Abstract

Modernization and the global fashion market demand continuous improvements in upland cotton cultivars (Gossypium hirustum L.) to meet these improved fiber characteristics (fiber length, fiber strength, micronaire) requirements. Researchers have centered their efforts on improved fiber quality; however, the efforts are not immediately supporting the textile sector. The daily mean and temperature amplitude fluctuation affect cotton yield and fiber characteristics. This study analyzed four newly developed cotton varieties in two cotton regions for fiber characteristics’ variations. It was observed that cotton fiber quality characteristics (fiber length, uniformity, strength, and micronaire) are impacted in diverse ways. Fiber quality is mainly affected by the genotype and environmental conditions, e.g., weather conditions, irrigation management, fertilization, and cultural practices. The Khanewal region had shown better fiber characteristics than the Multan region, whereas cotton variety CIM-785 had better fiber characteristics in both regions.

1. Introduction

Cotton (Gossypium hirsutum L.) is a plant fiber crop with a long history of textile usage due to its superior comfort over synthetic fibers. In addition, the natural cellulose fiber, cotton, has factually been the most used material in medical products (stitches, absorbent pads, dressings, and bandages) and continues to account for significant volumes of the absorbent and dressing products used worldwide. Cotton varieties in Punjab are certified based on fiber quality norms such as fiber strength of 25 g/tex and above, length of 28 mm, and micronaire of 3.8 to 4.9 [1]. Producers are offered a variety of upland cotton varieties each year. Plant type, maturity, fiber qualities, added-value features (e.g., insect and herbicide resistance transgenes), yield, and environmental adaptability characterize these types. Both governmental and private groups undertake multilocation cultivar trials to analyze plant and fiber performance to aid growers. Cotton fibers that are stronger, longer, finer, and more consistent are needed by contemporary textile manufacturers.

Cotton fiber growers and processors are concerned with the fiber’s strength, length, fineness, color, and trash content. Compared to traditional ring spinning technologies, the fiber quality standards for current high-speed yarn production procedures at higher spinning speeds [2,3]. As a result of this issue, processors are compelled to employ higher-strength cotton fiber in their yarn production.

Textile spinning mills are continually looking for methods to improve the quality-to-cost ratio. They must also establish processing ratios obtained by combining fibers from several bales with similar qualities. Cotton growers may see differences in the qualities of fibers, such as color variation, but no device can predict quality parameters as they develop in the boll [4,5]. There is no reference source, database, or model to foresee how atmospheric and genetic changes can be adapted to the cotton plant’s cultivating conditions. It is crucial to understand how climate and soil affect cotton cultivars.

Cotton quality may be determined by seed or fiber qualities. However, it is most typically connected to fiber attributes. Cotton fiber quality has improved due to increased global competition in production and use of cotton fiber and technical advancements in yarn manufacture. Genetics, crop management, and postharvest distribution may help improve cotton fiber quality. It is critical to understand the impact of fiber qualities on processing and their heredity, interactions, and environmental factors to develop improvement solutions. For yarn production systems, breeding to improve fiber quality has traditionally focused on improving measurements of the longest fibers or fiber strength. Variability in fiber qualities is caused by the environment, which makes it challenging to enhance them by breeding or biotechnological means. Because fiber processing is hindered by variability in fiber qualities, future breeding and biotechnological methods should simultaneously enhance fiber properties and lower variance [6].

The purpose of the current research project was to investigate regional and varietal variations in fiber quality features and their influence on yarn parameters in the final product. Currently, farmers produce cotton with high-yielding varieties without considering the fiber characteristics, and the textile mills have to import cotton for better fiber properties. The main objective of this study is to explore the varietal behavior of newly developed cotton varieties concerning environmental conditions.

2. Materials and Methods

The present research entitled “impact of novel varietal and regional differences on cotton fiber quality and their implication to yarn properties” was initiated in the College of Textile Engineering, Bahauddin Zakariya University, Multan, in the year 2021. The four cotton cultivars from Central Cotton Research Institute, Multan were selected with two cotton regions for this experiment. A significant reduction in flower and boll retention was observed at high temperatures (>36 °C), which ultimately resulted in a severe decrease in seed cotton yield and vice versa. The seed cotton was picked and ginned on a miniature ginning machine (Chaudhary Engineering Works, Multan, Pakistan). The following sections provide information on the materials and procedures utilized to test the different quality features of raw cotton. The following variables were selected for this research work, and all are given in Table 1.

Table 1.

Selected variables.

2.1. Analysis of Data

A least significant difference (LSD) test is used in the context of the analysis of variance. The LSD calculates the smallest significance between two means as if a test had been run on those two means (as opposed to all of the groups together). Any difference greater than the LSD is considered a significant result.

The formula for the least significant difference is:

where:

t = critical value from the t-distribution table;

MSw = mean square within, obtained from the results of your ANOVA test;

DFw is the degrees of freedom within groups from the ANOVA table;

n = sample size.

2.2. Fiber Physical Characteristics

High Volume Instrument (HVI) 1000 is used for fiber physical characteristics. The Length/Strength Module measures two samples simultaneously; places approximately 8 to 10 g of fiber in each sample bucket; and it automatically prepares the comb from the material in each bucket. The combs slide along the comb track until the first one is positioned in front of the brusher. As soon as the comb is in place, the brusher automatically removes loose fiber from the beard while simultaneously cleaning and aligning the remaining fibers. It is then moved along the comb track to the lens and jaw system, where the fiber beard is scanned from base to tip for measuring length, uniformity, and short fiber index. Length uniformity is the ratio between the mean length and upper half mean length of the fibers and is expressed as a percentage. Micronaire is the measure of fiber fineness and maturity. An airflow instrument measures the air permeability of weighing between 8.5 to 11.5 g of cotton fibers compressed to a fixed volume.

The testing technique shall be followed as specified by the ASTM committee (D-5867-12) [7]. The testing will be carried out under standard laboratory conditions, which include a relative humidity of (65 ± 2)% and (20 ± 2) °C temperature ASTM standard method (D-1776) [8].

2.3. Fiber Mechanical Characteristics

High Volume Instrument (HVI) 1000 is used for fiber mechanical characteristics. The Length/Strength Module measures two samples simultaneously; places approximately 8 to 10 g of fiber in each sample bucket; and it automatically prepares the comb from the ma-terial in each bucket. Fiber strength and elongation are measured by breaking the tapered beards using 3.2 mm (1/8 inch) clamp spacing. The testing technique shall be followed as specified by the ASTM committee (D-5867-12) [7]. The testing will be carried out under standard laboratory conditions, which include a relative humidity of (65 ± 2)% relative humidity and (20 ± 2) °C temperature ASTM standard method (D-1776) [8].

