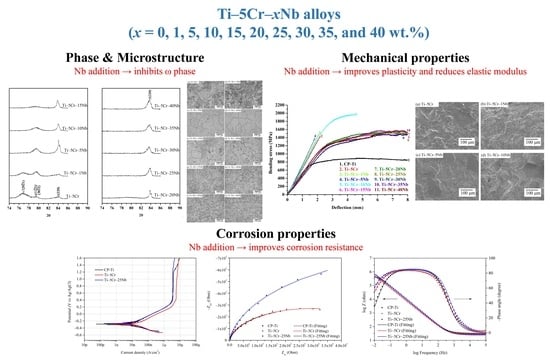

Experimental Investigation of the Impact of Niobium Additions on the Structural Characteristics and Properties of Ti–5Cr–xNb Alloys for Biomedical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Alloy Fabrication

2.2. Microstructural and Phase Analysis

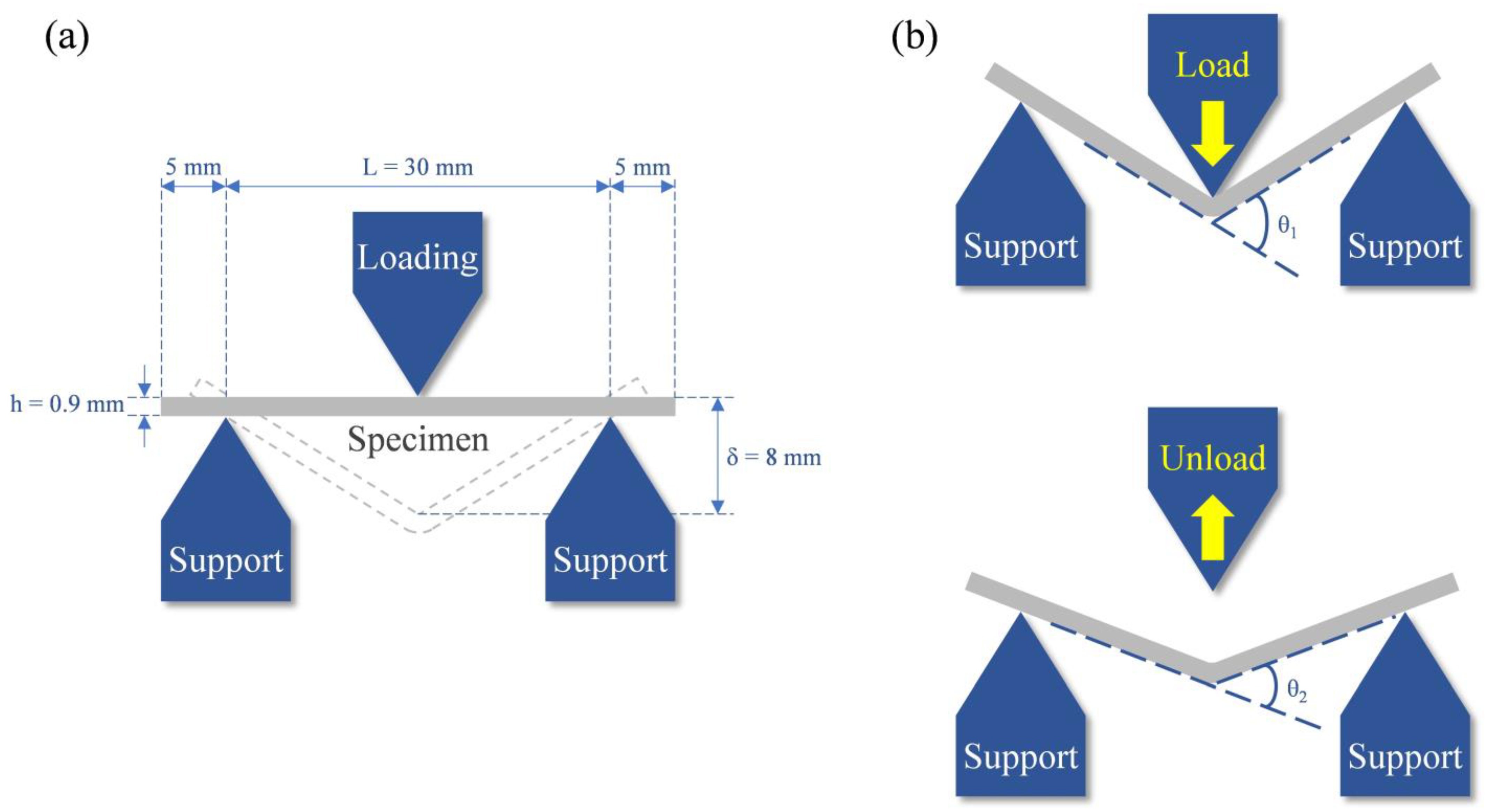

2.3. Mechanical Testing

2.4. Corrosion Testing

3. Results and Discussion

3.1. Phase Identification

3.2. Microstructure

3.3. Mechanical Properties

3.3.1. Microhardness

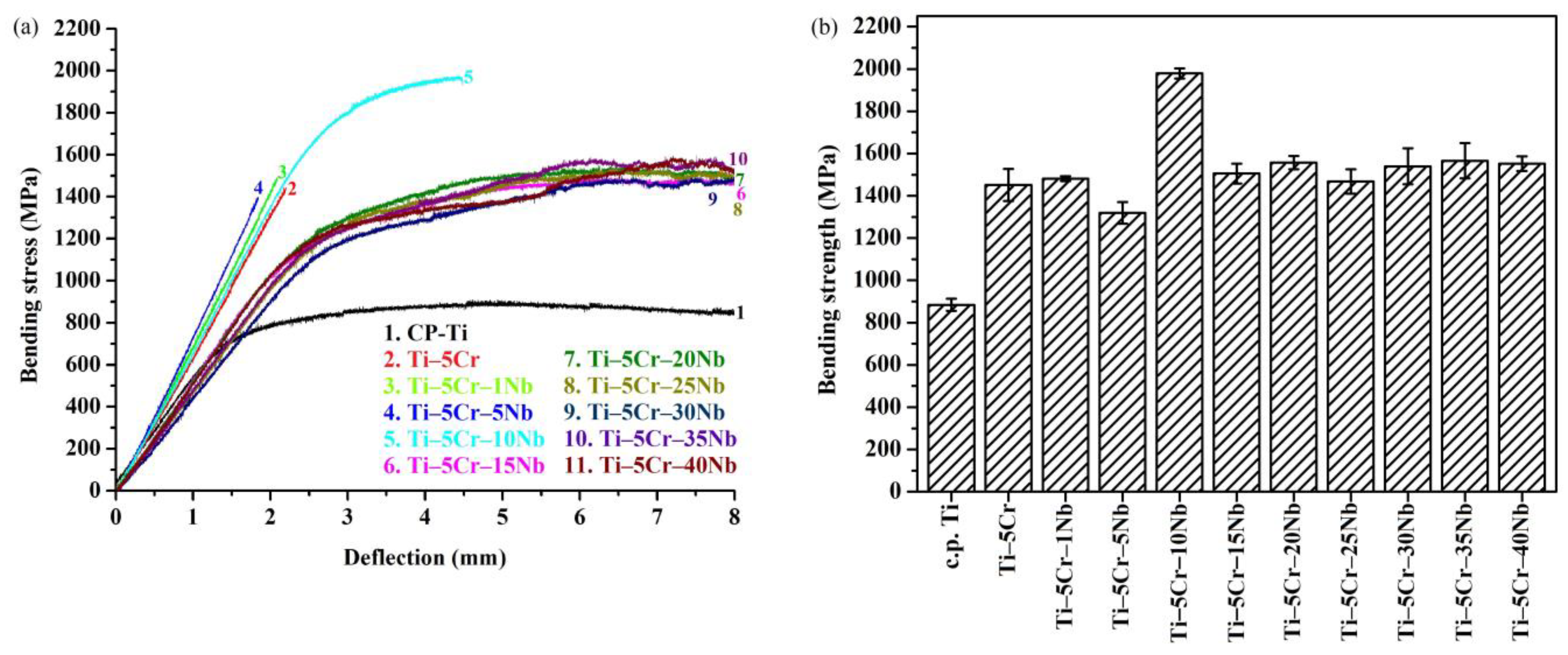

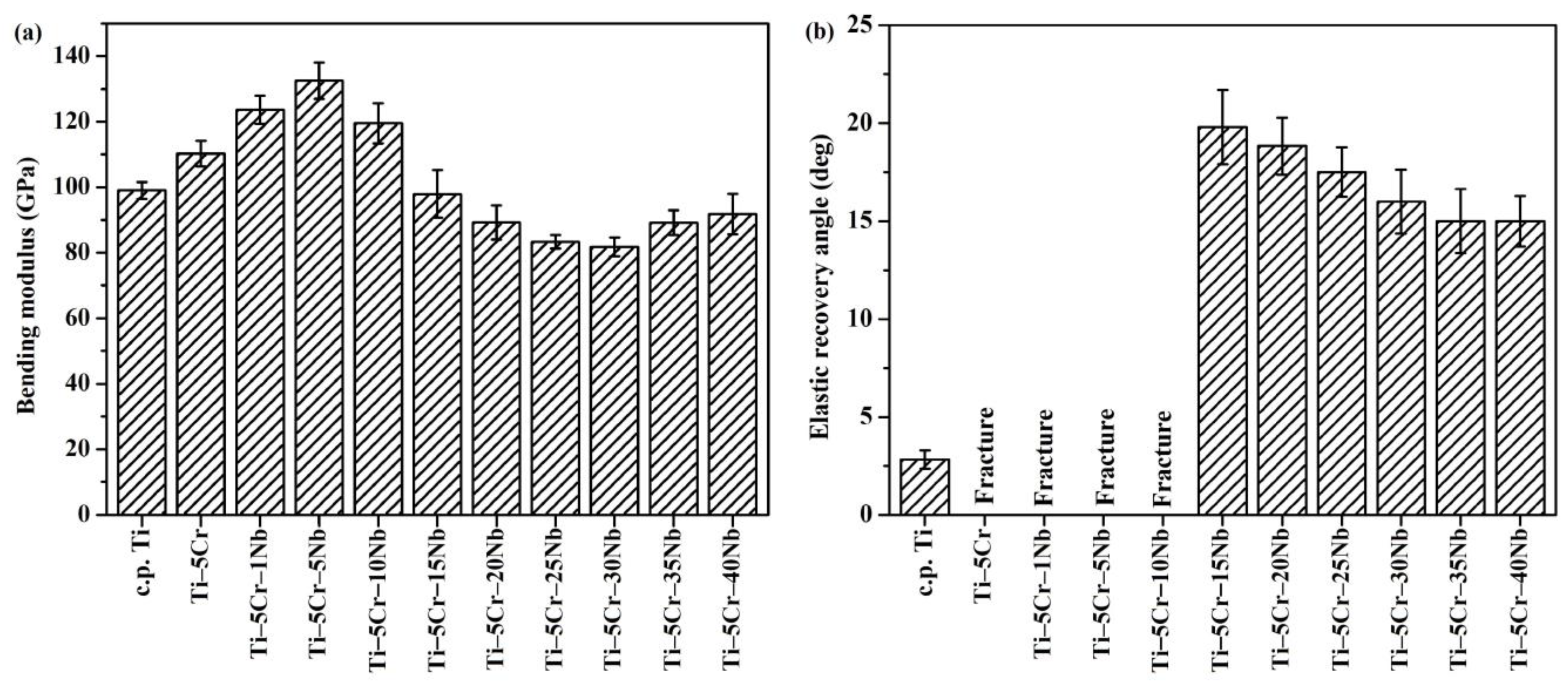

3.3.2. Bending Properties

3.3.3. Fracture Surface Topography

