Experimental Data Collection of Surface Quality Analysis of CuCrZr Specimens Manufactured with SLM Technology: Analysis of the Effects of Process Parameters

Abstract

1. Introduction

- product customization at an acceptable cost (due to the lack of tooling or fixtures needed);

- improved microstructure and properties [6].

2. Materials and Methods

2.1. Specimen Production

- layer thickness,

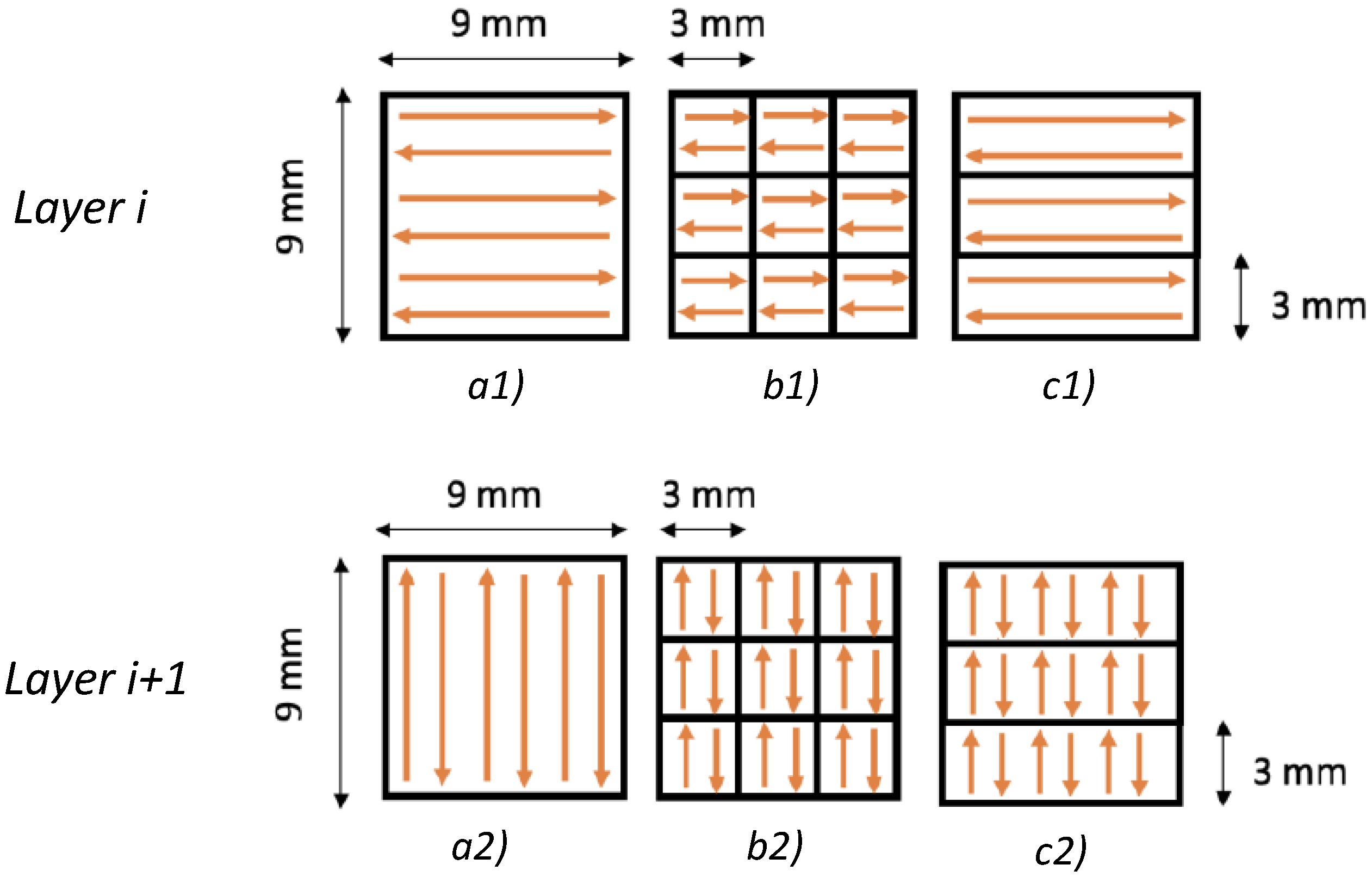

- laser pattern,

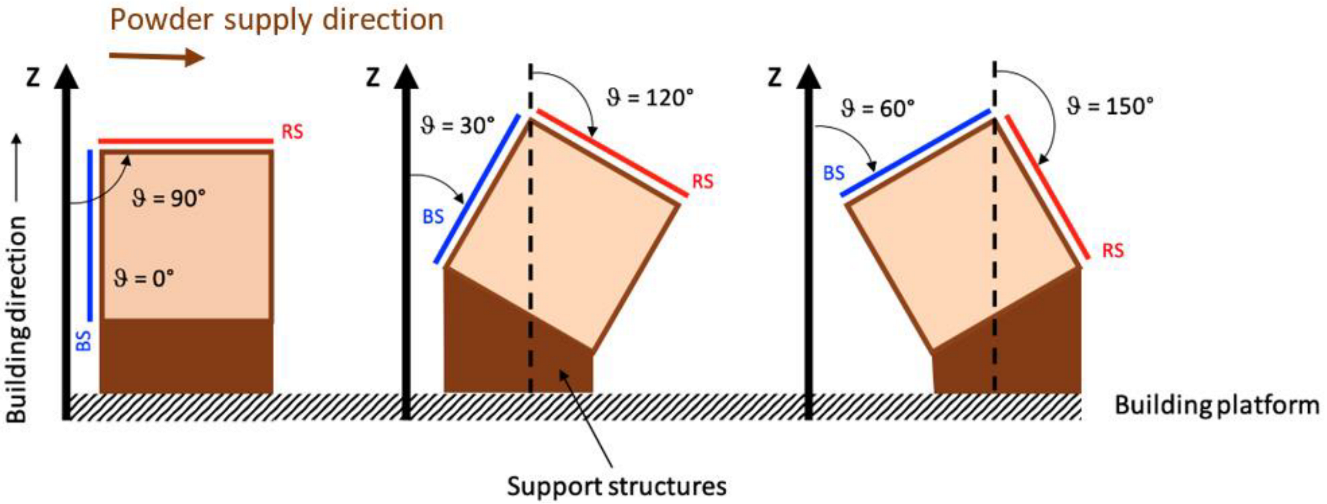

- building angle.

