Multi-Force Bio-Active™ Archwires and Various Contemporary NiTi Multi-Force Archwires: Properties and Characteristics—A Review

Abstract

1. Introduction

2. Brief Historical Overview of NiTi Archwires

2.1. The First Superelastic Wires

2.2. Thermodynamic Wires

2.3. Graded Thermodynamic NiTi (GT-NiTi) Archwires

3. Thermal Properties of Multi-Force NiTi Archwires

4. Mechanical Properties of Multi-Force NiTi Archwires

5. Overview of Various Studies on the Bio-Active™ and Contemporary Multi-Force NiTi Archwires

5.1. Bio-Active™ and TriTanium™ Multi-Force NiTi Archwire: Physicochemical, Mechanical, and Thermal Properties

5.2. Multi-Force NiTi Archwires

5.3. General Characteristics of the Studies

6. Concluding Remarks

- Multi-force archwires are made of NiTi alloys and have no additional elements mixed in, whereas the Bio-active ones contain traces of Fe and Cr, which should be taken into account for patients with allergies.

- With their graduated biologically tolerable forces, multi-force archwires are particularly suitable for patients with periodontal problems and minimal crowding.

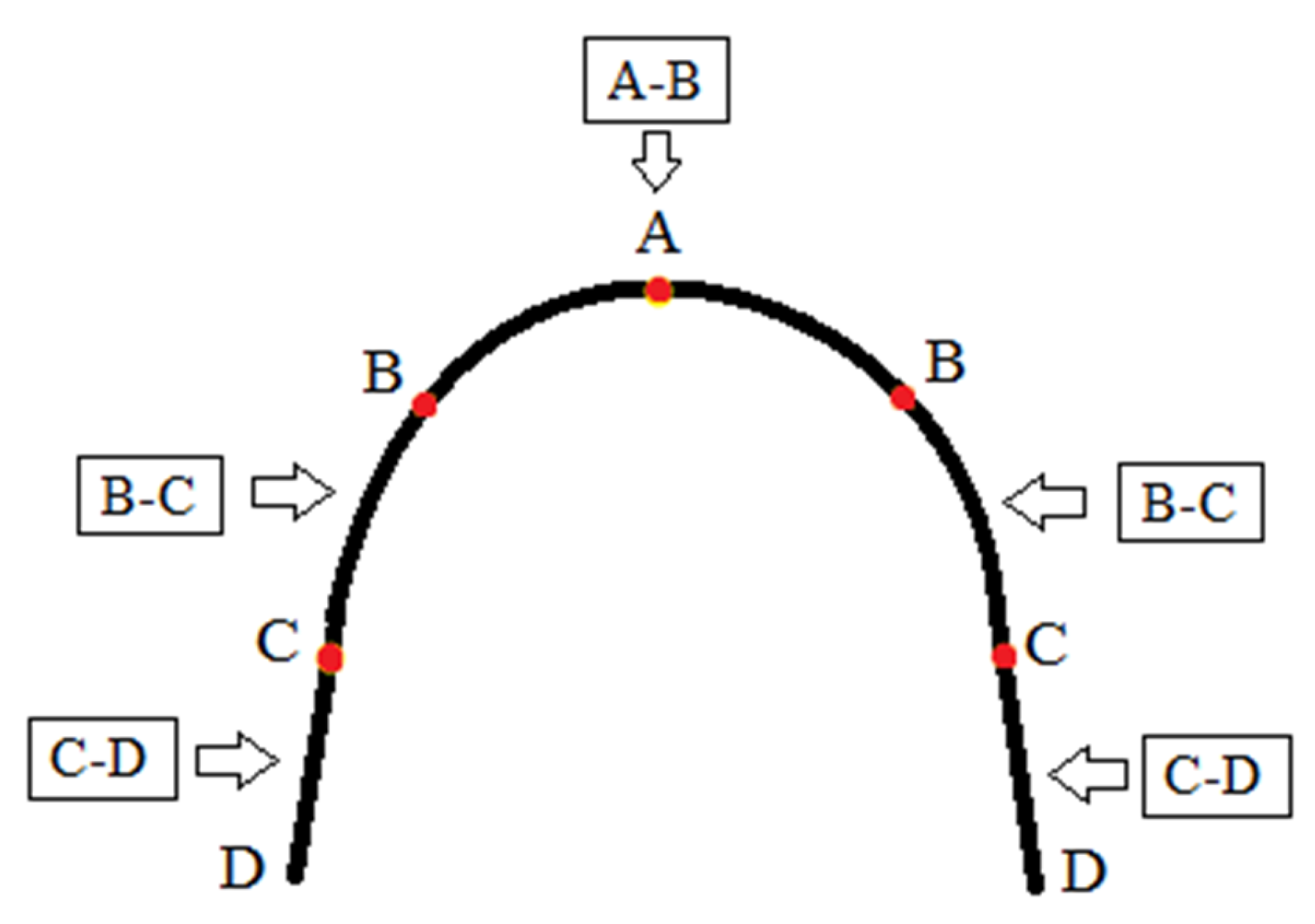

- In general, multi-force NiTi archwires release progressively increasing forces in a front-to-back direction along their length, while CuNiTi wires have a greater operating range than NiTi due to the material’s more horizontal force-deflection curve, providing a continuous, steady, and almost constant force along the tooth’s transition path during movement.

- Over a period of up to and exceeding 8 weeks, multi-force archwires (Bio-active and TriTanium) maintain their mechanical properties, reducing the need for patients to visit their treating orthodontist each month.

- The thermal properties of multi-force archwires depend on external factors, allowing patients to regulate the released forces by consuming cold or warm foods and drinks. Additional cooling can enable the use of Bio-Active and TriTanium archwires as, first, leveling archwires, but they are not recommended for patients with mouth breathing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schwarz, A.M. Tissue Changes Incidental to Orthodontic Tooth Movement. Int. J. Orthod. Oral Surg. Radiogr. 1932, 18, 331–352. [Google Scholar] [CrossRef]