3.4. Corrosion Properties

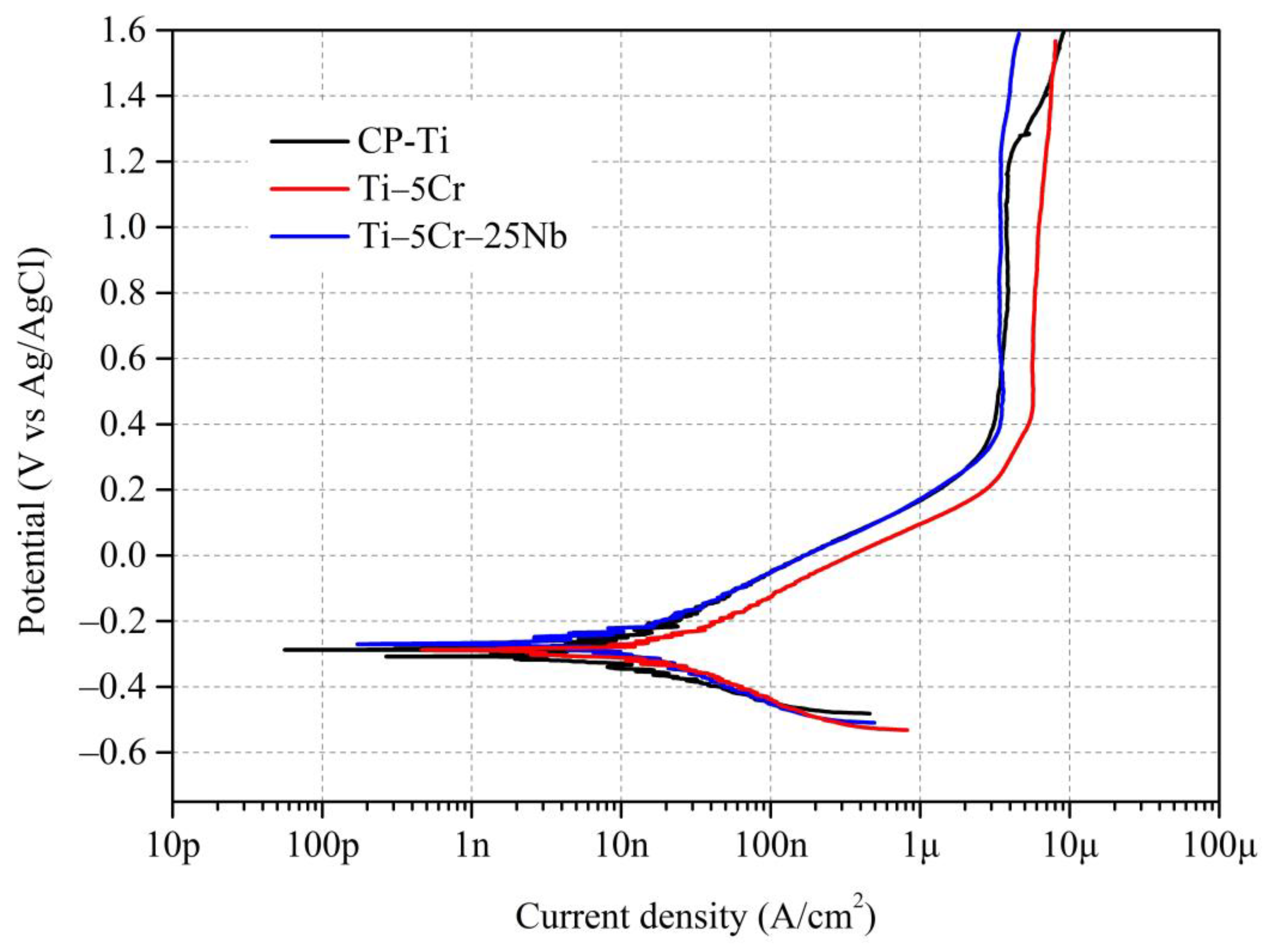

3.4.1. Potentiodynamic Polarization Tests

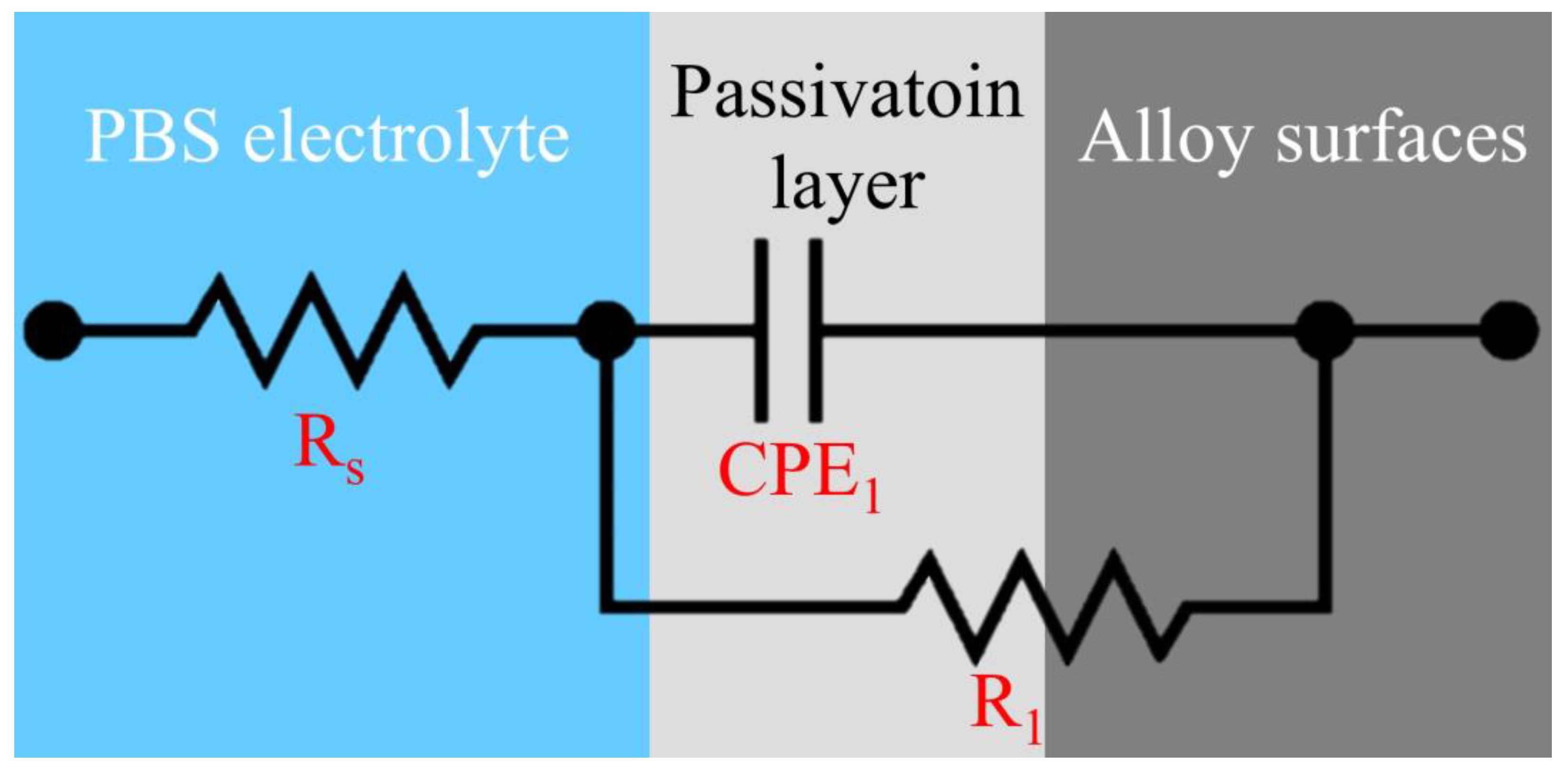

3.4.2. EIS Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Senopati, G.; Rahman Rashid, R.A.; Kartika, I.; Palanisamy, S. Recent Development of Low-Cost β-Ti Alloys for Biomedical Applications: A Review. Metals 2023, 13, 194. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Anene, F.A.; Jaafar, C.N.A.; Zainol, I.; Hanim, M.A.A.; Suraya, M.T. Biomedical materials: A review of titanium based alloys. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2021, 235, 3792–3805. [Google Scholar] [CrossRef]

