Corrosion Resistance of Coatings Based on Chromium and Aluminum of Titanium Alloy Ti-6Al-4V

Abstract

1. Introduction

2. Materials and Methods

3. Results

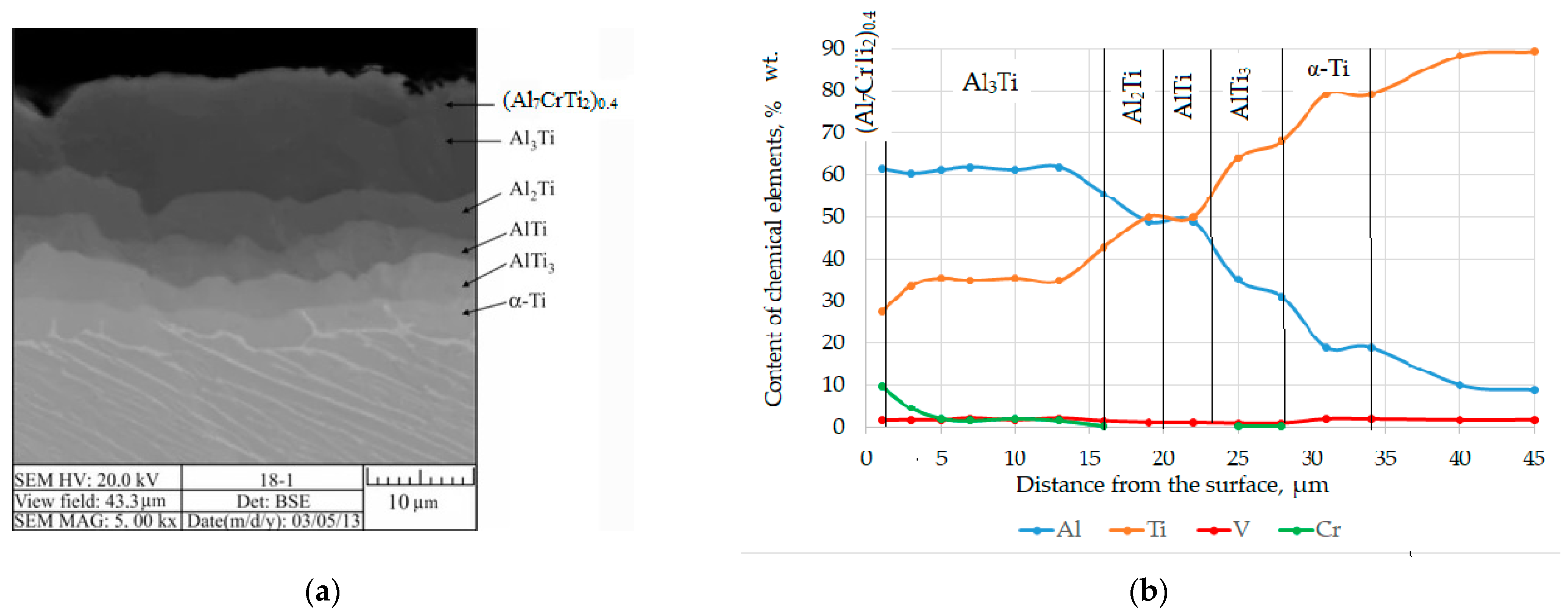

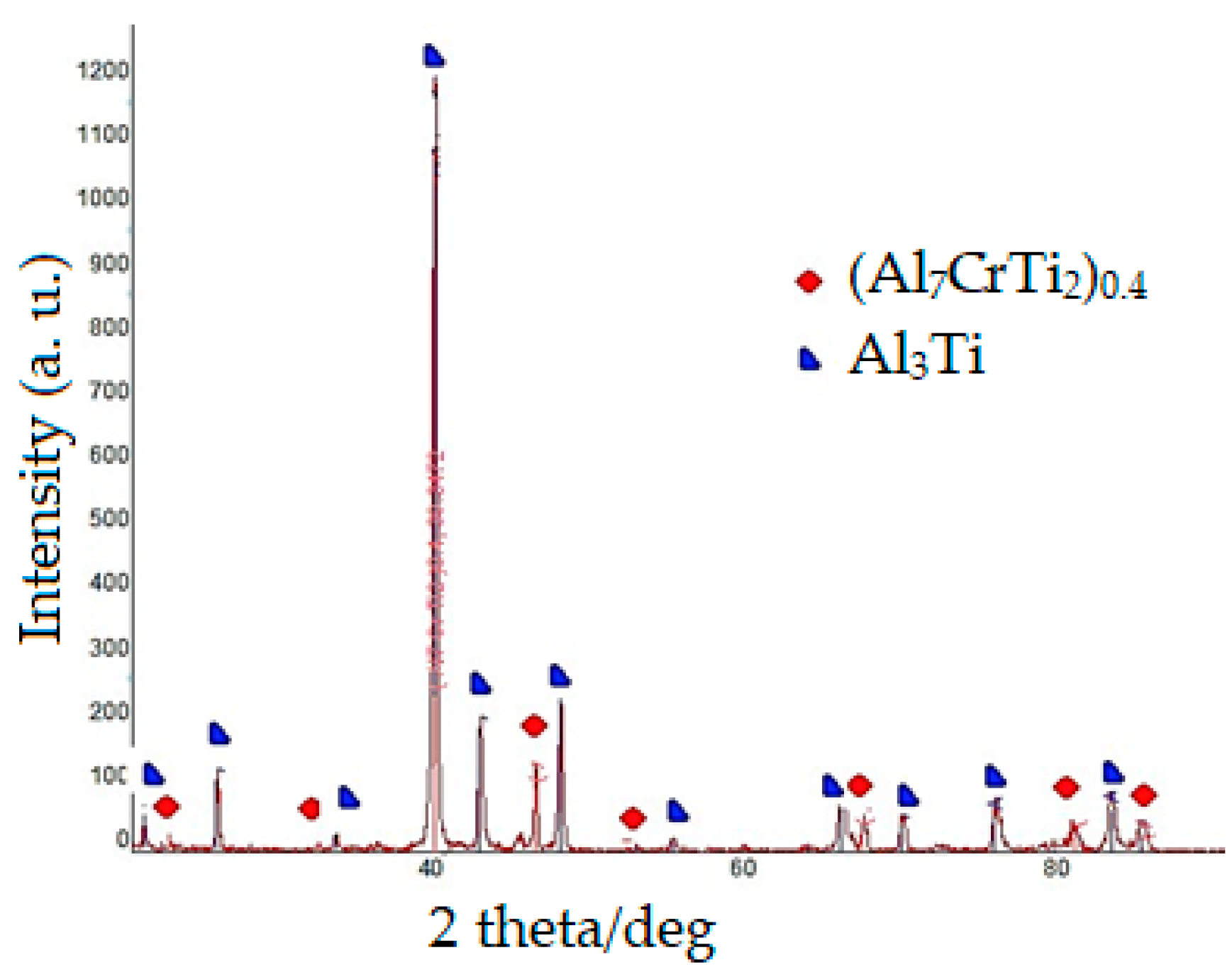

3.1. X-ray Structural and X-ray Spectral Analysis Results

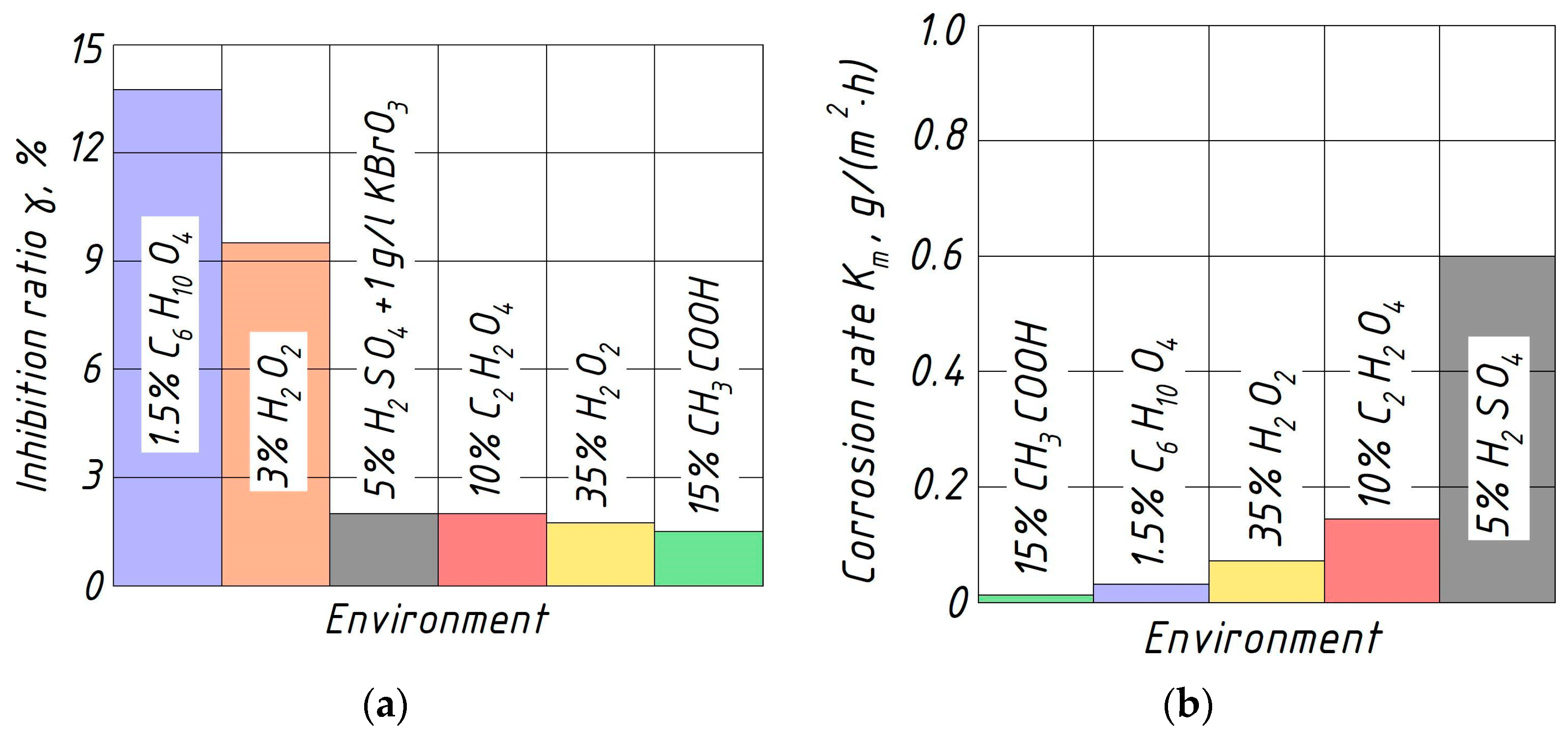

3.2. Massometric Tests Results

