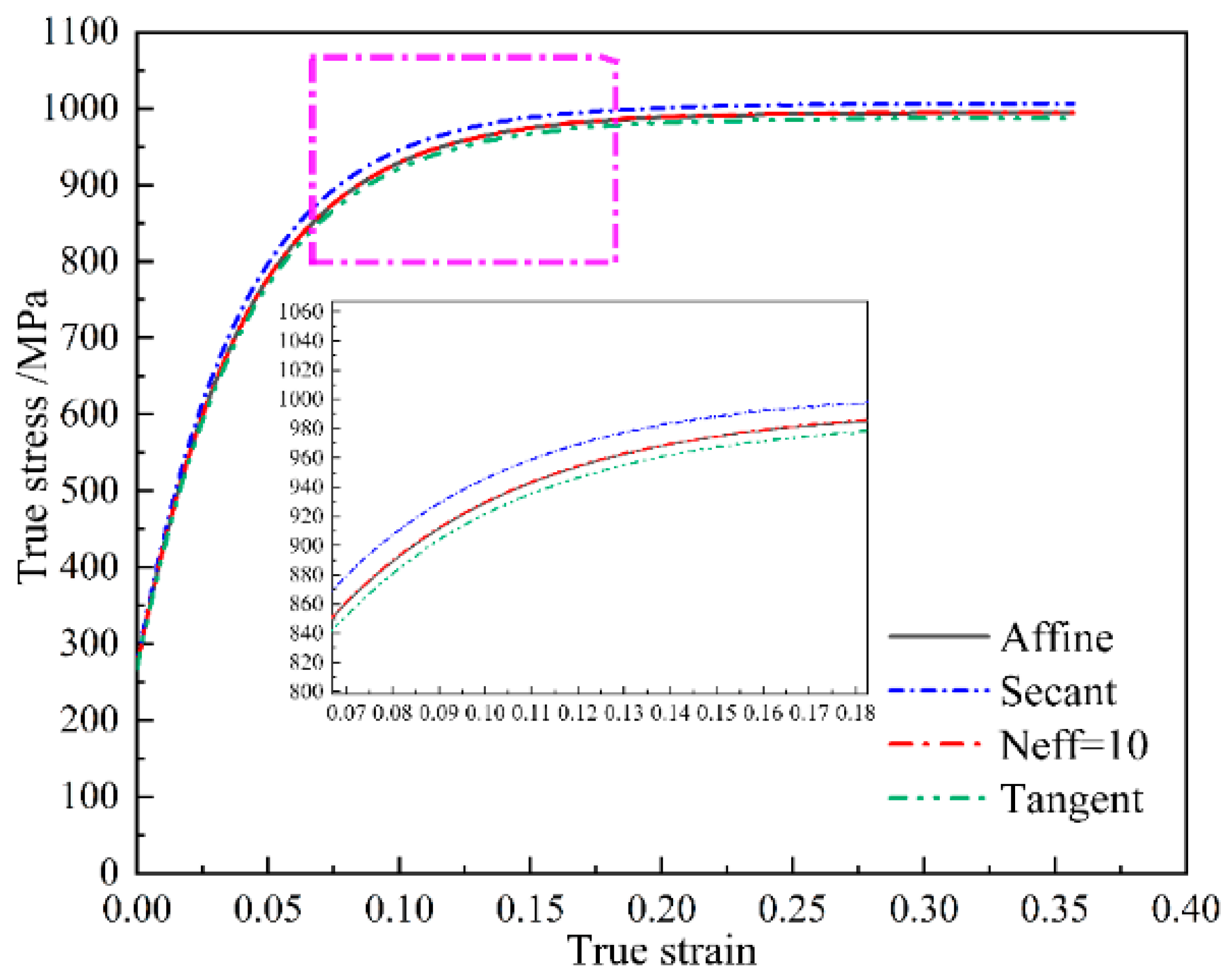

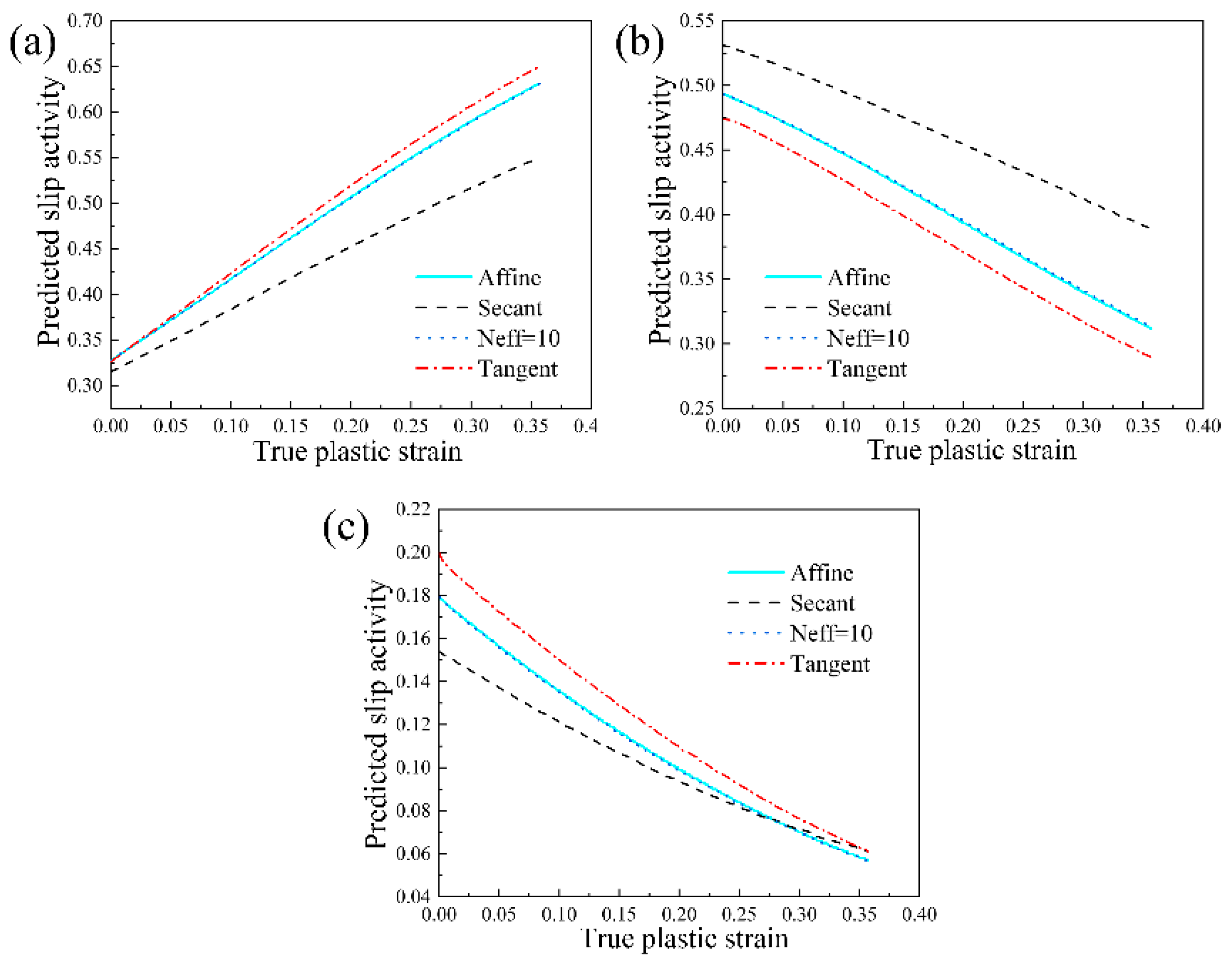

2.2. Identification of Material Parameters

2.3. Finite Element Modeling

3. Results and Discussion

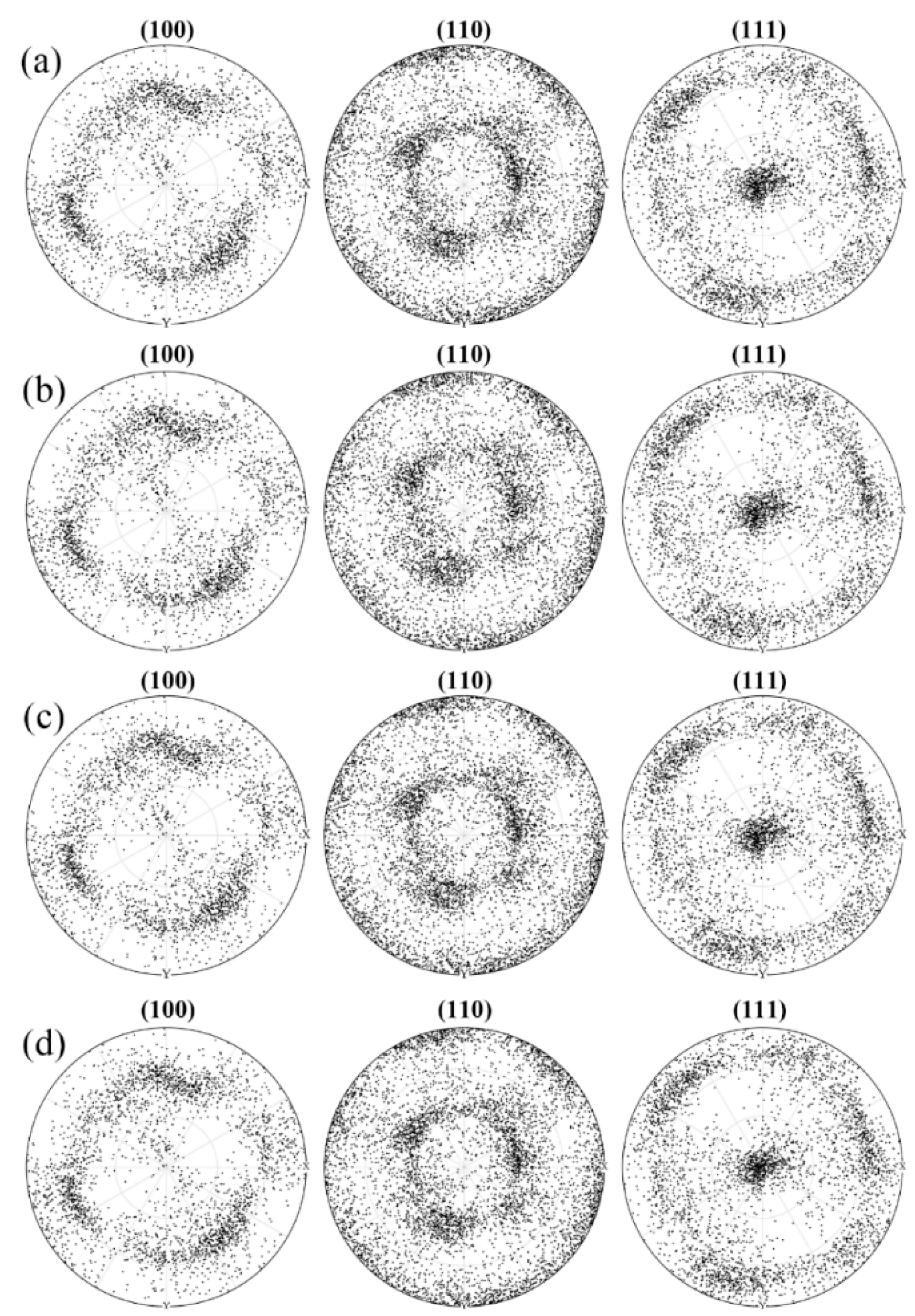

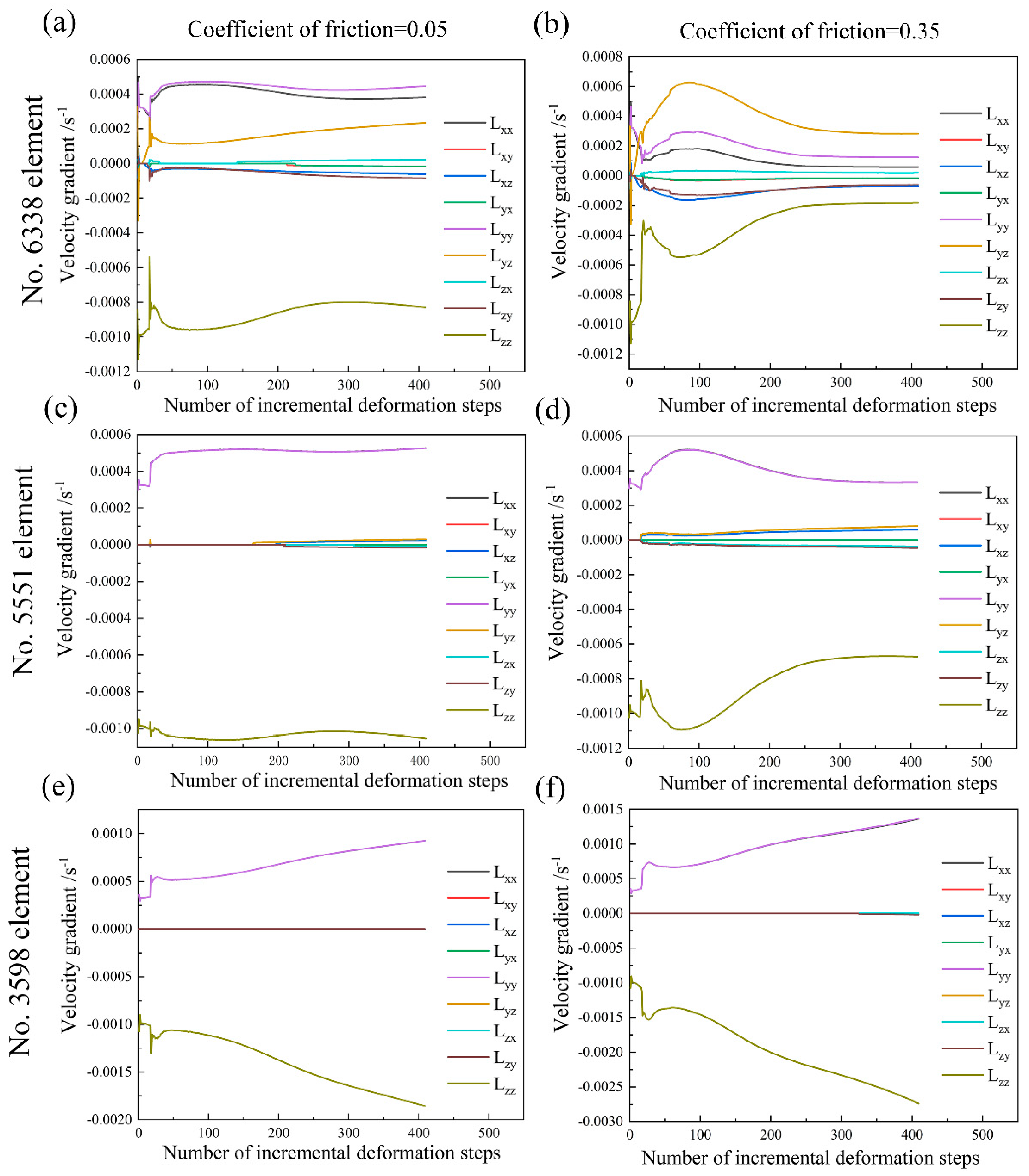

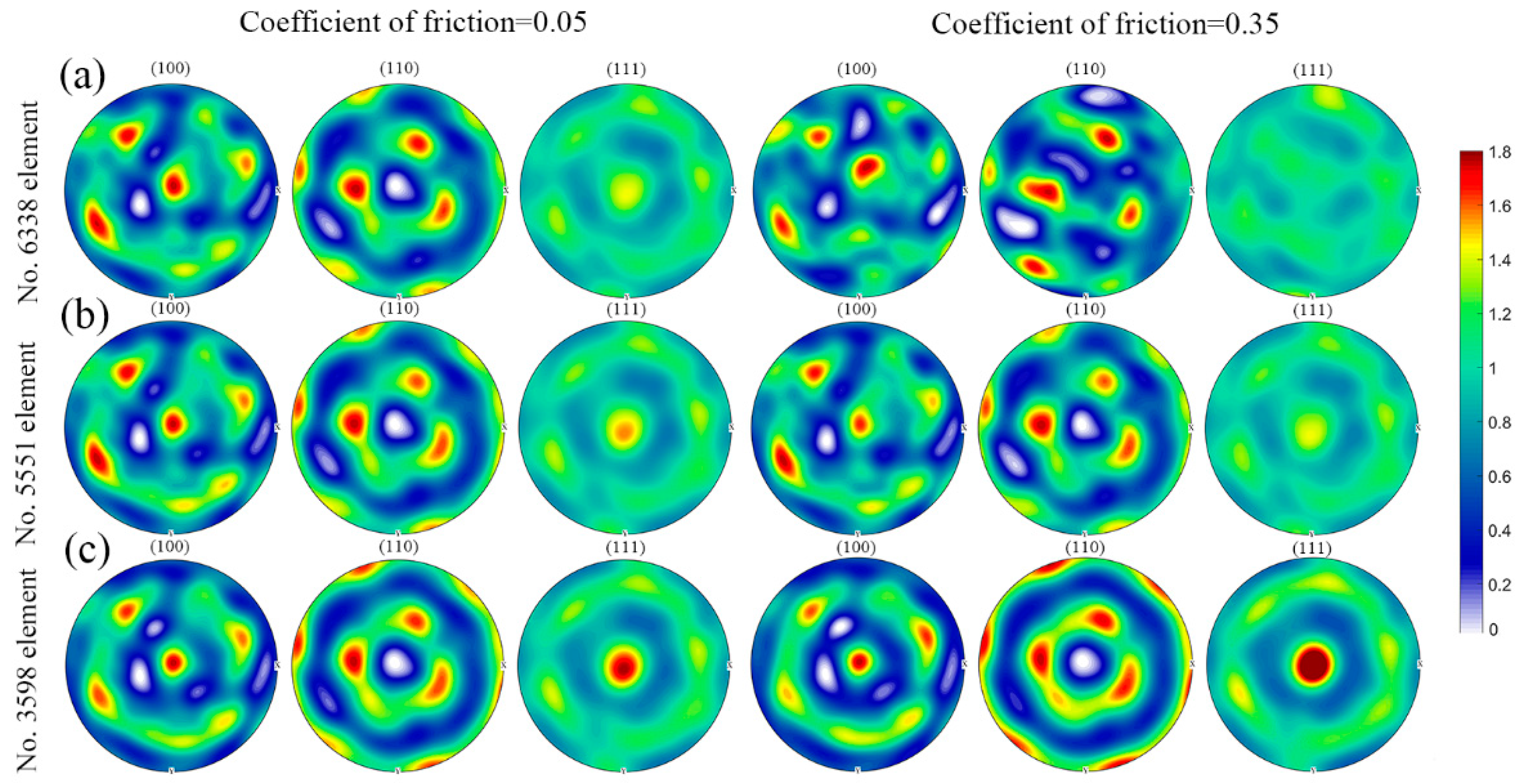

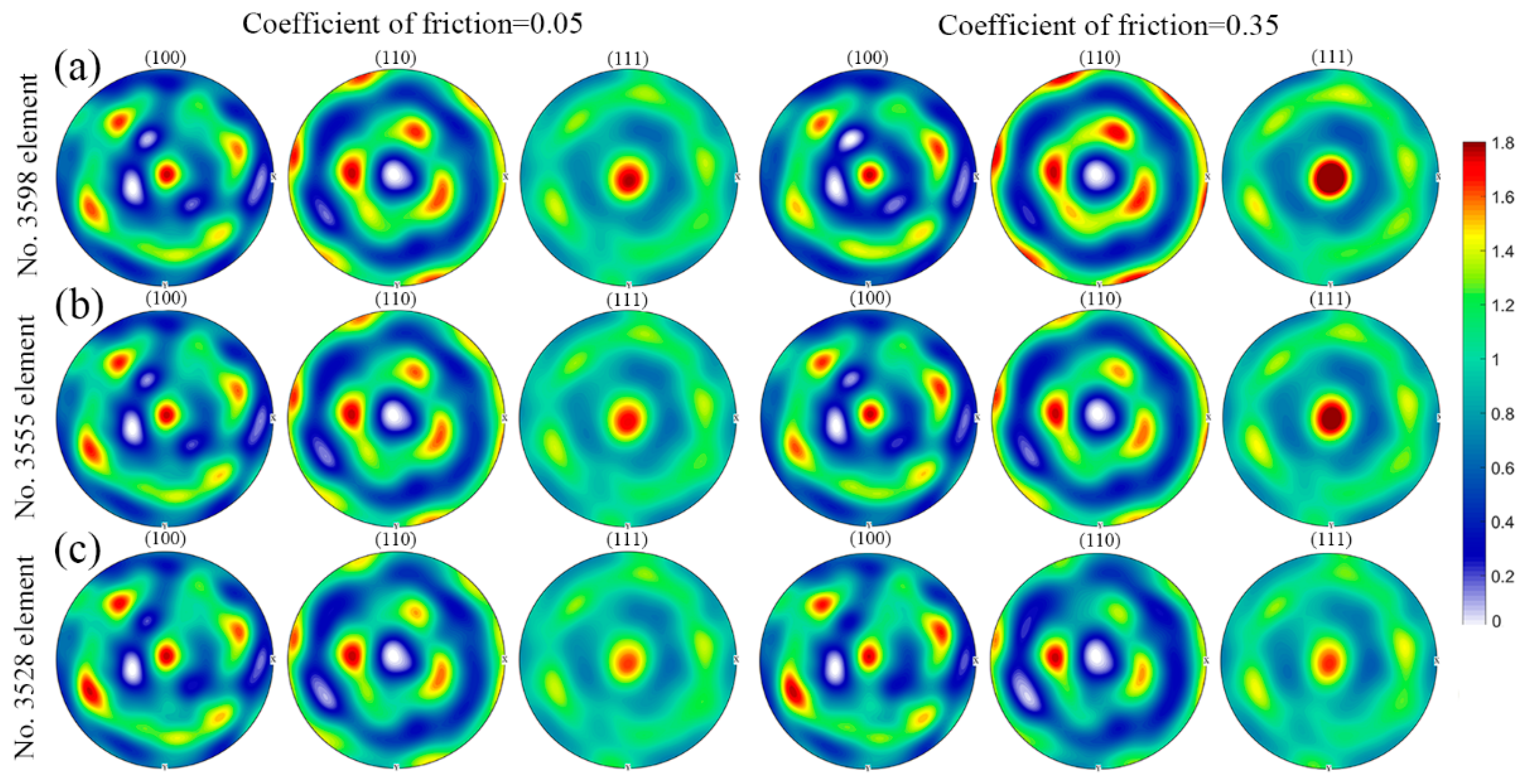

3.1. Texture Evolution in Minimum Deformation Zone and Principal Deformation Zone

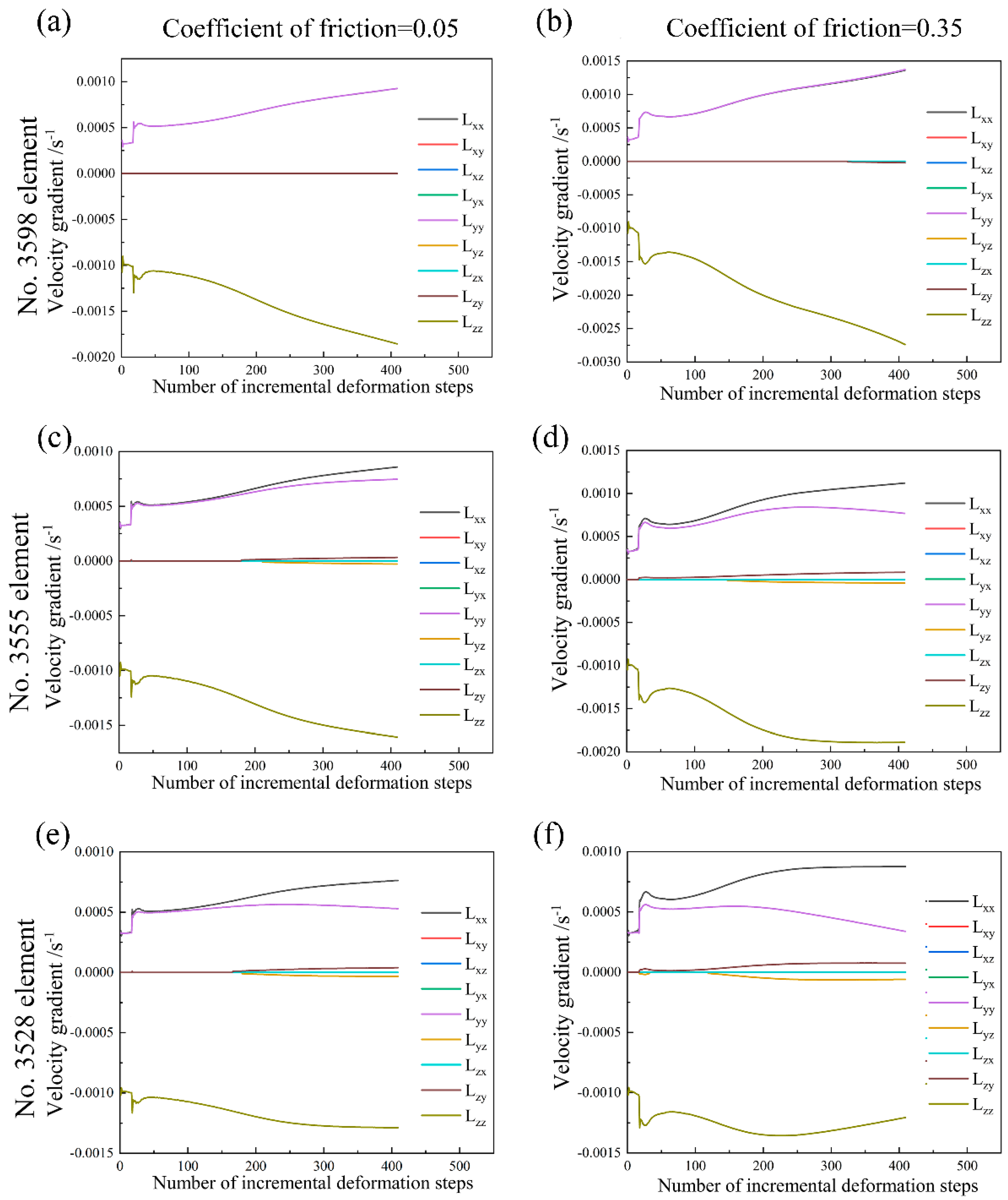

3.2. Texture Evolution in Principal Deformation Zone and Intermediate Deformation Zone

3.3. Deformation Mechanisms under Uniaxial Compression

4. Conclusions