2.4. Fiber Chemical Characteristics

Cellulose, Wax Content, and Ash Content

In cotton fibers, crystallites of native cellulose are composed of molecules with their reducing groups at one end of the crystal, described as similar packing. Since the crystallites are generally aligned with the fiber axis, one might describe the crystallite as oriented with the reducing end of the crystal towards the growth tip of cotton fiber. Cellulose, wax, and ash content were estimated by the method as prescribed by A.O.A.C. (1990) [9]. A weighted sample of one gram oven-dried cotton was digested in 200 mL, in addition to 1.25% H2SO4 for thirty minutes with gentle boiling on an electric heater up to 80°C using a condenser for maintaining a constant volume of solution. The sample was filtered through a thick linen cloth and washed with distilled water till it was free from acid. After that, the sample was digested in a 1.25 percent NaOH solution. The digested sample was filtered and thoroughly washed to the point that it gave no pink color with a phenolphthalein indicator. Finally, washing was done with 95 (%) ethanol. The samples were then dried at 70 °C to a constant weight and ash in an automatically controlled muffle furnace at 450 to 500 °C for not more than 30 min. The cellulose content of cotton was calculated using the following mathematical expression:

For wax content, a five-gram sample of raw cotton was placed in thimble filter paper in a Soxhlet extractor and the solvent “Light Petroleum Ether” poured through the condenser until the siphon operated. A further 10 to 20 mL solvent was added, and extraction was started by turning the water bath on, and thermo-state was fixed in the range of 85 °C to 95 °C. The extraction was done for three hours while solvent was siphoned at least six times per hour. The apparatus was disconnected and the extract was evaporated carefully to dryness, and the extract was weighted after oven drying. The amount of wax was represented based on the original cotton weight.

For ash content, a weighed amount of the material previously dried at 110 °C was placed in a muffle furnace at about 500 ± 50 °C for 30 min. The residual ash was weighed in a close vessel. Covered crucibles were used to put the sample in them. The amount of ash was calculated based on the original cotton weight.

3. Results and Discussion

3.1. Fiber Length (mm)

Fiber length is generally the object of trait development efforts in cotton since it is an important fiber quality feature in spinning technology, and it is genetically determined [10]. The results of the analysis of variance of the data related to fiber length are shown in Table 2, which demonstrates that the influence of cotton varieties (V) and cotton regions (R), as well as interactions, were highly significant in this study. The least significant difference (LSD) test is used in the context of the analysis of variance, and the comparison of individual treatment means for different varieties presented in Table 3 showed that the mean values of fiber length for V1, V2, V3, and V4 were 28.44, 27.91, 28.69, and 27.31 mm, respectively. Following the analysis, it was discovered that the fiber length values for various types are significantly varied from one another. The results are supported from Hameed [11], and the staple length of several Pakistani cotton cultivars ranges between 26.92 and 29.72 mm, which is extremely similar to the data obtained by this research. The length of the fiber was also highlighted by Hsieh and Hu [12], who said that it was influenced by both varietals and growth variables (environmental and developmental factors).

Table 2.

ANOVA table for fiber length (mm).

Table 3.

Individual mean comparison values for fiber length (mm).

The least significant difference (LSD) test and the comparison of individual treatment means for both regions shown in Table 3. The mean values of staple length for R1 and R2 were 27.60 and 28.48 mm, respectively. Fiber length values for distinct locations were shown to be considerably varied from one another, based on the findings of this study. These findings are supported by earlier research given by the author [13]. NIAB-111 had a mean span length of 29.64 and 30.00 mm, according to the researchers. In a similar vein, Nazar and Iftikhar [14] discovered that the staple length of several Pakistani cotton cultivars ranges from 26.92 to 29.72 mm, depending on the variety. In addition, El Mogahzy and Gowayed [15] indicated that fiber length was an essential property in assessing cotton quality, which was crucial to spinners since it was strongly connected to processability and the quality of yarn produced.

