Large-Scale Defect Clusters with Hexagonal Honeycomb-like Arrangement in Ammonothermal GaN Crystals

Abstract

1. Introduction

2. Samples and Experimental Techniques

2.1. Investigated Ammonothermal GaN Crystals

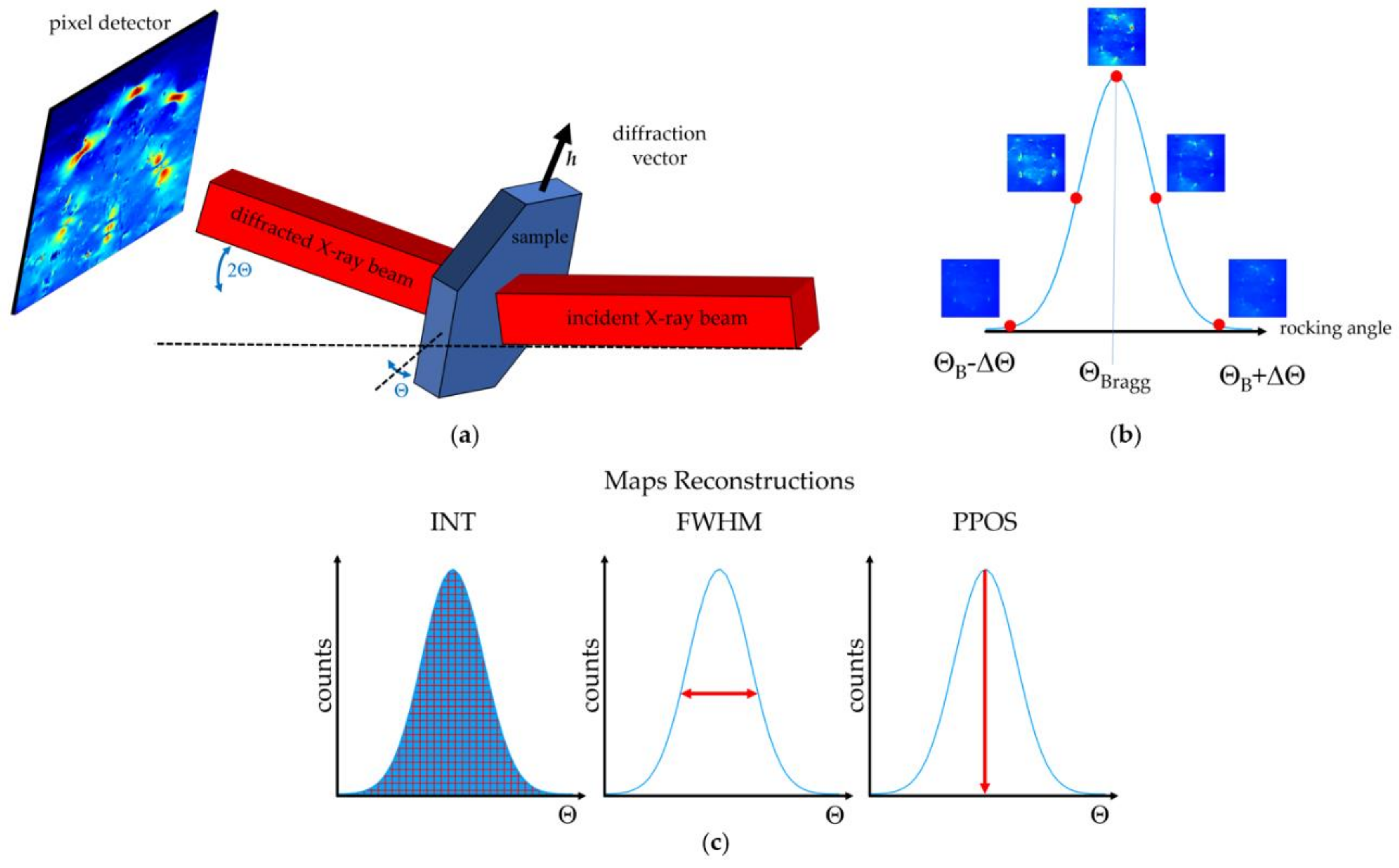

2.2. X-Ray Bragg Diffraction Imaging

2.3. Defect Selective Etching

3. Experimental Results

3.1. Results of X-ray Bragg Diffraction Imaging

3.1.1. Tracking of Honeycomb Defects (HCDs) by Lang X-ray Topography (L-XRT)

3.1.2. Diffraction Imaging Contrast of the Honeycomb Defect (HCD) in Transmission L-XRT

3.1.3. Diffraction Imaging Contrast of the Honeycomb Defect (HCD) in Back-Reflection SWB-XRT

3.1.4. Variations in the Honeycomb Defect Images

3.2. Results of Defect Selective Etching (DSE)

- (i)

