Influence of Thermocompression Conditions on the Properties and Chemical Composition of Bio-Based Materials Derived from Lignocellulosic Biomass

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material Preparation

2.2. Analytical Methods

2.3. Physical and Thermal Characterization of SCB

2.4. Uniaxial Thermocompression

2.5. Density Measurement of the Materials

2.6. Mechanical Bending Properties

2.7. Water Resistance Properties

2.8. Statistical Analysis

3. Results and Discussion

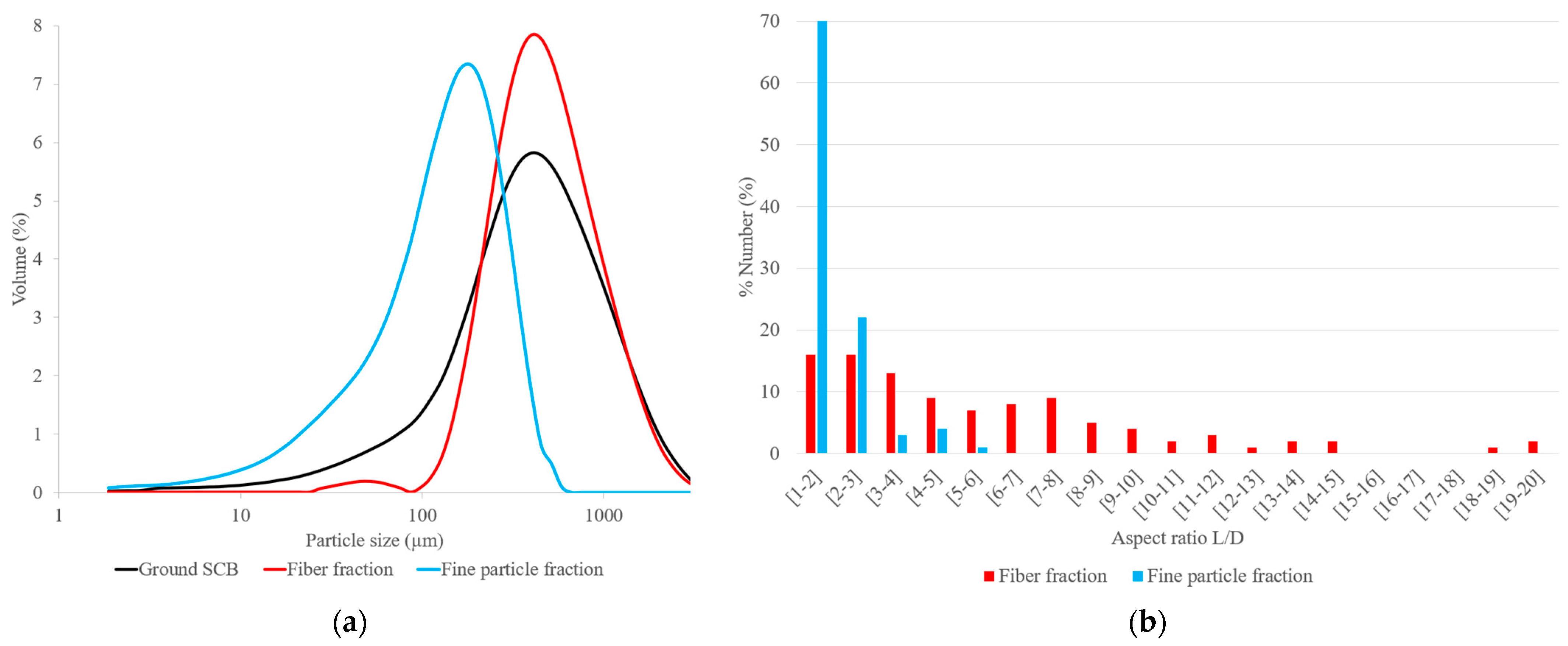

3.1. Characterization of Raw Sugarcane Bagasse

3.2. Properties and Chemical Composition of Binderless SCB Materials

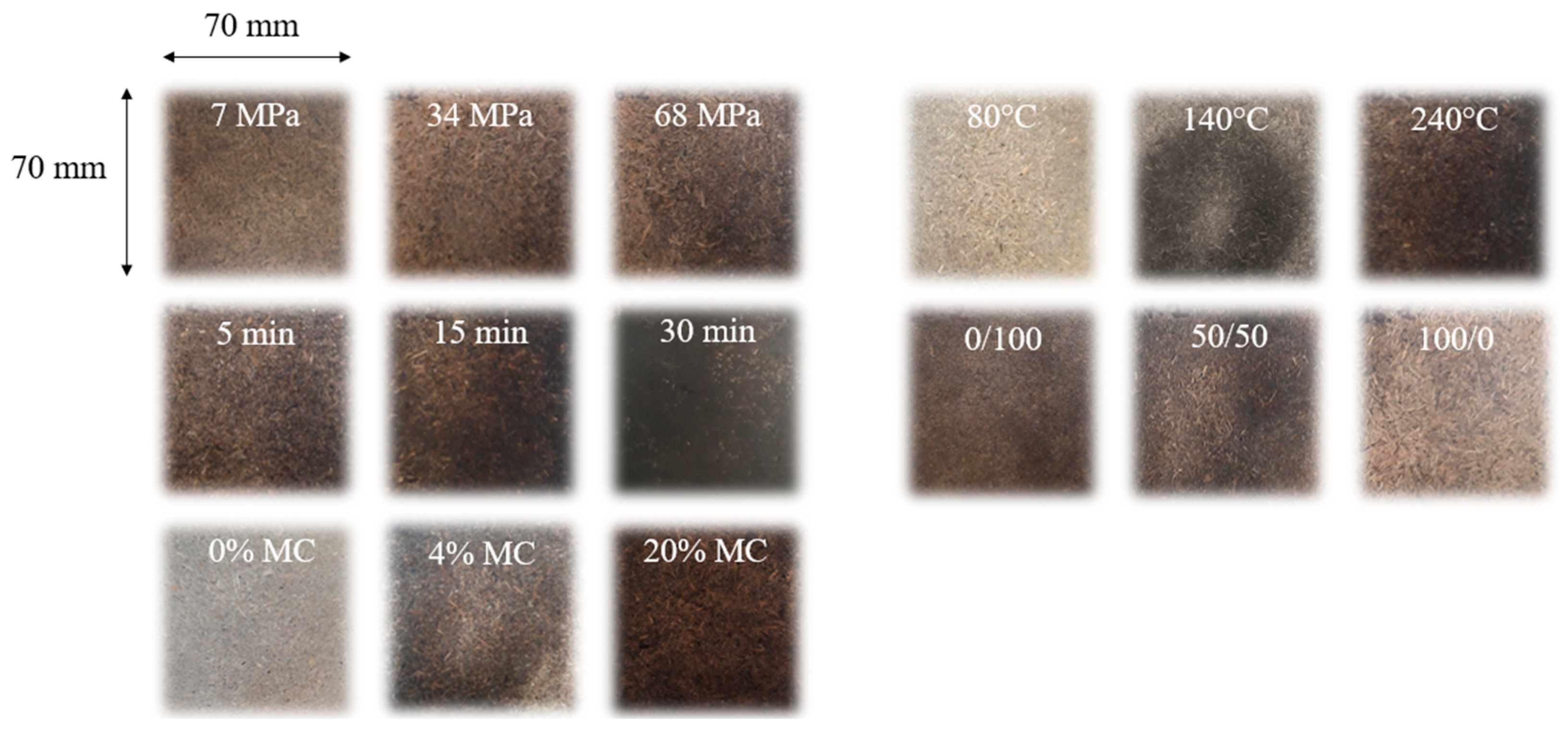

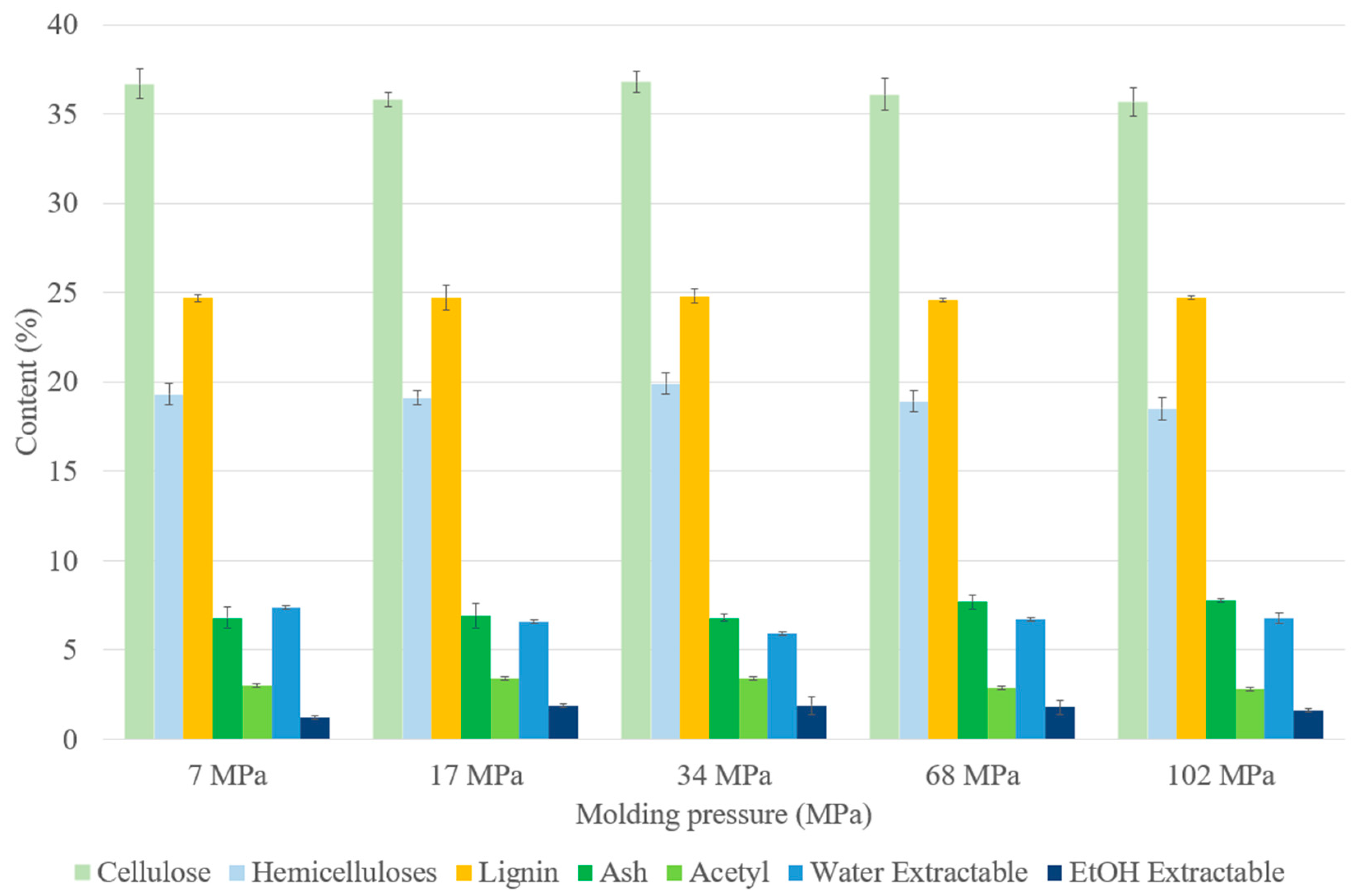

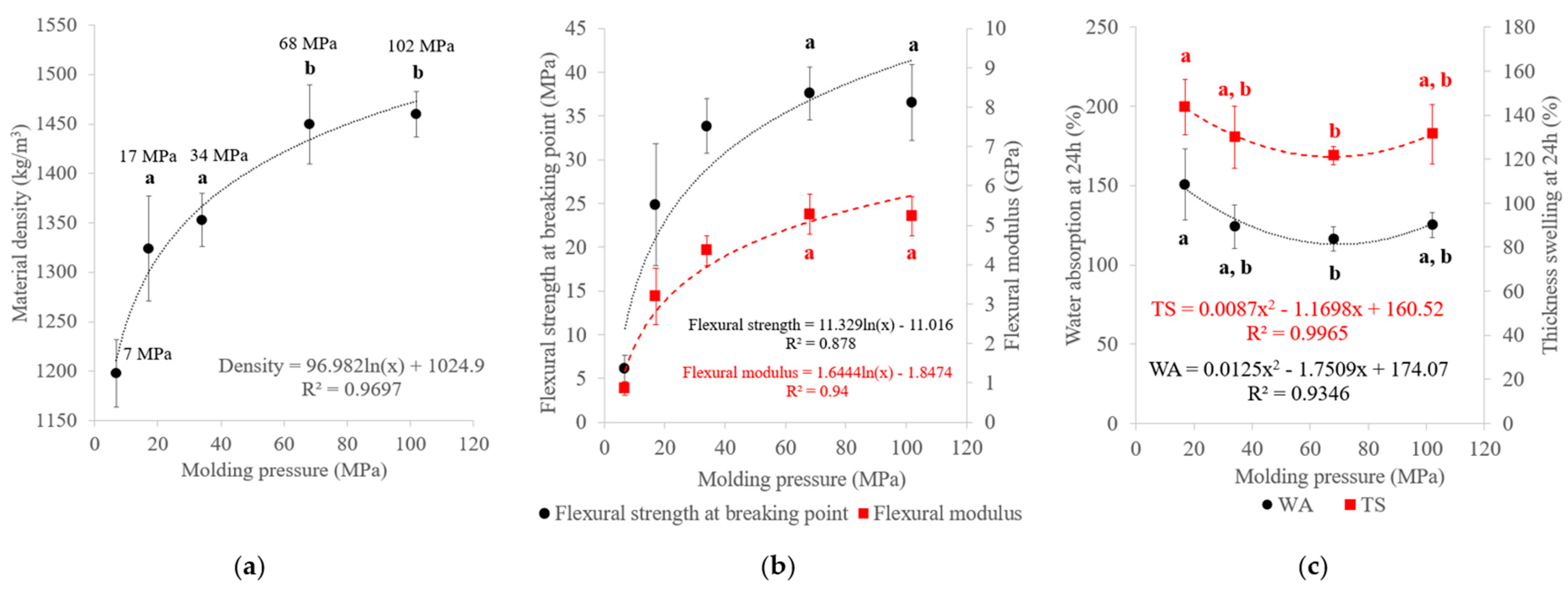

3.2.1. Effect of Molding Pressure

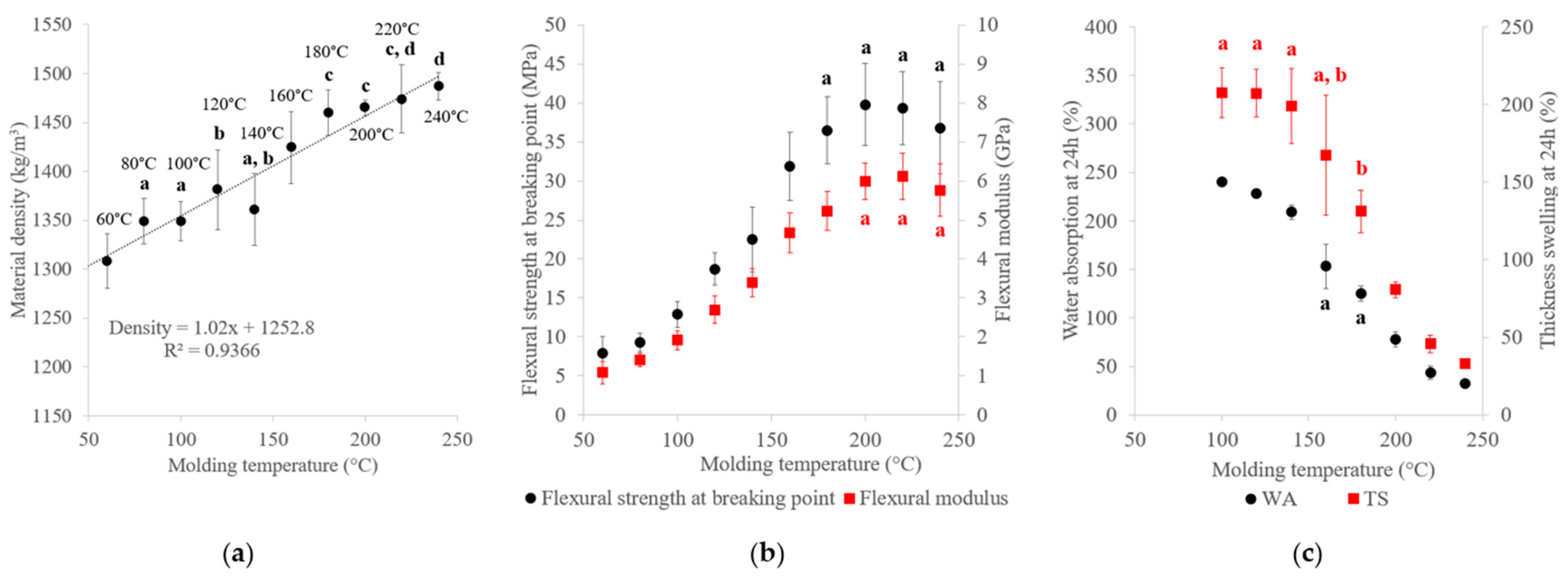

3.2.2. Effect of Molding Temperature

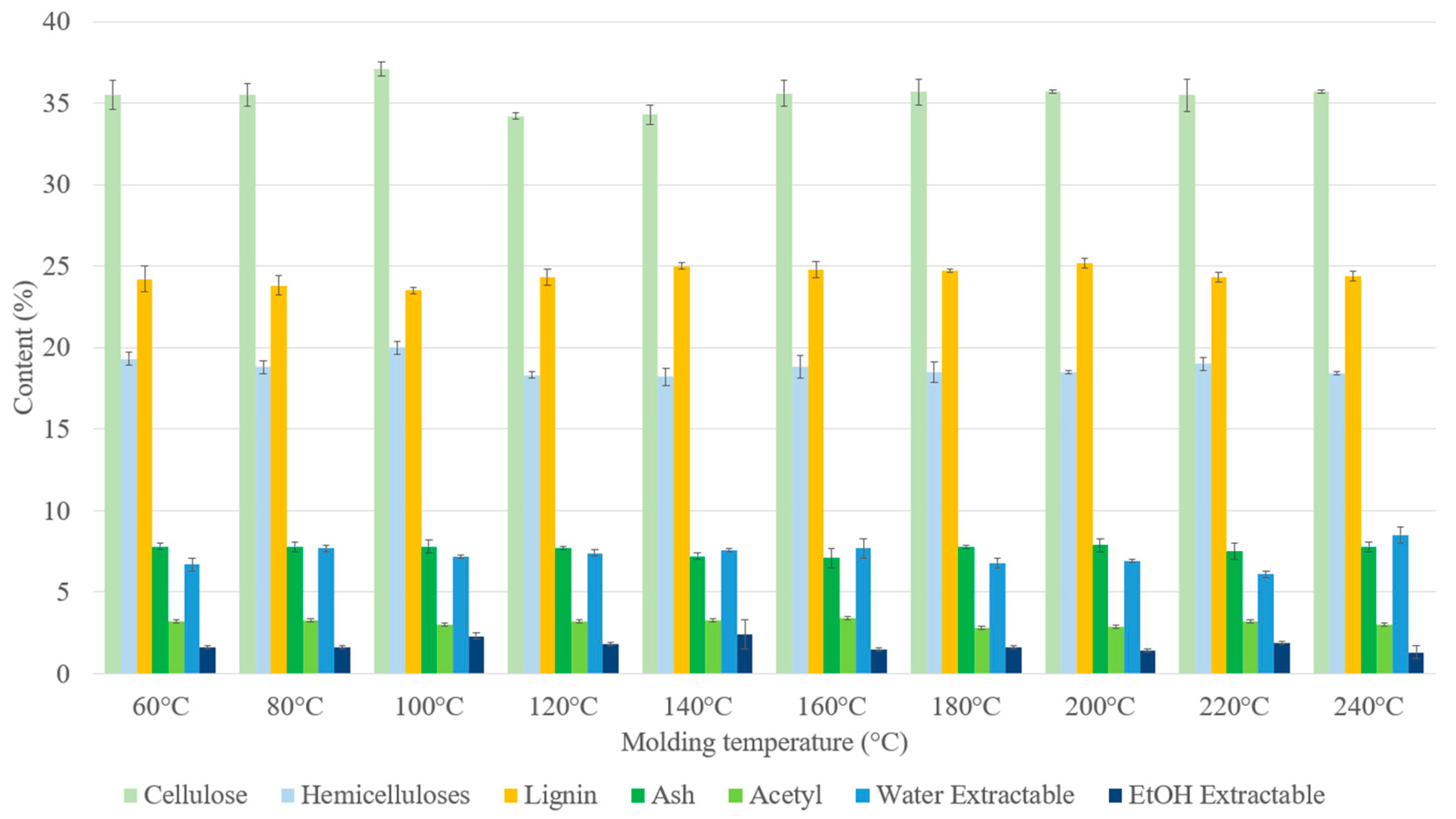

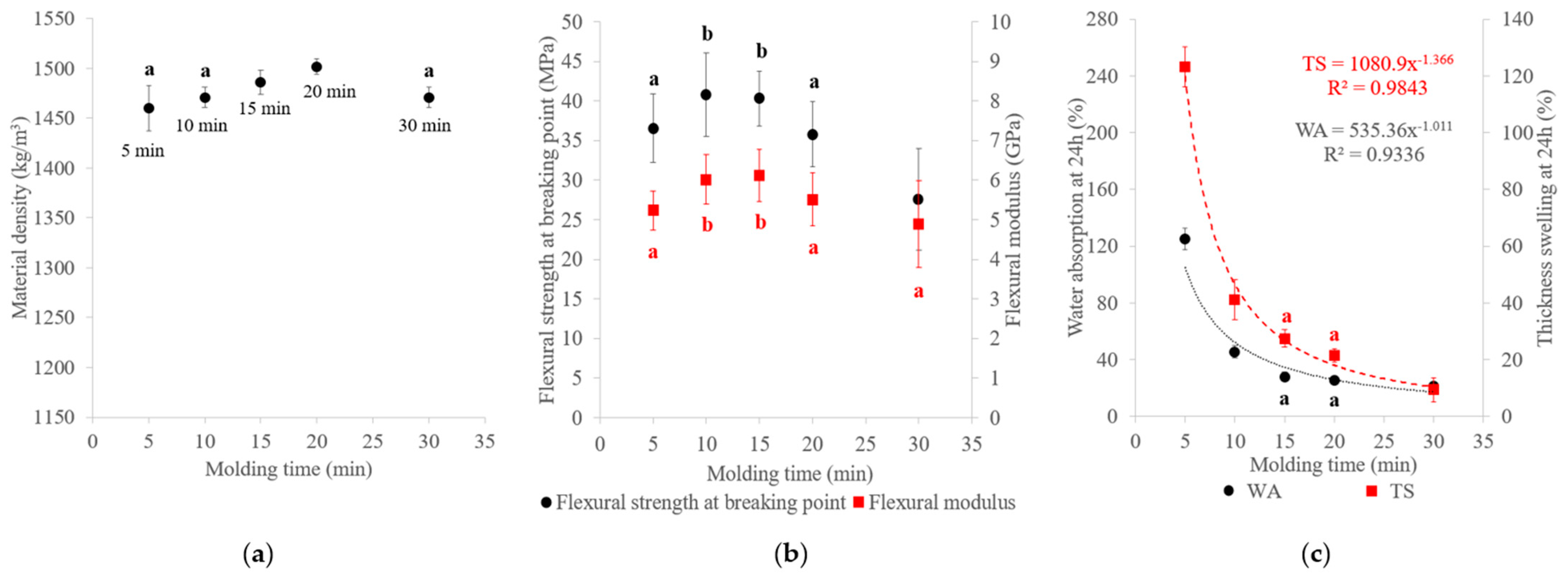

3.2.3. Effect of Molding Time

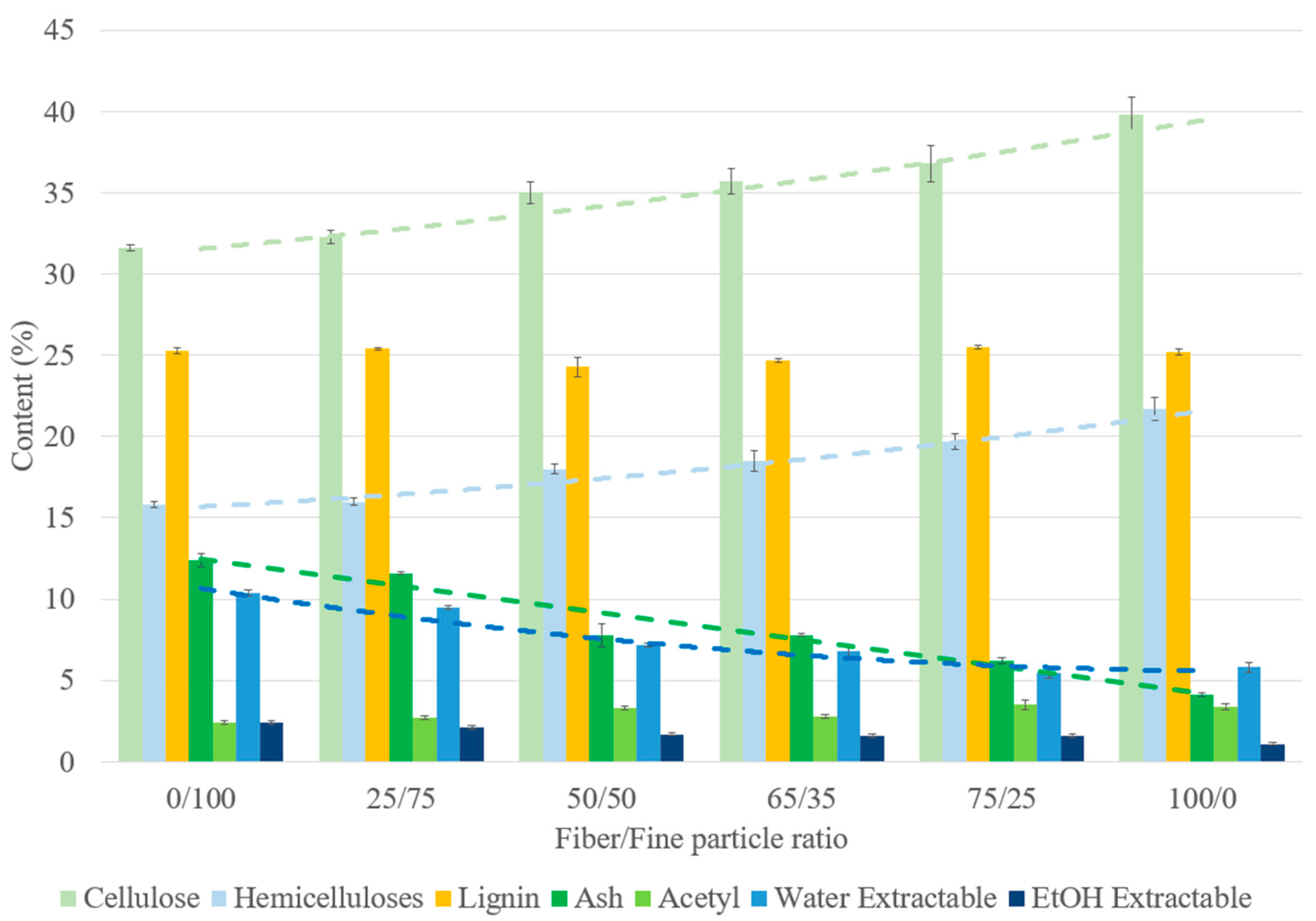

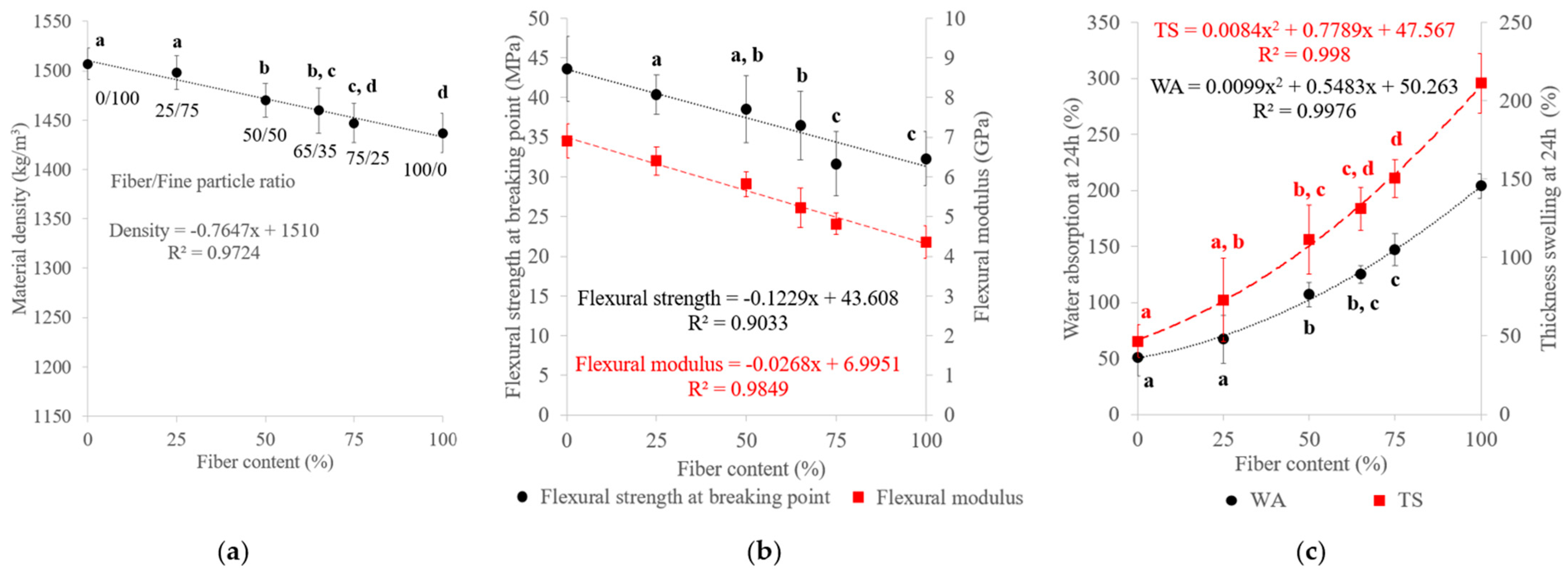

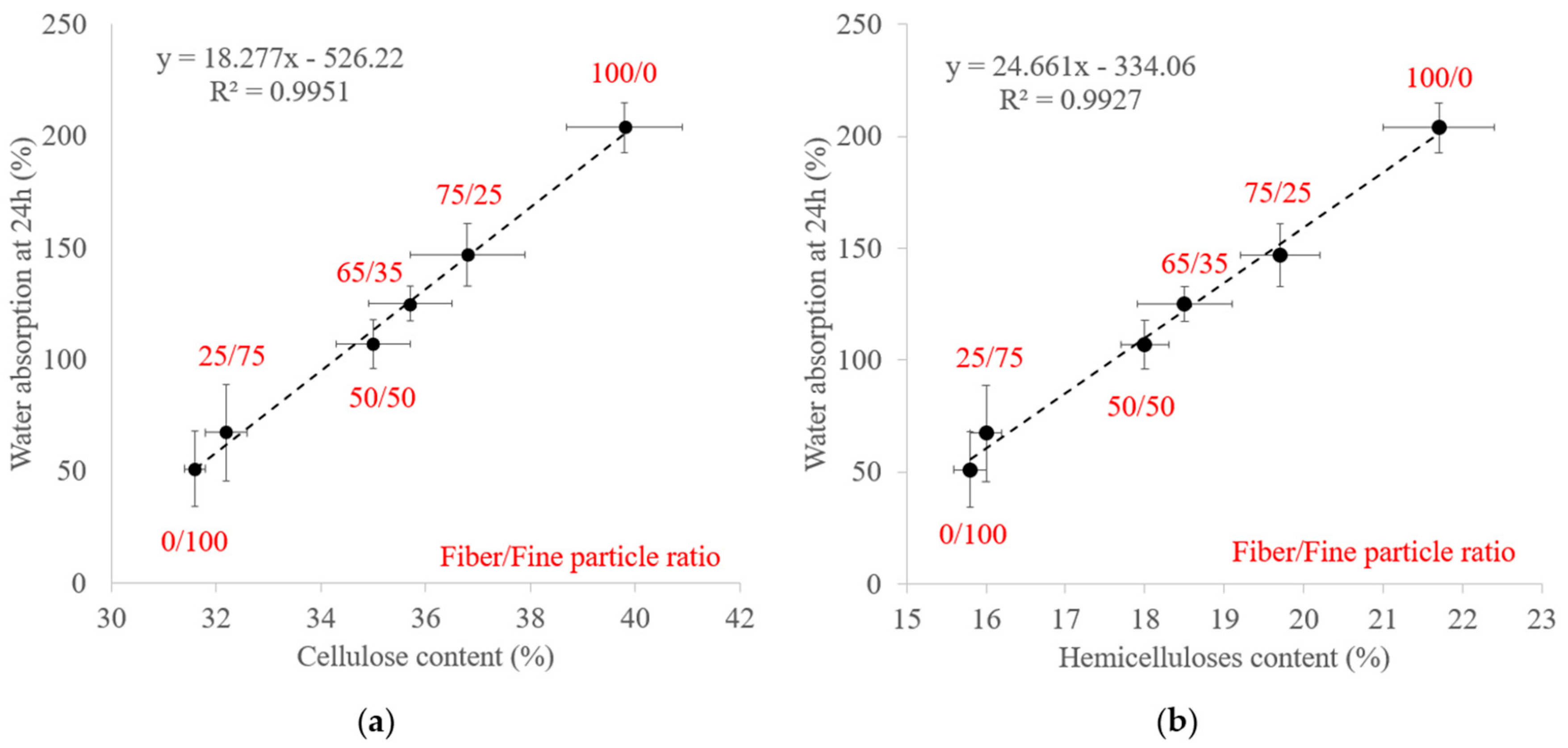