- Močnik, P.; Kosec, T. A Critical Appraisal of the Use and Properties of Nickel–Titanium Dental Alloys. Materials 2021, 14, 7859. [Google Scholar] [CrossRef] [PubMed]

- Ho, W.F.; Chiang, T.Y.; Wu, S.C.; Hsu, H.C. Mechanical properties and deformation behavior of cast binary Ti–Cr alloys. J. Alloys Compd. 2009, 468, 533–538. [Google Scholar] [CrossRef]

- Korneva, A.; Straumal, B.; Gornakova, A.; Kilmametov, A.; Gondek, Ł.; Lityńska-Dobrzyńska, L.; Chulist, R.; Pomorska, M.; Zięba, P. Formation and Thermal Stability of the ω-Phase in Ti–Nb and Ti–Mo Alloys Subjected to HPT. Materials 2022, 15, 4136. [Google Scholar] [CrossRef] [PubMed]

- Azmat, A.; Tufail, M.; Chandio, A.D. Synthesis and Characterization of Ti–Sn Alloy for Orthopedic Application. Materials 2021, 14, 7660. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Recent metallic materials for biomedical applications. Met. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Fikeni, L.; Annan, K.A.; Mutombo, K.; Machaka, R. Effect of Nb content on the microstructure and mechanical properties of binary Ti–Nb alloys. Mater. Today Proc. 2021, 38, 913–917. [Google Scholar] [CrossRef]

- Santos, R.F.; Rossi, M.C.; Vidilli, A.L.; Borrás, V.A.; Afonso, C.R.M. Assessment of β stabilizers additions on microstructure and properties of as-cast β Ti–Nb based alloys. J. Mater. Res. Technol. 