Influence of Higher Order Viscous and Thermal Effects on an Ultrasonic Wave Reflected from the First Interface of a Porous Material

Abstract

:1. Introduction

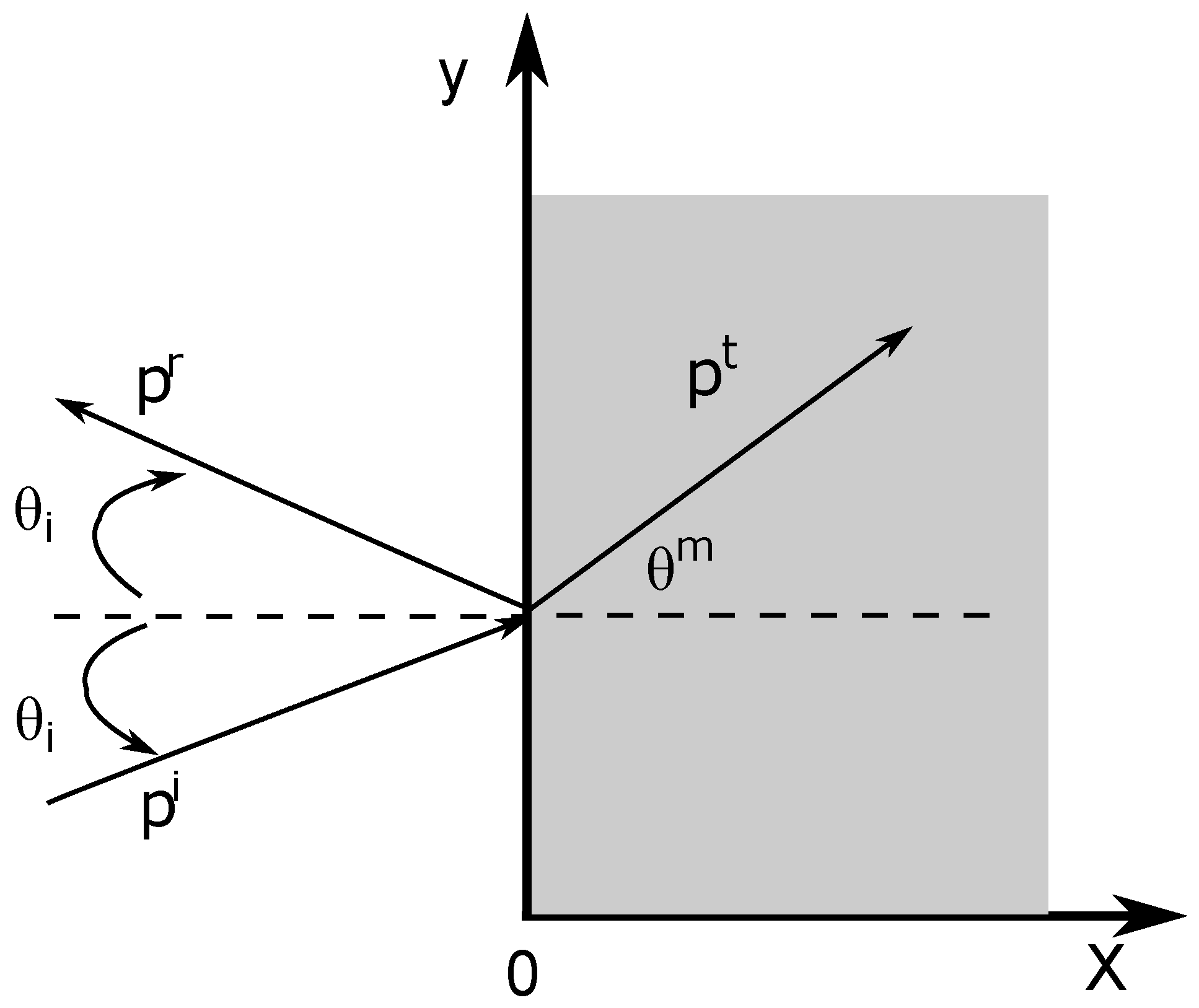

2. Model

Reflection Coefficient

3. Sensitivity Analysis

4. Ultrasonic Measurement

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Allard, J.F. Propagation of Sound in Porous Media: Modeling Sound Absorbing Materials; Chapman and Hall: London, UK, 1993. [Google Scholar]

