Wear Resistance of the Refractory WC–Co Diamond-Reinforced Composite with Zirconia Additive

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

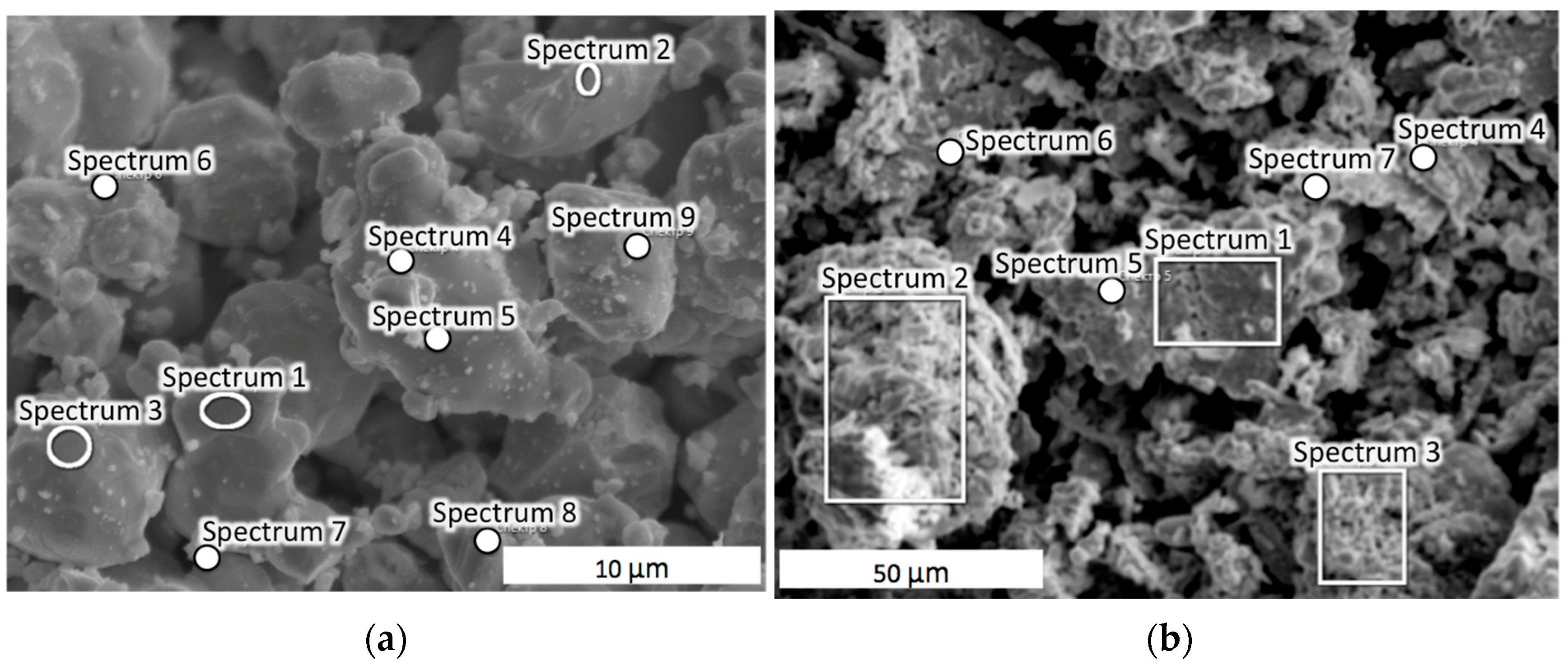

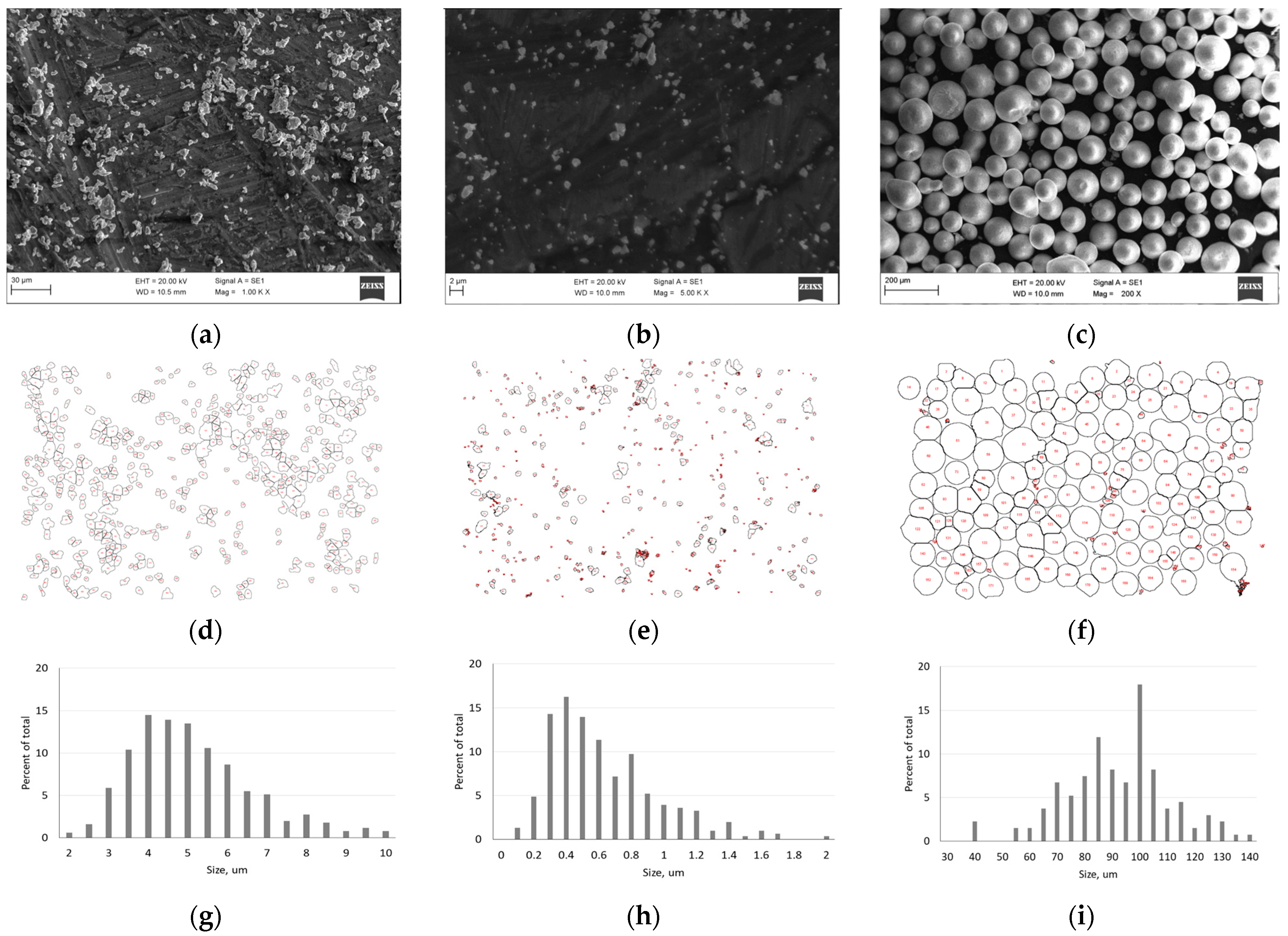

3.1. Analysis of the Initial Powders