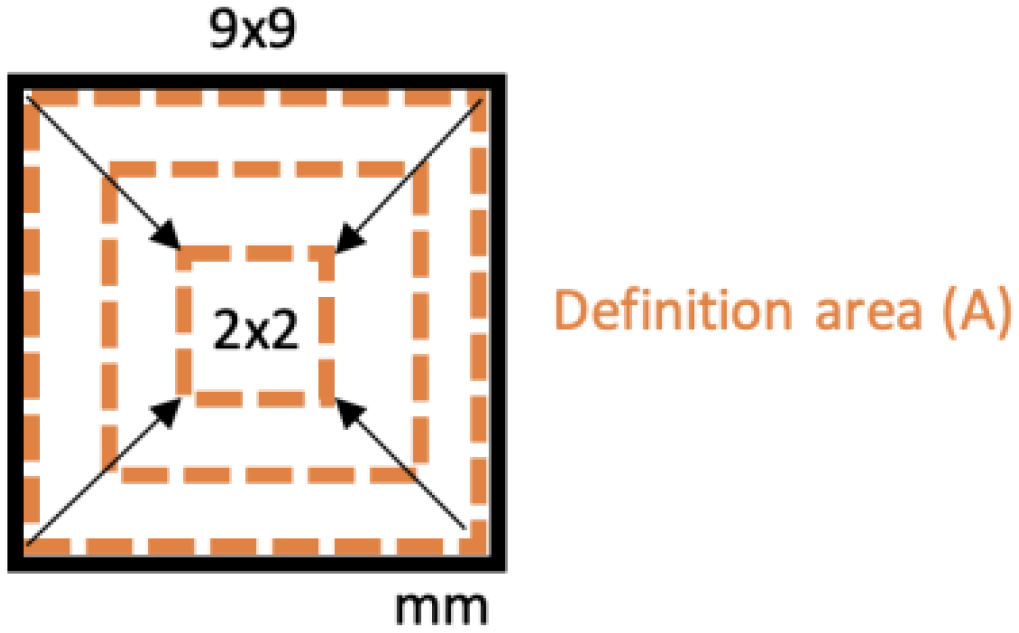

2.2. Surface Quality Analysis

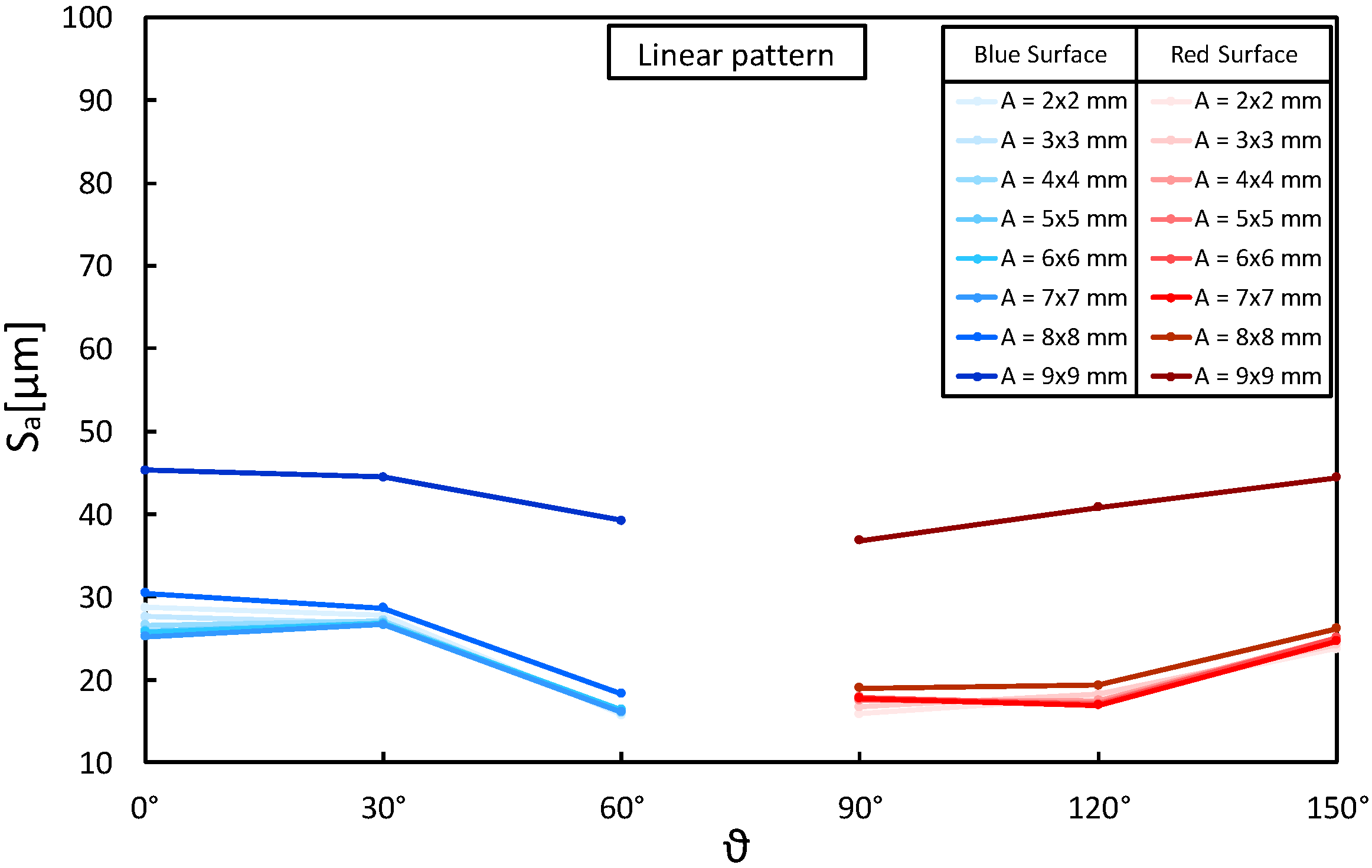

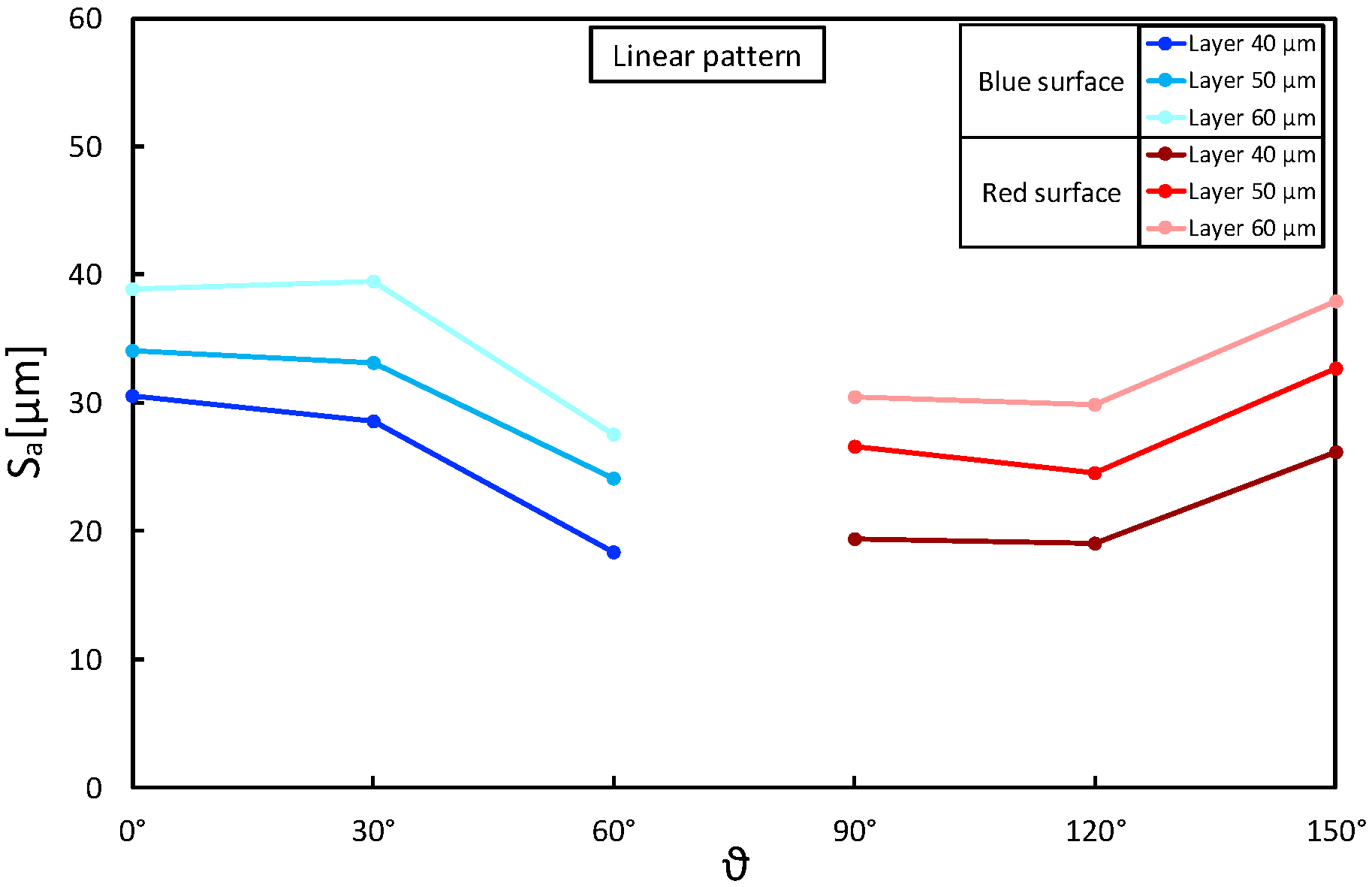

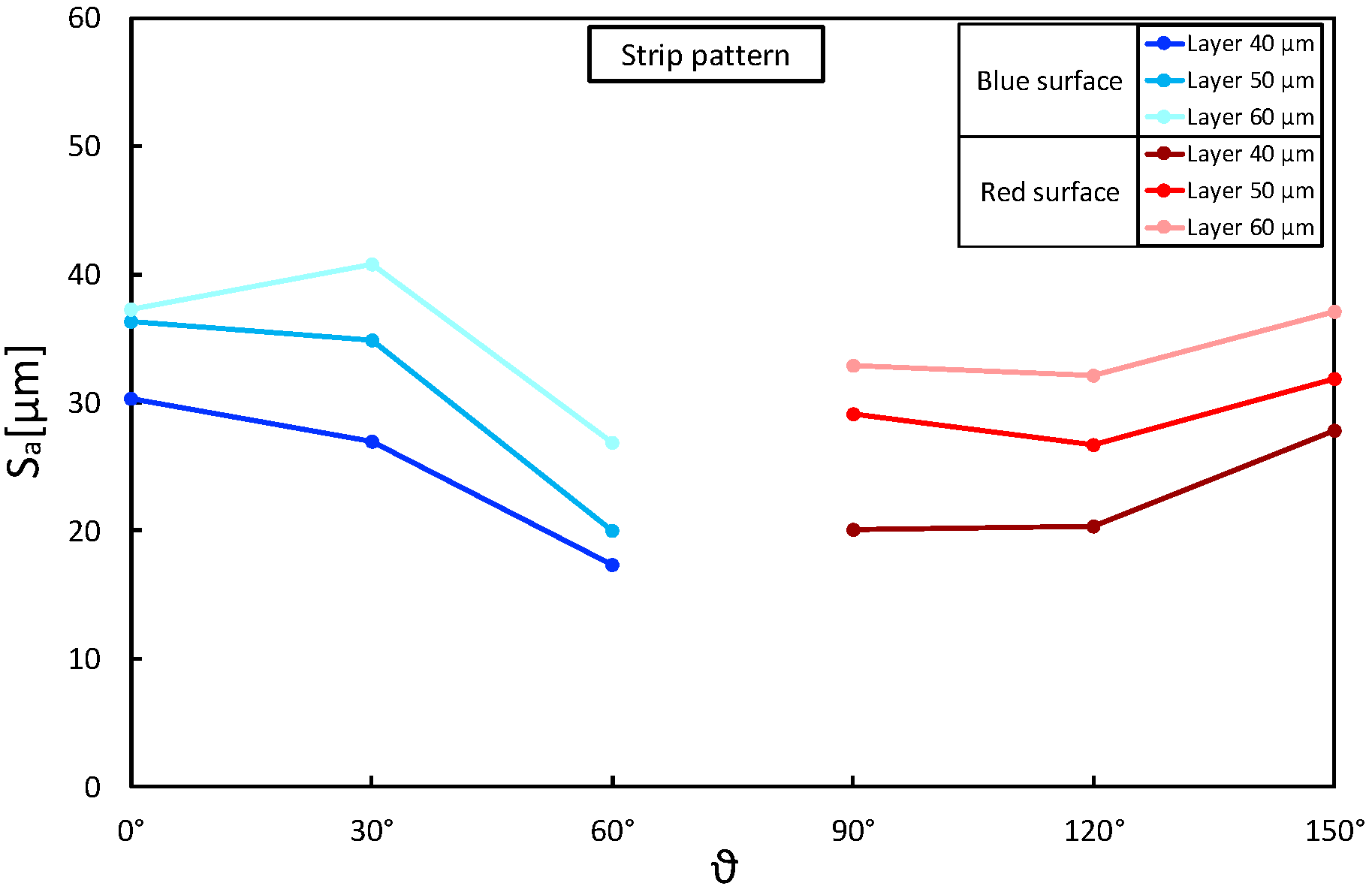

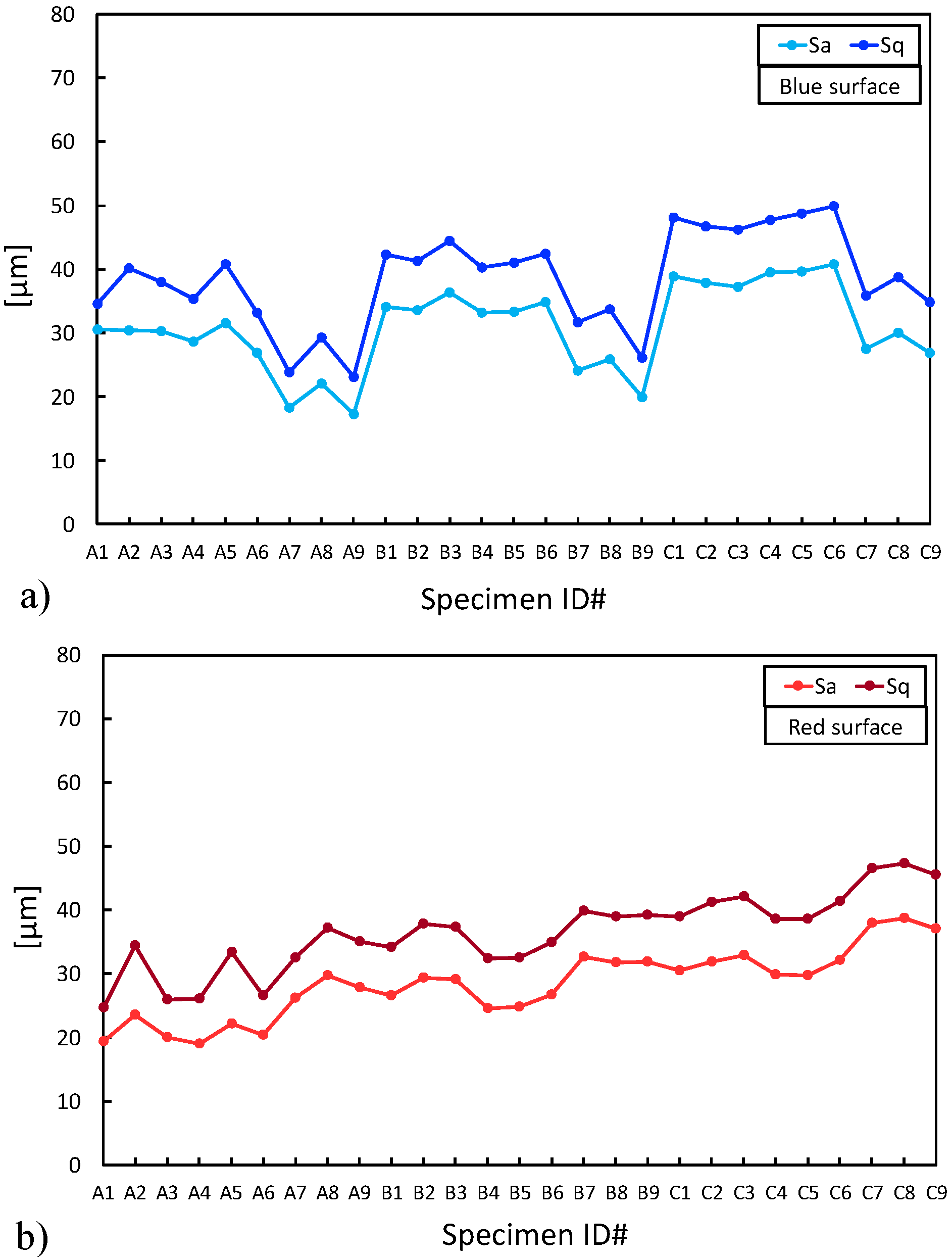

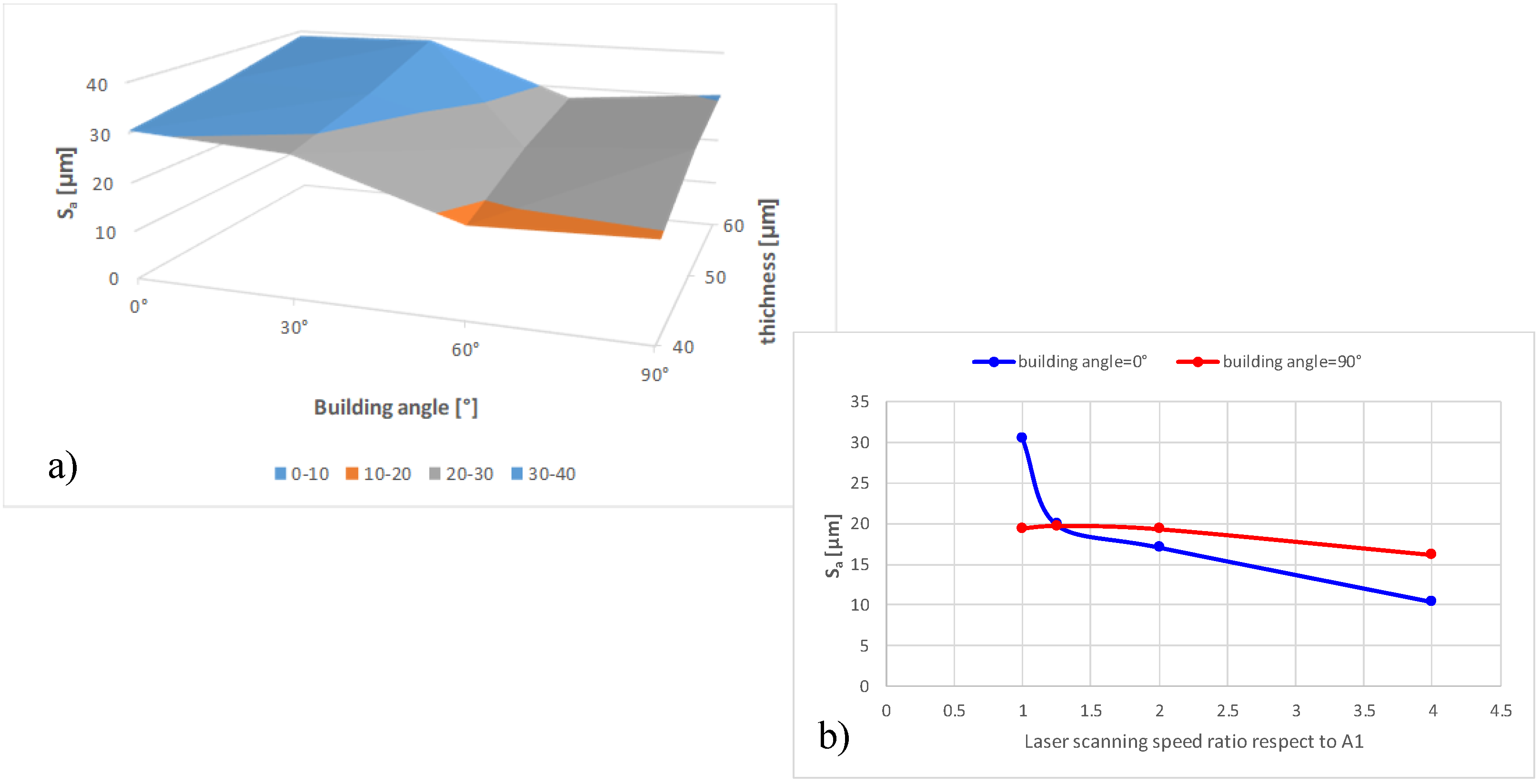

3. Results and Discussion

- the root mean square height () has the same trend as the (Figure 9a,b);

- the skewness () has a mean value of about 0.5 and 0.6 for the and , respectively; this indicates that the distribution of the measures (i.e., the ordinate value ) is almost similar to a Gaussian curve because it is not far from zero;

4. Conclusions

- layer thickness,

- laser pattern,

- building angle,

- laser scanning speed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yap, C.; Chua, C.; Dong, Z.; Liu, Z.; Zhang, D.; Loh, L.; Sing, S. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, D.; Zhou, Y.; Wang, W.; Cao, X. Study on topology optimization design, manufacturability, and performance evaluation of Ti-6Al-4V porous structures fabricated by selective laser melting (SLM). Materials 2017, 10, 1048. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Pang, J.; Zhang, H.; Li, S.; Zhang, Z. The high-cycle fatigue properties of selective laser melted Inconel 718 at room and elevated temperatures. Mater. Sci. Eng. A 2022, 836, 142716. