Microstructure and Mechanical Properties of TiB2/TiC Particle Modified Al-Mg-Si Alloys Fabricated by Wire-Arc Additive Manufacturing

Abstract

:1. Introduction

2. Experimental Methods

3. Results

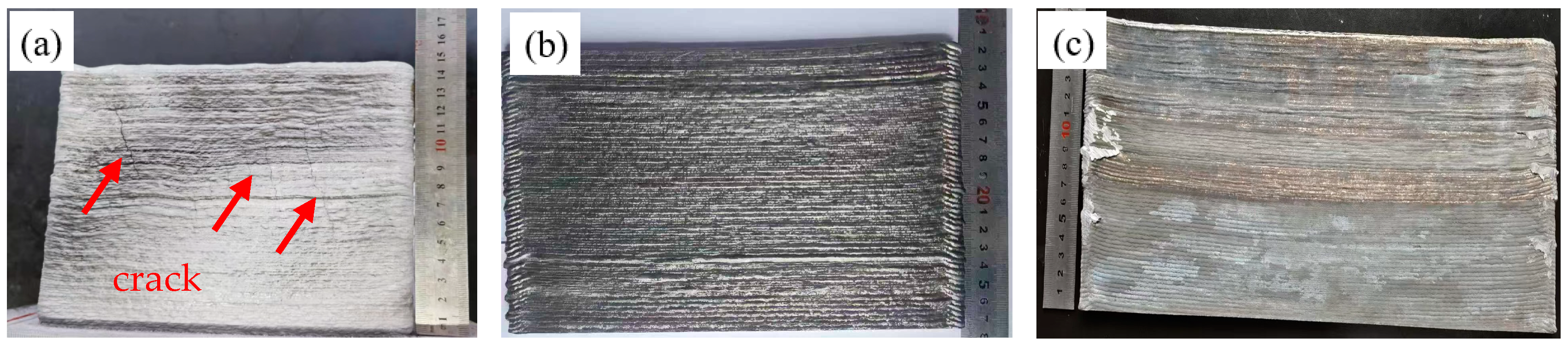