- -

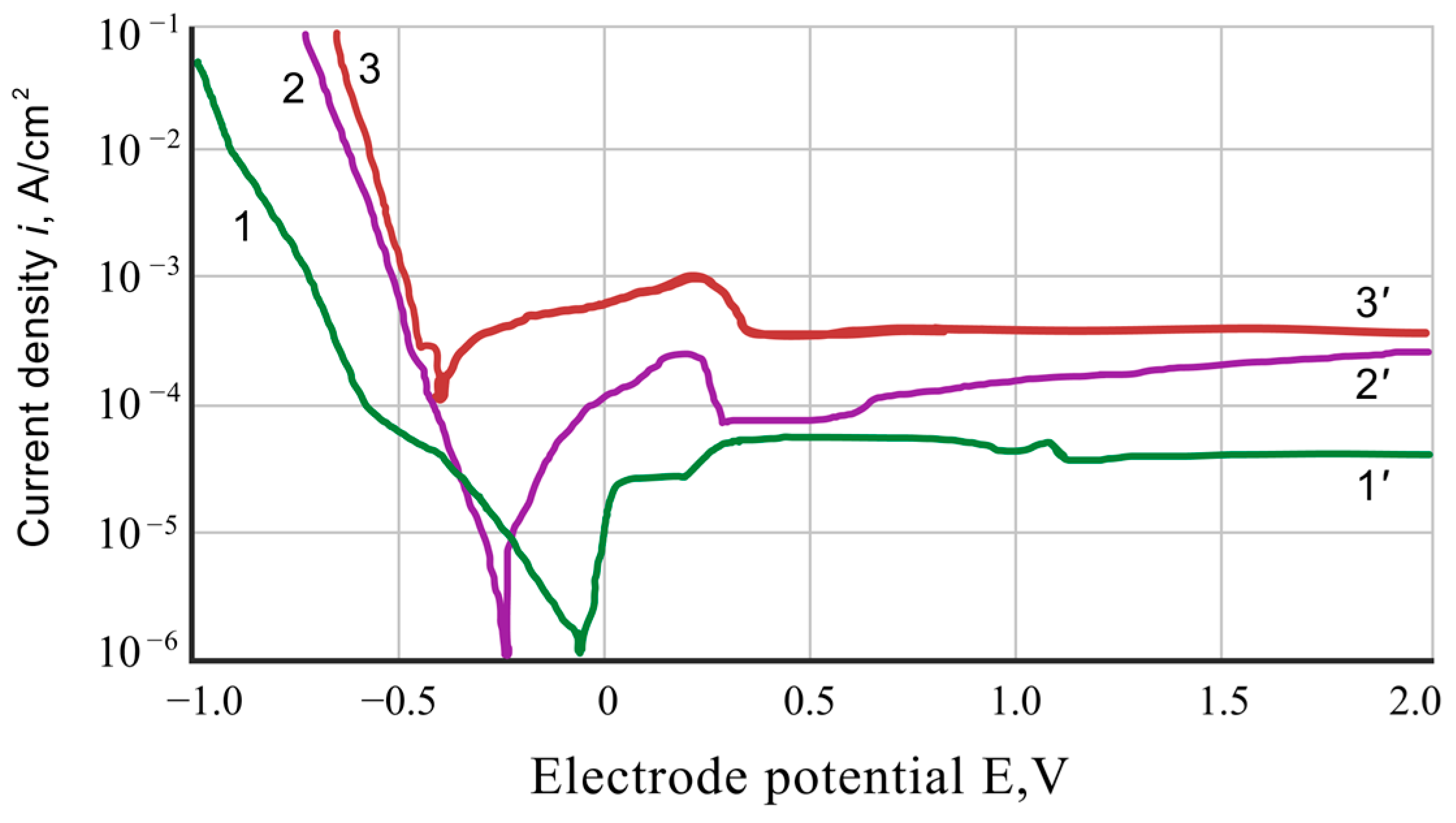

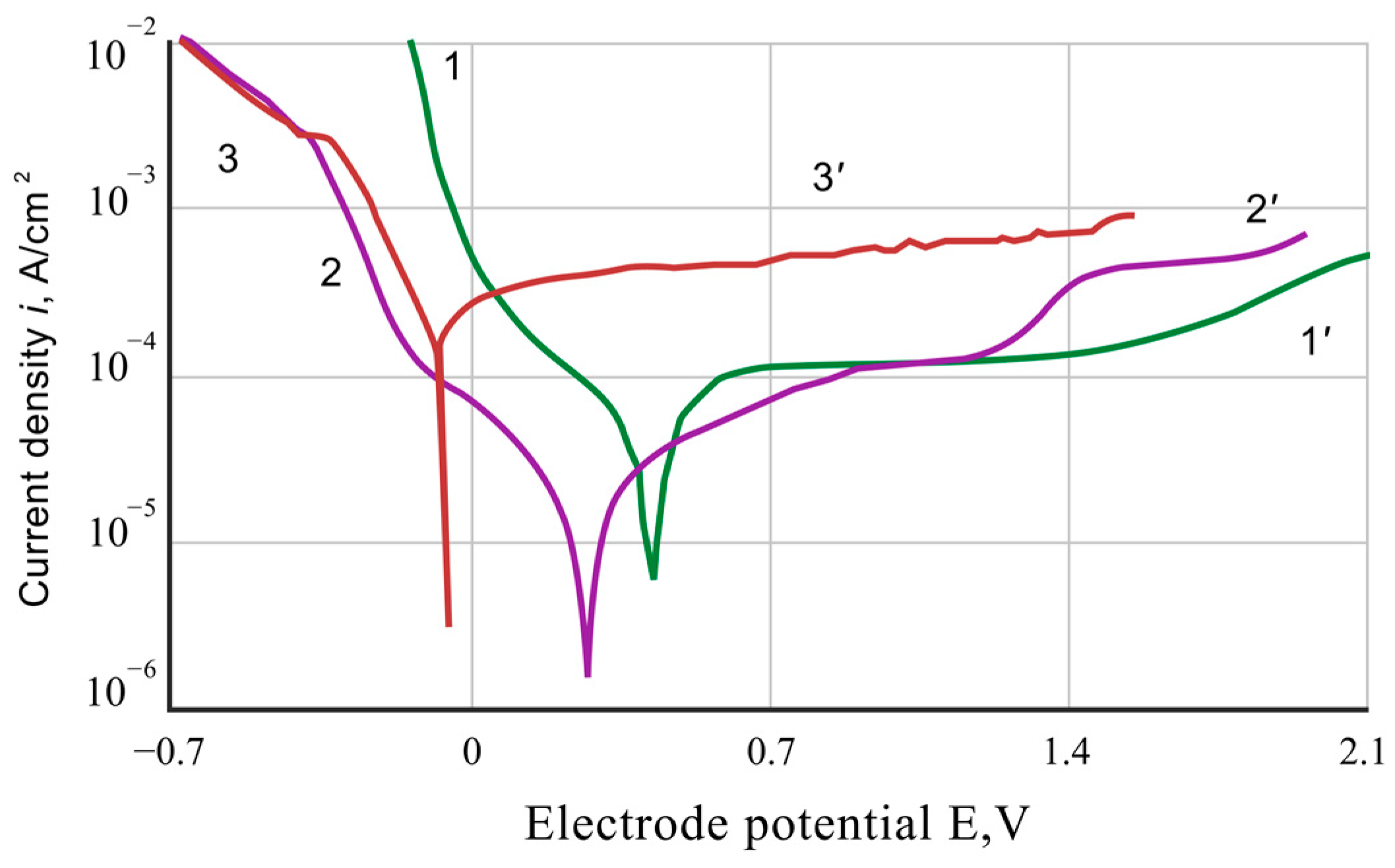

- the protective properties of oxide films that can form on the surface of the Ti-6Al-4 V titanium alloy may selectively affect its corrosion resistance in solutions of reducing acids (such as H3PO4 and H2SO4) due to chemical dissolution during the interaction of H+ ions, the protective properties of such films can significantly decrease, in solutions containing oxygen or other oxidizing agents (e.g., H2O2, HNO3) increase;

- -

- different types of depolarization of corrosion processes are as follows: oxygen depolarization in Na2CO3 solutions, oxygen or hydrogen-oxygen depolarization in organic acid solutions, hydrogen depolarization in H3PO4 and H2SO4 solutions, oxidizing in H2O2 solutions, hydrogen-oxidizing in HNO3 solutions;

- -

- by the selective effect of anions of the environment on the rate of the anodic reaction of dissolution of metals, since anions SO42−, HSO4− usually catalyze its flow, and anions NO2−, CO32− may lead to the passivation of metals.