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, X.; Zeng, H.; Yang, H.; Hei, H.; Li, X.; Wang, Y. Lightweight structure of a phase-change thermal controller based on lattice cells manufactured by SLM. Chin. J. Aeronaut. 2019, 32, 1727–1732. [Google Scholar] [CrossRef]

- Fashanu, O.; Murphy, D.; Spratt, M.; Newkirk, J.; Chandrashekhara, K.; Brown, B.; Porter, J. Effective elastic properties of additively manufactured metallic cellular structures using numerical unit-cell homogenization. Prog. Addit. Manuf. 2020, 5, 355–366. [Google Scholar] [CrossRef]

- Yan, X.; Yin, S.; Chen, C.; Huang, C.; Bolot, R.; Lupoi, R.; Kuang, M.; Ma, W.; Coddet, C.; Liao, H.; et al. Effect of heat treatment on the phase transformation and mechanical properties of Ti6Al4V fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 1056–1071. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, M.; Ma, W.; Kuang, T. Microstructural characterization and properties of selective laser melted maraging steel with different build directions. Sci. Technol. Adv. Mater. 2018, 19, 746–758. [Google Scholar] [CrossRef]

- Wang, D.; Song, C.; Yang, Y.; Bai, Y. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Des. 2016, 100, 291–299. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.; Zheng, Y.; Fraser, H.; StJohn, D.; Easton, M. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

