The Effects of In Situ Growth of SiC Nanowires on the Electromagnetic Wave Absorption Properties of SiC Porous Ceramics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation Process

2.2.1. Preparation of Matrix

2.2.2. Preparation of SiCnws

2.3. Characterization

3. Results and Discussion

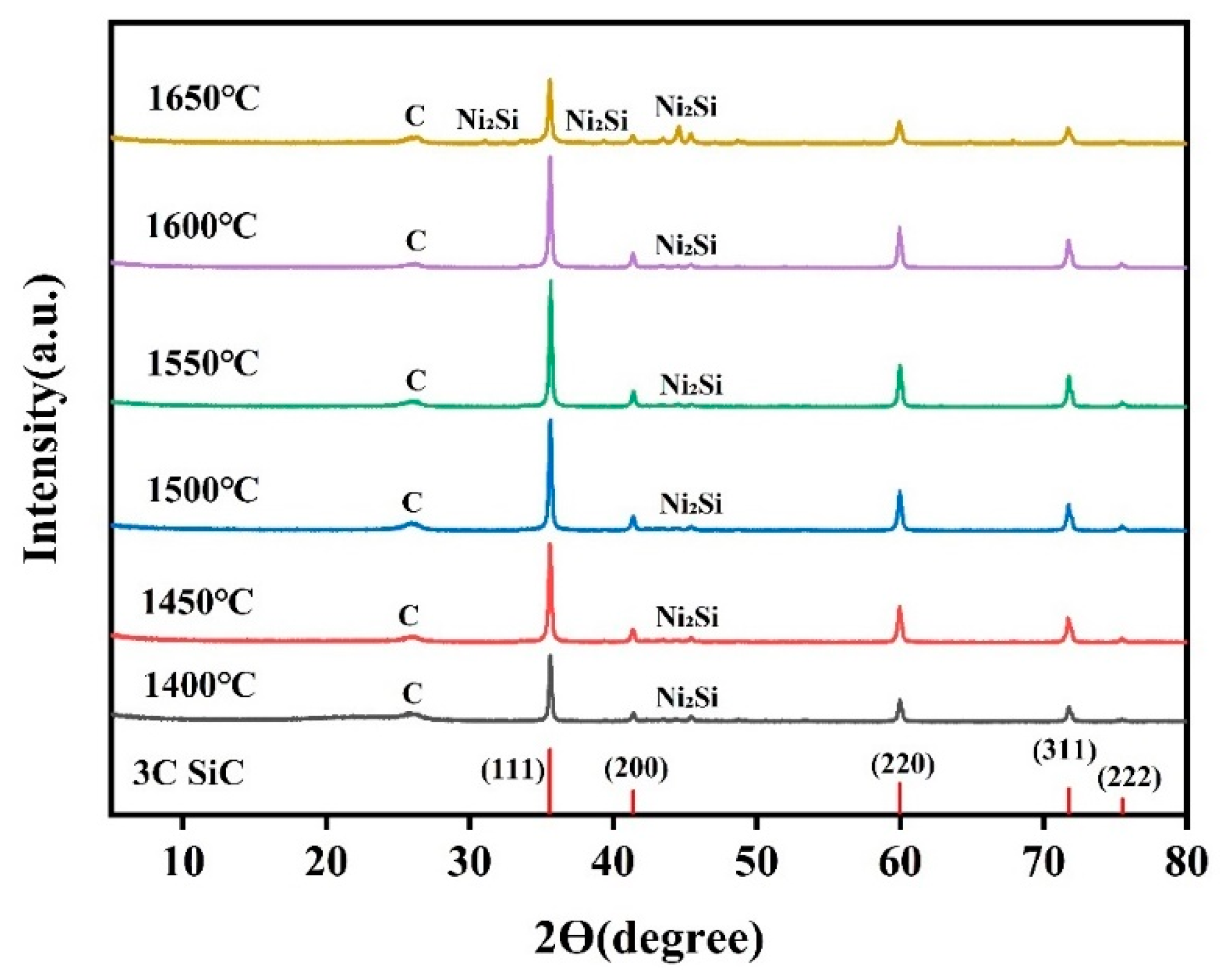

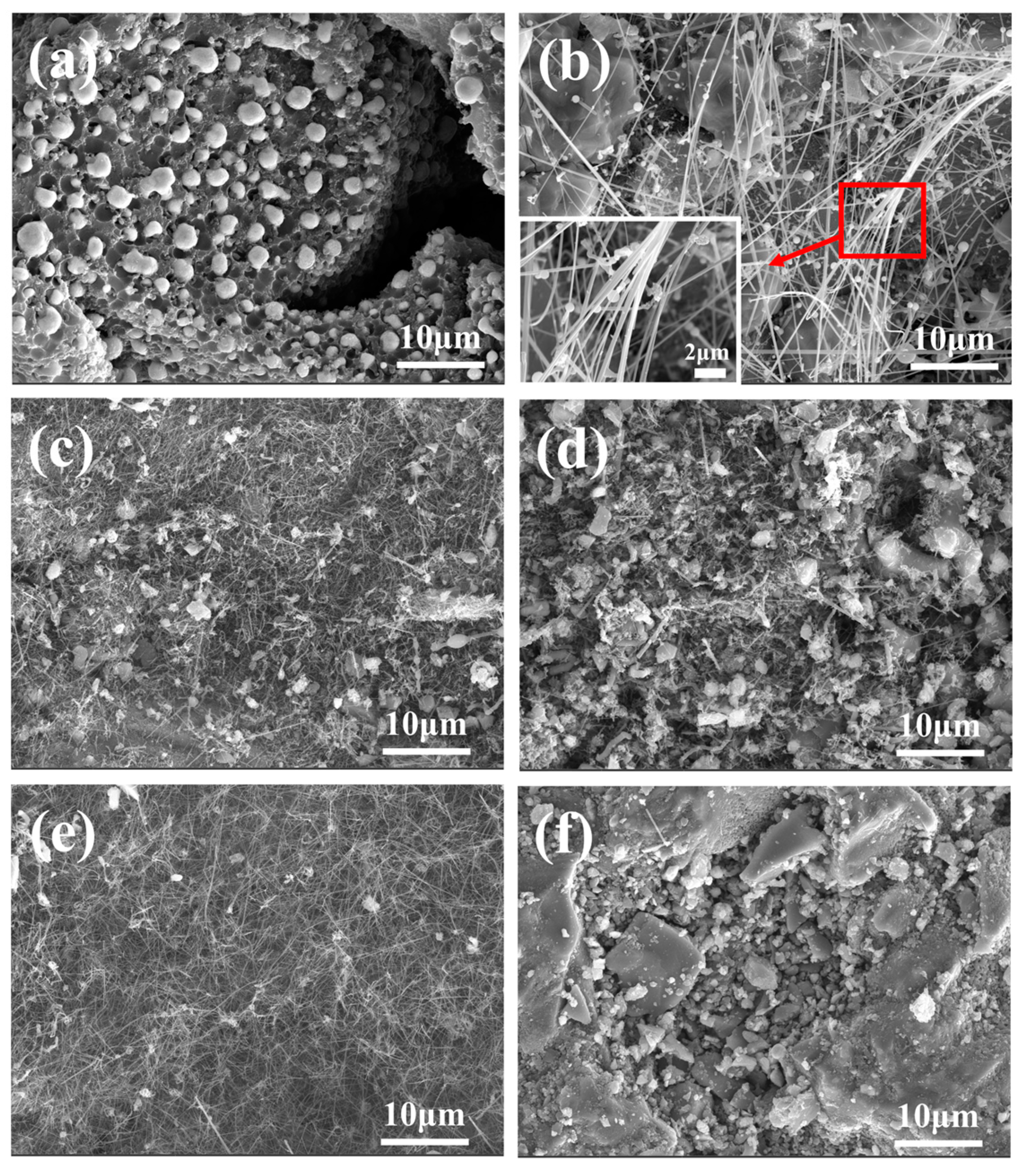

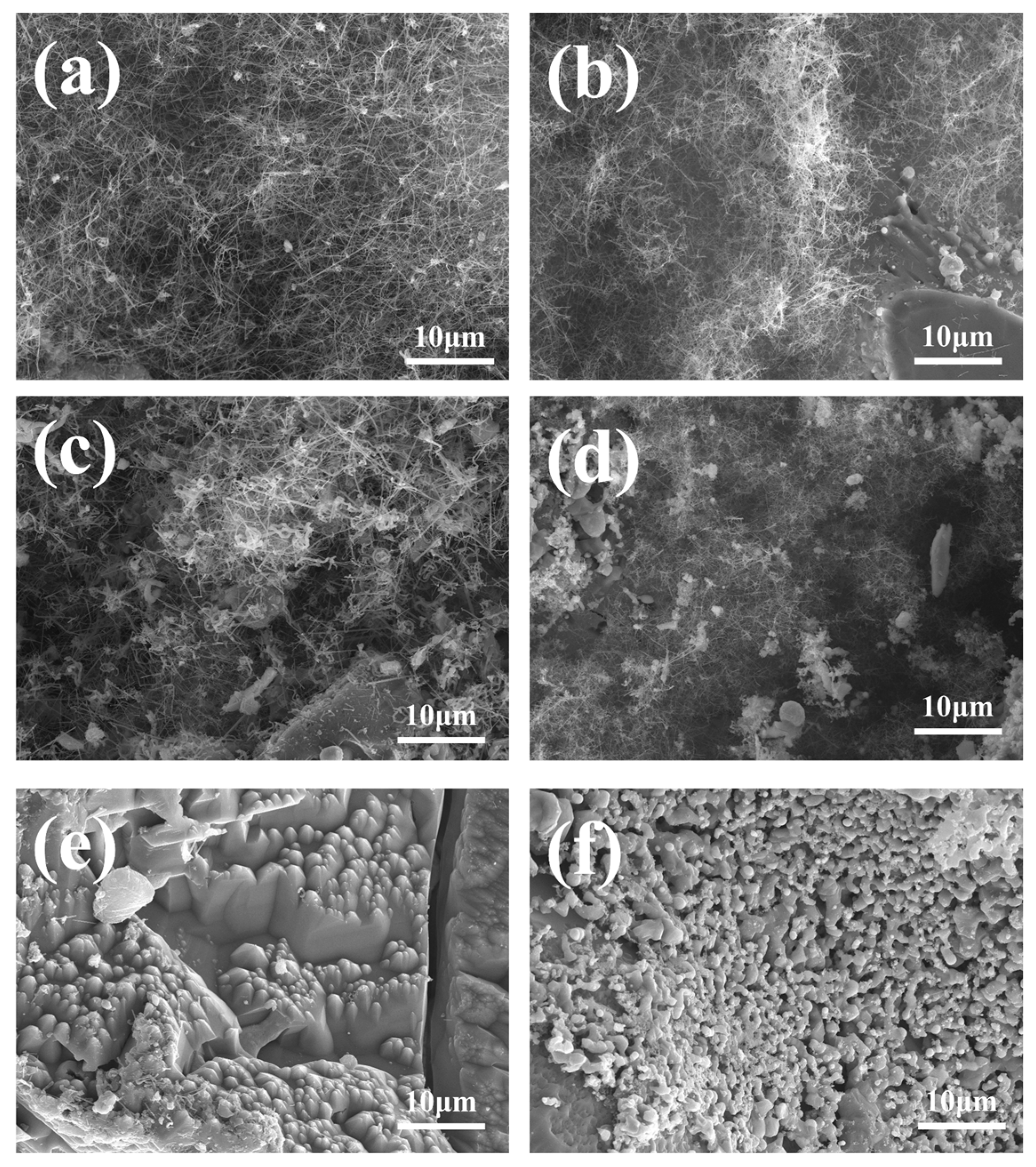

3.1. The Effect of Temperature on the Morphology of SiCnws

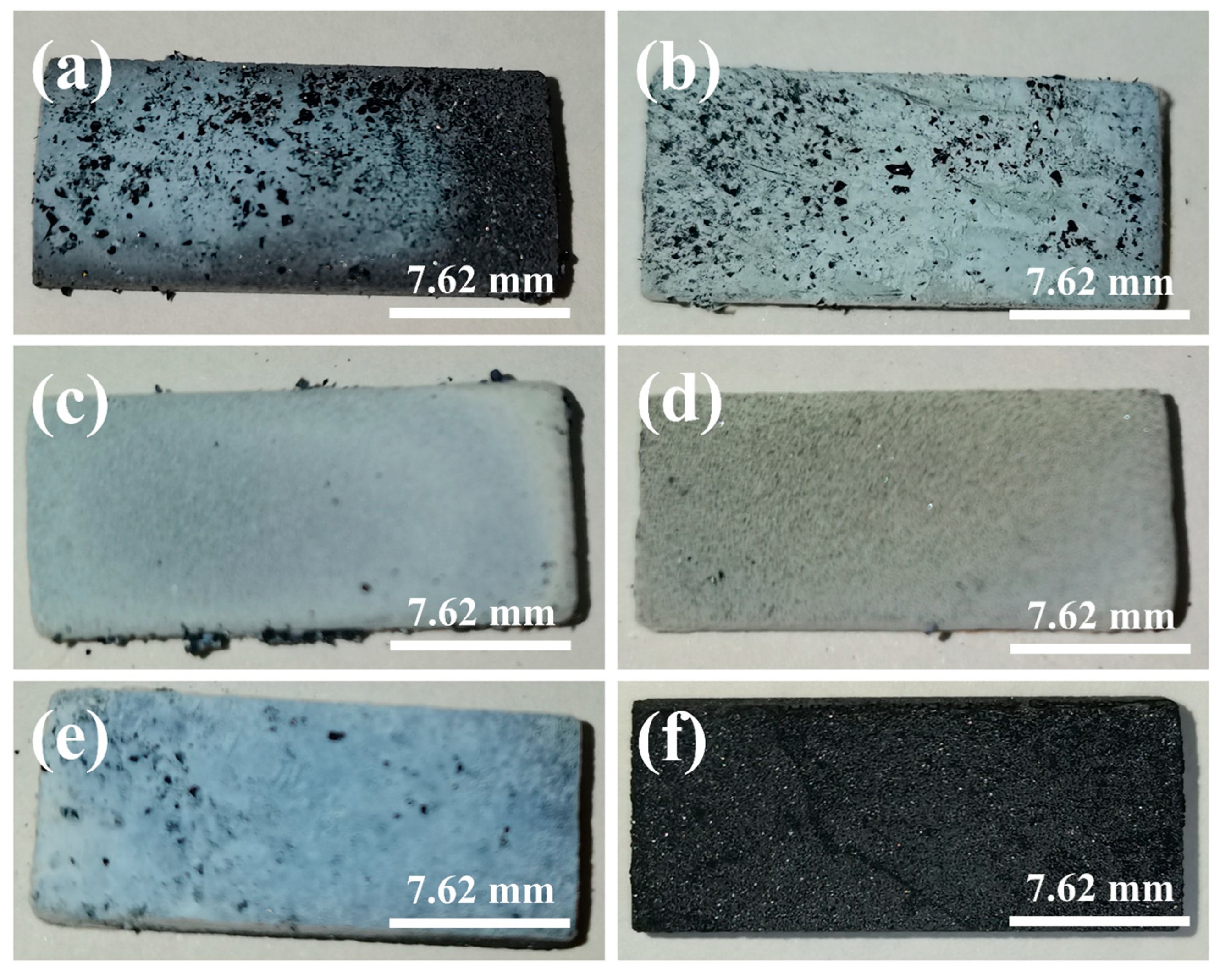

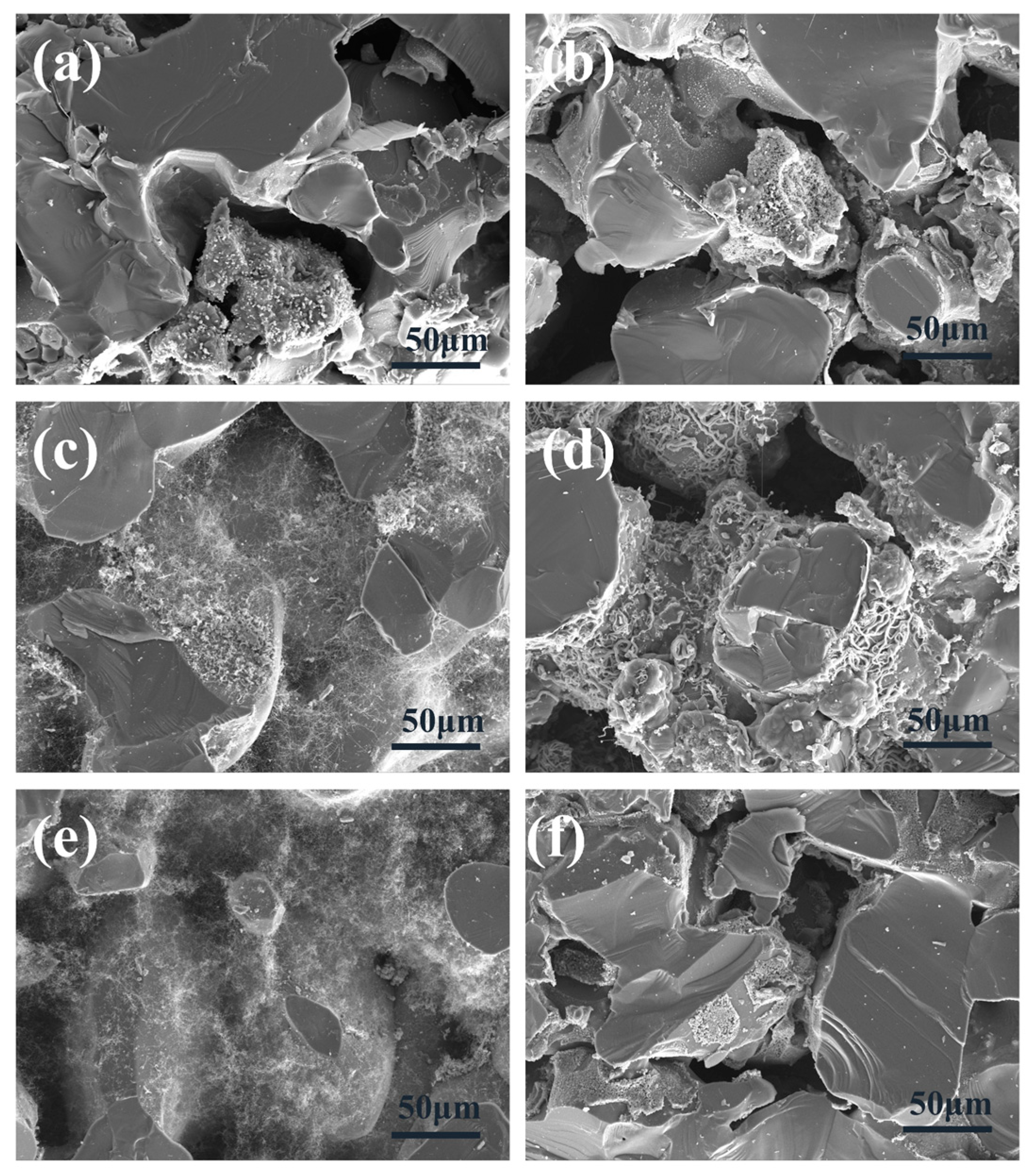

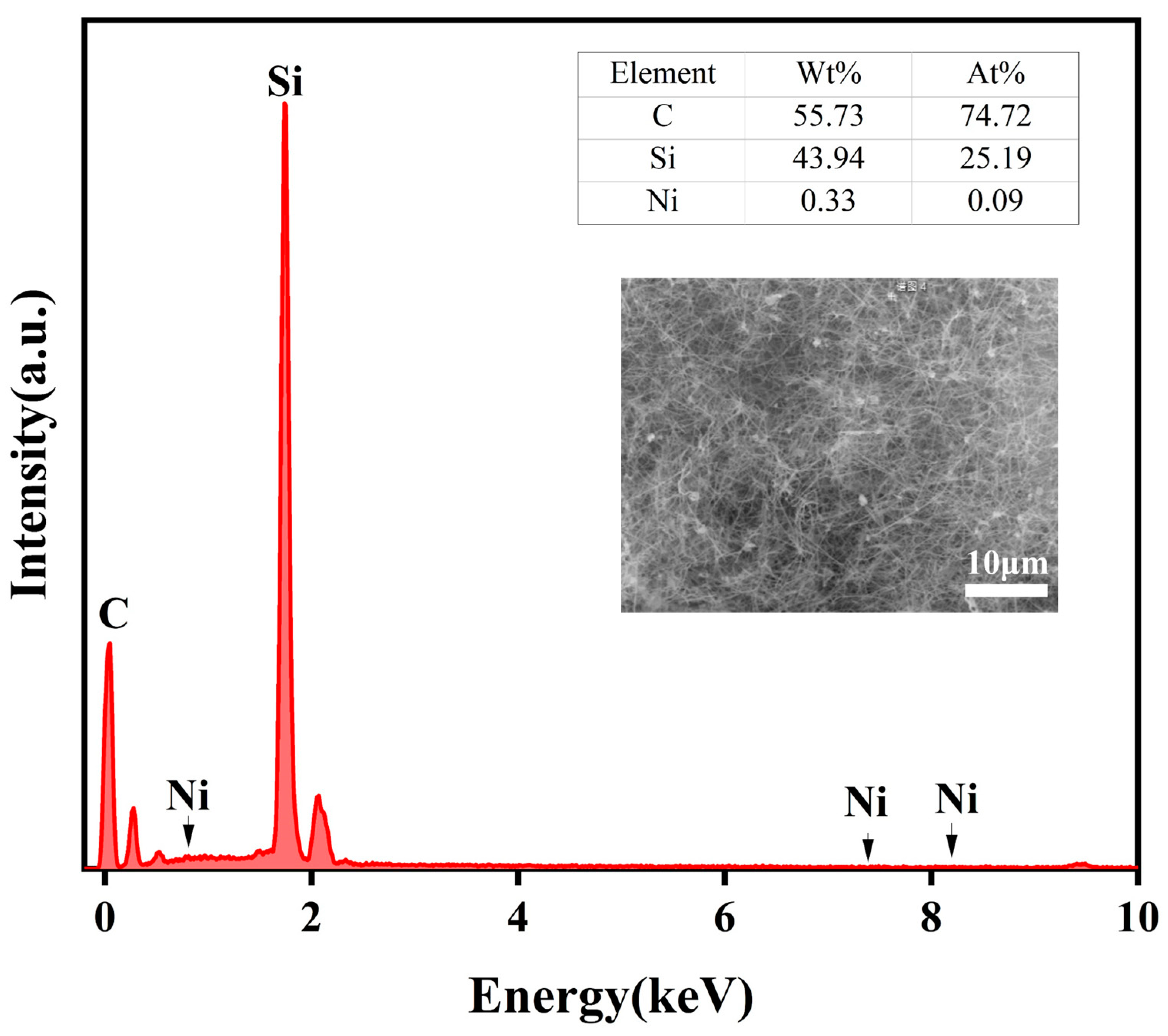

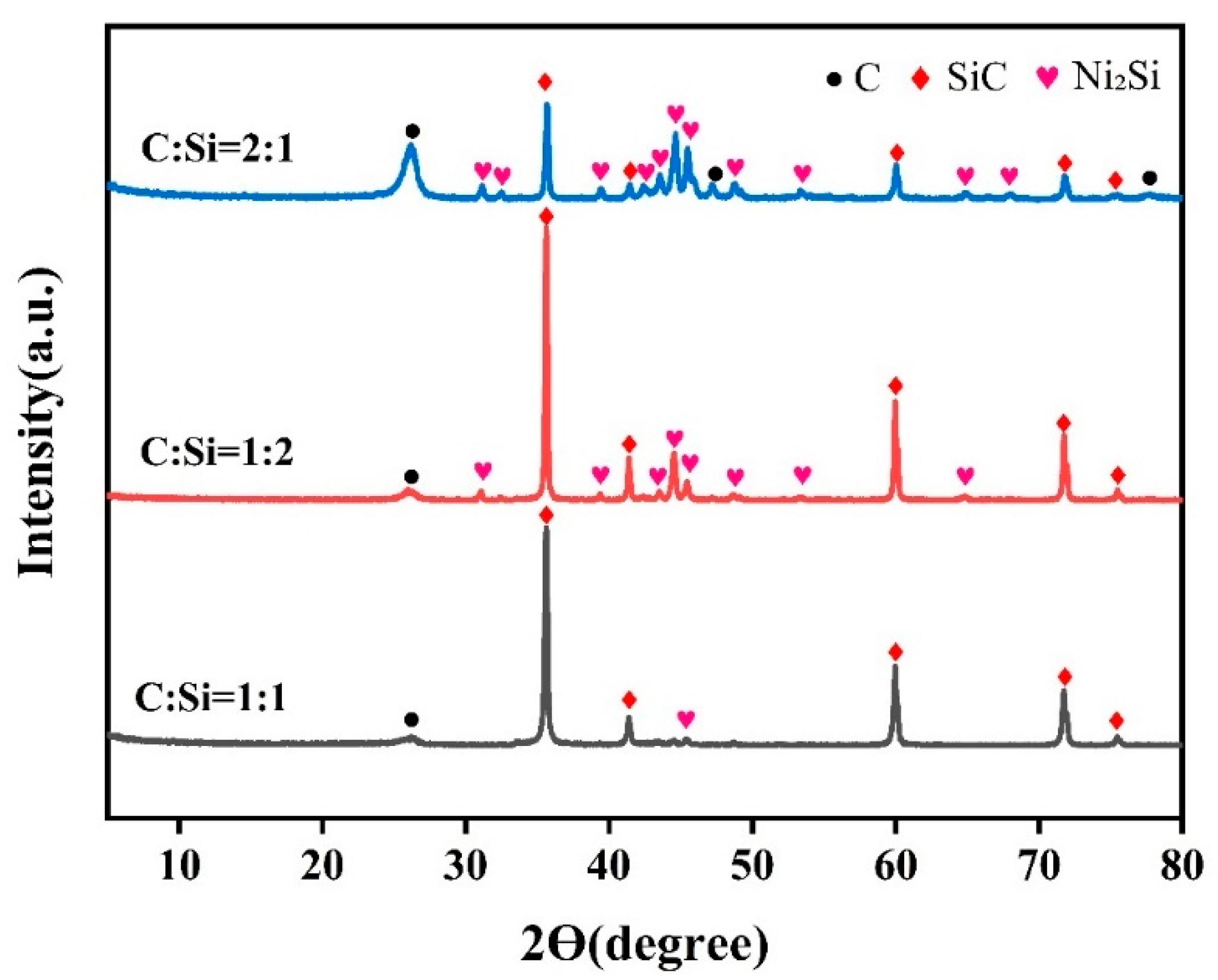

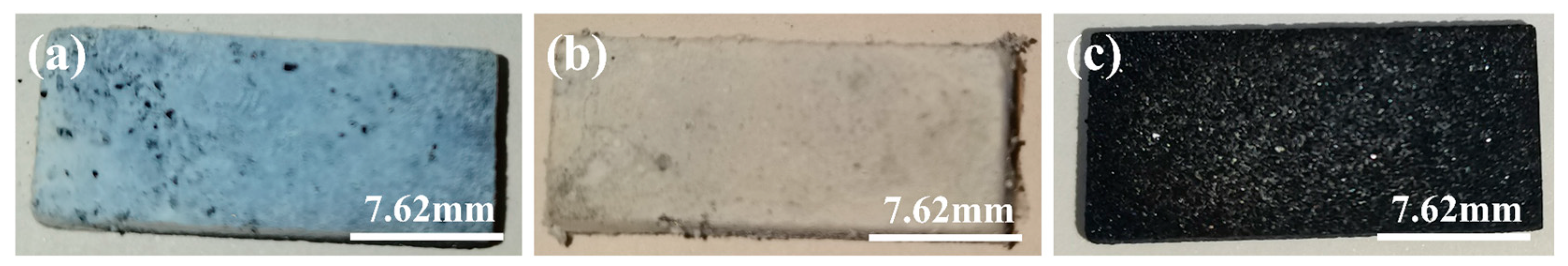

3.2. Morphology and Micromorphology of Composites

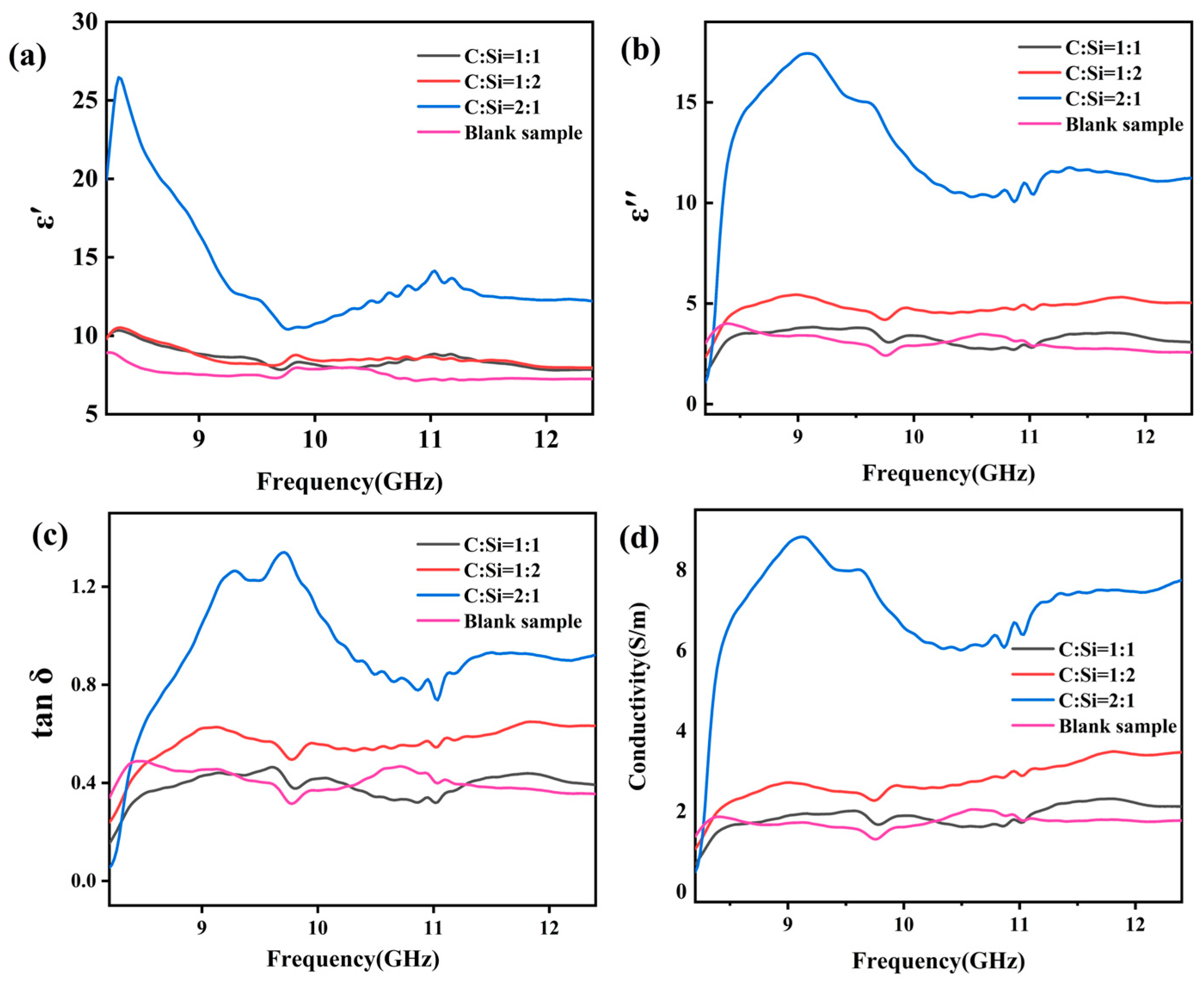

