Damage Imaging Identification of Honeycomb Sandwich Structures Based on Lamb Waves

Abstract

:1. Introduction

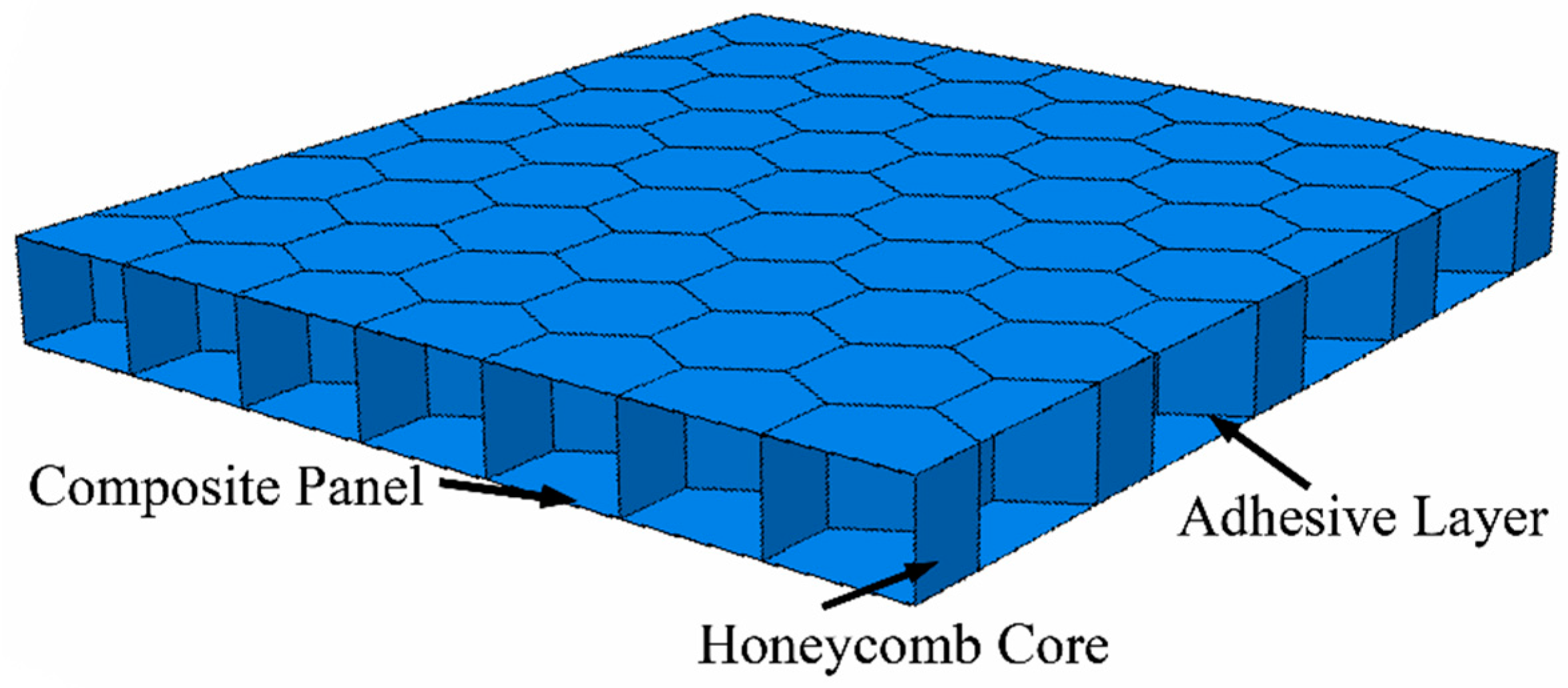

2. Lamb Wave Damage Mechanism

3. Basic Principles of Lamb Wave Tomography

3.1. Lamb Wave Tomography

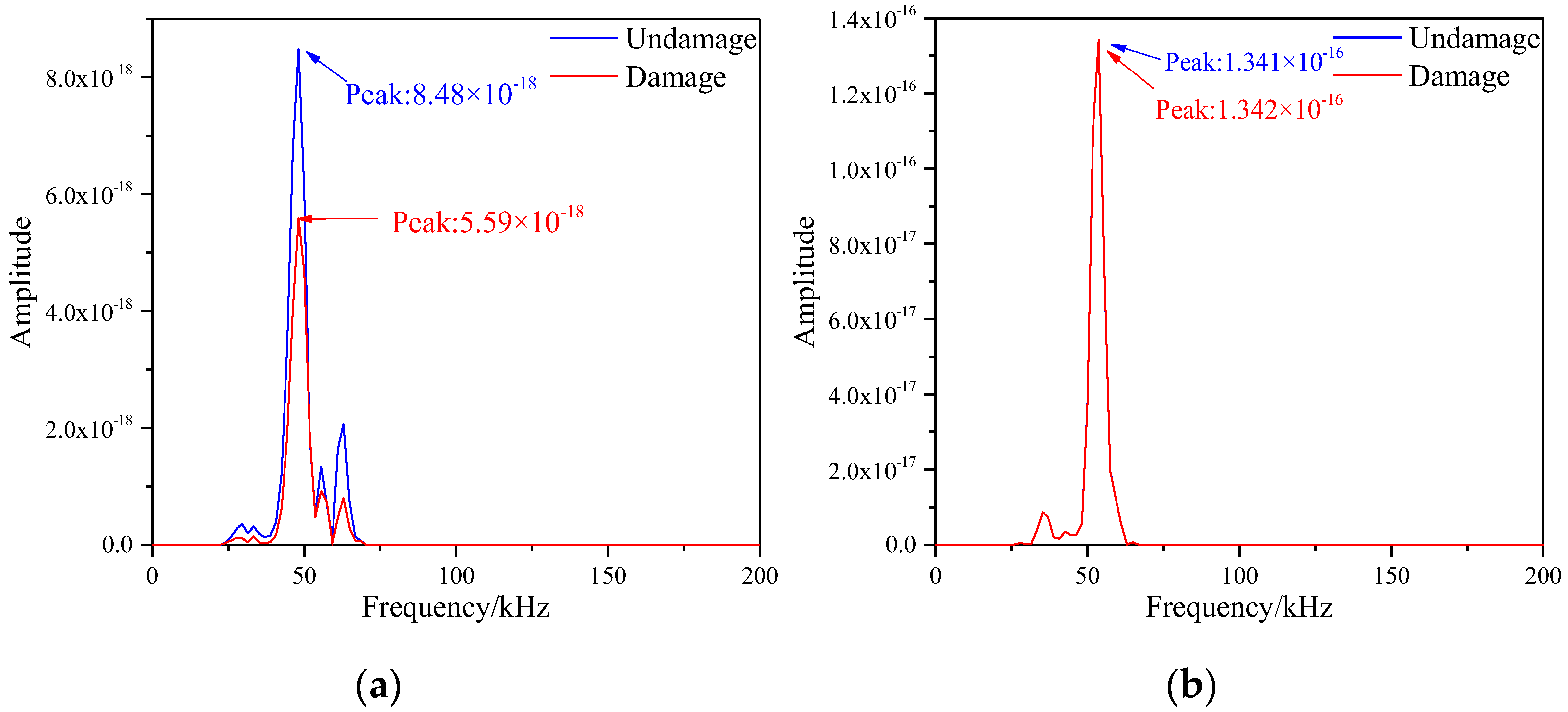

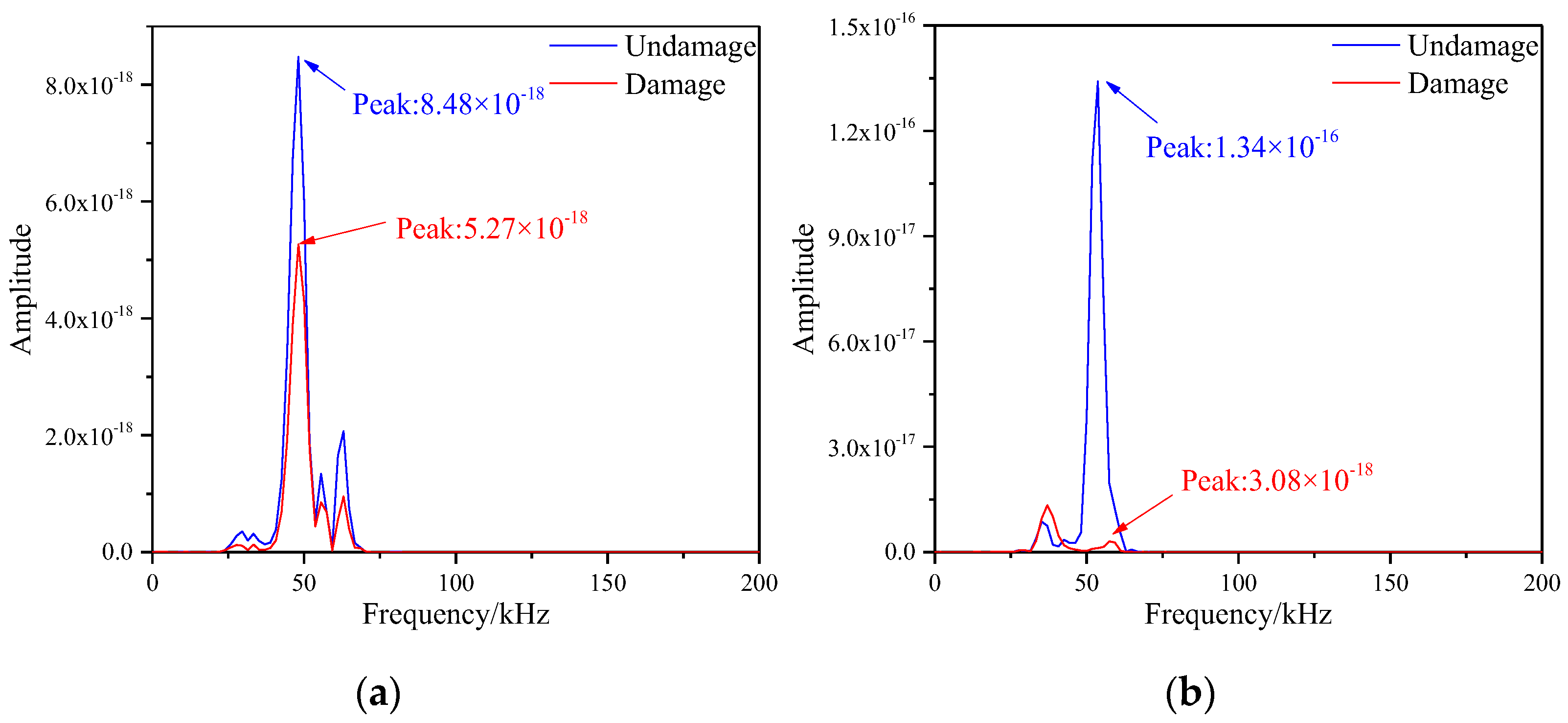

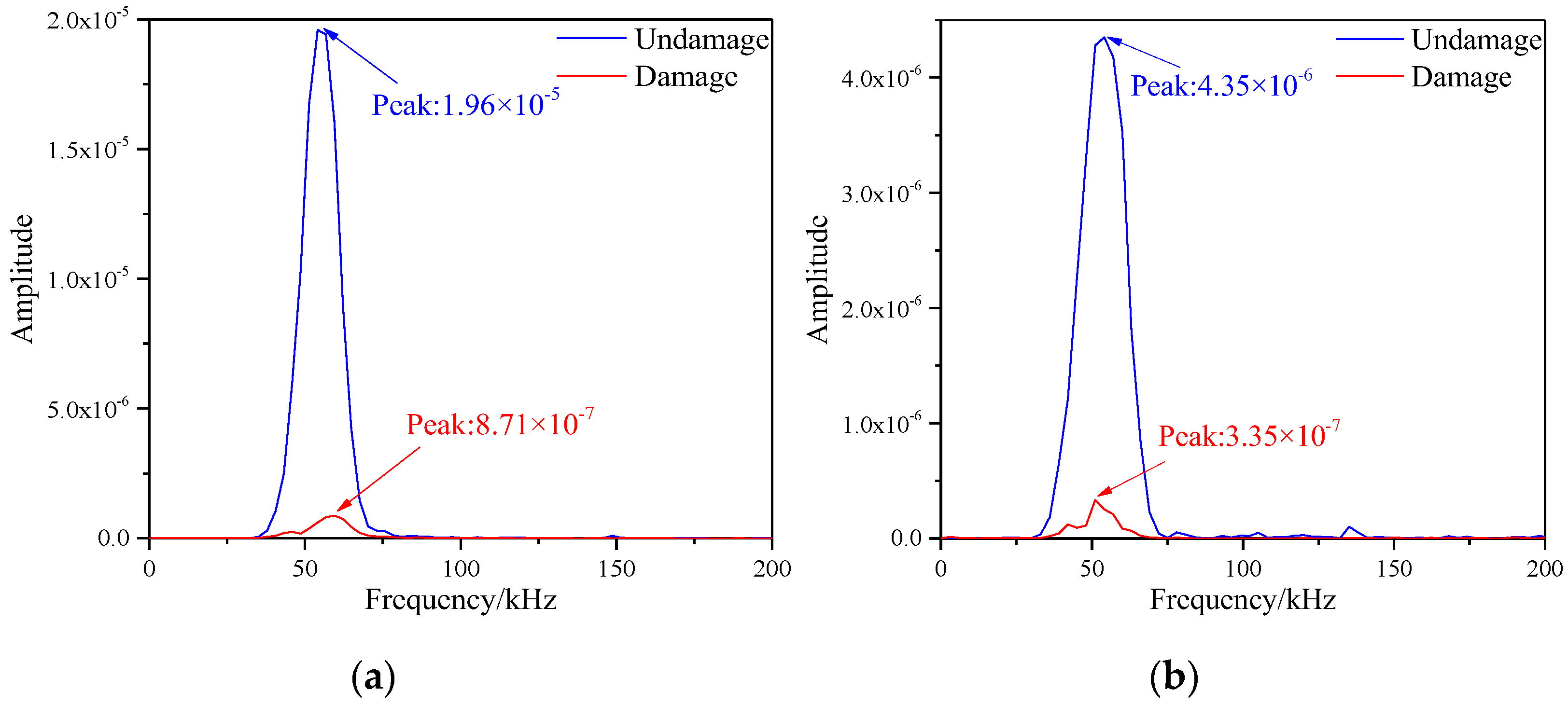

3.2. Damage Index Calculation Based on Frequency Spectrum

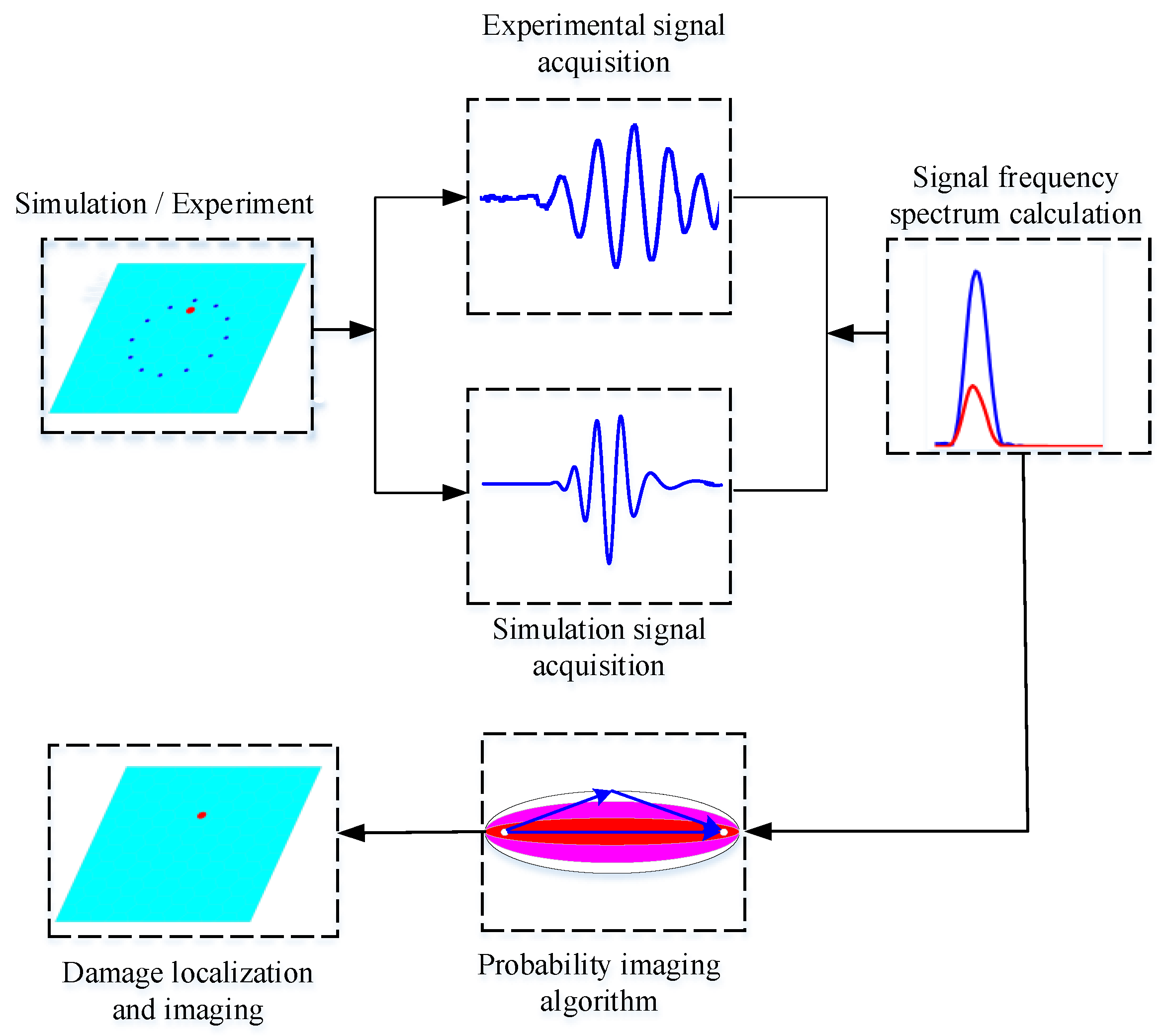

- Conduct damage detection of honeycomb sandwich structure by simulation and experiment respectively.

- Obtain the baseline signals and the signals after damage under the two approaches in step 1, respectively.

- Perform Fourier transform on the acquired signals to calculate the frequency spectrum of the signals.

- Calculate the DI by comparing the spectral differences of the signals before and after damage according to Equation (1).

- Calculate the damage probability distribution and realize the damage image reconstruction by Equation (2).