- Proffit, W.R.; Fields, H.; Msd, D.M.; Larson, B.; Sarver, D.M. Contemporary Orthodontics: South Asia Edition—E-Book, 6th ed.; Elsevier: Gurugram, India, 2019. [Google Scholar]

- Wang, Y.; Liu, C.; Jian, F.; McIntyre, G.T.; Millett, D.T.; Hickman, J.; Lai, W. Initial Arch Wires Used in Orthodontic Treatment with Fixed Appliances. Cochrane Database Syst. Rev. 2018, 7, CD007859. [Google Scholar] [CrossRef] [PubMed]

- Ballard, D.J.; Jones, A.S.; Petocz, P.; Darendeliler, M.A. Physical Properties of Root Cementum: Part 11. Continuous vs. Intermittent Controlled Orthodontic Forces on Root Resorption. A Microcomputed-Tomography Study. Am. J. Orthod. Dentofac. 2009, 136, 8.e1–8.e8. [Google Scholar] [CrossRef]

- Burstone, C.J. Variable-Modulus Orthodontics. Am. J. Orthod. 1981, 80, 1–16. [Google Scholar] [CrossRef]

- Linge, L.; Linge, B.O. Patient Characteristics and Treatment Variables Associated with Apical Root Resorption during Orthodontic Treatment. Am. J. Orthod. Dentofac. 1991, 99, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Burstone, C.J.; Qin, B.; Morton, J.Y. Chinese NiTi Wire—A New Orthodontic Alloy. Am. J. Orthod. 1985, 87, 445–452. [Google Scholar] [CrossRef] [PubMed]

- Kusy, R. A Review of Contemporary Archwires: Their Properties and Characteristics. Angle Orthod. 1997, 67, 197–207. [Google Scholar] [PubMed]

- Evans, T.J.W.; Durning, P. Aligning Archwires, the Shape of Things to Come?—A Fourth and Fifth Phase of Force Delivery. Br. J. Orthod. 1996, 23, 269–275. [Google Scholar] [CrossRef] [PubMed]

- Olsen, D. MSD Marc SmartArch Multi-Force Superelastic Archwires: A New Paradigm in Orthodontic Treatment Efficiency. J. Clin. Orthod. 2020, 2, 70–81. [Google Scholar]

- Segner, D.; Ibe, D. Properties of Superelastic Wires and Their Relevance to Orthodontic Treatment. Eur. J. Orthod. 1995, 17, 395–402. [Google Scholar] [CrossRef] [PubMed]

- Kauffman, G.B.; Mayo, I. The Story of Nitinol: The Serendipitous Discovery of the Memory Metal and Its Applications. Chem. Educ. 1997, 2, 1–21. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Oltjen, J.; Duncanson, M., Jr.; Ghosh, J.; Nanda, R.; Currier, G. Stiffness-Deflection Behavior of Selected Orthodontic Wires. Angle Orthod. 1997, 67, 209–2018. [Google Scholar] [PubMed]

- Thompson, S.A. An Overview of Nickel–Titanium Alloys Used in Dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef] [PubMed]

