Enhancing Flexural Behavior of Reinforced Concrete Beams Strengthened with Basalt Fiber-Reinforced Polymer Sheets Using Carbon Nanotube-Modified Epoxy

Abstract

:1. Introduction

2. Experimental Program

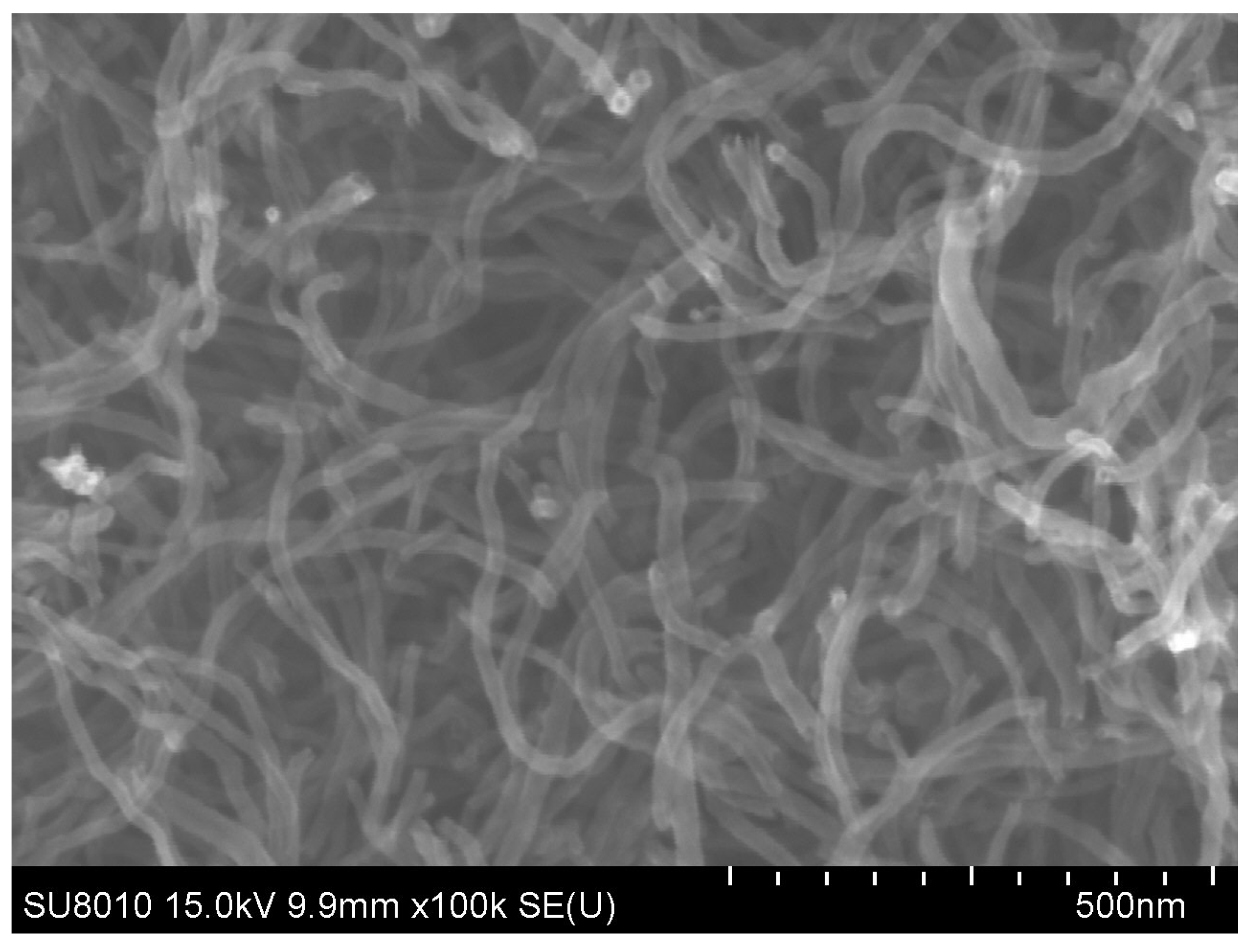

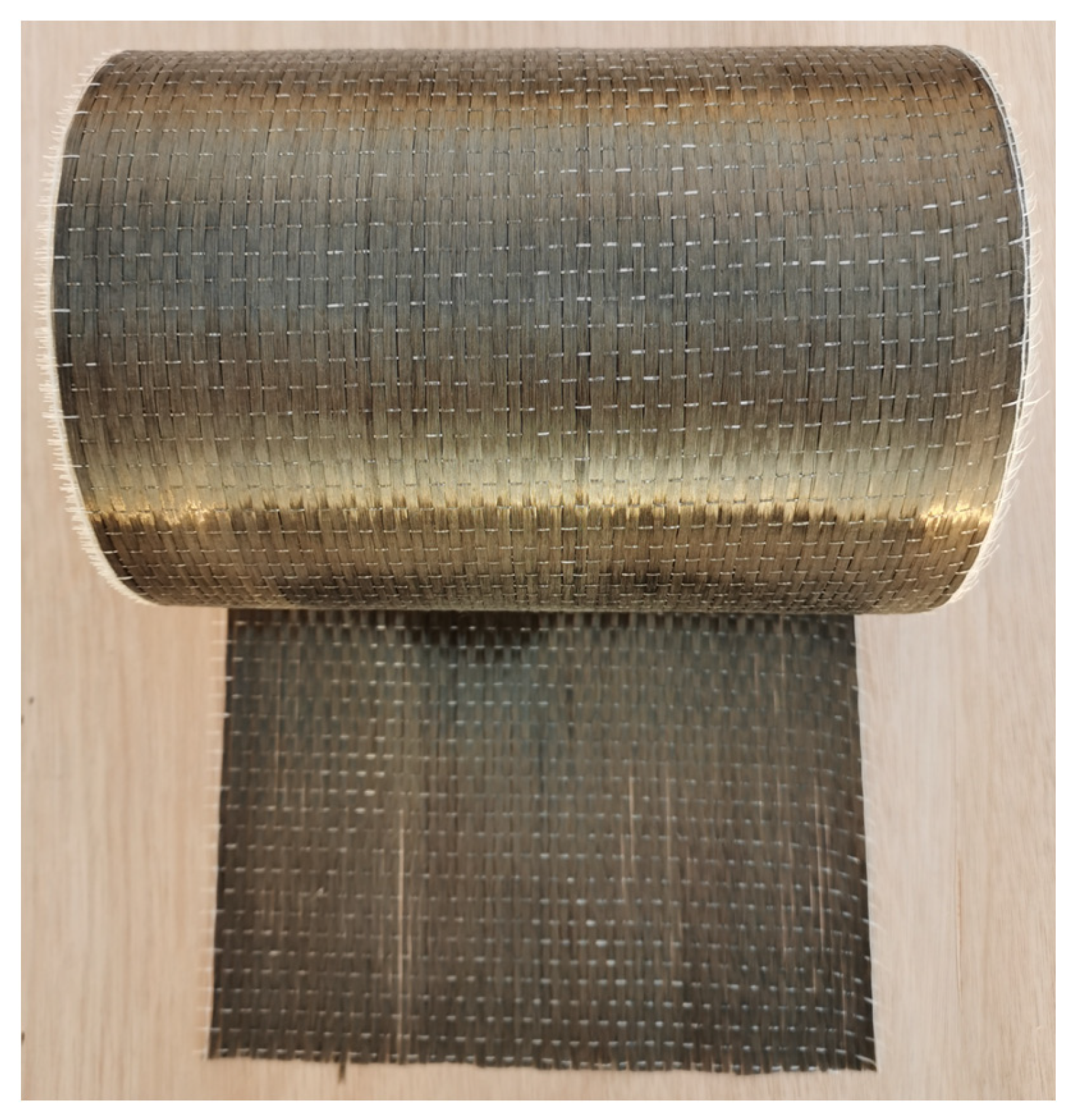

2.1. Material Properties

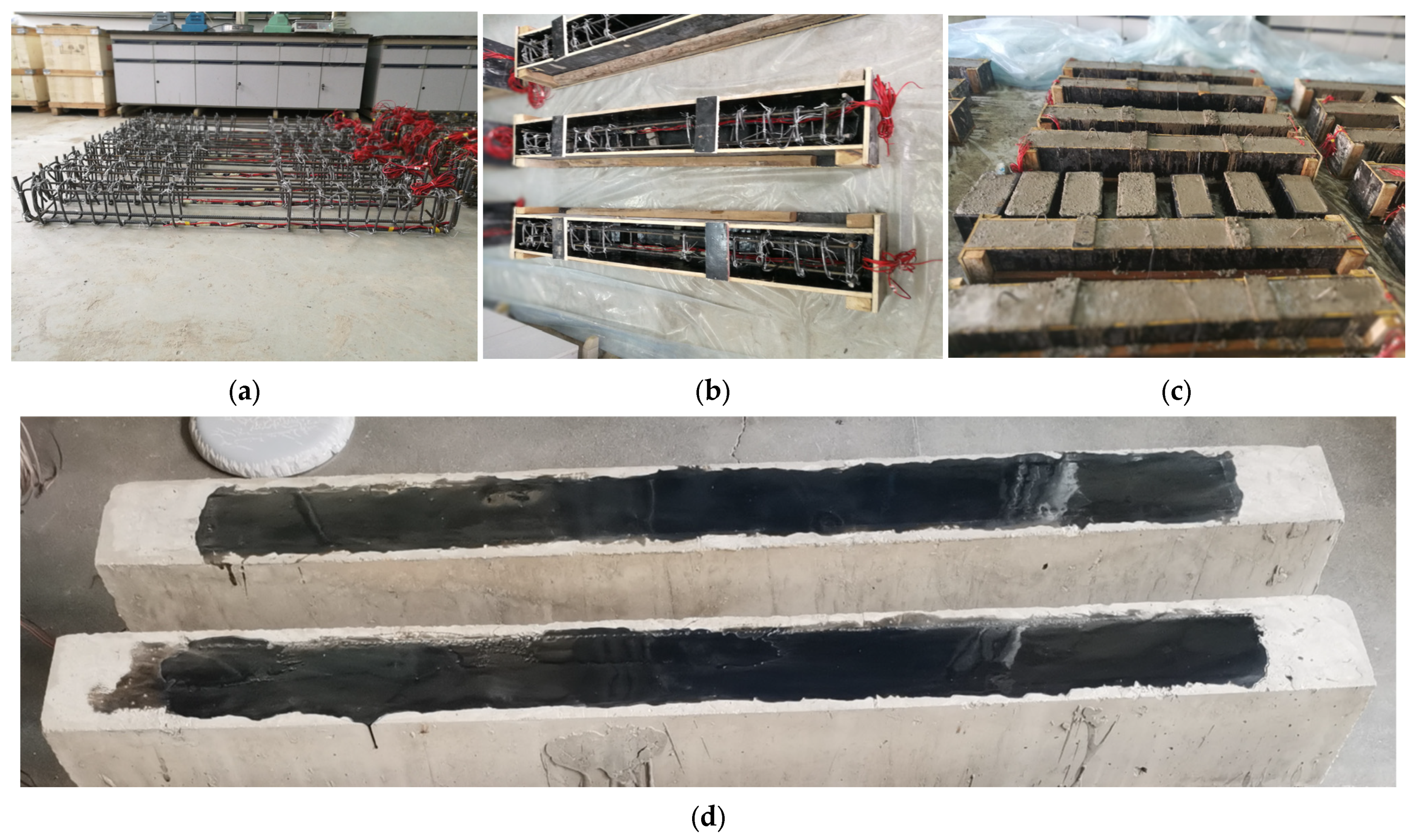

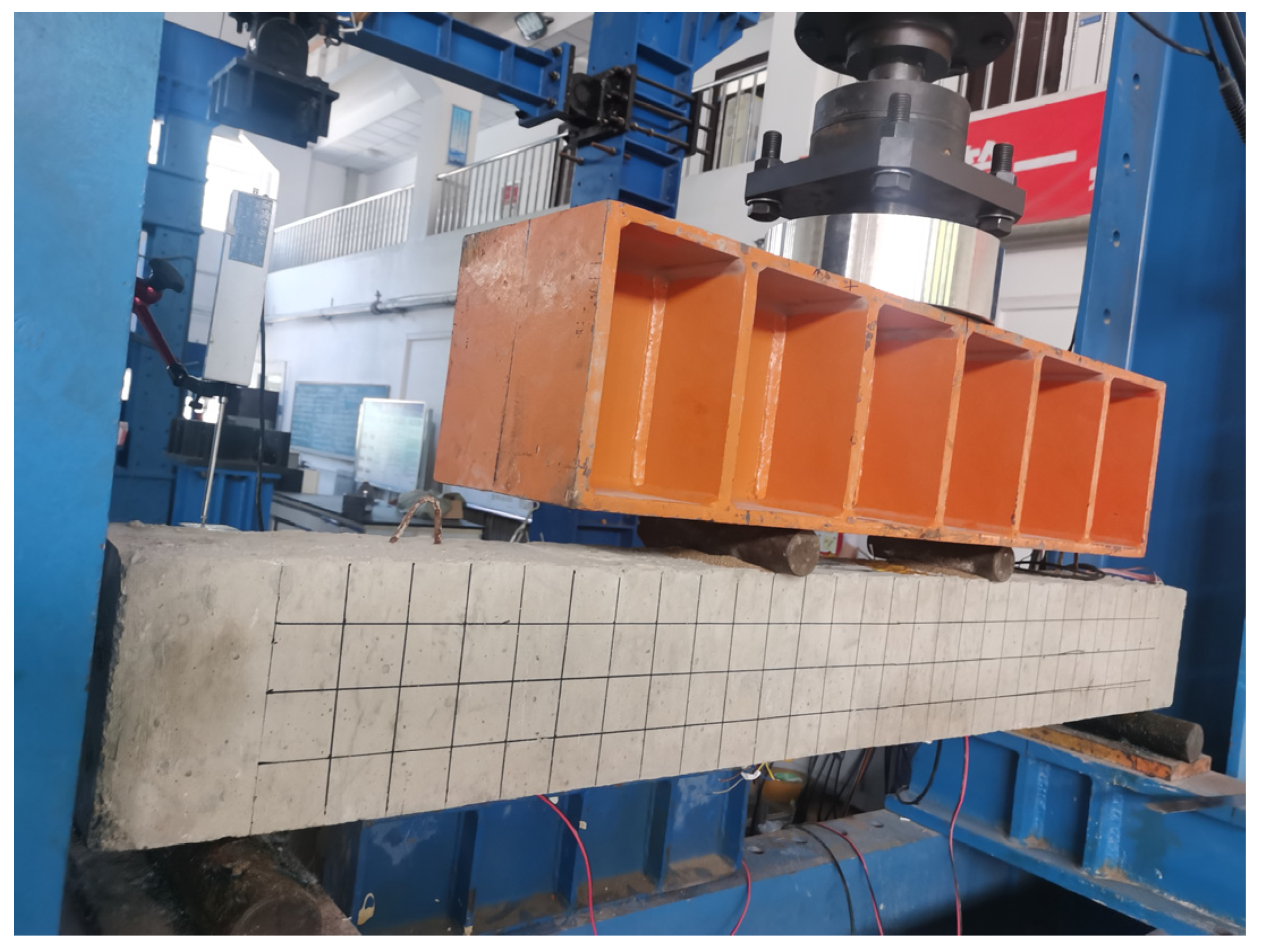

2.2. Preparation of Test Specimens

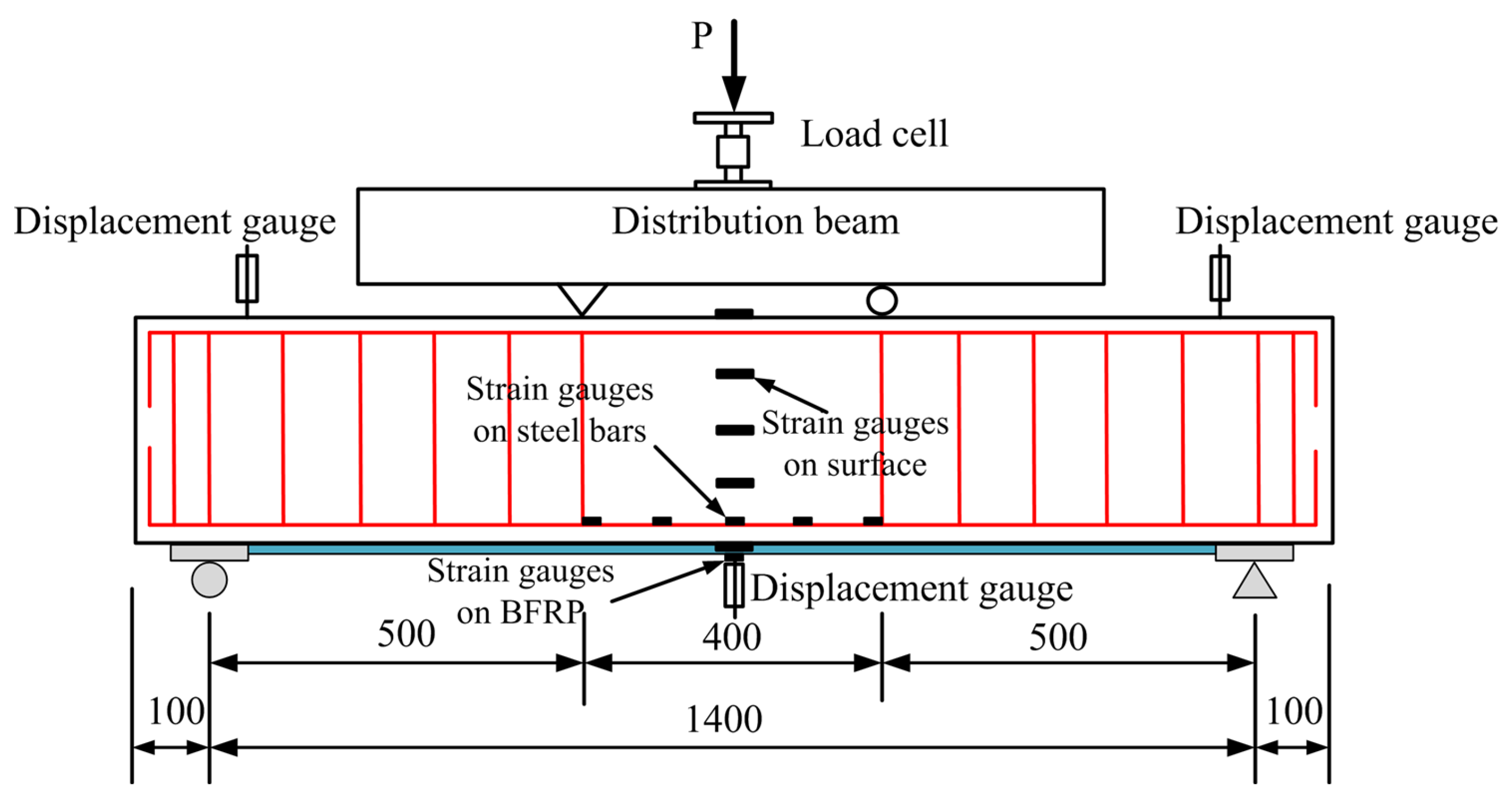