4. Finite Element Simulation

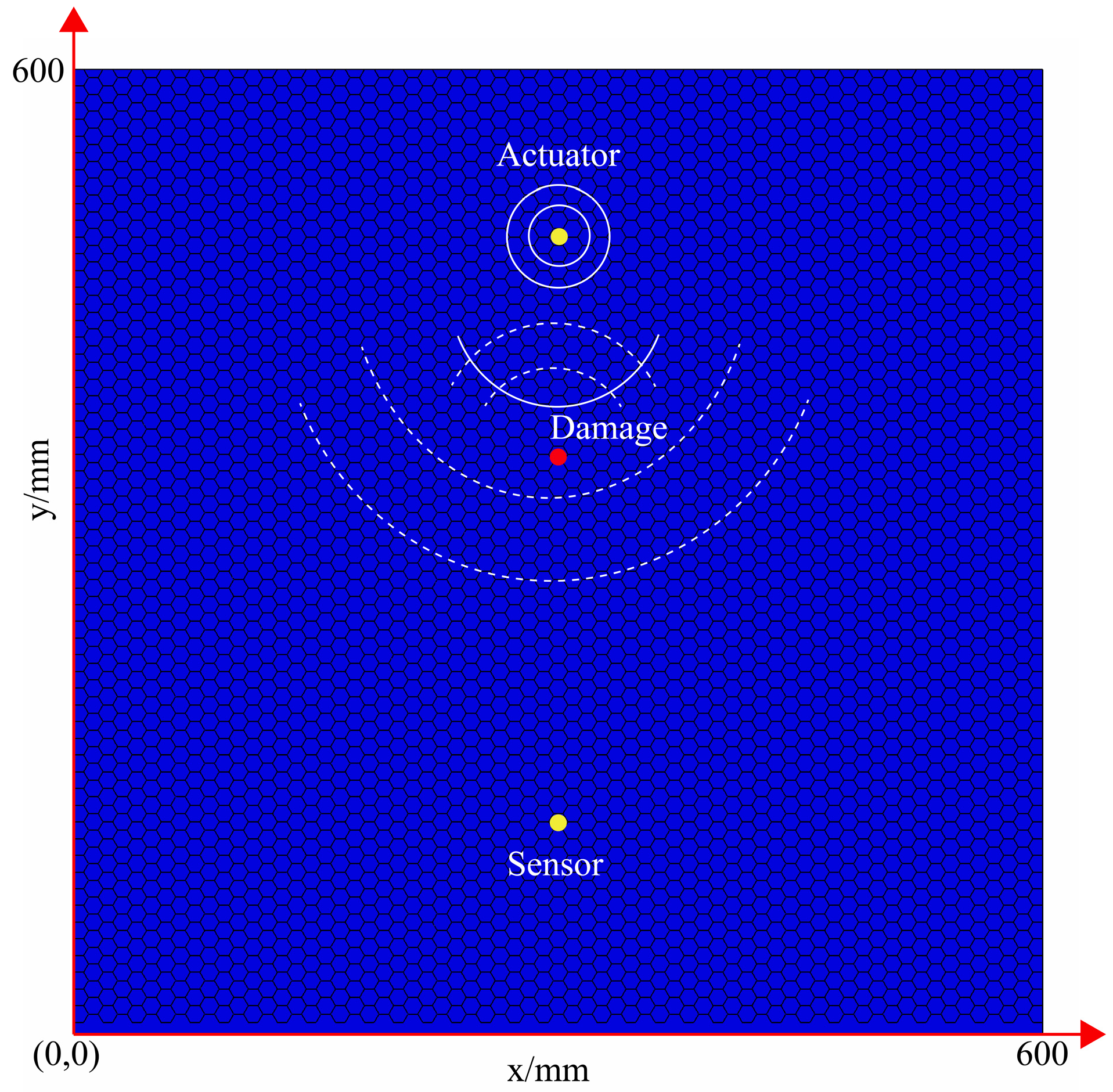

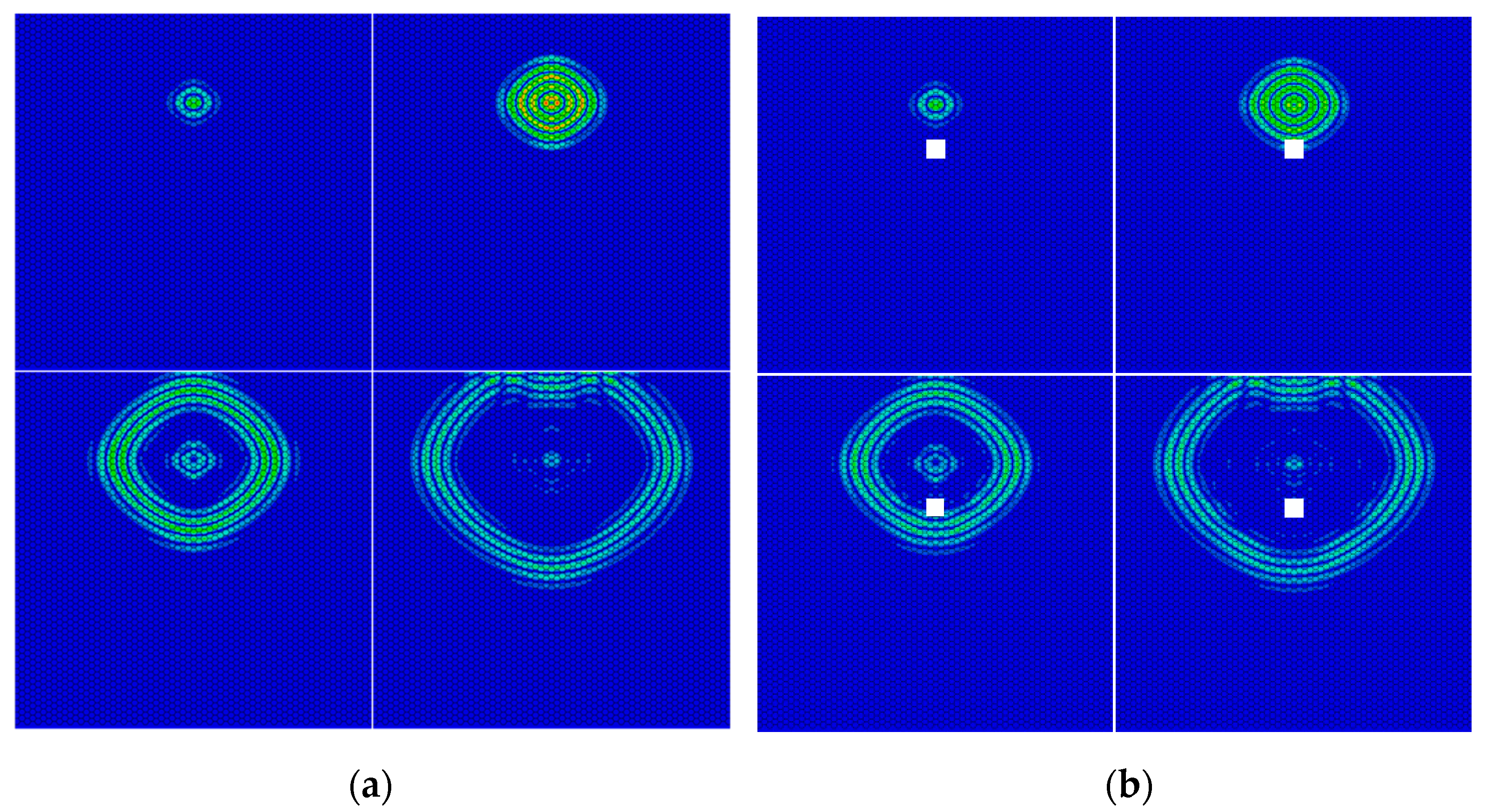

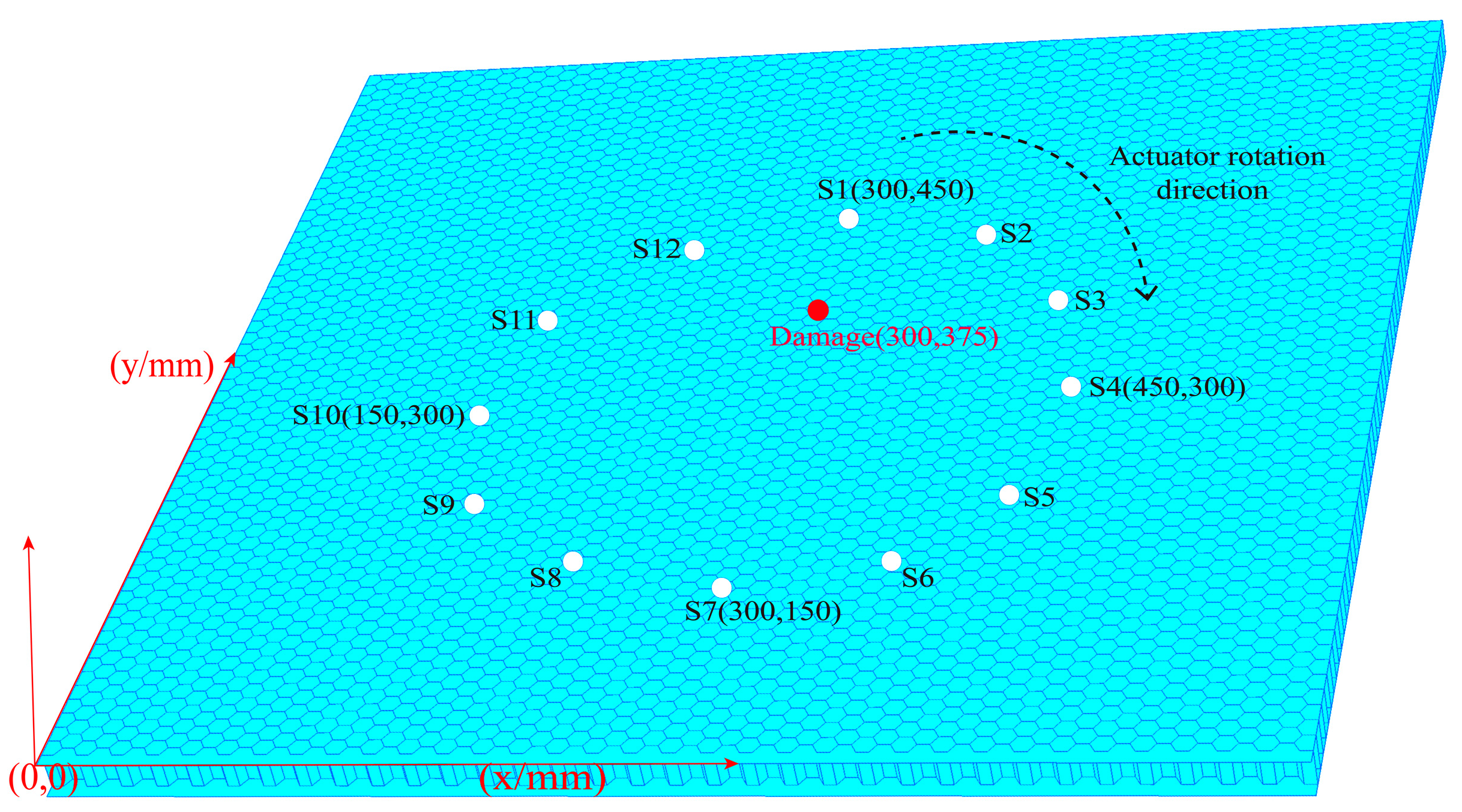

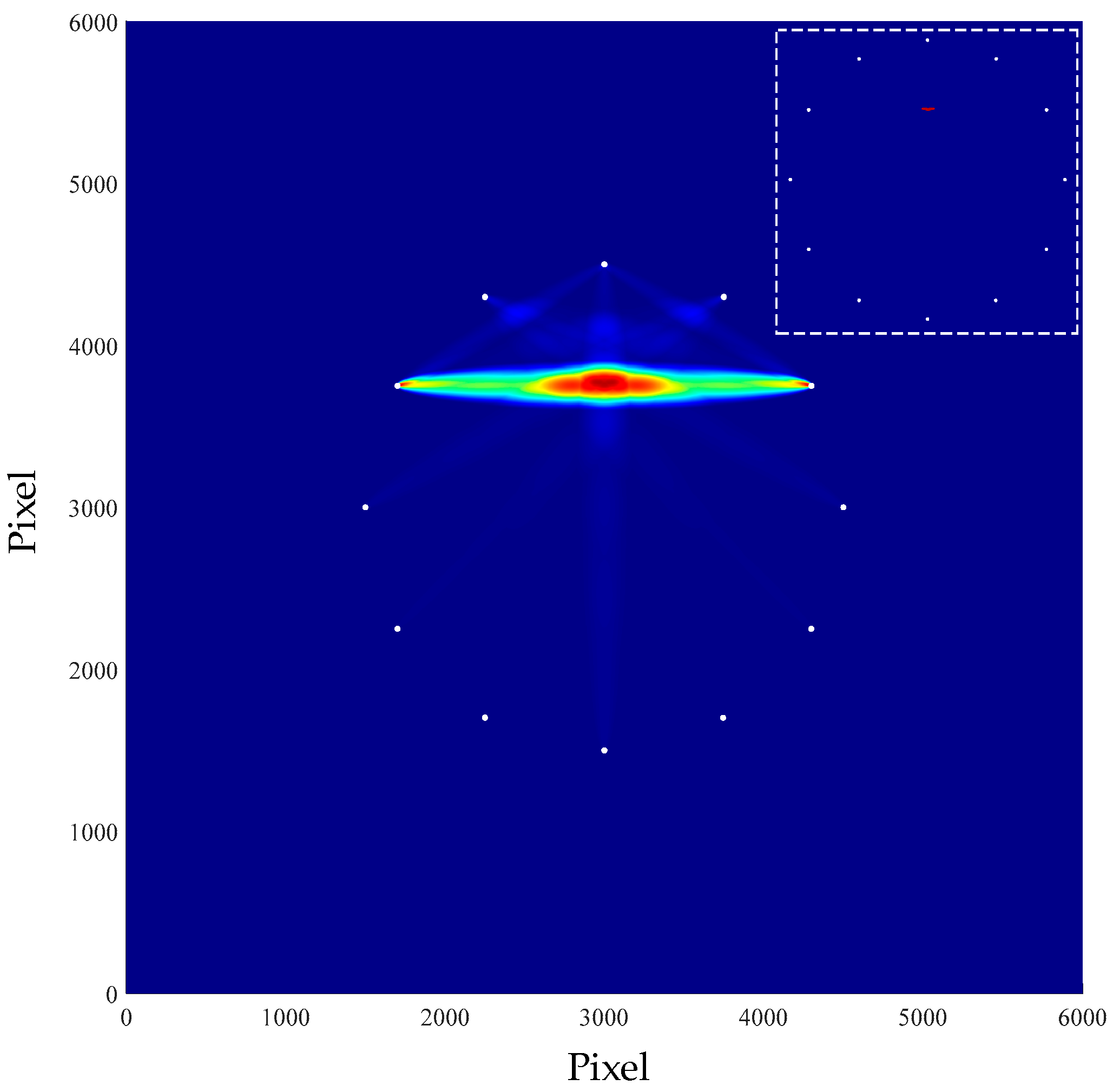

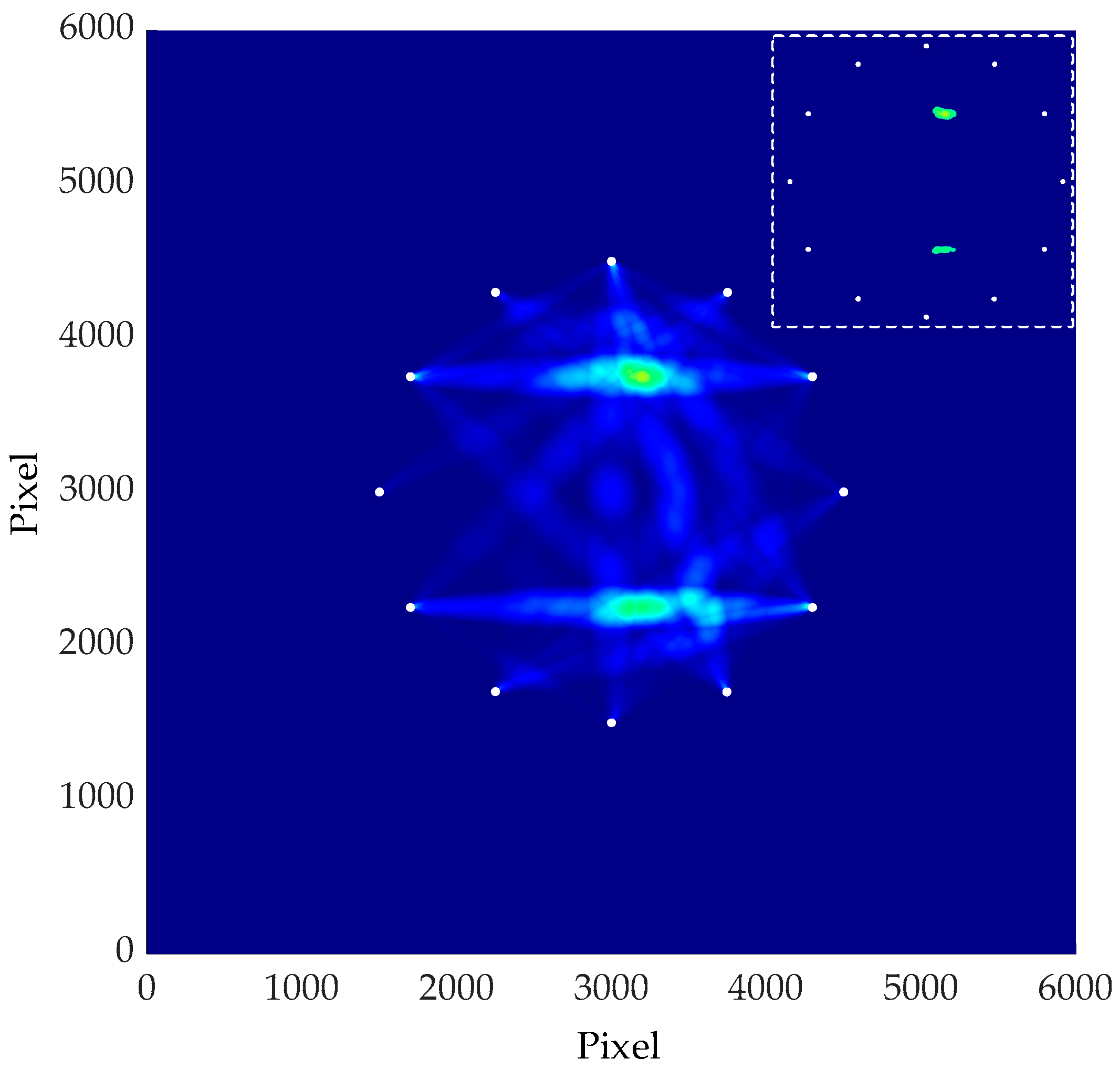

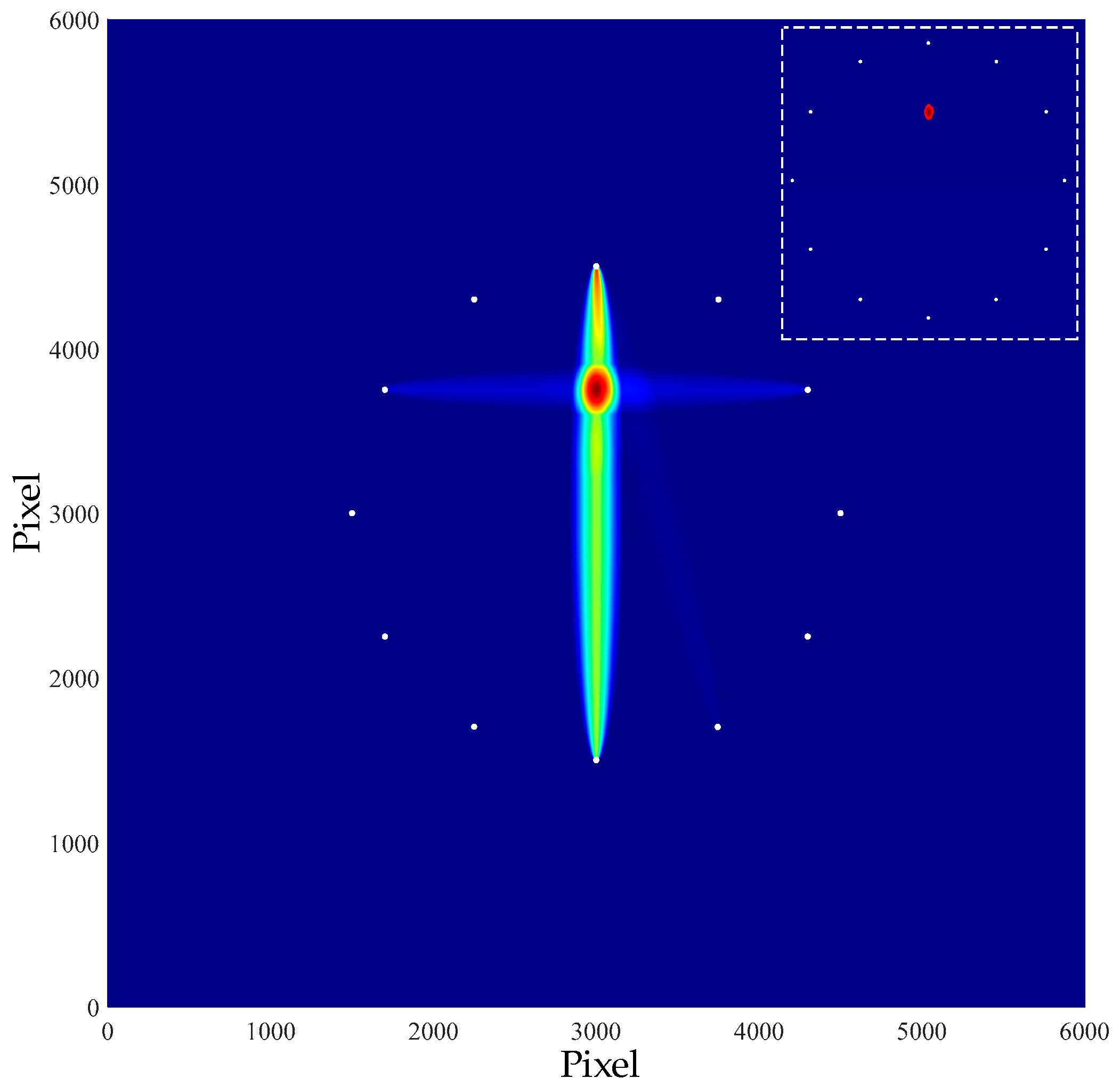

4.1. Single Damage Localization Imaging

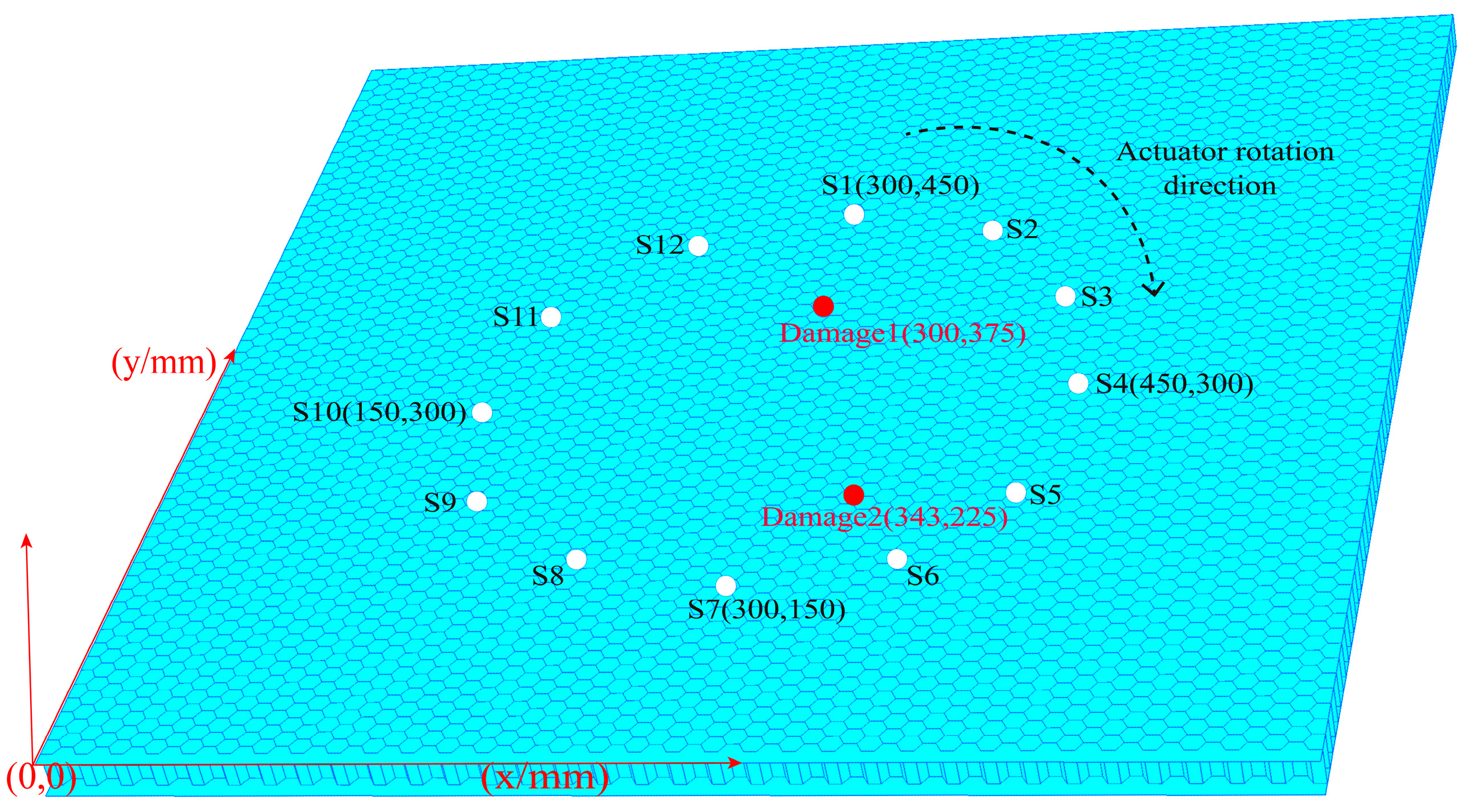

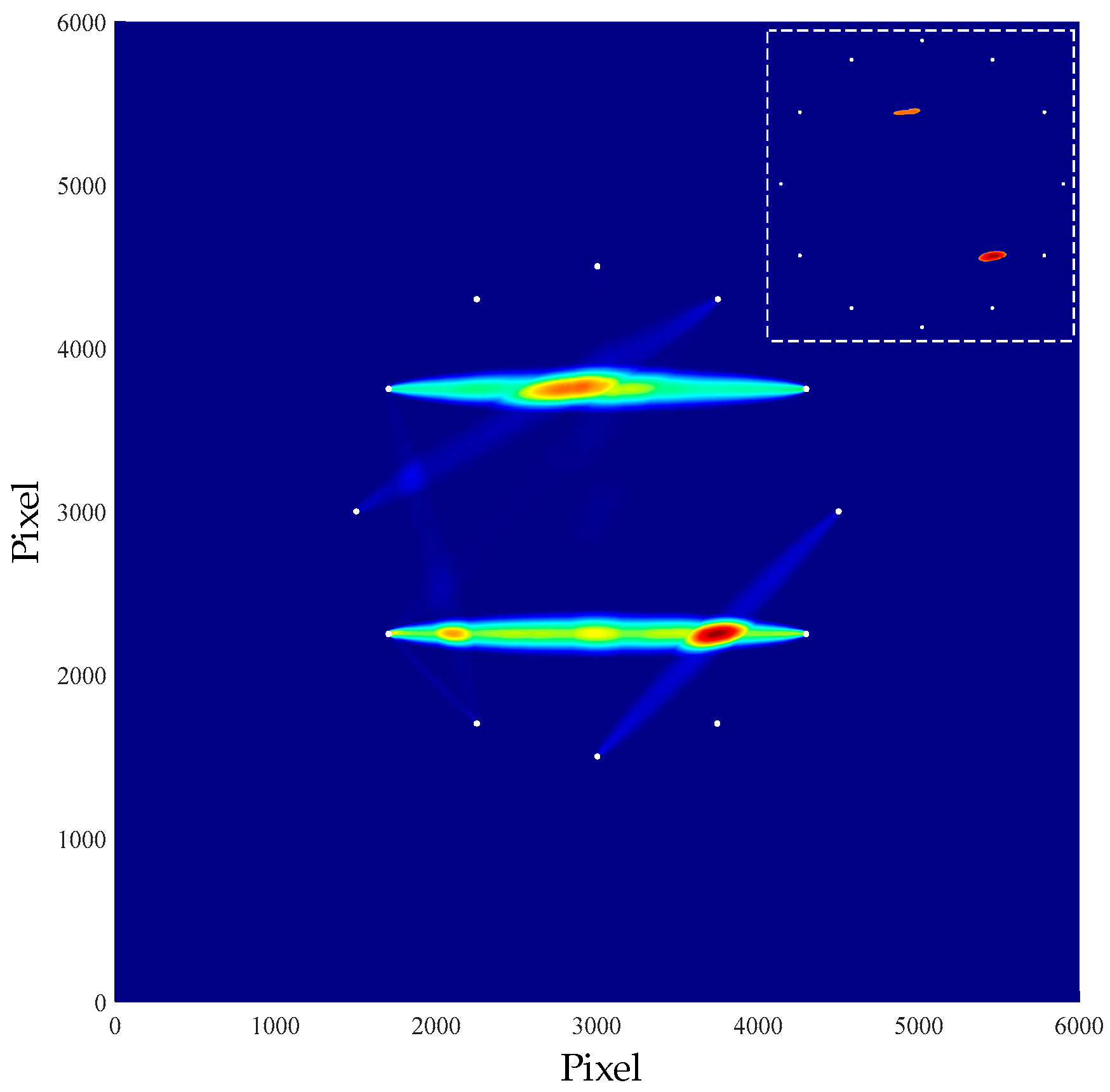

4.2. Multiple Damage Localization Imaging

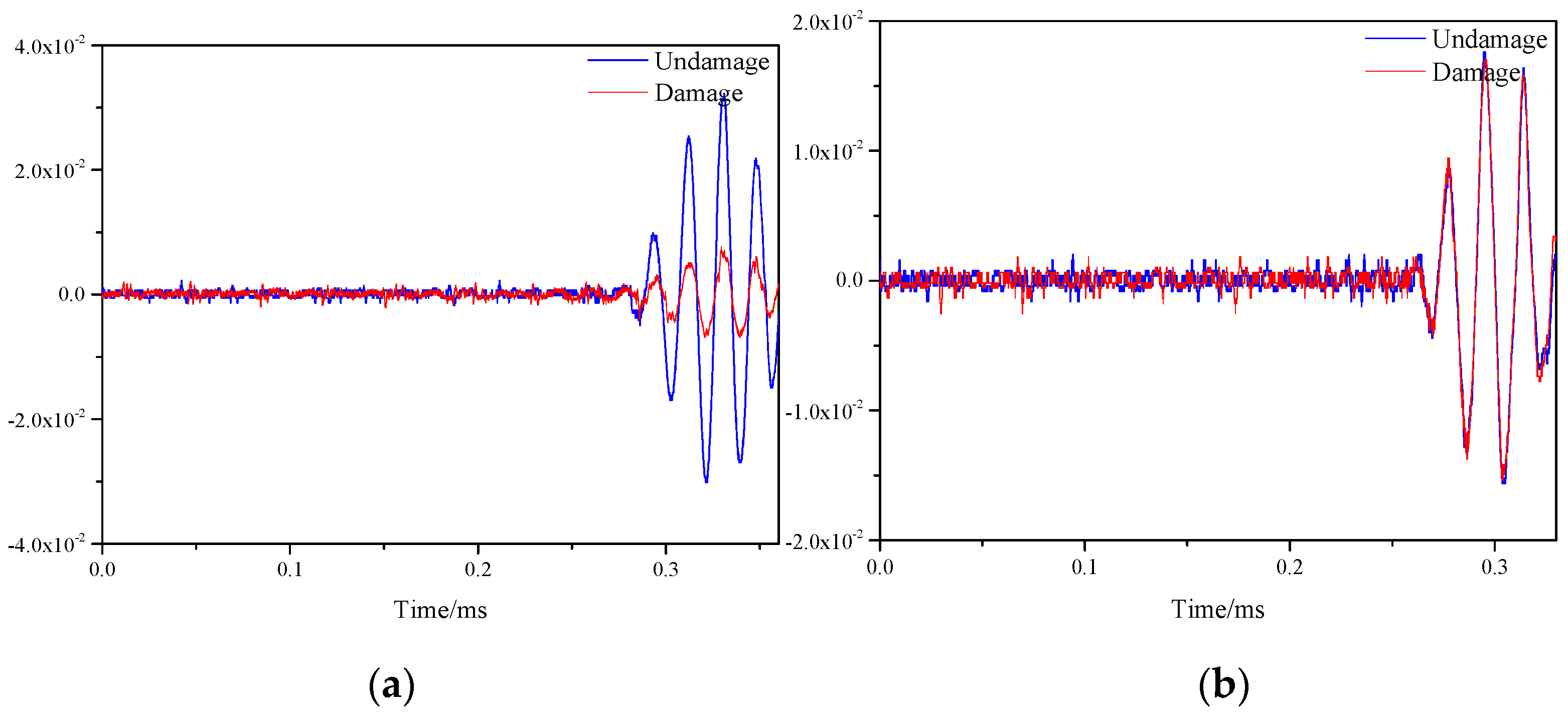

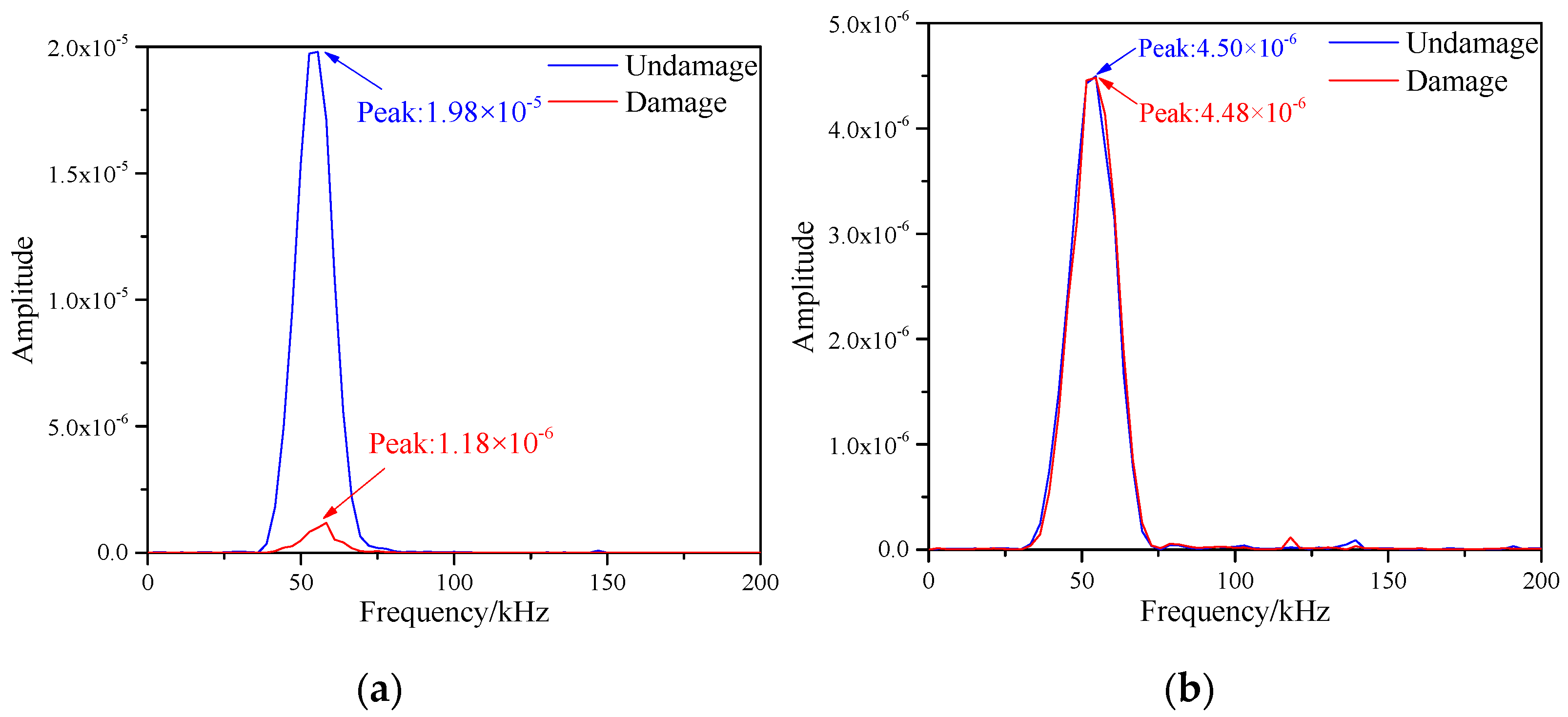

5. Experiment Research

6. Conclusions

