Crystallographic Engineering of CrN Buffer Layers for GaN Thin Film Epitaxy

Abstract

1. Introduction

2. Materials and Methods

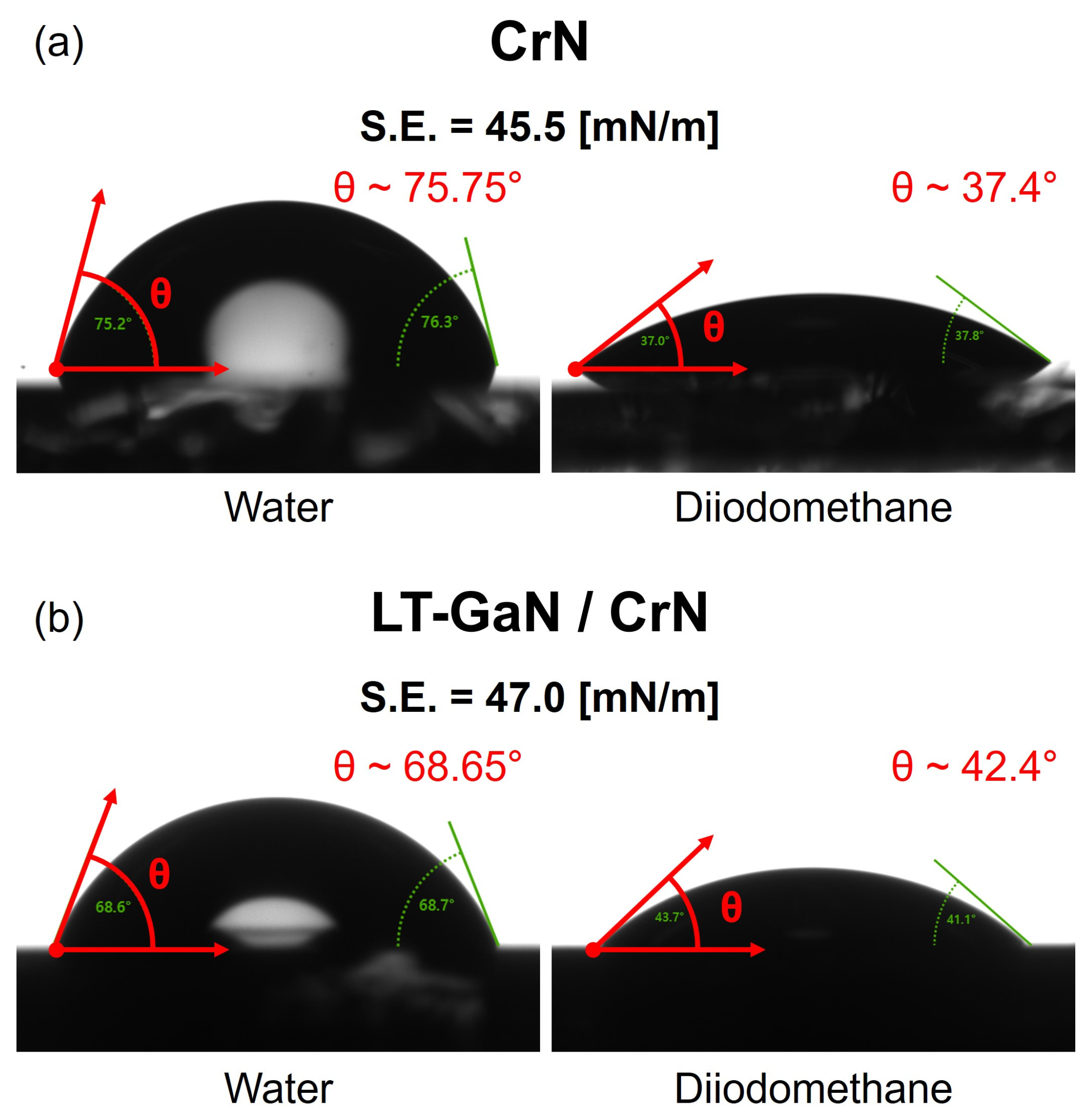

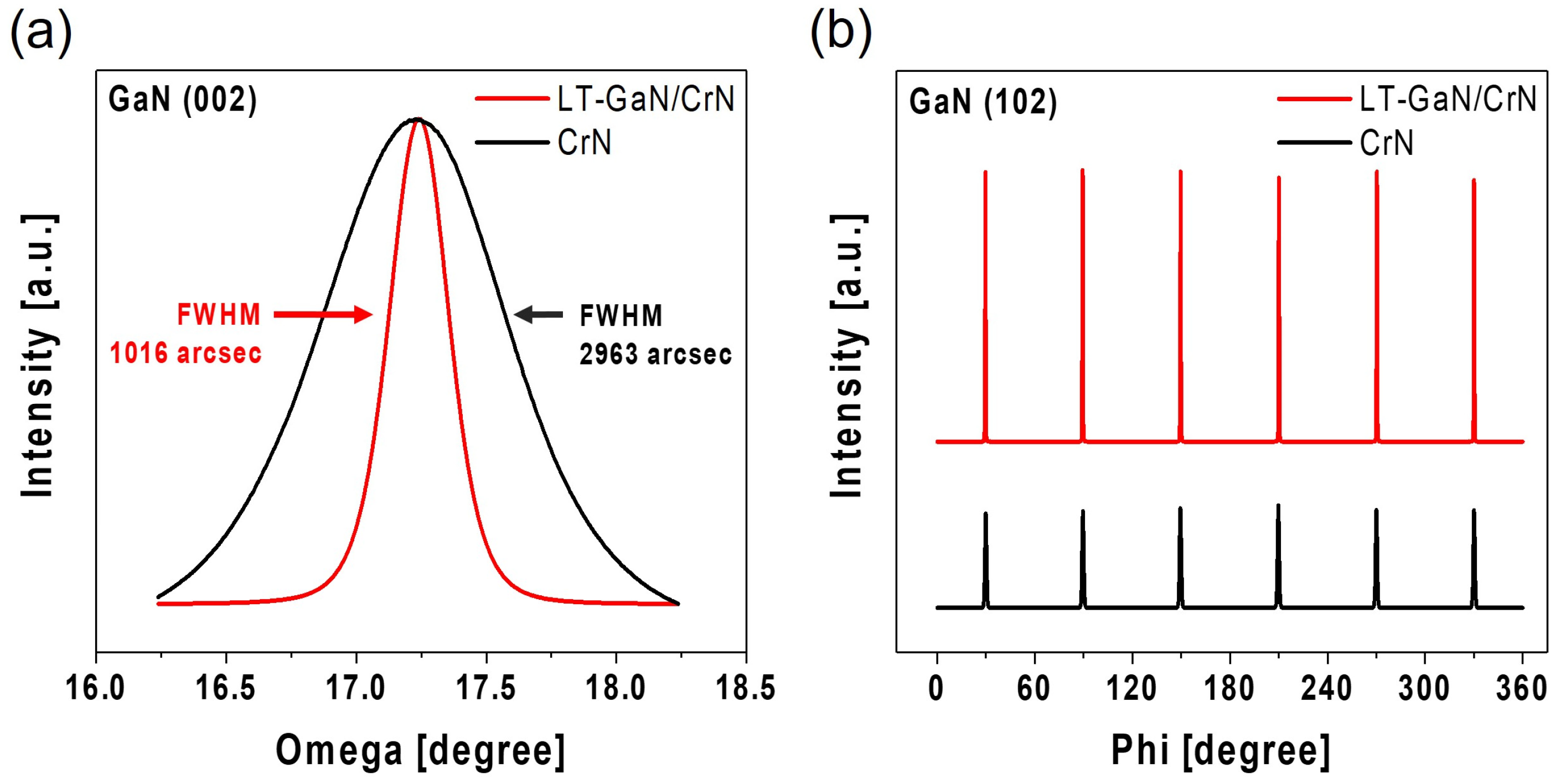

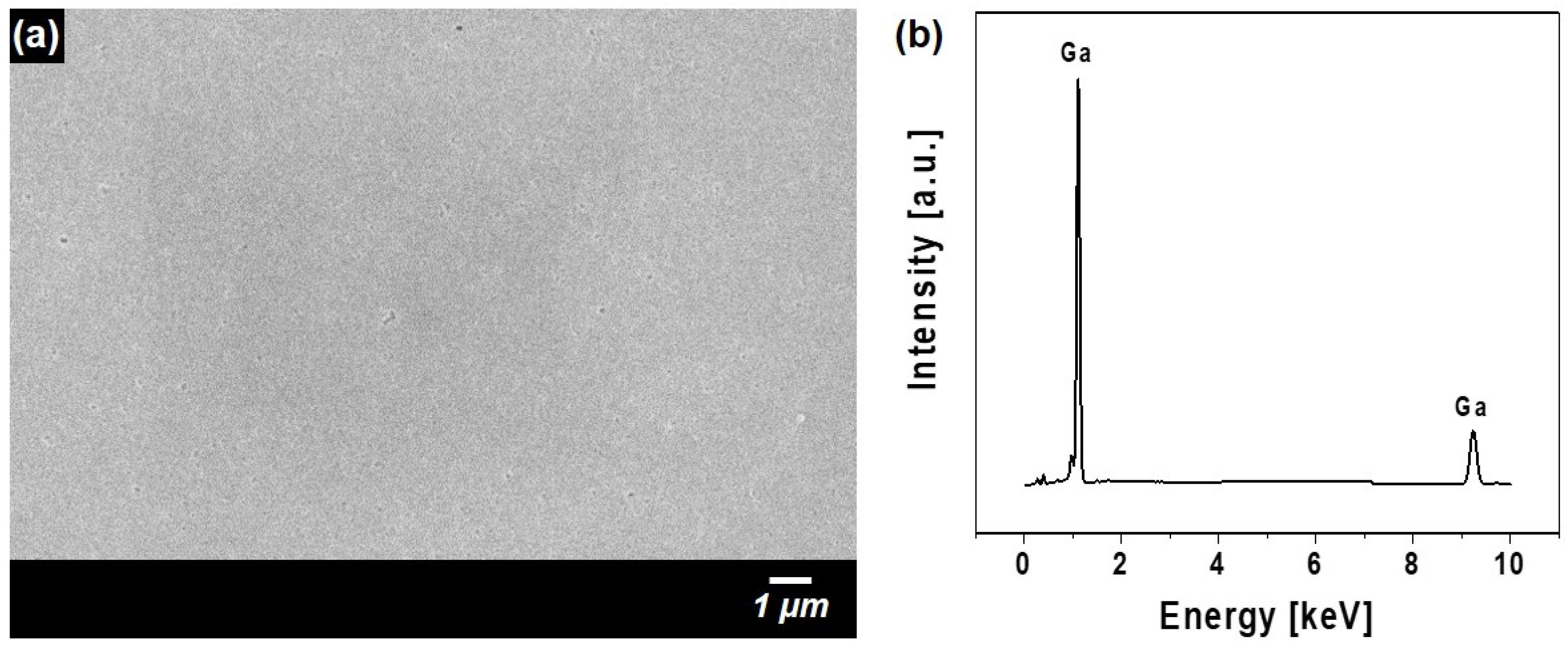

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GaN | gallium nitride |

| LED | light-emitting diode |

| MOCVD | metal–organic chemical vapor deposition |

| LT | low temperature |

| LLO | laser lift-off |

| CLO | chemical lift-off |

| RF | radio frequency |

| HT | high temperature |

| XRD | X-ray diffraction |

| EDX | energy-dispersive X-ray spectroscopy |

| FWHM | full-width at half maximum |

| AFM | atomic force microscopy |

| SEM | scanning electron microscopy |

| MFP | mean free path |

References

- Strite, S.; Morkoç, H. GaN, AlN, and InN: A Review. J. Vac. Sci. Technol. B: Microelectron. Nanometer Struct. Process. Meas. Phenom. 1992, 10, 1237–1266. [Google Scholar] [CrossRef]