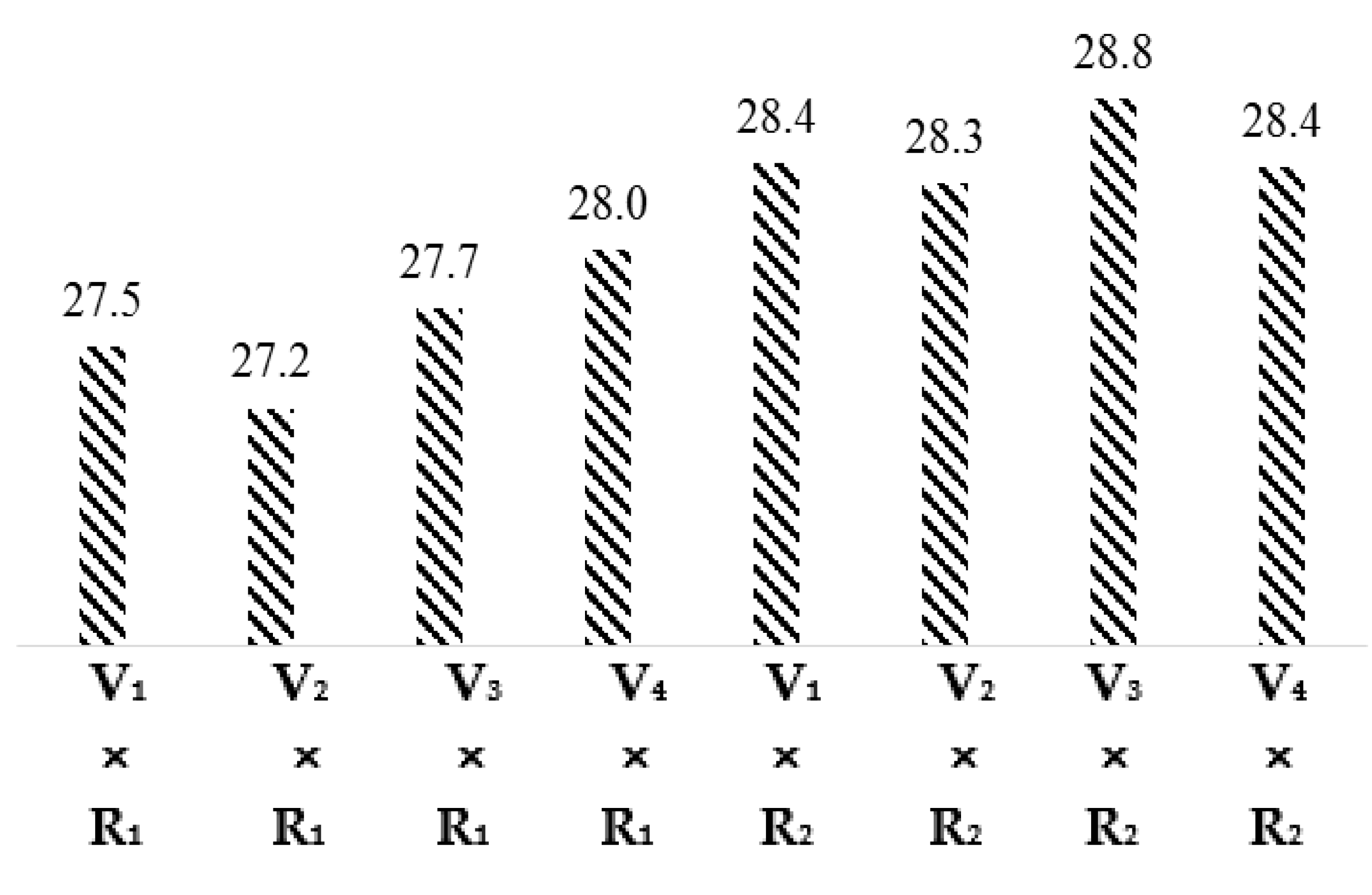

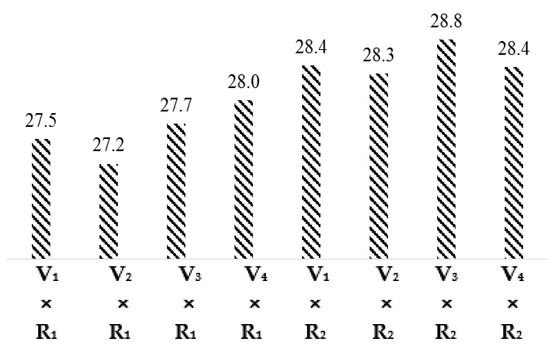

The least significant difference (LSD) test and the comparison of interaction means for varieties and regions presented in Figure 1 show that the fiber length values of interactions V1 × R1, V2 × R1, V3 × R1, V4 × R1, V1 × R2, V2 × R2, V3 × R2, and V4 × R2 are 27.5, 27.2, 27.7, 28.0, 28.4, 28.3, 28.8, and 28.4 mm, respectively. The fiber length of all cotton varieties in the Multan region was lower than the Khanewal region. This is due to the environmental effect and soil structure differentiation. The night temperature of Khanewal is lesser than in the Multan region during the cotton season.

Figure 1.

Graphical Representation interaction means for Fiber Length (mm).

3.2. Fiber Strength (g/tex)

Fiber strength is the link between the busted strength of the fiber and the assembly of the fiber that has been broken. Knowledge of yarn strength within a cotton cultivar or across cultivars may be beneficial in assisting with cultivar selection [16]. Table 4 demonstrated that the influence of cotton varieties (V) and cotton regions (R) and interactions were highly significant when it came to fiber strength measurements. The least significant difference (LSD) test is used in the context of the analysis of variance, and the comparison of individual treatment means for various cotton varieties given in Table 5 presented that the mean values of fiber strength for V1, V2, V3, and V4 were, 28.88, 28.90, 30.49, and 28.38 g/tex, respectively. The findings revealed that the fiber strength values for various types are statistically significantly different. These findings are supported by a research study conducted by Ahmad [17], who said that the fiber bundle strength of several cotton types in Pakistan ranged from 21.80 to 28.42 g/tex for distinct kinds. As previously indicated, Cui and Price [18] found that yarn strength was substantially described by fiber strength.

Table 4.

ANOVA table for fiber strength (g/tex).

Table 5.

Individual mean values comparison for Fiber Strength (g/tex).

The least significant difference (LSD) test and the comparison of individual treatment means for both regions given in Table 5 indicate that the mean values of fiber strength for R1 and R2 were 28.55 and 29.76 g/tex, respectively. The study discovered that the fiber strength values obtained from various places differed greatly from one another. These findings are supported by a study conducted by Hsieh and Hu [12], who found that poorer tensile characteristics of fibers from mature bolls might be caused by exposure to diverse settings, such as prolonged time on the plant or exposure to more significant amounts of moisture and heat.

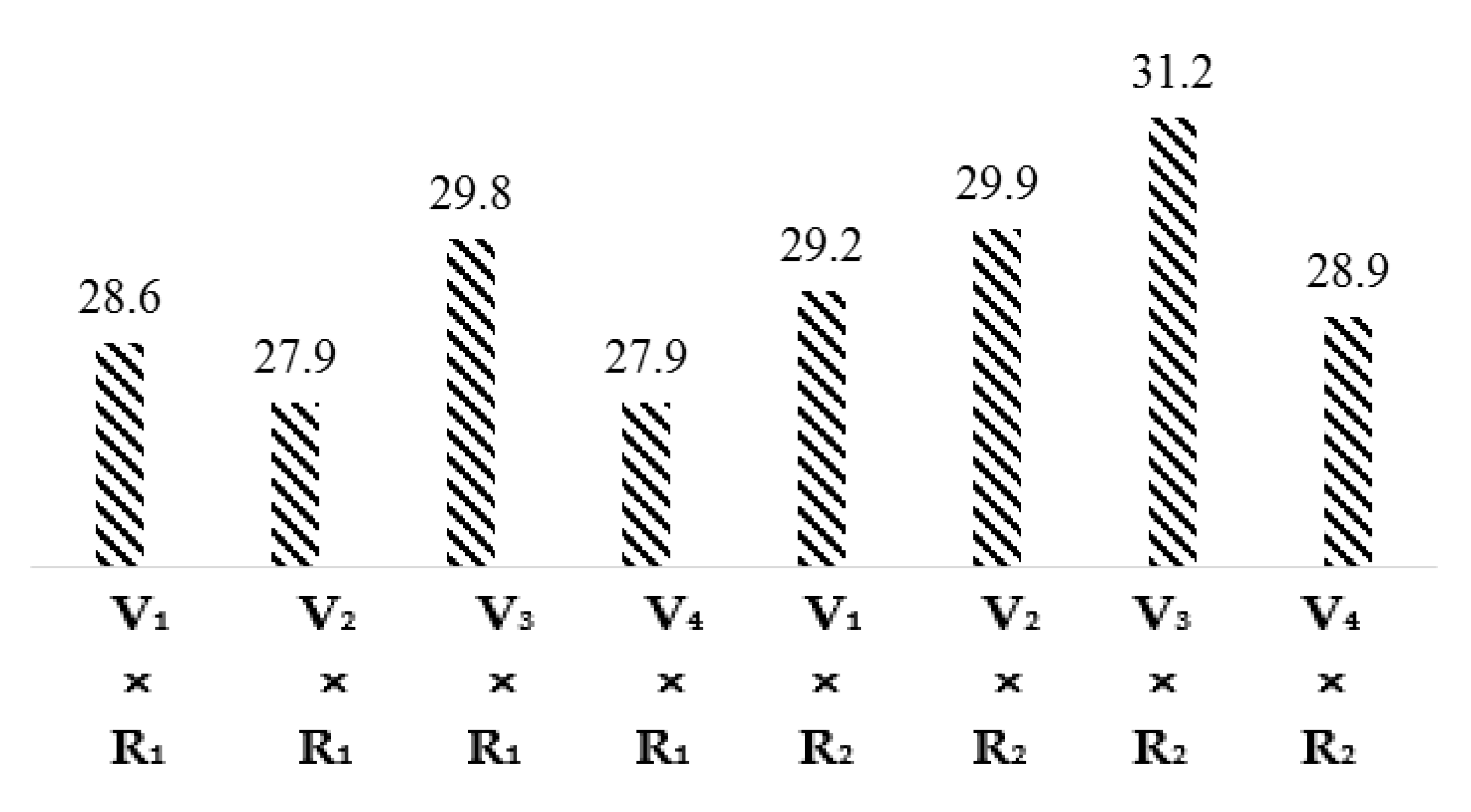

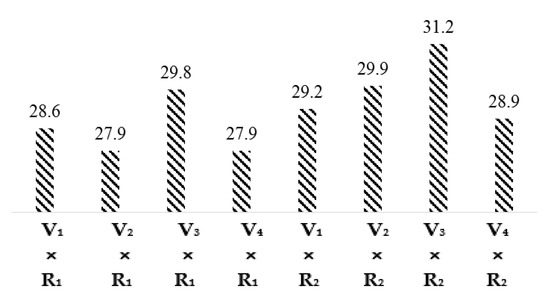

The least significant difference (LSD) test and the comparison of interaction means for varieties and regions given in Figure 2 indicated that the fiber strength values of interactions V1 × R1, V2 × R1, V3 × R1, V4 × R1, V1 × R2, V2 × R2, V3 × R2, V4 × R2 are 28.6, 27.9, 29.8, 27.9, 29.2, 29.9, 31.2, and 28.9 g/tex, respectively. Fiber strength of all cotton varieties in the Multan region was lower than the Khanewal region due to high night temperature in Multan.

