1. Introduction

Antifouling coatings are commonly applied to the hull and propeller of boats to minimize or eliminate the deposition of marine organisms and algae. In fact, these naturally settle on the submerged surfaces of boats creating incrustation, or biofouling, that can damage the surface itself. Moreover, during navigation, the accumulation of biofouling slows down the boat with a consequent increase in fuel consumption, therefore considered an urgent environmental and economic concern [

1,

2].

From an economic point of view, the application of the antifouling coating entails several expenses, such as the cost of maintenance of the boat, the cost related to the cleaning of the hull, the costs of removing the paint, and the cost of the paint itself. At the same time, the application of the coating is necessary to avoid decreasing the speed of the boat, for a personal safety factor and to consume less fuel. From an environmental point of view, however, the use of antifouling products represents a problem for the marine environment as they contain biocides, i.e., toxic substances that prevent the formation of incrustations, but at the same time pollute the marine environment [

2]. In fact, these biocidal toxins can slow down the proliferation of parasites such as algae, silt, coralline and other species, thus preventing the formation of biofouling on the hull of boats. These additives, in addition to being highly toxic, are also poorly biodegradable, therefore they can remain in marine sediments for a long time [

3]. In this context, more eco-friendly alternatives are required.

New antifouling biocides are transforming into less toxic products [

4], with a low tendency to bioaccumulate [

5], and a low toxicity to non-target organisms [

6,

7]. However, most of the research works focused on the evaluation of the chemical, physical, and mechanical properties of antifouling coatings without considering their environmental and economic impact [

8]. Among these, most of the studies investigated the effect on fisheries [

9,

10] and maritime transport [

11,

12], while there are not comprehensive studies that evaluate the environmental and economic impacts of antifouling paints only.

The choice of the right antifouling coating depends on several factors, e.g., type of boat, type of water, use, and frequency. It is therefore necessary to consider whether it is a fast boat rather than a slow one, if it is used frequently or occasionally, if it remains in the water all year round, or if it is stored appropriately during the winter. In general, antifouling paints can be divided into two distinct groups based on their composition: (i) self-polishing and (ii) hard-matrix paints. The self-polishing antifouling paints, also defined as water-soluble, self-cleaning, or ablative, have a combined chemical/mechanical action which increases their effectiveness [

13]. The chemical action of the water and the mechanical action of the movement of the boat regenerate each coat of antifouling applied [

14]. This type of paint has been designed to wear out during use, while keeping a new and smooth surface, against any type of marine incrustation. In fact, the water is gradually absorbed causing a gradual dissolution of the matrix. It is important to specify that the renewal takes place in the order of microns so there is no risk that the paint is completely consumed during the season. This feature makes self-polishing antifouling paints unsuitable for extremely fast boats. Furthermore, due to their progressive thinning during navigation, the removal of the remaining layers at the end of the season will be much easier. The advantages of applying this type of paint are the excellent protection of the submerged surface thanks to the combined chemical and mechanical action and easy removal using a pressure washer [

14]. On the other hand, hard-matrix antifouling paints act only chemically. Being based on a polymeric binder, they are very resistant to abrasion and for this reason they represent an excellent solution for fast boats or frequently hauled or wheeled ones [

15]. Moreover, they generally have lower costs than self-polishing antifouling paints and, as they suffer less from changes in water conditions, they are also suitable for long navigations [

16].

Among the strategies to produce an effective and eco-sustainable antifouling marine paint, amphiphilic coatings represent the most promising solution [

17,

18]. However, most of the compositions contain fluorinate species for the formation of the hydrophobic moieties [

19,

20], which are potentially toxic for the marine environment [

21,

22]. Moreover, the procedures adopted to produce such coatings are very complicated and time-consuming, therefore preventing their implementation in a proper paint product [

23]. To simplify the procedure, different alternatives have been proposed so far, e.g., by introducing surfactants into coating systems [

24], by using polyurethanes [

25], or through sol-gel processes [

26]. While the first two procedures still require long time and high temperature, sol-gel chemistry can provide a fast and easy to implement alternative [

27].