- Andreasen, G.F.; Morrow, R.E. Laboratory and Clinical Analyses of Nitinol Wire. Am. J. Orthod. 1978, 73, 142–151. [Google Scholar] [CrossRef]

- Santoro, M.; Nicolay, O.F.; Cangialosi, T.J. Pseudoelasticity and Thermoelasticity of Nickel-Titanium Alloys: A Clinically Oriented Review. Part I: Temperature Transitional Ranges. Am. J. Orthod. Dentofac. 2001, 119, 587–593. [Google Scholar] [CrossRef] [PubMed]

- Khier, S.E.; Brantley, W.A.; Fournelle, R.A. Bending Properties of Superelastic and Nonsuperelastic Nickel-Titanium Orthodontic Wires. Am. J. Orthod. Dentofac. 1991, 99, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Miura, F.; Mogi, M.; Ohura, Y. Japanese NiTi Alloy Wire: Use of the Direct Electric Resistance Heat Treatment Method. Eur. J. Orthod. 1988, 10, 187–191. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Zhi, Y.; Arvystas, M. Advanced Chinese NiTi Alloy Wire and Clinical Observations. Angle Orthod. 1992, 62, 59–66. [Google Scholar] [PubMed]

- Miura, F.; Mogi, M.; Ohura, Y.; Hamanaka, H. The Super-Elastic Property of the Japanese NiTi Alloy Wire for Use in Orthodontics. Am. J. Orthod. Dentofac. 1986, 90, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Tonner, R.I.M.; Waters, N.E. The Characteristics of Super-Elastic Ni-Ti Wires in Three-Point Bending. Part l: The Effect of Temperature. Eur. J. Orthod. 1994, 16, 409–419. [Google Scholar] [CrossRef] [PubMed]

- Mistakidis, I.; Gkantidis, N.; Topouzelis, N. Review of Properties and Clinical Applications of Orthodontic Wires. Hell. Orthod. Rev. 2011, 14, 45–66. [Google Scholar]

- Sakima, M.T. How Does Temperature Influence the Properties of Rectangular Nickel-Titanium Wires? Eur. J. Orthod. 2005, 28, 282–291. [Google Scholar] [CrossRef] [PubMed]

- Moore, R. Intra-Oral Temperature Variation over 24 Hours. Eur. J. Orthod. 1999, 21, 249–261. [Google Scholar] [CrossRef] [PubMed]

- Kuftinec, M. Making a Good Use of a Good Material: BioForce® Arch Wires. Available online: https://www.dentsplysirona.com/content/dam/master/education/documents/upload/W/WP---Making-a-Good-Use-of-a-good-material---Bio-Force-archwires-by-Mladen-Kuftinec-qg5cltu-en-1509.pdf (accessed on 2 April 2024).

- Product Page for the Titanol™ Triple Force Dental Archwire. Available online: https://www.forestadent.com/en-us/products/wires-and-arches/produktdetail/titanol-triple-force-2/ (accessed on 3 November 2023).

- Catalog Page for the Variable Force 3™ Archwire. Available online: https://maselortho.com/wp-content/uploads/2019/03/999-237-Rev-09-133Variable-Force-3-Archwires.pdf (accessed on 3 November 2023).

- Muth, J.F.; Poggie, M.; Kulesha, G.; Meneghini, R.M. Novel Highly Porous Metal Technology in Artificial Hip and Knee Replacement: Processing Methodologies and Clinical Applications. Jom 2013, 65, 318–325. [Google Scholar] [CrossRef]

- Mehta, A.S.K. Thermomechanical Characterization of Variable Force NiTi Orthodontic Archwires. Master’s Thesis, Marquette University, Milwaukee, WI, USA, 2015. [Google Scholar]

- Oguienko, O. Mechanical Properties of Graded Thermodynamic Nickel Titanium Archwires in Bending and Torsion. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2017. [Google Scholar]

- Meyers, M.A.; Chen, P.-Y.; Lopez, M.I.; Seki, Y.; Lin, A.Y.M. Biological Materials: A Materials Science Approach. J. Mech. Behav. Biomed. Mater. 2011, 4, 626–657. [Google Scholar] [CrossRef]

- Taneja, P.; Duncanson, M.G.; Khajotia, S.S.; Nanda, R.S. Deactivation Force-Deflection Behavior of Multistranded Stainless Steel Wires. Am. J. Orthod. Dentofac. 2003, 124, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Wever, D.J.; Veldhuizen, A.G.; de Vries, J.; Busscher, H.J.; Uges, D.R.A.; van Horn, J.R. Electrochemical and Surface Characterization of a Nickel–Titanium Alloy. Biomaterials 1998, 19, 761–769. [Google Scholar] [CrossRef] [PubMed]