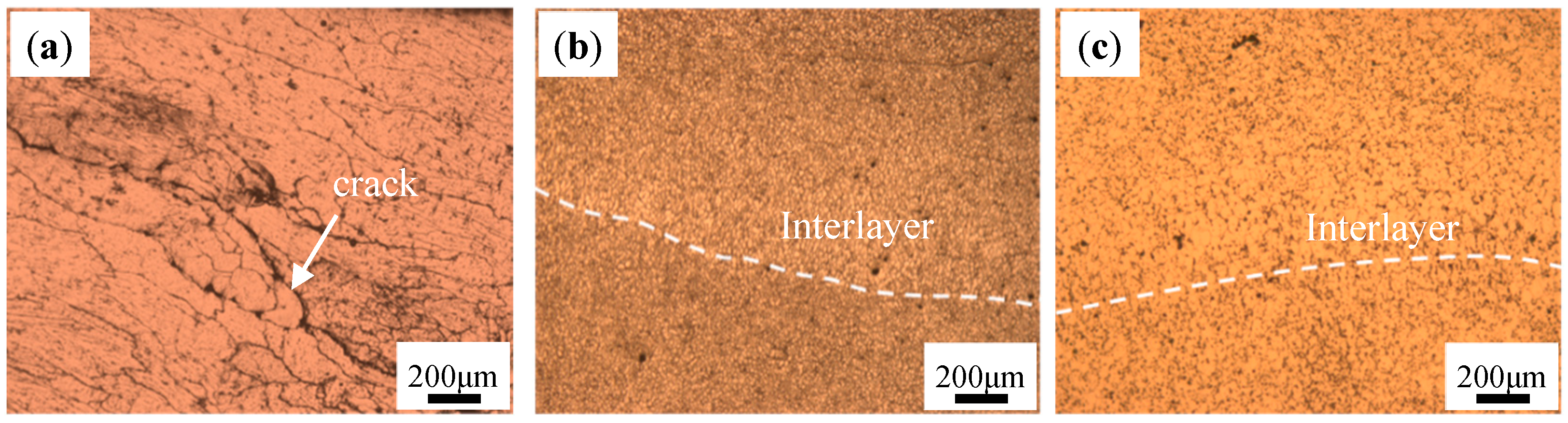

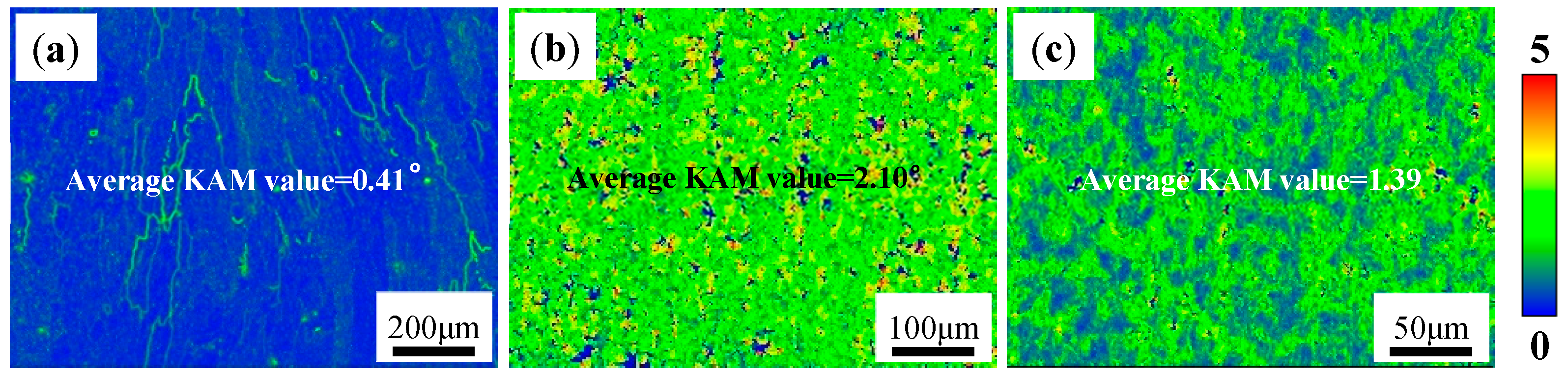

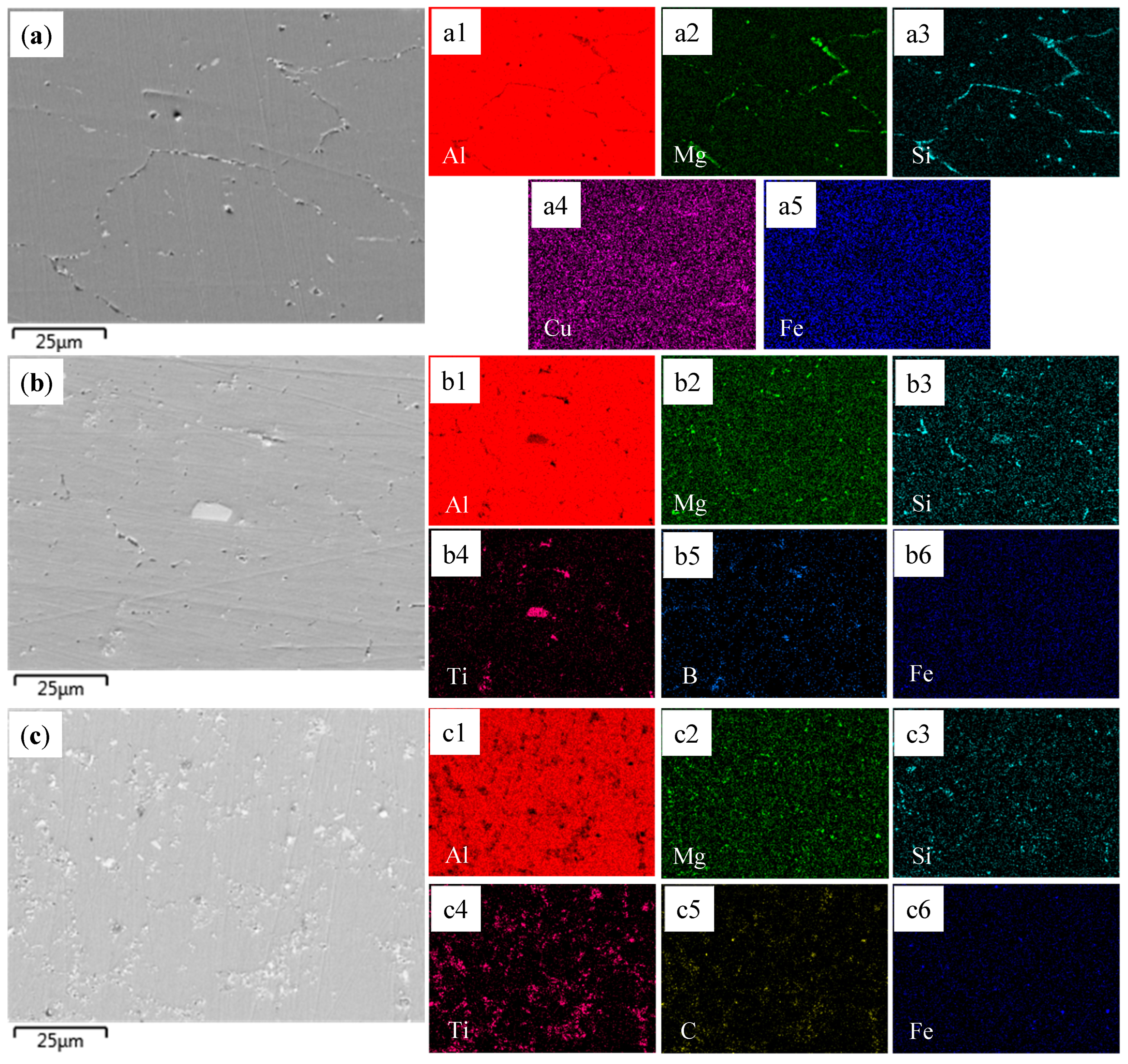

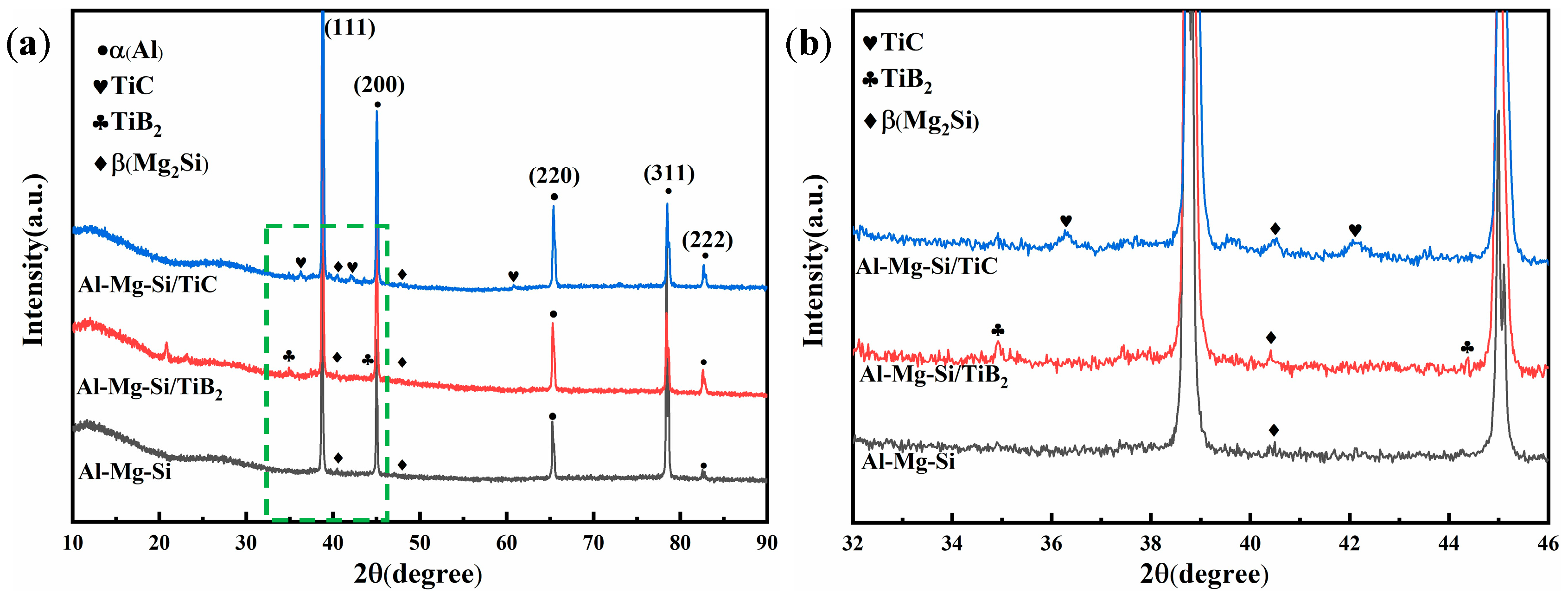

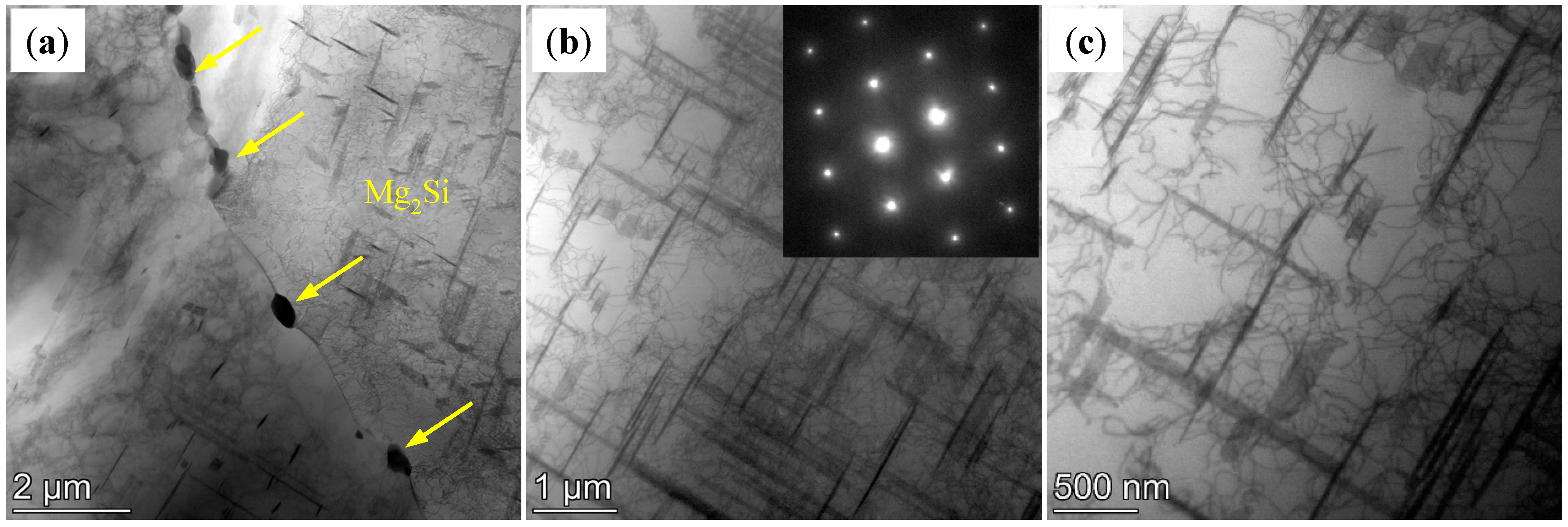