2.3. Testing and Loading Solutions

3. Experimental Results and Discussions

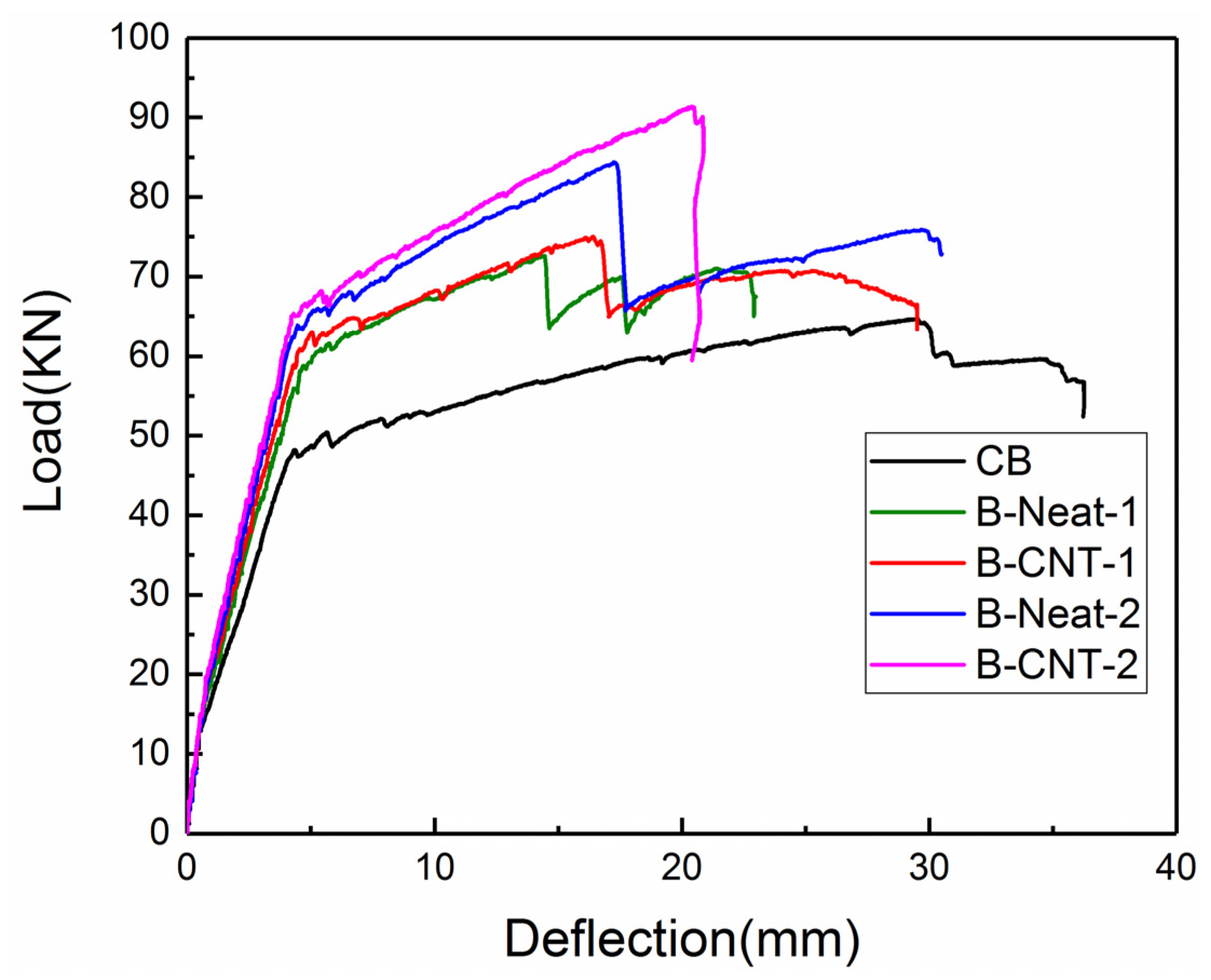

3.1. Load–Deflection Response

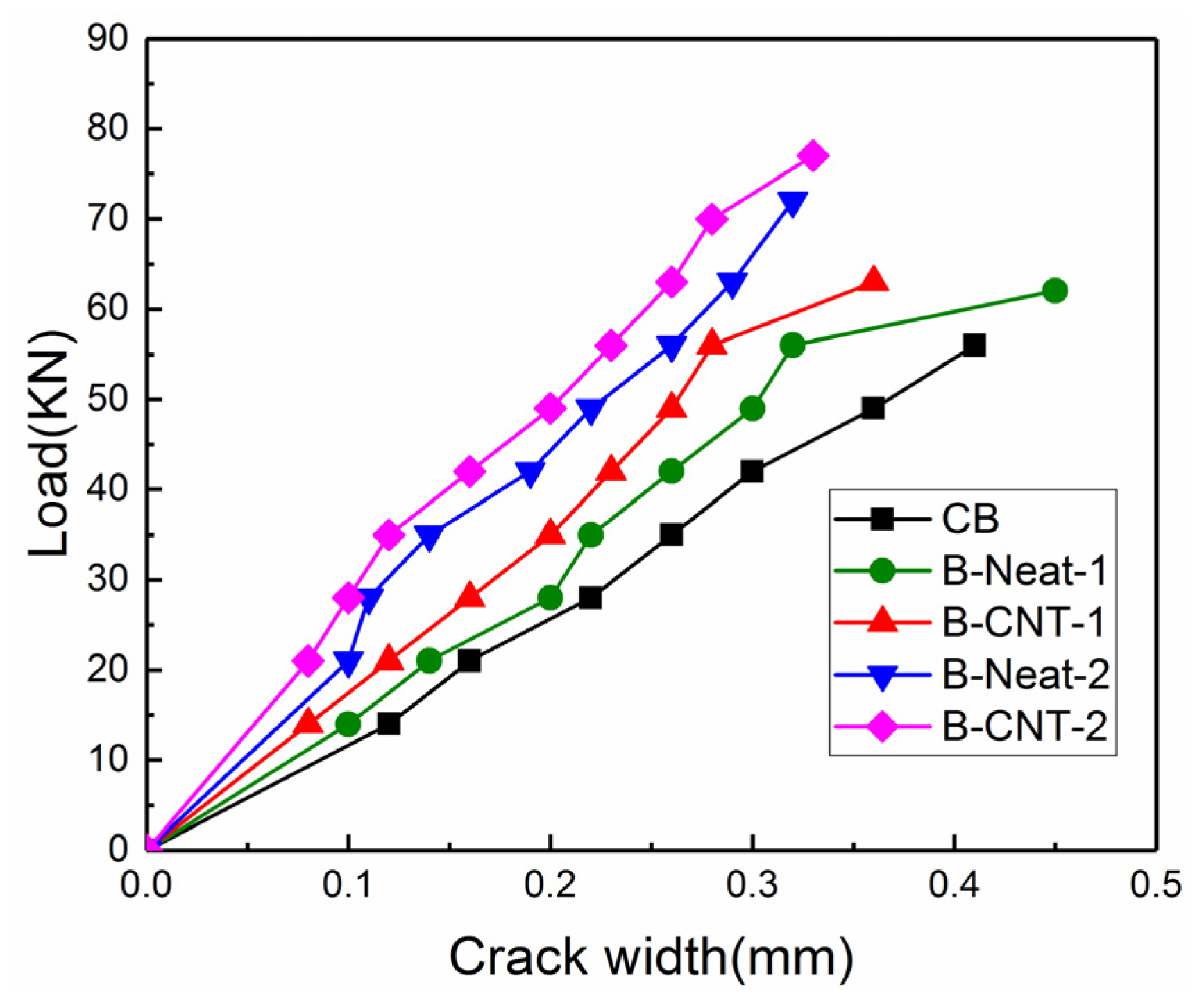

3.2. Failure Mode and Cracking Development

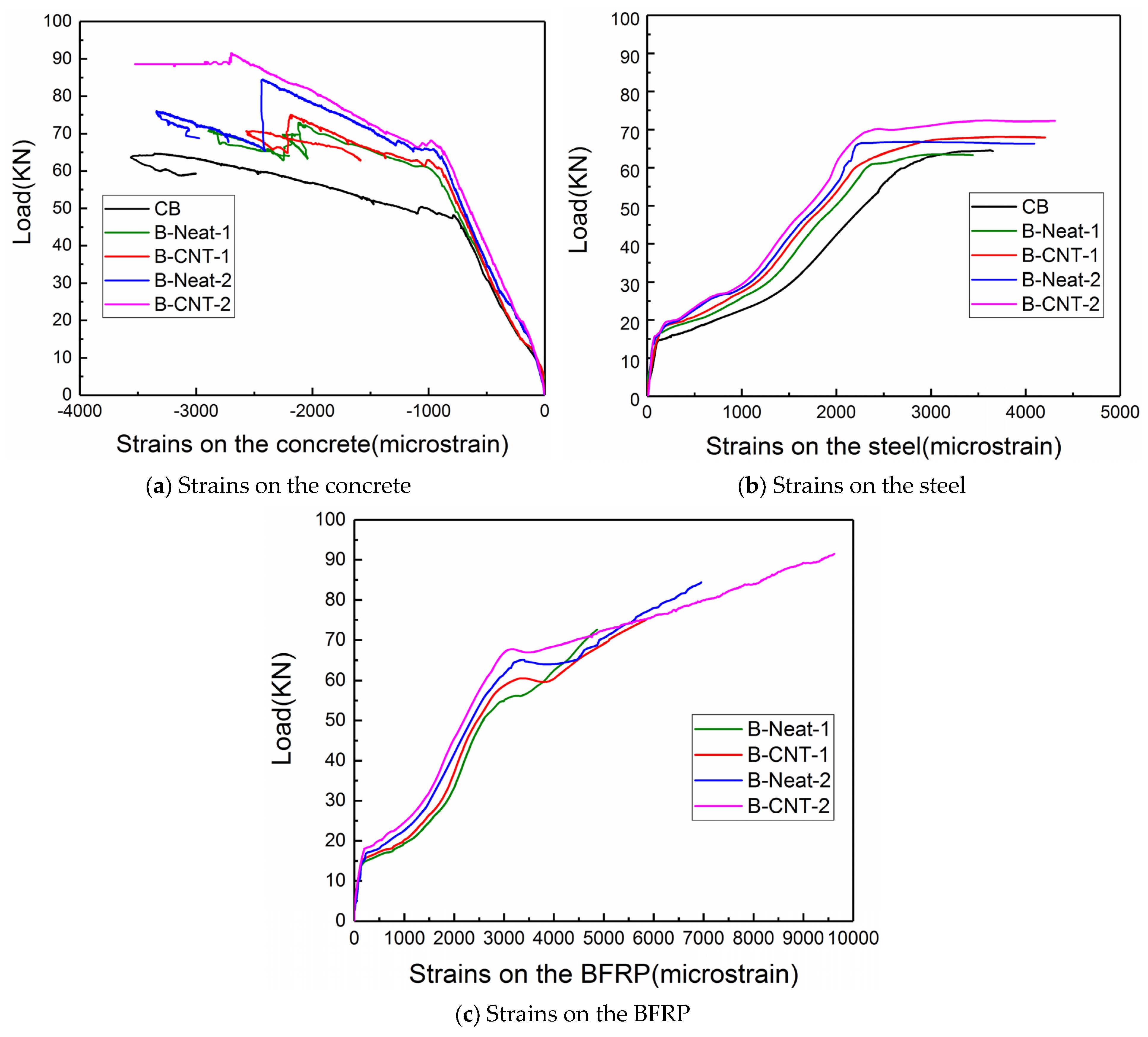

3.3. Strain Analysis

3.4. Energy Absorption Analysis

3.5. Ductility Analysis

3.6. Analysis of Enhancement Mechanism of MWCNTs Modified Epoxy

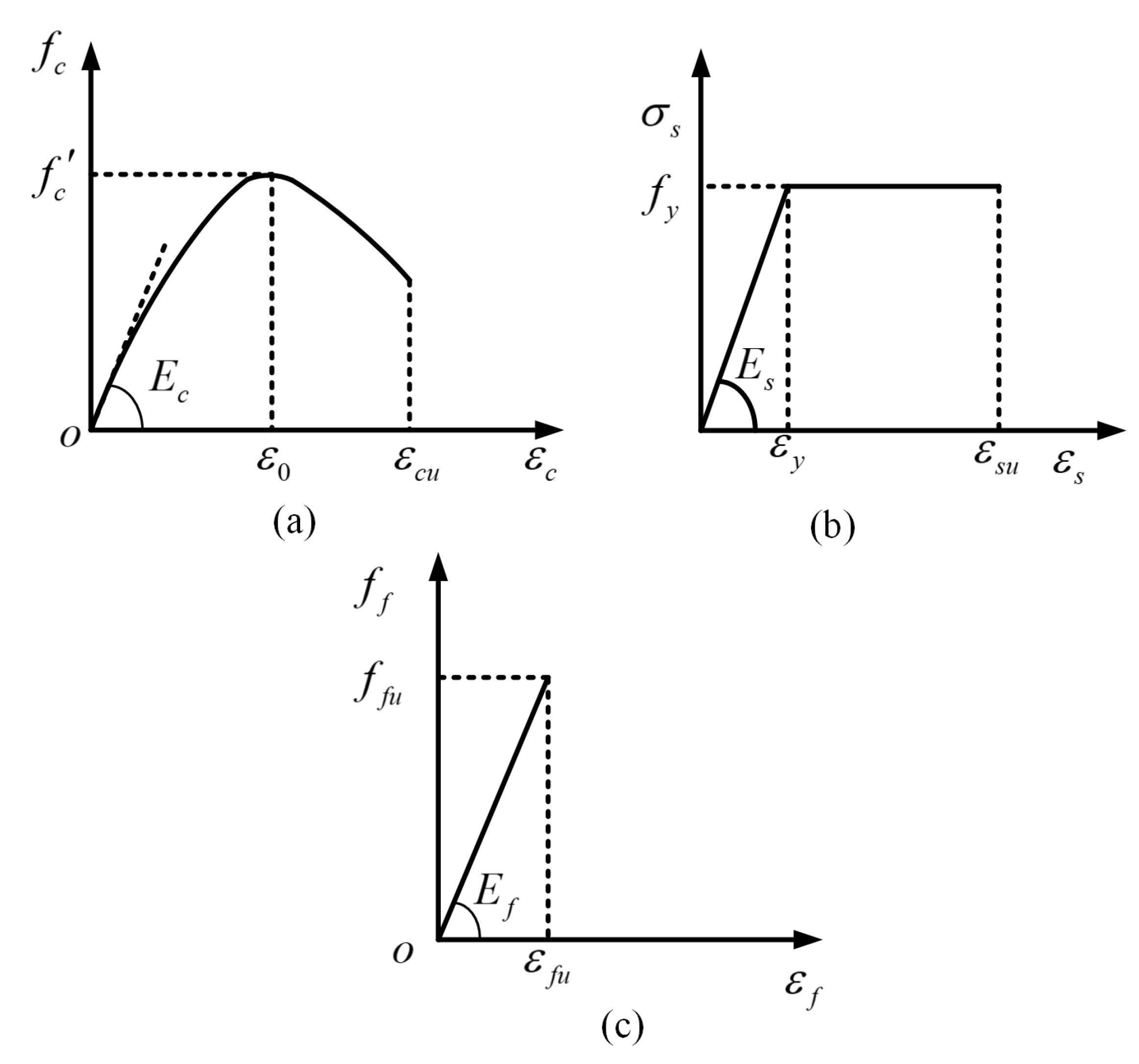

4. Analytical Predictions

