A Case Study: Electrically Assisted Stress Relief Annealing for Cold-Coiled Helical Automotive Springs

Abstract

1. Introduction

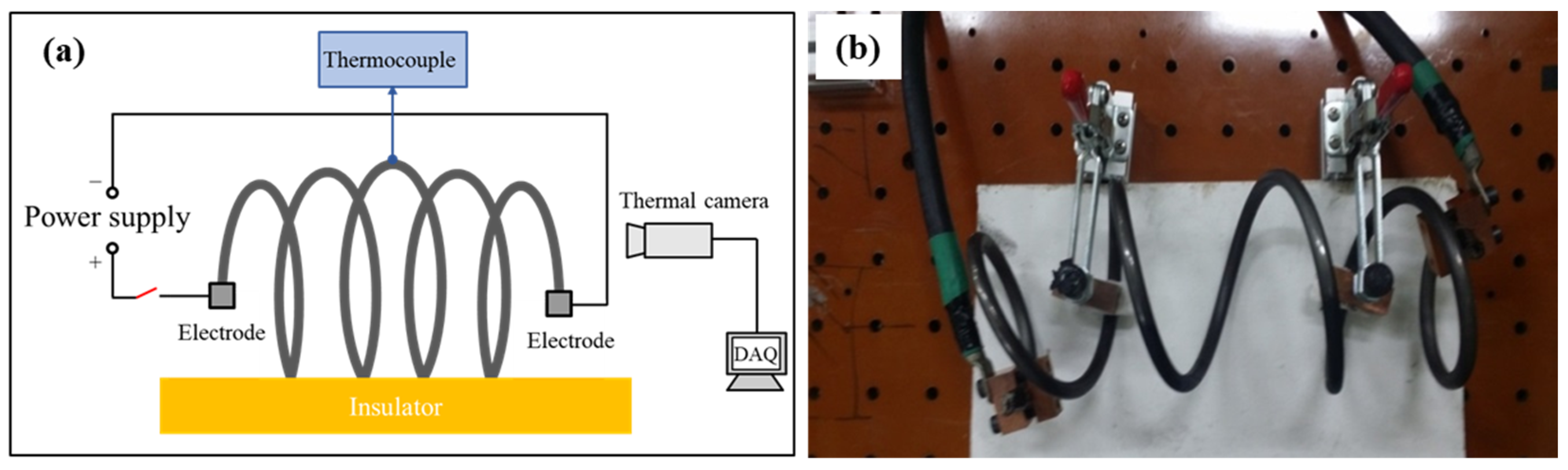

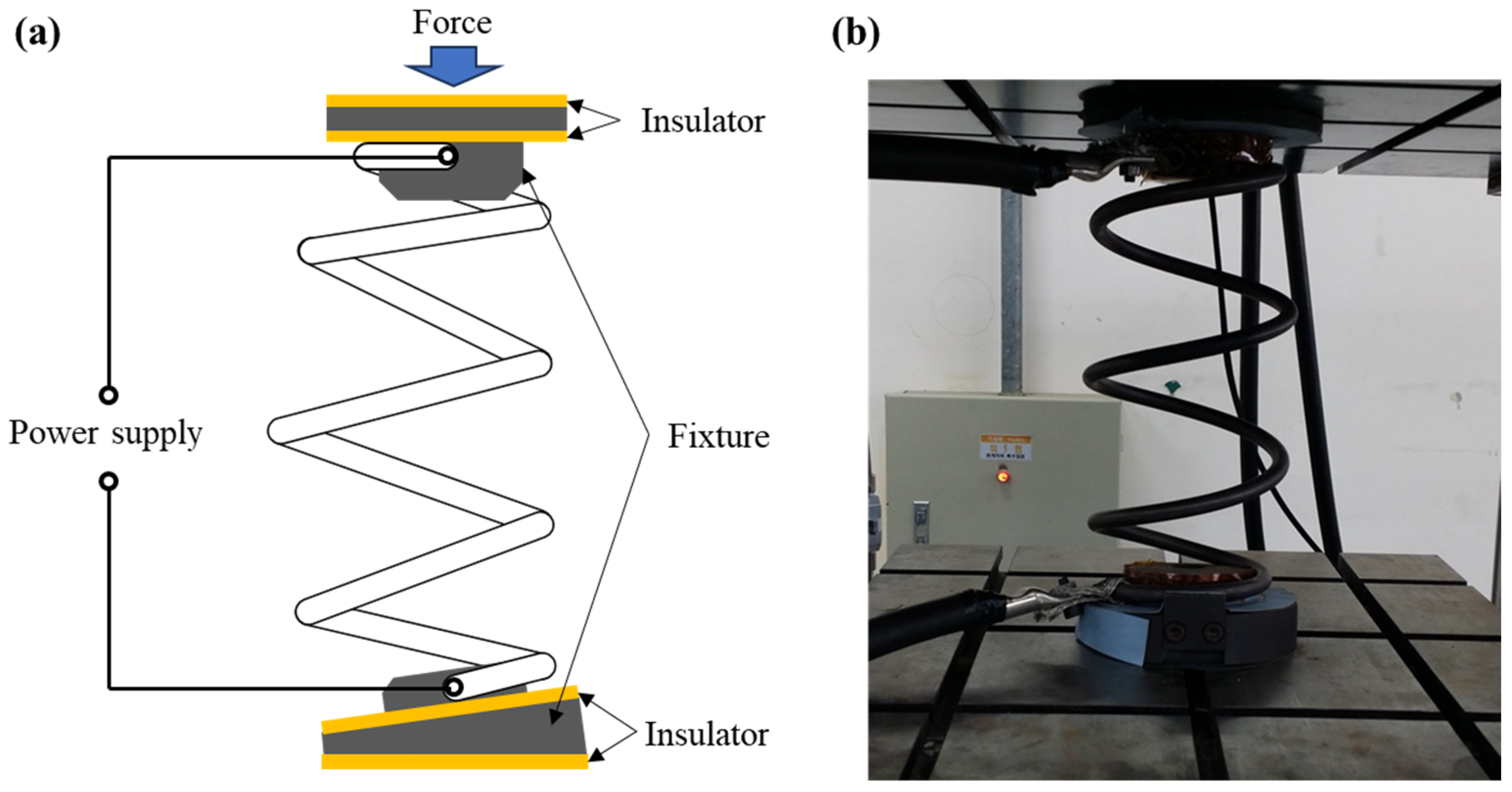

2. Experimental Set-Up

2.1. Materials

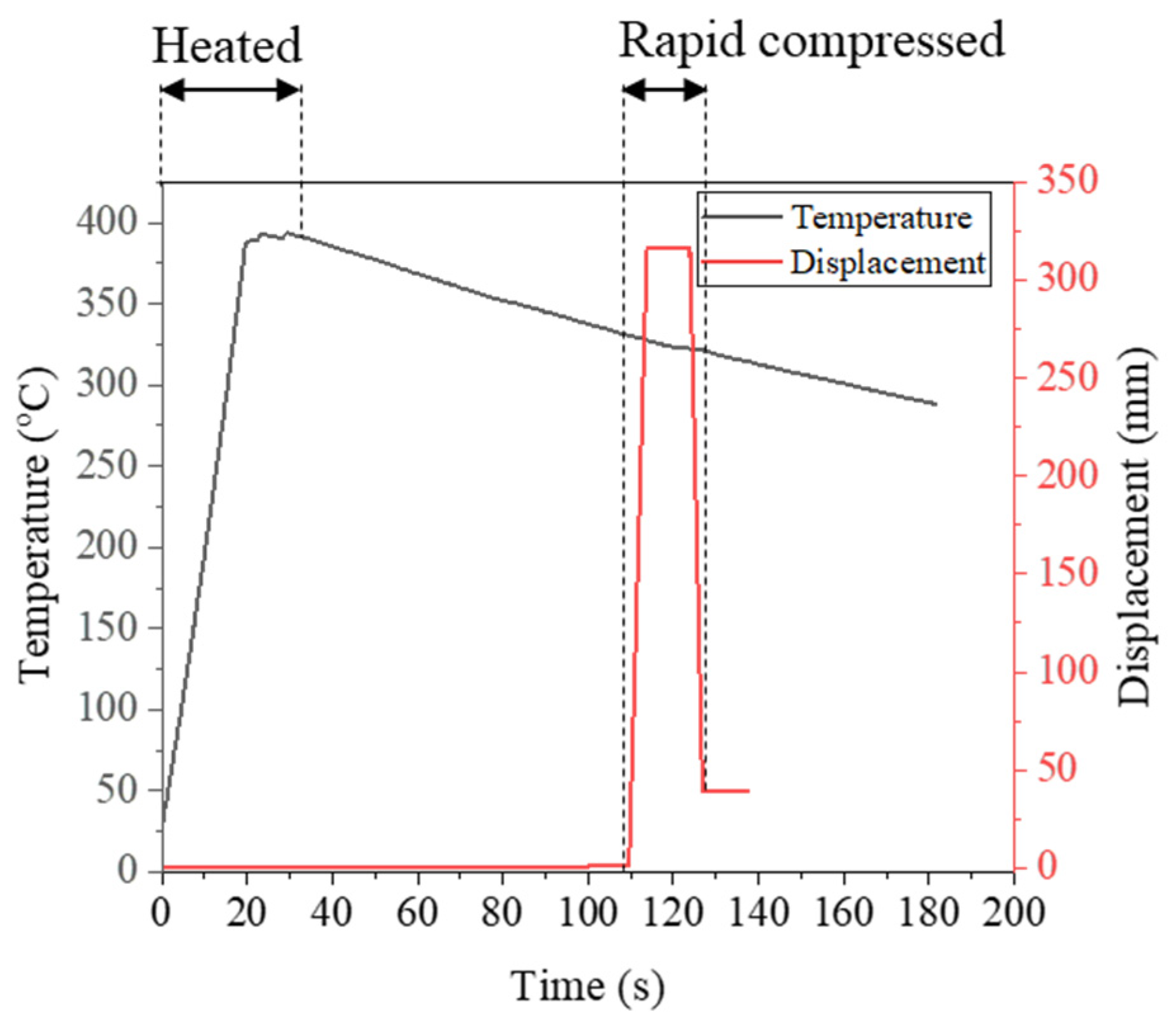

2.2. Effectiveness of EA Stress Relief Annealing