- single TEDs in the DBs arrange as a few (or even single) long chains, many short chains, or are distributed over an area of up to 250 µm. There appears to be a correlation between the way the TEDs are located and the images they produce on the topographs: when more TEDs in the DBs are arranged as chains, stronger contrast is recorded on L-XRT;

- (ii)

- the number of TEDs in the DBs differs significantly between HCDs. We can extract a correlation, shown in Figure 9, between the number of TEDs in the DBs and the size of the HCD clusters: the higher the number of TEDs in the corners of the hexagon, the larger the size of the corresponding HCD cluster.

3.3. Use of RCI for a Quantitative Determination of the HCD´s Associated Lattice Distortion

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| The following abbreviations are used in this manuscript: | |

| Am-GaN | ammonothermal gallium nitride |

| DB | dislocation bundle |

| DSE | defect selective etching |

| FWHM map | full-width at half-maximum map |

| GaN | gallium nitride |

| GND | geometrically necessary dislocation |

| HCD | honeycomb defect |

| HVPE-GaN | hydride vapor-phase epitaxy gallium nitride |

| INT map | integrated intensity map |

| L-XRT | Lang technique X-ray topography |

| PPOS map | peak position angle map |

| RCI | synchrotron monochromatic rocking curve imaging |

| SWB-XRT | synchrotron white-beam X-ray topography |

| TD | threading dislocation |

| TED | threading edge dislocation |

| TMD | threading mixed dislocation |

| TSD | threading screw dislocation |

| XRT | X-ray topography |

Appendix A. Contrast of the DBs Located at the HCDs´ Corners

Appendix A.1. Contrast of the DBs as a Function of the Reflection Type and Orientation of the Diffraction Vector

Appendix A.2. Contrast of the DBs as a Function of the X-ray Energy

Appendix A.3. Phenomenological Model for the Emergence of Contrast Differences in Symmetrically Equivalent DBs of the HCDs

Appendix B. Distances of the TEDs in the Limited Size Subgrain Boundaries

References

- Meneghini, M.; De Santi, C.; Abid, I.; Buffolo, M.; Cioni, M.; Abdul Khadar, R.; Nela, L.; Zagni, N.; Chini, A.; Medjdoub, F.; et al. GaN-based power devices: Physics, reliability, and perspectives. J. Appl. Phys. 2021, 130, 181101. [Google Scholar] [CrossRef]

- Bojarska-Cieślińska, A.; Marona, Ł.; Smalc-Koziorowska, J.; Grzanka, S.; Weyher, J.; Schiavon, D.; Perlin, P. Role of dislocations in nitride laser diodes with different indium content. Sci. Rep. 2021, 11, 21. [Google Scholar] [CrossRef]

- Zhang, Y.; Zubair, A.; Liu, Z.; Xiao, M.; Perozek, J.A.; Ma, Y.; Palacios, T. GaN FinFETs and trigate devices for power and RF applications: Review and perspective. Semicond. Sci. Technol. 2021, 36, 054001. [Google Scholar] [CrossRef]

- Bockowski, M.; Iwinska, M.; Amilusik, M.; Fijalkowski, M.; Lucznik, B.; Sochacki, T. Challenges and future perspectives in HVPE-GaN growth on ammonothermal GaN seeds. Semicond. Sci. Technol. 2016, 31, 093002. [Google Scholar] [CrossRef]

- Kucharski, R.; Sochacki, T.; Lucznik, B.; Bockowski, M. Growth of bulk GaN crystals. J. Appl. Phys. 2020, 128, 050902. [Google Scholar] [CrossRef]

- Grabianska, K.; Jaroszynski, P.; Sidor, A.; Bockowski, M.; Iwinska, M. GaN Single Crystalline Substrates by Ammonothermal and HVPE Methods for Electronic Devices. Electronics 2020, 9, 1342. [Google Scholar] [CrossRef]

- UNIPRESS. Available online: http://www.unipress.waw.pl/growth/index.php/ammono-gan-wafers-sales (accessed on 31 August 2022).