- Lamb Wave Tomography is a method to realize damage location through the difference between baseline signals and damage signals without the interference of factors such as understanding and modeling of material or structural characteristics, and has a high accuracy rate.

- In this paper, damage indexes calculation method based on frequency spectrum is proposed, which can effectively reflect the difference caused by damage and pay a way for damage probability imaging.

- Damage imaging of honeycomb sandwich structures is carried out by numerical simulation and experimental study, respectively. In both simulation and experiment, the localization errors of the damage conform to the detection requirements, which realizes the accurate localization of damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic metamaterials and structures: A review. Smart Mater. Struct. 2018, 27, 023001. [Google Scholar] [CrossRef]

- Zhang, J.H.; Zhu, X.F.; Yang, X.D.; Zhang, W. Transient nonlinear responses of an auxetic honeycomb sandwich plate under impact loads. Int. J. Impact Eng. 2019, 134, 103383. [Google Scholar] [CrossRef]

- Nguyen, N.V.; Nguyen-Xuan, H.; Nguyen, T.N.; Kang, J.; Lee, J. A comprehensive analysis of auxetic honeycomb sandwich plates with graphene nanoplatelets reinforcement. Compos. Struct. 2021, 259, 113213. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G.; Xiang, X. Energy absorption of a bio-inspired honeycomb sandwich panel. J. Mater. Sci. 2019, 54, 6286–6300. [Google Scholar] [CrossRef]

- Chandrasekaran, N.K.; Arunachalam, V. State of the art review on honeycomb sandwich composite structures with an emphasis on filler materials. Polym. Compos. 2021, 42, 5011–5020. [Google Scholar] [CrossRef]

- Mitra, A.K.; Aradhye, A.A.; Joglekar, D.M. Low frequency ultrasonic guided wave propagation through honeycomb sandwich structures with non-uniform core thickness. Mech. Syst. Signal Process. 2023, 191, 110155. [Google Scholar] [CrossRef]

- Liu, B.; Wei, Q.; Tu, J.; Arola, D.D.; Zhang, D.S. Inspection of the interior surface of cylindrical vessels using optic fiber shearography. Meas. Sci. Technol. 2017, 28, 095202. [Google Scholar] [CrossRef]

- Gao, Y.; Li, X.; Wang, X.V.; Wang, L.H.; Gao, L. A review on recent advances in vision-based defect recognition towards industrial intelligence. J. Manuf. Syst. 2022, 62, 753–766. [Google Scholar] [CrossRef]

- Manujesh, B.J.; Prajna, M.R. Damage detection and classification for sandwich composites using machine learning. Mater. Today Proc. 2022, 52, 702–709. [Google Scholar]