- Karia, M.; Popat, M.; Sangani, K. Selective laser melting of Inconel super alloy—A review. In Proceedings of the AIP Conference, Andhra Pradesh, India, 7–8 April 2017; Volume 1859. [Google Scholar]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Zhang, K.; Gaganidze, E.; Gorley, M. Development of the material property handbook and database of CuCrZr. Fusion Eng. Des. 2019, 144, 148–153. [Google Scholar] [CrossRef]

- Ordás, N.; Portolés, L.; Azpeleta, M.; Gómez, A.; Blasco, J.; Martinez, M.; Ureña, J.; Iturriza, I. Development of CuCrZr via electron beam powder bed fusion (EB-PBF). J. Nucl. Mater. 2021, 548, 152841. [Google Scholar] [CrossRef]

- Jahns, K.; Bappert, R.; Böhlke, P.; Krupp, U. Additive manufacturing of CuCr1Zr by development of a gas atomization and laser powder bed fusion routine. Int. J. Adv. Manuf. Technol. 2020, 107, 2151–2161. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Zhang, Y.; Chen, J.; Wang, H. Additively manufactured CuCrZr alloy: Microstructure, mechanical properties and machinability. Mater. Sci. Eng. A 2021, 819, 141528. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, K.; Ren, Z.; Zhang, D.; Tao, G.; Xu, H. Selective laser melting of Cu–Cr–Zr copper alloy: Parameter optimization, microstructure and mechanical properties. J. Alloys Compd. 2020, 828, 154350. [Google Scholar] [CrossRef]