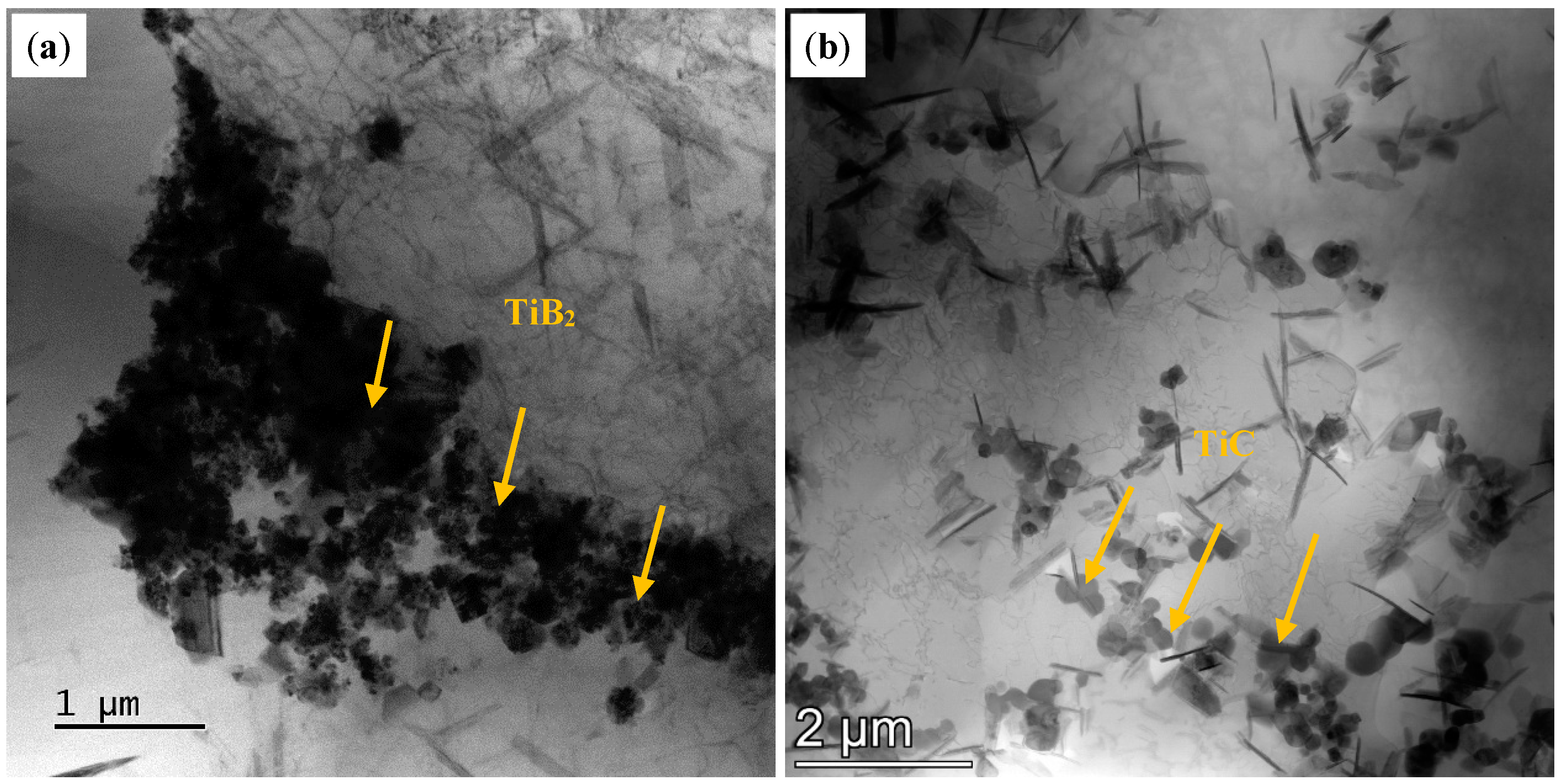

3.1. Microstructure of the As-Deposited Alloys

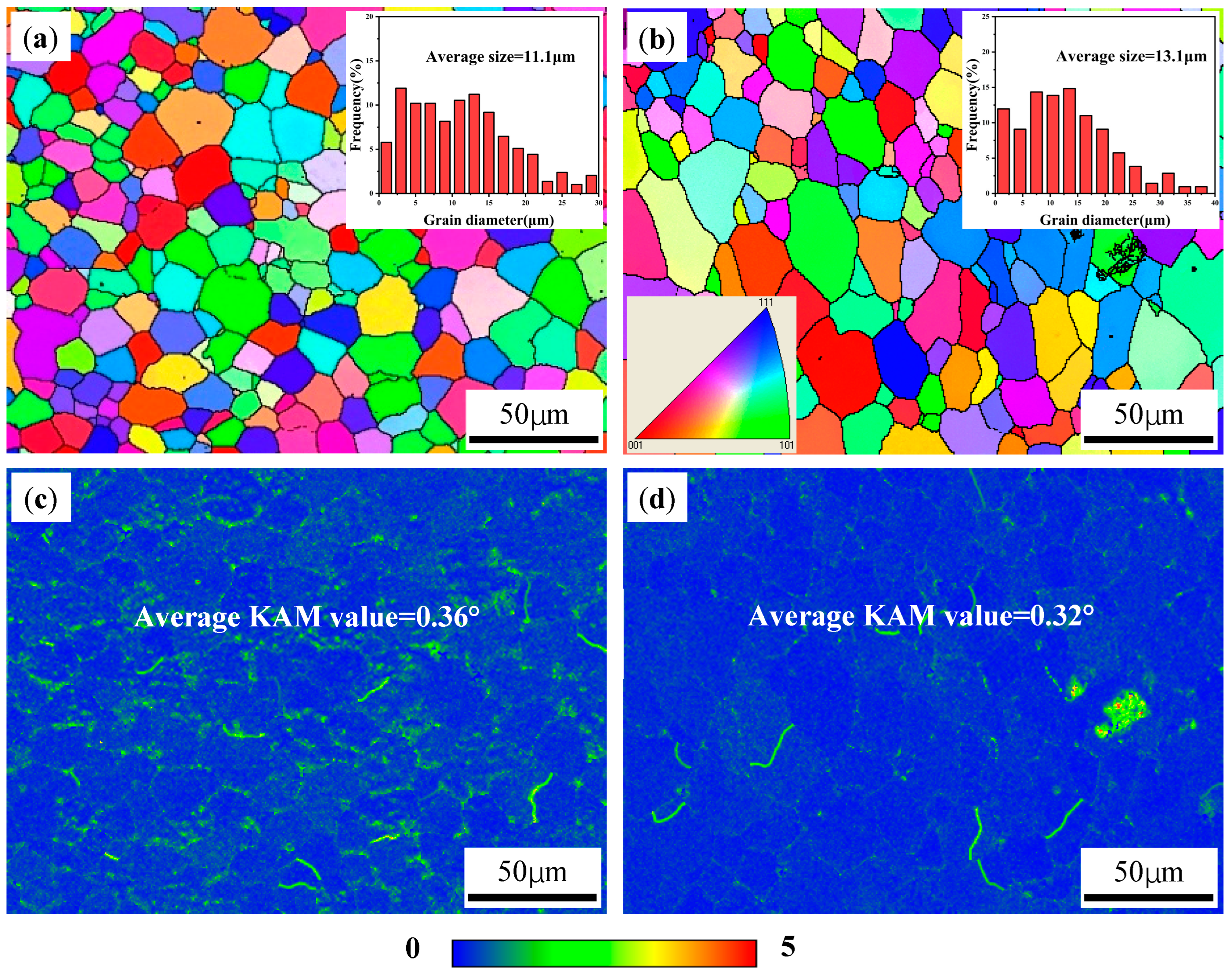

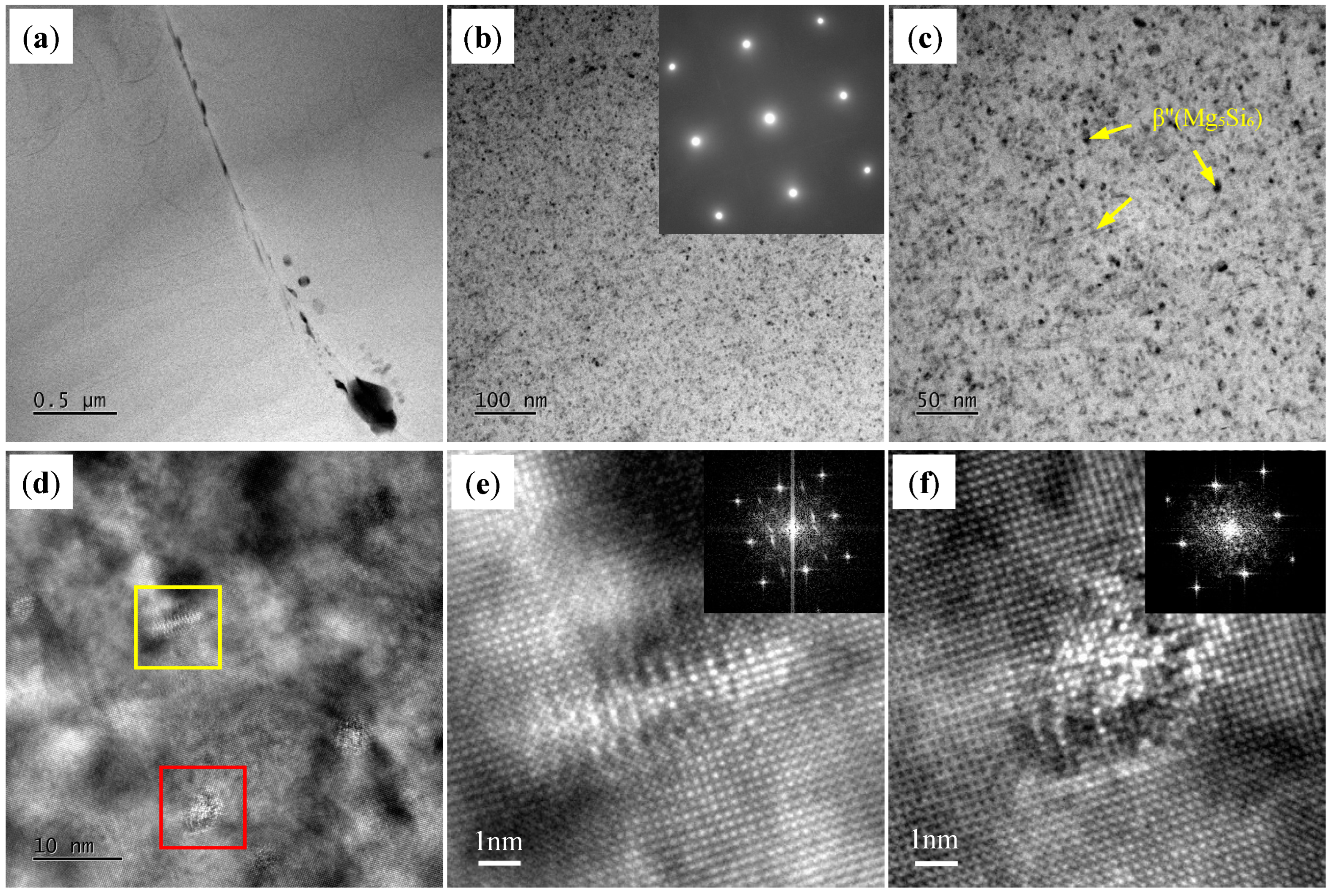

3.2. Microstructure of the T6-Treated Alloys