3.2.4. Effect of the Fiber/Fine-Particle Ratio

3.2.5. Effect of Moisture Content

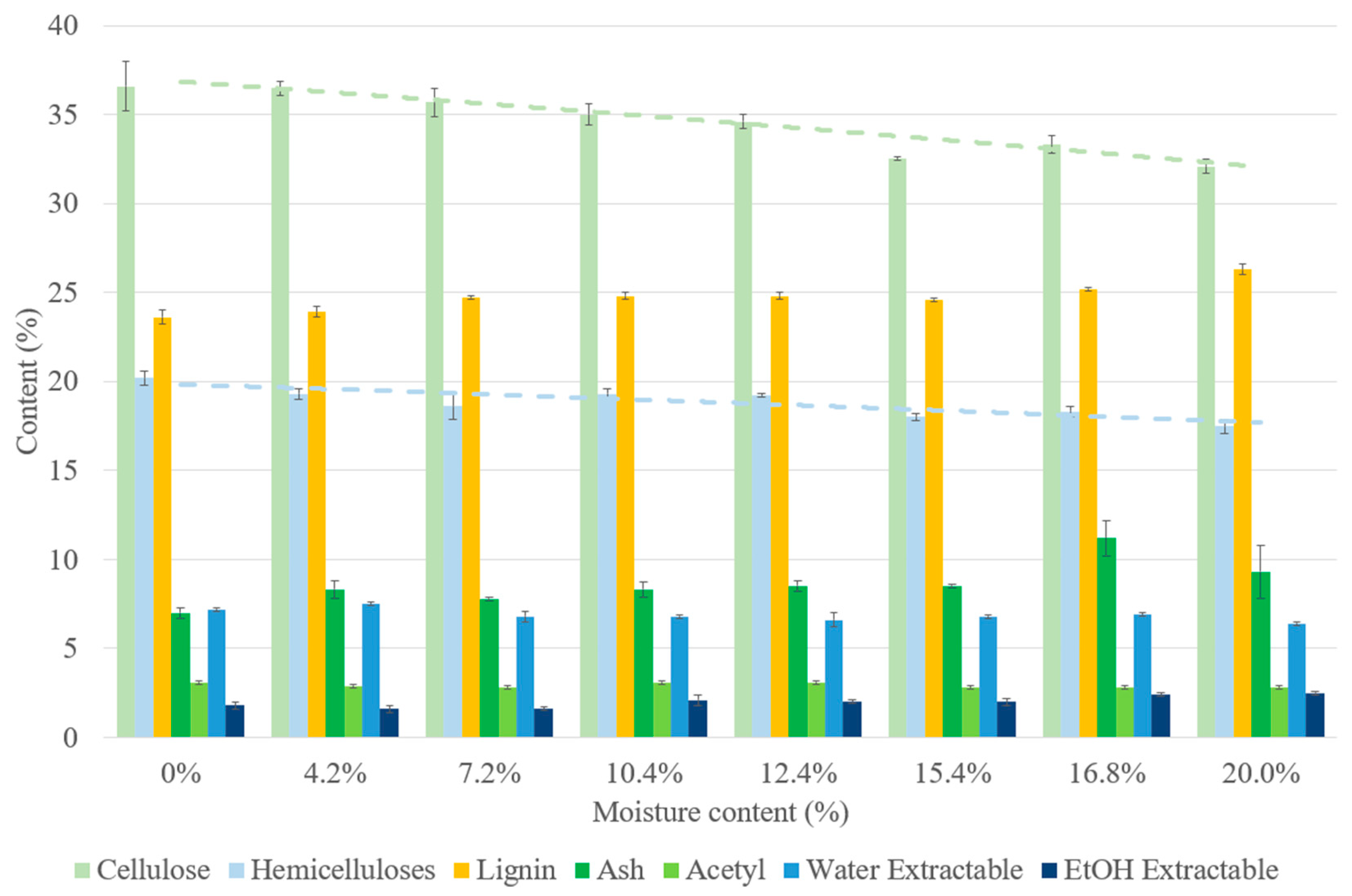

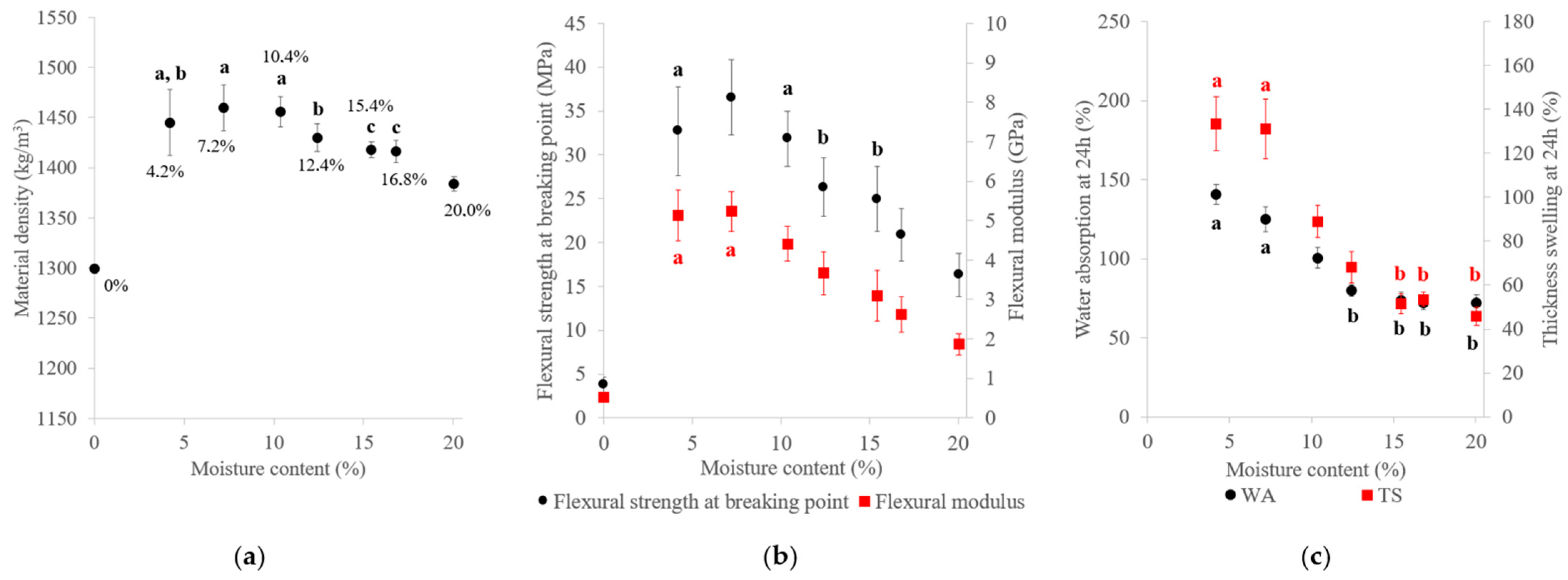

3.3. Choice of Best Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, B.; Luo, Z.; Chen, H.; Chen, C.; Cai, D.; Qin, P.; Cao, H.; Tan, T. Wood Plastic Composites from the Waste Lignocellulosic Biomass Fibers of Bio-Fuels Processes: A Comparative Study on Mechanical Properties and Weathering Effects. Waste Biomass Valorization 2020, 11, 1701–1710. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; Malha, M.; Bouhfid, R.; Benmoussa, K.; Qaiss, A. Tensile, Flexural and Torsional Properties of Chemically Treated Alfa, Coir and Bagasse Reinforced Polypropylene. Compos. Part B Eng. 2013, 47, 35–41. [Google Scholar] [CrossRef]

- Liu, C.; Luan, P.; Li, Q.; Cheng, Z.; Sun, X.; Cao, D.; Zhu, H. Biodegradable, Hygienic, and Compostable Tableware from Hybrid Sugarcane and Bamboo Fibers as Plastic Alternative. Matter 2020, 3, 2066–2079. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhou, C.; Rojas, O.J.; Nkeuwa, W.N.; Dai, C. Moulded Pulp Fibers for Disposable Food Packaging: A State-of-the-Art Review. Food Packag. Shelf Life 2022, 33, 100908. [Google Scholar] [CrossRef]