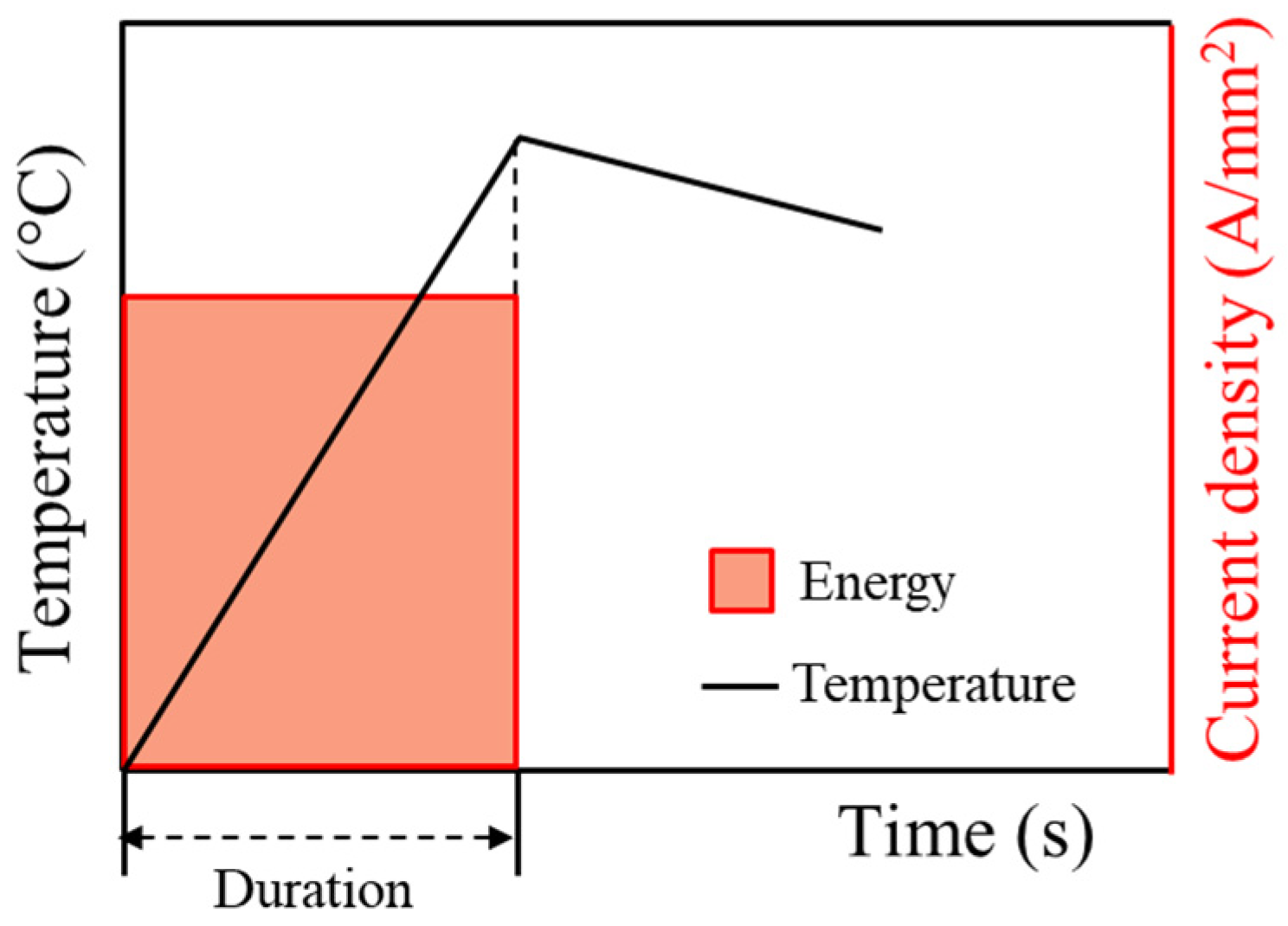

2.3. Effect of Energy Release Rate

3. Results and Discussion

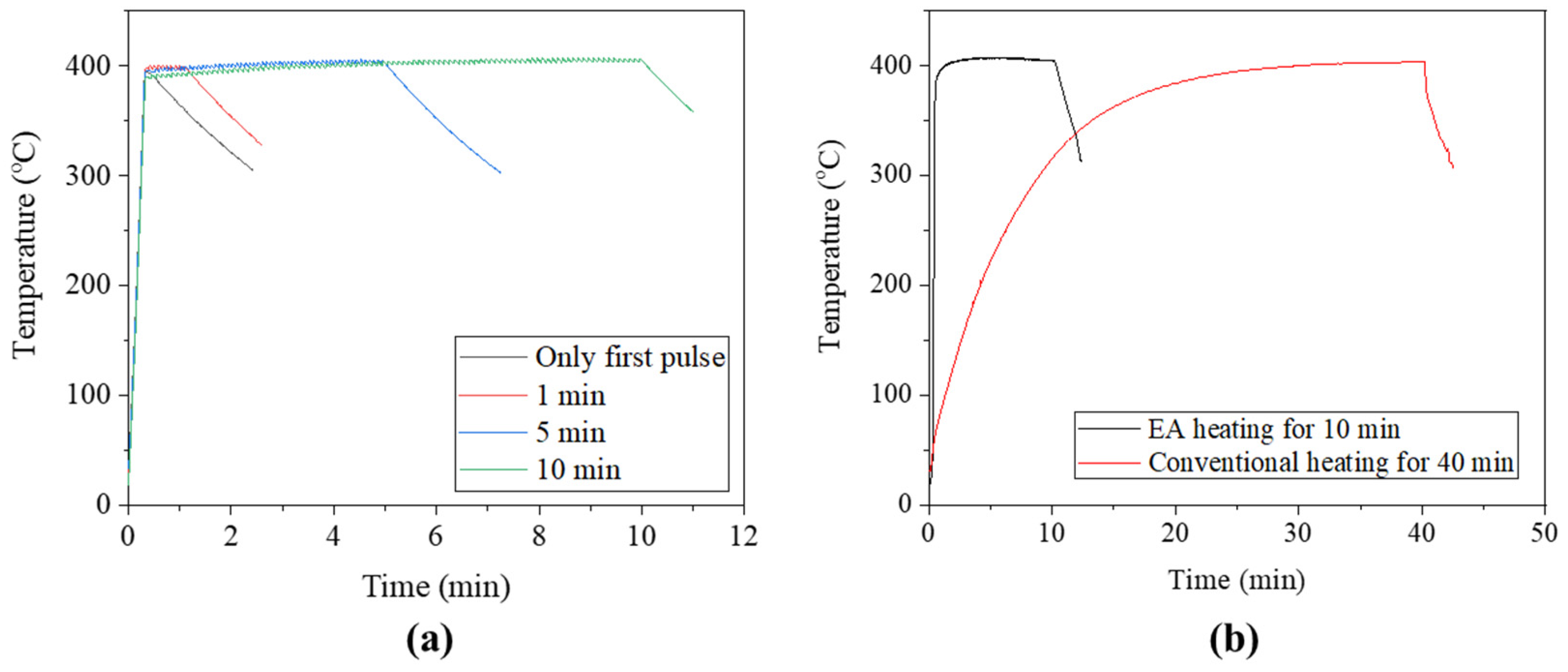

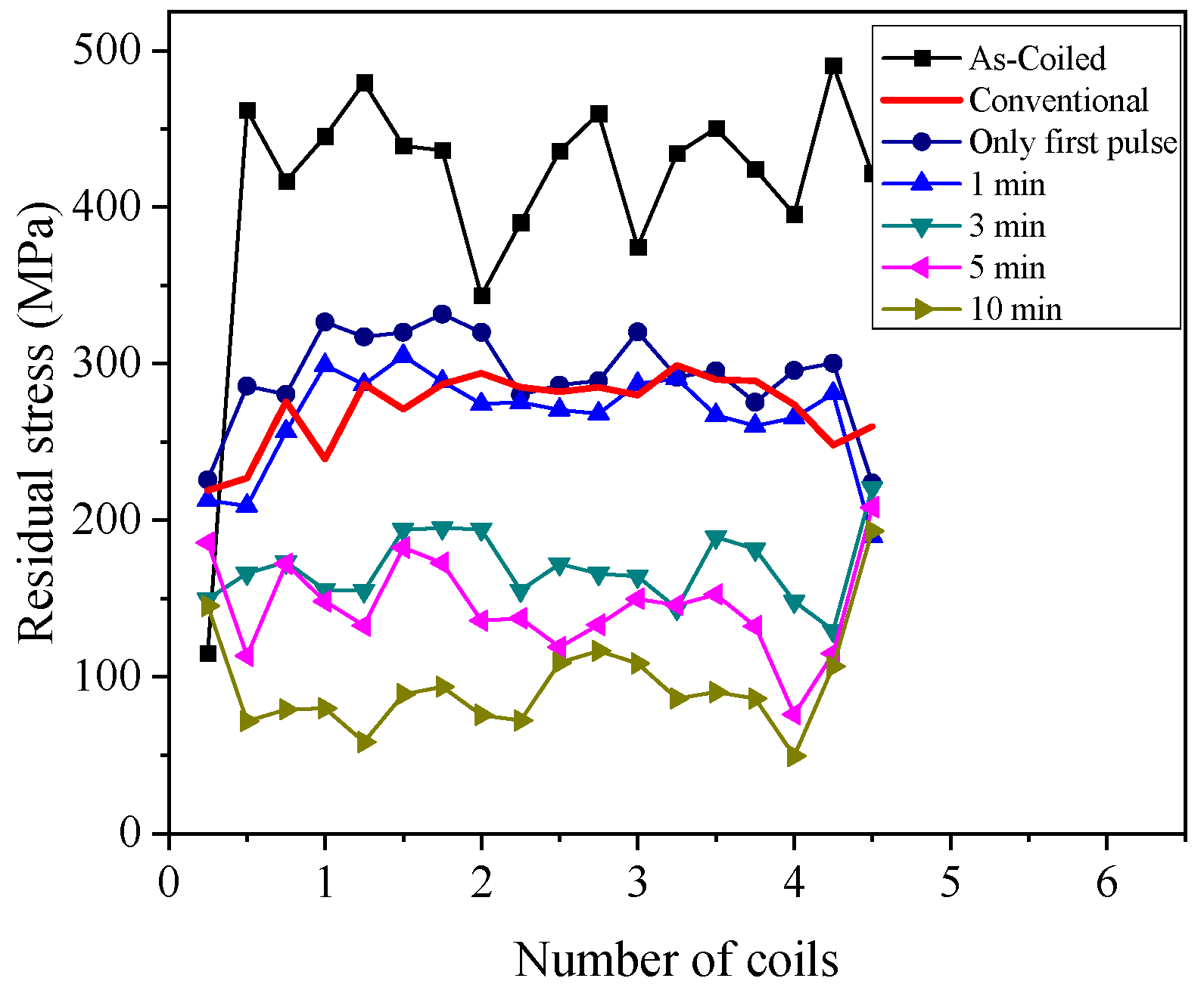

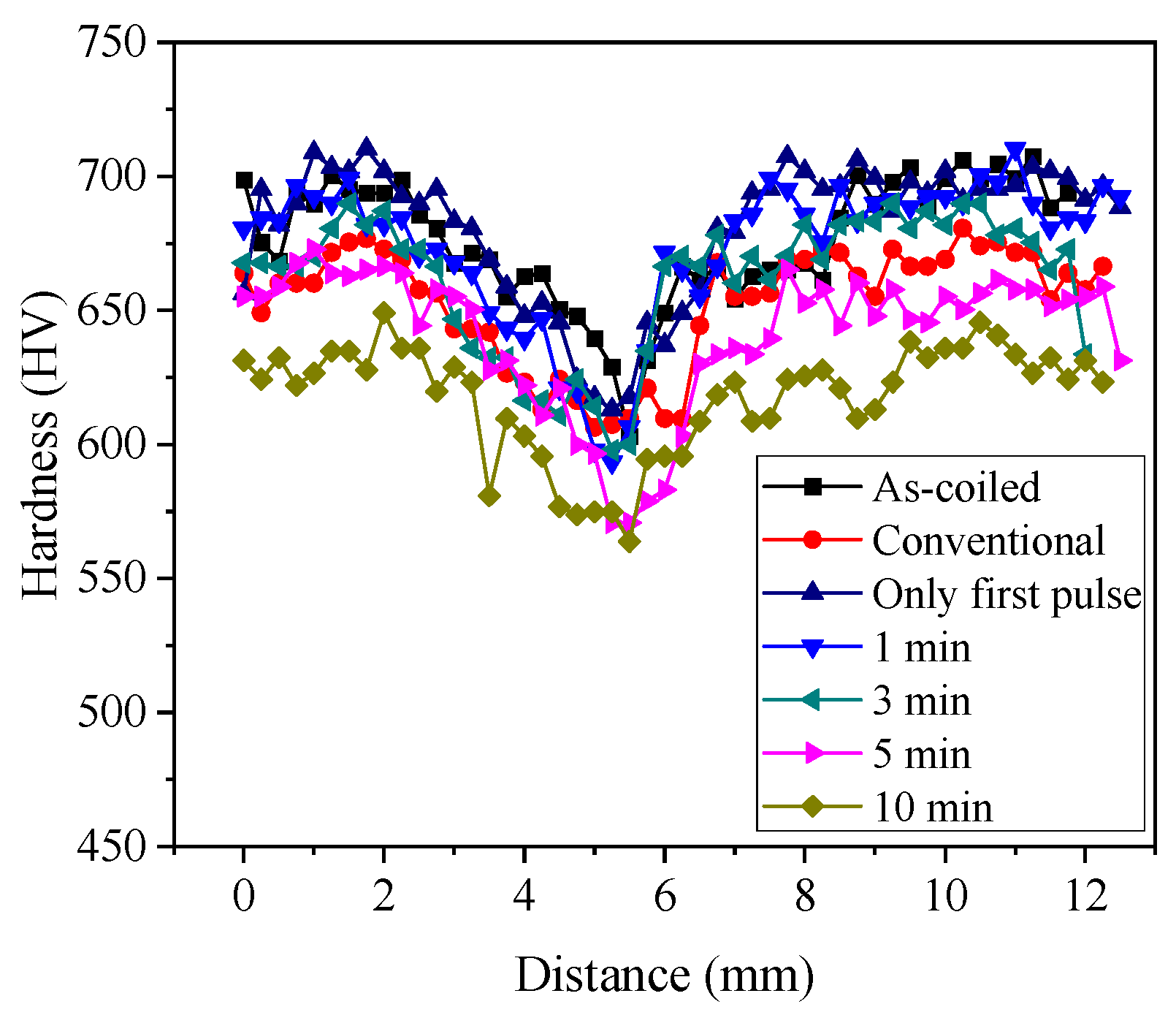

3.1. Effectiveness of EA Stress Relief Annealing

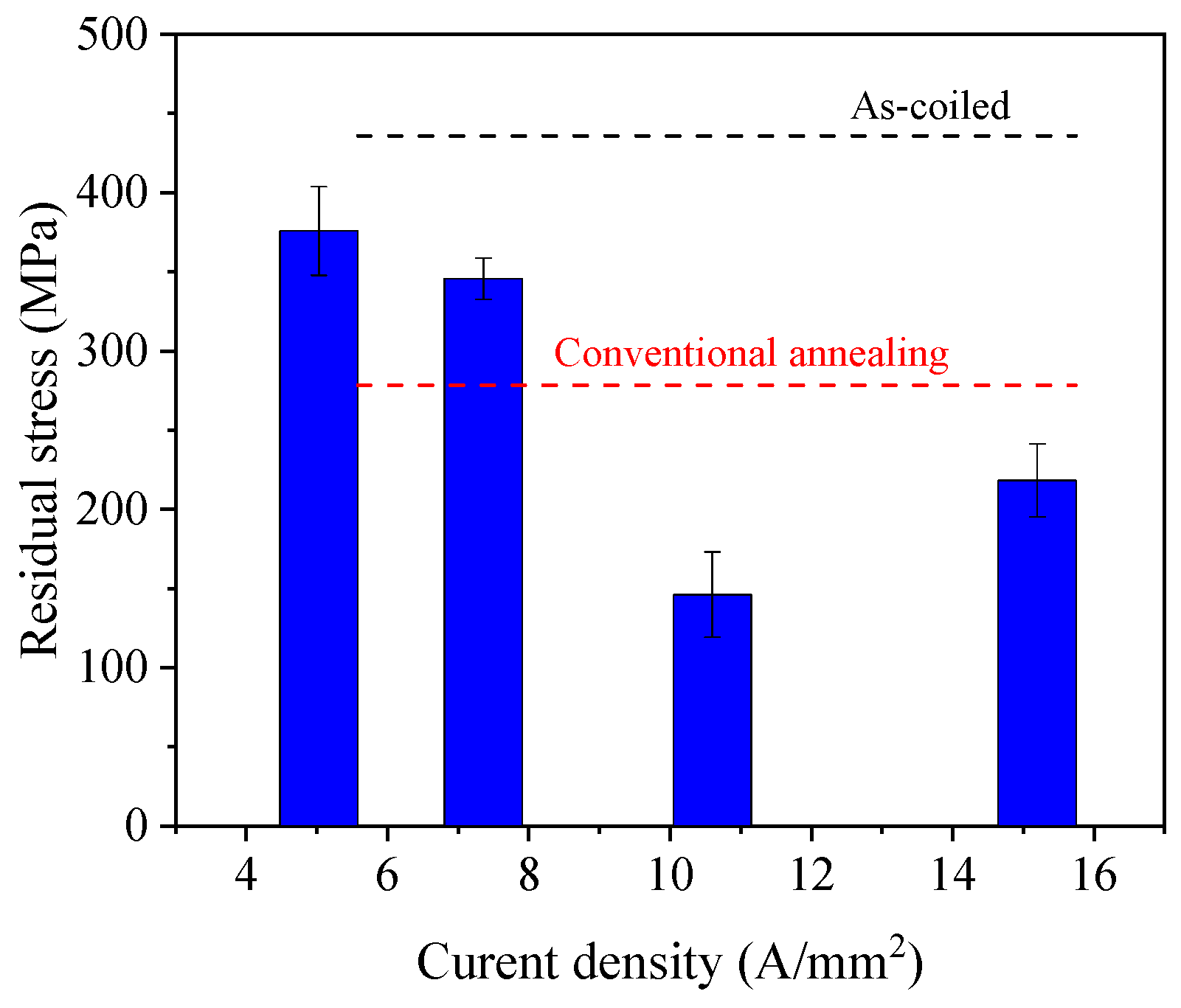