- DenBaars, S.P.; Feezell, D.; Kelchner, K.; Pimputkar, S.; Pan, C.-C.; Yen, C.-C.; Tanaka, S.; Zhao, Y.; Pfaff, N.; Farrell, R.; et al. Development of Gallium-Nitride-Based Light-Emitting Diodes (LEDs) and Laser Diodes for Energy-Efficient Lighting and Displays. Acta Mater. 2013, 61, 945–951. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y.; Kozaki, T.; Umemoto, H.; et al. InGaN/GaN/AlGaN-Based Laser Diodes with Modulation-Doped Strained-Layer Superlattices Grown on an Epitaxially Laterally Overgrown GaN Substrate. Appl. Phys. Lett. 1998, 72, 211–213. [Google Scholar] [CrossRef]

- Cho, Y.S.; Koh, E.K.; Park, Y.J.; Kim, E.K.; Hwang, S.-M.; Leem, S.-J.; Byun, D. Effects of GaN Buffer Layer Thickness on Characteristics of GaN Epilayer. Korean J. Mater. Res. 2001, 11, 575–579. [Google Scholar]

- Nakamura, S.; Harada, Y.; Seno, M. Novel Metalorganic Chemical Vapor Deposition System for GaN Growth. Appl. Phys. Lett. 1991, 58, 2021–2023. [Google Scholar] [CrossRef]

- Brückner, P.; Habel, F.; Scholz, F. HVPE Growth of High Quality GaN Layers. Phys. Status Solidi (C) 2006, 3, 1471–1474. [Google Scholar] [CrossRef]

- Byun, D.; Kim, G.; Lim, D.; Lee, D.; Choi, I.-H.; Park, D.; Kum, D.-W. Optimization of the GaN-Buffer Growth on 6H-SiC(0001). Thin Solid Films 1996, 289, 256–260. [Google Scholar] [CrossRef]

- Nakamura, S. GaN Growth Using GaN Buffer Layer. Jpn. J. Appl. Phys. 1991, 30, 1705–1707. [Google Scholar] [CrossRef]

- Kang, B.H.; Lee, J.E.; Kim, D.-S.; Bae, S.; Jung, S.; Park, J.; Jhin, J.; Byun, D. Effect of Amorphous and Crystalline AlN Buffer Layers Deposited on Patterned Sapphire Substrate on GaN Film Quality. J Nanosci. Nanotechnol. 2016, 16, 11563–11568. [Google Scholar] [CrossRef]

- Amano, H.; Sawaki, N.; Akasaki, I.; Toyoda, Y. Metalorganic Vapor Phase Epitaxial Growth of a High Quality GaN Film Using an AlN Buffer Layer. Appl. Phys. Lett. 1986, 48, 353–355. [Google Scholar] [CrossRef]

- Fischer, A.; Kühne, H.; Richter, H. New Approach in Equilibrium Theory for Strained Layer Relaxation. Phys. Rev. Lett. 1994, 73, 2712–2715. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.H.; Im, I.H.; Minegishi, T.; Hanada, T.; Cho, M.W.; Yao, T. Structural Properties of CrN Buffers for GaN Growth. J. Korean Phys. Soc. 2006, 49, 928–933. [Google Scholar]

- Park, J.S.; Minegishi, T.; Lee, S.H.; Im, I.H.; Park, S.H.; Hanada, T.; Goto, T.; Cho, M.W.; Yao, T.; Hong, S.K.; et al. Effects of Interfacial Layer Structures on Crystal Structural Properties of ZnO Films. J. Vac. Sci. Technol. A: Vac. Surf. Film. 2008, 26, 90–96. [Google Scholar] [CrossRef]

- Lee, W.; Lee, S.; Goto, H.; Ko, H.; Cho, M.; Yao, T. Novel Buffer Layer for the Growth of GaN on C-sapphire. Phys. Status Solidi (C) 2006, 3, 1388–1391. [Google Scholar] [CrossRef]

- Park, J.; Yao, T. Growth of N-Polar GaN Using a CrN Buffer Layer on (0001) Al2O3 via Plasma-Assisted Molecular Beam Epitaxy. Thin Solid Films 2013, 531, 88–92. [Google Scholar] [CrossRef]

- Li, G.; Wang, W.; Yang, W.; Lin, Y.; Wang, H.; Lin, Z.; Zhou, S. GaN-Based Light-Emitting Diodes on Various Substrates: A Critical Review. Rep. Prog. Phys. 2016, 79, 056501. [Google Scholar] [CrossRef]