- Trépanier, C.; Tabrizian, M.; Yahia, L.; Biolodeau, L.; Piron, D. Effect of Modification of Oxide Layer on NiTi Stent Corrosion Resistance. J. Biomed. Mater. Res. 1998, 43, 433–440. [Google Scholar] [CrossRef]

- Ren, Y.; Maltha, J.; Kuijpers-Jagtman, A. Optimum Force Magnitude for Orthodontic Tooth Movement: A Systematic Literature Review. Angle Orthod. 2003, 73, 86–92. [Google Scholar]

- GC Orthodontics. Available online: https://www.gcorthodontics.eu/GC/us/content/Bio-active (accessed on 29 October 2023).

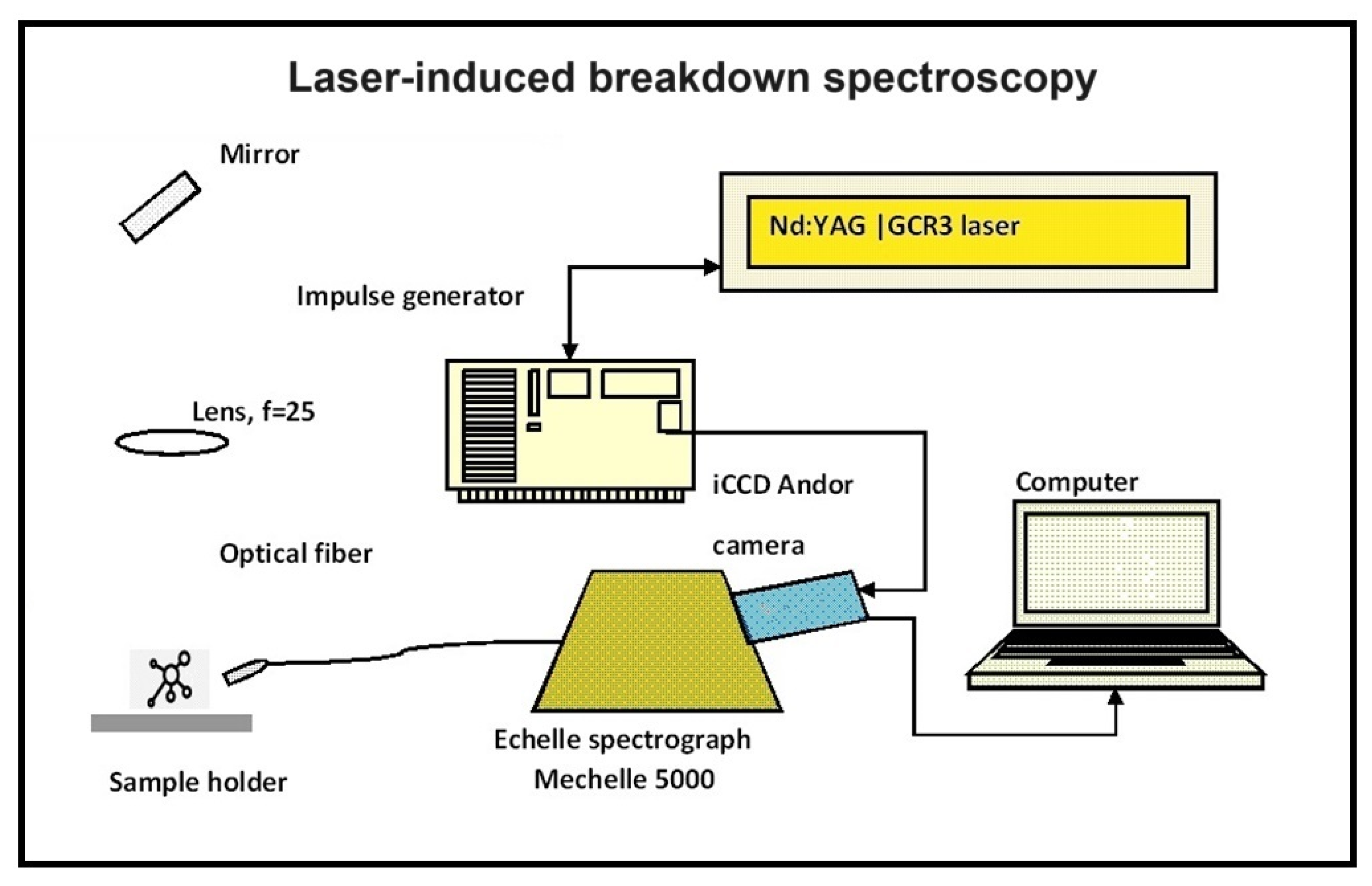

- Georgieva, M.; Stoyanova-Ivanova, A.; Cherneva, S.; Petrov, V.; Petrova, V.; Andreeva, L.; Mihailov, V.; Petkov, A.; Mikli, V. Characterization and comparison of as received and clinically retrieved Bio-active™ orthodontic archwires. Biotechnol. Biotechnol. Equip. 2021, 35, 1301–1311. [Google Scholar] [CrossRef]