Figure 2.

Graphical representation interaction means for Fiber Strength (g/tex).

3.3. Micronaire

Fiber micronaire is a key quality characteristic since it is an indirect indicator of fiber linear density (fineness) and maturation and is impacted by crop supply and assimilation partitioning to cotton fruit [19]. The results of the analysis of variance of the data related to micronaire are shown in Table 6, which demonstrates that the influence of cotton varieties (V) and cotton regions (R) and interactions were highly significant. The least significant difference (LSD) test is used in the context of the analysis of variance, and the comparison of individual treatment means for various cotton varieties given in Table 7, which presented that the mean values of micronaire for V1, V2, V3, and V4 were, 4.57, 4.58, 4.96, and 4.14, respectively. The research study conducted by Liu et. al. [20] supports these findings, and the substantial variability in single fiber qualities within a single variety shows that growing circumstances and development have a very strong impact on the fiber’s properties. Micronaire was the most critical cotton fiber quality in determining product quality and market value of yarn. In contrast, overall differences in single fiber tensile qualities were found to be more closely connected with seed location in the boll and less closely associated with fiber length. Brushwood [21] noted that fiber micronaire had a significant impact on the amount of noncellulosic ethanol extractable, wax, fiber ash residues, and potassium concentration on the fibers and the amount of friction created during the carding sliver processing.

Table 6.

ANOVA table for Micronaire.

Table 7.

Individual mean values comparison for Micronaire.

The least significant difference (LSD) test and the comparison of individual treatment means for both climatic regions given in Table 7 presented that the mean values of micronaire for R1 and R2 were 4.84 and 4.29, respectively. The findings demonstrated that the micronaire values for both locations differed considerably in a statistically meaningful way. Between 4.29 and 4.84 was a suitable range of micronaire for the chosen cultivars.

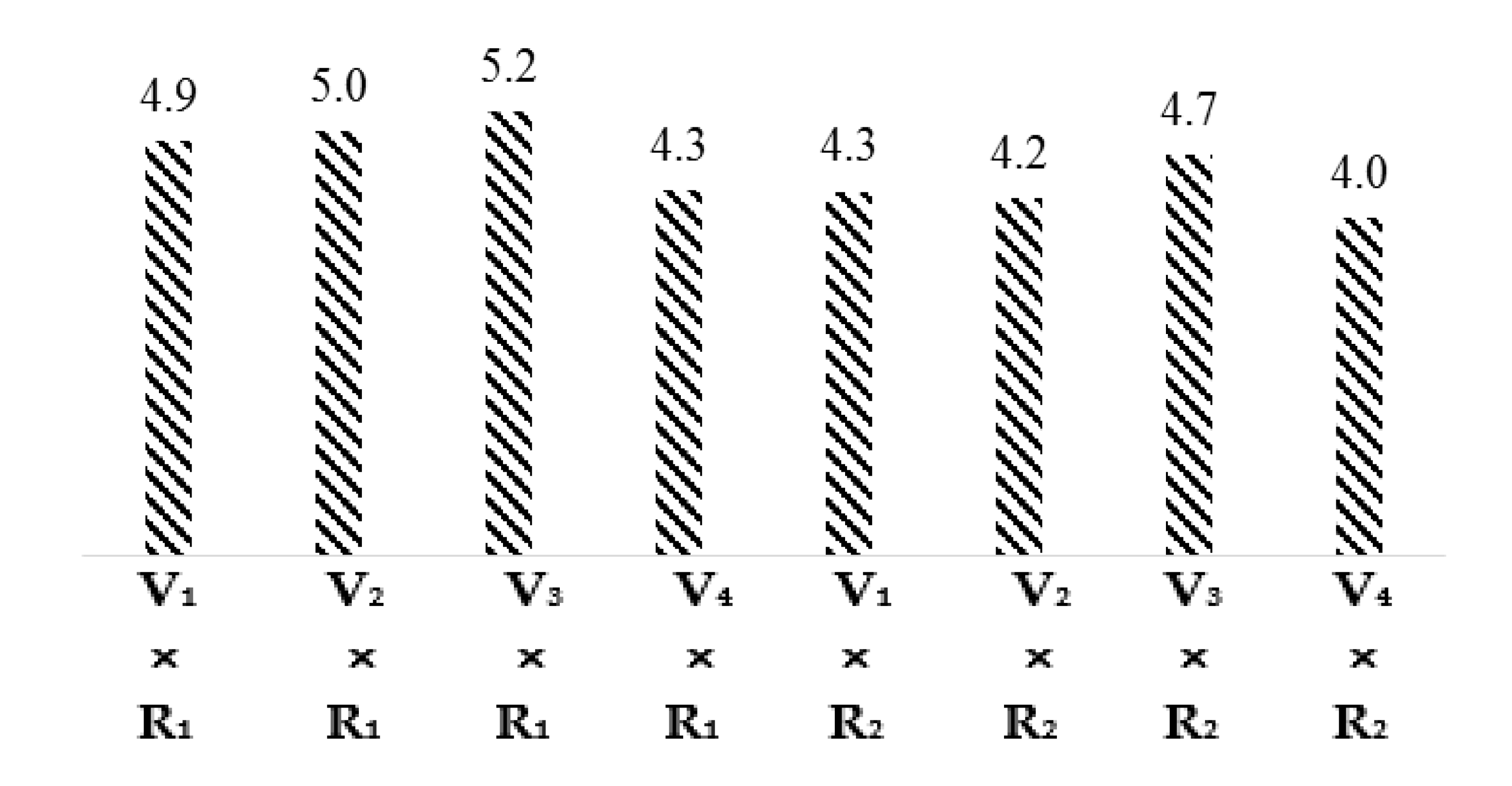

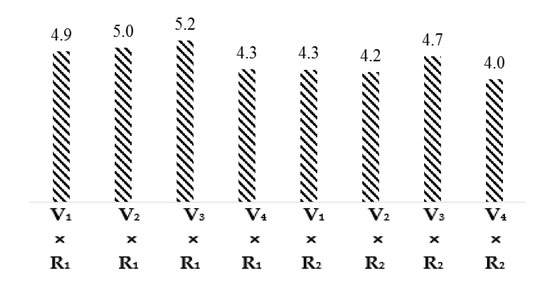

The least significant difference (LSD) test and the comparison of interaction means for cotton varieties and climatic regions given in Figure 3 demonstrated that the micronaire values of interactions V1 × R1, V2 × R1, V3 × R1, V4 × R1, V1 × R2, V2 × R2, V3 × R2, and V4 × R2 are 4.9, 5.0, 5.2, 4.3, 4.3, 4.2, 4.7, and 4.0, respectively. Micronaire of all cotton varieties in the Multan region was higher than in the Khanewal region because of the higher temperature in Multan regions, as previous researchers have found that linear responses of micronaire to temperature have been reported [22,23].

