Fatigue Analysis of Welded Joints Using a Thin-Walled Al/Fe Explosive Welded Transition Joints

Abstract

:1. Introduction

2. Materials and Methods

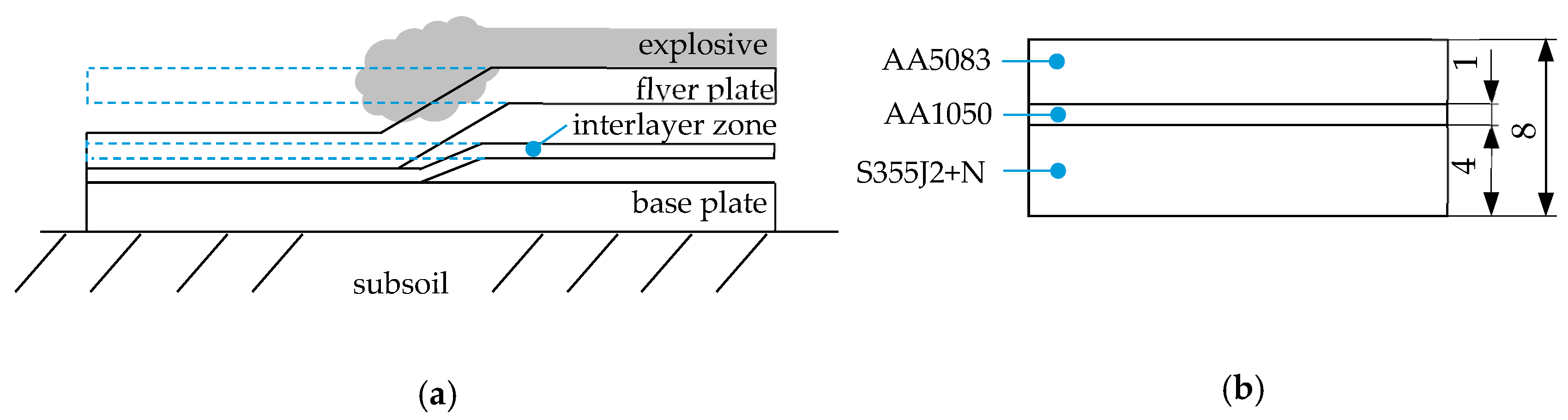

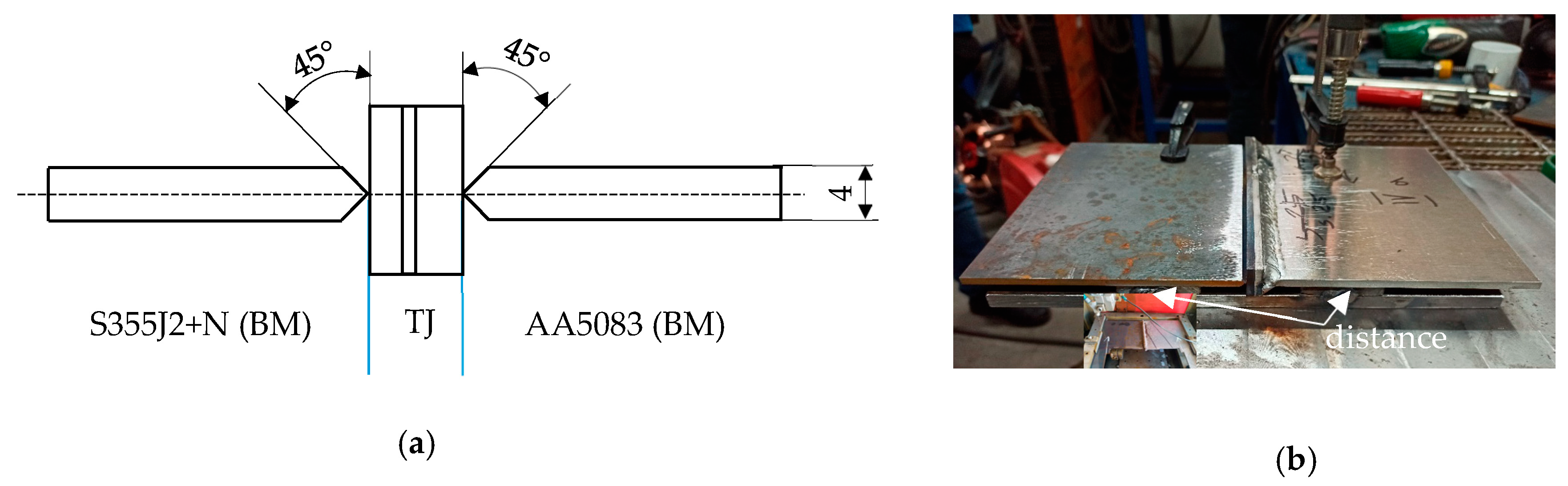