- Stoyanova-Ivanova, A.; Georgieva, M.; Petrov, V.; Andreeva, L.; Petkov, A.; Georgiev, V. Effects of Clinical Use on the Mechanical Properties of Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel-Titanium Orthodontic Archwires. Materials 2023, 16, 483. [Google Scholar] [CrossRef] [PubMed]

- Stoyanova-Ivanova, A.; Georgieva, M.; Petrov, V.; Martins, J.N.R.; Andreeva, L.; Petkov, A.; Petrova, N.; Georgiev, V. Thermal Behavior Changes of As-Received and Retrieved Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel–Titanium Orthodontic Archwires. Materials 2023, 16, 3776. [Google Scholar] [CrossRef] [PubMed]

- Obaisi, N.A.; Galang-Boquiren, M.T.S.; Evans, C.A.; Tsay, T.G.P.; Viana, G.; Berzins, D.; Megremis, S. Comparison of the Transformation Temperatures of Heat-Activated Nickel-Titanium Orthodontic Archwires by Two Different Techniques. Dent. Mater. 2016, 32, 879–888. [Google Scholar] [CrossRef]

- Spini, T.S.; Valarelli, F.P.; Cançado, R.H.; de Freitas, K.M.S.; Villarinho, D.J. Transition Temperature Range of Thermally Activated Nickel-Titanium Archwires. J. Appl. Oral Sci. 2014, 22, 109–117. [Google Scholar] [CrossRef] [PubMed]

- Berzins, D.W.; Roberts, H.W. Phase Transformation Changes in Thermocycled Nickel–Titanium Orthodontic Wires. Dent. Mater. 2010, 26, 666–674. [Google Scholar] [CrossRef] [PubMed]

- Funakubo, H.; Kennedy, J.B. Shape Memory Alloys; CRC Press: Boca Raton, FL, USA, 1987. [Google Scholar]

- Brantley, W.A.; Eliades, T. Orthodontic Materials Scientific and Clinical Aspects; Thieme: Stuttgart, Garmany, 2001; Volume 29, pp. 77–103. [Google Scholar]

- Kusy, R.P.; Whitley, J.Q. Thermal and Mechanical Characteristics of Stainless Steel, Titanium-Molybdenum, and Nickel-Titanium Archwires. Am. J. Orthod. Dentofac. Orthop. 2007, 131, 229–237. [Google Scholar] [CrossRef] [PubMed]

- Assawakawintip, T.; Santiwong, P.; Khantachawana, A.; Sipiyaruk, K.; Chintavalakorn, R. The Effects of Temperature and Time of Heat Treatment on Thermo-Mechanical Properties of Custom-Made NiTi Orthodontic Closed Coil Springs. Materials 2022, 15, 3121. [Google Scholar] [CrossRef] [PubMed]

- Savi, M.A.; Paiva, A.; de Araujo, C.J.; de Paula, A.S. Shape Memory Alloys in Dynamics of Smart Systems and Structures; Lopes, V., Jr., Steffen, V., Jr., Savi, M., Eds.; Springer: Cham, Switzerland, 2016; pp. 155–188. [Google Scholar]

- Ohara, A.T. Clinical Importance of Austenitic Final Point in the Selection of Nickel-Titanium Alloys for Application in Orthodontic-Use Arches. Rev. Odontológica Mex. 2016, 20, e162–e169. [Google Scholar] [CrossRef]

- Gatto, E.; Matarese, G.; Di Bella, G.; Nucera, R.; Borsellino, C.; Cordasco, G. Load-Deflection Characteristics of Superelastic and Thermal Nickel-Titanium Wires. Eur. J. Orthod. 2011, 35, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Lombardo, L.; Marafioti, M.; Stefanoni, F.; Mollica, F.; Siciliani, G. Load Deflection Characteristics and Force Level of Nickel Titanium Initial Archwires. Angle Orthod. 2012, 82, 507–521. [Google Scholar] [CrossRef] [PubMed]