Figure 3.

Graphical Representation interaction means for Micronaire.

3.4. Cellulose (%)

The results of the analysis of the variance of the data related to cellulose (%) are shown in Table 8, which demonstrates that the influence of cotton varieties (V) and cotton regions (R) and interactions were highly significant. The least significant difference (LSD) test is used in the context of the analysis of variance, and the comparison of individual treatment means for various cotton varieties given in Table 9, which presented that the mean values of cellulose (%) for V1, V2, V3, and V4 were 89.25, 90.71, 95.10, and 87.75, respectively. These results get support from the research study by Umar [24], which stated the range for cellulose content for some Pakistani medium staple cotton as 86.4 to 89.3 percent. In addition, Montalvo [25] stated that cotton with a much greater genetic diversity was being developed, and a more excellent range of both fiber perimeter and wall thickness, and their combinations, was probable. Wakelyn et al. [26] stated that there was 88.0 to 96.5% of cellulose in mature cotton fiber.

Table 8.

ANOVA Table for Cellulose (%).

Table 9.

Individual mean values comparison for Cellulose (%).

The least significant difference (LSD) test and the comparison of individual treatment means for both climatic regions given in Table 9 presented that the mean values of cellulose (%) for R1 and R2 were 89.85 and 91.55, respectively. The findings demonstrated that the cellulose (%) for both locations differed considerably from one another in a statistically meaningful way. These results support the research study by Wang et al. [27] which stated that fiber strength was positively related to the maximal rate of cellulose increase, and this difference is likely caused by temperature variation.

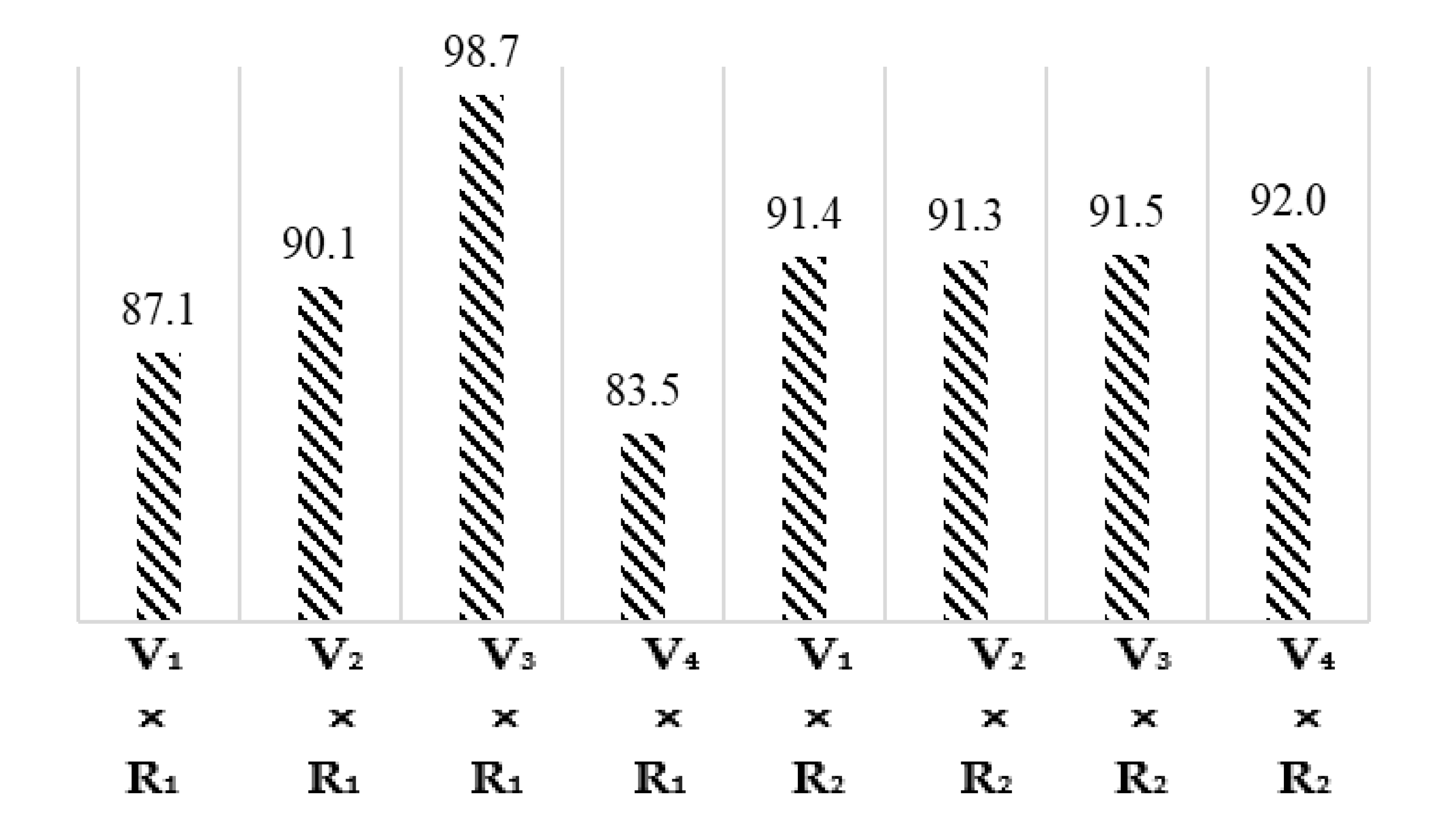

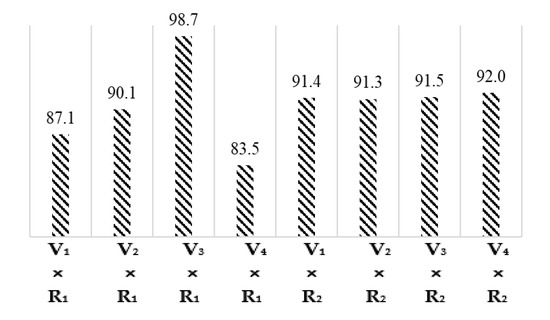

The least significant difference (LSD) test and the comparison of interaction means for cotton varieties and climatic regions given in Figure 4 demonstrated the micronaire values of interactions V1 × R1, V2 × R1, V3 × R1, V4 × R1, V1 × R2, V2 × R2, V3 × R2, V4 × R2 are 87.1, 90.1, 98.7, 83.5, 91.4, 91.3, 91.5, and 92.0, respectively. Cellulose (%) of all cotton varieties in the Multan region was higher than in the Khanewal region.

Figure 4.

Graphical representation of interaction means for Cellulose (%).

3.5. Wax (%)

Cotton fibre total wax has been proven to operate as a lubricant during textile processing, and also has been shown to be adversely linked with key quality characteristics. The fully grown cotton cuticle is constituted mostly of two types of lipids: free waxes and cutin [28]. The results of the analysis of the variance of the data related to wax (%) are shown in Table 10, which demonstrates that the influence of cotton varieties (V) and cotton regions (R) and interactions were highly significant. The least significant difference (LSD) test is used in the context of the analysis of variance, and the comparison of individual treatment means for various cotton varieties given in Table 11, which presented that the mean values of wax (%) for V1, V2, V3, and V4 were, 0.59, 0.63, 0.60, and 0.69, respectively. These results get support from the research study by Brushwood [29] which stated that fiber micronaire increased when the concentrations of waxes decreased.