- Lee, S.; Shupe, T.F.; Hse, C.Y. Mechanical and Physical Properties of Agro-Based Fiberboard. Eur. J. Wood Wood Prod. 2006, 64, 74–79. [Google Scholar] [CrossRef]

- Sugahara, E.S.; da Silva, S.A.M.; Buzo, A.L.S.C.; de Campos, C.I.; Morales, E.A.M.; Ferreira, B.S.; Azamnuja, M.; dos, A.; Lahr, F.A.R.; Christoforo, A.L. High-Density Particleboard Made from Agro-Industrial Waste and Different Adhesives. BioResources 2019, 14, 5162–5170. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Hui, L. Pulping and Papermaking of Non-Wood Fibers. In Pulp and Paper Processing; Kazi, S.N., Ed.; InTech: Berlin, Germany, 2018; ISBN 978-1-78923-847-1. [Google Scholar]

- Kariuki, S.W.; Wachira, J.; Kawira, M.; Murithi, G. Crop Residues Used as Lignocellulose Materials for Particleboards Formulation. Heliyon 2020, 6, e05025. [Google Scholar] [CrossRef]

- Liang, W.; Yang, S.; Yang, X. Long-Term Formaldehyde Emissions from Medium-Density Fiberboard in a Full-Scale Experimental Room: Emission Characteristics and the Effects of Temperature and Humidity. Environ. Sci. Technol. 2015, 49, 10349–10356. [Google Scholar] [CrossRef]