- Panhwar, M.A.; Memon, D.A.; Bhutto, A.A.; Jamali, Q.B. Impact of Noise Pollution on Human Health at Industrial SITE Area Hyderabad. Indian J. Sci. Technol. 2018, 11, 1–6. [Google Scholar]

- Del Pizzo, A.; Teti, L.; Moro, A.; Moro, A.; Bianco, F.; Fredianelli, L. Influence of texture on tyre road noise spectra in rubberized pavements. Appl. Acoust. 2020, 159, 107080. [Google Scholar] [CrossRef]

- Babisch, W.; Swart, W.; Houthuijs, D.; Selander, J.; Bluhm, G.; Pershagen, G.; Dimakopoulou, K.; Haralabidis, A.S.; Katsouyanni, K.; Davou, E.; et al. Exposure modifiers of the relationships of transportation noise with high blood pressure and noise annoyance. J. Acoust. Soc. Am. 2012, 132, 3788–3808. [Google Scholar] [CrossRef]

- Hooven, E.H.V.D.; Pierik, F.H.; Kluizenaar, Y.D.; Willemsen, S.P.; Hofman, A.; Ratingen, Q.W.V.; Zandveld, P.Y.J.; Mackenbach, J.P.; Steegers, E.A.P.; Miedema, H.M.E.; et al. Air pollution exposure during pregnancy, ultrasound measures of fetal growth, and adverse birth outcomes: A prospective cohort study. Environ. Health Perspect. 2012, 120, 150–156. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lakes, T.; Bruckner, M.; Kramer, A. Development of an environmental justice index to determine socio-economic disparities of noise pollution and green space in residential areas in Berlin. J. Environ. Plan. Manag. 2014, 57, 538–556. [Google Scholar] [CrossRef]

- Geravandi, S.; Takdastan, A.; Zallaghi, E.; Niri, M.V.; Mohammadi, M.J.; Saki, H.; Naiemabadi, A. Noise Pollution and Health Effects. Jundishapur J. Health Sci. 2015, 7, 60312. [Google Scholar] [CrossRef] [Green Version]

- Singh, N.; Davar, S.C. Noise Pollution-Sources, Effects and Control. J. Hum. Ecol. 2017, 16, 181–187. [Google Scholar] [CrossRef]

- Seidler, A.; Hegewald, J.; Schubert, M.; Popp, C.; Moebus, S. Effects of Noise Protection Measures on Annoyance, Sleep Disorders, and Cardiovascular Diseases: A Model Calculation. Gesundheitswesen 2021, 83, 398–408. [Google Scholar]

- Garay, R.; Nidia Pino, N.G. Acoustic Behavior in Three Types of Housing: Brick Social Housing, Structural Insulated Panel (SIP) Emergency Housing and Mediagua Emergency Housing. Environ. Sci. Rev. Constr. 2019, 18, 96–110. [Google Scholar] [CrossRef]

- Zhao, D.; Li, X.Y. A review of acoustic dampers applied to combustion chambers in aerospace industry. Prog. Aerosp. Sci. 2015, 74, 114–130. [Google Scholar] [CrossRef]

- Gao, N.; Zhang, Z.; Tang, L.; Hou, H.; Chen, K. Optimal design of broadband quasi-perfect sound absorption of composite hybrid porous metamaterial using TLBO algorithm. Appl. Acoust. 2021, 183, 108296. [Google Scholar] [CrossRef]

- Gao, N.; Guo, X.; Deng, J.; Cheng, B. Design and study of a hybrid composite structure that improves electromagnetic shielding and sound absorption simultaneously. Compos. Struct. 2022, 280, 114924. [Google Scholar] [CrossRef]