Table 10.

ANOVA table for Wax (%).

Table 11.

Individual mean values comparison for Wax (%).

The least significant difference (LSD) test and the comparison of individual treatment means for both climatic regions given in Table 11 presented that the mean values of wax (%) for R1 and R2 were 0.64 and 0.62, respectively. The findings demonstrated that the wax (%) for both locations differed considerably from one another in a statistically meaningful way. These results support the research study by Hussain [30], which concluded that wax content correlates positively with fiber staple length, CLSP value, elongation, and RKM value while being negatively correlated with thin places of yarn.

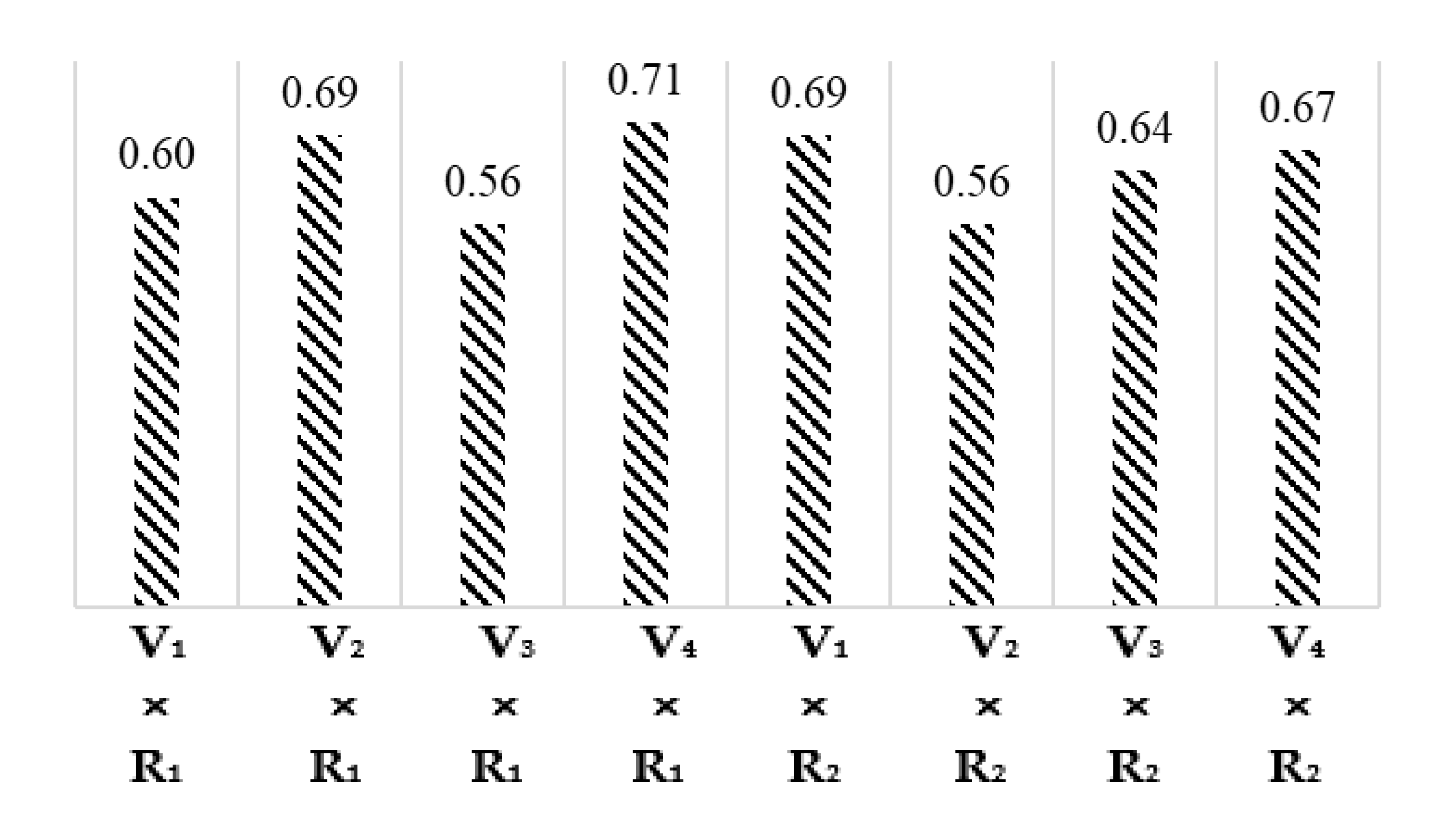

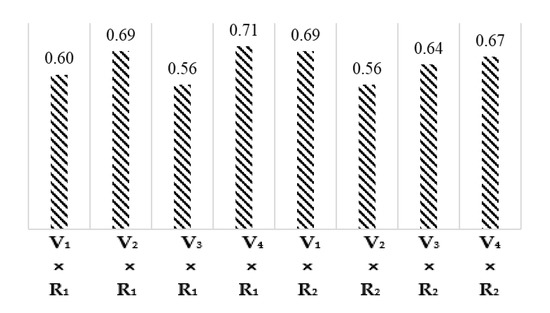

The least significant difference (LSD) test and the comparison of interaction means for cotton varieties and climatic regions given in Figure 5 demonstrated that the wax (%) values of interactions V1 × R1, V2 × R1, V3 × R1, V4 × R1, V1 × R2, V2 × R2, V3 × R2, and V4 × R2 are 0.60, 0.69, 0.56, 0.71, 0.69, 0.56, 0.64, and 0.67, respectively.

Figure 5.

Graphical representation interaction means for Wax (%).

3.6. Ash (%)

The results of the analysis of the variance of the data related to ash (%) are shown in Table 12, which demonstrates that the influence of cotton varieties (V) and cotton regions (R) and interactions were highly significant. The least significant difference (LSD) test is used in the context of the analysis of variance, and the comparison of individual treatment means for various cotton varieties given in Table 13, which presented that the mean values of ash (%) for V1, V2, V3, and V4 were, 1.44, 1.37, 1.46, and 1.41, respectively. These results support the research study by Naeem [31], which reported that ash contents for different varieties range between 1.397 to 1.526 percent.

Table 12.

ANOVA table for Ash (%).

Table 13.

Individual mean values comparison for Ash (%).

The least significant difference (LSD) test and the comparison of individual treatment means for both climatic regions given in Table 13 presented that the mean values of ash (%) for R1 and R2 were 1.43 and 1.41, respectively. The findings demonstrated that the ash (%) for both locations differed considerably in a statistically meaningful way. These results support the research study by Brushwood (2002) [32] that cotton from areas where open bolls normally were exposed to too little or no moisture generally had higher metal contents and ash residues.