3.2. Effect of Energy Release Rate

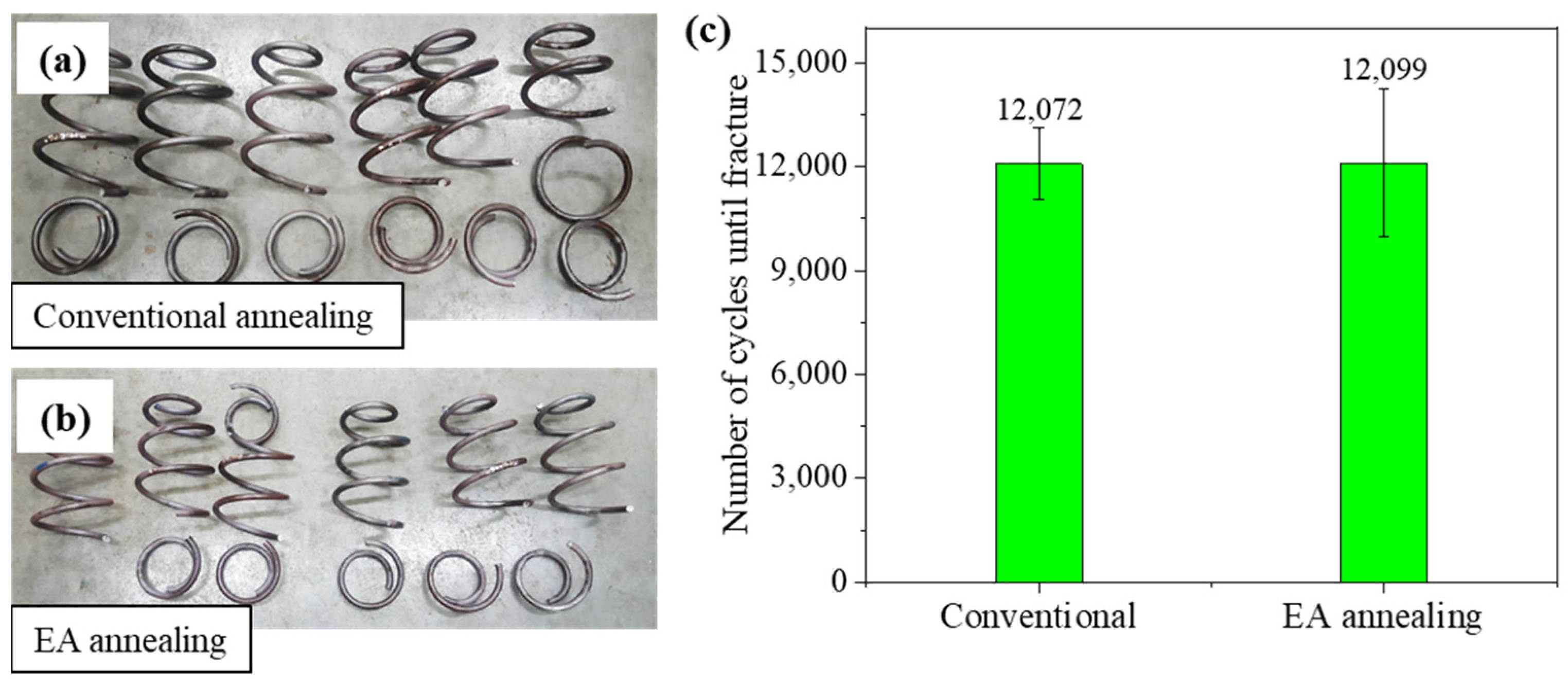

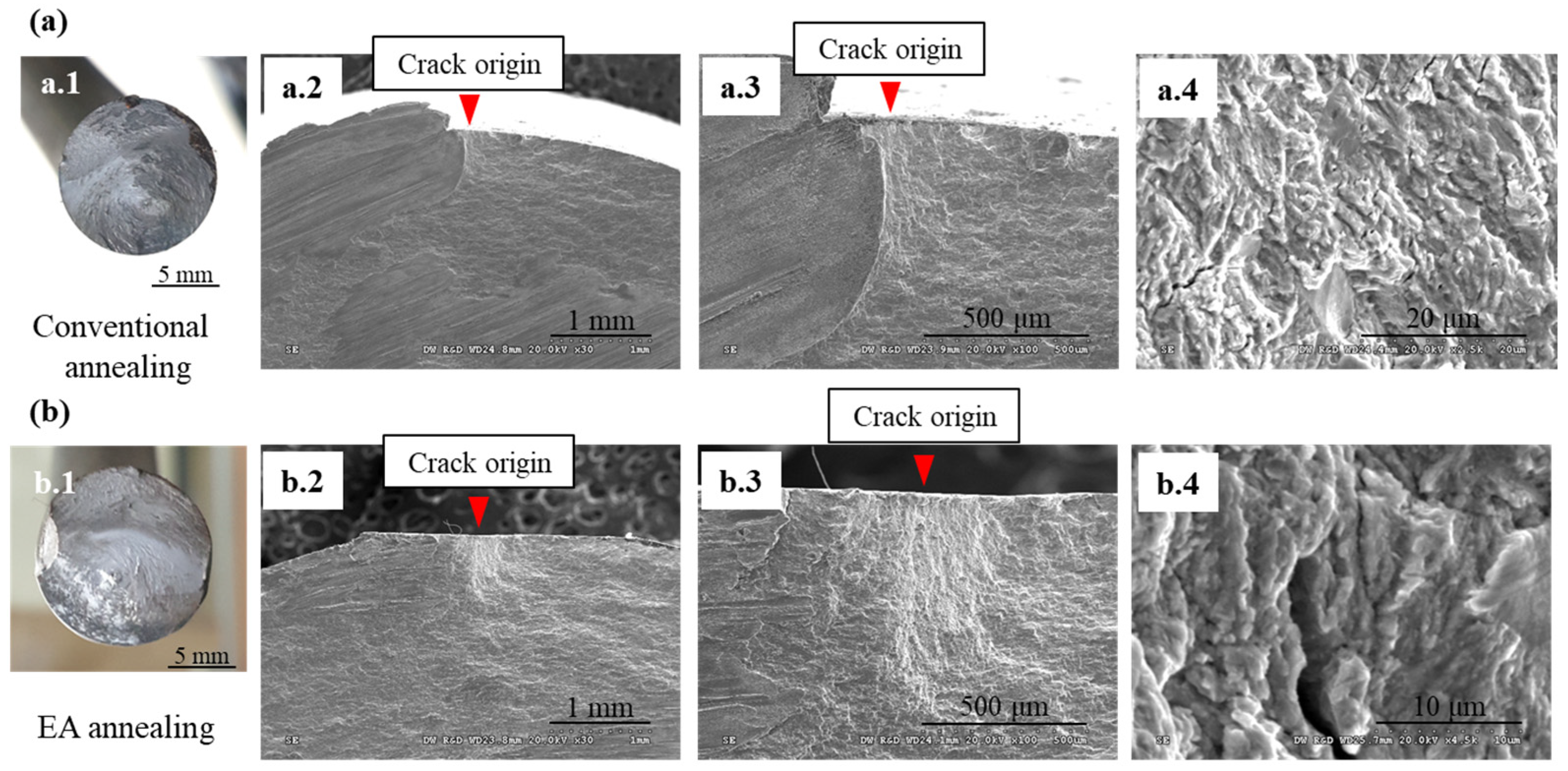

3.3. Validation of the Effectiveness of EA Stress Relief Annealing

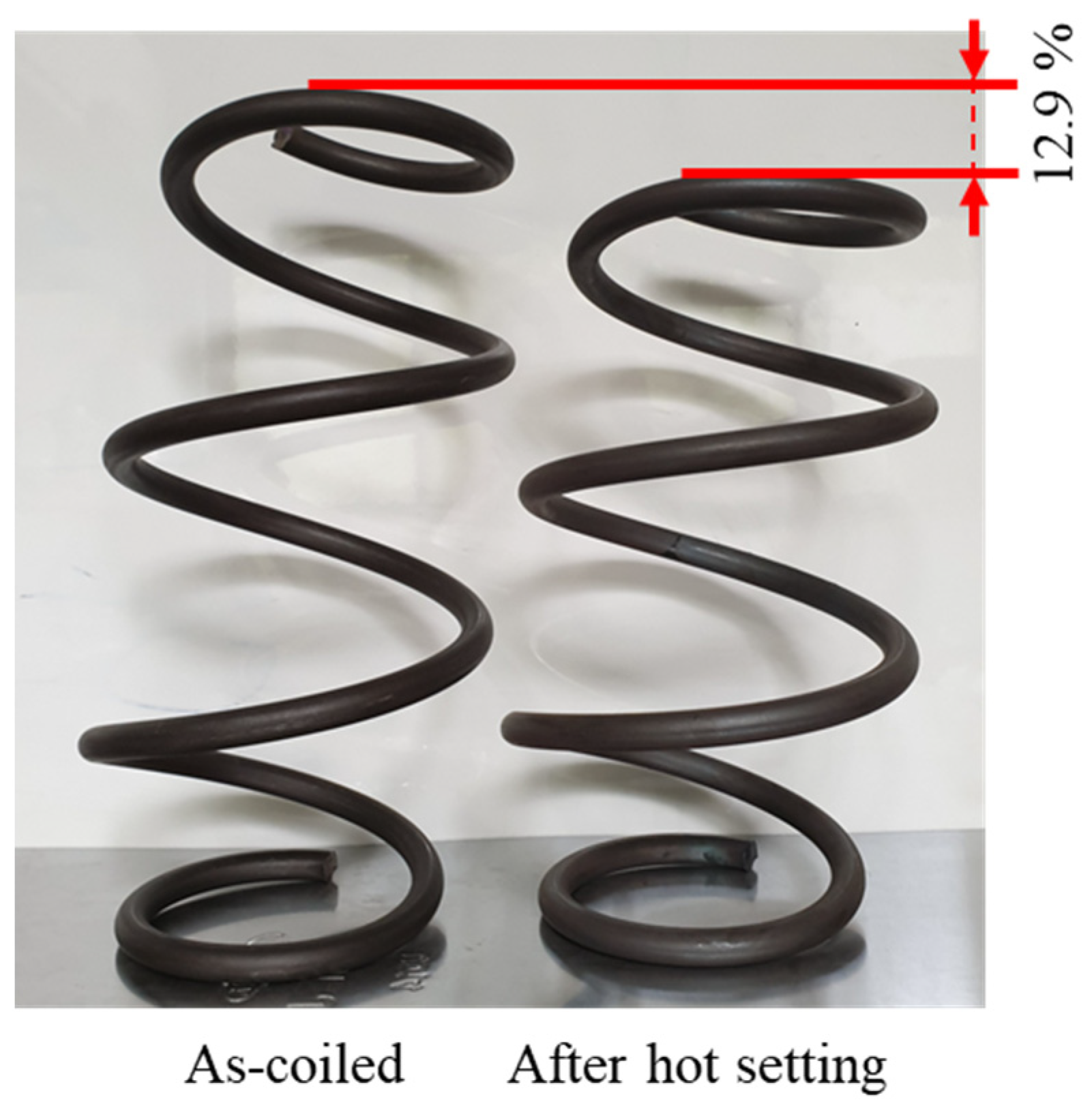

3.4. Combined EA Rapid Heating and Hot Setting