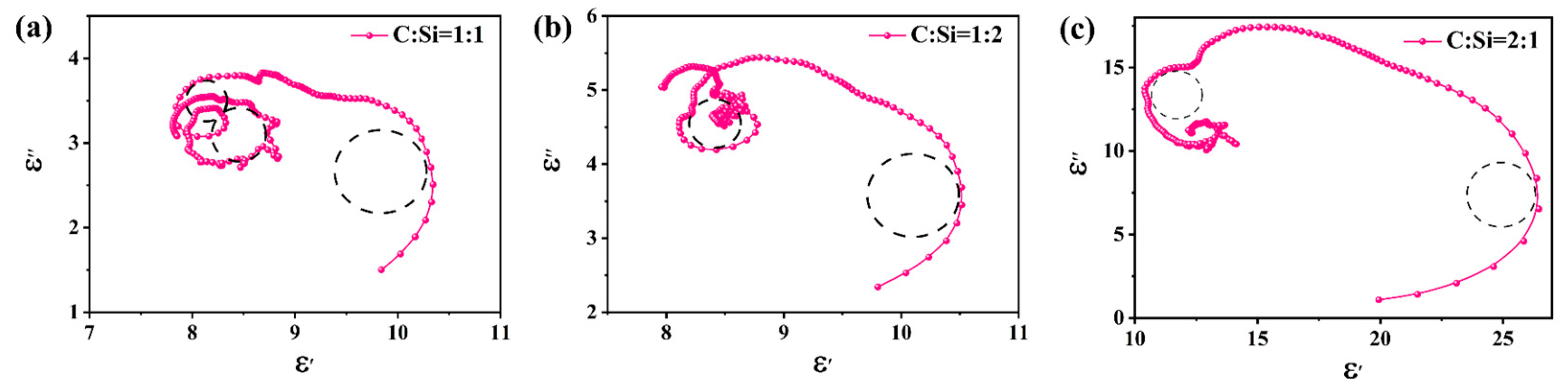

3.3. Dielectric Properties

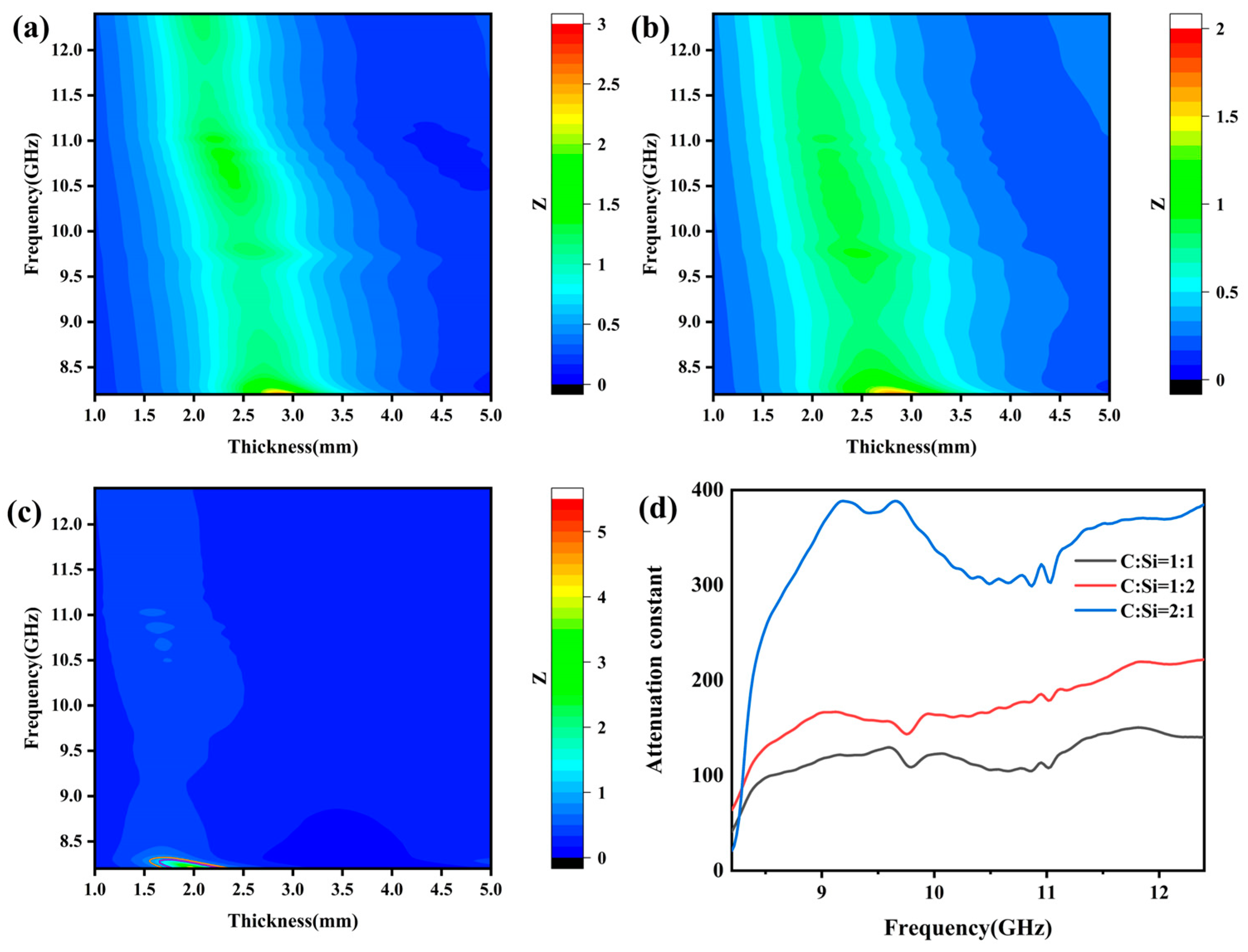

3.4. Electromagnetic Wave Absorption Properties

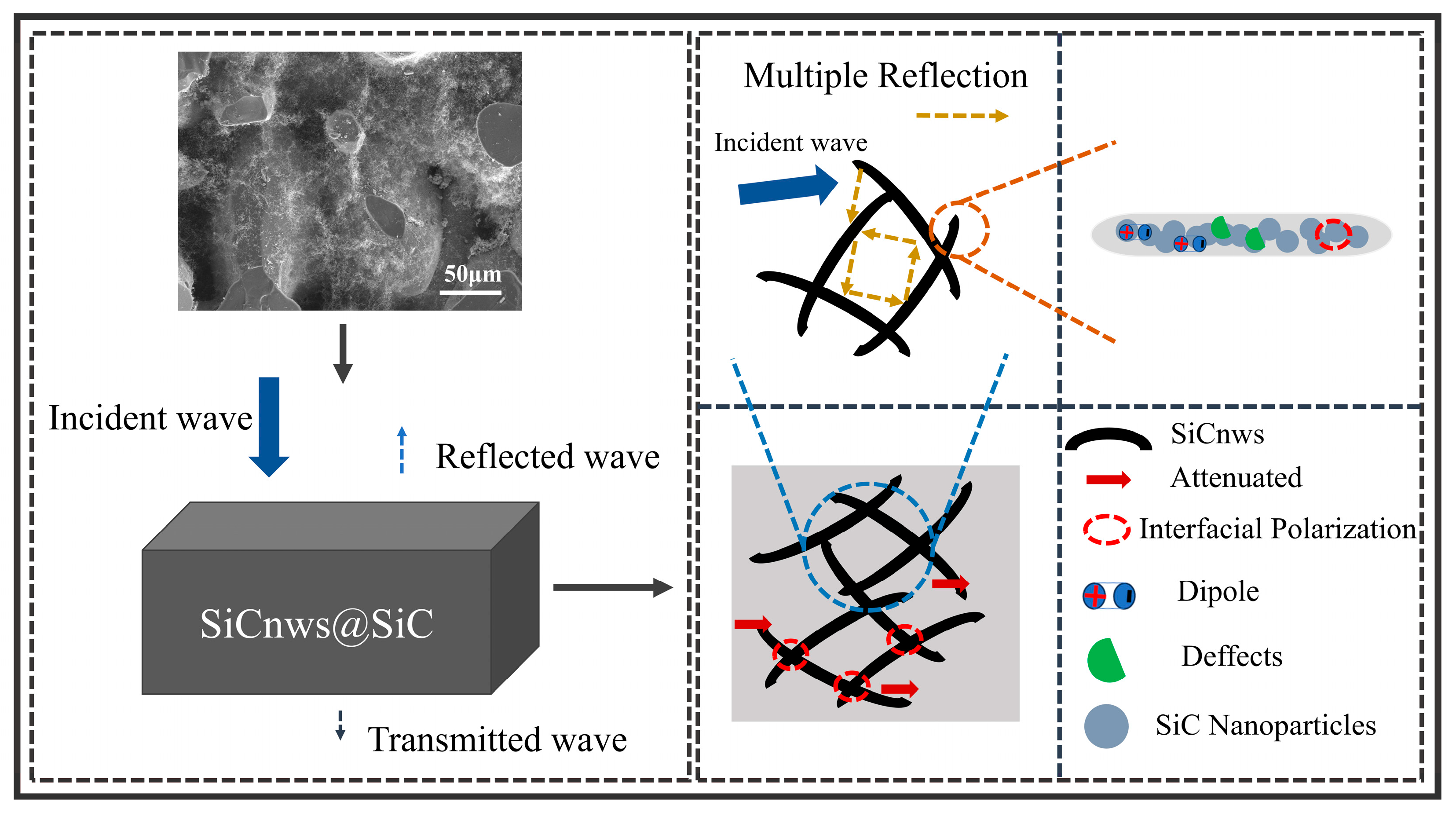

3.5. Electromagnetic Wave-Absorbing Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vinoy, K.J.; Jha, R.M. Trends in radar absorbing materials technology. Sadhana 1995, 20, 815–850. [Google Scholar] [CrossRef]

- Li, D.; Jia, D.; Yang, Z.; Zhou, Y. Principles, design, structure and properties of ceramics for microwave absorption or transmission at high-temperatures. Int. Mater. Rev. 2021, 67, 266–297. [Google Scholar] [CrossRef]

- Seyhan, N. Electromagnetic Pollution and Our Health. Nöropsikiyatri Arşivi 2010, 47, 2. [Google Scholar] [CrossRef]

