In Situ EBSD Study of Deformation Behavior at Grain Scale of Inconel 718 Alloy During Tensile Test at 650 °C

Abstract

:1. Introduction

2. Materials and Methods

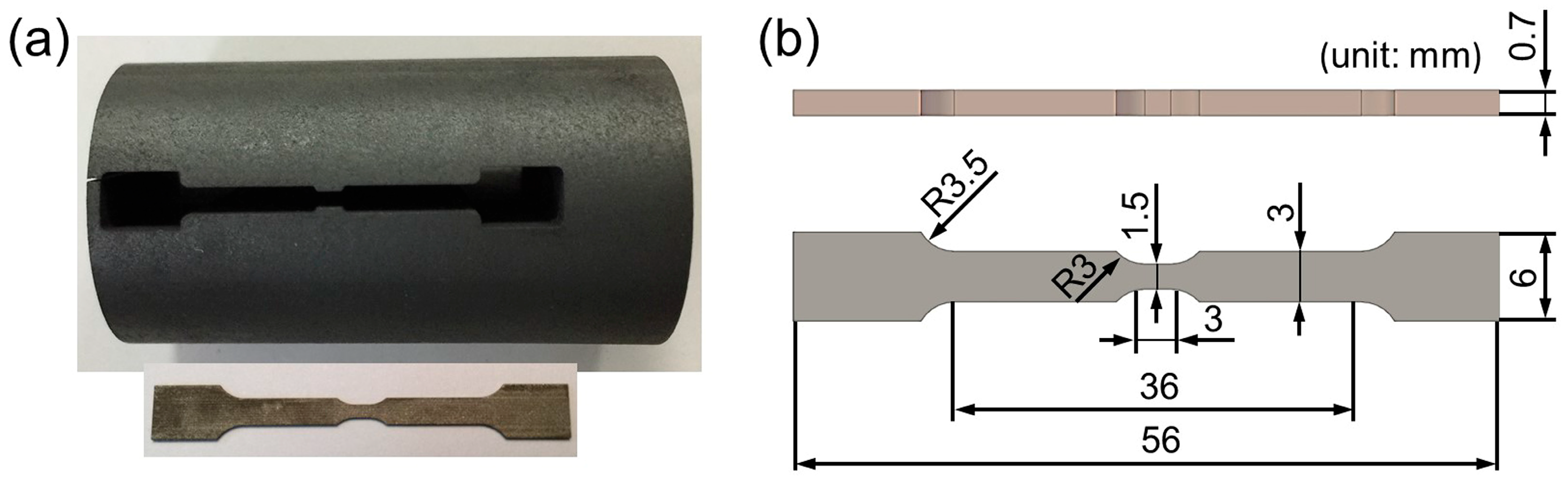

2.1. Sample Preparation

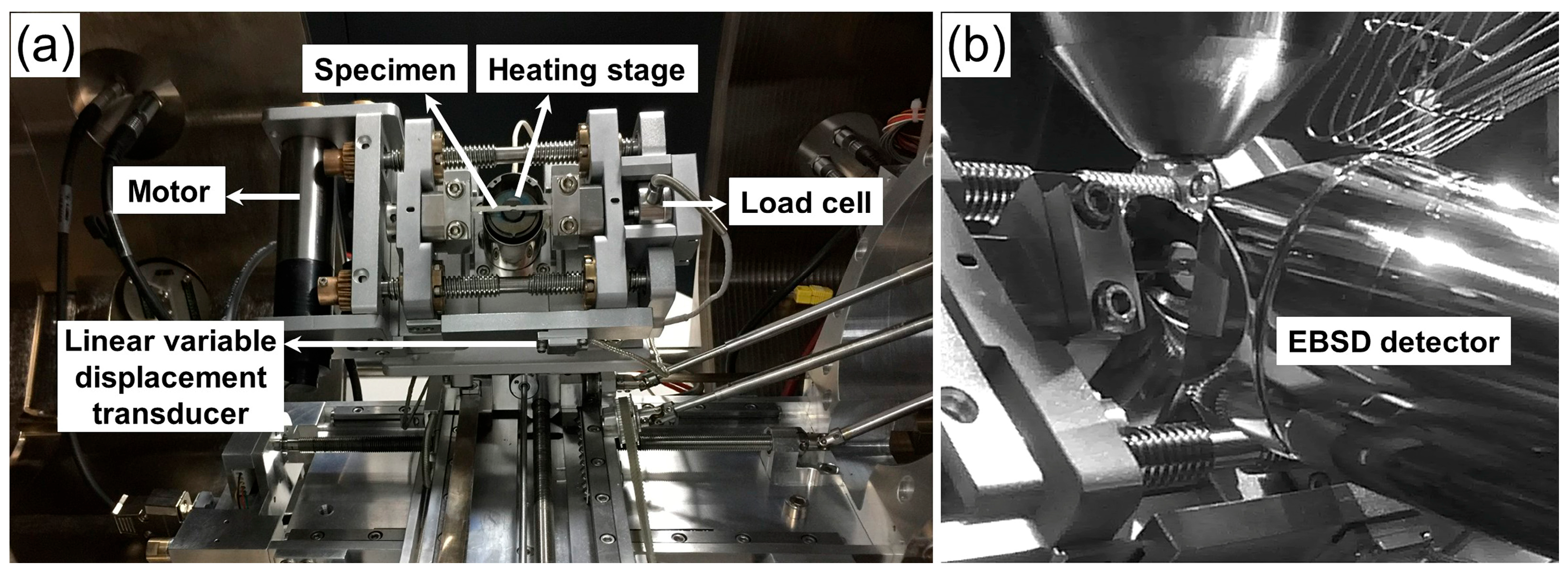

2.2. In Situ EBSD Tensile Test

3. Results

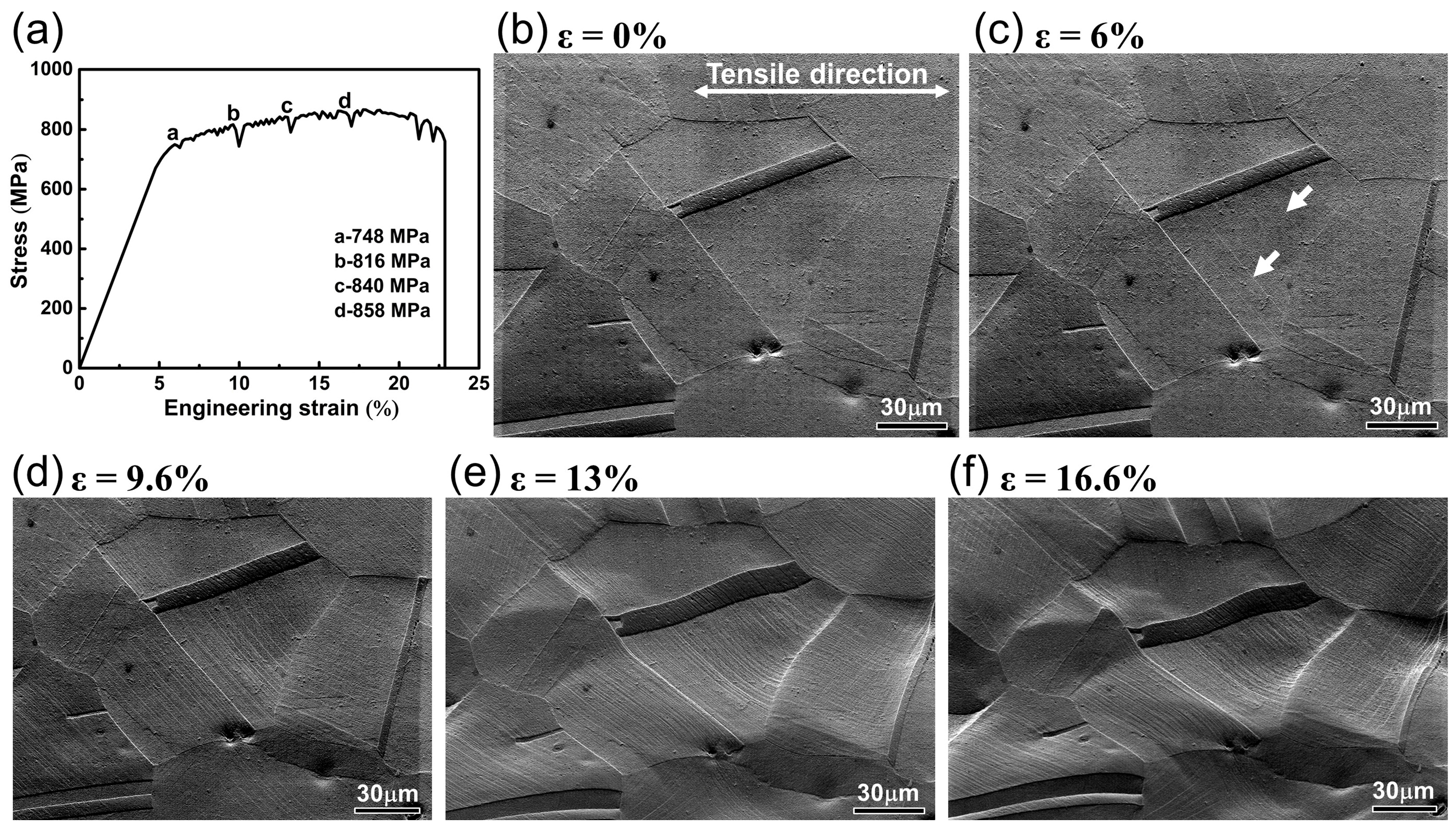

3.1. Morphology Changes During Tensile Deformation

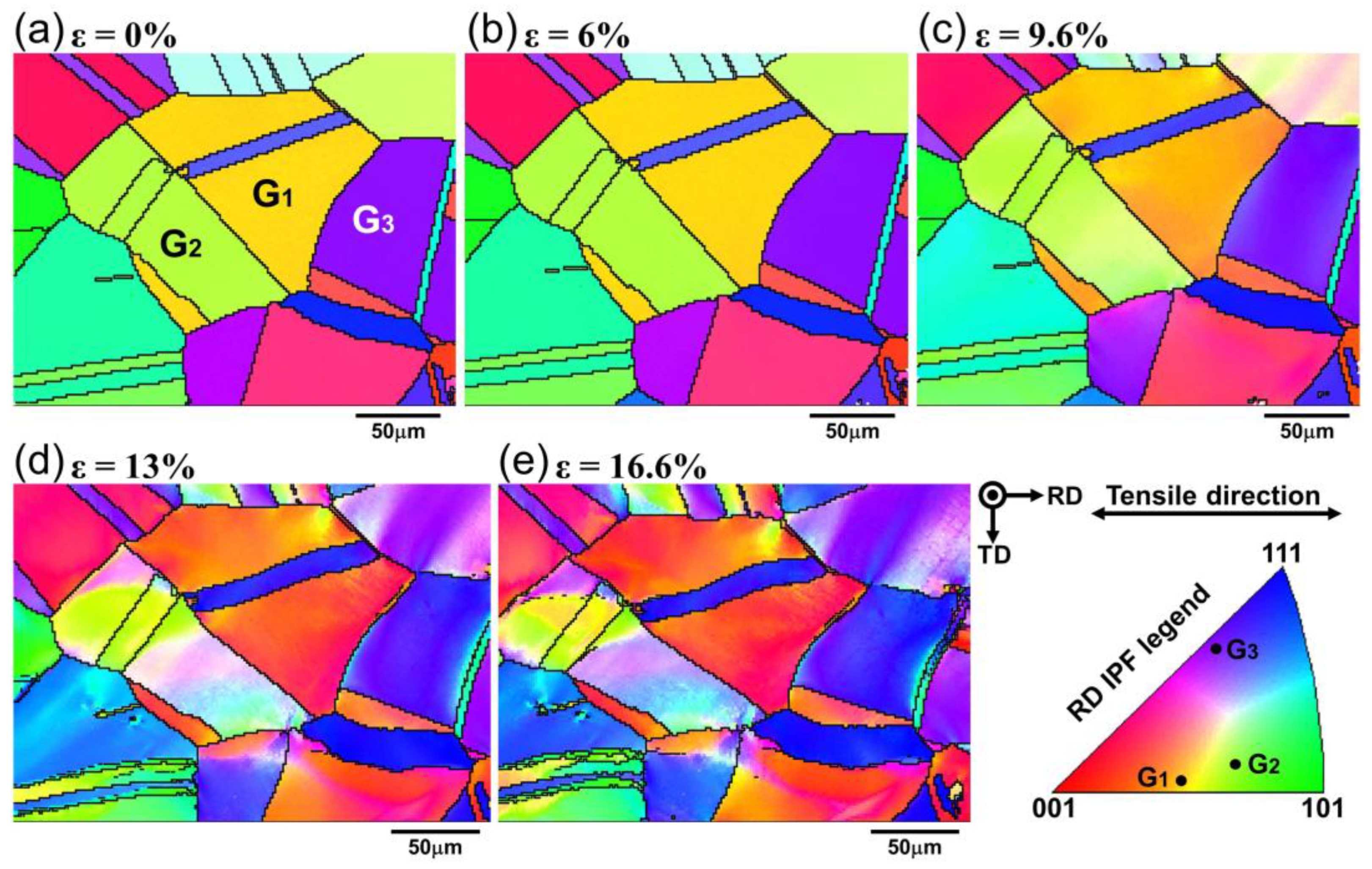

3.2. Grain Orientation Evolution with Straining