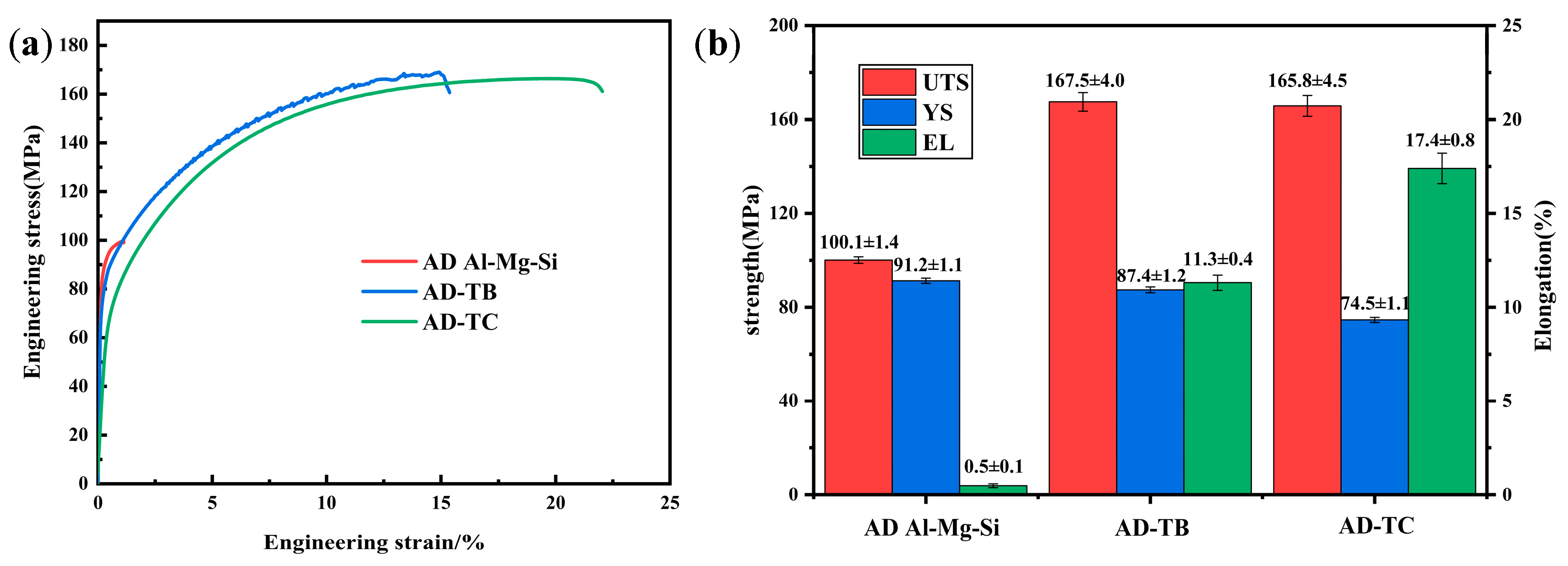

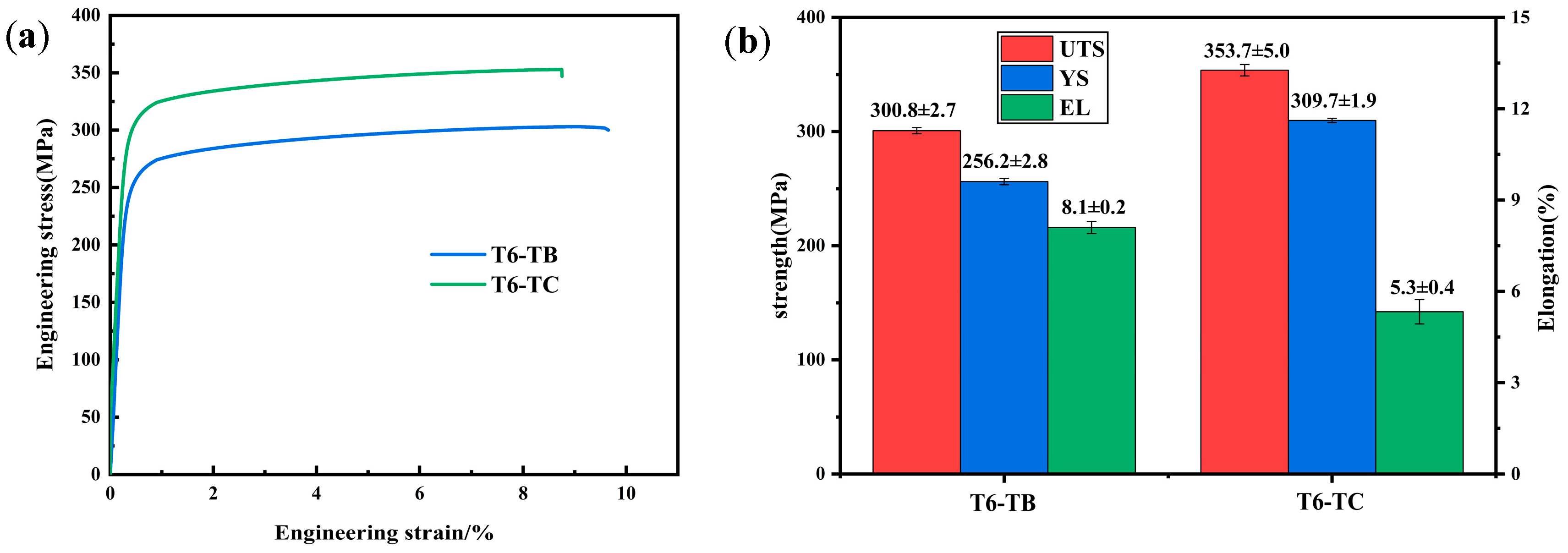

3.3. Mechanical Properties

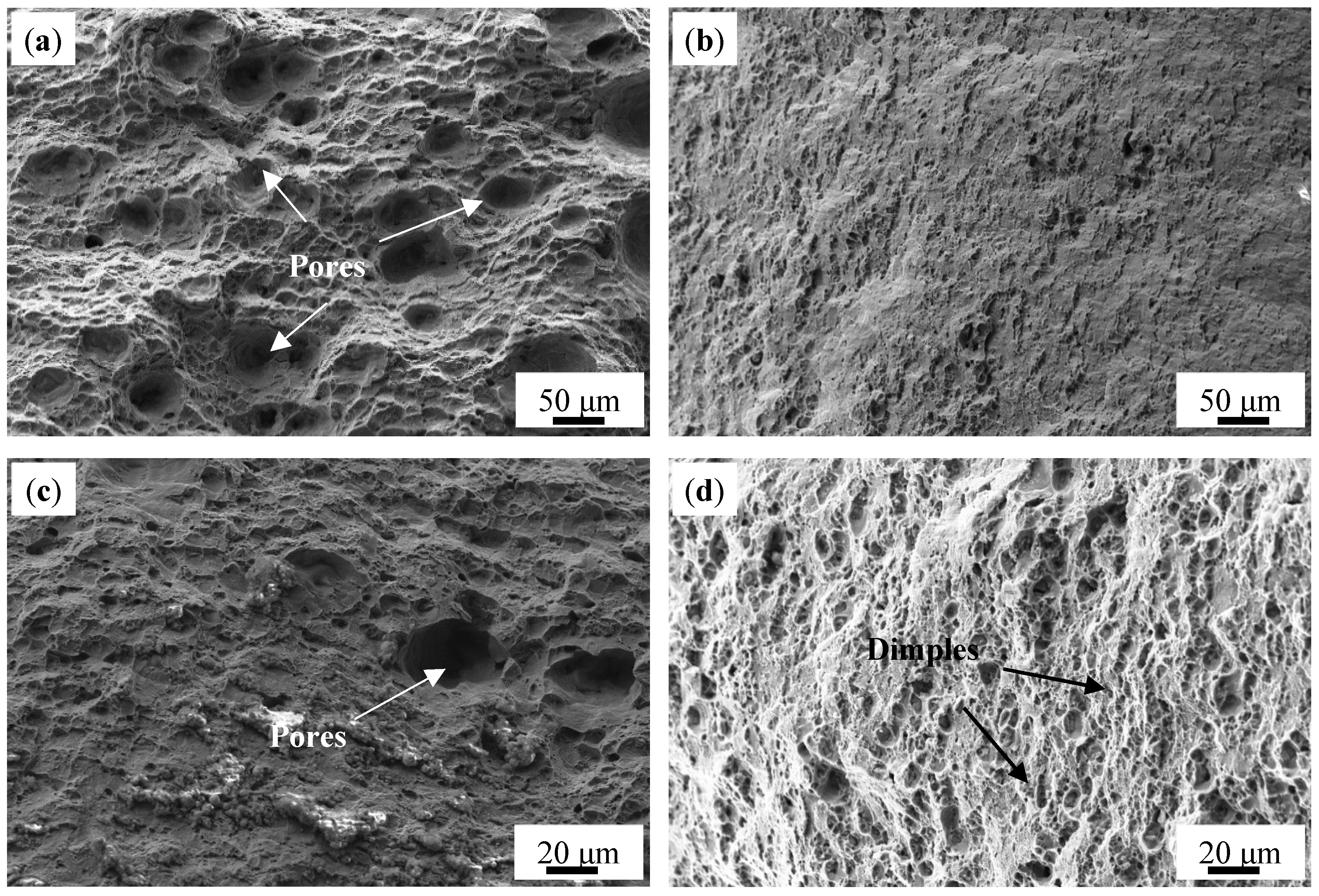

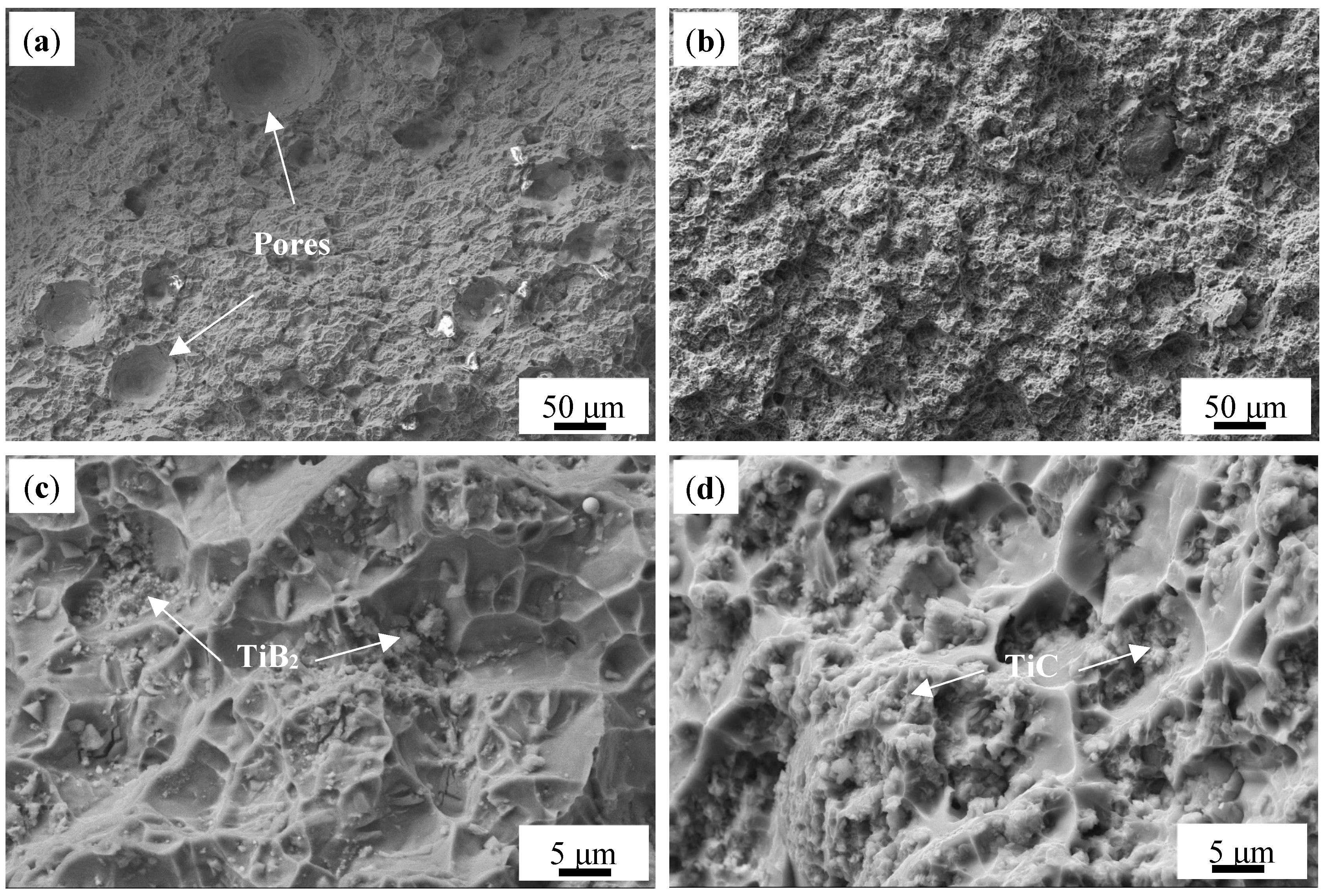

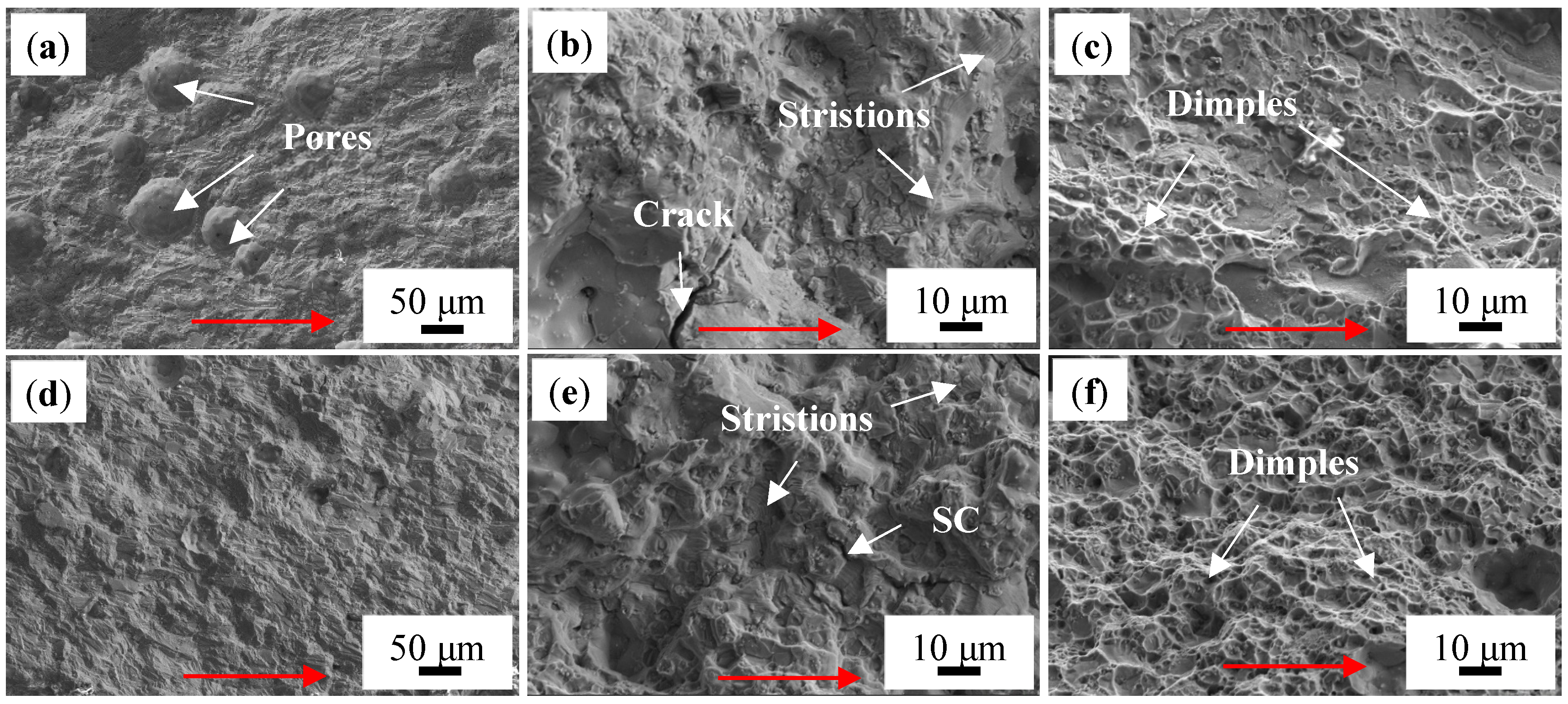