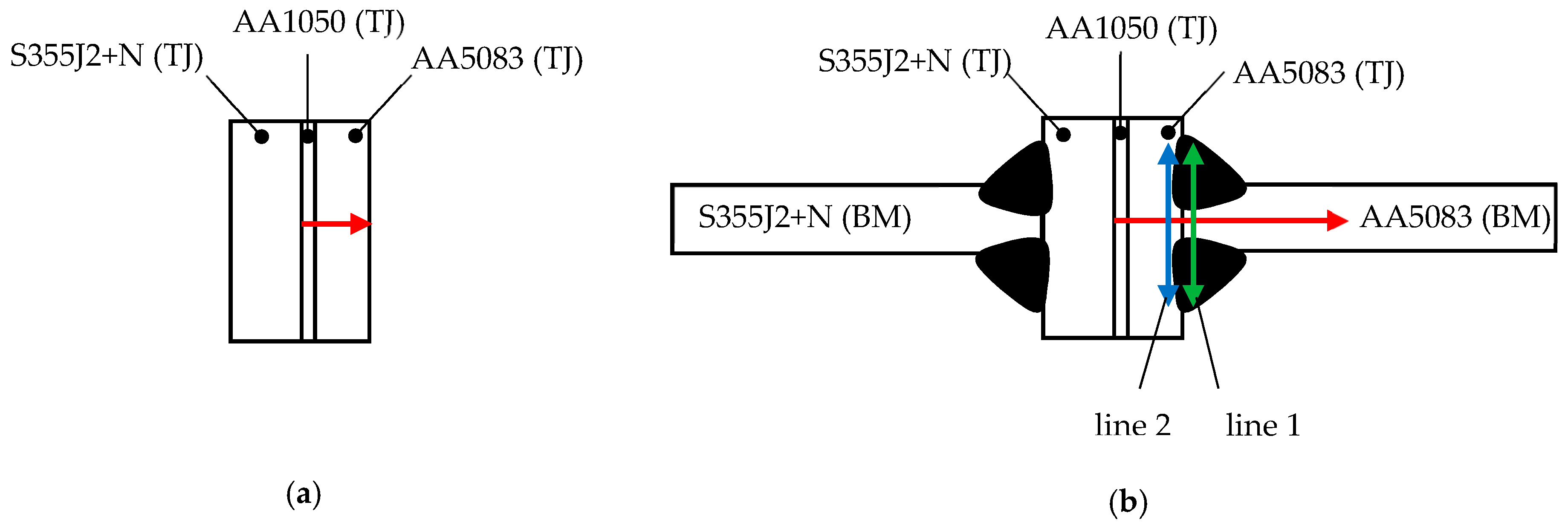

2.1. Material and Specimens Preparation

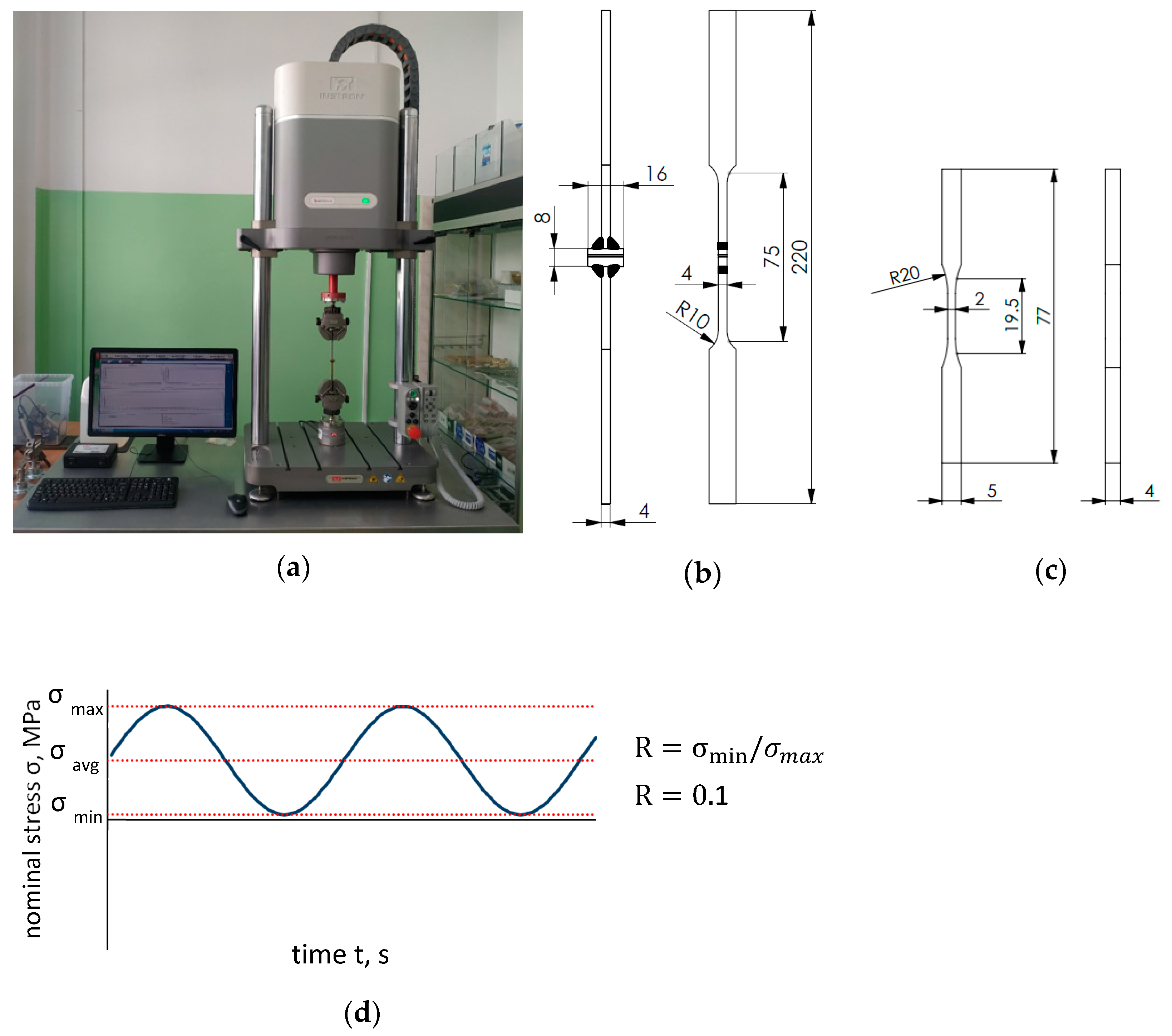

2.2. Methods

3. Results and Analysis

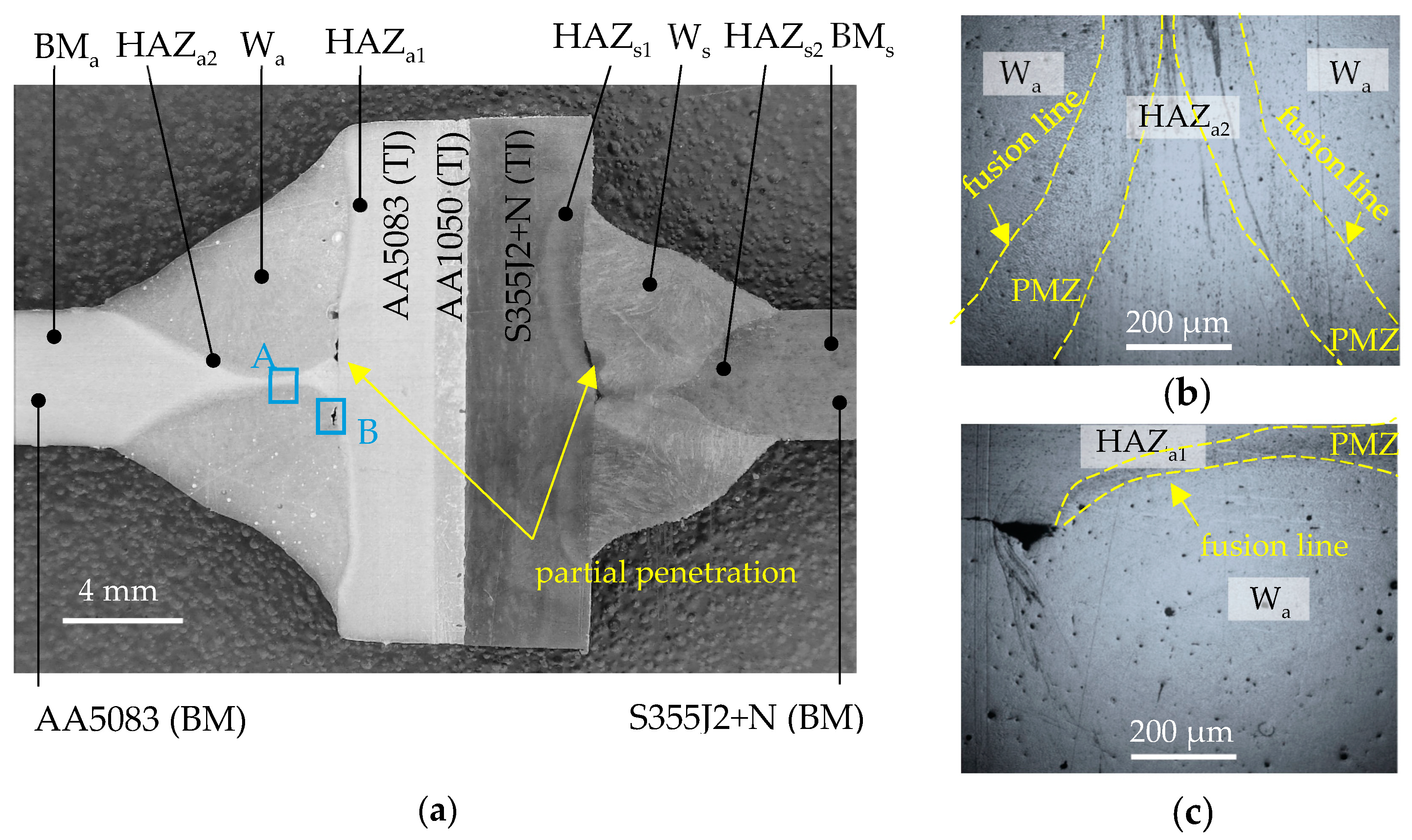