2023, 22, 3511–3524. [Google Scholar] [CrossRef]

- Ji, P.F.; Li, B.; Chen, B.H.; Wang, F.; Ma, W.; Zhang, X.Y.; Ma, M.Z.; Liu, R.P. Effect of Nb addition on the stability and biological corrosion resistance of Ti-Zr alloy passivation films. Corros. Sci. 2020, 170, 108696. [Google Scholar] [CrossRef]

- Han, M.K.; Hwang, M.J.; Yang, M.S.; Yang, H.S.; Song, H.J.; Park, Y.J. Effect of zirconium content on the microstructure, physical properties and corrosion behavior of Ti alloys. Mat. Sci. Eng. A 2014, 616, 268–274. [Google Scholar] [CrossRef]

- Seo, B.; Park, H.K.; Park, C.S.; Park, K. Role of Ta in improving corrosion resistance of titanium alloys under highly reducing condition. J. Mater. Res. Technol. 2023, 23, 4955–4964. [Google Scholar] [CrossRef]

- Zhao, H.; Xie, L.; Xin, C.; Li, N.; Zhao, B.; Li, L. Effect of molybdenum content on corrosion resistance and corrosion behavior of Ti-Mo titanium alloy in hydrochloric acid. Mater. Today Commun. 2023, 34, 105032. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Hsu, S.K.; Syu, J.Y.; Ho, W.F. The structure and mechanical properties of as-cast Ti–25Nb–xSn alloys for biomedical applications. Mater. Sci. Eng. A 2013, 568, 1–7. [Google Scholar] [CrossRef]