3.3. Voltammetric Test Results

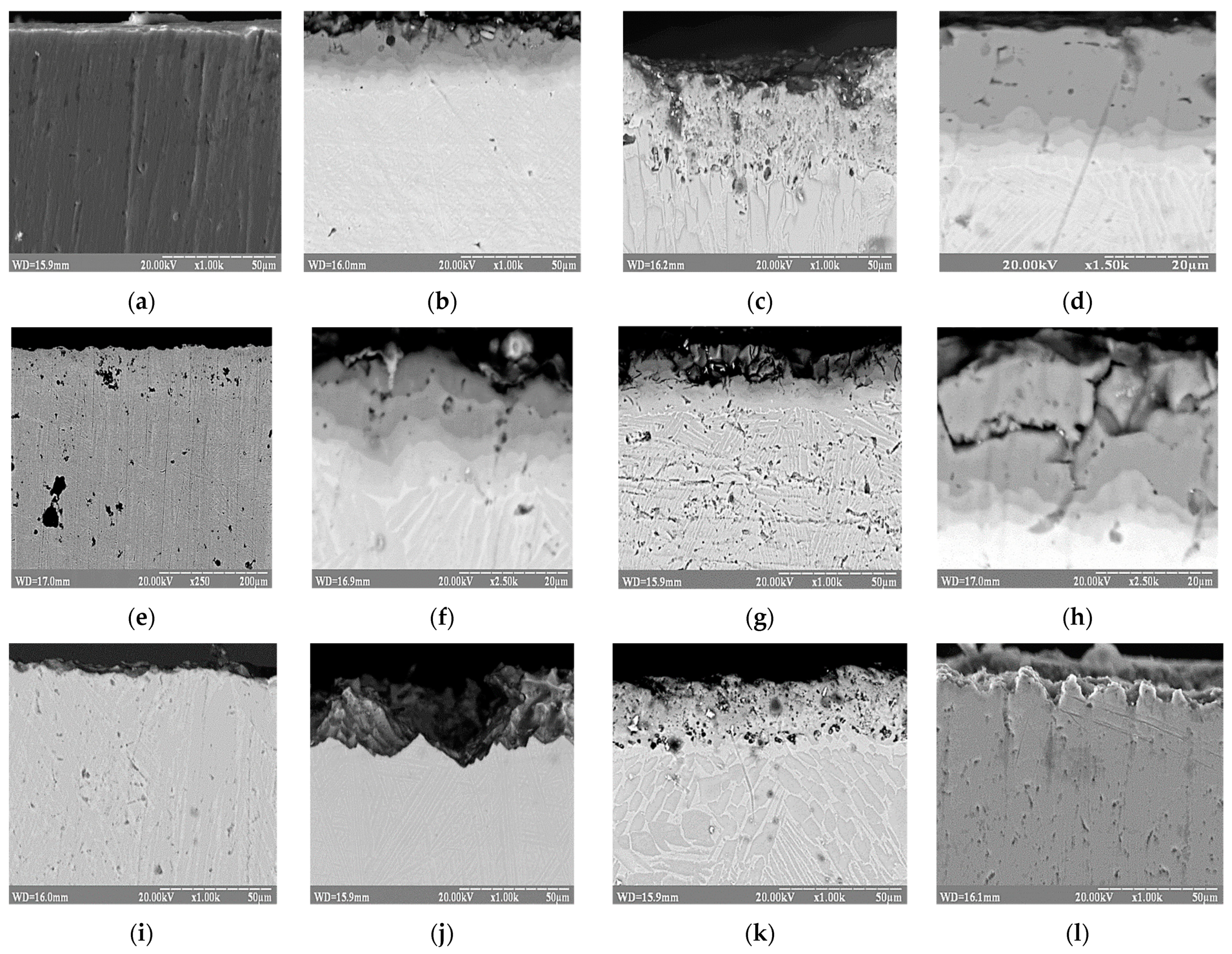

3.4. Microstructural Analysis Results

4. Discussion

5. Conclusions

- The multilayer coating is formed as a result of the chromaluminizing of the Ti-6Al-4V alloy and consists of layers (Al7CrTi2)0.4 to Al3Ti, Al2Ti, AlTi, AlTi3, and a solid solution of α-Ti The total thickness of the protective coating is 32.0–34.0 µm, and the microhardness of the obtained coatings is 2.3 times higher than the microhardness of VT6 in the initial state. It has been established that the surface layer of the coating contains 61.3–60.24% wt. Al, 27.5–33.62% wt. of Ti, 1.5–1.64% wt. V, and 9.7–4.5% wt. Cr.

- According to the decrease in corrosion resistance of initial Ti-6Al-4V alloy and Ti-6Al-4V alloy after chromaluminizing, aggressive environments can be arranged as follows: aqueous solution of 10% Na2CO3; 15% CH3COOH; 10% C2H2O4; 35% H2O2; 5–10% H2SO4; and 10% H3PO4.

- A lower corrosion resistance of Ti-6Al-4V alloy with chromium–aluminum diffusion coatings was recorded in comparison with the initial Ti-6Al-4V alloy in 40% aqueous solution of HNO3 and 10% aqueous solution of Na2CO3.

- The chromaluminizing of the Ti-6Al-4V alloy samples leads to a 1.5–2.0 times increase in their corrosion resistance in the investigated CH3COOH and C2H2O4 solutions, 1.8–9.5 times in H2O2 solutions, and 13.7 times in C6H10O4 solutions. However, it is somewhat reduced in the solutions of the investigated mineral acids.

- Corrosion of the chromaluminizing of the Ti-6Al-4V alloy, like the initial Ti-6Al-4V alloy, occurs in the studied solutions with different types of depolarization.

- The selectivity of the corrosion resistance of the chromaluminizing coating and the nature of its influence on the corrosion resistance of samples made of the Ti-6Al-4V alloy is due to different types of depolarization of the investigated corrosion processes, as well as different protective properties of the oxide films of the coating components and the products of its corrosion destruction (and first of all, the products of aluminum corrosion).