- Wang, X.X.; Cao, W.Q.; Cao, M.S.; Yuan, J. Assembling Nano–Microarchitecture for Electromagnetic Absorbers and Smart Devices. Adv. Mater. 2020, 32, 2002112. [Google Scholar] [CrossRef]

- Wu, F.; Yang, K.; Li, Q.; Shah, T.; Ahmad, M.; Zhang, Q.; Zhang, B. Biomass-derived 3D magnetic porous carbon fibers with a helical/chiral structure toward superior microwave absorption. Carbon 2021, 173, 918–931. [Google Scholar] [CrossRef]

- Yang, H.-J.; Yuan, J.; Li, Y.; Hou, Z.-L.; Jin, H.-B.; Fang, X.-Y.; Cao, M.-S. Silicon carbide powders: Temperature-dependent dielectric properties and enhanced microwave absorption at gigahertz range. Solid State Commun. 2013, 163, 1–6. [Google Scholar] [CrossRef]

- Ji, H.; Dai, G.; Chen, J.; Zhang, H.; Chen, Z.; Wang, N.; Xiao, H. Ultralight broadband microwave-absorbing materials based on the short fibers of glass-coated amorphous magnetic microwires. J. Alloys Compd. 2022, 911, 164904. [Google Scholar] [CrossRef]

- Lv, J.; Cheng, Y.; Liu, W.; Quan, B.; Liang, X.; Ji, G.; Du, Y. Achieving better impedance matching by a sulfurization method through converting Ni into NiS/Ni3S4 composites. J. Mater. Chem. C 2018, 6, 1822–1828. [Google Scholar] [CrossRef]

- Zhang, N.; Huang, Y.; Liu, P.; Ding, X.; Zong, M.; Wang, M. Synthesis of magnetical nanoparticles decorated with reduced graphene oxide as an efficient broad band EM wave absorber. J. Alloys Compd. 2017, 692, 639–646. [Google Scholar] [CrossRef]

- Zhou, J.; Yao, Z.; Yao, T. Synthesis and electromagnetic property of Li0.35Zn0.3Fe2.35O4 grafted with polyaniline fibers. Appl. Surf. Sci. 2017, 420, 154–160. [Google Scholar] [CrossRef]