- Jiang, C.; Li, D.; Zhang, P.; Li, J.; Wang, J.; Yu, J. Formaldehyde and Volatile Organic Compound (VOC) Emissions from Particleboard: Identification of Odorous Compounds and Effects of Heat Treatment. Build. Environ. 2017, 117, 118–126. [Google Scholar] [CrossRef]

- Pintiaux, T.; Viet, D.; Vandenbossche, V.; Rigal, L.; Rouilly, A. Binderless Materials Obtained by Thermo-Compressive Processing of Lignocellulosic Fibers: A Comprehensive Review. BioResources 2015, 10, 1915–1963. [Google Scholar] [CrossRef]

- Anglès, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of Steam Exploded Residual Softwood for the Production of Binderless Panels. E Ect of the Pre-Treatment Severity and Lignin Addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, A.; Xue, L. A Review of Preparation of Binderless Fiberboards and Its Self-Bonding Mechanism. Wood Sci. Technol. 2015, 49, 661–679. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical Changes of Kenaf Core Binderless Boards during Hot Pressing (II): Effects on the Binderless Board Properties. J. Wood Sci. 2006, 52, 249–254. [Google Scholar] [CrossRef]

- Widyorini, R.; Xu, J.; Watanabe, T.; Kawai, S. Chemical Changes in Steam-Pressed Kenaf Core Binderless Particleboard. J. Wood Sci. 2005, 51, 26–32. [Google Scholar] [CrossRef]

- Evon, P.; Vinet, J.; Labonne, L.; Rigal, L. Influence of Thermo-Pressing Conditions on the Mechanical Properties of Biodegradable Fiberboards Made from a Deoiled Sunflower Cake. Ind. Crops Prod. 2015, 65, 117–126. [Google Scholar] [CrossRef]

- Halvarsson, S.; Edlund, H.; Norgren, M. Manufacture of Non-Resin Wheat Straw Fibreboards. Ind. Crops Prod. 2009, 29, 437–445. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Farriol, X.; Salvadó, J. Binderless Fiberboard from Steam Exploded Miscanthus Sinensis. Wood Sci. Technol. 2003, 37, 269–278. [Google Scholar] [CrossRef]

- Quintana, G.; Velásquez, J.; Betancourt, S.; Gañán, P. Binderless Fiberboard from Steam Exploded Banana Bunch. Ind. Crops Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Xu, J.; Widyorini, R.; Yamauchi, H.; Kawai, S. Development of Binderless Fiberboard from Kenaf Core. J. Wood Sci. 2006, 52, 236–243. [Google Scholar] [CrossRef]

- Uitterhaegen, E.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T.; Evon, P. Impact of Thermomechanical Fiber Pre-Treatment Using Twin-Screw Extrusion on the Production and Properties of Renewable Binderless Coriander Fiberboards. Int. J. Mol. Sci. 2017, 18, 1539. [Google Scholar] [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Ngo, B.; Labonne, L.; Mutjé, P.; Evon, P. Production of Fiberboard from Rice Straw Thermomechanical Extrudates by Thermopressing: Influence of Fiber Morphology, Water and Lignin Content. Eur. J. Wood Wood Prod. 2019, 77, 15–32. [Google Scholar] [CrossRef]

- Evon, P.; de Langalerie, G.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T. Low-Density Insulation Blocks and Hardboards from Amaranth (Amaranthus Cruentus) Stems, a New Perspective for Building Applications. Coatings 2021, 11, 349. [Google Scholar] [CrossRef]

- Boon, J.G.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Sugimoto, T.; Sato, M. Influence of Processing Parameters on Some Properties of Oil Palm Trunk Binderless Particleboard. Eur. J. Wood Wood Prod. 2013, 71, 583–589. [Google Scholar] [CrossRef]