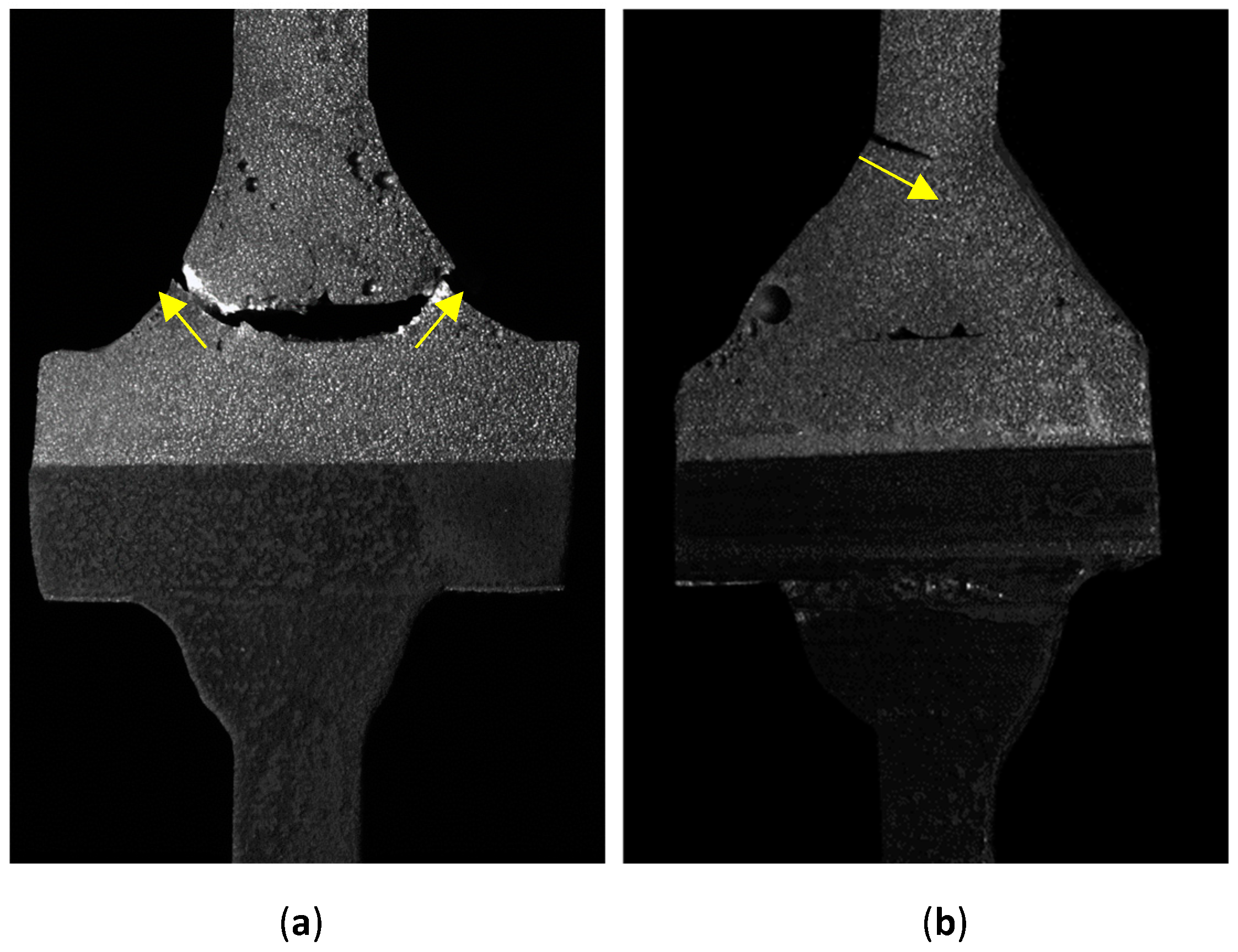

3.1. Macrostructure of Welded Joints

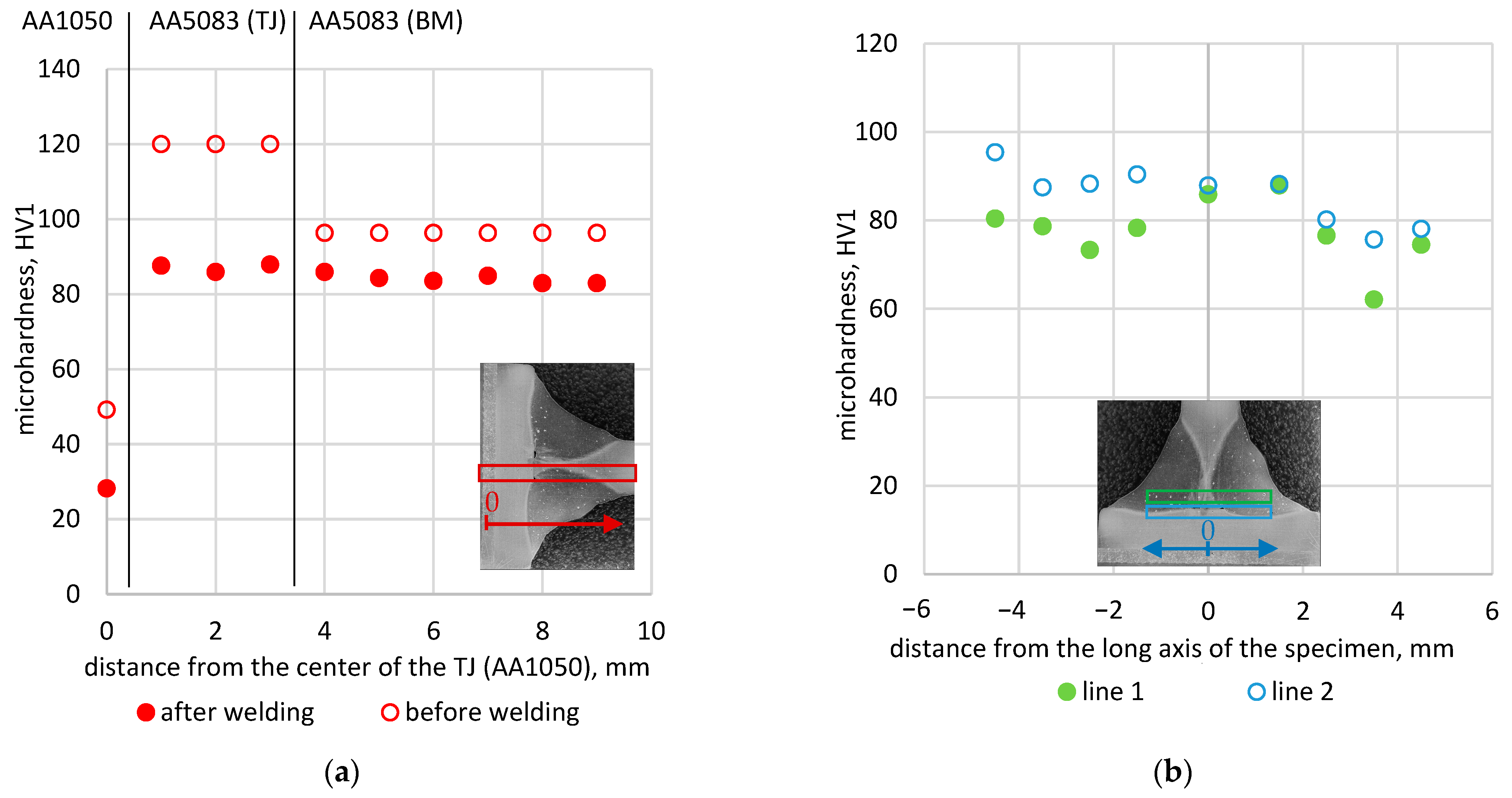

3.2. Microhardness Distributions

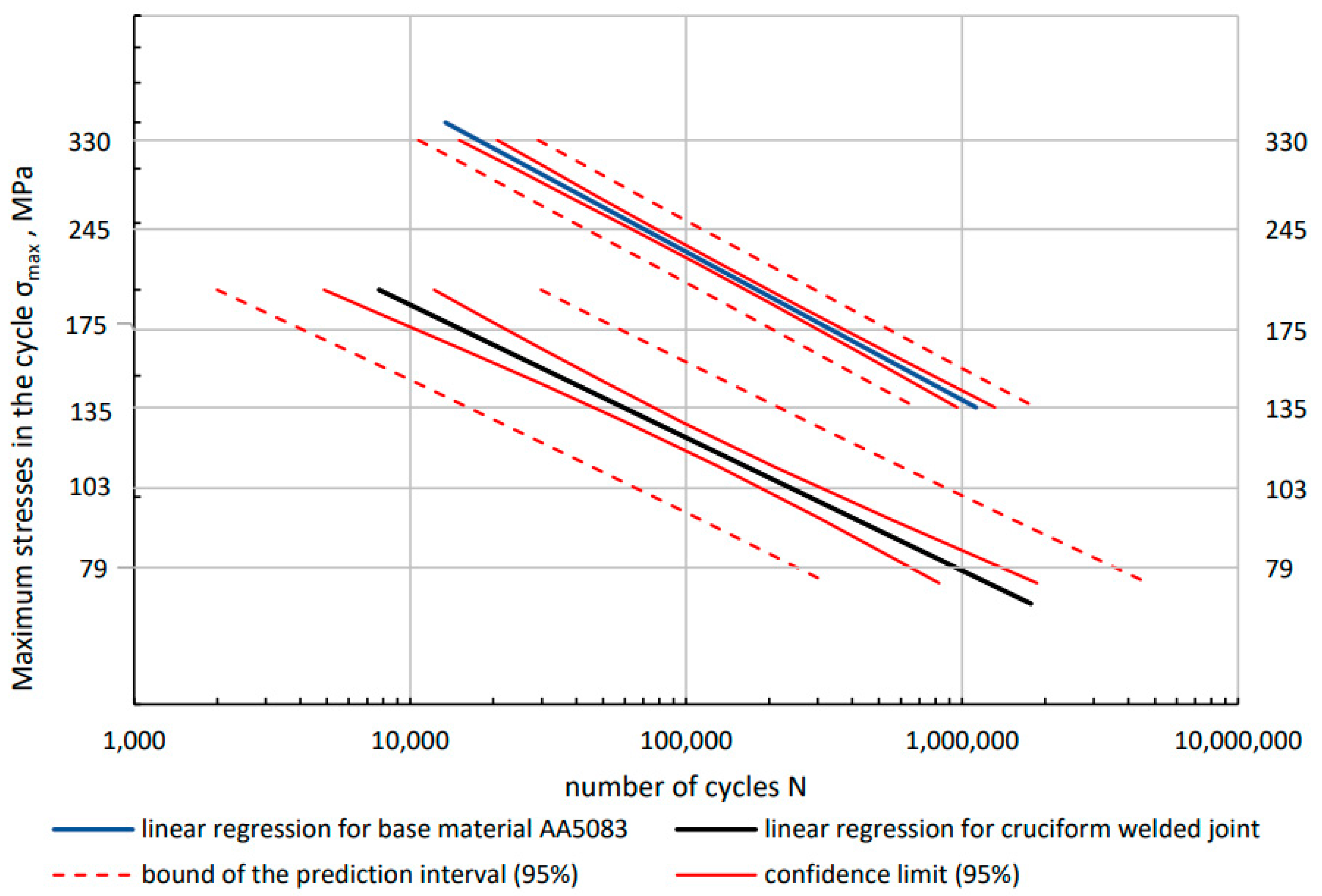

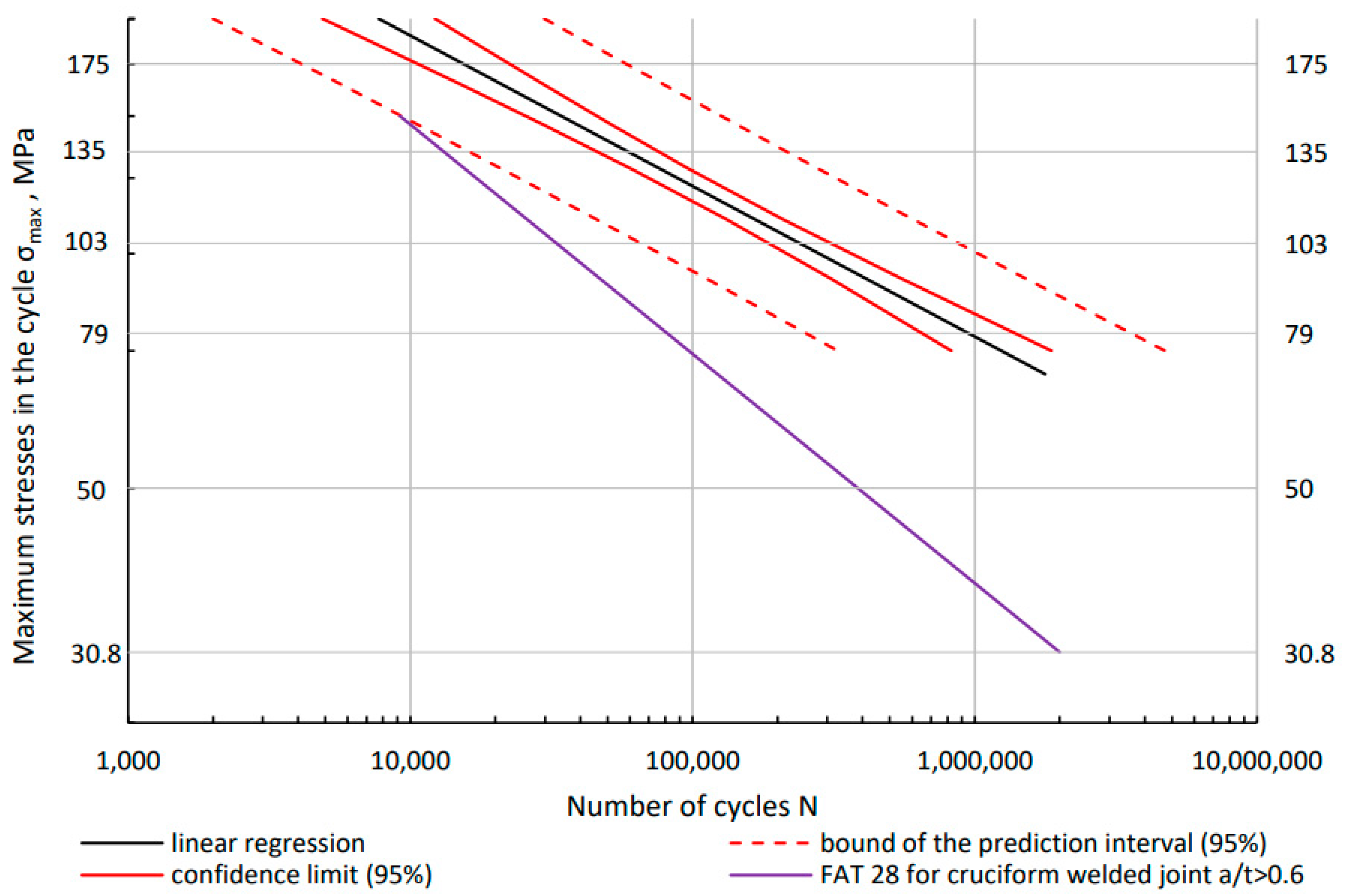

3.3. Fatigue Analysis in Terms of Stress

- m—slope of the linear regression

- A—constant of the linear regression

- m—slope exponent of S–N curve

- A—coefficient

- Δσ—nominal stress range (normal stress)