- Andreasen, G. A Clinical Trial of Alignment of Teeth Using a 0.019 Inch Thermal Nitinol Wire with a Transition Temperature Range between 31 °C. and 45 °C. Am. J. Orthod. 1980, 78, 528–537. [Google Scholar] [CrossRef]

- Krousbroeck, R.; Van der Perre, G.; Aernoudt, E.; Mulier, J.C. Shape memory effect in biomedical devices. In Advances in Biomaterials; Winter, G.D., Gibbons, D.F., Plenk, H., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 1982. [Google Scholar]

- Lombardo, L.; Ceci, M.; Mollica, F.; Mazzanti, V.; Palone, M.; Siciliani, G. Mechanical Properties of Multi-Force vs. Conventional NiTi Archwires. J. Orofac. Orthop./Fortschritte Kieferorthopädie 2019, 80, 57–67. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.; Nicholson, D. Nanoindentation. Mechanical Engineering Series. Appl. Mech. Rev. 2004, 57, B12. [Google Scholar] [CrossRef]

- Cherneva, S.; Stoyanova-Ivanova, A.; Gueorguieva, M.; Andreeva, L.; Petrov, V.; Petrov, V.; Petrova, V.; Mikli, V. Nanoindentation and Surface Characterization of Clinically Retrieved Multi-Force NiTi Orthodontic Archwires. Russ. J. Biomech. 2020, 24, 240–256. [Google Scholar] [CrossRef]

- Hartog, J.P.D. Advanced Strength of Materials; Courier Corporation: North Chelmsford, MA, USA, 2014. [Google Scholar]

- Ibe, D.M.; Segner, D. Superelastic Materials Displaying Different Force Levels within One Archwire. J. Orofac. Orthop./Fortschritte Kieferorthopedie 1998, 59, 29–38. [Google Scholar] [CrossRef]

- Sanders, E.; Johannessen, L.; Nadal, J.; Jäger, A.; Bourauel, C. Comparison of Multiforce Nickel–Titanium Wires to Multistrand Wires without Force Zones in Bending and Torque Measurements. J. Orofac. Orthop./Fortschritte Kieferorthopädie 2021, 83, 382–394. [Google Scholar] [CrossRef]

- Bartzela, T.N.; Senn, C.; Wichelhaus, A. Load-Deflection Characteristics of Superelastic Nickel-Titanium Wires. Angle Orthod. 2007, 77, 991–998. [Google Scholar] [CrossRef]

- Nakano, H.; Satoh, K.; Norris, R.; Jin, T.; Kamegai, T.; Ishikawa, F.; Katsura, H. Mechanical Properties of Several Nickel-Titanium Alloy Wires in Three-Point Bending Tests. Am. J. Orthod. Dentofac. Orthop. 1999, 115, 390–395. [Google Scholar] [CrossRef]

- Parvizi, F. The Load/Deflection Characteristics of Thermally Activated Orthodontic Archwires. Eur. J. Orthod. 2003, 25, 417–421. [Google Scholar] [CrossRef]

- Bolender, Y.; Vernière, A.; Rapin, C.; Filleul, M.-P. Torsional Superelasticity of NiTi Archwires. Angle Orthod. 2010, 80, 1100–1109. [Google Scholar] [CrossRef] [PubMed]

- Gurgel, J.d.A.; Kerr, S.; Powers, J.M.; Pinzan, A. Torsional Properties of Commercial Nickel-Titanium Wires during Activation and Deactivation. Am. J. Orthod. Dentofac. Orthop. 2001, 120, 76–79. [Google Scholar] [CrossRef] [PubMed]

- Sarul, M.; Kawala, B.; Kawala, M.; Antoszewska-Smith, J. Do the NiTi Low and Constant Force Levels Remain Stablein Vivo? Eur. J. Orthod. 2015, 37, 656–664. [Google Scholar] [CrossRef] [PubMed]

- Cherneva, S.; Petrunov, V. Comparison of Mechanical Properties of Last Generation Multi-Force Nickel-Titanium Archwires. Ser. Biomech. 2020, 34, 28–36. [Google Scholar]

- Orthodontic Products—Catalog 05. Available online: https://www.ortospecialized.es/wp-content/uploads/2020/09/ENG_Catalog-Web.pdf (accessed on 2 April 2024).