- Liu, H.F.; Liu, W.; Chua, S.J. Epitaxial Growth and Chemical Lift-off of GaInN/GaN Heterostructures on c- and r-Sapphire Substrates Employing ZnO Sacrificial Templates. J. Vac. Sci. Technol. A Vac. Surf. Films 2010, 28, 590–594. [Google Scholar] [CrossRef]

- Kelly, M.K.; Ambacher, O.; Dahlheimer, B.; Groos, G.; Dimitrov, R.; Angerer, H.; Stutzmann, M. Optical Patterning of GaN Films. Appl. Phys. Lett. 1996, 69, 1749–1751. [Google Scholar] [CrossRef]

- Wong, W.S.; Sands, T.; Cheung, N.W.; Kneissl, M.; Bour, D.P.; Mei, P.; Romano, L.T.; Johnson, N.M. Fabrication of Thin-Film InGaN Light-Emitting Diode Membranes by Laser Lift-Off. Appl. Phys. Lett. 1999, 75, 1360–1362. [Google Scholar] [CrossRef]

- Wong, W.S.; Sands, T.; Cheung, N.W.; Kneissl, M.; Bour, D.P.; Mei, P.; Romano, L.T.; Johnson, N.M. In x Ga 1−x N Light Emitting Diodes on Si Substrates Fabricated by Pd–In Metal Bonding and Laser Lift-Off. Appl. Phys. Lett. 2000, 77, 2822–2824. [Google Scholar] [CrossRef]

- Wong, W.S.; Cho, Y.; Weber, E.R.; Sands, T.; Yu, K.M.; Krüger, J.; Wengrow, A.B.; Cheung, N.W. Structural and Optical Quality of GaN/Metal/Si Heterostructures Fabricated by Excimer Laser Lift-Off. Appl. Phys. Lett. 1999, 75, 1887–1889. [Google Scholar] [CrossRef]

- Wu, Y.S.; Cheng, J.-H.; Ouyanga, H. Effects of Laser Sources on the Reverse-Bias Leakages of Laser Lift-Off GaN-Based LEDs. ECS Trans. 2007, 6, 285–287. [Google Scholar] [CrossRef]

- Chen, W.H.; Kang, X.N.; Hu, X.D.; Lee, R.; Wang, Y.J.; Yu, T.J.; Yang, Z.J.; Zhang, G.Y.; Shan, L.; Liu, K.X.; et al. Study of the Structural Damage in the (0001) GaN Epilayer Processed by Laser Lift-off Techniques. Appl. Phys. Lett. 2007, 91, 121114. [Google Scholar] [CrossRef]

- Park, J.; Goto, T.; Yao, T.; Lee, S.; Cho, M. Local Stress Distribution in GaN Vertical Light-Emitting Diodes Fabricated Using CLO and LLO Methods. J. Phys. D Appl. Phys. 2013, 46, 155104. [Google Scholar] [CrossRef]

- Lin, C.-F.; Dai, J.-J.; Wang, G.-M.; Lin, M.-S. Chemical Lift-Off Process for Blue Light-Emitting Diodes. Appl. Phys. Express 2010, 3, 092101. [Google Scholar] [CrossRef]

- Jeong, W.S.; Ahn, M.J.; Ko, H.-A.; Shim, K.; Kang, S.; Kim, H.; Kim, D.; Jhin, J.; Byun, D. Fabrication Method of GaN Template for High-Speed Chemical Lift-Off. AIP Advances 2023, 13, 035316. [Google Scholar] [CrossRef]

- Ahn, M.; Shim, K.; Jeong, W.; Kang, S.; Kim, H.; Cho, S.; Byun, D. Effective Chemical Lift-Off for Air-Tunnel GaN on a Trapezoid-Patterned Sapphire Substrate. Micromachines 2023, 14, 753. [Google Scholar] [CrossRef]

- Lin, C.-F.; Dai, J.-J.; Lin, M.-S.; Chen, K.-T.; Huang, W.-C.; Lin, C.-M.; Jiang, R.-H.; Huang, Y.-C. An AlN Sacrificial Buffer Layer Inserted into the GaN/Patterned Sapphire Substrate for a Chemical Lift-Off Process. Appl. Phys. Express 2010, 3, 031001. [Google Scholar] [CrossRef]