- N—total number of stress range cycles

- Nc—number of cycles (2 × 106) at which the reference fatigue strength is defined

- —reference fatigue strength

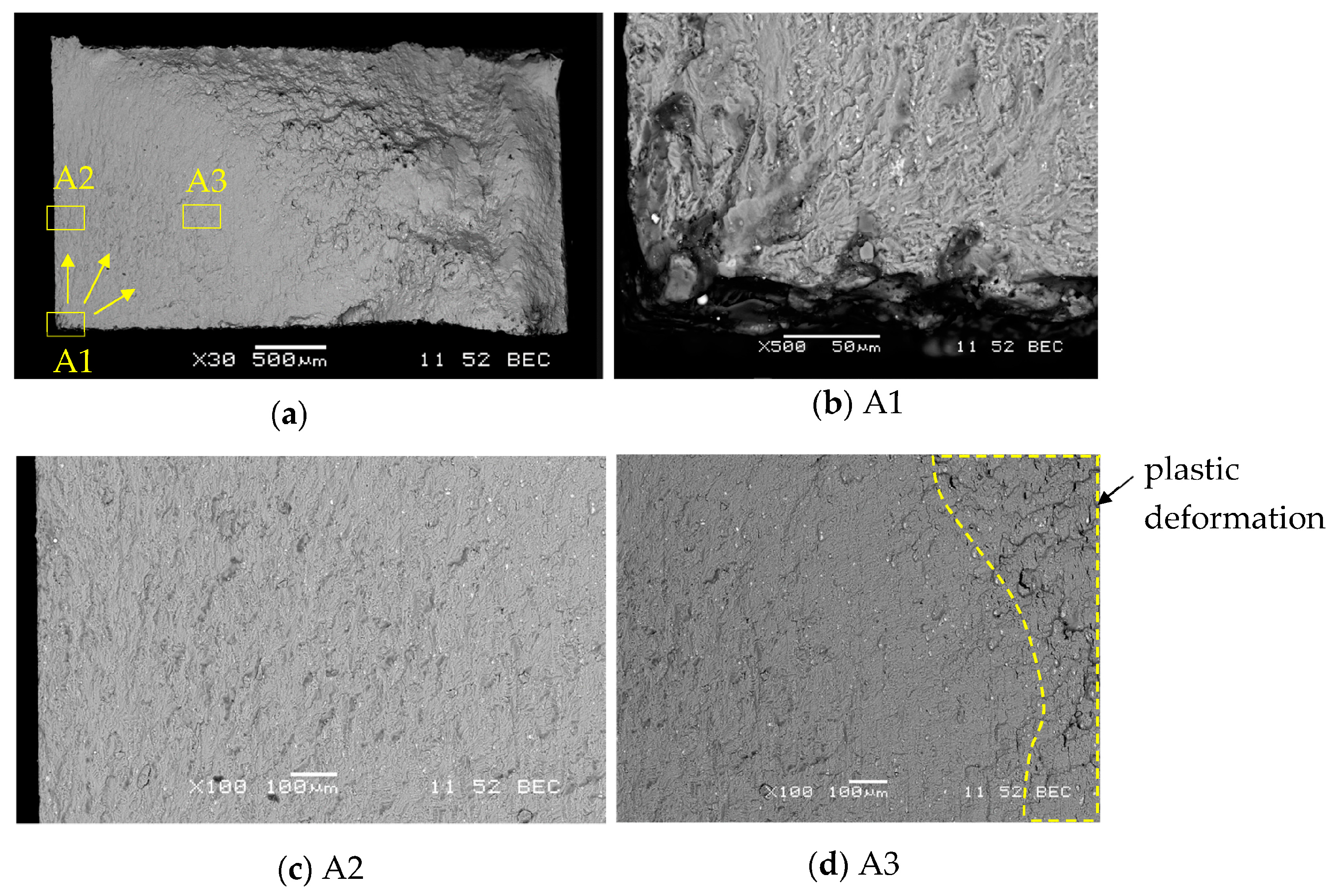

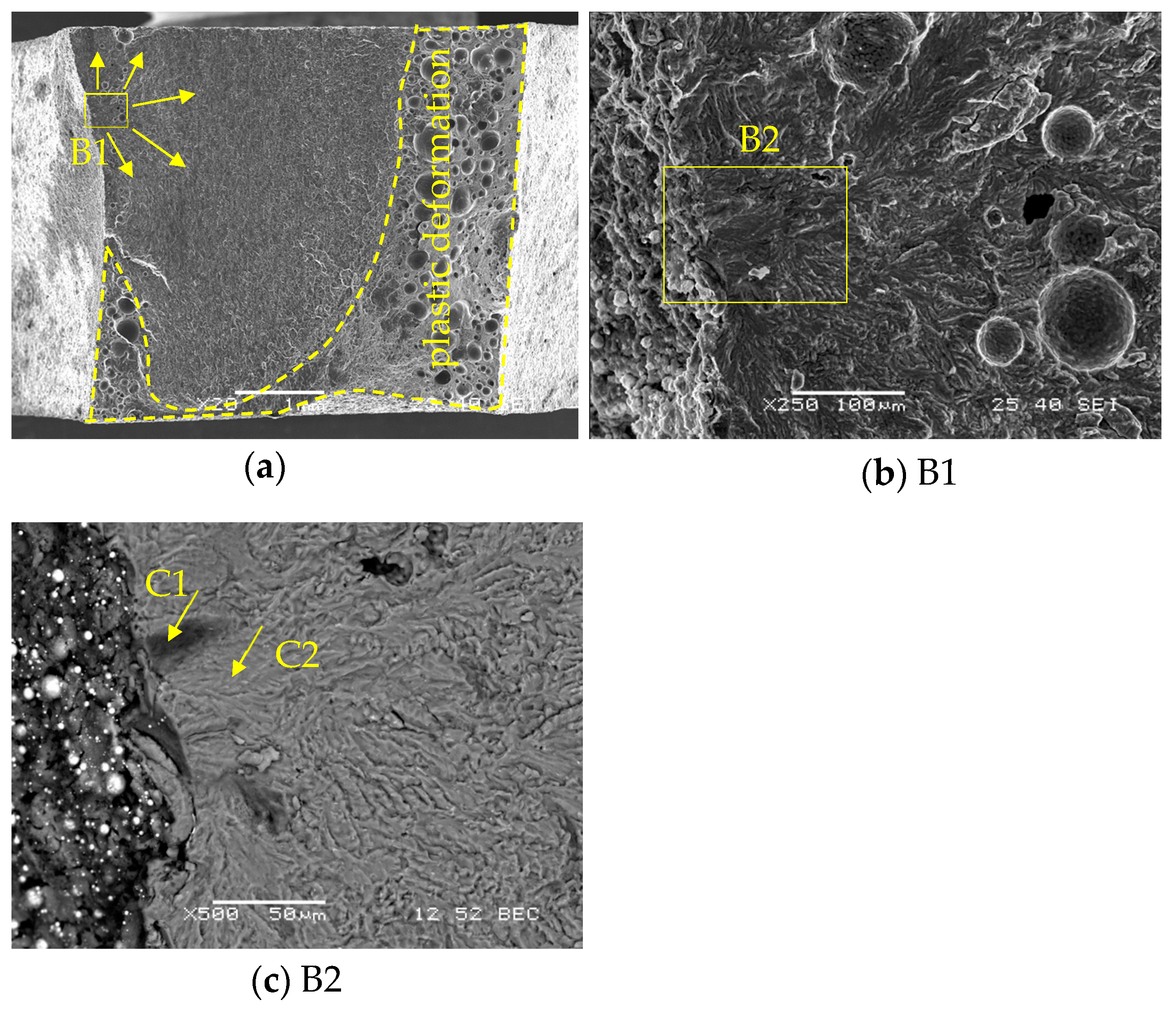

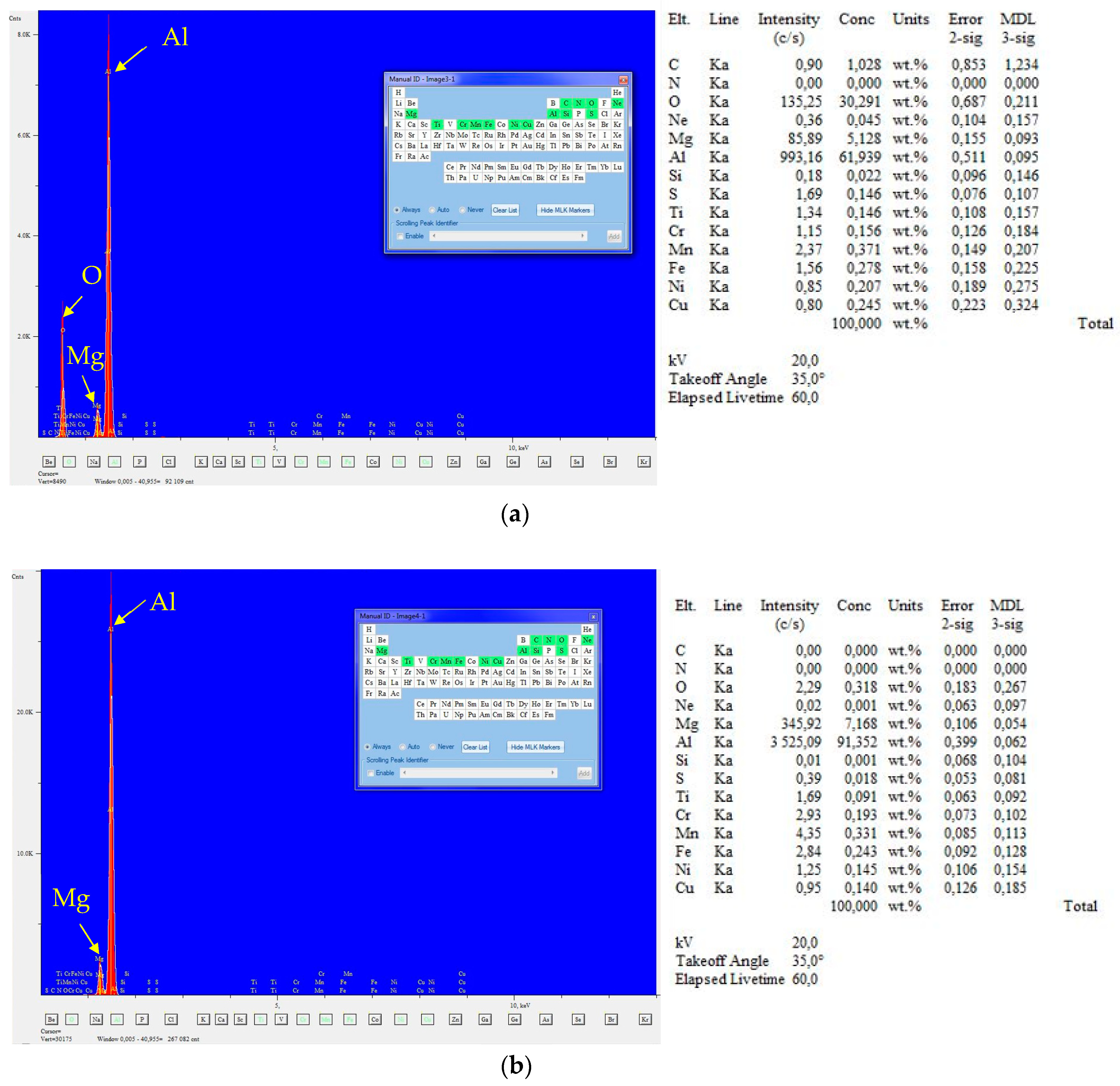

3.4. Analysis of Fatigue Fractures

4. Conclusions

- Minimized thickness of the explosive welded transition joints makes welding much more difficult due to the risk of damage to the Al/steel interface as a result of the high temperatures during welding. None of the Al/Fe welded joints subjected to fatigue tests failed in the AA1050 layer of the explosively welded transition joint. It can therefore be concluded that Al/steel welded joints can be successfully used with the use of explosively welded transition joint with reduced thicknesses.

- The obtained results of fatigue tests of Al/steel welded specimens were compared with the results of the BM AA5083. The welded joint reduces the fatigue life compared to the performance of the BM. However, a comparison of the experimental results to the design curve showed that the results of the Al/Fe combination met the design requirements.

- As expected, the welding process caused a change in the hardness of the materials in the HAZ. The reason for this is grain growth caused by the introduction of heat during welding [24].