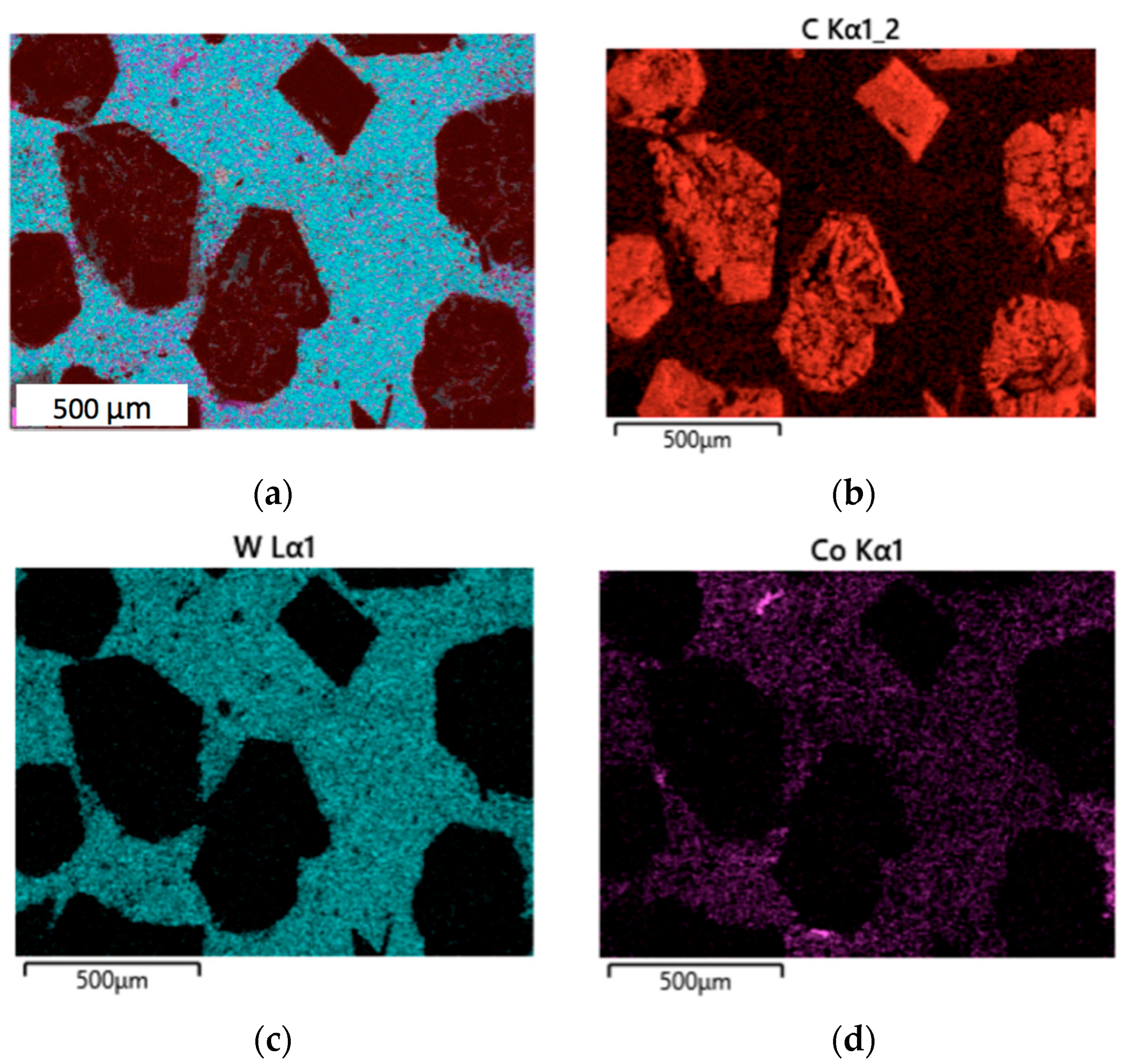

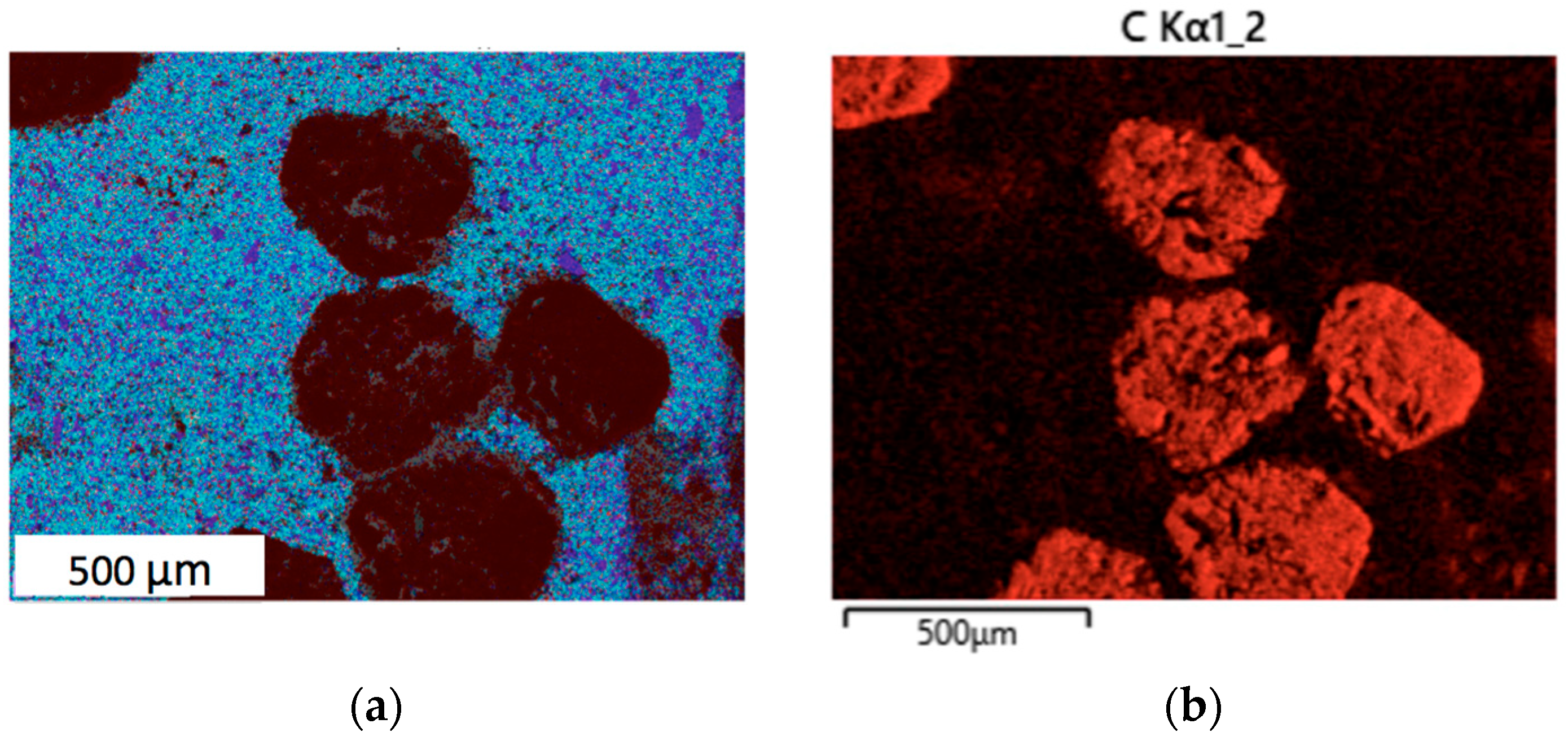

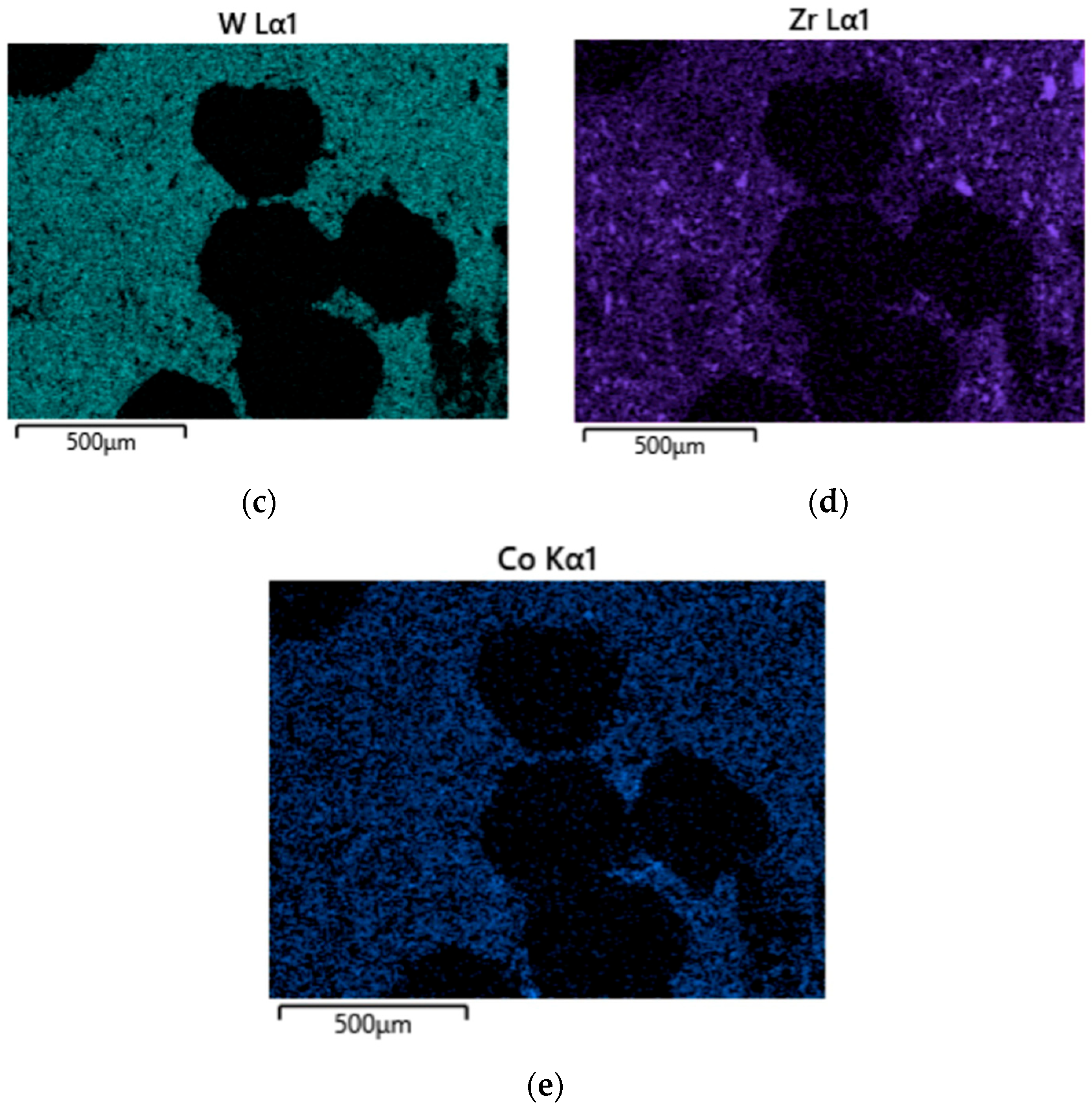

3.2. Sintered Composite Microstructures

3.3. Wear Resistance Results

3.4. Worn Surfaces of the Tested Composites

4. Conclusions

- The fracture mechanism of the composite 25Cdiamond–70.5WC–4.5Co exhibited a mainly intergranular mechanism, including the interfaces between the matrix and diamond grits. The addition of 4 wt.% and 10 wt.% of zirconia introduced a ductile fracture mechanism due to the increased plasticity of the matrix. Multiple crack branching and transglanular fracture mechanisms contributed to the increased fracture toughness and wear resistance of the composites with the zirconia additive. Interfaces between the matrix and diamond reinforcement became denser and revealed no pores or defects.