- Horng, R.-H.; Hsueh, H.-H.; Ou, S.-L.; Tsai, C.-T.; Tsai, T.-Y.; Wuu, D.-S. Chemical Lift-off Process for Nitride LEDs from an Eco-GaN Template Using an AlN/Strip-Patterned-SiO2 Sacrificial Layer: Chemical Lift-off Process for Nitride LEDs. Phys. Status Solidi A 2017, 214, 1600657. [Google Scholar] [CrossRef]

- Ha, J.-S.; Lee, H.-J.; Lee, S.W.; Lee, H.J.; Lee, S.H.; Goto, H.; Cho, M.W.; Yao, T.; Hong, S.-K.; Toba, R.; et al. Reduction of Dislocations in GaN Films on AlN/Sapphire Templates Using CrN Nanoislands. Appl. Phys. Lett. 2008, 92, 091906. [Google Scholar] [CrossRef]

- Goto, H.; Lee, S.W.; Lee, H.J.; Lee, H.; Ha, J.S.; Cho, M.W.; Yao, T. Chemical Lift-off of GaN Epitaxial Films Grown on C-sapphire Substrates with CrN Buffer Layers. Phys. Status Solidi (C) 2008, 5, 1659–1661. [Google Scholar] [CrossRef]

- Goto, H.; Lee, H.; Lee, S.; Cho, M.; Yao, T. Free-standing GaN Substrates Fabricated by a Combination of Substrate Fracturing and Chemical Lift-off. Phys. Status Solidi (C) 2011, 8, 2123–2126. [Google Scholar] [CrossRef]

- Ha, J.-S.; Lee, S.W.; Lee, H.-J.; Lee, H.-J.; Lee, S.H.; Goto, H.; Kato, T.; Fujii, K.; Cho, M.W.; Yao, T. The Fabrication of Vertical Light-Emitting Diodes Using Chemical Lift-Off Process. IEEE Photon. Technol. Lett. 2008, 20, 175–177. [Google Scholar] [CrossRef]

- Gharavi, M.A.; Kerdsongpanya, S.; Schmidt, S.; Eriksson, F.; Nong, N.V.; Lu, J.; Balke, B.; Fournier, D.; Belliard, L.; le Febvrier, A.; et al. Microstructure and Thermoelectric Properties of CrN and CrN/Cr2N Thin Films. J. Phys. D Appl. Phys. 2018, 51, 355302. [Google Scholar] [CrossRef]

- Gall, D.; Shin, C.-S.; Spila, T.; Odén, M.; Senna, M.J.H.; Greene, J.E.; Petrov, I. Growth of Single-Crystal CrN on MgO(001): Effects of Low-Energy Ion-Irradiation on Surface Morphological Evolution and Physical Properties. J. Appl. Phys. 2002, 91, 3589–3597. [Google Scholar] [CrossRef]

- Lin, P.-C.; Tsai, Y.-T.; Gan, N.-H.; Yang, J.-R.; Wang, S.-H.; Chang, H.-Y.; Lin, T.-R.; Chiu, P.-K. Characteristics of Flakes Stacked Cr2N with Many Domains in Super Duplex Stainless Steel. Crystals 2020, 10, 965. [Google Scholar] [CrossRef]

- Liu, H.Y.; Tang, G.S.; Zeng, F.; Pan, F. Influence of Sputtering Parameters on Structures and Residual Stress of AlN Films Deposited by DC Reactive Magnetron Sputtering at Room Temperature. J. Cryst. Growth 2013, 363, 80–85. [Google Scholar] [CrossRef]

- Asgary, S.; Vaghri, E.; Daemi, M.; Esmaili, P.; Ramezani, A.H.; Memon, S.; Hoseinzadeh, S. Magnetron Sputtering Technique for Analyzing the Influence of RF Sputtering Power on Microstructural Surface Morphology of Aluminum Thin Films Deposited on SiO2/Si Substrates. Appl. Phys. A 2021, 127, 1–7. [Google Scholar] [CrossRef]