- The significant hardness and high corrosion resistance of the chromaluminizing alloy in solutions of organic acids and hydrogen peroxide allow it to be recommended for practical use in conditions of simultaneous exposure to titanium products of the studied oxidizing environments and the action of mechanical loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chou, W.-J.; Yu, G.-P.; Huang, J.-H. Corrosion behavior of TiN-coated 304 stainless steel. Corros. Sci. 2001, 43, 2023–2035. [Google Scholar] [CrossRef]

- Bell, T. Surface engineering of austenitic stainless steel. Surf. Eng. 2002, 18, 415–422. [Google Scholar] [CrossRef]

- Saurabh, A.; Meghana, C.M.; Singh, P.K.; Verma, P.C. Titanium-based materials: Synthesis, properties, and applications. Mater. Today Proc. 2022, 56, 412–419. [Google Scholar] [CrossRef]

- Medvedovski, E.; Chinski, F.A.; Stewart, J. Thermal diffusion coatings for wear-resistant components for oil and gas industry. In Innovative Processing and Manufacturing of Advanced Ceramics and Composites II: Ceramic Transactions; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; Volume 243, pp. 13–29. [Google Scholar] [CrossRef]

- Kandeva, M.; Zagorski, M.; Nikolič, R.; Stojanović, B.; But, A.; Botko, F.; Piteľ, J.; Vencl, A. Friction properties of the heat-treated electroless Ni coatings embedded with c-BN nanoparticles. Coatings 2022, 12, 1008. [Google Scholar] [CrossRef]

- Loskutova, T.; Hatala, M.; Pogrebova, I.; Nikitina, N.; Bobina, M.; Radchenko, S.; Kharchenko, N.; Kotlyar, S.; Pavlenko, I.; Ivanov, V. Composition, structure, and properties of Ti, Al, Cr, N, C multilayer coatings on AISI W1-7 alloyed tool steel. Coatings 2022, 12, 616. [Google Scholar] [CrossRef]

- Bansal, D.G.; Eryilmaz, O.L.; Blau, P.J. Surface engineering to improve the durability and lubricity of Ti–6Al–4V alloy. Wear 2011, 271, 2006–2015. [Google Scholar] [CrossRef]

- Aljibori, H.S.; Alamiery, A.; Kadhum, A.A.H. Advances in corrosion protection coatings: A comprehensive review. Int. J. Corros. Scale Inhib. 2023, 12, 1476–1520. [Google Scholar] [CrossRef]

- Kowalski, S. The influence of selected PVD coatings on fretting wear in a clamped joint based on the example of a rail vehicle wheel set. Maint. Reliab. 2018, 20, 1–8. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Fedun, V.I.; Pastukhova, T.V.; Zurnadzhy, V.I.; Berezhnyy, S.P.; Efremenko, V.G. Modification of steel surface by pulsed plasma heating. Probl. At. Sci. Technol. 2017, 110, 97–102. [Google Scholar]

- Chabak, Y.; Efremenko, V.; Zurnadzhy, V.; Puchý, V.; Petryshynets, I.; Efremenko, B.; Fedun, V.; Shimizu, K.; Bogomol, I.; Kulyk, V.; et al. Structural and tribological studies of “(TiC + WC)/hardened steel” PMMC coating deposited by air pulsed plasma. Metals 2022, 12, 218. [Google Scholar] [CrossRef]

- Vencl, A.; Vucetic, F.; Bobic, B.; Pitel, J.; Bobic, I. Tribological characterisation in dry sliding conditions of compocasted hybrid A356/SiCp/Grp composites with graphite macroparticles. Int. J. Adv. Manuf. Technol. 2019, 100, 2135–2146. [Google Scholar] [CrossRef]

- Von Fieandt, L.; Larsson, T.; Lindahl, E.; Backe, O.; Boman, M. Chemical vapor deposition of TiN on transition metal substrates. Surf. Coat. Technol. 2018, 334, 373–383. [Google Scholar] [CrossRef]

- Makymova, S.V.; Voronov, V.V.; Kovalchuk, P.V.; Shapiro, A.E. Vacuum high-temperature brazing of 3003 aluminum alloy. J. Eng. Sci. 2023, 10, C1–C10. [Google Scholar] [CrossRef]

- Smokovich, I.Y.; Loskutova, T.V.; Khizhnyak, V.G. Heat resistance of VT6 alloy with and without aluminum–chromium diffusion coatings at 500, 700, and 900 °C. Powder Metall. Met. Ceram. 2014, 53, 48–56. [Google Scholar] [CrossRef]

- Toller, L.; Liu, C.; Holmstrom, E.; Larsson, T.; Norgren, S. Investigation of cemented carbides with alternative binders after CVD coating. Int. J. Refract. Met. Hard Mater. 2016, 62, 225–229. [Google Scholar] [CrossRef]

- Gatzen, C.; Smokovych, I.; Scheffler, M.; Krüger, M. Oxidation-resistant environmental barrier coatings for Mo-based alloys: A review. Adv. Eng. Mater. 2021, 23, 2001016. [Google Scholar] [CrossRef]

- Priyantha, N.; Jayaweera, P.; Sanjurjo, A.; Lau, K.; Lu, F.; Krist, K. Corrosion-resistant metallic coatings for applications in highly aggressive environments. Surf. Coat. Technol. 2003, 163–164, 31–36. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Wilkinson, D.S.; Veldhuis, S.C.; Dosbaeva, G.K.; Weatherly, G.C. Oxidation resistant Ti-Al-Cr alloy for protective coating applications. Intermetallics 2006, 14, 189–197. [Google Scholar] [CrossRef]