3.4. Fracture Morphology

3.5. Fatigue Crack Propagation Behavior

4. Discussion

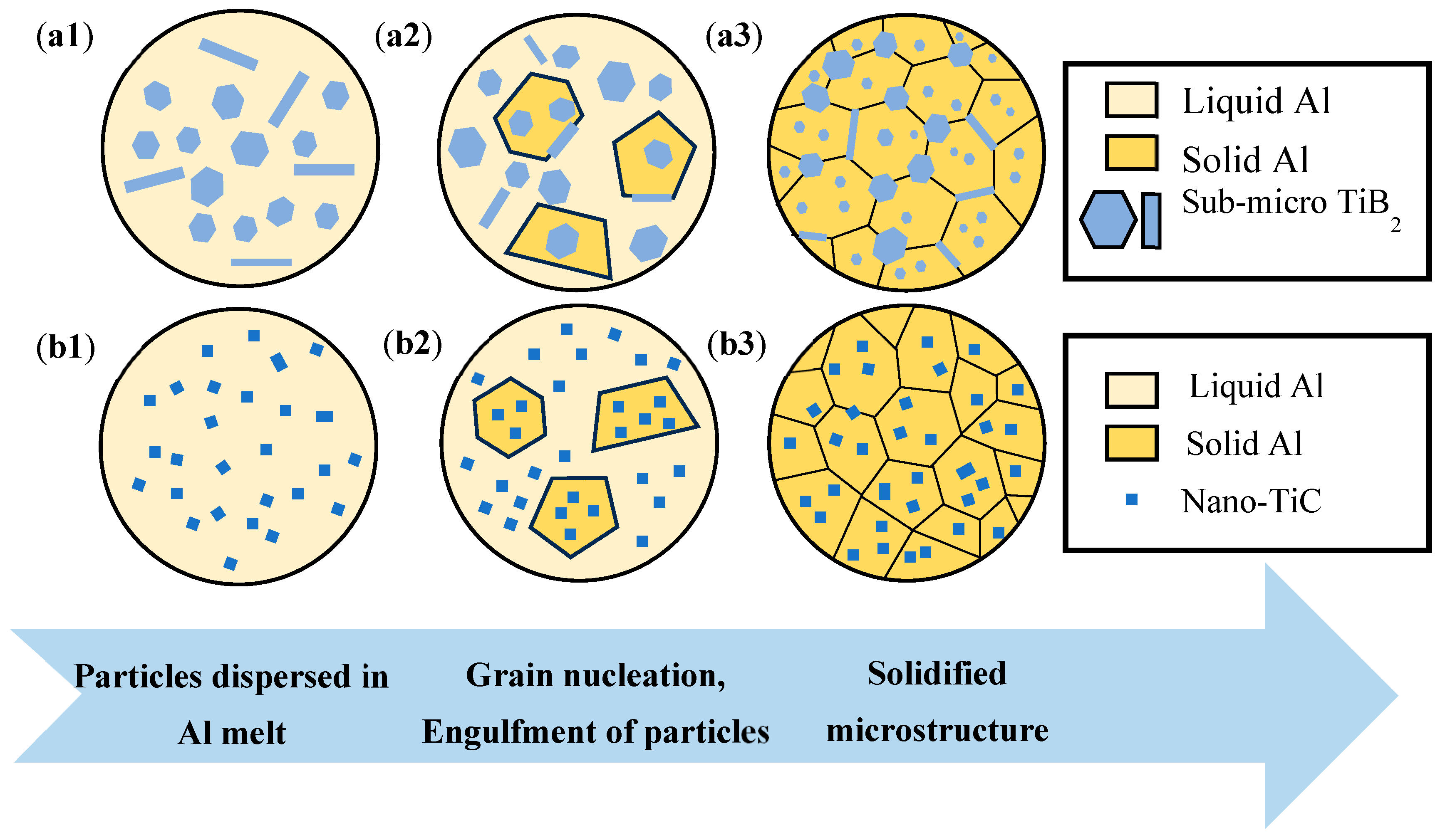

4.1. Comparison of the Grain Refinement Mechanism of the Alloys Modified by Two Different Particles

4.2. Comparison of the Strengthening Contributions of Two Different Particle-Modified Alloys

- i.

- Solid solution strengthening ()

- ii.

- Grain boundary strengthening ()

- iii.

- Dislocation strengthening ()

- iv.