- Stoyanova-Ivanova, A.; Petrov, V.; Petrova, V.; Andreeva, L.; Ilievska, I.; Zaleski, A.; Mikli, V. Physicochemical Research of Clinically Retrieved CU-NI-TI Orthodontic Archwires. Acta Medica Bulg. 2021, 48, 68–74. [Google Scholar] [CrossRef]

- Stoyanova-Ivanova, A.; Mihaylov, V.; Georgiev, V.; Georgieva, M.; Petrov, V.; Andreeva, L.; Petrova, N.; Mikli, V. Elemental Composition and Structural Characteristics of Bio-ActiveTM Orthodontic Archwire. J. Phys. Conf. Ser. 2024, 2710, 012029. [Google Scholar] [CrossRef]

- Petrov, V.; Terzieva, S.; Tumbalev, V.; Mikli, V.; Andreeva, L.; Stoyanova-Ivanova, A. Influence of the Treatment Period on the Morphology and the Chemical Composition of the Thermally Activated Orthodontic Archwires. Bulg. Chem. Commun. 2015, 47, 234–238. [Google Scholar]

- Brantley, W.; Guo, W.; Clark, W.; Iijima, M. Microstructural Studies of 35 °C Copper Ni–Ti Orthodontic Wire and TEM Confirmation of Low-Temperature Martensite Transformation. Dent. Mater. 2008, 24, 204–210. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, P.F.; Fernandes, F.M.B.; Magalhães, R.; Camacho, E.; Lopes, A.; Paula, A.S.; Basu, R.; Schell, N. Thermo-Mechanical Characterization of NiTi Orthodontic Archwires with Graded Actuating Forces. J. Mech. Behav. Biomed. Mater. 2020, 107, 103747. [Google Scholar] [CrossRef]

- Roulias, P.; Mylonopoulou, I.-M.; Sifakakis, I.; Bourauel, C.; Eliades, T. Thermo-Mechanical Properties in Bending of a Multizone Nickel-Titanium Archwire: A Retrieval Analysis. Korean J. Orthod. 2023, 53, 89–98. [Google Scholar] [CrossRef]

- Friedli, L.; Nalabothu, P.; Bosch, C.; Verna, C.; Steineck, M.; Dalstra, M. Influence of Different Storage Temperatures on the Mechanical Properties of NiTi, Cu-NiTi and SS Orthodontic Archwires: An in Vitro Study. Int. Orthod. 2020, 18, 561–568. [Google Scholar] [CrossRef] [PubMed]

- Nespoli, A.; Passaretti, F.; Szentmiklósi, L.; Maróti, B.; Placidi, E.; Cassetta, M.; Yada, R.Y.; Farrar, D.H.; Tian, K.V. Biomedical NiTi and β-Ti Alloys: From Composition, Microstructure and Thermo-Mechanics to Application. Metals 2022, 12, 406. [Google Scholar] [CrossRef]

- Alcaraz, I.; Moyano, J.; Pàmies, A.; Ruiz, G.; Artés, M.; Gil, J.; Puigdollers, A. Properties of Superelastic Nickel–Titanium Wires after Clinical Use. Materials 2023, 16, 5604. [Google Scholar] [CrossRef]

- Adly, M.S.; Adly, A.S.; Adly, A.S.; Carayon, D.; Estephan, E.; Cuisinier, F. Innovative Device for In-Vivo Quantitative Assessment of Different Wire Materials Using 3D Models. J. Sci. Adv. Mater. Devices 2024, 9, 100667. [Google Scholar] [CrossRef]

- Yordanova, G.; Gurgurova, G.; Kostov, I.; Georgieva, M. Software Orthodontics—Myth or Reality? Technological Management of Clinical Practice. In Proceedings of the 2023 International Scientific Conference on Computer Science (COMSCI), Sozopol, Bulgaria, 18–20 September 2023. [Google Scholar]

- Kostov, I.; Georgieva, M. The Use of Artificial Intelligence in Dental Practice and Patients’ Attitudes towards It. Knowl. Int. J. 2023, 61, 587–591. [Google Scholar]

| Bio-Active™ | TriTanium™ | ||

|---|---|---|---|

| Indicated | Counter Indicated | Indicated | Counter Indicated |

| Patients do not complain from pain when the archwire is first placed Leveling of teeth arches for small crowding up to 2 mm Patients with periodontal problems, due to the small forces exerted by the archwire Early expression of torque during the first phase of treatment Introducing retained canine teeth in the tooth arch, due to the constant force exerted by the archwire Appropriate for extended clinical use over 8 weeks | Application on mouth-breathing patients prior to removal of the habit Application on mouth-breathing patients with crowding in the front, since no temperature transition between phases can occur Ingestion of cold drinks during the first week of treatment | Leveling of teeth arches for small crowding up to 2 mm Patients with periodontal problems, due to the small forces exerted by the archwire Recommended for mouth-breathing patients Early expression of torque during the first phase of treatment Introducing retained canine teeth in the tooth arch, due to the constant force exerted by the archwire Appropriate for extended clinical use | Ingestion of cold food and drinks during the first week of treatment |