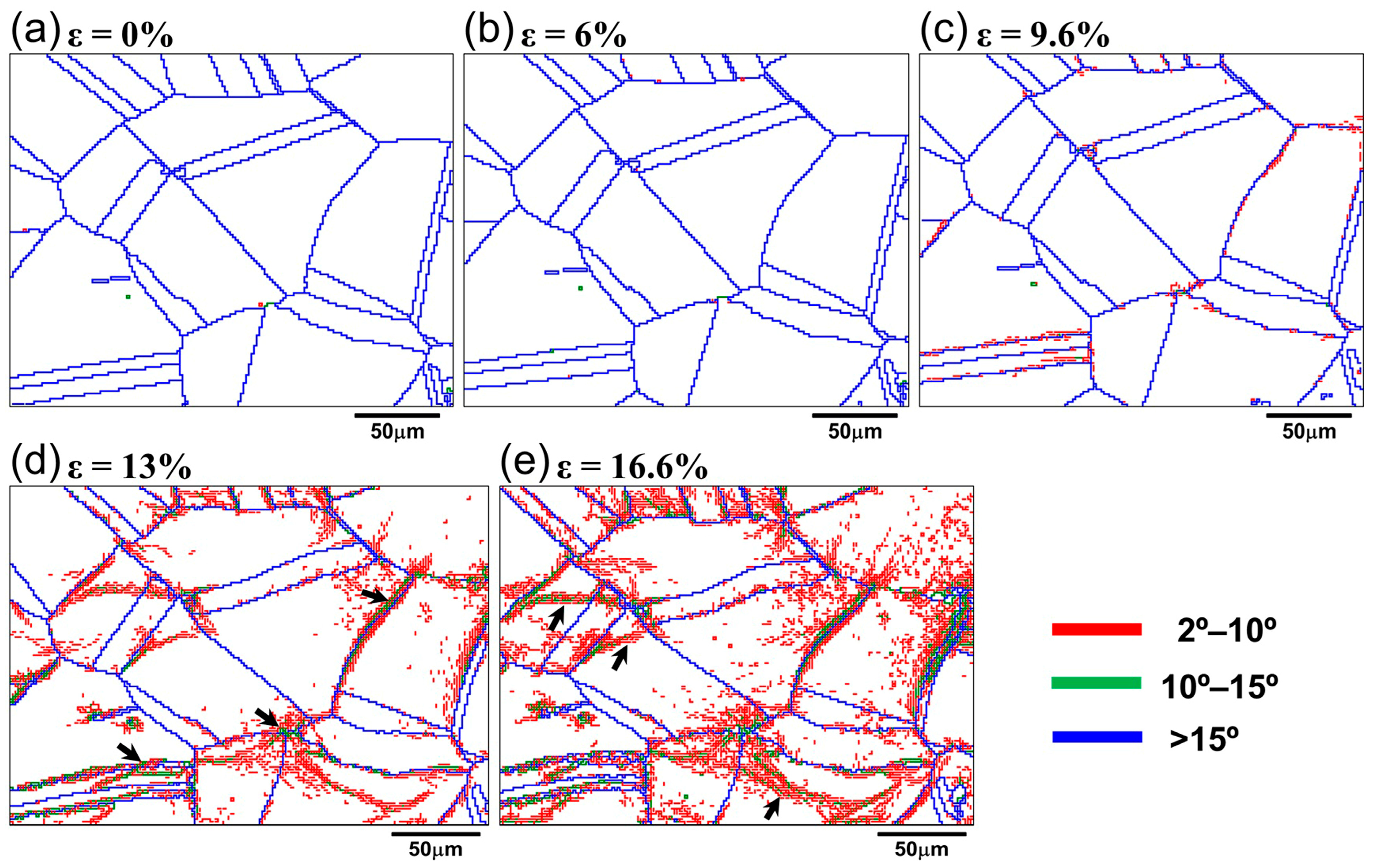

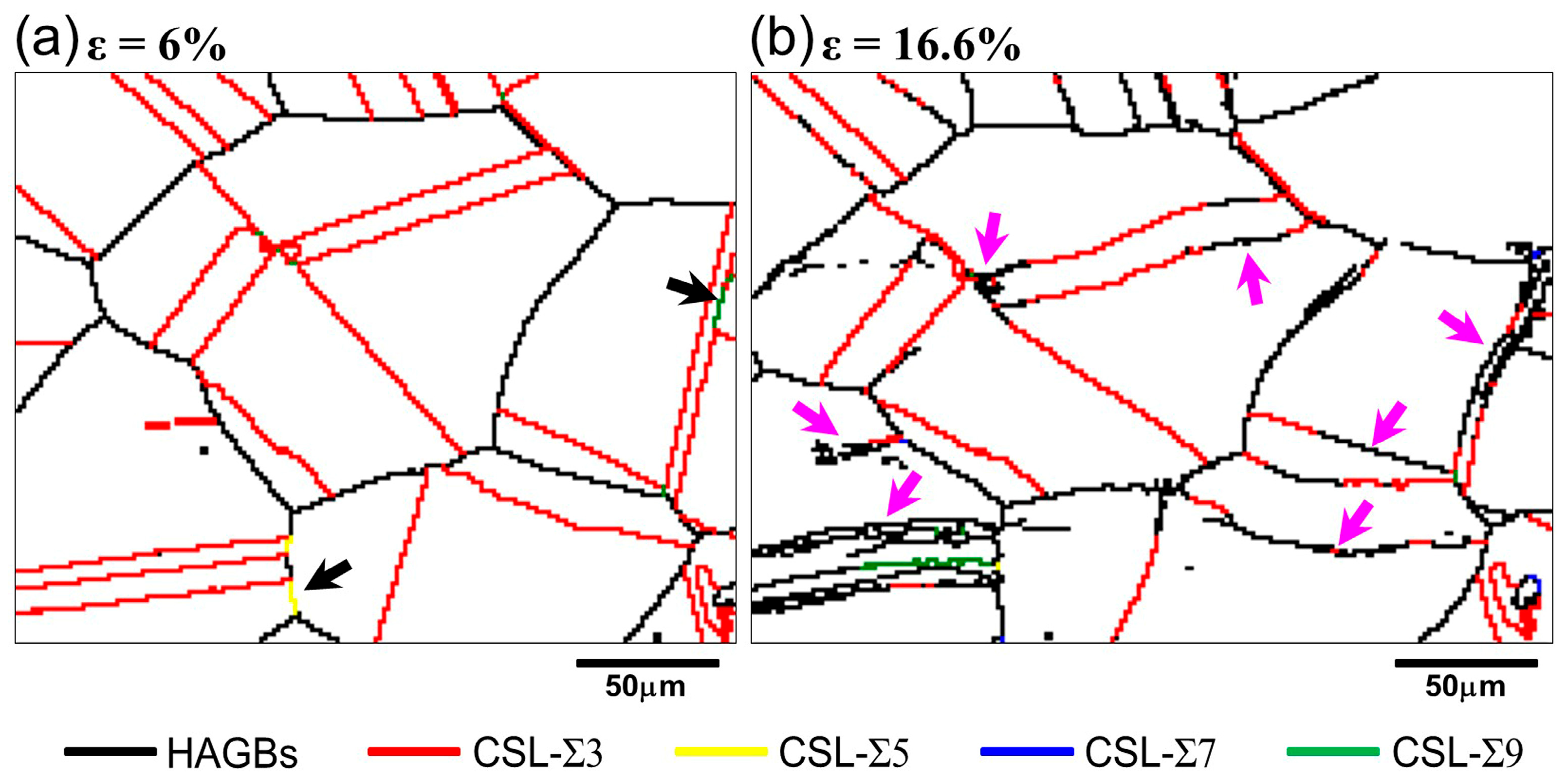

3.3. Evolution of Grain Boundaries

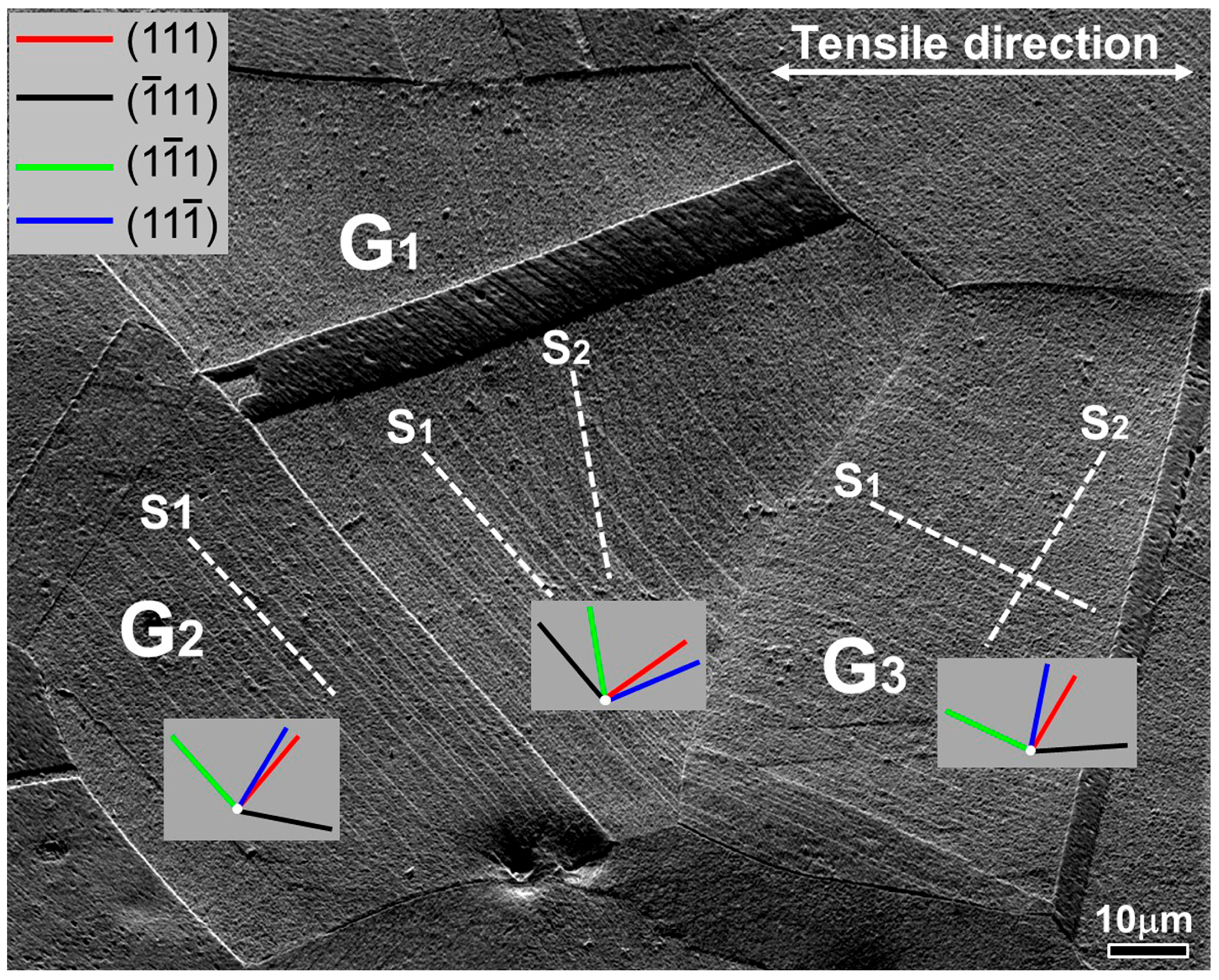

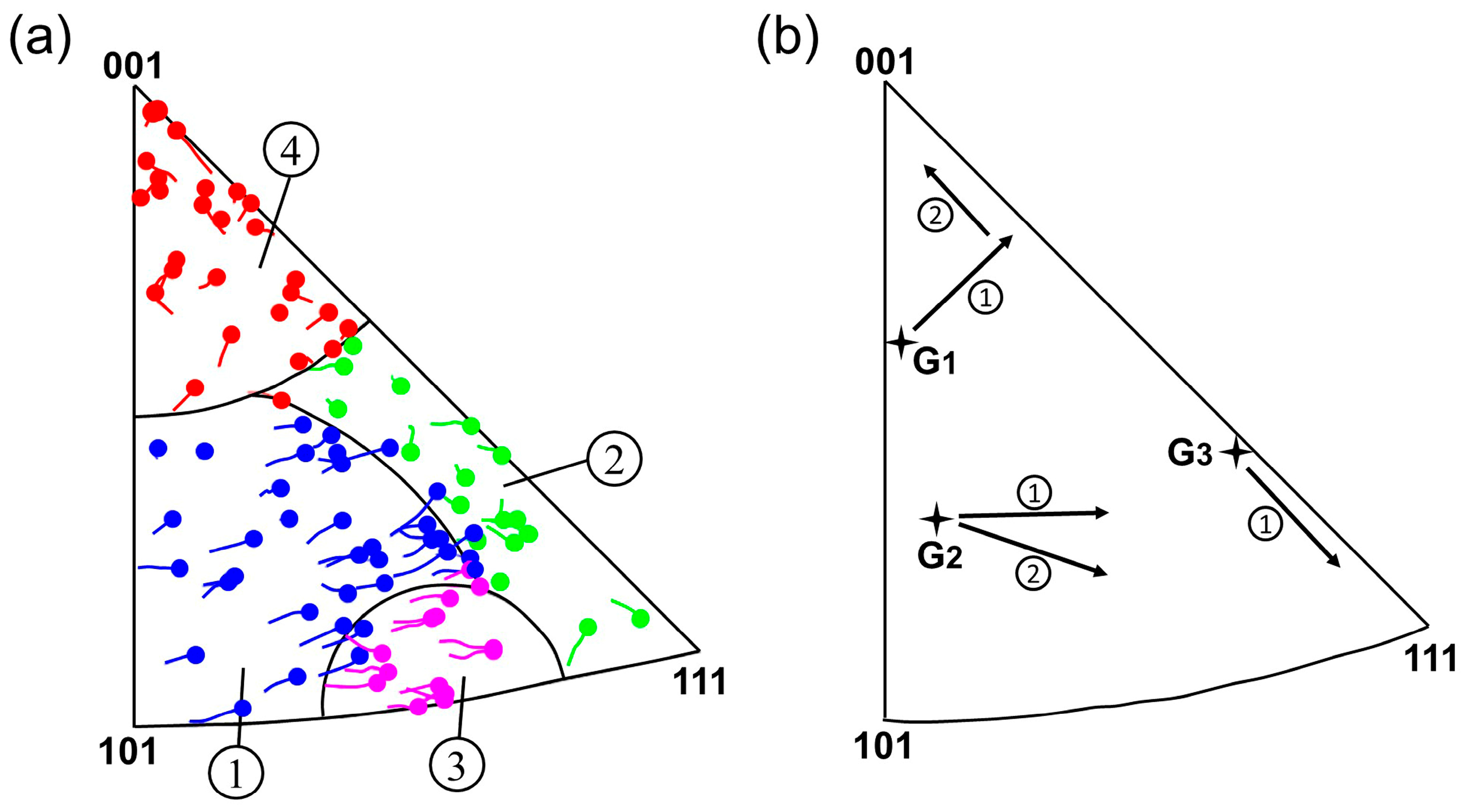

3.4. Slip System Activity and Schmid Factor

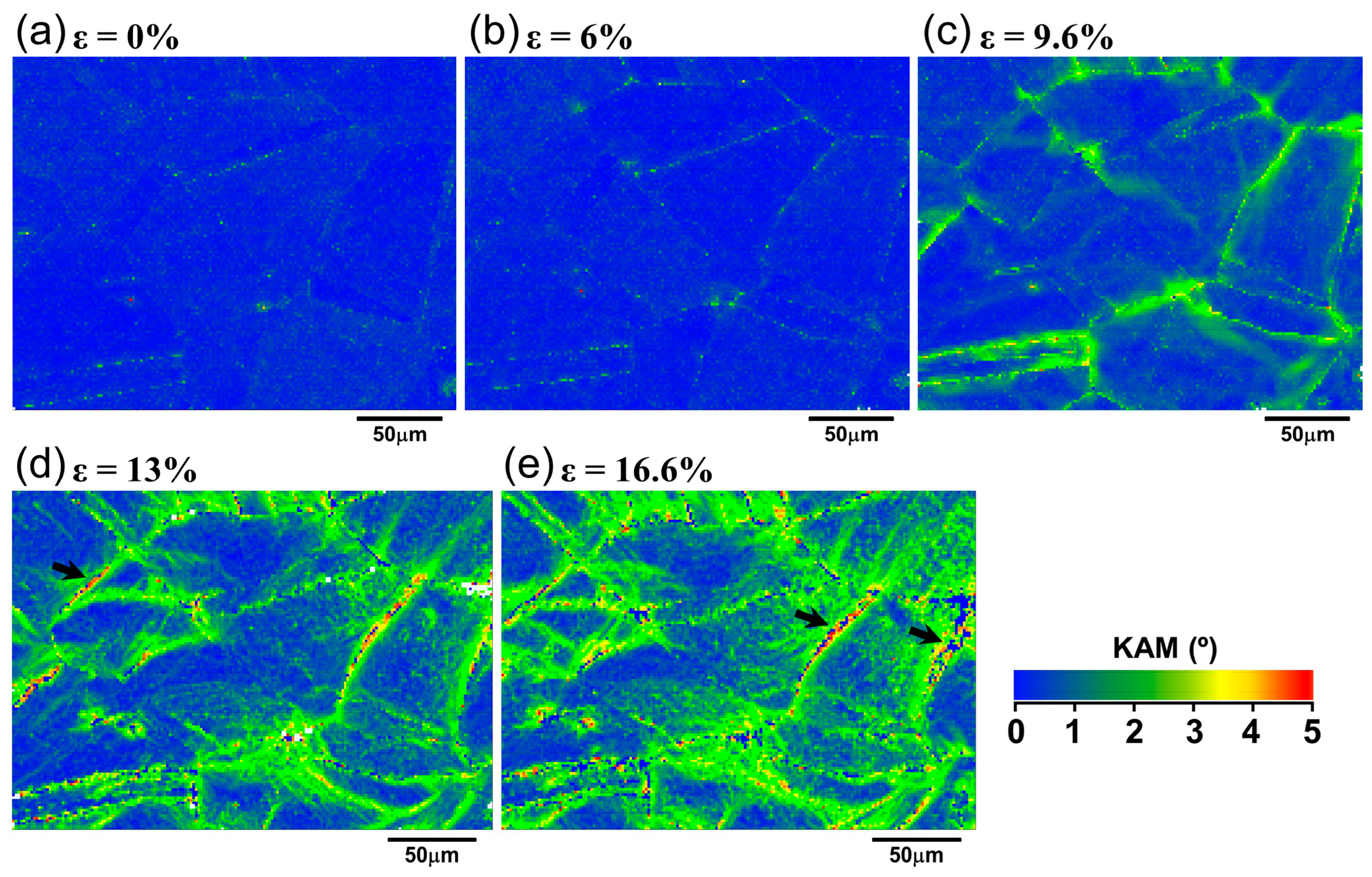

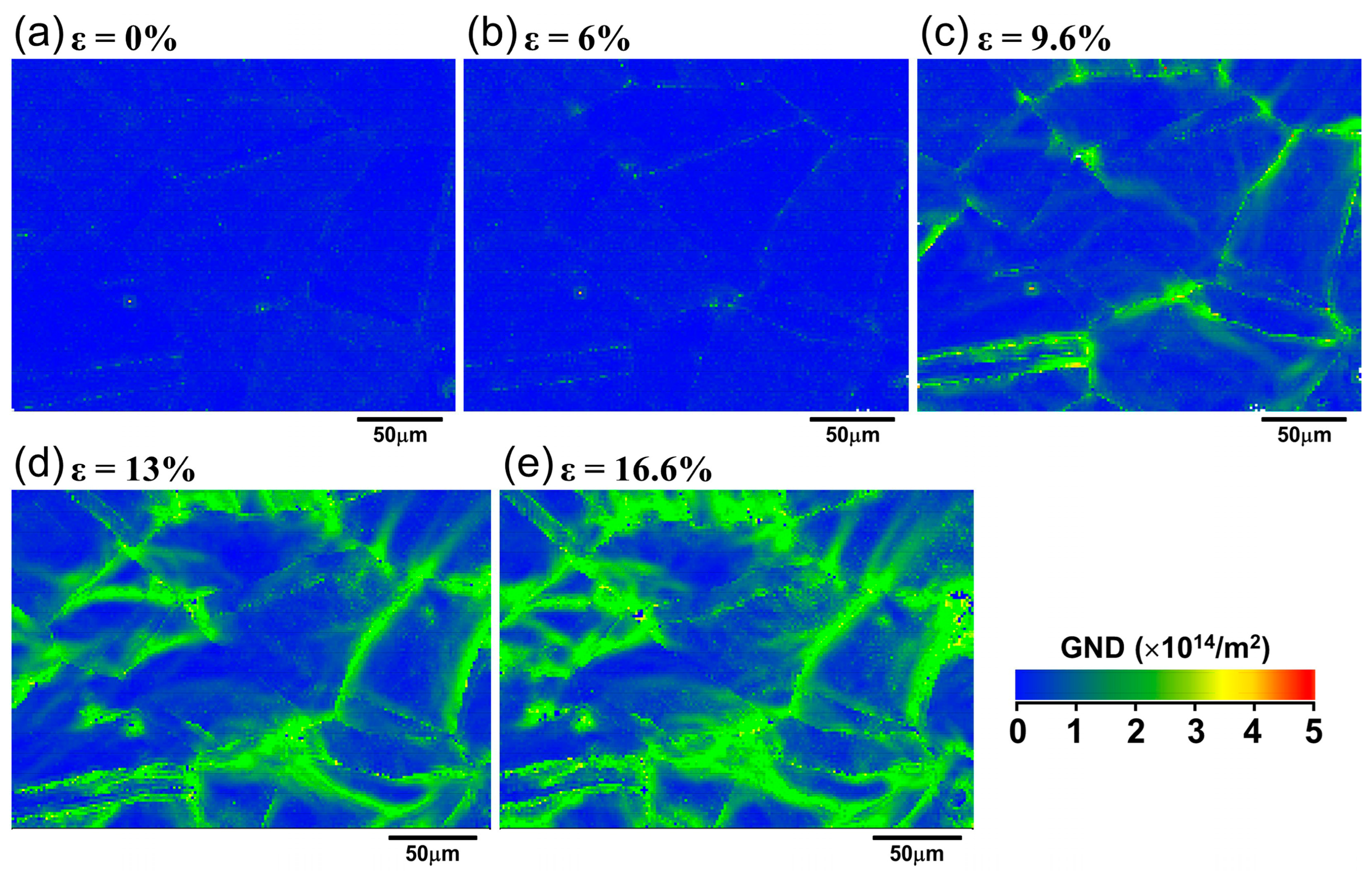

3.5. Evolution of Local Strain

4. Discussion

4.1. Coordinated Deformation of Adjacent Grains

4.1.1. Slip System Activity

4.1.2. Grain Rotation

4.2. Transformation Mechanism of Grain Boundaries