- Precipitation strengthening ()

5. Conclusions

- (1)

- The modification of Al-Mg-Si alloys with both TiB2 and TiC particles completely suppressed the hot cracks that are found in commercial Al-Mg-Si alloys fabricated by WAAM due to the transformation from columnar grains to fine equiaxed grains with an average size of around 10 μm.

- (2)

- The UTS and YS of the AD-TB and AD-TC are similar, but the EL of the latter is higher due to its low porosity. Meanwhile, the UTS (353.7 ± 5.0 MPa) and YS (309.7 ± 1.9 MPa) of the T6-TC are significantly higher than those (300.8 ± 2.7 MPa and 256.2 ± 2.8 MPa, respectively) of the T6-TB.

- (3)

- The fatigue life of the T6-TB and the T6-TC are 4.14 × 104 cycles and 9.05 × 104 cycles, respectively. The fatigue resistance of the T6-TC is better than that of the T6-TB due to its lower porosity and more uniform distribution of TiC particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarıkaya, M.; Başcıl Önler, D.; Dağlı, S.; Hartomacıoğlu, S.; Günay, M.; Królczyk, G.M. A review on aluminum alloys produced by wire arc additive manufacturing (WAAM): Applications, benefits, challenges and future trends. J. Mater. Res. Technol. 2024, 33, 5643–5670. [Google Scholar] [CrossRef]

- Zhan, T.; Xu, K.; Fan, Z.; Xiang, H.; Xu, C.; Mei, T.; Wei, Y.; Chen, W.; Li, L. Assessment of the effect of the process-induced porosity defects on the fatigue properties of wire arc additive manufactured Al–Si–Mg alloy. J. Mater. Res. Technol. 2025, 35, 777–791. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Srinivasan, D.; Sevvel, P.; John Solomon, I.; Tanushkumaar, P. A review on Cold Metal Transfer (CMT) technology of welding. Mater. Today Proc. 2022, 64, 108–115. [Google Scholar] [CrossRef]

- Laleh, M.; Sadeghi, E.; Revilla, R.I.; Chao, Q.; Haghdadi, N.; Hughes, A.E.; Xu, W.; De Graeve, I.; Qian, M.; Gibson, I.; et al. Heat treatment for metal additive manufacturing. Prog. Mater. Sci. 2023, 133, 101051. [Google Scholar] [CrossRef]

- Ren, G.; Zheng, Y.; Xiong, R.; Zhao, C.; Wang, T.; Li, L. Effect of heat treatment on microstructure and corrosion behavior of Al Cu alloy fabricated by wire arc additive manufacturing. Mater. Charact. 2024, 218, 114516. [Google Scholar] [CrossRef]

- Prabu, G.; Jeyaprakash, N.; Yang, C.-H.; Radhika, N. Analysis on the transformation of melt wear to self-healing crack of wire arc additive manufactured Al 5356 alloy. Tribol. Int. 2023, 188, 108802. [Google Scholar] [CrossRef]

- Gao, C.; Xie, H.; Huang, H.; Chen, J.; Hu, L.; Guo, L.; Yin, X. Effect of trace Sc addition on microstructure, mechanical and stress corrosion cracking properties of Al-Mg alloys fabricated by Wire Arc Additive Manufacturing (WAAM). J. Alloys Compd. 2025, 1021, 179575. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, P.; Pang, C.; Liu, Q.; Li, S.; Li, J. Microstructure and Mechanical Properties of a High-Ductility Al-Zn-Mg-Cu Aluminum Alloy Fabricated by Wire and Arc Additive Manufacturing. J. Mater. Eng. Perform. 2022, 31, 6459–6472. [Google Scholar] [CrossRef]

- Xiao, F.; Zhang, H.; Kong, L.; Zheng, Y.; Hu, X. Effect of pH on corrosion behavior of Al-Mg-Si alloy in NaCl solution. Int. J. Electrochem. Sci. 2022, 17, 221162. [Google Scholar] [CrossRef]

- Hagenlocher, C.; Weller, D.; Weber, R.; Graf, T. Reduction of the hot cracking susceptibility of laser beam welds in AlMgSi alloys by increasing the number of grain boundaries. Sci. Technol. Weld. Join. 2019, 24, 313–319. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Li, Z.; Cao, P.; Yuan, T.; Zhu, H. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: Crack-inhibiting and multiple strengthening mechanisms. Acta Mater. 2020, 193, 83–98. [Google Scholar] [CrossRef]

- Benoit, M.J.; Whitney, M.A.; Zhu, S.M.; Zhang, D.; Field, M.R.; Easton, M.A. The beneficial effect of minor iron additions on the crack susceptibility of rapidly solidified aluminum alloy 6060 toward additive manufacturing applications. Mater. Charact. 2023, 205, 113287. [Google Scholar] [CrossRef]

- Soysal, T.; Kou, S. Effect of filler metals on solidification cracking susceptibility of Al alloys 2024 and 6061. J. Mater. Process. Technol. 2019, 266, 421–428. [Google Scholar] [CrossRef]

- Deng, S.; Zhao, H.; Li, R.; Shao, J.; Li, J.; Qi, L.; Ojo, O.A.; Chen, J.; Zhang, L.; Li, W. Composition design of low hot-cracking susceptibility of Al-Zn-Mg-Sc alloy and its formability during laser additive manufacturing. Mater. Charact. 2022, 193, 112304. [Google Scholar] [CrossRef]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Liu, J.; Kou, S. Crack susceptibility of binary aluminum alloys during solidification. Acta Mater. 2016, 110, 84–94. [Google Scholar] [CrossRef]

- Dong, M.-y.; Zhao, Y.; Li, Q.; Wang, F.-d.; Wu, A.-p. Effects of Cd addition in welding wires on microstructure and mechanical property of wire and arc additively manufactured Al−Cu alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 750–764. [Google Scholar] [CrossRef]

- Fan, Z.; Li, C.; Yang, H.; Liu, Z. Effects of TiC nanoparticle inoculation on the hot-tearing cracks and grain refinement of additively-manufactured AA2024 Al alloys. J. Mater. Res. Technol. 2022, 19, 194–207. [Google Scholar] [CrossRef]

- Yuan, T.; Ren, X.; Chen, S.; Jiang, X. Grain refinement and property improvements of Al–Zn–Mg–Cu alloy by heterogeneous particle addition during wire and arc additive manufacturing. J. Mater. Res. Technol. 2022, 16, 824–839. [Google Scholar] [CrossRef]

- Klein, T.; Arnoldt, A.; Lahnsteiner, R.; Schnall, M. Microstructure and mechanical properties of a structurally refined Al–Mg–Si alloy for wire-arc additive manufacturing. Mater. Sci. Eng. A 2022, 830, 142318. [Google Scholar] [CrossRef]

- Doumenc, G.; Couturier, L.; Courant, B.; Paillard, P.; Benoit, A.; Gautron, E.; Girault, B.; Pirling, T.; Cabeza, S.; Gloaguen, D. Investigation of microstructure, hardness and residual stresses of wire and arc additive manufactured 6061 aluminium alloy. Materialia 2022, 25, 101520. [Google Scholar] [CrossRef]

- Ma, C.; Yan, Y.; Yan, Z.; Liu, Y.; Wu, X.; Li, D.; Zhang, M.; Liu, P.; Jin, H. Efficient manufacturing of Al–Mg alloys using controlled low heat input wire and arc additive manufacturing. J. Mater. Process. Technol. 2023, 314, 117899. [Google Scholar] [CrossRef]

- Guo, G.; Wei, J.; Wu, G.; Kang, C.; He, C. Achieving high strength and fatigue performance of wire-arc additive manufactured 6061 aluminum alloy via interlayer friction stir processing and heat treatment. Mater. Lett. 2024, 370, 136844. [Google Scholar] [CrossRef]

- GB/T 4340.1-2024; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. Standardization Administration of China: Beijing, China, 2024.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Test Methods at Room Temperature. Standardization Administration of China: Beijing, China, 2021.