4.1. Calculation of Flexural Capacity in Characteristic Points

4.1.1. Cracking Point

4.1.2. Yield Point

4.1.3. Peak Point

4.2. Deflection Prediction

5. Conclusions

- The reinforced specimens failed due to intermediate IC debonding after steel yielding, and the failure occurred within the concrete.

- The BFRP sheets bonded using the MWCNT-modified epoxy more effectively constrained crack development of strengthened beams, as well as delayed the IC debonding and the eventual rupture of BFRP sheets.

- The yielding load and, ultimate load, as well as the ultimate deflection of the reinforced specimens were enhanced by the MWCNT-modified epoxy. When the beam was reinforced with two-layer BFRP sheets, the yielding load and ultimate load, as well as the ultimate deflection of the strengthened specimen using MWCNT-modified epoxy increased by 7.4%, 8.3% and 18.2%, respectively, compared with the beam strengthened using pure epoxy.

- A significant enhancement of the flexural stiffness, energy absorption capacity and ductility of the reinforced specimens using BFRP sheets was achieved by using MWCNT-modified epoxy. When the beam was reinforced with two-layer BFRP sheets, the beam strengthened using MWCNT-modified epoxy significantly enhanced the post-yielding flexural stiffness, energy absorption capacity before the ultimate load, and deflection ductility index by 22.6%, 29.1% and 14.3%, respectively, compared with the beam strengthened using pure epoxy.