- Failure fractures were analyzed for specimens with the lowest load level. Slower fatigue failure shows the place of crack initiation and its propagation more clearly for BM AA5083 and Al/steel welded joint.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Geng, P.; Ma, Y.; Ma, N.; Ma, H.; Aoki, H.; Liu, H.; Fujii, H.; Chen, C. Effects of rotation tool-induced heat and material flow behaviour on friction stir lapped Al/steel joint formation and resultant microstructure. Int. J. Mach. Tools Manuf. 2022, 174, 103858. [Google Scholar] [CrossRef]

- Maćkowiak, P.; Ligaj, B.; Płaczek, D.; Kotyk, M. Verification of Selected Failure Criteria for Adhesive Bonded Elements with Different Stiffness through the Use of Methacrylic Adhesive. Materials 2020, 13, 4011. [Google Scholar] [CrossRef]

- Böhm, M.; Kowalski, M. Fatigue life estimation of explosive cladded transition joints with the use of the spectral method for the case of a random sea state. Mar. Struct. 2020, 71, 102739. [Google Scholar] [CrossRef]

- 70 m Benetti Superyacht FB273 Launched—Luxury Projects. Available online: https://www.luxury-projects.it/70m-benetti-superyacht-fb273-launched/ (accessed on 10 May 2023).

- Benetti 65-Meter Custom Yacht fb274 Takes Shape. Hull and Superstructure Joined Together|Benetti Yachts. Available online: https://www.benettiyachts.it/news-events/benetti-65-meter-custom-yacht-fb274-takes-shape-hull-and-superstructure-joined-together/ (accessed on 8 May 2023).