- Floro, J.A.; Hearne, S.J.; Hunter, J.A.; Kotula, P.; Chason, E.; Seel, S.C.; Thompson, C.V. The Dynamic Competition between Stress Generation and Relaxation Mechanisms during Coalescence of Volmer–Weber Thin FIlms. J. Appl. Phys. 2001, 89, 4886–4897. [Google Scholar] [CrossRef]

- Itagaki, N.; Nakamura, Y.; Narishige, R.; Takeda, K.; Kamataki, K.; Koga, K.; Hori, H.; Shiratani, M. Growth of Single Crystalline Films on Lattice-Mismatched Substrates through 3D to 2D Mode Transition. Sci. Rep. 2020, 10, 4669. [Google Scholar] [CrossRef]

- Huang, W.-C.; Chu, C.-M.; Wong, Y.-Y.; Chen, K.-W.; Lin, Y.-K.; Wu, C.-H.; Lee, W.-I.; Chang, E.-Y. Investigations of GaN Growth on the Sapphire Substrate by MOCVD Method with Different AlN Buffer Deposition Temperatures. Mater. Sci. Semicond. Process. 2016, 45, 1–8. [Google Scholar] [CrossRef]

- Rosová, A.; Dobročka, E.; Eliáš, P.; Hasenöhrl, S.; Kučera, M.; Gucmann, F.; Kuzmík, J. In (Ga)N 3D Growth on GaN-Buffered On-Axis and Off-Axis (0001) Sapphire Substrates by MOCVD. Nanometerials 2022, 12, 3496. [Google Scholar] [CrossRef] [PubMed]

- Kozbial, A.; Li, Z.; Conaway, C.; McGinley, R.; Dhingra, S.; Vahdat, V.; Zhou, F.; D’Urso, B.; Liu, H.; Li, L. Study on the Surface Energy of Graphene by Contact Angle Measurements. Langmuir 2014, 30, 8598–8606. [Google Scholar] [CrossRef] [PubMed]

- Ahn, M.; Jeong, W.; Shim, K.; Kang, S.; Kim, H.; Kim, D.; Jhin, J.; Kim, J.; Byun, D. Selective-Area Growth Mechanism of GaN Microrods on a Plateau Patterned Substrate. Materials 2023, 16, 2462. [Google Scholar] [CrossRef]

- Smith, D.L.; Hoffman, D.W. Thin-Film Deposition: Principles and Practice. Phys. Today 1996, 49, 60–62. [Google Scholar] [CrossRef]