- By using the PSO algorithm in parameter calibration, the material parameters used in VPSC model are identified with efficiency and accuracy. In addition, among the accessible linearization schemes in VPSC model, the affine scheme and Neff = 10 scheme give the best predictions.

- The friction effect has an obvious influence on the plastic deformation in the minimum deformation zone close to the dies and further affects the corresponding texture evolution during uniaxial compression. In the intermediate deformation zone and the principal deformation zone, the friction effect on the velocity gradient rapidly decrease and therefore has a minor influence on the texture evolution.

- In the minimum deformation zone close to the dies, the friction coefficient not only affects the evolution laws with respect to the slip mode activities but also the suffered plastic strain. Whereas in the intermediate deformation zone and the principal deformation zone, there exist relatively similar evolution laws with respect to the slip mode activities, but the evolution rates with respect to {110} <100> slip mode and {110} <111> slip mode are fastest in the principal deformation zone, which contributes to the change of intensity with respect to <111> fiber texture component.

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

References

- Mata, M.; Alcala, J. The role of friction on sharp indentation. J. Mech. Phys. Solids 2004, 52, 145–165. [Google Scholar] [CrossRef]

- Li, S.; Beyerlein, I.J.; Necker, C.T.; Alexander, D.J.; Bourke, M. Heterogeneity of deformation texture in equal channel angular extrusion of copper. Acta Mater. 2004, 52, 4859–4875. [Google Scholar] [CrossRef]

- Liu, M.; Tieu, A.K.; Lu, C.; Zhu, H.; Deng, G. A crystal plasticity study of the effect of friction on the evolution of texture and mechanical behaviour in the nano-indentation of an aluminium single crystal. Comput. Mater. Sci. 2014, 81, 30–38. [Google Scholar] [CrossRef]