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kobelev, V. Durability of Springs; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Kim, M.-J.; Lee, K.; Oh, K.H.; Choi, I.S.; Yu, H.H.; Hong, S.T.; Han, H.N. Electric current-induced annealing during uniaxial tension of aluminum alloy. Scr. Mater. 2014, 75, 58–61. [Google Scholar] [CrossRef]

- Roh, J.-H.; Seo, J.J.; Hong, S.T.; Kim, M.J.; Han, H.N.; Roth, J.T. The mechanical behavior of 5052-H32 aluminum alloys under a pulsed electric current. Int. J. Plast. 2014, 58, 84–99. [Google Scholar] [CrossRef]

- Kim, M.-S.; Vinh, N.T.; Yu, H.H.; Hong, S.T.; Lee, H.W.; Kim, M.J.; Han, H.N.; Roth, J.T. Effect of electric current density on the mechanical property of advanced high strength steels under quasi-static tensile loads. Int. J. Precis. Eng. Manuf. 2014, 15, 1207–1213. [Google Scholar] [CrossRef]

- Luu, V.; Nguyen, T.; Hong, S.-T.; Jeong, H.-J.; Han, H. Feasibility of a Two-Stage Forming Process of 316L Austenitic Stainless Steels with Rapid Electrically Assisted Annealing. Metals 2018, 8, 815. [Google Scholar] [CrossRef]

- Kim, W.; Yeom, K.H.; Thien, N.T.; Hong, S.T.; Min, B.K.; Oh, S.I.; Lee, H.W. Electrically assisted blanking using the electroplasticity of ultra-high strength metal alloys. CIRP Ann. 2014, 63, 273–276. [Google Scholar] [CrossRef]