In this context, the present study aims at proposing the evaluation of the environmental and economic impact of an innovative hard-matrix amphiphilic formulation prepared via a sol-gel process [

23]. The authors evaluated different strategies to manufacture amphiphilic coating systems, verifying the feasibility of the proposed method for the manufacturing of anti-fouling paints, through wettability analysis, as well as through an assessment of anti-fouling activity of the coatings [

18,

23]. In particular, previous works verified the effective antifouling/foul-release action of the coatings using a natural protein probe, namely white egg [

18,

23], as well as testing them against marine organisms, such as mussels and algae [

17]. The excellent results obtained in tests against amphiphilic proteins, such as white egg, well simulated the behavior of amphiphilic gluing proteins used by most of marine organisms, animal or vegetal, to adhere to the surfaces of a hull, thus verifying the effectiveness of the innovative amphiphilic coatings developed [

17,

23].

The next step, here investigated, concerns the life cycle assessment and the life cycle costing evaluation of the proposed coating intended for naval applications. To this end, the first activity involved the study of the materials, energy, and waste flows, associated with each phase of the life cycle, i.e., paint production, application, navigation, and disposal. Then, an environmental assessment was performed in order to verify the eco-compatibility of the innovative solution, evaluating the savings in terms of fuel consumption, linked to the increased efficiency of the antifouling action, which improves boat’s hydrodynamic performance, and comparing both its life cycle and CO2 production with the traditional solution. Finally, an economic assessment of the production, application, navigation and disposal costs, for a diesel-powered motor yacht, was completed, in order to evaluate the economics benefits linked to fuel consumption reduction and biocides absence during all the life cycle.

2. Materials and Methods

The present work aims at comparing, from both the economic and the environmental point of view, the impact of an innovative biocide-free antifouling coating for naval applications, named EXP in the following, against the traditional commercial paint “Unigloss” sold by Veneziani Yachting (Boero, Genoa, Italy) [

28], with the addition of two biocides, i.e., tralopyril [

29] and zinc pyrithione [

30], named TRD. The following sections highlight the main characteristics. However, it is worth mentioning here that the innovative biocide-free coating has been previously demonstrated to have antifouling properties against amphiphilic proteins, using white egg as testing probe [

18,

23], as well as testing them against marine organisms [

17], thus proving the effectiveness of the innovative hard-matrix amphiphilic formulation in producing a robust antifouling coating [

23].

The Life Cycle Assessment (LCA) and the Life Cycle Costing (LCC) methodologies have been considered to evaluate the environmental and economic negative impacts and benefits in decision-making processes towards a more sustainable antifouling paint throughout its life cycle.

The LCA is a methodology that allows to record, quantify, and evaluate the environmental footprint of a specific product or service along its entire life cycle. It is a standardized procedure [

31,

32] that examines the entire life of a product “from cradle to grave” [

33]. This therefore means that the entire process is analyzed starting from the extraction of raw materials up to their disposal, through their use and consumption [

34]. The same procedure is applied through the LCC methodology [

35], but with the aim of evaluating the costs associated with the life cycle of the product.