- The zirconia additive improved the wear resistance of the diamond-reinforced composite, reducing the specific wear rate by 44% with a content of 4 wt.% and by 80% with a content of 10 wt.% of ZrO2. This result is consistent with previously published reports indicating a substantial increase of the index of tolerance to abrasion damage 1/(E2H) after the addition of the respective proportions of zirconia.

- In the composite with a zirconia content of 10 wt.%, a larger percentage of tetragonal phase t-ZrO2 transformed into the densely packed monoclinic one, i.e., m-ZrO2, contributing to the improvement of wear resistance.

- In the tested composite without zirconia addition, the abrasive wear mechanism dominated, accompanied by the pullout of diamond grit from the matrix and, thus, increased three-body abrasive damage to the soft cobalt matrix. The zirconia additive contributed to the increase of the retention force and reduced the intensity of the abrasive mechanism. These improvements can be attributed to the dispersion hardening of the refractory matrix and subsequent stronger clasping of the diamond grits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EDS | Energy Dispersive Spectrometry |

| FAST | Field-Assisted Sintering Technique |

| SEM | Scanning Electron Microscope |

| SPS | Spark Plasma Sintering |

References

- Ngwekhulu, T.T.; Whitefield, D.J.; Sigalas, I.; Sithebe, H.S.L.; Naidoo, S.R. Analysis of the structure and magnetic behaviour of cobalt phase in polycrystalline diamond compacts. Open Ceram. 2025, 21, 100734. [Google Scholar] [CrossRef]

- Ratov, B.; Rucki, M.; Fedorov, B.; Hevorkian, E.; Siemiatkowski, Z.; Muratova, S.; Omirzakova, E.; Kuttybayev, A.; Mechnik, V.; Bondarenko, N. Calculations on Enhancement of Polycrystalline Diamond Bits through Addition of Superhard Diamond-Reinforced Elements. Machines 2023, 11, 453. [Google Scholar] [CrossRef]

- Tyrala, D.; Romanski, A.; Konstanty, J. The Effects of Powder Composition on Microstructure and Properties of Hot-Pressed Matrix Materials for Sintered Diamond Tools. J. Mater. Eng. Perform. 2020, 29, 1467–1472. [Google Scholar] [CrossRef]

- Su, W.; Luo, W.; Lu, J.; Zeng, S.; Zhou, W. Coarse-grained WC–6Co hardmetals with dual-scale and plate-like WC structures fabricated by convention powder metallurgy process. Int. J. Refract. Met. Hard Mater. 2024, 125, 106886. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, R.; Liu, X.; Luo, B.; Dong, X.; Liang, X. The influence of diamond grain sizes on the tribological performance and ultimate loading capacity of polycrystalline diamond self-mated friction pairs under water lubricated condition. Int. J. Refract. Met. Hard Mater. 2025, 128, 107071. [Google Scholar] [CrossRef]

- Bertalan, C.; Moseley, S.; Pereira, L.; Useldinger, R. Influence of sintering parameters on the microstructure and mechanical properties of WC-Co hardmetals. Int. J. Refract. Met. Hard Mater. 2024, 118, 106439. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Ma, S.; Li, C.; Zheng, S.; Lv, W.; Wang, L.; Zhou, A.; Wang, X. Preparation of Ti3Si0.8Al0.2C2 bonded diamond composites and their friction properties coupled with different counterfaces. Adv. Mater. Sci. Eng. 2023, 2023, 1740345. [Google Scholar] [CrossRef]

- Čep, R.; Janásek, A.; Valíček, J.; Čepová, L. Testing of Greenleaf Ceramic Cutting Tools with an Interrupted Cutting. Teh. Vjesn.–Tech. Gaz. 2011, 18, 327–332. [Google Scholar]

- Artini, C.; Muolo, M.L.; Passerone, A. Diamond–metal interfaces in cutting tools: A review. J. Mater. Sci. 2012, 47, 3252–3264. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, S.; Bai, R.; Zhou, H.; Su, Z.; Wu, J.; Wang, J. Effect of nano-vanadium nitride on microstructure and properties of sintered Fe–Cu-based diamond composites. Int. J. Refract. Met. Hard Mater. 2020, 91, 105256. [Google Scholar] [CrossRef]