- Wallis, C.; Buchmayr, B. Effect of heat treatments on microstructure and properties of CuCrZr produced by laser-powder bed fusion. Mater. Sci. Eng. A 2019, 744, 215–223. [Google Scholar] [CrossRef]

- Guan, P.; Chen, X.; Liu, P.; Sun, F.; Zhu, C.; Zhou, H.; Fu, S.; Wu, Z.; Zhu, Y. Effect of selective laser melting process parameters and aging heat treatment on properties of CuCrZr alloy. Mater. Res. Express 2019, 6, 1165c1. [Google Scholar] [CrossRef]

- Salvan, C.; Briottet, L.; Baffie, T.; Guetaz, L.; Flament, C. CuCrZr alloy produced by laser powder bed fusion: Microstructure, nanoscale strengthening mechanisms, electrical and mechanical properties. Mater. Sci. Eng. A 2021, 826, 141915. [Google Scholar] [CrossRef]

- Simoni, F.; Huxol, A.; Villmer, F. Improving surface quality in selective laser melting based tool making. J. Intell. Manuf. 2021, 32, 1927–1938. [Google Scholar] [CrossRef]

- Fraunhofer, I. Reduction of Surface Roughness of SLM Components by Means of Modulated Laser Radiation; Annual Report; Fraunhofer Institute for Laser Technology ILT: Aachen, Germany, 2015; p. 71. [Google Scholar]

- Di Angelo, L.; Di Stefano, P.; Marzola, A. Surface quality prediction in FDM additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 93, 3655–3662. [Google Scholar] [CrossRef]

- Metal4Printing— CuCrZr—Technical Data Sheet (Rev.V01/11-18). Available online: https://www.metals4printing.com/products/ (accessed on 27 November 2022).