- Cen, C.; Yi, Z.; Zhang, G.; Zhang, Y.; Liang, C.; Chen, X.; Tang, Y.; Ye, X.; Yi, Y.; Wang, J.; et al. Theoretical design of a triple-band perfect metamaterial absorber in the THz frequency range. Results Phys. 2019, 14, 102463. [Google Scholar] [CrossRef]

- Feng, P.; Wei, H.; Shang, P.; Shi, Y.; Wei, X.; Luo, S.; Liang, X.; Zhang, W.; Yu, Y.; He, W. Enhanced electromagnetic microwave absorption of SiC nanowire-reinforced PDC-SiC ceramics catalysed by rare earth. Ceram. Int. 2022, 48, 24915–24924. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, S.; Singh, D. Effect of heat treatment on morphology and microwave absorption behavior of milled SiC. J. Alloys Compd. 2019, 772, 1017–1023. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Li, M.; Wang, T.; Wu, C.; Zhang, J.; Zhou, Q.; Liu, H.; Cui, S. Hollow SiC foam with a double interconnected network for superior microwave absorption ability. J. Alloys Compd. 2020, 817, 153276. [Google Scholar] [CrossRef]

- Su, K.; Wang, Y.; Hu, K.; Fang, X.; Yao, J.; Li, Q.; Yang, J. Ultralight and High-Strength SiCnw@SiC Foam with Highly Efficient Microwave Absorption and Heat Insulation Properties. ACS Appl. Mater. Interfaces 2021, 13, 22017–22030. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, X.; Li, X.; Chen, J.; Hu, P.; Han, J. SiC whiskers-reduced graphene oxide composites decorated with MnO nanoparticles for tunable microwave absorption. Chem. Eng. J. 2020, 392, 123817. [Google Scholar] [CrossRef]