- Kirste, L.; Grabianska, K.; Kucharski, R.; Sochacki, T.; Lucznik, B.; Bockowski, M. Structural Analysis of Low Defect Ammonothermally Grown GaN Wafers by Borrmann Effect X-ray Topography. Materials 2021, 14, 5472. [Google Scholar] [CrossRef] [PubMed]

- Authier, A. Dynamical Theory of X-ray Diffraction, 2nd ed.; Oxford University Press: Oxford, UK, 2003. [Google Scholar] [CrossRef]

- Doradziński, R.; Dwiliński, R.; Garczyński, J.; Sierzputowski, L.P.; Kanbara, Y. Ammonothermal Growth of GaN Under Ammono-Basic Conditions. In Technology of Gallium Nitride Crystal Growth; Ehrentraut, D., Meissner, E., Bockowski, M., Eds.; Springer: Heidelberg, Germany, 2010; pp. 137–160. [Google Scholar] [CrossRef]

- Hashimoto, T.; Nakamura, S. A Pathway Toward Bulk Growth of GaN by the Ammonothermal Method. In Technology of Gallium Nitride Crystal Growth; Ehrentraut, D., Meissner, E., Bockowski, M., Eds.; Springer: Heidelberg, Germany, 2010; pp. 161–182. [Google Scholar] [CrossRef]

- Zajac, M.; Kucharski, R.; Grabianska, K.; Gwardys-Bak, A.; Puchalski, A.; Wasik, D.; Litwin-Staszewska, E.; Piotrzkowski, R.; Domagala, J.Z.; Bockowski, M. Basic ammonothermal growth of Gallium Nitride—State of the art, challenges, perspectives. Prog. Cryst. Growth Charact. Mater. 2018, 64, 63–74. [Google Scholar] [CrossRef]

- Klapper, H. Defects in Non-metal Crystals. In Characterization of Crystal Growth Defects by X-Ray Methods; Tanner, B.K., Bowen, D.K., Eds.; Plenum Press: New York, NY, USA, 1980; pp. 133–160. [Google Scholar] [CrossRef]

- Lübbert, D.; Baumbach, T.; Härtwig, J.; Boller, E.; Pernot, E. μm-resolved high-resolution X-ray diffraction imaging for semiconductor quality control. Nucl. Inst. Meth. Phys. Res. B 2000, 160, 521–527. [Google Scholar] [CrossRef]

- Lang, A.R. Direct Observation of Individual Dislocations by X-Ray Diffraction. J. Appl. Phys. 1958, 29, 597–598. [Google Scholar] [CrossRef]

- Borrmann, G. Die Absorption von Röntgenstrahlen im Fall der Interferenz. Z. Phys. 1950, 127, 297–323. [Google Scholar] [CrossRef]

- Rozgonyi, G.A.; Miller, D.C. X-ray characterization of stresses and defects in thin films and substrates. Thin Solid Films 1976, 31, 185–216. [Google Scholar] [CrossRef]

- Rack, A.; Weitkamp, T.; Bauer, S.; Modregger, P.; Cecilia, A.; Rolo, T.; Rack, T.; Haas, D.; Simon, R.; Hedele, R.; et al. The micro-imaging station of the TopoTomo beamline at the ANKA synchrotron light source. Nucl. Inst. Meth. Phys. Res. B 2009, 267, 1978–1988. [Google Scholar] [CrossRef]

- Tuomi, T.; Naukkarinen, K.; Rabe, P. Use of synchrotron radiation in X-ray diffraction topography. Phys. Status Solidi A 1974, 25, 93–106. [Google Scholar] [CrossRef]

- Miltat, H. White beam synchrotron radiation topography. In Characterization of Crystal Growth Defects by X-ray Methods; Tanner, B.K., Bowen, D.K., Eds.; Plenum Press: New York, NY, USA, 1980; pp. 401–420. [Google Scholar] [CrossRef]

- Huang, X.R. LauePt, a graphical-user-interface program forsimulating and analyzing white-beam X-raydiffraction Laue patterns. J. Appl. Cryst. 2010, 43, 926–928. [Google Scholar] [CrossRef]

- Tran Thi Caliste, T.N. RCIA Software. Available online: https://gitlab.com/l_sim/scripts/rcia (accessed on 31 August 2022).