- Huxol, A.; Villmer, F. Experimental approach towards parameter evaluation in laser powder bed fusion of metals. Int. J. Comput. Integr. Manuf. 2022, 35, 556–567. [Google Scholar] [CrossRef]

- Gogolewski, D. Fractional spline wavelets within the surface texture analysis. Measurement 2021, 175, 109435. [Google Scholar] [CrossRef]

- EN ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal. Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2012.

- EN ISO 25178-605:2014; Geometrical Product Specifications (GPS)—Surface Texture: Areal. Part 605: Nominal Characteristics of Noncontact (Point Autofocus Probe) Instruments. ISO: Geneva, Switzerland, 2014.

- EN ISO 4287:2009; Geometrical Product Specifications (GPS)—Surface texture: Profile Method—Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2009.

| Element | Min | Max | |

|---|---|---|---|

| Cr | 0.5 | 1.2 | |

| Zr | 0.03 | 0.3 | |

| Fe | 0.08 | ||

| Si | 0.01 | ||

| Cu | Base |

| Print Job | N. | Specimen #ID | Variables & Level (−1, 0, +1) | ||

|---|---|---|---|---|---|

| Layer Thickness t [µl | Building Angle [] | Laser Pattern | |||

| 1 | 1 | A1 | 40 | 0°/90° | Linear |

| 2 | A2 | 40 | 0°/90° | Chess 3 × 3 mm | |

| 3 | A3 | 40 | 0°/90° | Strip 3 mm | |

| 4 | A4 | 40 | 30°/120° | Linear | |

| 5 | A5 | 40 | 30°/120° | Chess 3 × 3 mm | |

| 6 | A6 | 40 | 30°/120° | Strip 3 mm | |

| 7 | A7 | 40 | 60°/150° | Linear | |

| 8 | A8 | 40 | 60°/150° | Chess 3 × 3 mm | |

| 9 | A9 | 40 | 60°/150° | Strip 3 mm | |

| 2 | 10 | A10 | 50 | 0°/90° | Linear |

| 11 | A11 | 50 | 0°/90° | Chess 3 × 3 mm | |

| 12 | A12 | 50 | 0°/90° | Strip 3 mm | |

| 13 | A13 | 50 | 30°/120° | Linear | |

| 14 | A14 | 50 | 30°/120° | Chess 3 × 3 mm | |

| 15 | A15 | 50 | 30°/120° | Strip 3 mm | |

| 16 | A16 | 50 | 60°/150° | Linear | |

| 17 | A17 | 50 | 60°/150° | Chess 3 × 3 mm | |

| 18 | A18 | 50 | 60°/150° | Strip 3 mm | |

| 3 | 19 | A19 | 60 | 0°/90° | Linear |

| 20 | A20 | 60 | 0°/90° | Chess 3 × 3 mm | |

| 21 | A21 | 60 | 0°/90° | Strip 3 mm | |

| 22 | A22 | 60 | 30°/120° | Linear | |

| 23 | A23 | 60 | 30°/120° | Chess 3 × 3 mm | |

| 24 | A24 | 60 | 30°/120° | Strip 3 mm | |

| 25 | A25 | 60 | 60°/150° | Linear | |

| 26 | A26 | 60 | 60°/150° | Chess 3 × 3 mm | |

| 27 | A27 | 60 | 60°/150° | Strip 3 mm | |

| Parameter | Symbol | Definition |

|---|---|---|

| Arithmetical mean height | Arithmetic mean of the absolute of the ordinate values | |

| Maximum peak height | Largest peak height value | |

| Maximum pit height | Minus the smallest pit height value | |

| Maximum height | Sum of the maximum peak height value and the maximum pit height value | |

| Skewness | Quotient of the mean cube value of the ordinate values and the cube of | |

| Kurtosis | Quotient of the mean quartic value of the ordinate values and the fourth power of |