4.2.1. Formation Mechanism of LAGBs

4.2.2. The Loss of TB Integrity

5. Conclusions

- (1)

- The plastic deformation of the IN718 alloy at 650 °C is mainly characterized by the dislocation slip of soft-orientation grains, accompanied by an inhomogeneous lattice rotation within hard-orientation grains. The changes in local misorientation start from the grain boundaries and gradually expand into the interior of grains. The intersection of slip bands and lattice rotation within the grains leads to changes in grain shape;

- (2)

- The initial orientation of the grains has a significant impact on the activation of slip systems. The SF value is not a necessary condition for the activation of slip systems, as it is closely related to the stress state around the grains;

- (3)

- The initial orientation of the grains is the main factor affecting the rotation behavior of grains during the deformation of alloys, while the interaction between grains is the second key factor related to grain orientation. The lattice rotation inside individual grains is non-uniform, which is not only related to the activation of different slip systems inside the grain, but also closely related to the different microstructures of the grains, such as annealing twins within the grain;

- (4)

- The short-segment LAGBs are first formed near the HAGBs with a strain concentration and gradually expand into the interior of the grains. As the density of the LAGBs increases, the LAGBs gradually transform into deformation-induced grain boundaries with higher angles, subdividing the grains into substructures with different misorientations. No deformation twins are observed. Annealing TBs lose their integrity due to the accumulation of dislocations at and in the vicinity of the boundaries at high strain levels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, K.; Fan, J.; Liu, X. Microstructure and mechanical properties of nickel-based wrought superalloys under thermal-mechanical coupling: A review with Inconel 718,625 as main cases. Prog. Nat. Sci. Mater. 2024, 35, 65–82. [Google Scholar] [CrossRef]