- Barabash, O.M.; Milman, Y.V.; Miracle, D.V.; Karpets, M.B.; Korzhova, N.P.; Legkaya, T.N.; Mordovets, N.M.; Podresov, Y.N.; Voskoboinik, I.V. Formation of periodic microstructures involving the L12 phase in eutectic Al–Ti–Cr alloys. Intermetallics 2003, 11, 953–962. [Google Scholar] [CrossRef]

- Furuta, T. Chapter 4—Automobile applications of titanium. In Titanium for Consumer Applications. Real World Use of Titanium; Elsevier: Amsterdam, The Netherlands, 2019; pp. 77–90. [Google Scholar] [CrossRef]

- Zeng, S.; Li, F. Research Status of Aluminum Base Coating on Titanium Alloy. Coatings 2023, 13, 1525. [Google Scholar] [CrossRef]

- Xu, Y.; Yao, Z.; Jia, F.; Wang, Y.; Jiang, Z.; Bu, H. Preparation of PEO ceramic coating on Ti alloy and its high temperature oxidation resistance. Curr. Appl. Phys. 2010, 10, 698–702. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Ye, W.; Zhang, T.; Wan, J.; Zhou, Q.; Shen, J.; Li, J.; Lu, W.F.; Wang, H. Simultaneously improving mechanical, thermal, and anti-wear properties of Ti alloys using 3D-networked graphene as reinforcement. Carbon 2023, 213, 118152. [Google Scholar] [CrossRef]

- Taghipour, M.; Eslami, A.; Bahrami, A. High temperature oxidation behavior of aluminide coatings applied on HP-MA heat resistant steel using a gas-phase aluminizing process. Surf. Coat. Technol. 2022, 434, 128181. [Google Scholar] [CrossRef]

- Raj, A.; Goswami, B.; Kumar, S.B.; Krishna, G.; Roy, N.; Ray, A.K. Damage analysis of service exposed reformer tubes in petrochemical industries. High Temp. Mater. Process. 2014, 33, 201–216. [Google Scholar] [CrossRef]

- Lu, J.; Huang, J.; Wang, J.; Yang, Z.; Gu, Y. Long-term degradation behavior of slurry aluminide coating on Super304H stainless steel at 650 °C. Corros. Sci. 2021, 178, 109054. [Google Scholar] [CrossRef]

- Mahmoudi, H.; Mehdi Hadavi, S.M.; Palizdar, Y. Characterization, growth kinetics and formation mechanism of aluminide coating by plasma paste aluminizing on IN738. Vacuum 2021, 184, 109968. [Google Scholar] [CrossRef]

- Mahini, S.; Asl, S.K.; Rabizadeh, T.; Aghajani, H. Effects of the pack Al content on the microstructure and hot corrosion behavior of aluminide coatings applied on Inconel-600. Surf. Coat. Technol. 2020, 397, 125949. [Google Scholar] [CrossRef]

- Goral, M.; Ochal, K.; Kubaszek, T.; Drajewicz, M. The influence of deposition technique of aluminide coatings on oxidation resistance of different nickel superalloys. Mater. Today Proc. 2020, 33, 1746–1751. [Google Scholar] [CrossRef]

- Loskutova, T.; Sigova, V.; Khizhnyak, V.; Loskutov, V. Complex Carbide Coatings on Metals and Alloys; Sumy State Univesrity: Sumy, Ukraine, 2009. [Google Scholar]

- Muboyadzhian, S.; Budynovsky, S.; Terekhova, V. Ion-plasma diffusion aluminide coatings for gas turbine blades (structure and properties). Met. Sci. Therm. Process. Met. 2003, 1, 14–21. [Google Scholar]

- Leyens, C.; Schmidt, M.; Peters, M.; Kaysser, W.A. Sputtered intermetallic Ti–Al–X coatings: Phase formation and oxidation behavior. Mater. Sci. Eng. A 1997, 239–240, 680–687. [Google Scholar] [CrossRef]

- Bai, C.Y.; Luo, Y.J.; Koo, C.H. Improvement of high temperature oxidation and corrosion resistance of superalloy IN-738LC by pack cementation. Surf. Coat. Technol. 2004, 183, 74–88. [Google Scholar] [CrossRef]

- Buchanan, K.G.; Kral, M.V. Crystallography and morphology of niobium carbide in as-cast HP-Niobium reformer tubes. Metall. Mater. Trans. A 2012, 43, 1760–1769. [Google Scholar] [CrossRef]

- Garbiak, M.; Jasiński, W.; Piekarski, B. Materials for reformer furnace tubes. History of evolution. Arch. Foundry Eng. 2011, 11, 47–52. [Google Scholar]

- Hu, C.; Zhang, J.; Chen, L.; Xu, Y.X.; Kong, Y.; Du, J.W.; Mayrhofer, P.H. Self-layering of (Ti,Al)N by interface-directed spinodal decomposition of (Ti,Al)N/TiN multilayers: First-principles and experimental investigations. Mater. Des. 2022, 224, 111392. [Google Scholar] [CrossRef]

- ASTM E92-82(2003); Standard Test Method for Vickers Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- Schuster, J.C.; Palm, M. Reassessment of the binary aluminum-titanium phase diagram. J. Phase Equilibria Diffus. 2006, 27, 255–277. [Google Scholar] [CrossRef]