- Widyorini, R.; Xu, J.; Umemura, K.; Kawai, S. Manufacture and Properties of Binderless Particleboard from Bagasse I: Effects of Raw Material Type, Storage Methods, and Manufacturing Process. J. Wood Sci. 2005, 51, 648–654. [Google Scholar] [CrossRef]

- Mahieu, A.; Alix, S.; Leblanc, N. Properties of Particleboards Made of Agricultural By-Products with a Classical Binder or Self-Bound. Ind. Crops Prod. 2019, 130, 371–379. [Google Scholar] [CrossRef]

- Hashim, R.; Said, N.; Lamaming, J.; Baskaran, M.; Sulaiman, O.; Sato, M.; Hiziroglu, S.; Sugimoto, T. Influence of Press Temperature on the Properties of Binderless Particleboard Made from Oil Palm Trunk. Mater. Des. 2011, 32, 2520–2525. [Google Scholar] [CrossRef]

- Nadhari, W.N.A.W.; Karim, N.A.; Boon, J.G.; Salleh, K.M.; Mustapha, A.; Hashim, R.; Sulaiman, O.; Azni, M.E. Sugarcane (Saccharum Officinarium L.) Bagasse Binderless Particleboard: Effect of Hot Pressing Time Study. Mater. Today Proc. 2020, 31, 313–317. [Google Scholar] [CrossRef]

- Mobarak, F.; Fahmy, Y.; Augustin, H. Binderless Lignocellulose Composite from Bagasse and Mechanism of Self-Bonding. Holzforschung 1982, 36, 131–136. [Google Scholar] [CrossRef]

- Evon, P.; Vandenbossche, V.; Rigal, L. Manufacturing of Renewable and Biodegradable Fiberboards from Cake Generated during Biorefinery of Sunflower Whole Plant in Twin-Screw Extruder: Influence of Thermo-Pressing Conditions. Polym. Degrad. Stab. 2012, 97, 1940–1947. [Google Scholar] [CrossRef][Green Version]

- Ahmad, Z.; Tajuddin, M.; Maleque, M.A.; Halim, Z. Effects of Particle Sizes on the Properties of Binderless Boards Made from Rattan Furniture Waste. J. Eng. Sci. 2019, 15, 49–61. [Google Scholar] [CrossRef]

- FAO FAOSTAT. The Europa Directory of International Organizations 2021. In Food and Agriculture Organization of the United Nations; Routledge: London, UK, 2021. [Google Scholar]

- Sluiter, A. Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process Samples: Laboratory Analytical Procedure (LAP). Technol. Rep. 2008, 2008, 2–5. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. Lab. Anal. Proced. LAP 2008, 1617, 1–16. [Google Scholar]

- Chimenez, T.A.; Gehlen, M.H.; Marabezi, K.; Curvelo, A.A.S. Characterization of Sugarcane Bagasse by Autofluorescence Microscopy. Cellulose 2014, 21, 653–664. [Google Scholar] [CrossRef]

- Oriez, V.; Beyerle, M.; Pontalier, P.-Y.; Peydecastaing, J. Sugarcane Bagasse Mild Alkaline Fractionation and Production of Purified Fractions by Pulse Chromatography with Water. Ind. Crops Prod. 2018, 125, 370–378. [Google Scholar] [CrossRef]

- Ribeiro, D.P.; Vilela, A.P.; Silva, D.W.; Napoli, A.; Mendes, R.F. Effect of Heat Treatment on the Properties of Sugarcane Bagasse Medium Density Particleboard (MDP) Panels. Waste Biomass Valorization 2020, 11, 6429–6441. [Google Scholar] [CrossRef]

- Magzoub, R.; Osman, Z.; Tahir, P.; Nasroon, T.H.; Kantner, W. Comparative Evaluation of Mechanical and Physical Properties of Particleboard Made from Bagasse Fibers and Improved by Using Different Methods. Cellul. Chem. Technol. 2015, 49, 537–542. [Google Scholar]

- Miki, T.; Takakura, N.; Iizuka, T.; Yamaguchi, K.; Kanayama, K. Possibility of Extrusion of Wood Powders. JSME Int. J. Ser. Solid Mech. Mater. Eng. 2003, 46, 371–377. [Google Scholar] [CrossRef]

- Miki, T.; Takeuchi, K.; Sugimoto, H.; Kanayama, K. Material Development from Wood Powder without Adhesive by Vapor Steaming Compaction Process. J. Mater. Process. Technol. 2008, 199, 396–401. [Google Scholar] [CrossRef]

- Tabarsa, T.; Ashori, A.; Gholamzadeh, M. Evaluation of Surface Roughness and Mechanical Properties of Particleboard Panels Made from Bagasse. Compos. Part B Eng. 2011, 42, 1330–1335. [Google Scholar] [CrossRef]

- Liao, R.; Xu, J.; Umemura, K. Low Density Sugarcane Bagasse Particleboard Bonded with Citric Acid and Sucrose: Effect of Board Density and Additive Content. BioResources 2016, 11, 2174–2185. [Google Scholar] [CrossRef]

- Wong, E.-D.; Zhang, M.; Wang, Q.; Kawai, S. Formation of the Density Profile and Its Effects on the Properties of Particleboard. Wood Sci. Technol. 1999, 33, 327–340. [Google Scholar] [CrossRef]

- Zhang, Y.-H.; Huang, Y.-X.; Ma, H.-X.; Yu, W.-J.; Qi, Y. Effect of Different Pressing Processes and Density on Dimensional Stability and Mechanical Properties of Bamboo Fiber-Based Composites. J. Korean Wood Sci. Technol. 2018, 46, 355–361. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A.; Karegarfard, A. Properties of Medium Density Fiberboard Based on Bagasse Fibers. J. Compos. Mater. 2009, 43, 1927–1934. [Google Scholar] [CrossRef]

- Werner, K.; Pommer, L.; Broström, M. Thermal Decomposition of Hemicelluloses. J. Anal. Appl. Pyrolysis 2014, 110, 130–137. [Google Scholar] [CrossRef]

- Shafizadeh, F.; Bradbury, A.G.W. Thermal Degradation of Cellulose in Air and Nitrogen at Low Temperatures. J. Appl. Polym. Sci. 1979, 23, 1431–1442. [Google Scholar] [CrossRef]

- Zhao, J.; Xiuwen, W.; Hu, J.; Liu, Q.; Shen, D.; Xiao, R. Thermal Degradation of Softwood Lignin and Hardwood Lignin by TG-FTIR and Py-GC/MS. Polym. Degrad. Stab. 2014, 108, 133–138. [Google Scholar] [CrossRef]

- Barthod-Malat, B.; Hauguel, M.; Behlouli, K.; Grisel, M.; Savary, G. Influence of the Compression Molding Temperature on VOCs and Odors Produced from Natural Fiber Composite Materials. Coatings 2023, 13, 371. [Google Scholar] [CrossRef]

- Cristescu, C.; Karlsson, O. Changes in Content of Furfurals and Phenols in Self-Bonded Laminated Boards. BioResources 2013, 8, 4056–4071. [Google Scholar] [CrossRef]

- Vaca-Medina, G.; Jallabert, B.; Viet, D.; Peydecastaing, J.; Rouilly, A. Effect of Temperature on High Pressure Cellulose Compression. Cellulose 2013, 20, 2311–2319. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New Thermal Insulation Boards Made from Coconut Husk and Bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Nonaka, S.; Umemura, K.; Kawai, S. Characterization of Bagasse Binderless Particleboard Manufactured in High-Temperature Range. J. Wood Sci. 2013, 59, 50–56. [Google Scholar] [CrossRef]

- Bouajila, J.; Limare, A.; Joly, C.; Dole, P. Lignin Plasticization to Improve Binderless Fiberboard Mechanical Properties. Polym. Eng. Sci. 2005, 45, 809–816. [Google Scholar] [CrossRef]

- Nasir, M.; Khali, D.P.; Jawaid, M.; Tahir, P.M.; Siakeng, R.; Asim, M.; Khan, T.A. Recent Development in Binderless Fiber-Board Fabrication from Agricultural Residues: A Review. Constr. Build. Mater. 2019, 211, 502–516. [Google Scholar] [CrossRef]