- Guha, A.; Boyer, H.E.; Gall, T.L. Metals Handbook; American Society for Metals, Metals Park: Novelty, OH, USA, 1985; pp. 133–136. [Google Scholar]

- Zhao, X.; Niinomi, M.; Nakai, M.; Hieda, J. Beta type Ti–Mo alloys with changeable Young’s modulus for spinal fixation applications. Acta Biomater. 2012, 8, 1990–1997. [Google Scholar] [CrossRef] [PubMed]

- Sidhu, S.S.; Singh, H.; Gepreel, M.A.H. A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials. Mat. Sci. Eng. C 2021, 121, 111661. [Google Scholar] [CrossRef]

- Peters, J.O.; Lütjering, G. Comparison of the fatigue and fracture of α+β and β titanium alloys. Metall. Mater. Trans. A 2001, 32, 2805–2818. [Google Scholar] [CrossRef]

- Gunawarman, M.; Niinomi, T.; Akahori, T.; Souma, M.; Ikeda, H.; Toda, K. Terashima, Fatigue Characteristics of Low Cost β Titanium Alloys for Healthcare and Medical Applications. Mater. Trans. 2005, 46, 7. [Google Scholar] [CrossRef]

- Héraud, L.; Castany, P.; Ijaz, M.F.; Gordin, D.M.; Gloriant, T. Large-strain functional fatigue properties of superelastic metastable β titanium and NiTi alloys: A comparative study. J. Alloys Compd. 2023, 953, 170170. [Google Scholar] [CrossRef]

- Wong, K.K.; Hsu, H.C.; Wu, S.C.; Ho, W.F. Structure and properties of Ti-rich Ti–Zr–Nb–Mo medium-entropy alloys. J. Alloys Compd. 2021, 868, 159137. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Hsu, S.K.; Lin, T.F.; Ho, W.F. Structure and mechanical properties of as-cast Ti–5Nb–xCr alloys. Mater. Des. 2013, 51, 268–273. [Google Scholar] [CrossRef]

- Semenova, I.P.; Modina, Y.M.; Stotskiy, A.G.; Polyakov, A.V.; Pesin, M.V. Fatigue Properties of Ti Alloys with an Ultrafine Grained Structure: Challenges and Achievements. Metals 2022, 12, 312. [Google Scholar] [CrossRef]

- Matković, T.; Matković, P.; Malina, J. Effects of Ni and Mo on the microstructure and some other properties of Co–Cr dental alloys. J. Alloys Compd. 2004, 366, 293–297. [Google Scholar] [CrossRef]

- Poondla, N.; Srivatsan, T.S.; Patnaik, A.; Petraroli, M. A study of the microstructure and hardness of two titanium alloys: Commercially pure and Ti–6Al–4V. J. Alloys Compd. 2009, 48, 162–167. [Google Scholar] [CrossRef]

- Rabadia, C.D.; Liu, Y.J.; Cao, G.H.; Li, Y.H.; Zhang, C.W.; Sercombe, T.B.; Sun, H.; Zhang, L.C. High-strength β stabilized Ti–Nb–Fe–Cr alloys with large plasticity. Mat. Sci. Eng. A 2018, 732, 368–377. [Google Scholar] [CrossRef]

- Ballor, J.; Li, T.; Prima, F.; Boehlert, C.J.; Devaraj, A. A review of the metastable omega phase in beta titanium alloys: The phase transformation mechanisms and its effect on mechanical properties. Int. Mater. Rev. 2023, 68, 26–45. [Google Scholar] [CrossRef]

- Xia, C.; Song, L.; Liu, S.; Chen, B.; Yang, T.; Liu, D.; Yang, Y.; Wang, Y.; Li, Q. Influence of Cr addition on microstructure evolution and corrosion behavior of the Ti–Zr alloys. Mater. Charact. 2021, 174, 111045. [Google Scholar] [CrossRef]