- Lv, Z.; Zhou, Y.; Zhan, L.; Zang, Z.; Zhou, B.; Qin, S. Electrically assisted deep drawing on high-strength steel sheet. Int. J. Adv. Manuf. Technol. 2021, 112, 763–773. [Google Scholar] [CrossRef]

- Xie, H.; Dong, X.; Ai, Z.; Wang, Q.; Peng, F.; Liu, K.; Chen, F.; Wang, J. Experimental investigation on electrically assisted cylindrical deep drawing of AZ31B magnesium alloy sheet. Int. J. Adv. Manuf. Technol. 2016, 86, 1063–1069. [Google Scholar] [CrossRef]

- Nguyen-Tran, H.-D.; Oh, H.S.; Hong, S.T.; Han, H.N.; Cao, J.; Ahn, S.H.; Chun, D.M. A review of electrically-assisted manufacturing. Int. J. Precis. Eng. Manuf. Green Tech. 2015, 2, 365–376. [Google Scholar] [CrossRef]

- Hong, S.-T.; Jeong, Y.H.; Chowdhury, M.N.; Chun, D.M.; Kim, M.J.; Han, H.N. Feasibility of electrically assisted progressive forging of aluminum 6061-T6 alloy. CIRP Ann. 2015, 64, 277–280. [Google Scholar] [CrossRef]

- Khal, A.; Ruszkiewicz, B.J.; Mears, L. Springback Evaluation of 304 Stainless Steel in an Electrically Assisted Air Bending Operation. In Proceedings of the International Manufacturing Science and Engineering Conference, Blacksburg, VI, USA, 27 June–1 July 2016; American Society of Mechanical Engineers: Blacksburg, VI, USA, 2016; Volume 1, p. V001T02A020. [Google Scholar] [CrossRef]

- Ng, M.-K.; Li, L.; Fan, Z.; Gao, R.X.; Smith, E.F., III; Ehmann, K.F.; Cao, J. Joining sheet metals by electrically-assisted roll bonding. CIRP Ann. 2015, 64, 273–276. [Google Scholar] [CrossRef]

- Nguyen TA, N.; Choi, H.; Kim, M.-J.; Hong, S.-T.; Han, H.N. Evaluation of Efficiency of Electrically Assisted Rapid Annealing Compared to Rapid Induction Heat Treatment. Int. J. Precis. Eng. Manuf. Green Tech. 2022, 9, 485–492. [Google Scholar] [CrossRef]

- Park, G.D.; Tran, V.L.; Hong, S.T.; Jeong, Y.H.; Yeo, T.S.; Nam, M.J.; Kim, M.J.; Jin, S.W.; Han, H.N. Electrically assisted stress relief annealing of automotive springs. J. Mech. Sci. Technol. 2017, 31, 3943–3948. [Google Scholar] [CrossRef]

- Venter, A.M.; Luzin, V.; Hattingh, D.G. Residual Stresses Associated with the Production of Coiled Automotive Springs. MSF 2014, 777, 78–83. [Google Scholar] [CrossRef]

- Shi, F.; Zheng, J.; Zhang, J.; Zhao, Y.; Chen, L. Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness. Metals 2024, 14, 180. [Google Scholar] [CrossRef]

- Kim, M.-J.; Yoon, S.; Park, S.; Jeong, H.J.; Park, J.W.; Kim, K.; Jo, J.; Heo, T.; Hong, S.T.; Cho, S.H.; et al. Elucidating the origin of electroplasticity in metallic materials. Appl. Mater. Today 2020, 21, 100874. [Google Scholar] [CrossRef]

- Jeong, K.; Jin, S.W.; Kang, S.G.; Park, J.W.; Jeong, H.J.; Hong, S.T.; Cho, S.H.; Kim, M.J.; Han, H.N. Athermally enhanced recrystallization kinetics of ultra-low carbon steel via electric current treatment. Acta Mater. 2022, 232, 117925. [Google Scholar] [CrossRef]

- Kikuchi, S.; Minamizawa, K.; Arakawa, J.; Akebono, H.; Takesue, S.; Hayakawa, M. Combined effect of surface morphology and residual stress induced by fine particle and shot peening on the fatigue limit for carburized steels. Int. J. Fatigue 2023, 168, 107441. [Google Scholar] [CrossRef]

| First Pulse (Heating) | Repeated Pulse (Holding) | Holding Time (min) | |||

|---|---|---|---|---|---|

| Current Density (A/mm2) | Duration (s) | Current Density (A/mm2) | Duration (s) | Period (s) | |

| 13.75 | 18 | 7.15 | 1 | 5 | 0, 1, 3, 5, 10 |

| Number of Pulses | Current Density (A/mm2) | Duration (s) | Total Energy (J/Ω) |

|---|---|---|---|

| 1 | 15.75 | 15 | 65.52 |

| 1 | 11.15 | 30 | 65.71 |

| 1 | 7.91 | 60 | 66.15 |

| 1 | 5.58 | 120 | 65.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, V.L.; Hong, S.-T.; Hong, J.Y.; Yeo, T.S. A Case Study: Electrically Assisted Stress Relief Annealing for Cold-Coiled Helical Automotive Springs. Materials 2024, 17, 1774. https://doi.org/10.3390/ma17081774

Tran VL, Hong S-T, Hong JY, Yeo TS. A Case Study: Electrically Assisted Stress Relief Annealing for Cold-Coiled Helical Automotive Springs. Materials. 2024; 17(8):1774. https://doi.org/10.3390/ma17081774

Chicago/Turabian StyleTran, Van Loi, Sung-Tae Hong, Ji Ye Hong, and Tae Shik Yeo. 2024. "A Case Study: Electrically Assisted Stress Relief Annealing for Cold-Coiled Helical Automotive Springs" Materials 17, no. 8: 1774. https://doi.org/10.3390/ma17081774

APA StyleTran, V. L., Hong, S.-T., Hong, J. Y., & Yeo, T. S. (2024). A Case Study: Electrically Assisted Stress Relief Annealing for Cold-Coiled Helical Automotive Springs. Materials, 17(8), 1774. https://doi.org/10.3390/ma17081774