- Nemli, G.; Aydın, I.; Zekoviç, E. Evaluation of Some of the Properties of Particleboard as Function of Manufacturing Parameters. Mater. Des. 2007, 28, 1169–1176. [Google Scholar] [CrossRef]

- Sar, B. Effects of Chemical Composition of Wood and Resin Type on Properties of Particleboard. Lignocellulose 2012, 1, 174–184. [Google Scholar]

- Fahmy, T.Y.A.; Mobarak, F. Advanced Binderless Board-like Green Nanocomposites from Undebarked Cotton Stalks and Mechanism of Self-Bonding. Cellulose 2013, 20, 1453–1457. [Google Scholar] [CrossRef]

- Alharbi, M.A.H.; Hirai, S.; Tuan, H.A.; Akioka, S.; Shoji, W. Effects of Chemical Composition, Mild Alkaline Pretreatment and Particle Size on Mechanical, Thermal, and Structural Properties of Binderless Lignocellulosic Biopolymers Prepared by Hot-Pressing Raw Microfibrillated Phoenix Dactylifera and Cocos Nucifera Fibers and Leaves. Polym. Test. 2020, 84, 106384. [Google Scholar] [CrossRef]

- Shen, K.C. Process for Manufacturing Composite Products from Lignocellulosic Materials. U. S. Pat. 1986, 4627951. [Google Scholar]

- Chen, M.; Zheng, S.; Wu, J.; Xu, J. Study on Preparation of High-Performance Binderless Board from Broussonetia Papyrifera. J. Wood Sci. 2023, 69, 17. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Abiodun, Y.O.; Ogundare, A.A.; Adefuye, O.A.; Ojolo, S.J.; Jekayinfa, S.O. Effects of Manufacturing Parameters on the Properties of Binderless Boards Produced from Corncobs. Trans. Indian Natl. Acad. Eng. 2022, 7, 1311–1325. [Google Scholar] [CrossRef]

- Mendes, R.F.; Mendes, L.M.; Oliveira, S.L.; Freire, T.P. Use of Sugarcane Bagasse for Particleboard Production. Key Eng. Mater. 2014, 634, 163–171. [Google Scholar] [CrossRef]

- Kelley, S.S.; Rials, T.G.; Glasser, W.G. Relaxation Behaviour of the Amorphous Components of Wood. J. Mater. Sci. 1987, 22, 617–624. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural Binders and Solid Bridge Type Binding Mechanisms in Briquettes and Pellets Made from Corn Stover and Switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef] [PubMed]

- Hidayat, H.; Keijsers, E.R.P.; Prijanto, U.; Van Dam, J.E.G.; Heeres, H.J. Preparation and Properties of Binderless Boards from Jatropha Curcas L. Seed Cake. Ind. Crops Prod. 2014, 52, 245–254. [Google Scholar] [CrossRef]

- Sui, W.; Chen, H. Effects of Water States on Steam Explosion of Lignocellulosic Biomass. Bioresour. Technol. 2016, 199, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Jamaludin, M.A.; Bahari, S.A.; Zakaria, M.N.; Saipolbahri, N.S. Influence of Rice Straw, Bagasse, and Their Combination on the Properties of Binderless Particleboard. J. Korean Wood Sci. Technol. 2020, 48, 22–31. [Google Scholar] [CrossRef]

- Syamani, F.A.; Sudarmanto; Subyakto; Subiyanto, B. High Quality Sugarcane Bagasse-Citric Acid Particleboards. IOP Conf. Ser. Earth Environ. Sci. 2020, 415, 012006. [Google Scholar] [CrossRef]

- NF EN 312; Panneaux de Particules—Exigences. Afnor Editions: Paris, France, 2010.

| Studied Parameter | Pressure (MPa) | Temperature (°C) | Time (min) | Fiber/Fine- Particle Ratio (%) | Moisture Content (%) |

|---|---|---|---|---|---|

| Pressure | 7–102 | 180 | 5 | 65/35 | 7.2 |

| Temperature | 102 | 60–240 | 5 | 65/35 | 7.2 |

| Time | 102 | 180 | 5–30 | 65/35 | 7.2 |

| Fiber/Fine-particle ratio | 102 | 180 | 5 | 0/100–100/0 | 7.2 |

| Moisture content | 102 | 180 | 5 | 65/35 | 0–20.0 |

| Ground SCB | Fibers | Fine Particles | |

|---|---|---|---|

| Bulk density (kg/m3) | 132 ± 3 | 118 ± 1 | 138 ± 4 |

| Tapped density (kg/m3) | 198 ± 7 | 176 ± 2 | 208 ± 4 |

| SSA (m2/g) | 39 ± 3 | 15 ± 1 | 98 ± 8 |

| D10 (µm) | 106 ± 28 | 226 ± 2 | 34 ± 3 |

| D50 (µm) | 423 ± 60 | 490 ± 4 | 145 ± 11 |

| D90 (µm) | 1237 ± 114 | 1210 ± 28 | 161 ± 12 |

| Composition | Ground SCB | Fibers | Fine Particles |

|---|---|---|---|

| Dry matter (%) | 91.5 ± 0.1 | 91.3 ± 0.1 | 92.7 ± 0.1 |

| Ash (%) | 7.0 ± 0.4 | 4.1 ± 0.1 | 12.3 ± 0.8 |

| AIL (%) | 20.4 ± 0.4 | 19.8 ± 0.7 | 21.6 ± 1.6 |

| ASL (%) | 4.6 ± 0.1 | 5.1 ± 0.1 | 4.1 ± 0.2 |

| Total lignin (%) | 24.9 ± 0.5 | 24.9 ± 0.6 | 25.2 ± 1.6 |

| Cellulose (%) | 36.0 ± 0.8 | 39.5 ± 0.4 | 31.6 ± 0.3 |

| Xylose (%) | 18.3 ± 0.6 | 21.0 ± 0.3 | 14.8 ± 0.1 |

| Arabinose (%) | 1.5 ± 0.2 | 1.5 ± 0.1 | 1.4 ± 0.2 |

| Hemicellulose (%) | 19.9 ± 0.5 | 22.5 ± 0.3 | 16.2 ± 0.5 |

| Acetyl (%) | 2.9 ± 0.1 | 3.2 ± 0.1 | 2.4 ± 0.1 |

| Extractable H2O (%) | 7.1 ± 0.1 | 4.4 ± 0.6 | 11.7 ± 0.3 |

| Extractable EtOH (%) | 1.1 ± 0.1 | 1.1 ± 0.1 | 1.1 ± 0.1 |

| Total (%) | 99 | 99 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavailles, J.; Vaca-Medina, G.; Wu-Tiu-Yen, J.; Peydecastaing, J.; Pontalier, P.-Y. Influence of Thermocompression Conditions on the Properties and Chemical Composition of Bio-Based Materials Derived from Lignocellulosic Biomass. Materials 2024, 17, 1713. https://doi.org/10.3390/ma17081713

Cavailles J, Vaca-Medina G, Wu-Tiu-Yen J, Peydecastaing J, Pontalier P-Y. Influence of Thermocompression Conditions on the Properties and Chemical Composition of Bio-Based Materials Derived from Lignocellulosic Biomass. Materials. 2024; 17(8):1713. https://doi.org/10.3390/ma17081713

Chicago/Turabian StyleCavailles, Julie, Guadalupe Vaca-Medina, Jenny Wu-Tiu-Yen, Jérôme Peydecastaing, and Pierre-Yves Pontalier. 2024. "Influence of Thermocompression Conditions on the Properties and Chemical Composition of Bio-Based Materials Derived from Lignocellulosic Biomass" Materials 17, no. 8: 1713. https://doi.org/10.3390/ma17081713

APA StyleCavailles, J., Vaca-Medina, G., Wu-Tiu-Yen, J., Peydecastaing, J., & Pontalier, P.-Y. (2024). Influence of Thermocompression Conditions on the Properties and Chemical Composition of Bio-Based Materials Derived from Lignocellulosic Biomass. Materials, 17(8), 1713. https://doi.org/10.3390/ma17081713