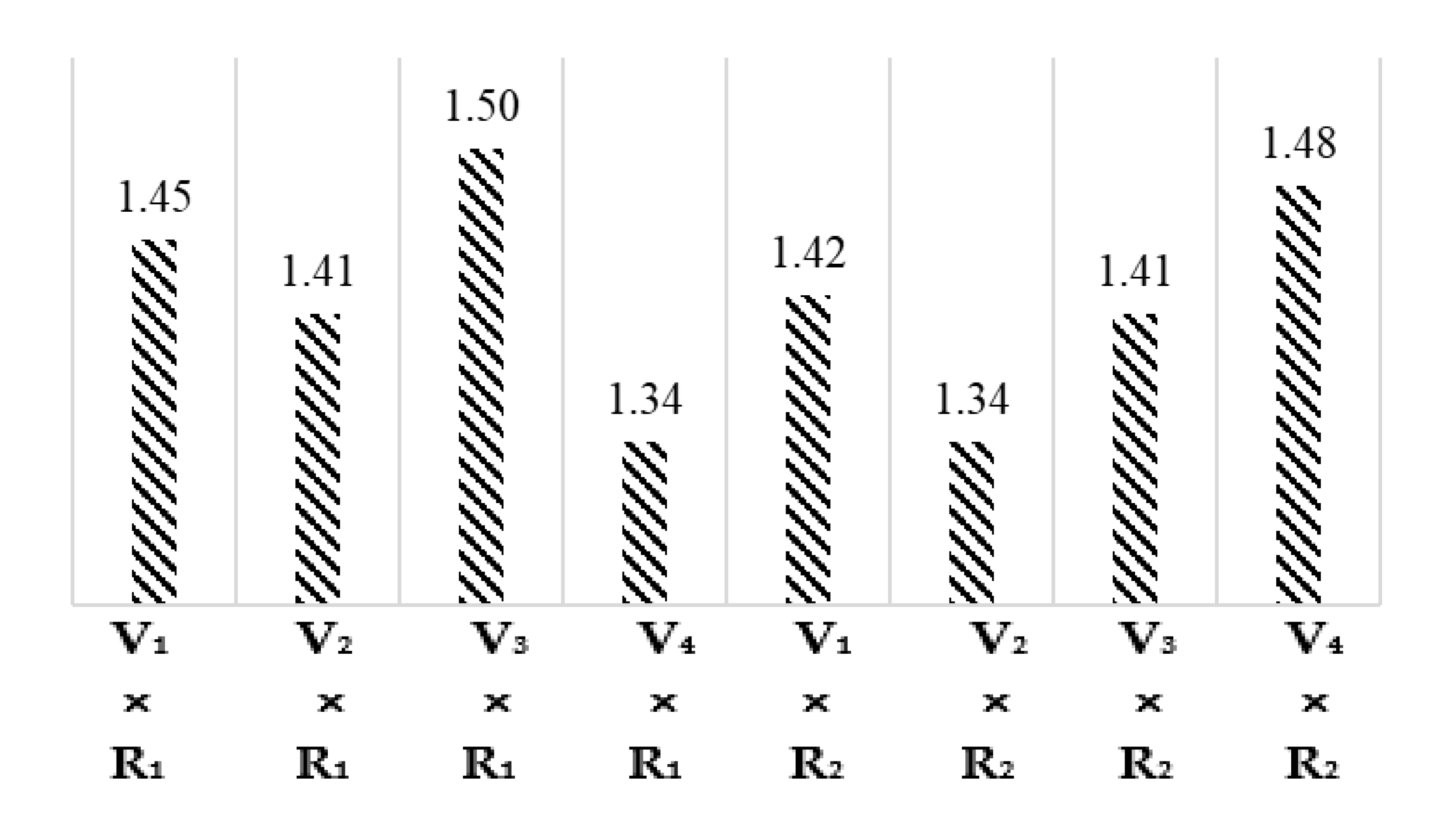

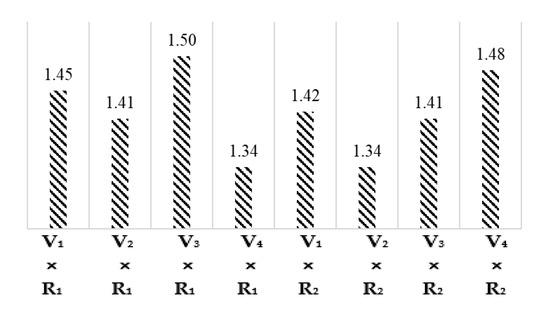

The least significant difference (LSD) test and the comparison of interaction means for cotton varieties and climatic regions given in Figure 6 demonstrated that the ash (%) values of interactions V1 × R1, V2 × R1, V3 × R1, V4 × R1, V1 × R2, V2 × R2, V3 × R2, and V4 × R2 are 1.45, 1.41, 1.50, 1.34, 1.42, 1.34, 1.41, and 1.48%, respectively.

Figure 6.

Graphical representation interaction means for Ash (%).

3.7. Correlation Analysis

Correlation coefficients among the different characteristics of cotton fiber are presented in Table 14. The table shows that the fiber strength was found to be highly correlated with fiber length, cellulose (%), and wax (%) with values of 0.683, 0.539, and −0.578, respectively. Similarly, micronaire was correlated with fiber length (−0.675) and ash (%) (0.433), whereas wax (%) was also correlated with cellulose (%) with a value of 0.529.

Table 14.

Correlation coefficient among different characteristics of cotton fiber.

4. Conclusions

Production regions affect cotton quality characteristics, which means that areas may be chosen, so cultivars are most effectively differentiated in cotton fiber quality. Aside from that, the growing zones must be selected to enhance fiber characteristics to achieve the best possible level of fiber quality. Cotton fiber quality characteristics (both physical and chemical) are impacted by environmental fluctuations, which means that ranking cultivars according to environmental variations are critical for improving cotton fiber quality. The environment affected the speed of fiber elongation even though genetic factors played a significant role. Fiber parameters that are important for the textile industry were altered by temperature. The decline in fiber length at high temperatures was more significant than at low temperatures. Fiber strength increased linearly with temperature. Micronaire and fiber uniformity showed quadratic trends with temperature. Cotton cultivar CIM-785 displayed better fiber characteristics in both regions. All varieties showed better performance in the Khanewal region than in the Multan region, implying that the Khanewal region has a favorable climate for cotton fiber characteristics.

Author Contributions

Formal analysis, A.H., M.S. and D.I.; Investigation, M.S., M.I.S., A.F. and A.S.; Methodology, D.I., A.H. and M.I.S.; Supervision, M.Q.K. and I.-S.K.; Writing—original draft, D.I., M.S., A.S. and A.H.; Writing—review and editing, D.I., A.H. and M.I.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. This article is a part of my thesis.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The reported data is available from the corresponding authors on a reasonable request.

Acknowledgments

The authors acknowledge the support from the Central Cotton Research Institute, Multan, Pakistan for their support in this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Council, P.S. In Proceedings of the 53rd meeting of the Special Experts Sub-Committee of the Punjab Seed Corporation, Lahore, Pakistan, 2 June 2007.