| Print Job | Specimen | Specimen Dimension | ||

|---|---|---|---|---|

| x [mm] | y [mm] | z [mm] | ||

| I | A1 | 9.14 | 9.12 | 8.94 |

| A2 | 9.15 | 9.14 | 9.1 | |

| A3 | 9.05 | 9.14 | 9.19 | |

| A4 | 8.91 | 9.12 | 9.12 | |

| A5 | 9.08 | 9.11 | 9.12 | |

| A6 | 9.11 | 8.97 | 9.11 | |

| A7 | 9.12 | 9.03 | 9.11 | |

| A8 | 9.04 | 9.11 | 9.12 | |

| A9 | 9.07 | 9.12 | 9.1 | |

| II | A10 | 9.2 | 9.18 | 9.17 |

| A11 | 9.17 | 9.18 | 9.17 | |

| A12 | 9.21 | 9.19 | 9.2 | |

| A13 | 9.17 | 9.1 | 9.08 | |

| A14 | 9.16 | 9.09 | 8.99 | |

| A15 | 9.16 | 9.09 | 9.17 | |

| A16 | 9.16 | 9.04 | 9.18 | |

| A17 | 9.17 | 9.03 | 9.12 | |

| A18 | 8.99 | 9.16 | 9.17 | |

| III | A19 | 9.11 | 9.23 | 9.07 |

| A20 | 8.98 | 9.22 | 9.09 | |

| A21 | 9.24 | 9.23 | 9.21 | |

| A22 | 9.21 | 9.15 | 9.06 | |

| A23 | 9.22 | 8.89 | 8.85 | |

| A24 | 9.22 | 8.89 | 9.06 | |

| A25 | 9.21 | 9.05 | 9.22 | |

| A26 | 9.05 | 9.21 | 9.23 | |

| A27 | 9.09 | 8.98 | 9.17 | |

| mean | 9.13 | 9.10 | 9.12 | |

| std. dev. | ±0.08 | ±0.09 | ±0.09 | |

| Specimen #ID | Blue Surface (BS) − Definition Area (A) = 8 × 8 mm | ||||||

|---|---|---|---|---|---|---|---|

| [µm] | [µm] | [µm] | [µm] | [µm] | |||

| A1-1 | 30.5 | 195.6 | 117.3 | 313.5 | 34.6 | 0.33 | 0.36 |

| A1-2 | 30.5 | 194.9 | 89.9 | 284.8 | 37.4 | 0.55 | 0.07 |

| A1-3 | 30.7 | 180.9 | 81.7 | 262.6 | 37.6 | 0.36 | −0.26 |

| Mean | 30.6 | 190.5 | 96.3 | 287.0 | 36.5 | 0.4 | 0.1 |

| Std. Dev. | 0.12 | 8.29 | 18.64 | 25.52 | 1.68 | 0.12 | 0.31 |

| Specimen #ID | Red Surface (RS) − Definition Area (A) = 8 × 8 mm | ||||||

|---|---|---|---|---|---|---|---|

| [µm] | [µm] | [µm] | [µm] | [µm] | |||

| A1-1 | 19.4 | 146.8 | 112.3 | 259.1 | 24.7 | 0.22 | 1.1 |

| A1-2 | 19.5 | 157.8 | 105.8 | 263.6 | 25.7 | 0.66 | 1.54 |

| A1-3 | 19.1 | 196.3 | 104.2 | 300.5 | 25.2 | 0.65 | 2.04 |

| Mean | 19.3 | 167.0 | 107.4 | 274.4 | 25.2 | 0.5 | 1.6 |

| Std. Dev. | 0.21 | 25.99 | 4.29 | 22.71 | 0.50 | 0.25 | 0.47 |

| Specimen #ID | Building Angle | Blue Surface (BS) − Definition Area (A) = 8 × 8 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| [µm] | [µm] | [µm] | [µm] | [µm] | ||||

| A1 | 0° | 30.5 | 195.6 | 117.3 | 313.5 | 34.6 | 0.33 | 0.36 |

| A2 | 0° | 30.4 | 245.8 | 96.9 | 342.7 | 40.2 | 1.26 | 3.1 |

| A3 | 0° | 30.3 | 193.7 | 133.1 | 326.8 | 38 | 0.49 | 0.45 |

| A4 | 30° | 28.6 | 225.4 | 118.1 | 343.4 | 35.4 | 0.63 | 0.41 |

| A5 | 30° | 31.6 | 253.7 | 124.2 | 377.9 | 40.8 | 1.17 | 2.44 |

| A6 | 30° | 26.9 | 181.9 | 94.8 | 276.7 | 33.2 | 0.57 | 0.12 |

| A7 | 60° | 18.3 | 122.9 | 110.1 | 232.9 | 23.9 | 0.64 | 1.19 |

| A8 | 60° | 22.1 | 242.2 | 113.1 | 355.3 | 29.3 | 0.92 | 2.53 |

| A9 | 60° | 17.3 | 164.7 | 84.9 | 249.6 | 23.1 | 0.96 | 1.98 |

| B1 | 0° | 34.1 | 219.8 | 120.5 | 340.3 | 42.4 | 0.2 | −0.01 |

| B2 | 0° | 33.6 | 199.7 | 151.8 | 351.5 | 41.2 | 0.38 | −0.14 |

| B3 | 0° | 36.3 | 202 | 111.4 | 313.4 | 44.5 | 0.25 | −0.31 |

| B4 | 30° | 33.2 | 201 | 121.4 | 322.5 | 40.3 | 0.61 | 0 |

| B5 | 30° | 33.4 | 236.8 | 190.1 | 427 | 41.1 | 0.54 | 0.33 |

| B6 | 30° | 34.8 | 230.4 | 114.4 | 344.8 | 42.5 | 0.6 | 0.09 |

| B7 | 60° | 24.1 | 178.5 | 135.6 | 314 | 31.7 | 0.58 | 1.08 |

| B8 | 60° | 25.9 | 174.4 | 146.4 | 320.8 | 33.7 | 0.45 | 0.82 |

| B9 | 60° | 19.9 | 157.7 | 108.8 | 266.5 | 26.2 | 0.67 | 1.13 |

| C1 | 0° | 38.9 | 203.7 | 147.5 | 351.2 | 48.2 | 0.14 | −0.21 |

| C2 | 0° | 37.9 | 230 | 132.2 | 362.2 | 46.7 | 0.39 | −0.11 |

| C3 | 0° | 37.3 | 200 | 140.1 | 340.1 | 46.2 | 0.26 | −0.1 |

| C4 | 30° | 39.5 | 195.6 | 171.1 | 366.7 | 47.7 | 0.43 | −0.32 |

| C5 | 30° | 39.7 | 225.8 | 173 | 398.8 | 48.7 | 0.45 | −0.04 |

| C6 | 30° | 40.8 | 255.2 | 155.6 | 410.7 | 49.8 | 0.49 | −0.02 |

| C7 | 60° | 27.6 | 155.5 | 154.2 | 309.7 | 35.9 | 0.43 | 0.74 |

| C8 | 60° | 30.1 | 231.6 | 163.4 | 395 | 38.8 | 0.41 | 0.68 |

| C9 | 60° | 26.8 | 212.5 | 139.8 | 352.3 | 34.9 | 0.79 | 1.14 |

| Specimen #ID | Building Angle | Red Surface (RS) − Definition Area (A) = 8 × 8 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| [µm] | [µm] | [µm] | [µm] | [µm] | ||||