- The SEM images indicated the MWCNTs could penetrate into the concrete pores. Both crack-bridging and pull-out of high-strength MWCNTs consumed more energy, which greatly increased the interfacial fracture energy and remarkably enhanced flexural behavior of the strengthened beams.

- Based on the ACI Code, an analytical model was proposed for calculating the flexural capacity and mid-deflection of RC beams strengthened with FRP sheets using MWCNT-modified epoxy. The predicted characteristic loads and characteristic deflections showed a reasonably good correlation with the experimental results. The predicted values of the beams strengthened using MWCNT-modified epoxy were slightly more reliable and conservative than those of the beams strengthened with neat epoxy. The analytical model can provide theoretical references for practical application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Teng, J.G.; Chen, J.F.; Smith, S.T.; Lam, L. Behaviour and strength of FRP-strengthened RC structures: A state-of-the-art review. Proc. Inst. Civ. Eng.-Struct. Build. 2003, 156, 51–62. [Google Scholar] [CrossRef]

- Teng, J.; Yao, J. Plate end debonding in FRP-plated RC beams—II: Strength model. Eng. Struct. 2007, 29, 2472–2486. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; Guan, Z. Structural behaviour of RC beams with external flexural and flexural–shear strengthening by FRP sheets. Compos. B Eng. 2013, 44, 604–612. [Google Scholar] [CrossRef]

- Chen, W.S.; Hao, H.; Jong, M.; Cui, J.; Shi, Y.C.; Chen, L.; Pham, T.M. Quasi-static and dynamic tensile properties of basalt fibre reinforced polymer. Compos. Part B Eng. 2017, 125, 123–133. [Google Scholar] [CrossRef]

- Moghaddas, A.; Mostofinejad, D.; Ilia, E. Empirical FRP-concrete effective bond length model for externally bonded reinforcement on the grooves. Compos. Part B Eng. 2019, 172, 323–338. [Google Scholar] [CrossRef]

- Wu, Z.S.; Yuan, H.; Niu, H.D. Stress transfer and fracture propagation in different kinds of adhesive joints. J. Eng. Mech. 2002, 128, 562–573. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, C.; Lu, R.; Su, S.; Qin, J. Fracture investigation of functionalized carbon nanotubes-grown carbon fiber fabrics/epoxy composites. Compos. Sci. Technol. 2020, 195, 108161. [Google Scholar] [CrossRef]

- Al-Obaidi, S.; Saeed, Y.; Rad, F. Flexural strengthening of reinforced concrete beams with NSM-CFRP bars using mechanical interlocking. J. Build Eng. 2020, 31, 101422. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, W.; Pham, T.M.; Hao, H.; Chen, L.; Wang, J. Experimental and analytical study of flexural behaviour of BFRP sheets strengthened RC beams with new epoxy anchors. Eng. Struct. 2021, 241, 112441. [Google Scholar] [CrossRef]

- Ababneh, A.N.; Al-Rousan, R.Z.; Ghaith, I.M.N. Experimental study on anchoring of FRP-strengthened concrete beams. Structures 2019, 23, 26–33. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Moghaddas, A. Bond efficiency of EBR and EBROG methods in different flexural failure mechanisms of FRP strengthened RC beams. Constr. Build. Mater. 2014, 54, 605–614. [Google Scholar] [CrossRef]

- Shi, C.; Jin, S.; Jin, K.; Yang, Y.; Xu, L. Improving bonding behavior between basalt fiber-reinforced polymer sheets and concrete using multi-wall carbon nanotubes modified epoxy composites. Case Stud. Constr. Mater. 2023, 18, e02216. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Chan, T.K.; Cheong, H.K. Brittle failure and bond development length of CFRP–concrete beams. J. Compos. Constr. 2001, 5, 12–17. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Chastre, C.; Borba, I.S.; Silva, C.; Cruz, D. Experimental evaluation of bonding between CFRP laminates and different structural materials. J. Compos. Constr. 2015, 20, 04015070. [Google Scholar] [CrossRef]

- Zunjarrao, S.C.; Singh, R.P. Characterization of the fracture behavior of epoxy reinforced with nanometer and micrometer sized aluminum particles. Compos. Sci Technol. 2006, 66, 2296–2305. [Google Scholar] [CrossRef]

- Naeem, M.; Kuan, H.C.; Michelmore, A.; Ma, J. A new method for preparation of functionalized graphene and its epoxy nanocomposites. Compos. Part B Eng. 2020, 196, 108096. [Google Scholar] [CrossRef]

- Cha, J.; Jun, G.H.; Park, J.K.; Kim, J.C.; Ryu, H.J.; Hong, S.H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B Eng. 2017, 129, 169–179. [Google Scholar] [CrossRef]

- Pinto, V.C.; Ramos, T.; Alves, A.S.F.; Xavier, J.; Tavares, P.J.; Moreira, P.M.G.P.; Guedesa, R.M. Dispersion and failure analysis of PLA, PLA/GNP and PLA/CNT-COOH biodegradable nanocomposites by SEM and DIC inspection. Eng. Fail. Anal. 2017, 71, 63–71. [Google Scholar] [CrossRef]

- Treacy, M.M.J.; Ebbesen, T.W.; Gibson, J.M. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Zeng, S.; Duan, P.; Shen, M.; Xue, Y.; Lu, F.; Yang, L. Interface enhancement of glass fiber fabric/epoxy composites by modifying fibers with functionalized MWCNTs. Compos. Interfac. 2018, 26, 291–308. [Google Scholar] [CrossRef]

- Lee, S.O.; Choi, S.H.; Kwon, S.H.; Rhee, K.Y.; Park, S.J. Modification of surface functionality of multi-walled carbon nanotubes on fracture toughness of basalt fiber-reinforced composites. Compos. Part B Eng. 2015, 79, 47–52. [Google Scholar] [CrossRef]

- Chen, W.; Shen, H.; Auad, M.L.; Huang, C.; Nutt, S. Basalt fiber–epoxy laminates with functionalized multi-walled carbon nanotubes. Compos. Part A-Appl. S. 2009, 40, 1082–1089. [Google Scholar] [CrossRef]

- Suresha, B.; Indushekhara, N.M.; Varun, C.A.; Sachin, D.; Pranao, K. Effect of Carbon Nanotubes Reinforcement on Mechanical Properties of Aramid/Epoxy Hybrid Composites. Mater. Today Proc. 2021, 43, 1478–1484. [Google Scholar] [CrossRef]

- Salam, M.B.A.; Hosur, M.V.; Jahan, N.; Rahman, M.M.; Jeelani, S. Improvement in mechanical and thermo-mechanical properties of carbon fibre/epoxy composites using carboxyl functionalized multi-walled carbon nanotubes. Polym. Polym. Compos. 2013, 21, 495–507. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.X.; He, J.; Gao, Y.W.; Hu, Z. Effect of functionalized nano-SiO2 addition on bond behavior of adhesively bonded CFRP-steel double-lap joint. Constr. Build. Mater. 2020, 244, 118400. [Google Scholar] [CrossRef]