- Trethewey, K.R. Explosion-bonded transition joints for structural applications. Constr. Build. Mater. 1989, 3, 64–72. [Google Scholar] [CrossRef]

- McKenney, C.R.; Banker, J.G. Explosion-Bonded Metals for Marine Structural Applications. Mar. Technol. SNAME News 1971, 8, 285–292. [Google Scholar] [CrossRef]

- Gaines, E.; Banker, J. Shipyard Aluminum/Steel Welded Transition Joints. Proceedings of 1991 Ship Production Symposium, San Diego, CA, USA, 6 September 1991; The Society of Naval Architects and Marine Engineers: Jersey City, NJ, USA, 1991; p. IVB4: 1–6. [Google Scholar]

- Song, W.; Liu, X.; Razavi, N. Fatigue assessment of steel load-carrying cruciform welded joints by means of local approaches. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2598–2613. [Google Scholar] [CrossRef]

- Radaj, D. Review of fatigue strength assessment of nonwelded and welded structures based on local parameters. Int. J. Fatigue 1996, 18, 153–170. [Google Scholar] [CrossRef]

- Lee, J.-M.; Seo, J.-K.; Kim, M.-H.; Shin, S.-B.; Han, M.-S.; Park, J.-S.; Mahendran, M. Comparison of hot spot stress evaluation methods for welded structures. Int. J. Nav. Archit. Ocean. Eng. 2010, 2, 200–210. [Google Scholar] [CrossRef]

- Radaj, D.; Sonsino, C.M.; Fricke, W. Recent developments in local concepts of fatigue assessment of welded joints. Int. J. Fatigue 2009, 31, 2–11. [Google Scholar] [CrossRef]

- Atzori, B.; Lazzarin, P.; Meneghetti, G. Fatigue strength assessment of welded joints: From the integration of Paris’ law to a synthesis based on the notch stress intensity factors of the uncracked geometries. Eng. Fract. Mech. 2008, 75, 364–378. [Google Scholar] [CrossRef]

- Lazzarin, P.; Tovo, R. A notch intensity factor approach to the stress analysis of welds. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 1089–1103. [Google Scholar] [CrossRef]

- Berto, F.; Campagnolo, A.; Chebat, F.; Cincera, M.; Santini, M. Fatigue strength of steel rollers with failure occurring at the weld root based on the local strain energy values: Modelling and fatigue assessment. Int. J. Fatigue 2016, 82, 643–657. [Google Scholar] [CrossRef]

- Meneghetti, G.; De Marchi, A.; Campagnolo, A. Assessment of root failures in tube-to-flange steel welded joints under torsional loading according to the Peak Stress Method. Theor. Appl. Fract. Mech. 2016, 83, 19–30. [Google Scholar] [CrossRef]

- Meneghetti, G. The peak stress method applied to fatigue assessments of steel and aluminium fillet-welded joints subjected to mode I loading. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 346–369. [Google Scholar] [CrossRef]

- Hobbacher, A. Recommendations for Fatigue Design of Welded Joints and Components. In International Institute of Welding; Springer: Cham, Switzerland, 2016. [Google Scholar]

- den Besten, H. Fatigue damage criteria classification, modelling developments and trends for welded joints in marine structures. Ships Offshore Struct. 2018, 13, 787–808. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V. Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures. Metals 2022, 12, 1010. [Google Scholar] [CrossRef]

- Song, W.; Liu, X.; Xu, J.; Fan, Y.; Shi, D.; He, M.; Wang, X.; Berto, F. Fatigue fracture assessment of 10CrNi3MoV welded load-carrying cruciform joints considering mismatch effect. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1739–1759. [Google Scholar] [CrossRef]

- Meneghetti, G.; Campagnolo, A.; Berto, D.; Pullin, E.; Masaggia, S. Fatigue strength of austempered ductile iron-to-steel dissimilar arc-welded joints. Weld. World 2021, 65, 667–689. [Google Scholar] [CrossRef]

- Boroński, D.; Skibicki, A.; Maćkowiak, P.; Płaczek, D. Modeling and analysis of thin-walled Al/steel explosion welded transition joints for shipbuilding applications. Mar. Struct. 2020, 74, 102843. [Google Scholar] [CrossRef]

- Ship Structure Committee; Anderson, T. Welding Aluminum: Questions and Answers: A Practical Guide for Troubleshooting Aluminum Welding-Related Problems, 2nd ed.; Americal Welding Society: Miami, FL, USA, 2010. [Google Scholar]

- Liu, Y.; Wang, W.; Xie, J.; Sun, S.; Wang, L.; Qian, Y.; Meng, Y.; Wei, Y. Microstructure and mechanical properties of aluminum 5083 weldments by gas tungsten arc and gas metal arc welding. Mater. Sci. Eng. A 2012, 549, 7–13. [Google Scholar] [CrossRef]

- Smith, C.B.; Mishra, R.S. Case Study of Aluminum 5083-H116 Alloy. In Friction Stir Processing for Enhanced Low Temperature Formability; Butterworth-Heinemann: Oxford, UK, 2014; pp. 19–124. [Google Scholar] [CrossRef]

- Kim, S.-J.; Kim, S.-K.; Park, J.-C. The corrosion and mechanical properties of Al alloy 5083-H116 in metal inert gas welding based on slow strain rate test. Surf. Coat. Technol. 2010, 205, S73–S78. [Google Scholar] [CrossRef]

- Milovanović, V.; Živković, M.; Jovičić, G.; Dišić, A. Experimental determination of fatigue properties and fatigue life of S355J2+N steel grade. Mater. Today Proc. 2019, 12, 455–461. [Google Scholar] [CrossRef]

- Oikonomou, A.G.; Aggidis, G.A. Determination of optimum welding parameters for the welding execution of steels used in underwater marine systems (including the submerged parts of Wave Energy Converters). Mater. Today Proc. 2019, 18, 455–461. [Google Scholar] [CrossRef]

- Wachowski, M.; Kosturek, R.; Sniezek, L.; Mróz, S.; Gloc, M.; Krawczyńska, A.; Malek, M. Analysis of the microstructure of an AZ31/AA1050/AA2519 laminate produced using the explosive-welding method. Mater. Tehnol. 2019, 53, 239–243. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Rogalski, G.; Fydrych, D.; Walczak, W. Zastosowanie zgrzewania wybuchowego do wytwarzania kompozytów metalowych z osnową aluminiową. Weld. Technol. Rev. 2013, 85, 54–59. [Google Scholar] [CrossRef]

- ISO 18273; Welding Consumables—Wire Electrodes, Wires and Rods for Welding of Aluminium and Aluminium Alloys—Classification. ISO: Brussels, Belgium, 2015.

- Tricarico, L.; Spina, R. Experimental investigation of laser beam welding of explosion-welded steel/aluminum structural transition joints. Mater. Des. 2010, 31, 1981–1992. [Google Scholar] [CrossRef]

- ISO 14341; Welding Consumables—Wire Electrodes and Weld Deposits for Gas Shielded Metal Arc Welding of Non Alloy and Fine Grain Steels—Classification. ISO: Brussels, Belgium, 2020.

- Sonsino, C.M.; Radaj, D.; Brandt, U.; Lehrke, H.P. Fatigue assessment of welded joints in AlMg 4.5Mn aluminium alloy (AA 5083) by local approaches. Int. J. Fatigue 1999, 21, 985–999. [Google Scholar] [CrossRef]

- Aluminum Structure Design and Fabrication Guide; Report No. SSC-452; Ship Structure Committee: Washington, DC, USA, 2007.

- EN 1999-1-3; Eurocode 9: Design of Aluminium Structures—Part 1–3: Structures Susceptible to Fatigue. CEN: Brussels, Belgium, 2011.