- Deng, J.; Guasch, O.; Maxit, L.; Zheng, L. Annular acoustic black holes to reduce sound radiation from cylindrical shells. Mech. Syst. Signal Process. 2021, 158, 107722. [Google Scholar] [CrossRef]

- Deng, J.; Guasch, O.; Maxit, L.; Zheng, L. Transmission loss of plates with multiple embedded acoustic black holes using statistical modal energy distribution analysis. Mech. Syst. Signal Process. 2021, 150, 107262. [Google Scholar] [CrossRef]

- Deng, J.; Zheng, L. Noise reduction via three types of acoustic black holes. Mech. Syst. Signal Process. 2022, 165, 108323. [Google Scholar] [CrossRef]

- Zhang, X.; Ba, M.; Kang, J.; Meng, Q. Effect of soundscape dimensions on acoustic comfort in urban open public spaces. Appl. Acoust. 2018, 133, 73–81. [Google Scholar] [CrossRef] [Green Version]

- Atalla, Y.; Panneton, R. Inverse acoustical characterization of open cell porous media using impedance tube measurements. Can. Acoust. 2005, 33, 11–24. [Google Scholar]

- Panneton, R.; Olny, X. Acoustical determination of the parameters governing viscous dissipation in porous media. J. Acoust. Soc. Am. 2006, 119, 2027–2040. [Google Scholar] [CrossRef]

- Ogam, E.; Fellah, Z.E.A.; Sebaa, N.; Groby, J.P. Non-ambiguous recovery of Biot poroelastic parameters of cellular panels using ultrasonicwaves. J. Sound Vib. 2011, 330, 1074–1090. [Google Scholar] [CrossRef]

- Roncen, R.; Fellah, Z.E.A.; Simon, F.; Piot, E.; Fellah, M.; Ogam, E.; Depollier, C. Bayesian inference for the ultrasonic characterization of rigid porous materials using reflected waves by the first interface. J. Acoust. Soc. Am. 2018, 144, 210–221. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fellah, Z.E.A.; Fellah, M.; Motri, F.G.; Sebaa, N.; Depollier, C.; Lauriks, W. Measuring permeability of porous materials at low-frequency range via acoustic transmitted waves. Rev. Sci. Instrum. 2007, 78, 114902. [Google Scholar] [CrossRef] [PubMed]

- Brown, N.; Melon, M.; Montembault, V.; Castagnede, B.; Lauriks, W.; Leclaire, P. Evaluation of the viscous characteristic length of air-saturated porous materials from the ultrasonic dispersion curve. C. R. Acad. Sci. 1996, 322, 122–127. [Google Scholar]

- Leclaire, P.; Kelders, L.; Lauriks, W.; Melon, M.; Brown, N.; Castagnede, B. Determination of the viscous and thermal characteristic lengths of plastic foams by ultrasonic measurements in helium and air. J. Appl. Phys. 1996, 80, 2009–2012. [Google Scholar] [CrossRef] [Green Version]

- Konarski, S.G.; Roohde, C.A.; Gotoh, R.; Roberts, S.N.; Naify, C.J. Acoustic measurement and statistical characterization of direct-printed, variable-porosity aluminum foams. J. Acoust. Soc. Am. 2021, 149, 4327–4336. [Google Scholar] [CrossRef] [PubMed]

- Cuenca, J.; Goransson, P.; De Ryck, L.; Lahivaara, T. Deterministic and statistical methods for the characterisation of poroelastic media from multi-observation sound absorption measurements. Mech. Syst. Signal Process. 2022, 163, 108186. [Google Scholar] [CrossRef]

- Groby, J.P.; Ogam, E.; Deryck, L.; Sebaa, N.; Lauriks, W. Analytical method for the ultrasonic characterization of homogeneous rigid porous materials from transmitted and reflected coefficients. J. Acoust. Soc. Am. 2010, 127, 764–772. [Google Scholar] [CrossRef]