- Zeng, L.; Stetina, S.R.; Erpelding, J.E.; Bechere, E.; Turley, R.B.; Scheffler, J. History and current research in the USDA-ARS cotton breeding program at Stoneville, MS. J. Cotton Sci. 2018, 22, 24–35. [Google Scholar]

- Xia, Z.; Xu, W. A review of ring staple yarn spinning method development and its trend prediction. J. Nat. Fibers 2013, 10, 62–81. [Google Scholar] [CrossRef]

- Tan, J.; Tu, L.; Deng, F.; Hu, H.; Nie, Y.; Zhang, X. A genetic and metabolic analysis revealed that cotton fiber cell development was retarded by flavonoid naringenin. Plant Physiol. 2013, 162, 86–95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, S.; Teng, Z.; Zhai, T.; Fang, X.; Liu, F.; Liu, D.; Zhang, J.; Liu, D.; Wang, S.; Zhang, K. Construction of genetic map and QTL analysis of fiber quality traits for Upland cotton (Gossypium hirsutum L.). Euphytica 2015, 201, 195–213. [Google Scholar] [CrossRef]

- May, O.L. Quality improvement of upland cotton (Gossypium hirsutum L.). J. Crop Prod. 2002, 5, 371–394. [Google Scholar] [CrossRef]

- ASTM Designation: D-5867-12; Standard Test Methods for Measurement of Physical Properties of Raw cotton by Cotton Classification Instruments. American Society for Testing and Materials: Philadelphia, PA, USA, 2020.

- ASTM Designation: D-1776; Standard Practice for Conditioning and Testing Textiles. American Society for Testing and Materials: Philadelphia, PA, USA, 2020.

- Christensen, R.R. Executive Director’s Report. J. Assoc. Off. Anal. Chem. 1990, 73, 170–171. [Google Scholar] [CrossRef]

- Campbell, B.T.; Dever, J.K.; Hugie, K.L.; Kelly, C.M. Cotton fiber improvement through breeding and biotechnology. In Cotton Fiber: Physics, Chemistry and Biology; Springer: Cham, Switzerland, 2018; pp. 193–215. [Google Scholar]

- Hameed, A. A Comparative Study of Physical Characteristics and Spinning Performance of New Cotton Varieties, CIM-446, CIM-443, FVH-53 with MNH-93. Master’s Thesis, University of Agriculture, Faisalabad, Pakistan, 2000. [Google Scholar]

- Hsieh, Y.-L.; Hu, X.-P.; Wang, A. Single fiber strength variations of developing cotton fibers—strength and structure of G. hirsutum and G. barbedense. Text. Res. J. 2000, 70, 682–690. [Google Scholar] [CrossRef]

- Ali, M.F. Physico-Chemical Characteristics and Spinning Performance Comparison of New Strains NIAB-884, NIAB-814 and NIAB101 with Prevalent NIAB-111 Variety. Master’s Thesis, University of Agriculture, Faisalabad, Pakistan, 2005. [Google Scholar]

- Nazar, A.; Iftikhar, M.; Shahbaz, B.; Ishaq, W. Influence of irrigation water types and stress levels on cotton fiber and yarn quality for different varieties. Pak. J. Agric. Sci. 2012, 49, 597–601. [Google Scholar]

- El Mogahzy, Y.E.; Gowayed, Y. Theory and Practice of Cotton Fiber Selection: Part I: Fiber Selection Techniques and Bale Picking Algorithms. Text. Res. J. 1995, 65, 32–40. [Google Scholar] [CrossRef]

- Liu, Y.; Todd Campbell, B.; Delhom, C. Study to relate mini-spun yarn tenacity with cotton fiber strength. Text. Res. J. 2019, 89, 4491–4501. [Google Scholar] [CrossRef]

- Ahmad, M. Comparative Study of Physical Characteristics and Spinning Performance of Some Early Maturing Varieties NIAB-78, NIAB-Krishma and Late Maturing Varieties FH-634, FH-682. Master’s Thesis, University of Agriculture, Faisalabad, Pakistan, 2000. [Google Scholar]

- Cui, X.L.; Price, J.B.; Calamari, T.A., Jr.; Hemstreet, J.M.; Meredith, W. Cotton wax and its relationship with fiber and yarn properties: Part I: Wax content and fiber properties. Text. Res. J. 2002, 72, 399–404. [Google Scholar] [CrossRef]

- Bange, M.P.; Long, R.L.; Caton, S.J.; Finger, N. Prediction of upland cotton micronaire accounting for the effects of environment and crop demand from fruit growth. Crop Sci. 2022, 62, 397–409. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Hsieh, Y.-L. Variations of mature cotton fiber tensile properties: Association with seed position and fiber length. Text. Res. J. 2001, 71, 1079–1086. [Google Scholar] [CrossRef]

- Brushwood, D.E. Predicting yarn processing performance from the noncellulosic content of raw cottons. Text. Res. J. 2005, 75, 1–5. [Google Scholar] [CrossRef]

- Gipson, J.R.; Joham, H.E. Influence of night temperature on growth and development of cotton (Gossypium hirisutum L.). II. Fiber properties. Agron. J. 1968, 60, 296–298. [Google Scholar] [CrossRef]

- Gipson, J.R.; Ray, L.L. Fiber elongation rates in five varieties of cotton (Gossypium hirisutum L.) as influenced by night temperature. Crop Sci. 1969, 9, 339–341. [Google Scholar] [CrossRef]

- Umar, S. Physico-Chemical Characteristics and Spinning Performance Comparison of New Varieties NIAB-999 and NIAB-111/S with Prevalent NIAB-98, NIAB-Krishma and CRIS-134 Varieties. Master’s Thesis, University of Agriculture, Faisalabad, Pakistan, 2002. [Google Scholar]

- Montalvo, J.G., Jr. Relationships between micronaire, fineness, and maturity. J. Cotton Sci. 2005, 9, 379–392. [Google Scholar]

- Wakelyn, P.J.; Bertoniere, N.R.; French, A.D.; Thibodeaux, D.P.; Triplett, B.A.; Rousselle, A.A.; Goynes, W.R., Jr.; Edwards, J.V.; Hunter, L.; Mcalister, D.D.; et al. Cotton Fiber Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 2007; pp. 11–14. [Google Scholar]

- Wang, Y.; Shu, H.; Chen, B.; McGiffen, M.E.; Zhang, W.; Xu, N.; Zhou, Z. The rate of cellulose increase is highly related to cotton fiber strength and is significantly determined by its genetic background and boll period temperature. Plant Growth Regul. 2009, 57, 203–209. [Google Scholar] [CrossRef]

- Thompson, A.L.; Pauli, D.; Tomasi, P.; Yurchenko, O.; Jenks, M.A.; Dyer, J.M.; Gore, M.A. Chemical variation for fiber cuticular wax levels in upland cotton (Gossypium hirsutum L.) evaluated under contrasting irrigation regimes. Ind. Crops Prod. 2017, 100, 153–162. [Google Scholar] [CrossRef] [Green Version]

- Brushwood, D.E. Changes in non-fibrous material content of cotton during yarn processing. Text. Res. J. 2005, 75, 616–621. [Google Scholar] [CrossRef]

- Hussain, A.A. Comparative Study of Physico-Chemical Characteristics and Spinning Performance of Some Pakistani Cotton Varieties and New Strains Grown at Ayub Agriculture Research Institute (A.A.R.I.), Faisalabad and Cotton Research Station (CRS) Sahiwal. Master’s Thesis, University of Agriculture, Faisalabad, Pakistan, 1994. [Google Scholar]

- Naeem, I.A. Pyhsico-Chemical Studies on MNH-93 and Other Cotton Varieties with Special Reference to Spinning Performance. Master’s Thesis, University of Agriculture, Faisalabad, Paksitan, 1982. [Google Scholar]

- Brushwood, D.E. Metals in Domestic and Non-Domestic Cottons and their Frictional Properties. AATCC Rev. 2002, 2, 20–24. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).