2.1. Life Cycle Assessment

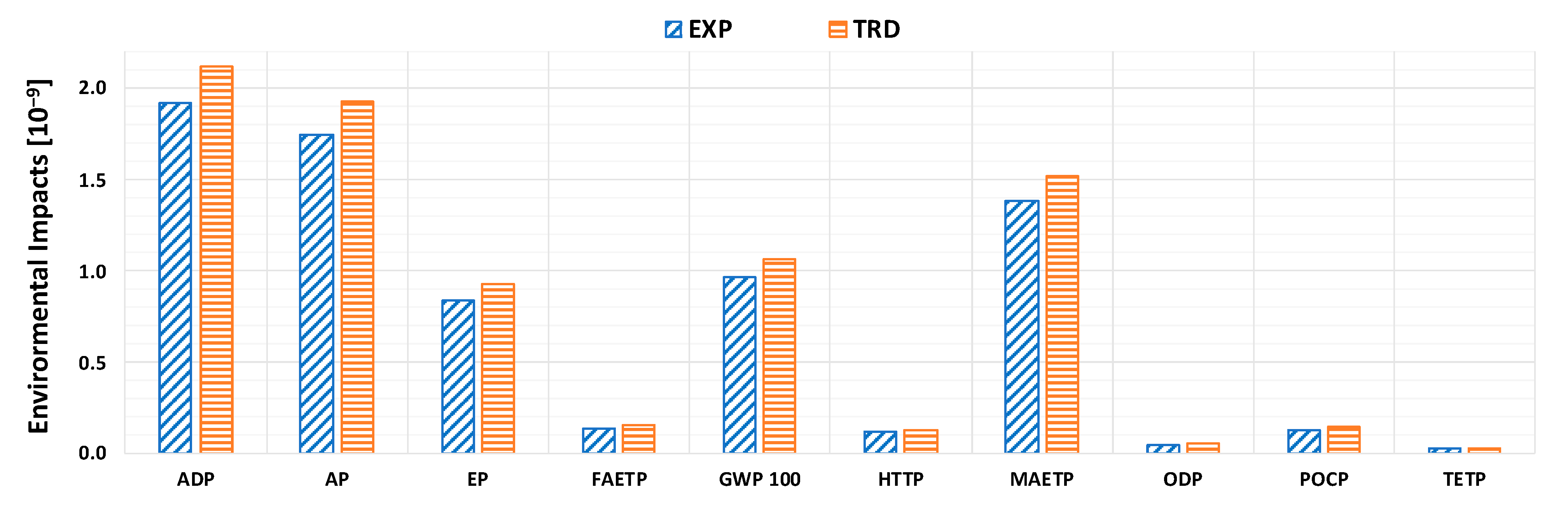

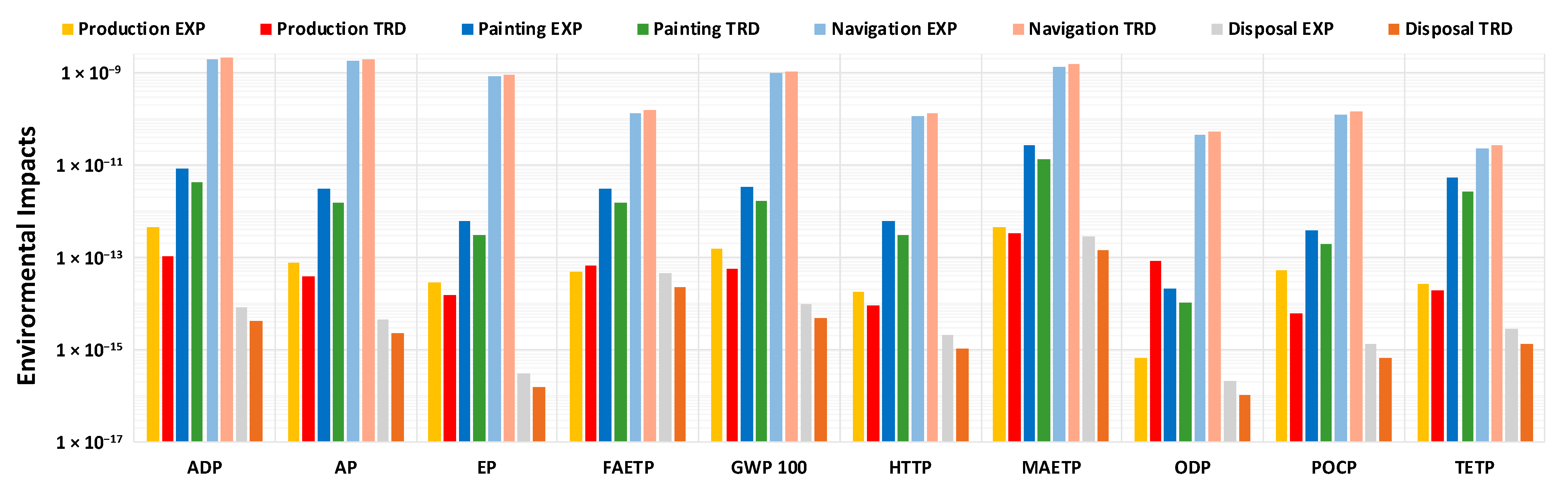

The LCA analysis has been carried out by using the software SimaPro® 7.1. The latter allows the creation of models related to the entire life cycle of a product with the aim of analyzing and quantifying the environmental impact. Moreover, it is possible to compare the results with those of other products, identifying any critical issue within the life cycle, through CML 2001 baseline method.

In general, the Life Cycle Assessment methodology is divided into four phases, which will be analyzed in detail in the following sections:

definition of scope and objective,

inventory analysis,

assessment of potential environmental impact,

interpretation and improvement of results.

2.1.1. Definition of Scope and Objective

In this first phase, the most important decisions are made and the study of the entire LCA analysis is planned. To implement the analysis, three main items must be defined:

- 5.

the target of the study, which in this case is to analyze the environmental sustainability of two antifouling paints, whose function is to protect the hull of boats from any biological incrustations;

- 6.

the functional unit, which is chosen as the painting coverage of 1 m2 of hull;

- 7.

the system limits, which correspond to the entire hull coating life cycle, therefore starting from the extraction of raw materials up to the disposal of waste.

It is important to underline that for the operational phase of the paint, 500 h of use of the boat per year will be considered and that the application of the two coatings was performed on the same boat, i.e., a motor yacht, 23.6 m long, 5.5 m wide, with a hull surface of 105 m2.

2.1.2. Inventory Analysis

In this second phase, the flows of materials and energy (input) and waste (output) are defined, taking into consideration the entire life of the products and building an appropriate model. Specifically, the following will be analyzed:

the stage of production of 1 kg of paint;

the painting process of 1 m2 of hull;