| Archwires Studied | Type of Performed Characterization | Clinical Use of Investigated Arcfhwires | Authors and Year Published |

|---|---|---|---|

| Bio-active™ (TOMY Inc., Tokyo, Japan) | Physicochemical and mechanical | As received and clinically used | Gerogieva et.al. (2021) [38] |

| Bio-active™ (TOMY Inc., Tokyo, Japan) TriTanium™ (American Orthodontics, Sheboygan, WI, USA) | Mechanical | As received and clinically used | Stoyanova-Ivanova et.al. (2023) [40] |

| Bio-active™ (TOMY Inc., Tokyo, Japan) TriTanium™ (American Orthodontics, Sheboygan, WI, USA) | Thermal | As received and clinically used | Stoyanova-Ivanova et.al. (2023) [40] |

| DuoForce™ (Forestadent, Pforzheim, Germany) TriTanium™ (American Orthodontics, Sheboygan, WI, USA) Triple Force™ (ODS, Kisdorf, Germany) Bio-active™ (GC, Breckerfeld, Germany) TurboWire™ (Ormco, Orange, CA, USA) Multibraid™ (GAC, Dentsply Sirona, York, PA, USA) | Mechanical | Clinically used | Sanders et.al. (2021) [59] |

| 35 °C Thermo-Active Copper NiTi | Physicochemical and thermal | As received and clinically used | Stoyanova-Ivanova et.al. (2021) [68] |

| Bio-active™ (TOMY Inc., Tokyo, Japan) | Physicochemical, mechanical, and thermal | As received | Stoyanova-Ivanova et.al. (2024) [69] |

| Round thermal activated copper–nickel–titanium Rectangular thermal activated copper–nickel–titanium | Physicochemical | As received and clinically used | Petrov et.al. (2015) [70] |

| 35 °C Thermo-Active Copper NiTi | Thermal | As received | Brantley et.al. (2008) [71] |

| Bioforce™ (GAC, Dentsply Sirona, York, PA, USA) | Thermal | As received | Rodrigues et.al. (2020) [72] |

| Bioforce™ (GAC, Dentsply Sirona, York, PA, USA) | Physicochemical, mechanical, and thermal | Clinically used | Roulias et.al. (2023) [73] |

| Ormco stainless steel (SS) Ormco nickel titanium (NiTi) Ormco 27 °C, 35 °C and 40 °C Copper NiTi (CuNiti) | Mechanical | As received | Friedli et.al. (2020) [74] |

| GC Orthodontics Europe GmbH (Breckerfeld, Germany) Nickel Titanium archwire Nitinol® SuperElastic, Euro NiTi Opto TH Plus Titanol® Superelastic, Sentalloy® superelastic | Mechanical | As received and clinically used | Alcaraz et.al. (2023) [76] |

| M5™ Thermal Copper NiTi, G4™ Nickel Titanium | Cone beam computed tomographies (CBCTs) | Clinically used | Adly et.al. (2024) [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoyanova-Ivanova, A.; Petrov, V.; Martins, J.N.R.; Andreeva, L.; Georgiev, V. Multi-Force Bio-Active™ Archwires and Various Contemporary NiTi Multi-Force Archwires: Properties and Characteristics—A Review. Materials 2024, 17, 2603. https://doi.org/10.3390/ma17112603

Stoyanova-Ivanova A, Petrov V, Martins JNR, Andreeva L, Georgiev V. Multi-Force Bio-Active™ Archwires and Various Contemporary NiTi Multi-Force Archwires: Properties and Characteristics—A Review. Materials. 2024; 17(11):2603. https://doi.org/10.3390/ma17112603

Chicago/Turabian StyleStoyanova-Ivanova, Angelina, Valeri Petrov, Jorge N. R. Martins, Laura Andreeva, and Velizar Georgiev. 2024. "Multi-Force Bio-Active™ Archwires and Various Contemporary NiTi Multi-Force Archwires: Properties and Characteristics—A Review" Materials 17, no. 11: 2603. https://doi.org/10.3390/ma17112603

APA StyleStoyanova-Ivanova, A., Petrov, V., Martins, J. N. R., Andreeva, L., & Georgiev, V. (2024). Multi-Force Bio-Active™ Archwires and Various Contemporary NiTi Multi-Force Archwires: Properties and Characteristics—A Review. Materials, 17(11), 2603. https://doi.org/10.3390/ma17112603