- Korayem, A.H.; Shu, J.C.; Qian, H.Z.; Chen, Y.L.; Xiao, L.Z.; Wen, H.D. Failure of CFRP-to-steel double strap joint bonded using carbon nanotubes modified epoxy adhesive at moderately elevated temperatures. Compos. Part B Eng. 2016, 94, 95–101. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H. Effect of using carbon nanotube modified epoxy on bond-slip behavior between concrete and FRP sheets. Constr. Build. Mater. 2016, 105, 511–518. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H.; Almashagbeh, H. Effect of carbon nanotubes on strengthening of RC beams retrofitted with carbon fiber/epoxy composites. Mater. Des. 2016, 89, 225–234. [Google Scholar] [CrossRef]

- Shen, D.; Ji, Y.; Yin, F.; Zhang, J. Dynamic bond stress-slip relationship between basalt FRP sheet and concrete under initial static loading. J. Compos. Constr. 2015, 19, 04015012. [Google Scholar] [CrossRef]

- Shen, D.; Shi, H.; Ji, Y.; Yin, F. Strain rate effect on effective bond length of basalt FRP sheet bonded to concrete. Constr. Build. Mater. 2015, 82, 206–218. [Google Scholar] [CrossRef]

- Shen, D.; Shi, X.; Ji, Y.; Yin, F. Strain rate effect on bond stress–slip relationship between basalt fiber-reinforced polymer sheet and concrete. J. Reinforc. Plast. Compos. 2015, 34, 547–563. [Google Scholar] [CrossRef]

- He, J.T.; Lei, D.; She, Z.S.; Xi, B. Investigation on bonding behavior of basalt fiber reinforced polymer (BFRP) sheet reinforced concrete beam. J. Build Eng. 2023, 75, 106963. [Google Scholar] [CrossRef]

- Soliman, E.M.; Kandil, U.F.; Taha, M.M.R. Investigation of FRP Lap Splice Using Epoxy Containing Carbon Nanotubes. J. Compos. Constr. 2015, 19, 04014045. [Google Scholar] [CrossRef]

- GB 50010-2010; Chinese Standard, Code for Design of Concrete Structures. Chinese Building Press: Beijing, China, 2010. (In Chinese)

- Sabzi, J.; Esfahani, M.R.; Ozbakkaloglu, T.; Farahi, B. Effect of concrete strength and longitudinal reinforcement arrangement on the performance of reinforced concrete beams strengthened using EBR and EBROG methods. Eng. Struct. 2020, 205, 110072. [Google Scholar] [CrossRef]

- GB 50367-2013; Chinese Standard, Code for Design of Strengthening Concrete Structure. Chinese Building Press: Beijing, China, 2013. (In Chinese)

- GB 50608-2010; Chinese Standard, Technical Code for Infrastructure Application of FRP Composites. China Planning Press: Beijing, China, 2011. (In Chinese)

- Fu, B.; Chen, G.M.; Teng, J.G. Mitigation of intermediate crack debonding in FRP-plated RC beams using FRP U-jackets. Compos. Struct. 2017, 176, 883–897. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G.; Harries, K.A. Intermediate crack-induced debonding in RC beams externally strengthened with prestressed FRP laminates. J. Reinf. Plast. Compos. 2013, 32, 1842–1857. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.A.A.; Ferdous, W.; Alyousef, R. Performances, challenges and opportunities in strengthening reinforced concrete structures by using FRPs—A state-of-the-art review. Eng. Fail. Anal. 2020, 111, 104480. [Google Scholar] [CrossRef]

- Attari, N.; Amziane, S.; Chemrouk, M. Flexural strengthening of concrete beams using CFRP, GFRP and hybrid FRP sheets. Constr. Build. Mater. 2012, 37, 746–757. [Google Scholar] [CrossRef]

- Do-Dai, T.; Chu-Van, T.; Tran, D.T.; Nassif, A.Y.; Nguyen-Minh, L. Efficacy of CFRP/BFRP laminates in flexurally strengthening of concrete beams with corroded reinforcement. J. Build. Eng. 2022, 53, 104606. [Google Scholar] [CrossRef]

- Yu, F.; Zhou, H.; Jiang, N.; Fang, Y.; Song, J.; Feng, C.; Guan, Y. Flexural experiment and capacity investigation of CFRP repaired RC beams under heavy pre-damaged level. Constr. Build. Mater. 2020, 230, 117030. [Google Scholar] [CrossRef]

- Kamae, T.; Drzal, L.T. Carbon fiber/epoxy composite property enhancement through incorporation of carbon nanotubes at the fiber–matrix interphase—Part I: The development of carbon nanotube coated carbon fibers and the evaluation of their adhesion. Compos. Part A 2012, 43, 1569–1577. [Google Scholar] [CrossRef]

- Qeshta, I.M.I.; Shafigh, P.; Jumaat, M.Z.; Abdulla, A.I.; Ibrahim, Z.; Alengaram, U.J. The use of wire mesh–epoxy composite for enhancing the flexural performance of concrete beams. Mater. Des. 2014, 60, 250–259. [Google Scholar] [CrossRef]

- Abbas, H.; Abadel, A.; Almusallam, T.; Al-Salloum, Y. Experimental and analytical study of flexural performance of concrete beams reinforced with hybrid of GFRP and steel rebars. Eng. Fail. Anal. 2022, 138, 106397. [Google Scholar] [CrossRef]

- Liu, D.; Qin, F.; Di, J.; Zhang, Z. Flexural behavior of reinforced concrete (RC) beams strengthened with carbon fiber reinforced polymer (CFRP) and ECC. Case Stud. Constr. Mater. 2023, 19, e02270. [Google Scholar] [CrossRef]

- Song, S.F.; Deng, M.K.; Zhang, M.; Guo, L.Y.; Dong, Z.F.; Li, P.P. Flexural strengthening of reinforced concrete beams using textile-reinforced mortar improved with short PVA fibers. Structures 2023, 56, 104824. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Nawaz, W.; Abdalla, J.A. Flexural behavior of reinforced concrete beams externally strengthened with Hardwire Steel-Fiber sheets. Constr. Build. Mater. 2018, 172, 562–573. [Google Scholar] [CrossRef]

- Nawaz, W.; Elchalakani, M.; Karrech, A.; Yehia, S.; Yang, B.; Youssf, O. Flexural behavior of all lightweight reinforced concrete beams externally strengthened with CFRP sheets. Constr. Build. Mater. 2022, 327, 126966. [Google Scholar] [CrossRef]

- D’Amato, M.; Braga, F.; Gigliotti, R.; Kunnath, S.; Laterza, M. A numerical general-purpose confinement model for non-linear analysis of R/C members. Compos. Struct. 2012, 102, 64–75. [Google Scholar] [CrossRef]

- Attard, M.M.; Setunge, S. Stress-strain relationship of confined and unconfined concrete. ACI Mater. J. 1996, 93, 432–442. [Google Scholar] [CrossRef]

- Kara, I.F.; Ashour, A.F. Flexural performance of FRP reinforced concrete beams. Compos. Struct. 2012, 94, 1616–1625. [Google Scholar] [CrossRef]

- A. 440.2R-08; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. ACI Committee 440: Farmington Hills, MI, USA, 2008.

- Tran, T.T.; Pham, T.M.; Hao, H. Experimental and analytical investigation on flexural behaviour of ambient cured geopolymer concrete beams reinforced with steel fibers. Eng Struct. 2019, 200, 109707. [Google Scholar] [CrossRef]

- ACI 318–11; Building Code Requirements for Structural Concrete. American Concrete Institute: Detroit, MI, USA, 2011.