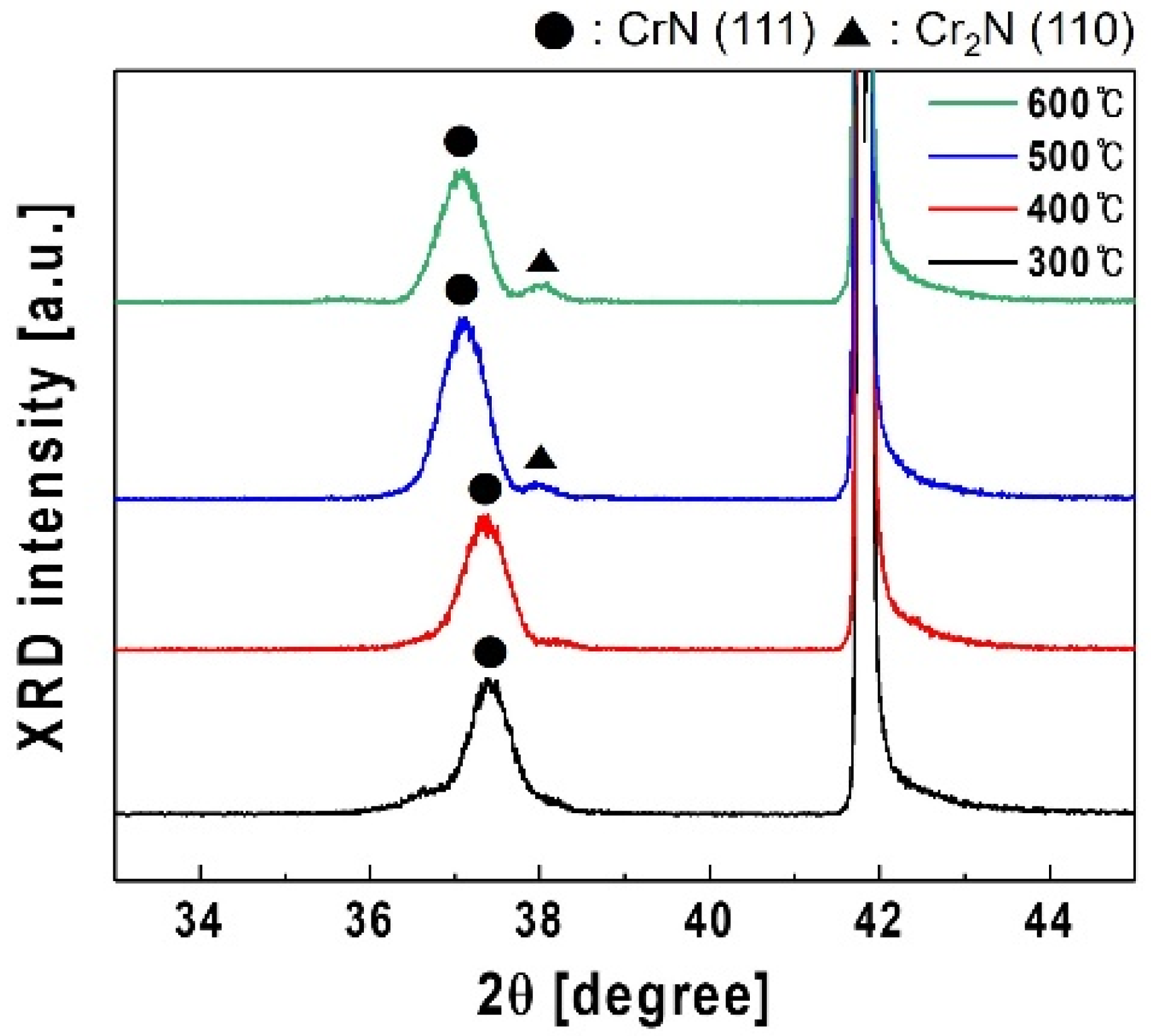

| Sample Code | 2θ (°) | d (Å) | a0 (Å) | Lattice Mismatch | |

|---|---|---|---|---|---|

| with Al2O3 (0001) (%) | with GaN (002) (%) | ||||

| CrN 300 °C | 37.402 | 2.402 | 4.161 | 7.11 | −7.73 |

| CrN 400 °C | 37.350 | 2.406 | 4.167 | 7.26 | −7.61 |

| CrN 500 °C | 37.104 | 2.421 | 4.193 | 7.94 | −7.02 |

| CrN 600 °C | 37.071 | 2.423 | 4.197 | 8.03 | −6.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shim, K.-Y.; Kang, S.; Ahn, M.-J.; Cha, Y.; Ham, E.-G.; Kim, D.; Byun, D. Crystallographic Engineering of CrN Buffer Layers for GaN Thin Film Epitaxy. Materials 2025, 18, 1817. https://doi.org/10.3390/ma18081817

Shim K-Y, Kang S, Ahn M-J, Cha Y, Ham E-G, Kim D, Byun D. Crystallographic Engineering of CrN Buffer Layers for GaN Thin Film Epitaxy. Materials. 2025; 18(8):1817. https://doi.org/10.3390/ma18081817

Chicago/Turabian StyleShim, Kyu-Yeon, Seongho Kang, Min-Joo Ahn, Yukyeong Cha, Eojin-Gyere Ham, Dohoon Kim, and Dongjin Byun. 2025. "Crystallographic Engineering of CrN Buffer Layers for GaN Thin Film Epitaxy" Materials 18, no. 8: 1817. https://doi.org/10.3390/ma18081817

APA StyleShim, K.-Y., Kang, S., Ahn, M.-J., Cha, Y., Ham, E.-G., Kim, D., & Byun, D. (2025). Crystallographic Engineering of CrN Buffer Layers for GaN Thin Film Epitaxy. Materials, 18(8), 1817. https://doi.org/10.3390/ma18081817