- Wang, C.; Xia, L.; Zhong, B.; Yang, H.; Huang, L.; Xiong, L.; Huang, X.; Wen, G. Fabrication and mechanical properties of carbon fibers/lithium aluminosilicate ceramic matrix composites reinforced by in-situ growth SiC nanowires. J. Eur. Ceram. Soc. 2019, 39, 4625–4633. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Zhu, F.; Zhao, Z.; Yang, Y.; Sheng, H.; Hou, X.; Li, H. SiC Nanowire–Si3N4 Nanobelt Interlocking Interfacial Enhancement of Carbon Fiber Composites with Boosting Mechanical and Frictional Properties. ACS Appl. Mater. Interfaces 2021, 13, 20746–20753. [Google Scholar] [CrossRef]

- Hu, W.; Wang, L.; Wu, Q.; Wu, H. Preparation, characterization and microwave absorption properties of bamboo-like β-SiC nanowhiskers by molten-salt synthesis. J. Mater. Sci. Mater. Electron. 2014, 25, 5302–5308. [Google Scholar] [CrossRef]

- Han, M.; Yin, X.; Hou, Z.; Song, C.; Li, X.; Zhang, L.; Cheng, L. Flexible and Thermostable Graphene/SiC Nanowire Foam Composites with Tunable Electromagnetic Wave Absorption Properties. ACS Appl. Mater. Interfaces 2017, 9, 11803–11810. [Google Scholar] [CrossRef]

- Wang, J.; Wu, F.; Cui, Y.; Zhang, A.; Zhang, Q.; Zhang, B. Efficient synthesis of N-doped porous carbon nanoribbon composites with selective microwave absorption performance in common wavebands. Carbon 2021, 175, 164–175. [Google Scholar] [CrossRef]

- Ma, Q.; Cai, L. Fabrication and oxidation resistance of mullite/yttrium silicate multilayer coatings on C/SiC composites. J. Adv. Ceram. 2017, 6, 360–367. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Li, Y.; Gou, Y.; Zhou, X. In-situ synthesis of ternary layered Y3Si2C2 ceramic on silicon carbide fiber for enhanced electromagnetic wave absorption. Ceram. Int. 2022, 48, 1908–1915. [Google Scholar] [CrossRef]

- Wu, R.; Yang, Z.; Fu, M.; Zhou, K. In-situ growth of SiC nanowire arrays on carbon fibers and their microwave absorption properties. J. Alloys Compd. 2016, 687, 833–838. [Google Scholar] [CrossRef]

- Dong, M.; Peng, M.; Wei, W.; Xu, H.; Liu, C.; Shen, C. Improved microwave absorption performance of double helical C/Co@CNT nanocomposite with hierarchical structures. J. Mater. Chem. C 2021, 9, 2178–2189. [Google Scholar] [CrossRef]

- Wei, H.; Zhou, C.; Feng, P.; Yu, Y.; Xue, J.; Zhao, F.; Wang, Q. Rear earth (Re: Sc, Y, and Ce) modified PDCs-SiC ceramics for efficient microwave absorption. Mater. Charact. 2022, 190, 112048. [Google Scholar] [CrossRef]

- Su, J.; Wang, B.; Cao, X.; Yang, R.; Zhao, H.; Zhang, P.; Wang, W.; Wang, C. Simultaneously enhancing mechanical and microwave absorption properties of Cf/SiC composites via SiC nanowires additions. Ceram. Int. 2022, 48, 36238–36248. [Google Scholar] [CrossRef]

- Chen, J. Properties and Mechanism of SiC Nanowires. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2008. [Google Scholar]

- Hao, J.-G.; Guo, X.-Y. Synthesis of Silicon Carbide Nanowires with Different Morphologies by Carbothermal Reduction. Chin. J. Inorg. Chem. 2006, 41, 1833–1837. [Google Scholar] [CrossRef]

- Meng, G.W.; Zhang, L.D.; Mo, C.M.; Zhang, S.Y.; Qin, Y.; Feng, S.P.; Li, H.J. Preparation of β-SiC nanorods with and without amorphous SiO2 wrapping layers. Mater. Res. 1998, 13, 2533–2538. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Wen, G.; Geng, X.; Zhu, J.; Zhang, T.; Bai, H. Novel SiOC nanocomposites for high-yield preparation of ultra-large-scale SiC nanowires. Nanotechnology 2010, 21, 385601. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, Y.; Li, X.; Zhang, H.; Guo, Y.; Wang, T.; Qiao, X.; Lei, W. Recent progress in synthesis, growth mechanisms, and electromagnetic wave absorption properties of silicon carbide nanowires. Ceram. Int. 2022, 48, 35966–35985. [Google Scholar] [CrossRef]

- Duan, W.; Yin, X.; Li, Q.; Liu, X.; Cheng, L.; Zhang, L. Synthesis and microwave absorption properties of SiC nanowires reinforced SiOC ceramic. J. Eur. Ceram. Soc. 2014, 34, 257–266. [Google Scholar] [CrossRef]

- Wei, H.; Xue, J.; Ma, Y.; Hou, Z.; Dong, Y.; Cheng, L. Enhanced electromagnetic absorption properties of Fe-doped Sc2Si2O7 ceramics. Ceram. Int. 2021, 47, 4504–4511. [Google Scholar] [CrossRef]

- Wei, H.; Yu, Y.; Jiang, F.; Xue, J.; Zhao, F.; Wang, Q. Carbon@SiC(SiCnws)-Sc2Si2O7 ceramics with multiple loss mediums for improving electromagnetic shielding performance. J. Eur. Ceram. Soc. 2022, 42, 2274–2281. [Google Scholar] [CrossRef]

- Wang, Y.-F.; Zhu, L.; Han, L.; Zhou, X.-H.; Gao, Y.; Lv, L.-H. Research status and development trends of electromagnetic wave absorbing materials. Acta Mater. Compos. Sin. 2023, 40, 1–12. [Google Scholar] [CrossRef]

- Chen, Z.-W.; Fan, X.-M.; Huang, X.-X.; Jia, D.C.; Li, J.; Shao, G.; Shao, C.-W.; Wang, H.-L.; Yin, X.-W.; Yang, Z.-H.; et al. Research progress in high-temperature microwave-absorbing ceramic materials. Adv. Ceram. 2024, 52, 24–33. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Luo, H.; Li, Z.; Li, Z.; Zhou, W.; Xiao, P. Improved microwave absorption properties of polycarbosilane-derived SiC core-shell particles by oxidation. J. Alloys Compd. 2019, 786, 409–417. [Google Scholar] [CrossRef]

- Dou, Y.-K.; Li, J.-B.; Fang, X.-Y.; Jin, H.-B.; Cao, M.-S. The enhanced polarization relaxation and excellent high-temperature dielectric properties of N-doped SiC. Appl. Phys. Lett. 2014, 104, 052102. [Google Scholar] [CrossRef]

- Chiu, S.-C.; Yu, H.-C.; Li, Y.-Y. High Electromagnetic Wave Absorption Performance of Silicon Carbide Nanowires in the Gigahertz Range. J. Phys. Chem. C. Nanomater. Interfaces 2010, 114, 1947–1952. [Google Scholar] [CrossRef]

- Guo, T.; Tang, L.-B.; Deng, W.-N.; Liu, G.-D.; Zhou, W.; Wan, H.; Meng, L.-C.; Chen, H. CuxO as an ultra-stable voltage plateaus and long-life cathode material in aqueous ammonium-ion batteries. Rare Met. 2025, 1–11. [Google Scholar] [CrossRef]

- Jiang, S.; Fang, J.; Liu, H.; Tang, X.; Zhu, H.; Zong, E.; Cai, Y.; Zhao, Z.; Guo, J.; Liu, Y. Bioelectricity-driven, sulfurized Fe species anode in situ generate sulfate radicals from sulfates in antibiotic wastewater for enhanced ciprofloxacin hydrochloride removal: Performance and mechanism. Chem. Eng. J. 2024, 502, 157745. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, T.; Tian, Z.; Jiang, S. Study on capacitive performance of bamboo-derived thick carbon electrodes using one-step activation method. J. For. Eng. 2024, 9, 103–109. [Google Scholar] [CrossRef]