- Jung, H.G.; Jung, D.J.; Kim, K.Y. Effect of Cr addition on the properties of aluminide coating layers formed on TiAl alloys. Surf. Coat. Technol. 2002, 154, 75–81. [Google Scholar] [CrossRef]

- Zhoua, C.; Xu, H.; Gong, S.; Yang, Y.; Kim, K.Y. A study on aluminide and Cr-modified aluminide coatings on TiAl alloys by pack cementation method. Surf. Coat. Technol. 2000, 132, 117–123. [Google Scholar] [CrossRef]

- Pesterfield, L.L.; Maddox, J.B.; Crocker, M.S.; Schweitzer, G.K. Pourbaix (E–pH-M) diagrams in three dimensions. J. Chem. Educ. 2012, 89, 891–899. [Google Scholar] [CrossRef]

- Yang, J.; Song, Y.; Dong, K.; Han, E.-H. Research progress on the corrosion behavior of titanium alloys. Corros. Rev. 2023, 41, 5–20. [Google Scholar] [CrossRef]

- Maniam, K.K.; Paul, S. A review on the electrodeposition of aluminum and aluminum alloys in ionic liquids. Coatings 2021, 11, 80. [Google Scholar] [CrossRef]

- Li, J.; Lin, X.; Tan, H.; Zhu, G.; Liu, Y.; Chan, K.C.; Shi, S. Electrochemical dissolution behavior of Ti6Al4V alloy: Effect of microstructure and processing method. J. Mater. Process. Technol. 2022, 307, 117646. [Google Scholar] [CrossRef]

- Heakal, F.E.T.; Shehata, O.S. Insight into the electrochemical and semiconducting properties of native oxide films on ti metal and its Ti–6Al–4V alloy in borate buffer solutions. Prot. Met. Phys. Chem. Surf. 2020, 56, 333–342. [Google Scholar] [CrossRef]

| Phase Composition | Coating Thickness, μm | Microhardness, GPa |

|---|---|---|

| (Al7CrTi2)0.4 | 1.0–1.5 | – |

| Al3Ti | 11.0–13.0 | 8.0 |

| Al2Ti | 4.0–5.0 | 7.8 |

| AlTi | 3.0–4.0 | 5.0 |

| AlTi3 | 4.0–5.0 | 4.0 |

| α-Ti | 4.0–5.0 | 3.6 |

| Environment 1 | Km, g/(m2∙h) | Inhibition Ratio γ | Protection Degree PD, % | |

|---|---|---|---|---|

| Ti-6Al-4V Alloy | With Cr-Al Coatings | |||

| 15% CH3COOH, pH4 | 0.0091 | 0.0061 | 1.50 | 34 |

| 1.5% C6H10O4, pH3 | 0.1426 | 0.0104 | 13.71 | 92.7 |

| 10% C2H2O4, pH1 | 0.1518 | 0.0759 | 2.00 | 50 |

| 10% H2SO4, pH2 | 0.8957 | 0.9460 | 0.94 | – |

| 40% HNO3, pH1 | 0.0901 | 0.2120 | 0.74 | – |

| 3% H2O2, pH6 | 0.3430 | 0.0360 | 9.50 | 89.5 |

| 35% H2O2, pH4 | 0.3002 | 0.1715 | 1.75 | 43 |

| 10% H3PO4, pH2 | 0.9759 | 1.0460 | 0.93 | – |

| 10% Na2CO3, pH9 | 0.0017 | 0.0050 | 0.34 | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loskutova, T.; Scheffler, M.; Pavlenko, I.; Zidek, K.; Pohrebova, I.; Kharchenko, N.; Smokovych, I.; Dudka, O.; Palyukh, V.; Ivanov, V.; et al. Corrosion Resistance of Coatings Based on Chromium and Aluminum of Titanium Alloy Ti-6Al-4V. Materials 2024, 17, 3880. https://doi.org/10.3390/ma17153880

Loskutova T, Scheffler M, Pavlenko I, Zidek K, Pohrebova I, Kharchenko N, Smokovych I, Dudka O, Palyukh V, Ivanov V, et al. Corrosion Resistance of Coatings Based on Chromium and Aluminum of Titanium Alloy Ti-6Al-4V. Materials. 2024; 17(15):3880. https://doi.org/10.3390/ma17153880

Chicago/Turabian StyleLoskutova, Tetiana, Michael Scheffler, Ivan Pavlenko, Kamil Zidek, Inna Pohrebova, Nadiia Kharchenko, Iryna Smokovych, Oleksandr Dudka, Volodymyr Palyukh, Vitalii Ivanov, and et al. 2024. "Corrosion Resistance of Coatings Based on Chromium and Aluminum of Titanium Alloy Ti-6Al-4V" Materials 17, no. 15: 3880. https://doi.org/10.3390/ma17153880

APA StyleLoskutova, T., Scheffler, M., Pavlenko, I., Zidek, K., Pohrebova, I., Kharchenko, N., Smokovych, I., Dudka, O., Palyukh, V., Ivanov, V., & Kononenko, Y. (2024). Corrosion Resistance of Coatings Based on Chromium and Aluminum of Titanium Alloy Ti-6Al-4V. Materials, 17(15), 3880. https://doi.org/10.3390/ma17153880