- Laurindo, Q.M.G.; Rosa, J.M.B.; da Silva Guimarães, R.; Teixeira, S.R.; Lima, L.S.; Xing, Y.; Filgueira, M. Polycrystalline diamond obtained in the diamond-Mo system with enhanced thermal stability sintered by HPHT. Int. J. Refract. Met. Hard Mater. 2024, 118, 106464. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Li, L.; Han, M.; He, J. In Situ Synthesis and Tribological Characterization of TiC–Diamond Composites: Effect of the Counterface Material on Wear Rate and Mechanism. Coatings 2024, 14, 735. [Google Scholar] [CrossRef]

- Yin, C.; Peng, Y.; Ruan, J.; Zhao, L.; Zhang, R.; Du, Y. Influence of Cr3C2 and VC Content on WC Grain Size, WC Shape and Mechanical Properties of WC–6.0 wt. % Co Cemented Carbides. Materials 2021, 14, 1551. [Google Scholar] [CrossRef]

- Ponomarev, S.S.; Shatov, A.V.; Mikhailov, A.A.; Firstov, S.A. Mechanisms for the degradation of strength and wear-resistance of WC based cemented carbides due to faster cooling. Int. J. Refract. Met. Hard Mater. 2015, 49, 161–169. [Google Scholar] [CrossRef]

- Ponomarev, S.S.; Shatov, A.V.; Mikhailov, A.A.; Firstov, S.A. Carbon distribution in WC based cemented carbides. Int. J. Refract. Met. Hard Mater. 2015, 49, 42–56. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Zhang, Z.H.; Cheng, X.W.; Wang, F.C.; Zhang, Y.F.; Li, S.L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Tokita, M. Progress of Spark Plasma Sintering (SPS) Method, Systems, Ceramics Applications and Industrialization. Ceramics 2021, 4, 160–198. [Google Scholar] [CrossRef]

- Su, W.; Zou, J.; Sun, L. Effects of nano-alumina on mechanical properties and wear resistance of WC–8Co cemented carbide by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2020, 92, 105337. [Google Scholar] [CrossRef]

- Zhao, S.X.; Song, X.Y.; Zhang, J.X.; Liu, X.M. Effects of scale combination and contact condition of raw powders on SPS sintered near-nano crystalline WC-Co alloy. Mater. Sci. Eng. A 2008, 473, 323–329. [Google Scholar] [CrossRef]

- Rosado, E.; Marín-Cortés, S.; Moreno, R. Sintering, mechanical properties and hydrothermal resistance of ZrO2/ZrSiO4 slip cast composites. J. Eur. Ceram. Soc. 2024, 44, 6576–6585. [Google Scholar] [CrossRef]

- Choi, J.H.; Nam, M.S.; Ryu, S.S.; Jung, I.H.; Nahm, S.; Kim, S. Thermodynamic stability and mechanical evaluation of YSZ-WC composite ceramics fabricated by pressureless sintering and hot pressing. Ceram. Int. 2023, 49 Pt A, 13414–13424. [Google Scholar] [CrossRef]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Ratov, B.; Mechnik, V.A.; Rucki, M.; Hevorkian, E.; Bondarenko, N.; Prikhna, T.; Moshchil, V.E.; Kolodnitskyi, V.; Morozow, D.; Gusmanova, A.; et al. Enhancement of the Refractory Matrix Diamond-Reinforced Cutting Tool Composite with Zirconia Nano-Additive. Materials 2024, 17, 2852. [Google Scholar] [CrossRef] [PubMed]

- Mechnik, V.A.; Rucki, M.; Ratov, B.T.; Bondarenko, N.A.; Gevorkyan, E.S.; Kolodnitskyi, V.M.; Chishkala, V.A.; Morozova, O.M.; Kulich, V.G. Structure of Cdiamond–(WC–6Co)–ZrO2 composites formed by electrical plasma spark sintering. J. Superhard Mater. 2022, 44, 301–322. [Google Scholar] [CrossRef]

- Ratov, B.T.; Mechnik, V.A.; Rucki, M.; Gevorkyan, E.S.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Chishkala, V.A.; Kudaikulova, G.A.; Muzaparova, A.B.; Korostyshevskyi, D.L. Cdiamond–(WC–Co)–ZrO2 composite materials with improved mechanical and adhesive properties. J. Superhard Mater. 2023, 45, 103–117. [Google Scholar] [CrossRef]

- Hevorkian, E.S.; Nerubatskyi, V.P.; Rucki, M.; Kilikevicius, A.; Mamalis, A.G.; Samociuk, W.; Morozow, D. Electroconsolidation Method for Fabrication of Fine-Dispersed High-Density Ceramics. Nanotechnol. Percept. 2024, 20, 100–113. [Google Scholar]