| C | Si | Mn | P | S | N | Al | Cu | Cr | Ni | Mo | Nb | Ti | V | Fe | Mg | Zn | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AA5083 | - | 0.11 | 0.77 | - | - | - | balance | 0.09 | 0.06 | - | - | - | 0.01 | - | 0.31 | 4.7 | 0.01 |

| AA1050 | - | 0.12 | 0.02 | - | - | - | 99.52 | - | - | - | - | - | 0.03 | - | 0.27 | - | - |

| S355J2+N | 0.14 | 0.05 | 1.5 | 0.015 | 0.001 | 0.006 | 0.038 | 0.03 | 0.04 | 0.04 | 0.01 | 0.01 | 0.002 | 0.004 | - | - | - |

| Material | , MPa | , MPa | , % | E, MPa | |

|---|---|---|---|---|---|

| Explosive welding transition joint (TJ) | S355J2+N | 527 | 606 | 25 | 210,000 |

| AA1050 | 101 | 107 | 5 | 73,000 | |

| AA5083 | 257 | 356 | 14 | 71,000 | |

| Base material (BM) | S355J2+N | 370 | 524 | 27 | 207,300 |

| AA5083 | 225 | 362 | 15 | 77,000 |

| Weld | Welding Speed [mm/min] | I [A] | U [V] | Wire Feed [m/min] | Power P [W] |

|---|---|---|---|---|---|

| AA5083 | 541 | 136 | 18.6 | 7.4 | 2630 |

| S355J2+N | 436 | 145 | 19.5 | 10.4 | 2815 |

| HAZ | Weld | AA1050 | AA5083 TJ | AA5083 BM | |

|---|---|---|---|---|---|

| After welding | 86.6 | 77.6 | 28.2 | 87.1 | 82.9 |

| Before welding | - | - | 49.2 | 120.0 | 96.3 |

| Al/Fe Welded Joints | AA5083 (BM) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Specimen | Stress σ | Number of Cycles N | log σ | log N | Fatigue Failure Points | Number of Specimen | Stress σ | Number of Cycles N | log σ | log N |

| MPa | - | - | - | MPa | - | - | - | |||

| Al/steel_1 | 79 | 3,765,329 | 1.8976 | 6.5758 | root | AA5083_1 | 135 | 1,536,149.00 | 2.1303 | 6.1864 |

| Al/steel_2 | 79 | 947,946 | 1.8976 | 5.9768 | root | AA5083_2 | 135 | 881,809.75 | 2.1303 | 5.9454 |

| Al/steel_3 | 79 | 452,000 | 1.8976 | 5.6551 | root | AA5083_3 | 135 | 782,027 | 2.1303 | 5.8932 |

| Al/steel_4 | 79 | 686,373 | 1.8976 | 5.8366 | root | AA5083_4 | 135 | 1,471,946.75 | 2.1303 | 6.1679 |

| Al/steel_5 | 79 | 2,278,247 | 1.8976 | 6.3576 | root | AA5083_5 | 135 | 1,768,942 | 2.1303 | 6.2477 |

| Al/steel_6 | 79 | 581,135 | 1.8976 | 5.7643 | toe | AA5083_6 | 135 | 1,009,250 | 2.1303 | 6.004 |

| Al/steel_7 | 79 | 552,342 | 1.8976 | 5.7422 | toe | AA5083_7 | 180 | 211,199.75 | 2.2553 | 5.3247 |

| Al/steel_8 | 79 | 313,957 | 1.8976 | 5.4969 | toe | AA5083_8 | 180 | 175,191,75 | 2.2553 | 5.2435 |

| Al/steel_9 | 103 | 337,235 | 2.0128 | 5.5279 | root | AA5083_9 | 180 | 286,420.25 | 2.2553 | 5.457 |

| Al/steel_10 | 103 | 224,644 | 2.0128 | 5.3515 | root | AA5083_10 | 180 | 27,484.75 | 2.2553 | 5.4391 |

| Al/steel_11 | 103 | 262,865 | 2.0128 | 5.4197 | toe | AA5083_11 | 180 | 318,084.75 | 2.2553 | 5.5025 |

| Al/steel_12 | 103 | 508,069 | 2.0128 | 5.7059 | root | AA5083_12 | 180 | 337,226.5 | 2.2553 | 5.5279 |

| Al/steel_13 | 103 | 418,474 | 2.0128 | 5.6217 | root | AA5083_13 | 180 | 342,419 | 2.2553 | 5.5346 |

| Al/steel_14 | 103 | 264,370 | 2.0128 | 5.4222 | toe | AA5083_14 | 245 | 78,532.75 | 2.3892 | 4.8951 |

| Al/steel_15 | 103 | 141,606 | 2.0128 | 5.1511 | toe | AA5083_15 | 245 | 78,859.00 | 2.3892 | 4.8969 |

| Al/steel_16 | 103 | 170,746 | 2.0128 | 5.2324 | root | AA5083_16 | 245 | 83,264.00 | 2.3892 | 4.9205 |

| Al/steel_17 | 135 | 21,845 | 2.1303 | 4.3394 | root | AA5083_17 | 245 | 66,117.75 | 2.3892 | 4.8203 |

| Al/steel_18 | 135 | 221,116 | 2.1303 | 5.3446 | root | AA5083_18 | 245 | 61,106.75 | 2.3892 | 4.7861 |

| Al/steel_19 | 135 | 136,318 | 2.1303 | 5.1346 | toe | AA5083_19 | 245 | 79,962.5 | 2.3892 | 4.9029 |

| Al/steel_20 | 135 | 56,302 | 2.1303 | 4.7505 | toe | AA5083_20 | 245 | 64,683 | 2.3892 | 4.8108 |

| Al/steel_21 | 135 | 58,127 | 2.1303 | 4.7644 | root | AA5083_21 | 330 | 22,573.75 | 2.5185 | 4.3536 |

| Al/steel_22 | 135 | 40,012 | 2.1303 | 4.6022 | root | AA5083_22 | 330 | 14,957.75 | 2.5185 | 4.1749 |

| Al/steel_23 | 135 | 80,025 | 2.1303 | 4.9032 | toe | AA5083_23 | 330 | 14,274.75 | 2.5185 | 4.1546 |

| Al/steel_24 | 135 | 65,245 | 2.1303 | 4.8145 | root | AA5083_24 | 330 | 19,495.75 | 2.5185 | 4.2899 |

| Al/steel_25 | 175 | 16,508 | 2.243 | 4.2177 | root | AA5083_25 | 330 | 17,583.50 | 2.5185 | 4.2451 |

| Al/steel_26 | 175 | 6647 | 2.243 | 3.8226 | root | AA5083_26 | 330 | 19,124.75 | 2.5185 | 4.2816 |

| Al/steel_27 | 175 | 12,049 | 2.243 | 4.081 | root | |||||

| Al/steel_28 | 175 | 9300 | 2.243 | 3.9685 | root | |||||

| Al/steel_29 | 175 | 17,890 | 2.243 | 4.2526 | toe | |||||

| Al/steel_30 | 175 | 27,472 | 2.243 | 4.4389 | root | |||||

| Al/steel_31 | 175 | 12,011 | 2.243 | 4.0796 | root | |||||

| Al/steel_32 | 175 | 15,615 | 2.243 | 4.1935 | root | |||||

| M | A | R2 | σmax for N = 5 × 106 | |

|---|---|---|---|---|

| - | - | - | MPa | |

| AA5083 (BM) | 4.65 | 15.95 | 0.98 | 99.5 |

| Al/Fe Transition Joint | 5.18 | 15.80 | 0.87 | 63.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Płaczek, D.; Maćkowiak, P.; Boroński, D. Fatigue Analysis of Welded Joints Using a Thin-Walled Al/Fe Explosive Welded Transition Joints. Materials 2023, 16, 6259. https://doi.org/10.3390/ma16186259

Płaczek D, Maćkowiak P, Boroński D. Fatigue Analysis of Welded Joints Using a Thin-Walled Al/Fe Explosive Welded Transition Joints. Materials. 2023; 16(18):6259. https://doi.org/10.3390/ma16186259

Chicago/Turabian StylePłaczek, Dominika, Paweł Maćkowiak, and Dariusz Boroński. 2023. "Fatigue Analysis of Welded Joints Using a Thin-Walled Al/Fe Explosive Welded Transition Joints" Materials 16, no. 18: 6259. https://doi.org/10.3390/ma16186259

APA StylePłaczek, D., Maćkowiak, P., & Boroński, D. (2023). Fatigue Analysis of Welded Joints Using a Thin-Walled Al/Fe Explosive Welded Transition Joints. Materials, 16(18), 6259. https://doi.org/10.3390/ma16186259