- Tran Thi, T.N.; Morse, J.; Caliste, D.; Fernandez, B.; Eon, D.; Härtwig, J.; Barbay, C.; Mer-Calfati, C.; Tranchant, N.; Arnault, J.C.; et al. Synchrotron Bragg diffraction imaging characterization of synthetic diamond crystals for optical and electronic power device applications. J. Appl. Cryst. 2017, 50, 561–569. [Google Scholar] [CrossRef]

- Klapper, H. X-Ray Diffraction Topography: Principles and Techniques. In X-Ray and Neutron Dynamical Diffraction: Theory and Applications; Authier, A., Lagomarsino, S., Tanner, B.K., Eds.; Plenum Press: New York, NY, USA, 1996; pp. 137–146. [Google Scholar] [CrossRef]

- Tsoutsouva, M.G.; Amaral De Oliveira, V.; Baruchel, J.; Camel, D.; Marie, B.; Lafford, T. Characterisation of defects in mono-like silicon for photovoltaic applications using X-ray Bragg diffraction imaging. J. Appl. Cryst. 2015, 48, 645–654. [Google Scholar] [CrossRef]

- Weyher, J.L.; Brown, P.D.; Rouvière, J.L.; Wosinski, T.; Zauner, A.R.A.; Grzegory, I. Recent advances in defect-selective etching of GaN. J. Cryst. Growth 2000, 210, 151–156. [Google Scholar] [CrossRef]

- Kamler, G.; Weyher, J.L.; Grzegory, I.; Jezierska, E.; Wosinski, T. Defect-selective etching of GaN in a modified molten bases system. J. Cryst. Growth 2002, 246, 21–24. [Google Scholar] [CrossRef]

- Weyher, J.L.; Lazar, S.; Macht, L.; Liliental-Weber, Z.; Molnar, R.J.; Müller, S.; Sivel, V.G.M.; Nowak, G.; Grzegory, I. Orthodox etching of HVPE-grown GaN. J. Cryst. Growth 2007, 305, 384–392. [Google Scholar] [CrossRef]

- Knoke, I.Y.; Berwian, P.; Meissner, E.; Friedrich, J.; Strunk, H.P.; Müller, G. Selective etching of dislocations in GaN grown by low-pressure solution growth. J. Cryst. Growth 2010, 312, 3040–3045. [Google Scholar] [CrossRef]

- Weyher, J.L.; Kelly, J.J. Defect-selective etching of semiconductors. In Springer Handbook of Crystal Growth; Dhanaraj, G., Byrappa, K., Prasad, V., Dudley, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1453–1476. [Google Scholar] [CrossRef]

- Okkerse, B. Anomalous transmission of X-rays in germanium. Philips Res. Rpts. 1962, 17, 464–478. [Google Scholar]

- Builov, A.N.; Danil’chuk, L.N. Edge dislocations with large burgers vector in sphalerite crystals. Tech. Phys. Lett. 2002, 28, 762–764. [Google Scholar] [CrossRef]

- Möck, P. Analysis of thermal-treatment-induced dislocation bundles in GaAs wafers by means of X-ray transmission topography and complementary methods. J. Appl. Cryst. 2001, 34, 65–75. [Google Scholar] [CrossRef]

- Yildirim, C.; Gout, E.; Pagot, A.; Tran Thi Caliste, T.N.; Baruchel, J.; Brellier, D.; Ballet, P. Bragg Diffraction Imaging of CdZnTe Single Crystals. J. Electron. Mater. 2020, 49, 4550–4556. [Google Scholar] [CrossRef]

- Okunev, A.O.; Verozubova, G.A.; Trukhanov, E.M.; Dzjuba, I.V.; Galtier, P.R.J.; Said Hassani, S.A. Study of structural defects in ZnGeP2 crystals by X-ray topography based on the Borrmann effect. J. Appl. Cryst. 2009, 42, 994–998. [Google Scholar] [CrossRef]

- Okunev, A.O.; Verozubova, G.A. X-ray topography contrast from edge dislocations in ZnGeP2 single crystals. J. Appl. Cryst. 2015, 48, 1228–1233. [Google Scholar] [CrossRef]

- Lei, Z.; Okunev, A.; Zhu, C.; Verozubova, G.; Yang, C. Low-angle boundaries in ZnGeP2 single crystals. J. Appl. Cryst. 2018, 51, 361–367. [Google Scholar] [CrossRef]