the annual fuel consumption for a total of 500 h of navigation.

Production Process

Table 1 and

Table 2 report the formulations used to produce 1 kg of paints, respectively for the innovative and the traditional coatings. Each material of the two formulations corresponds to a specific item within the SimaPro

® 7.1 software database.

Painting Process

For the application of the coatings, data are calculated considering a surface of 1 m2 of hull, and that the innovative painting is applied twice per year while the traditional one only once per year. Seven steps were involved to create the process trees, which were applied with the same procedures and on the same vessel:

- 8.

the boat is transported on land with consequent fuel consumption, and the hull is cleaned using a pressure washer, with consumption of water and low voltage (LV) electricity;

- 9.

the old paint is removed with an orbital pneumatic sander, which involves the use of both the compressed air machine and the use of abrasive paper discs;

- 10.

the surface is prepared for the application of the new antifouling coating. The same sander as the previous step is used, which involves the use of both the compressed air machine and the abrasive paper discs;

- 11.

the parts of the boat that do not require the coating are covered with paper tape and plastic sheets;

- 12.

the primer and a thinner are applied to the hull of the boat using a spray gun;

- 13.

the hull of the boat is coated with antifouling paint by using the same spray gun of the previous step;

- 14.

the boat is brought back to the sea, ready for sailing.

Table 3 reports the items consumed during the seven steps and their values.

Navigation

The annual diesel consumption is calculated on the basis of an average of 500 h of navigation per year, according to [

36]. In the literature, the lifetime of a motor yacht is estimated between 20 and 30 years [

37,

38], so in the present work an average value of 25 years was set for the ship navigation phase, in accordance with other papers [

36,

39].