- Ding, J.; Xue, S.; Shang, Z.; Li, J.; Zhang, Y.; Su, R.; Niu, T. Characterization of precipitation in gradient Inconel 718 superalloy. Mater. Sci. Eng. A 2021, 804, 140718. [Google Scholar] [CrossRef]

- Chen, J.; Lu, J.; Cai, W.; Zhang, Y.; Wang, Y.; Jiang, W.; Rizwan, M.; Zhang, Z. In-situ study of adjacent grains slip transfer of Inconel 718 during tensile process at high temperature. Int. J. Plast. 2023, 163, 103554. [Google Scholar] [CrossRef]

- Rizwan, M.; Ullah, R.; Lu, J.; Wang, J.; Zhang, Y.; Zhang, Z. Insight into elongation and strength enhancement of heat-treated LPBF Ni-based superalloy 718 using in-situ SEM-EBSD. Mater. Sci. Eng. A 2024, 914, 147163. [Google Scholar] [CrossRef]

- Theska, F.; Stanojevic, A.; Oberwinkler, B.; Primig, S. Microstructure-property relationships in directly aged Alloy 718 turbine disks. Mater. Sci. Eng. A 2020, 776, 138967. [Google Scholar] [CrossRef]

- Zhang, H.; Hao, H.; Li, J.; Zhang, X.; Liu, Y. Evaluation on static mechanical stability of wrought Inconel 718 superalloy; effect of grain configuration and δ precipitation. J. Mater. Res. Technol. 2023, 24, 1776–1791. [Google Scholar] [CrossRef]

- Guan, H.; Jiang, W.; Lu, J.; Zhang, Y.; Zhang, Z. Precipitation of δ phase in Inconel 718 superalloy: The role of grain boundary and plastic deformation. Mater. Today Commun. 2023, 36, 106582. [Google Scholar] [CrossRef]

- Farias, F.W.C.; Duarte, V.R.; Filho, J.C.P. High-performance Ni-based superalloy 718 fabricated via arc plasma directed energy deposition: Effect of post-deposition heat treatments on microstructure and mechanical properties. Addit. Manuf. 2024, 88, 104252. [Google Scholar] [CrossRef]

- Lin, Y.; Deng, J.; Jiang, Y.; Wen, D.; Liu, G. Hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater. Des. 2014, 55, 949–957. [Google Scholar] [CrossRef]

- Kang, J.; Li, R.; Wu, D.; Wang, Y.; Ma, H.; Wang, Q. On the low cycle fatigue behaviors of Ni-based superalloy at room temperature: Deformation and fracture mechanisms. Mater. Charact. 2024, 211, 113920. [Google Scholar] [CrossRef]

- Saumitra, V. Microstructural evolution and precipitation kinetics of carbides in L-PBF processed Inconel 718 during long-term homogenization. Mater. Today Commun. 2025, 41, 111192. [Google Scholar] [CrossRef]

- Kruch, S.; Toualbi, L. Grain size sensitive modelling of the nonlinear behavior and fatigue damage of Inconel 718 superalloy. Int. J. Plast. 2024, 187, 108422. [Google Scholar]

- Boehlert, C.J.; Li, H.; Wang, L.; Bartha, B. Slip system characterization of Inconel 718 using in-situ scanning electron microscopy. Adv. Mater. Process 2010, 11, 41–45. [Google Scholar]

- Charpagne, M.A.; Hestroffer, J.M.; Polonsky, A.T.; Echlin, M.P.; Texier, D. Slip localization in Inconel 718: A three-dimensional and statistical perspective. Acta Mater. 2021, 215, 117037. [Google Scholar] [CrossRef]

- Texier, D.; Milanese, J.; Jullien, M.; Genee, J. Strain localization in the Alloy 718 Ni-based superalloy: From room temperature to 650 °C. Acta Mater. 2024, 268, 119759. [Google Scholar] [CrossRef]

- Jullien, M.; Black, R.L.; Stinville, J.C.; Legros, M.; Texier, D. Grain size effect on strain location, slip-grain boundary interaction and damage in the Alloy 718 Ni-based superalloy at 650 °C. Mater. Sci. Eng. A 2024, 912, 146927. [Google Scholar] [CrossRef]

- Gao, W.; Lu, J.; Zhou, J.; Liu, L.; Wang, J.; Zhang, Y.; Zhang, Z. Effects of grain size on deformation and fracture of Inconel 718: An in-situ SEM-EBSD-DIC investigation. Mater. Sci. Eng. A 2022, 861, 144361. [Google Scholar] [CrossRef]

- Chen, J.; Lu, J.; Cheng, X.; Zhang, Y.; Zhang, Z. In-situ study of the effect of grain boundary misorientation on plastic deformation of Inconel 718 at high temperature. J. Mater. Sci. 2024, 59, 7473–7488. [Google Scholar] [CrossRef]

- Ullah, R.; Lu, J.; Sang, L.; Rizwan, M.; Zhang, Y.; Zhang, Z. Investigating the microstructural evolution during deformation of laser additive manufactured Ti-6Al-4V at 400 °C using in-situ EBSD. Mater. Sci. Eng. A 2021, 823, 141761. [Google Scholar] [CrossRef]

- Hurley, P.J.; Humphreys, F.J. The application of EBSD to the study of substructural development in a cold rolled single-phase aluminium alloy. Acta Mater. 2003, 51, 1087–1102. [Google Scholar] [CrossRef]

- Sang, L.; Lu, J.; Wang, J.; Ullah, R.; Sun, X.; Zhang, Y.; Zhang, Z. In-situ SEM study of temperature-dependent tensile behavior of Inconel 718 superalloy. J. Mater. Sci. 2021, 56, 16097–16112. [Google Scholar] [CrossRef]

- Ma, J.; Lu, J.; Tang, L.; Wang, J.; Sang, L.; Zhang, Y. A novel instrument for investigating the dynamic microstructure evolution of high temperature service materials up to 1150 °C in scanning electron microscope. Rev. Sci. Instrum. 2020, 91, 043704. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, G.; Tasan, C. Slip-twinning interdependent activation across phase boundaries: An in-situ investigation of a Ti-Al-V-Fe (α+β) alloy. Acta Mater. 2021, 206, 116520. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, J.; Wang, J.; Zhang, Y. In-situ EBSD study of deformation behavior of Inconel 740H alloy at high-temperature tensile loading. J. Alloys Compd. 2019, 820, 153424. [Google Scholar] [CrossRef]