- Saleh, A.A.; Haase, C.; Pereloma, E.V.; Molodov, D.A.; Gazder, A.A. On the evolution and modelling of brass-type texture in cold-rolled twinning-induced plasticity steel. Acta Mater. 2014, 70, 259–271. [Google Scholar] [CrossRef]

- Raabe, D.; Sachtleber, M.; Zhao, Z.; Roters, F.; Zaefferer, S. Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation. Acta Mater. 2001, 49, 3433–3441. [Google Scholar] [CrossRef]

- Deng, G.; Lu, C.; Tieu, A.; Su, L.; Huynh, N.N.; Liu, X. Crystal plasticity investigation of friction effect on texture evolution of al single crystal during ECAP. J. Mater. Sci. 2010, 45, 4711–4717. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.Y.; Zhang, Y.Q.; Sun, D. Crystal plasticity finite element simulation of NiTi shape memory alloy based on representative volume element. Met. Mater. Int. 2017, 23, 1075–1086. [Google Scholar] [CrossRef]

- Li, S.; Bourke, M.; Beyerlein, I.; Alexander, D.; Clausen, B. Finite element analysis of the plastic deformation zone and working load in equal channel angular extrusion. Mater. Sci. Eng. A 2004, 382, 217–236. [Google Scholar] [CrossRef]

- Bong, H.J.; Leem, D.; Lee, J.; Ha, J.; Lee, M.G. A coupled crystal plasticity and anisotropic yield function model to identify the anisotropic plastic properties and friction behavior of an AA 3003 alloy. Met. Mater. Trans. A 2018, 49, 282–294. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.Y.; Zhou, T.; Tu, J.; Shi, L.X.; Chen, Q.; Yang, M.B. Multiscale modeling of polycrystalline NiTi shape memory alloy under various plastic deformation conditions by coupling microstructure evolution and macroscopic mechanical response. Materials 2017, 10, 1172. [Google Scholar] [CrossRef] [PubMed]

- Chapuis, A.; Wang, Z.Q.; Liu, Q. Influence of material parameters on modeling plastic deformation of Mg alloys. Mater. Sci. Eng. A 2016, 655, 244–250. [Google Scholar] [CrossRef]