- Cahill, J.T.; Graeve, O.A. Hexaborides: A review of structure, synthesis and processing. J. Mater. Res. Technol. 2019, 8, 6321–6335. [Google Scholar] [CrossRef]

- Hevorkian, E.; Michalczewski, R.; Rucki, M.; Sofronov, D.; Osuch-Słomka, E.; Nerubatskyi, V.; Krzysiak, Z.; Latosińska, J.N. Effect of the sintering parameters on the structure and mechanical properties of zirconia-based ceramics. Ceram. Int. 2024, 50 Pt A, 35226–35235. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Żurowski, W.; Zepchło, J.; Kanaška, D.; Rucki, M. Concept and assessment of the novel design of tribological tester. Measurement 2021, 170, 108724. [Google Scholar] [CrossRef]

- Walczak, M.; Caban, J. Tribological characteristics of polymer materials used for slide bearings. Open Eng. 2021, 11, 624–629. [Google Scholar] [CrossRef]

- Genovese, A.; D’Angelo, G.A.; Sakhnevych, A.; Farroni, F. Review on Friction and Wear Test Rigs: An Overview on the State of the Art in Tyre Tread Friction Evaluation. Lubricants 2020, 8, 91. [Google Scholar] [CrossRef]

- Osipov, V.N.; Fadin, Y.A.; Nikanorov, S.P. Wear and Coefficient of Friction of a Supermodified Hypereutectic Aluminum–Silicon Alloy. Tech. Phys. 2020, 65, 1981–1986. [Google Scholar] [CrossRef]

- Ray, S.K.; Banerjee, A.; Bhangi, B.K.; Pyne, D.; Dutta, B. Tribological analysis—General test standards. In Tribology of Polymers, Polymer Composites, and Polymer Nanocomposites; George, S.C., Haponiuk, J.T., Thomas, S., Reghunath, R., Sarath, P.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 17–50. [Google Scholar] [CrossRef]

- Wang, S.F.; Zhang, J.; Luo, D.W.; Gu, F.; Tang, D.Y.; Dong, Z.L.; Tan, G.E.B.; Que, W.X.; Zhang, T.S.; Li, S.; et al. Transparent ceramics: Processing, materials and applications. Prog. Solid State Chem. 2013, 41, 20–54. [Google Scholar] [CrossRef]

- Lima, M.J.S.; Silva, F.E.S.; Lima, H.D.; Souto, M.V.M.; Oliveira, A.G.F.; Raimundo, R.A.; Souza, C.P.; Gomes, U.U. Spark plasma sintering of nanostructured powder composites (WC–Ni) prepared by carboreduction reaction. Mater. Chem. Phys. 2020, 254, 123439. [Google Scholar] [CrossRef]

- Ren, J.; Ma, Y.; Zhou, Q.; Sun, Z.; Liu, X.; Li, Y. Effect of basalt fiber particles on the holding strength and wear resistance of sintered Cu-based diamond composites. Ceram. Int. 2024, 50, 24979–24986. [Google Scholar] [CrossRef]

- Mao, X.; Meng, Q.; Yuan, M.; Wang, S.; Wang, J.; Huang, S.; Liu, B.; Gao, K. Wear performance of the Fe-Ni-WC-based impregnated diamond bit with Mo2C-coated diamonds: Effect of the interface layer. Wear 2023, 522, 204683. [Google Scholar] [CrossRef]

- Kwak, N.; Kang, S.G.; Min, G.; Arredondo, R.; Jeong, K.; Kim, H.; Schwarz-Selinger, T.; Balden, M.; Manhard, A.; You, J.H.; et al. Bimodal structured chromium-tungsten composite as plasma-facing materials: Sinterability, mechanical properties, and deuterium retention assessment. Acta Mater. 2024, 262, 119453. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, M.; He, K.; Fang, C.; Zeng, C.; Huang, Q. Improving the sinterability of ZrC–SiC composite powders by Mg addition. Ceram. Int. 2021, 47, 18330–18338. [Google Scholar] [CrossRef]

- Saito, H.; Iwabuchi, A.; Shimizu, T. Effects of Co content and WC grain size on wear of WC cemented carbide. Wear 2006, 261, 126–132. [Google Scholar] [CrossRef]

- Garcia, J.; Ferreira, A.R.; Silva, F.S.; Carvalho, O.; Trindade, B. Production and tribological characterization of a textured diamond-reinforced copper-beryllium alloy. Tribol. Int. 2019, 140, 105843. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Ding, J. Effect of the additive graphene oxide on tribological properties of WC-Co cemented carbide. Int. J. Refract. Met. Hard Mater. 2022, 109, 105962. [Google Scholar] [CrossRef]