- Reyno, T.; Marsden, C.; Wowk, D. Surface damage evaluation of honeycomb sandwich aircraft panels using 3D scanning technology. NDT E Int. 2018, 97, 11–19. [Google Scholar] [CrossRef]

- Rellinger, T.; Underhill, P.R.; Krause, T.W.; Wowk, D. Combining eddy current, thermography and laser scanning to characterize low-velocity impact damage in aerospace composite sandwich panels. NDT E Int. 2021, 120, 102421. [Google Scholar] [CrossRef]

- Zarei, A.; Farahani, S.; Pilla, S. An experimental study on the manufacturing of engineered defects in composite plates. Compos. Part C Open Access 2022, 9, 100327. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Tan, X. Review on vibration-based structural health monitoring techniques and technical codes. Symmetry 2021, 13, 1998. [Google Scholar] [CrossRef]

- Seguel, F.; Meruane, V. Damage assessment in a sandwich panel based on full-field vibration measurements. J. Sound Vib. 2018, 417, 1–18. [Google Scholar] [CrossRef]

- Friedrich, L.; Colpo, A.; Maggi, A.; Becker, T.; Lacidogna, G.; Iturrioz, I. Damage process in glass fiber reinforced polymer specimens using acoustic emission technique with low frequency acquisition. Compos. Struct. 2021, 256, 113105. [Google Scholar] [CrossRef]

- Sikdar, S.; Mirgal, P.; Banerjee, S.; Ostachowicz, W. Damage-induced acoustic emission source monitoring in a honeycomb sandwich composite structure. Compos. Part B Eng. 2019, 158, 179–188. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Y.; Wang, Y.; Xue, P.; Gong, C.; Wang, W.; Wei, X.; Xiong, J. Failure mechanisms and acoustic emission pattern recognition of all-CFRP cylindrical honeycomb sandwich shell under three-point bending. Compos. Sci. Technol. 2023, 237, 110003. [Google Scholar] [CrossRef]

- Liu, Z.; Ardabilian, M.; Zine, A.; Ichchou, M. Crack damage identification of a thick composite sandwich structure based on Gaussian Processes classification. Compos. Struct. 2021, 255, 112825. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Z.; Liao, W.; Hong, L.; Ding, Y.; Zhou, Z. A data fusion based diagnostic methodology for in-situ debonding detection in beam-like honeycomb sandwich structures with fiber Bragg grating sensors. Measurement 2022, 191, 110810. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, B.; Jia, H.; Zhang, C.; Zhang, Z.; Wang, S.; Yang, Y.; Wang, X.; Cheng, X.; Yan, Z.; et al. A novel nondestructive testing method for honeycomb structure using acoustic band gap. Mech. Syst. Signal Process. 2023, 188, 110053. [Google Scholar] [CrossRef]

- Fiborek, P.; Kudela, P. Model-Assisted Guided-Wave-Based Approach for Disbond Detection and Size Estimation in Honeycomb Sandwich Composites. Sensors 2021, 21, 8183. [Google Scholar] [CrossRef] [PubMed]

- Baptista, F.G.; Vieira, F.J.; Inman, D.J. Sizing PZT transducers in impedance-based structural health monitoring. IEEE Sens. J. 2010, 11, 1405–1414. [Google Scholar] [CrossRef]

- Na, W.S. History data free piezoelectric based non-destructive testing technique for debonding detection of composite structures. Compos. Struct. 2019, 226, 111225. [Google Scholar] [CrossRef]

- Chertishchev, V.Y.; Boichuk, A.S.; Dikov, I.A.; Yakovleva, S.I.; Generalov, A.S. Determining the Depth of Occurrence of Defects in Multilayer PCM Structures by Acoustic Methods Based on the Mechanical Impedance Value. Russ. J. Nondestruct. Test. 2018, 54, 556–569. [Google Scholar] [CrossRef]

- Deng, P.; Saito, O.; Okabe, Y.; Soejima, H. Simplified modeling method of impact damage for numerical simulation of Lamb wave propagation in quasi-isotropic composite structures. Compos. Struct. 2020, 243, 112150. [Google Scholar] [CrossRef]

- Nandyala, A.R.; Darpe, A.K.; Singh, S.P. Damage localization in cross-ply laminated composite plates under varying temperature conditions using Lamb waves. Meas. Sci. Technol. 2020, 31, 064003. [Google Scholar] [CrossRef]

- Su, C.H.; Jiang, M.S.; Liang, J.Y.; Tian, A.Q.; Sun, L.; Zhang, L.; Zhang, F.Y.; Sui, Q.M. Damage localization of composites based on difference signal and lamb wave tomography. Materials 2020, 13, 218. [Google Scholar] [CrossRef] [Green Version]

- Yao, C.; Zhu, W.F.; Chai, X.D.; Sun, L.J.; Fan, G.P.; Zheng, S.B.; Zhang, H. Sparse array ultrasonic Lamb wave TDTE imaging method. IEEE Sens. J. 2021, 21, 20910–20920. [Google Scholar]

- Yang, Z.; Wei, J.; Jiang, M.; Sui, Q.; Jia, L. Damage identification for isotropic structures using Lamb wave based on a reference-free location imaging method. IEEE Sens. J. 2022, 23, 2630–2642. [Google Scholar] [CrossRef]

- Zhang, W.; Su, C.; Zhang, Y.; Yang, H. Locating and imaging composite damage based on frequency spectrum detection of lamb waves. Front. Phys. 2022, 10, 1151. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Lamb wave generation with piezoelectric wafer active sensors for structural health monitoring. In Proceedings of the SPIE’s 10th Annual International Symposium on Smart Structures and Materials and 8th Annual International Symposium on NDE for Health Monitoring and Diagnostics, San Diego, CA, USA, 2–6 March 2002; Volume 5056, pp. 111–122. [Google Scholar]

- Prasad, S.M.; Balasubramaniam, K.; Krishnamurthy, C.V. Structural health monitoring of composite structures using Lamb wave tomography. Smart Mater. Struct. 2004, 13, N73. [Google Scholar] [CrossRef]

- Leonard, K.R.; Hinders, M.K. Lamb wave tomography of pipe-like structures. Ultrasonics 2005, 43, 574–583. [Google Scholar] [CrossRef] [PubMed]

- Hinders, M.K.; Leonard, K.R. Lamb wave tomography of pipes and tanks using frequency compounding. AIP Conf. Proc. 2005, 760, 867–874. [Google Scholar]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 053001. [Google Scholar] [CrossRef]

- Bracewell, R.N.; Bracewell, R.N. The Fourier Transform and Its Applications, 3rd ed.; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Yue, S.Y.; Wang, Y.G.; Wei, L.G.; Zhang, Z.; Wang, H. The joint empirical mode decomposition-local mean decomposition method and its application to time series of compressor stall process. Aerosp. Sci. Technol. 2020, 105, 105969. [Google Scholar] [CrossRef]

| Elastic Properties | Strength | Fracture Energy | Density | |||

|---|---|---|---|---|---|---|

| E1 | 110 GPa | XT | 2093 MPa | Gft | 10 N/mm | 1700 kg/m3 |

| E2 | 7.8 GPa | XC | 870 MPa | Gfc | 10 N/mm | |

| ν12 | 0.32 | YT | 50 MPa | Gmt | 1 N/mm | |

| G12 | 40 GPa | YC | 198 MPa | Gmc | 1 N/mm | |

| G13 | 40 GPa | SL | 104 MPa | |||

| G23 | 40 GPa | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, C.; Zhang, W.; Liang, L.; Zhang, Y.; Sui, Q. Damage Imaging Identification of Honeycomb Sandwich Structures Based on Lamb Waves. Materials 2023, 16, 4658. https://doi.org/10.3390/ma16134658

Su C, Zhang W, Liang L, Zhang Y, Sui Q. Damage Imaging Identification of Honeycomb Sandwich Structures Based on Lamb Waves. Materials. 2023; 16(13):4658. https://doi.org/10.3390/ma16134658

Chicago/Turabian StyleSu, Chenhui, Wenchao Zhang, Lihua Liang, Yuhang Zhang, and Qingmei Sui. 2023. "Damage Imaging Identification of Honeycomb Sandwich Structures Based on Lamb Waves" Materials 16, no. 13: 4658. https://doi.org/10.3390/ma16134658

APA StyleSu, C., Zhang, W., Liang, L., Zhang, Y., & Sui, Q. (2023). Damage Imaging Identification of Honeycomb Sandwich Structures Based on Lamb Waves. Materials, 16(13), 4658. https://doi.org/10.3390/ma16134658