Table 4 reports the mean fuel consumption during the navigation phase for both paintings, based on experimental towing campaigns, carried out with ~2.5 m scale model boats DTMB (David Tailor Model Basin USA, Series 62-4667-1), into the Iseo Lake (Lombardy, Italy), sailing at a speed of 7.65 m/s, i.e., ~15 knots.

The towing campaigns, by data detection via IMU electronic control unit (such as speed, trim angles, pitch, roll, and yaw), strain gauge load cell (sensitivity of at least one gram of load), plus analogical detection on the towing dynamometer, were applied on clean and heavily fouled hulls, analyzing the trends of the resistance-velocity (R-V) curves for the two coatings. No differences were detected for clean boats, while experimental tests showed a better performance for tests conducted on heavily-fouled hulls painted with the EXP coating. Scaling up the performance from the model to a 120 tons motor yacht, with a hull surface of ~157.33 m

2, equipped with a ~2.65 MW 4xVolvo D13-900 engine, the presence of a strong layer of vegetation, more detrimental for the TRD coating, results in an estimated hourly diesel consumption of approximately 41 kg/h higher than the EXP, due to a higher absorption of required power of ~200 kW. It follows that the application of EXP coating allows a significant slowdown in the vegetation growth over time, and a consequent improvement of the hydrodynamic performance of the hull, resulting in a reduction of the hourly fuel consumption of ~0.26 kg/(h × m

2), as reported in

Table 4.

Finally, data obtained on hourly specific fuel consumption, i.e., for 1 m2 of hull surface, were used to model the sailing phase of the motor yacht under investigation, i.e., with a hull surface of 105 m2.

Disposal

For the disposal of each material used in the production and application phase of the paints, the conditions selected on the SimaPro® SW are based on the following assumptions:

For abrasive discs, an inert landfill disposal process is considered, since they are nonhazardous wastes;

For both plastic sheets and paper scotch, an end-of-life recycling process is considered;

For paints, primer and solvents residues, waste from the coating stage, disposal within a hazardous waste incinerator is considered;

For the water, necessary for the boat cleaning phase, a purification process of the sewage is considered.

Table 5 reports the items consumed during the seven steps and their values.

2.2. Life Cycle Costing

To carry out the economic assessment the following assumptions were made:

all the costs must be considered before tax;

all costs are average values referring to the year 2022;

all the processes involved are located in Italy.

Table 6 reports the items considered for the estimation of the production costs of the two paints, based on the formulations reported in

Table 1 and

Table 2, considering the production of paint batches of 150 kg. While

Table 7 lists the hypotheses related to the painting process (i.e., manpower, electricity, diesel, water, etc.). It is worth noting that the values reported in the latter tables are chosen according to the authors’ experience and the available information of datasheets and producers’ reports.

In order to estimate the total costs, it should be considered the consumption of the machinery, i.e., the pneumatic orbital sander with compressed air used in steps 2 and 3, and the spray gun for steps 5 and 6. Based on a mean efficiency value of 0.7 of the air compressor, as well as on an operating pressure of 6.2 bar, for both the pneumatic orbit sander and the spray painting equipment, it was possible to derive the electrical power absorbed by the machinery, based on the volumetric flow rate, as well as the absorbed energy and the overall cost.

Table 8 reports the values adopted. The cost for using these two machines is the same for the two types of paint applied. Finally, the waste created during the painting process is disposed of. In

Table 9, the costs for the disposal of each individual material have been calculated, divided by category.

Finally, to model the life cycle costs for 25 years of service, the presence of a sailor and a captain on the yacht for the entire annual navigation period, i.e., 500 h/y, was considered. An hourly cost of ~19.23 EUR/h for a captain, and ~9.62 EUR/h for a deckhand, respectively, was considered, in accordance with the Italian national contracts for 2022.