- Zhao, S.; Li, C.; Davoodi, D.; Soltani, H.M.; Tayebi, M. Tribological behavior of PDC-cutter including cemented carbide and polycrystalline diamond composites produced by HPHT for drilling applications. Int. J. Refract. Met. Hard Mater. 2024, 123, 106756. [Google Scholar] [CrossRef]

- Ratov, B.T.; Hevorkian, E.; Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Prikhna, T.O.; Moshchil, V.E.; Nerubaskyi, V.P.; Kalzhanova, A.B.; Bayamirova, R.U.; et al. Effect of the ZrO2 content on the strength characteristics of the matrix material of Cdiamond–(WC–Co) composites synthesized by spark plasma sintering. J. Superhard Mater. 2024, 46, 175–186. [Google Scholar] [CrossRef]

- Scherrer, S.S.; Lohbauer, U.; Della Bona, A.; Vichi, A.; Tholey, M.J.; Kelly, J.R.; van Noort, R.; Cesar, P.F. ADM guidance—Ceramics: Guidance to the use of fractography in failure analysis of brittle materials. Dent. Mater. 2017, 33, 599–620. [Google Scholar] [CrossRef]

- Lozynskyi, V.; Trembach, B.; Hossain, M.M.; Kabir, M.H.; Silchenko, Y.; Krbata, M.; Sadovyi, K.; Kolomiitse, O.; Ropyak, L. Prediction of phase composition and mechanical properties Fe–Cr–C–B–Ti–Cu hardfacing alloys: Modeling and experimental Validations. Heliyon 2024, 10, e25199. [Google Scholar] [CrossRef]

| Spectrum | 9 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|---|

| C, % | 9.52 | 6.37 | 11.72 | - | 10.73 | 9.14 | 8.89 | 9.10 | - |

| W, % | 90.48 | 93.63 | 88.28 | 100.00 | 89.27 | 90.86 | 91.11 | 90.90 | 100.00 |

| Total, % | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Spectrum | 7 | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| O, % | 0.21 | 0.42 | - | 0.98 | 0.29 | 1.18 | 1.12 |

| Fe, % | 0.25 | - | 0.34 | - | - | 0.19 | 0.43 |

| Co, % | 99. 54 | 99.58 | 99.66 | 99.02 | 99.71 | 98.63 | 98.45 |

| Total, % | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Sample | Composition, wt.% | Wear Rate by Mass WR, 10−5 g/m | Wear Rate by Volume WV, 10−12 m3/s | Specific Wear Rate WS, 10−13 m3/(N·m) |

|---|---|---|---|---|

| 1 | 25Cdiamond–70.5WC–4.5Co | 9.380 ± 0.657 | 9.487 ± 0.759 | 7.552 ± 0.529 |

| 2 | 25Cdiamond–66.74WC–4.26Co–4 ZrO2 | 4.986 ± 0.399 | 4.470 ± 0.451 | 4.272 ± 0.299 |

| 3 | 25Cdiamond–61.1WC–3.9Co–10 ZrO2 | 1.751 ± 0.123 | 2.302 ± 0.138 | 1.571 ± 0.126 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ratov, B.; Mechnik, V.; Hevorkian, E.; Rucki, M.; Pieniak, D.; Bondarenko, N.; Kolodnitskyi, V.; Starik, S.; Bilorusets, V.; Chishkala, V.; et al. Wear Resistance of the Refractory WC–Co Diamond-Reinforced Composite with Zirconia Additive. Materials 2025, 18, 1965. https://doi.org/10.3390/ma18091965

Ratov B, Mechnik V, Hevorkian E, Rucki M, Pieniak D, Bondarenko N, Kolodnitskyi V, Starik S, Bilorusets V, Chishkala V, et al. Wear Resistance of the Refractory WC–Co Diamond-Reinforced Composite with Zirconia Additive. Materials. 2025; 18(9):1965. https://doi.org/10.3390/ma18091965

Chicago/Turabian StyleRatov, Boranbay, Volodymyr Mechnik, Edvin Hevorkian, Miroslaw Rucki, Daniel Pieniak, Nikolai Bondarenko, Vasyl Kolodnitskyi, Sergii Starik, Viktor Bilorusets, Volodymyr Chishkala, and et al. 2025. "Wear Resistance of the Refractory WC–Co Diamond-Reinforced Composite with Zirconia Additive" Materials 18, no. 9: 1965. https://doi.org/10.3390/ma18091965

APA StyleRatov, B., Mechnik, V., Hevorkian, E., Rucki, M., Pieniak, D., Bondarenko, N., Kolodnitskyi, V., Starik, S., Bilorusets, V., Chishkala, V., Sundetova, P., Bektilevov, A., Shukmanova, A., & Seidaliyev, A. (2025). Wear Resistance of the Refractory WC–Co Diamond-Reinforced Composite with Zirconia Additive. Materials, 18(9), 1965. https://doi.org/10.3390/ma18091965