- Hognestad, E. Study of Combined Bending and Axial Load in Reinforced Concrete Members, University of Illinois at Urbana Champaign, College of Engineering; 1951. Available online: https://www.ideals.illinois.edu/items/4902 (accessed on 11 May 2024).

- Toutanji, H.; Zhao, L.; Zhang, Y. Flexural behavior of reinforced concrete beams externally strengthened with CFRP sheets bonded with an inorganic matrix. Eng. Struct. 2006, 28, 557–566. [Google Scholar] [CrossRef]

- ACI Committee 440; State of the Art Report on Fiber Reinforced Plastic Reinforcement for Concrete Structures. American Concrete Institute (ACI): Detroit, MI, USA, 1996.

- ACI 318–14; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- Arabshahi, A.; Tavakol, M.; Sabzi, J.; Gharaei-Moghaddam, N. Prediction of the effective moment of inertia for concrete beams reinforced with FRP bars using an evolutionary algorithm. Structures 2022, 35, 684–705. [Google Scholar] [CrossRef]

- Said, H. Deflection prediction for FRP-strengthened concrete beams. J. Compos. Constr. 2009, 14, 244–248. [Google Scholar] [CrossRef]

- Hosen, A.; Jumaat, M.Z.; Alengaram, U.J.; Sulong, N.R. CFRP strips for enhancing flexural performance of RC beams by SNSM strengthening technique. Constr. Build. Mater. 2018, 165, 28–44. [Google Scholar] [CrossRef]

| Type | Diameter (mm) | Yield Strength (MPa) | Ultimate Strength (MPa) | Yield Microstrain (με) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|

| HPB300 | 8 | 300 | 420 | 1430 | 210 |

| HRB335 | 12 | 400 | 550 | 2100 | 200 |

| Scheme | Number of BFRP Layers | Adhesive |

|---|---|---|

| CB | 0 | |

| B-Neat-1 | 1 | Neat epoxy resin |

| B-CNT-1 | 1 | MWCNT-modified epoxy resin |

| B-Neat-2 | 2 | Neat epoxy resin |

| B-CNT-2 | 2 | MWCNT-modified epoxy resin |

| Specimen Number | Cracking Load Pcr (KN) | Yield Load Py (KN) | Ultimate Load Pu (KN) | Deflection at Cracking Load (mm) | Deflection at Yield Load (mm) | Deflection at Ultimate Load (mm) | EI (KN/mm) | EII (KN/mm) |

|---|---|---|---|---|---|---|---|---|

| CB | 12.87 | 45.95 | 64.65 | 0.52 | 3.95 | 29.52 | 9.17 | 0.94 |

| B-Neat-1 | 12.96 | 52.98 | 72.62 | 0.44 | 4.09 | 14.44 | 11.11 | 1.08 |

| B-CNT-1 | 13.04 | 57.01 | 75.02 | 0.51 | 4.11 | 16.41 | 11.36 | 1.26 |

| B-Neat-2 | 13.11 | 60.59 | 84.35 | 0.61 | 4.08 | 17.24 | 13.33 | 1.33 |

| B-CNT-2 | 13.15 | 65.06 | 91.38 | 0.63 | 4.23 | 20.38 | 13.64 | 1.63 |

| Specimen Number | Jc (kN·mm) | Jy (kN·mm) | Ju (kN·mm) |

|---|---|---|---|

| CB | 2.75 | 103.19 | 1578.33 |

| B-Neat-1 | 3.33 | 147.72 | 809.29 |

| B-CNT-1 | 3.40 | 150.73 | 970.43 |

| B-Neat-2 | 3.41 | 135.12 | 1116.05 |

| B-CNT-2 | 3.51 | 158.62 | 1440.91 |

| Specimen Number | CB to CB Specimen | CB to CB Specimen | ||

|---|---|---|---|---|

| CB | 7.47 | 1 | 12.72 | 1 |

| B-Neat-1 | 3.53 | 0.47 | 5.48 | 0.36 |

| B-CNT-1 | 3.99 | 0.53 | 6.44 | 0.42 |

| B-Neat-2 | 4.23 | 0.56 | 7.20 | 0.54 |

| B-CNT-2 | 4.82 | 0.64 | 8.22 | 0.59 |

| Specimen Number | Pcr,the (KN) | Pcr,exp (KN) | Pcr,the/ Pcr,exp | Py,the (KN) | Py,exp (KN) | Py,the/ Pyexp | Pu,the (KN) | Pu,exp (KN) | Pu,the/ Pu,exp |

|---|---|---|---|---|---|---|---|---|---|

| CB | 12.23 | 12.87 | 0.95 | 53.44 | 47.95 | 1.11 | 56.68 | 64.65 | 0.92 |

| B-Neat-1 | 12.23 | 12.96 | 0.94 | 55.94 | 52.98 | 1.06 | 64.33 | 72.62 | 0.93 |

| B-CNT-1 | 12.25 | 13.04 | 0.94 | 56.15 | 57.01 | 0.98 | 65.19 | 75.02 | 0.91 |

| B-Neat-2 | 12.26 | 13.11 | 0.94 | 57.61 | 60.59 | 0.95 | 74.31 | 84.35 | 0.88 |

| B-CNT-2 | 12.26 | 13.15 | 0.93 | 57.98 | 65.06 | 0.89 | 75.72 | 91.38 | 0.83 |

| Specimen Number | Δcr,the (mm) | Δcr,exp (mm) | Δcr,the/ Δcr,exp | Δy,the (mm) | Δy,exp (mm) | Δy,the/ Δy,exp | Δu,the (mm) | Δu,exp (mm) | Δu,the/ Δu,exp |

|---|---|---|---|---|---|---|---|---|---|

| CB | 0.43 | 0.52 | 0.83 | 3.49 | 3.95 | 0.88 | 29.85 | 29.52 | 1.01 |

| B-Neat-1 | 0.41 | 0.48 | 0.85 | 3.60 | 4.09 | 0.88 | 16.03 | 14.44 | 1.11 |

| B-CNT-1 | 0.41 | 0.48 | 0.85 | 3.61 | 4.11 | 0.88 | 16.26 | 16.41 | 0.99 |

| B-Neat-2 | 0.41 | 0.47 | 0.87 | 3.67 | 4.08 | 0.90 | 17.39 | 17.24 | 1.01 |

| B-CNT-2 | 0.41 | 0.46 | 0.89 | 3.68 | 4.21 | 0.87 | 17.60 | 18.77 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, C.; Jin, S.; Wang, C.; Yang, Y. Enhancing Flexural Behavior of Reinforced Concrete Beams Strengthened with Basalt Fiber-Reinforced Polymer Sheets Using Carbon Nanotube-Modified Epoxy. Materials 2024, 17, 3250. https://doi.org/10.3390/ma17133250

Shi C, Jin S, Wang C, Yang Y. Enhancing Flexural Behavior of Reinforced Concrete Beams Strengthened with Basalt Fiber-Reinforced Polymer Sheets Using Carbon Nanotube-Modified Epoxy. Materials. 2024; 17(13):3250. https://doi.org/10.3390/ma17133250

Chicago/Turabian StyleShi, Changchun, Shengji Jin, Chengjie Wang, and Yuhao Yang. 2024. "Enhancing Flexural Behavior of Reinforced Concrete Beams Strengthened with Basalt Fiber-Reinforced Polymer Sheets Using Carbon Nanotube-Modified Epoxy" Materials 17, no. 13: 3250. https://doi.org/10.3390/ma17133250