| A1 | 90° | 19.4 | 146.8 | 112.3 | 259.1 | 24.7 | 0.22 | 1.1 |

| A2 | 90° | 23.5 | 294.6 | 113.4 | 408 | 34.4 | 1.84 | 7.76 |

| A3 | 90° | 20 | 142.7 | 103.9 | 246.6 | 25.9 | 0.37 | 0.8 |

| A4 | 120° | 19.0 | 225.1 | 92 | 317.1 | 26 | 0.93 | 2.56 |

| A5 | 120° | 22.2 | 276.3 | 138.5 | 414.8 | 33.4 | 2.34 | 9.45 |

| A6 | 120° | 20.3 | 128.4 | 160.1 | 288.5 | 26.6 | 0.19 | 1.03 |

| A7 | 150° | 26.2 | 183.1 | 111.4 | 294.5 | 32.5 | 0.7 | 0.32 |

| A8 | 150° | 29.7 | 217.2 | 108.8 | 325.9 | 37.2 | 0.87 | 1.06 |

| A9 | 150° | 27.8 | 174.9 | 227.3 | 402.3 | 35.1 | 0.5 | 0.84 |

| B1 | 90° | 26.6 | 156.1 | 169.3 | 325.3 | 34.2 | 0.28 | 0.59 |

| B2 | 90° | 29.4 | 187.9 | 149.7 | 337.6 | 37.8 | 0.18 | 0.61 |

| B3 | 90° | 29.1 | 229.7 | 150.6 | 380.3 | 37.3 | 0.08 | 0.55 |

| B4 | 120° | 24.5 | 223.9 | 152.5 | 376.4 | 32.4 | 0.73 | 1.76 |

| B5 | 120° | 24.8 | 192.7 | 136.8 | 329.5 | 32.5 | 0.58 | 1.31 |

| B6 | 120° | 26.7 | 214.6 | 161.3 | 375.8 | 34.9 | 0.22 | 0.94 |

| B7 | 150° | 32.7 | 186.2 | 115.8 | 302.1 | 39.8 | 0.59 | −0.18 |

| B8 | 150° | 31.7 | 163.9 | 121.8 | 285.7 | 38.9 | 0.53 | −0.07 |

| B9 | 150° | 31.9 | 198.7 | 135.5 | 334.2 | 39.2 | 0.53 | 0.06 |

| C1 | 90° | 30.5 | 172 | 169.1 | 341.1 | 39 | 0.09 | 0.39 |

| C2 | 90° | 31.8 | 205.9 | 185.7 | 391.6 | 41.2 | −0.05 | 0.69 |

| C3 | 90° | 32.9 | 168.2 | 176.6 | 344.8 | 42.1 | −0.08 | 0.34 |

| C4 | 120° | 29.8 | 151.1 | 188.1 | 339.2 | 38.5 | 0.35 | 0.53 |

| C5 | 120° | 29.9 | 206.9 | 183.3 | 390.1 | 38.6 | 0.45 | 0.79 |

| C6 | 120° | 32.1 | 206.3 | 209 | 415.3 | 41.4 | 0.19 | 0.64 |

| C7 | 150° | 37.9 | 231.6 | 160.2 | 391.9 | 46.5 | 0.53 | −0.03 |

| C8 | 150° | 38.7 | 207.2 | 153.1 | 360.3 | 47.3 | 0.44 | −0.21 |

| C9 | 150° | 37.1 | 206.7 | 184.4 | 391 | 45.5 | 0.29 | −0.07 |

| Variables | Level | Mean Value | Difference | |

|---|---|---|---|---|

| Layer thickness ** | a. 40 | 26.2 * | a.−b. | −4.4 |

| b. 50 | 30.6 | a.− c. | −9.2 ** | |

| c. 60 | 35.4 | b.−c. | −4.8 | |

| Building angle ** | a. 0° | 34 | a.−b. | −0.2 |

| b. 30° | 34.3 | a.−c. | 10.5 | |

| c. 60° | 23.6 * | b.−c. | 10.7 ** | |

| Laser pattern | a. Linear | 30.1* | a.−b. | −1.5 |

| b. Chess 3 × 3 mm | 31.6 | a.−c. | 0.1 | |

| c. Strip 3 mm | 30.2 | b.−c. | 1.6 | |

| Variables | Level | Mean Value | Difference | |

|---|---|---|---|---|

| Layer thickness ** | a. 40 | 23.1* | a.−b. | −5.5 |

| b. 50 | 28.6 | a.−c. | −10.3 ** | |

| c. 60 | 33.4 | b.−c. | −4.8 | |

| Building angle ** | a. 90° | 27.0 | a.−b. | −1.5 |

| b. 120° * | 25.5 * | a.−c. | −5.7 | |

| c. 150° | 32.6 * | b.−c. | 7.1 ** | |

| Laser pattern | a. Linear | 27.4 * | a.−b. | −1.7 |

| b. Chess 3 × 3 mm | 29.1 | a.−c. | −1.3 | |

| c. Strip 3 mm | 28.7 | b.−c. | 0.4 | |

| Specimen #ID | Laser Scan Speed * | Blue Surface (BS) − Definition Area (A) = 8 × 8 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| [µm] | [µm] | [µm] | [µm] | [µm] | ||||

| A1-4 | x4.0 | 10.4 | 61.2 | 101.4 | 162.6 | 13.5 | −0.66 | 1.53 |

| A1-5 | x2.0 | 17.1 | 76.7 | 85.2 | 162.0 | 20.9 | −0.05 | −0.30 |

| A1-6 | x1.25 | 19.9 | 89.3 | 90.4 | 179.7 | 24.3 | −0.21 | −0.43 |

| Specimen #ID | Laser Scan Speed * | Red Surface (RS) − Definition Area (A) = 8 × 8 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| [µm] | [µm] | [µm] | [µm] | [µm] | ||||

| A1-4 | x4.0 | 16.1 | 101.9 | 86.3 | 188.2 | 20.3 | 0.05 | 0.13 |

| A1-5 | x2.0 | 19.3 | 132.5 | 107.4 | 239.9 | 24.9 | 0.16 | 0.61 |

| A1-6 | x1.25 | 19.7 | 106.3 | 105.6 | 211.9 | 25.6 | −0.05 | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caravella, I.; Cortis, D.; Di Angelo, L.; Orlandi, D. Experimental Data Collection of Surface Quality Analysis of CuCrZr Specimens Manufactured with SLM Technology: Analysis of the Effects of Process Parameters. Materials 2023, 16, 98. https://doi.org/10.3390/ma16010098

Caravella I, Cortis D, Di Angelo L, Orlandi D. Experimental Data Collection of Surface Quality Analysis of CuCrZr Specimens Manufactured with SLM Technology: Analysis of the Effects of Process Parameters. Materials. 2023; 16(1):98. https://doi.org/10.3390/ma16010098

Chicago/Turabian StyleCaravella, Ilaria, Daniele Cortis, Luca Di Angelo, and Donato Orlandi. 2023. "Experimental Data Collection of Surface Quality Analysis of CuCrZr Specimens Manufactured with SLM Technology: Analysis of the Effects of Process Parameters" Materials 16, no. 1: 98. https://doi.org/10.3390/ma16010098

APA StyleCaravella, I., Cortis, D., Di Angelo, L., & Orlandi, D. (2023). Experimental Data Collection of Surface Quality Analysis of CuCrZr Specimens Manufactured with SLM Technology: Analysis of the Effects of Process Parameters. Materials, 16(1), 98. https://doi.org/10.3390/ma16010098