- Guo, X.; Chapuis, A.; Wu, P.; Agnew, S. On twinning and anisotropy in rolled Mg alloy AZ31 under uniaxial compression. Int. J. Solids Struct. 2015, 64, 42–50. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.Y.; Zhang, Y.Q. A combined experimental-numerical approach for investigating texture evolution of NiTi shape memory alloy under uniaxial compression. Metals 2017, 7, 356. [Google Scholar]

- Lebensohn, R.A.; Tomé, C. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta Met. Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.Y.; Zhang, Y.Q.; Zhao, Y.N.; Liu, S.W.; Zhao, C.Z. Multiple plastic deformation mechanisms of NiTi shape memory alloy based on local canning compression at various temperatures. Intermetallics 2016, 70, 45–52. [Google Scholar] [CrossRef]

- Benafan, O.; Noebe, R.; Padula Ii, S.; Garg, A.; Clausen, B.; Vogel, S.; Vaidyanathan, R. Temperature dependent deformation of the B2 austenite phase of a NiTi shape memory alloy. Int. J. Plast. 2013, 51, 103–121. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.Y.; Zhang, Y.Q.; Zhu, X.M.; Zhao, Y.N.; Sun, D. Influence of slip system combination models on crystal plasticity finite element simulation of NiTi shape memory alloy undergoing uniaxial compression. Prog. Nat. Sci. Mater. Int. 2017, 27, 598–605. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Zhang, Y.Q.; Zhao, Y.N.; Tang, M.; Yi, W.L. Constitutive behavior of Ni-Ti shape memory alloy under hot compression. J. Cent. South Univ. 2013, 20, 24–29. [Google Scholar] [CrossRef]

- Esmin, A.A.; Coelho, R.A.; Matwin, S. A review on particle swarm optimization algorithm and its variants to clustering high-dimensional data. Artif. Intell. Rev. 2015, 44, 23–45. [Google Scholar] [CrossRef]

- Guo, X.; Wu, P.; Wang, H.; Mao, X.; Neale, K. Study of large strain behavior of OFHC copper: The role of polycrystal plasticity model. Int. J. Solids Struct. 2016, 90, 12–21. [Google Scholar] [CrossRef]

- Wang, H.; Raeisinia, B.; Wu, P.; Agnew, S.; Tomé, C. Evaluation of self-consistent polycrystal plasticity models for magnesium alloy AZ31B sheet. Int. J. Solids Struct. 2010, 47, 2905–2917. [Google Scholar] [CrossRef]

- Latypov, M.I.; Lee, M.G.; Beygelzimer, Y.; Prilepo, D.; Gusar, Y.; Kim, H.S. Modeling and characterization of texture evolution in twist extrusion. Met. Mater. Trans. A 2016, 47, 1248–1260. [Google Scholar] [CrossRef]

- Abaqus Analysis User’s Manual Version 6.10. Available online: https://www.sharcnet.ca/Software/Abaqus610/Documentation/docs/v6.10/books/usb/default.htm?startat=pt01ch01s01abo01.html (accessed on 29 September 2018).

| Material Parameter | ||||||

| Parameter Value | 174.80 MPa | 465.13 MPa | 5173.25 MPa | 5.30 MPa | 0.001 s−1 | 0.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, L.; Jiang, S.; Zhou, T.; Chen, Q. A Coupled Finite Element and Crystal Plasticity Study of Friction Effect on Texture Evolution in Uniaxial Compression of NiTi Shape Memory Alloy. Materials 2018, 11, 2162. https://doi.org/10.3390/ma11112162

Hu L, Jiang S, Zhou T, Chen Q. A Coupled Finite Element and Crystal Plasticity Study of Friction Effect on Texture Evolution in Uniaxial Compression of NiTi Shape Memory Alloy. Materials. 2018; 11(11):2162. https://doi.org/10.3390/ma11112162

Chicago/Turabian StyleHu, Li, Shuyong Jiang, Tao Zhou, and Qiang Chen. 2018. "A Coupled Finite Element and Crystal Plasticity Study of Friction Effect on Texture Evolution in Uniaxial Compression of NiTi Shape Memory Alloy" Materials 11, no. 11: 2162. https://doi.org/10.3390/ma11112162

APA StyleHu, L., Jiang, S., Zhou, T., & Chen, Q. (2018). A Coupled Finite Element and Crystal Plasticity Study of Friction Effect on Texture Evolution in Uniaxial Compression of NiTi Shape Memory Alloy. Materials, 11(11), 2162. https://doi.org/10.3390/ma11112162