- Gomez Alvarez-Arenasa, T.E.; De la Fuente, S.; Gomez, G. Simultaneous determination of apparent tortuosity and microstructure length scale and shape: Application to rigid open cell foams. Appl. Phys. Lett. 2006, 88, 221910. [Google Scholar] [CrossRef]

- El Abassi, D.; Ibhi, A.; Faiz, B.; Aboudaoud, I. A simple method for the determination of the porosity and tortuosity of meteorites with ultrasound. J. Geophys. Eng. 2013, 10, 1–9. [Google Scholar] [CrossRef]

- Jaouen, L.; Gourdon, E.; Gle, P. Estimation of all six parameters of Johnson-Champoux-Allard-Lafarge model for acoustical porous materials from impedance tube measurements. J. Acoust. Soc. Am. 2020, 148, 1998–2005. [Google Scholar] [CrossRef]

- Leclaire, P.; Dupont, T.; Panneton, R. Acoustics of porous materials with partially opened porosity. J. Acoust. Soc. Am. 2013, 134, 4630–4641. [Google Scholar] [CrossRef] [Green Version]

- Lieblappen, R.; Fegyveresi, J.M.; Courville, Z.; Albert, D.G. Using Ultrasonic Waves to Determine the Microstructure of Snow. Front. Earth Sci. 2020, 8, 1–11. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Berger, S.; Lauriks, W.; Depollier, C.; Aristegui, C.; Chapelon, J.-Y. Measuring the porosity and the tortuosity of porous materials via reflected waves at oblique incidence. J. Acoust. Soc. Am. 2003, 113, 2424–2433. [Google Scholar] [CrossRef] [Green Version]

- Fellah, Z.E.A.; Depollier, C.; Berger, S.; Lauriks, W.; Trompette, P.; Chapelon, J.Y. Determination of transport parameters in air-saturated porous materials via reflected ultrasonic waves. J. Acoust. Soc. Am. 2003, 114, 2561–2569. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Fellah, M.; Mitri, F.G.; Sebaa, N.; Lauriks, W.; Depollier, C. Transient acoustic wave propagation in air-saturated porous media at low frequencies. J. Appl. Phys. 2007, 102, 084906. [Google Scholar] [CrossRef]

- Umnova, O.; Attenborough, K.; Shin, H.-C.; Cummings, A. Deduction of tortuosity and porosity from acoustic reflection and transmission measurements on thick samples of rigid-porous materials. Appl. Acoust. 2005, 66, 607–624. [Google Scholar] [CrossRef]

- Zielinski, T.G. Normalized inverse characterization of sound absorbing rigid porous media. J. Acoust. Soc. Am. 2015, 137, 3232–3243. [Google Scholar] [CrossRef] [Green Version]

- Johnson, D.L.; Koplik, J.; Dashen, R. Theory of dynamic permeability and tortuosity in fluid-saturated porous media. J. Fluid Mech. 1987, 176, 379–402. [Google Scholar] [CrossRef]

- Lafarge, D.; Lemarinier, P.; Allard, J.-F.; Tarnow, V. Dynamic compressibility of air in porous structures at audible frequencies. J. Acoust. Soc. Am. 1997, 102, 1995–2006. [Google Scholar] [CrossRef] [Green Version]

- Kergomard, J.; Lafarge, D.; Gilbert, J. Transients in porous media: Exact and modelled time-domain Green’s functions. Acta Acust. Acust. 2013, 99, 557–571. [Google Scholar] [CrossRef] [Green Version]

- Horoshenkov, K.V.; Groby, J.P.; Dazel, O. Asymptotic limits of some models for sound propagation in porous media and the assignment of the pore characteristic lengths. J. Acoust. Soc. Am. 2016, 139, 2463–2474. [Google Scholar] [CrossRef] [Green Version]