- Brewer, L.N.; Field, D.P.; Merriman, C.C. Mapping and assessing plastic deformation using EBSD. In Electron Backscatter Diffraction in Materials Science; Schwartz, A., Kumar, M., Adams, B., Eds.; Springer: Boston, MA, USA, 2009; pp. 251–262. [Google Scholar]

- Zhang, L.; Zhao, L.; Roy, A.; Silberschmidt, V.V.; McColvin, G. In-situ SEM study of slip-controlled short-crack growth in single-crystal nickel superalloy. Mater. Sci. Eng. A 2019, 742, 564–572. [Google Scholar] [CrossRef]

- Xu, S.; Xiong, L.; Chen, Y.; McDowell, D.L. Shear stress- and line length-dependent screw dislocation cross-slip in FCC Ni. Acta Mater. 2017, 122, 412–419. [Google Scholar] [CrossRef]

- Jiang, W.; Lu, J.; Li, F.; Wang, J.; Zhang, Y.; Zhang, Z. In-situ EBSD investigation of the effect of orientation on plastic deformation behavior of a single crystal superalloy. Mater. Sci. Eng. A 2022, 849, 14453. [Google Scholar] [CrossRef]

- Wu, X.; Suo, H.; Ji, Y.; Li, J.; Ma, L.; Liu, M. Systematical analysis on the grain orientation evolution of pure nickel under plastic deformation by using in-situ EBSD. Mater. Sci. Eng. A 2020, 792, 139722. [Google Scholar] [CrossRef]

- Poulsen, H.F.; Margulies, L.; Schmidt, S.; Winther, G. Lattice rotations of individual bulk grains-Part I: 3D X-ray characterization. Acta Mater. 2003, 51, 3821–3830. [Google Scholar] [CrossRef]

- Winther, G.; Margulies, L.; Schmidt, S.; Poulsen, H.F. Lattice rotations of individual bulk grains Part II: Correlation with initial orientation and model comparison. Acta Mater. 2004, 52, 2863–2872. [Google Scholar] [CrossRef]

- Chen, P.; Mao, S.; Liu, Y.; Wang, F.; Zhang, Y.; Zhang, Z. In-situ EBSD study of the active slip systems and lattice rotation behavior of surface grains in aluminum alloy during tensile deformation. Mater. Sci. Eng. A 2013, 580, 114–124. [Google Scholar] [CrossRef]

- Bridier, F.; Villechaise, P.; Mendez, J. Analysis of the different slip systems activated by tension in a α/β titanium alloy in relation with local crystallographic orientation. Acta Mater. 2005, 53, 555–567. [Google Scholar] [CrossRef]

- Yvell, K.; Grehk, T.M.; Hedström, P.; Borgenstam, A.; Engberg, G. Microstructure development in a high-nickel austenitic stainless steel using EBSD during in situ tensile deformation. Mater. Charact. 2018, 135, 228–237. [Google Scholar] [CrossRef]

- Mishra, S.K.; Pant, P.; Narasimhan, K.; Rollett, A.D.; Samajdar, I. On the widths of orientation gradient zones adjacent to grain boundaries. Scr. Mater. 2009, 61, 273–276. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Byun, T.S. On the stress dependence of partial dislocation separation and deformation microstructure in austenitic stainless steels. Acta Mater. 2003, 51, 3063–3071. [Google Scholar] [CrossRef]

- Kuo, C.M.; Lin, C.S. Static recovery activation energy of pure copper at room temperature. Scr. Mater. 2007, 57, 667–670. [Google Scholar] [CrossRef]

- Bibhanshu, N.; Gussev, M.N.; Gussev, C.P.; Massey, C.P.; Field, K.G. Investigation of deformation mechanisms in an advanced FeCrAl alloy using in-situ SEM-EBSD testing. Mater. Sci. Eng. A 2022, 832, 142373. [Google Scholar] [CrossRef]

- Wang, W.; Liu, T.; Cao, X.; Lu, Y.; Shoji, T. In-situ observation on twin boundary evolution and crack initiation behavior during tensile test on 316L austenitic stainless steel. Mater. Charact. 2017, 132, 169–174. [Google Scholar] [CrossRef]

| Element | Fe | Cr | C | Nb | Mo | Al | Ti | Co | Mn | V | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 19.3 | 17.3 | 0.07 | 5.26 | 3.52 | 0.52 | 0.83 | 0.01 | 0.05 | 0.01 | Bal. |

| Grain | Slip Trace | Slip Plane | Slip Direction | Schmid Factor |

|---|---|---|---|---|

| G1 | S1 | (11) | [01] | 0.49 |

| [101] | 0.2 | |||

| [110] | 0.3 | |||

| S2 | (11) | [011] | 0.48 | |

| 01] | 0.15 | |||

| [110] | 0.33 | |||

| G2 | S1 | (11) | [011] | 0.2 |

| 01] | 0.29 | |||

| [110] | 0.49 | |||

| G3 | S1 | (11) | [011] | 0.12 |

| [01] | 0.27 | |||

| [110] | 0.39 | |||

| S2 | (111) | [01] | 0.4 | |

| [01] | 0.28 | |||

| [10] | 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sang, L.; Lu, J.; Cheng, X.; Zhang, Y.; Zhang, Z. In Situ EBSD Study of Deformation Behavior at Grain Scale of Inconel 718 Alloy During Tensile Test at 650 °C. Materials 2025, 18, 1934. https://doi.org/10.3390/ma18091934

Sang L, Lu J, Cheng X, Zhang Y, Zhang Z. In Situ EBSD Study of Deformation Behavior at Grain Scale of Inconel 718 Alloy During Tensile Test at 650 °C. Materials. 2025; 18(9):1934. https://doi.org/10.3390/ma18091934

Chicago/Turabian StyleSang, Lijun, Junxia Lu, Xiaopeng Cheng, Yuefei Zhang, and Ze Zhang. 2025. "In Situ EBSD Study of Deformation Behavior at Grain Scale of Inconel 718 Alloy During Tensile Test at 650 °C" Materials 18, no. 9: 1934. https://doi.org/10.3390/ma18091934

APA StyleSang, L., Lu, J., Cheng, X., Zhang, Y., & Zhang, Z. (2025). In Situ EBSD Study of Deformation Behavior at Grain Scale of Inconel 718 Alloy During Tensile Test at 650 °C. Materials, 18(9), 1934. https://doi.org/10.3390/ma18091934