- Xu, W.; Chen, M.; Lu, X.; Zhang, D.; Singh, H.; Yu, J.; Pan, Y.; Qu, X.; Liu, C. Effects of Mo content on corrosion and tribocorrosion behaviours of Ti−Mo orthopaedic alloys fabricated by powder metallurgy. Corros. Sci. 2020, 168, 108557. [Google Scholar] [CrossRef]

- Yazdi, R.; Ghasemi, H.-M.; Wang, C.; Neville, A. Bio-corrosion behaviour of oxygen diffusion layer on Ti−6Al−4V during tribocorrosion. Corros. Sci. 2017, 128, 23–32. [Google Scholar] [CrossRef]

- Qu, W.; Pan, B.; Gong, H.; Yang, Z.; Ma, Y. Electrochemical corrosion and impedance studies of Ti–30Zr–xNb (x = 7, 10, 13 at.%) alloy in simulated downhole environment. J. Solid State Electrochem. 2023, 27, 1155–1164. [Google Scholar] [CrossRef]

| Alloys | Ecorr (V) | icorr (A/cm2) | Epass (V) | Epass − Ecorr (V) | ipass (A/cm2) | βa (V/dec) | βc (V/dec) | Rp (MΩ·cm2) | Corrosion Rate (mm/year) |

|---|---|---|---|---|---|---|---|---|---|

| CP-Ti | −0.30 | 3.82 × 10−9 | 0.27 | 0.57 | 2.12 × 10−6 | 0.13 | 0.09 | 6.05 | 3.60 × 10−5 |

| Ti–5Cr | −0.27 | 7.10 × 10−9 | 0.21 | 0.48 | 2.90 × 10−6 | 0.09 | 0.10 | 2.90 | 7.37 × 10−5 |

| Ti–5Cr–25Nb | −0.26 | 4.03 × 10−9 | 0.27 | 0.53 | 2.23 × 10−6 | 0.11 | 0.08 | 4.99 | 3.88 × 10−5 |

| Alloys | Rs (Ω·cm2) | CPE1 (10−5 F·cm2) | R1 (MΩ·cm2) | n1 | Ceff (10−5 F·cm2) | x2 (10−4) |

|---|---|---|---|---|---|---|

| CP-Ti | 30.72 | 3.54 | 0.60 | 0.93 | 4.47 × 10−5 | 1.19 |

| Ti–5Cr | 32.80 | 1.69 | 0.61 | 0.95 | 1.96 × 10−5 | 1.01 |

| Ti–5Cr–25Nb | 25.60 | 1.70 | 1.60 | 0.94 | 2.10 × 10−5 | 1.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, H.-C.; Wu, S.-C.; Fang, W.-C.; Ho, W.-F. Experimental Investigation of the Impact of Niobium Additions on the Structural Characteristics and Properties of Ti–5Cr–xNb Alloys for Biomedical Applications. Materials 2024, 17, 1667. https://doi.org/10.3390/ma17071667

Hsu H-C, Wu S-C, Fang W-C, Ho W-F. Experimental Investigation of the Impact of Niobium Additions on the Structural Characteristics and Properties of Ti–5Cr–xNb Alloys for Biomedical Applications. Materials. 2024; 17(7):1667. https://doi.org/10.3390/ma17071667

Chicago/Turabian StyleHsu, Hsueh-Chuan, Shih-Ching Wu, Wei-Ching Fang, and Wen-Fu Ho. 2024. "Experimental Investigation of the Impact of Niobium Additions on the Structural Characteristics and Properties of Ti–5Cr–xNb Alloys for Biomedical Applications" Materials 17, no. 7: 1667. https://doi.org/10.3390/ma17071667

APA StyleHsu, H.-C., Wu, S.-C., Fang, W.-C., & Ho, W.-F. (2024). Experimental Investigation of the Impact of Niobium Additions on the Structural Characteristics and Properties of Ti–5Cr–xNb Alloys for Biomedical Applications. Materials, 17(7), 1667. https://doi.org/10.3390/ma17071667