- Fellah, Z.E.A.; Depollier, C.; Fellah, M.; Lauriks, W.; Chapeelon, J.-Y. Influence of dynamic tortuosity and compressibility on the propagation of transient waves in porous media. Wave Motion 2005, 41, 145–161. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Fellah, M.; Lauriks, W.; Depollier, C.; Chapelon, J.Y.; Angel, Y.C. Solution in time domain of ultrasonic propagation equation in a porous material. Wave Motion 2003, 38, 151–163. [Google Scholar] [CrossRef]

- Roncen, R.; Fellah, Z.E.; Lafarge, D.; Piot, E.; Simon, F.; Ogam, E.; Fellah, M.; Depollier, C. Acoustical modeling and Bayesian inference for rigid porous media in the low-mid frequency regime. J. Acoust. Soc. Am. 2018, 144, 3084–3101. [Google Scholar] [CrossRef]

- Ogam, E.; Fellah, Z.E.A.; Ogam, G.; Ongwen, N.O.; Oduor, A.O. Investigation of long acoustic waveguides for the very low-frequency characterization of monolayer and stratified air-saturated poroelastic materials. Appl. Acoust. 2021, 182, 108200. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Sadouki, M.; Fellah, M.; Mitri, F.G.; Ogam, E.; Depollier, C. Simultaneous determination of porosity, tortuosity, viscous and thermal characteristic lengths of rigid porous materials. J. Appl. Phys. 2013, 114, 204902. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Berger, S.; Lauriks, W.; Depollier, C.; Chapelon, J.-Y. Inverse problem in air-saturated porous media via reflected waves. Rev. Sci. Instrum. 2003, 74, 2871–2879. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Mitri, F.G.; Depollier, C.; Berger, S.; Lauriks, W.; Chapelon, J.Y. Characterization of porous materials with a rigid frame via reflected waves. J. Appl. Phys. 2003, 94, 7914–7922. [Google Scholar] [CrossRef]

- Roncen, R.; Fellah, Z.E.A.; Piot, E.; Simon, F.; Ogam, E.; Fellah, M.; Depollier, C. Inverse identification of a higher order viscous parameter of rigid porous media in the high frequency domain. J. Acoust. Soc. Am. 2019, 145, 1629–1639. [Google Scholar] [CrossRef]

- Biot, M.A. Theory of propagation of elastic waves in a fluid-saturated porous solid. I. J. Acoust. Soc. Am. 1956, 28, 168–178. [Google Scholar] [CrossRef]

- Biot, M.A. Theory of propagation of elastic waves in a fluid-saturated porous solid. II. J. Acoust. Soc. Am. 1956, 28, 179–191. [Google Scholar] [CrossRef]

- Carcione, J.M.; Gurevich, B.; Cavallini, F. A generalized Biot-Gassmann model for the acoustic properties of shaley sandstones. Geophys. Prospect. 2001, 48, 539–557. [Google Scholar] [CrossRef] [Green Version]

- Fellah, Z.E.A.; Chapelon, J.-Y.; Berger, S.; Lauriks, W.; Depollier, C. Ultrasonic wave propagation in human cancellous bone: Application of Biot theory. J. Acoust. Soc. Am. 2004, 116, 61–73. [Google Scholar] [CrossRef]

- Roncen, R.; Fellah, Z.E.A.; Piot, E.; Ogam, E. Bayesian inference of a human bone and biomaterials using ultrasonic transmitted signals. J. Acoust. Soc. Am. 2019, 146, 1629–1640. [Google Scholar] [CrossRef]

- Haire, T.J.; Langton, C.M. Biot theory: A review of its application to ultrasound propagation through cancellous bone. Bone 1999, 24, 291–295. [Google Scholar] [CrossRef]

- Hughes, E.R.; Leighton, T.G.; White, P.R. Investigation of an anisotropic tortuosity in a Biot model of ultrasonic propagation in cancellous bone. J. Acoust. Soc. Am. 2007, 121, 568–574. [Google Scholar] [CrossRef] [PubMed]