- Sintonen, S.; Rudziński, M.; Suihkonen, S.; Jussila, H.; Knetzger, M.; Meissner, E.; Danilewsky, A.; Tuomi, T.O.; Lipsanen, H. Synchrotron radiation x-ray topography and defect selective etching analysis of threading dislocations in GaN. J. Appl. Phys. 2014, 116, 083504. [Google Scholar] [CrossRef]

- Yao, Y.; Ishikawa, Y.; Sugawara, Y.; Takahashi, Y.; Hirano, K. Observation of Threading Dislocations in Ammonothermal Gallium Nitride Single Crystal Using Synchrotron X-ray Topography. J. Electron. Mater. 2018, 47, 5007–5012. [Google Scholar] [CrossRef]

- Barrett, R.; Baruchel, J.; Härtwig, J.; Zontone, F. The present status of the ESRF diffraction topography beamline: New experimental results. J. Phys. D Appl. Phys. 1995, 28, A25O–A255. [Google Scholar] [CrossRef]

- Baruchel, J.; Härtwig, J. X-Ray Topography. In Encyclopedia of Condensed Matter Physics; Bassani, F., Liedl, G.L., Wyder, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 342–348. [Google Scholar] [CrossRef]

- Hughes, D.A.; Hansen, N.; Bammann, D.J. Geometrically necessary boundaries, incidental dislocation boundaries and geometrically necessary dislocations. Scr. Mater. 2003, 48, 147–153. [Google Scholar] [CrossRef]

- Cai, W.; Nix, W.D. ; Imperfections in Crystalline Solids; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar] [CrossRef]

| Technique | Reflection hkil | Energy [keV] | Wavelength λ [pm] | Bragg Angle ΘΒ [°] | Absorption µt * |

|---|---|---|---|---|---|

| L-XRT | 8.05 (Cu-Kα1) | 154.06 | 28.89 | 9.1–13.6 | |

| SWB-XRT | 18.70 | 66.30 | 12.00 | 7.1 | |

| 12.47 | 99.45 | 10.37 | 20.5 | ||

| 18.00 | 68.88 | 12.47 | 7.9 | ||

| RCI | 30.00 | 41.33 | 7.45 | 1.9 | |

| 30.00 | 41.33 | 4.29 | 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirste, L.; Tran Thi Caliste, T.N.; Weyher, J.L.; Smalc-Koziorowska, J.; Zajac, M.A.; Kucharski, R.; Sochacki, T.; Grabianska, K.; Iwinska, M.; Detlefs, C.; et al. Large-Scale Defect Clusters with Hexagonal Honeycomb-like Arrangement in Ammonothermal GaN Crystals. Materials 2022, 15, 6996. https://doi.org/10.3390/ma15196996

Kirste L, Tran Thi Caliste TN, Weyher JL, Smalc-Koziorowska J, Zajac MA, Kucharski R, Sochacki T, Grabianska K, Iwinska M, Detlefs C, et al. Large-Scale Defect Clusters with Hexagonal Honeycomb-like Arrangement in Ammonothermal GaN Crystals. Materials. 2022; 15(19):6996. https://doi.org/10.3390/ma15196996

Chicago/Turabian StyleKirste, Lutz, Thu Nhi Tran Thi Caliste, Jan L. Weyher, Julita Smalc-Koziorowska, Magdalena A. Zajac, Robert Kucharski, Tomasz Sochacki, Karolina Grabianska, Malgorzata Iwinska, Carsten Detlefs, and et al. 2022. "Large-Scale Defect Clusters with Hexagonal Honeycomb-like Arrangement in Ammonothermal GaN Crystals" Materials 15, no. 19: 6996. https://doi.org/10.3390/ma15196996

APA StyleKirste, L., Tran Thi Caliste, T. N., Weyher, J. L., Smalc-Koziorowska, J., Zajac, M. A., Kucharski, R., Sochacki, T., Grabianska, K., Iwinska, M., Detlefs, C., Danilewsky, A. N., Bockowski, M., & Baruchel, J. (2022). Large-Scale Defect Clusters with Hexagonal Honeycomb-like Arrangement in Ammonothermal GaN Crystals. Materials, 15(19), 6996. https://doi.org/10.3390/ma15196996