- Dodony, E.; Rečnik, A.; Dódony, I.; Sáfrán, G. In situ TEM study of Ni-silicides formation up to 973K. J. Alloys Compd. 2022, 918, 165466. [Google Scholar] [CrossRef]

- Tong, W.; Liang, X.; Zhou, X.; Huang, F.; Chen, L.; Niu, M. Comparation of porous bamboo activated carbon using KOH co-thermal activation and hydrothermal activation methods. J. For. Eng. 2024, 9, 77–83. [Google Scholar] [CrossRef]

- Li, M.; Bai, L.; Jiang, S.; Sillanpää, M.; Huang, Y.; Liu, Y. Electrocatalytic transformation of oxygen to hydroxyl radicals via three-electron pathway using nitrogen-doped carbon nanotube-encapsulated nickel nanocatalysts for effective organic decontamination. J. Hazard. Mater. 2023, 452, 131352. [Google Scholar] [CrossRef]

- Varela, C.F.; Moreno-Aldana, L.C.; Agámez-Pertuz, Y.Y. Adsorption of pharmaceutical pollutants on ZnCl2-activated biochar from corn cob: Efficiency, selectivity and mechanism. J. Bioresour. Bioprod. 2024, 9, 58–73. [Google Scholar] [CrossRef]

- Liu, Y.; Xiang, K.; Zhou, W.; Deng, W.; Zhu, H.; Chen, H. Investigations on Tunnel-Structure MnO2 for Utilization as a High-Voltage and Long-Life Cathode Material in Aqueous Ammonium-Ion and Hybrid-Ion Batteries. Small 2024, 20, 2308741. [Google Scholar] [CrossRef]

- Wen, X.-Y.; Li, W.; Chen, H.; Zhou, W.; Xiang, K.-X. Zn3V3O8 nanorods with outstanding electrochemical kinetics as novel anode for aqueous ammonium-ion batteries. Rare Met. 2025, 1–12. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, G. Effect of ZIF-8/nanocellulose on deodorization of bamboo-wood composite fibers. J. For. Eng. 2024, 9, 55–62. [Google Scholar] [CrossRef]

- Li, Y.; Tang, Z.; Zhou, X.; Zhang, J.; Song, X.; Li, K.; Liu, W.; Zhang, Z. Development of Methylene Bis-Benzotriazolyl Tetramethylbutylphenol-grafted lignin sub-microspheres loaded with TiO2 for sunscreen applications. J. Bioresour. Bioprod. 2024, 9, 534–547. [Google Scholar] [CrossRef]

- Wei, H.; Yang, S.; Feng, P.; Xue, J.; Zhao, F.; Wang, Q. Construction of Si3N4/SiO2/SiC–Y2Si2O7 composite ceramics with gradual impedance matching structure for high-temperature electromagnetic wave absorption. Ceram. Int. 2022, 48, 23172–23181. [Google Scholar] [CrossRef]

- Bi, Y.; Ma, M.; Liao, Z.; Tong, Z.; Chen, Y.; Wang, R.; Ma, Y.; Wu, G. One-dimensional Ni@Co/C@PPy composites for superior electromagnetic wave absorption. J. Colloid Interface Sci. 2022, 605, 483–492. [Google Scholar] [CrossRef] [PubMed]

- Kuang, B.; Dou, Y.; Wang, Z.; Ning, M.; Jin, H.; Guo, D.; Cao, M.; Fang, X.; Zhao, Y.; Li, J. Enhanced microwave absorption properties of Co-doped SiC at elevated temperature. Appl. Surf. Sci. 2018, 445, 383–390. [Google Scholar] [CrossRef]

- Zhou, W.; Long, L.; Xiao, P.; Li, Y.; Luo, H.; Hu, W.-d.; Yin, R.-m. Silicon carbide nano-fibers in-situ grown on carbon fibers for enhanced microwave absorption properties. Ceram. Int. 2017, 43, 5628–5634. [Google Scholar] [CrossRef]

- Wei, H.; Yin, X.; Li, X.; Li, M.; Dang, X.; Zhang, L.; Cheng, L. Controllable synthesis of defective carbon nanotubes/Sc2Si2O7 ceramic with adjustable dielectric properties for broadband high-performance microwave absorption. Carbon 2019, 147, 276–283. [Google Scholar] [CrossRef]

- Wei, H.; Yin, X.; Dang, X.; Zhang, L.; Cheng, L. In situ growth of one-dimensional carbon-rich SiC nanowires in porous Sc2Si2O7 ceramics with excellent microwave absorption properties. Ceram. Int. 2018, 44, 22784–22793. [Google Scholar] [CrossRef]

- Lan, X.; Wang, Z. Efficient high-temperature electromagnetic wave absorption enabled by structuring binary porous SiC with multiple interfaces. Carbon 2020, 170, 517–526. [Google Scholar] [CrossRef]

- Tatarko, P.; Casalegno, V.; Hu, C.; Salvo, M.; Ferraris, M.; Reece, M.J. Joining of CVD-SiC coated and uncoated fibre reinforced ceramic matrix composites with pre-sintered Ti3SiC2 MAX phase using Spark Plasma Sintering. J. Eur. Ceram. Soc. 2016, 36, 3957–3967. [Google Scholar] [CrossRef]

- Zheng, G.; Yin, X.; Liu, S.; Liu, X.; Deng, J.; Li, Q. Improved electromagnetic absorbing properties of Si3N4–SiC/SiO2 composite ceramics with multi-shell microstructure. J. Eur. Ceram. Soc. 2013, 33, 2173–2180. [Google Scholar] [CrossRef]

- Yuan, Y.; Wei, S.; Liang, Y.; Wang, B.; Wang, Y.; Xin, W.; Wang, X.; Zhang, Y. Solvothermal assisted synthesis of CoFe2O4/CNTs nanocomposite and their enhanced microwave absorbing properties. J. Alloys Compd. 2021, 867, 159040. [Google Scholar] [CrossRef]

| Sample | Dry Weight (m1) | Wet Weight (m3) | Suspended Weight (m2) | Porosity |

|---|---|---|---|---|

| 1 | 5.61 | 6.36 | 3.85 | 29.9% |

| 2 | 5.47 | 6.20 | 3.75 | 29.8% |

| 3 | 5.58 | 6.34 | 3.83 | 30.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Li, G.; Zhao, T.; Gong, Z.; Li, F.; Xie, W.; Zhao, S.; Jiang, S. The Effects of In Situ Growth of SiC Nanowires on the Electromagnetic Wave Absorption Properties of SiC Porous Ceramics. Materials 2025, 18, 1910. https://doi.org/10.3390/ma18091910

Liu J, Li G, Zhao T, Gong Z, Li F, Xie W, Zhao S, Jiang S. The Effects of In Situ Growth of SiC Nanowires on the Electromagnetic Wave Absorption Properties of SiC Porous Ceramics. Materials. 2025; 18(9):1910. https://doi.org/10.3390/ma18091910

Chicago/Turabian StyleLiu, Jingxiong, Genlian Li, Tianmiao Zhao, Zhiqiang Gong, Feng Li, Wen Xie, Songze Zhao, and Shaohua Jiang. 2025. "The Effects of In Situ Growth of SiC Nanowires on the Electromagnetic Wave Absorption Properties of SiC Porous Ceramics" Materials 18, no. 9: 1910. https://doi.org/10.3390/ma18091910

APA StyleLiu, J., Li, G., Zhao, T., Gong, Z., Li, F., Xie, W., Zhao, S., & Jiang, S. (2025). The Effects of In Situ Growth of SiC Nanowires on the Electromagnetic Wave Absorption Properties of SiC Porous Ceramics. Materials, 18(9), 1910. https://doi.org/10.3390/ma18091910