- Roncen, R.; Fellah, Z.E.A.; Ogam, E. Bayesian inference of human bone sample properties using ultrasonic reflected signals. J. Acoust. Soc. Am. 2020, 148, 3797–3808. [Google Scholar] [CrossRef] [PubMed]

- Attia, A.M. Effects of petrophysical rock properties on tortuosity factor. J. Pet. Sci. Eng. 2005, 48, 185–198. [Google Scholar] [CrossRef]

- Gao, N.; Tang, L.; Deng, J.; Lu, K.; Hou, H.; Chen, K. Design, fabrication and sound absorption test of composite porous metamaterial with embedding I-plates into porous polyurethane sponge. Appl. Acoust. 2021, 175, 107845. [Google Scholar] [CrossRef]

- Gao, N.; Wu, J.; Lu, K.; Zhong, H. Hybrid composite meta-porous structure for improving and broadening sound absorption. Mech. Syst. Signal Process. 2021, 154, 107504. [Google Scholar] [CrossRef]

- Pride, S.R.; Morgan, F.D.; Gangi, A.F. Drag forces of a porous-medium acoustics. Phys. Rev. B 1993, 47, 4964–4978. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Fellah, M.; Lauriks, W.; Depollier, C. Direct and inverse scattering of transient acoustic waves by a slab of rigid porous material. J. Acoust. Soc. Am. 2003, 113, 61–72. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Berger, S.; Lauriks, W.; Depollier, C.; Trompette, P.; Chapelon, J.-Y. Ultrasonic measurement of the porosity and tortuosity of air-saturated random packings of beads. J. Appl. Phys. 2003, 93, 9352–9359. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Berger, S.; Lauriks, W.; Depollier, C. Measuring the porosity of porous materials having a rigid frame via reflected waves: A time domain analysis with fractional derivatives. J. Appl. Phys. 2003, 93, 296–303. [Google Scholar] [CrossRef]

- Beranek, L.L. Acoustic impedance of porous materials. J. Acoust. Soc. Am. 1942, 13, 248–260. [Google Scholar] [CrossRef]

- Champoux, Y.; Stinson, M.R.; Daigle, G.A. Air-based system for the measurement of porosity. J. Acoust. Soc. Am. 1991, 89, 910–916. [Google Scholar] [CrossRef]

- Fellah, Z.E.A.; Mitri, F.G.; Fellah, M.; Ogam, E.; Depollier, C. Ultrasonic characterization of porous absorbing materials: Inverse problem. J. Sound Vib. 2007, 302, 746–759. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fellah, Z.E.A.; Roncen, R.; Ongwen, N.O.; Ogam, E.; Fellah, M.; Depollier, C. Influence of Higher Order Viscous and Thermal Effects on an Ultrasonic Wave Reflected from the First Interface of a Porous Material. Materials 2022, 15, 798. https://doi.org/10.3390/ma15030798

Fellah ZEA, Roncen R, Ongwen NO, Ogam E, Fellah M, Depollier C. Influence of Higher Order Viscous and Thermal Effects on an Ultrasonic Wave Reflected from the First Interface of a Porous Material. Materials. 2022; 15(3):798. https://doi.org/10.3390/ma15030798

Chicago/Turabian StyleFellah, Zine El Abiddine, Rémi Roncen, Nicholas O. Ongwen, Erick Ogam, Mohamed Fellah, and Claude Depollier. 2022. "Influence of Higher Order Viscous and Thermal Effects on an Ultrasonic Wave Reflected from the First Interface of a Porous Material" Materials 15, no. 3: 798. https://doi.org/10.3390/ma15030798

APA StyleFellah, Z. E. A., Roncen, R., Ongwen, N. O., Ogam, E., Fellah, M., & Depollier, C. (2022). Influence of Higher Order Viscous and Thermal Effects on an Ultrasonic Wave Reflected from the First Interface of a Porous Material. Materials, 15(3), 798. https://doi.org/10.3390/ma15030798