- Qi, Y.; Zhang, H.; Zhu, J.; Nie, X.; Hu, Z.; Zhu, H.; Zeng, X. Mechanical behavior and microstructure evolution of Al-Cu-Mg alloy produced by laser powder bed fusion: Effect of heat treatment. Mater. Charact. 2020, 165, 110364. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, S.; Li, D.; Tang, H.; Dong, T.; Lin, Y. Effect of Er addition on the microstructure, mechanical properties and corrosion behaviour of Al-Zn-Mg-Cu alloy manufactured by laser powder bed fusion. Mater. Today Commun. 2024, 40, 109547. [Google Scholar] [CrossRef]

- Zhao, N.; Ma, H.; Hu, Z.; Yan, Y.; Chen, T. Microstructure and mechanical properties of Al-Mg-Si alloy during solution heat treatment and forging integrated forming process. Mater. Charact. 2022, 185, 111762. [Google Scholar] [CrossRef]

- Li, D.; Li, S.; Zhang, Z.; Chen, J.; Zhang, Y.; Yang, J.; Li, W.; Li, Y.; Ojo, O.A. Regulate the microstructure, tensile properties and fatigue crack growth behavior of an Al–Zn–Mg–Cu alloys fabricated by laser powder bed fusion via post-heat treatment. J. Mater. Res. Technol. 2023, 27, 6947–6960. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, H.; Li, S.; Zhao, H.; Chen, J.; Qi, L. Microstructure, mechanical properties and fatigue crack growth behavior of friction stir welded joint of 6061-T6 aluminum alloy. Int. J. Fatigue 2020, 135, 105556. [Google Scholar] [CrossRef]

- Miao, J.; Chen, J.; Ting, X.; Hu, W.; Ren, J.; Li, T.; Zeng, L.; Guan, R.; Ojo, O.A. Effect of solution treatment on porosity, tensile properties and fatigue resistance of Al–Cu alloy fabricated by wire arc additive manufacturing. J. Mater. Res. Technol. 2024, 28, 1864–1874. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, Q.; Jiang, H.-x.; Liu, C.; Cao, L.-f. Micro porosity and its effect on fatigue performance of 7050 aluminum thick plates. J. Cent. South Univ. 2022, 29, 912–923. [Google Scholar] [CrossRef]

- Tang, D.; He, X.; Wu, B.; Wang, X.; Wang, T.; Li, Y. The effect of porosity defects on the mid-cycle fatigue behavior of directed energy deposited Ti-6Al-4V. Theor. Appl. Fract. Mech. 2022, 119, 103322. [Google Scholar] [CrossRef]

- Geng, R.; Jia, S.-Q.; Qiu, F.; Zhao, Q.-L.; Jiang, Q.-C. Effects of nanosized TiC and TiB2 particles on the corrosion behavior of Al-Mg-Si alloy. Corros. Sci. 2020, 167, 108479. [Google Scholar] [CrossRef]

- Zhou, L.; Gao, F.; Peng, G.S.; Alba-Baena, N. Effect of potent TiB2 addition levels and impurities on the grain refinement of Al. J. Alloys Compd. 2016, 689, 401–407. [Google Scholar] [CrossRef]

- Gu, M.; Chen, J.; Luo, Z.; Ren, J.; Zhong, S.; Li, T.; Zeng, L. Scalable manufacturing of the Al-based master composites containing TiB2 and TiC particles and their modification effect on the hot cracking of rapidly solidified Al alloys. Mater. Today Commun. 2023, 37, 107142. [Google Scholar] [CrossRef]

- Wu, K.; Jeppsson, J.; Mason, P. Mean Field Modeling of Grain Growth and Zener Pinning. J. Phase Equilibria Diffus. 2022, 43, 866–875. [Google Scholar] [CrossRef]

- Wang, H.; Li, B.; Li, Y.; Yu, W.; Wang, Y.; Lu, B.; Li, J.; Xu, G. Effect of nano-TiC/TiB2 on recrystallization, texture and mechanical properties of Al–Cu–Li alloy during solid-solution treatment. J. Mater. Res. Technol. 2023, 27, 372–385. [Google Scholar] [CrossRef]

- Jin, S.; Shen, P.; Lin, Q.; Zhan, L.; Jiang, Q. Growth Mechanism of TiCx during Self-Propagating High-Temperature Synthesis in an Al−Ti−C System. Cryst. Growth Des. 2010, 10, 1590–1597. [Google Scholar] [CrossRef]

- Sokoluk, M.; Cao, C.; Pan, S.; Li, X. Nanoparticle-enabled phase control for arc welding of unweldable aluminum alloy 7075. Nat. Commun. 2019, 10, 98. [Google Scholar] [CrossRef]

- Xi, H.; Xiao, W.; Li, H.; Fu, Y.; Yi, G.; Qie, J.; Ma, X.; Ma, C. Effects of submicron-sized TiC particles on the microstructure modification and mechanical properties of Al-Si-Mg alloy. J. Alloys Compd. 2023, 968, 171963. [Google Scholar] [CrossRef]

- Sun, J.e.; Wen, Y.; Wang, Z.; Zhang, J.; Wang, L.; Qu, X.; Zhang, B. Effect of lithium anti-ablation and grain refinement introduced by TiC nanoparticles in LPBF Al–Li alloy. J. Mater. Res. Technol. 2023, 27, 3473–3486. [Google Scholar] [CrossRef]

- Chen, F.; Yang, Y.; Chen, C.; Wang, Q.; Xie, R. Effect of La2O3 particle size on the microstructure and properties of Al Si alloys deposited via wire arc additive manufacturing. J. Manuf. Process. 2021, 68, 523–533. [Google Scholar] [CrossRef]

- Greer, A.L.; Bunn, A.M.; Tronche, A.; Evans, P.V.; Bristow, D.J. Modelling of inoculation of metallic melts: Application to grain refinement of aluminium by Al-Ti-B. Acta Mater. 2000, 48, 2823–2835. [Google Scholar] [CrossRef]

- Ma, S.; Li, Y.; Kan, W.; Zhang, J. Enhancement of grain refinement and heat resistance in TiB2-reinforced Al-Cu-Mg-Fe-Ni matrix composite additive manufactured by electron beam melting. J. Alloys Compd. 2022, 924, 166395. [Google Scholar] [CrossRef]

- Xu, S.; Lei, D.; Yang, X.; Lu, X.; Chen, J.; Li, M.V. Wire arc additive manufacturing of components using TiC/Ti reinforced Al-Zn-Mg-Cu alloy wire: Microstructure evolution, strengthening mechanism, and fracture behavior. Mater. Charact. 2024, 217, 114452. [Google Scholar] [CrossRef]

- Zeng, C.; Cai, X.; Qi, Z.; Tan, Z.; Wang, H.; Peng, Y.; Guo, W.; Qi, B.; Cong, B. Effect of in-situ synthesized TiC particles on microstructure and mechanical properties of directed energy deposited AA2219 Al-Cu alloy. J. Alloys Compd. 2023, 964, 171331. [Google Scholar] [CrossRef]

- Chen, J.; Li, S.; Cong, H.; Yin, Z. Microstructure and Mechanical Behavior of Friction Stir-Welded Sc-Modified Al-Zn-Mg Alloys Made Using Different Base Metal Tempers. J. Mater. Eng. Perform. 2019, 28, 916–925. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Andersen, S.J. Modelling of the age hardening behaviour of Al–Mg–Si alloys. Acta Mater. 2001, 49, 65–75. [Google Scholar] [CrossRef]

- Li, D.; Li, S.; Chen, J.; Zhang, Z.; Tang, H. A novel Al-Zn-Mg-Cu-Si-Zr-Er alloy fabricated by laser powder bed fusion. Mater. Charact. 2024, 214, 114129. [Google Scholar] [CrossRef]

- Yi, X.; Bai, S.; Liu, Z. Effects of small pre-stretching on the microstructural evolution and strengthening of an Al–Cu–Mg–Ag alloy. J. Mater. Res. Technol. 2023, 26, 1214–1237. [Google Scholar] [CrossRef]

- Chen, J.; Wen, F.; Liu, C.; Li, W.; Zhou, Q.; Zhu, W.; Zhang, Y.; Guan, R. The microstructure and property of Al–Si alloy improved by the Sc-microalloying and Y2O3 nano-particles. Sci. Technol. Adv. Mater. 2021, 22, 205–217. [Google Scholar] [CrossRef]

| Alloys | Mg | Si | Cu | Fe | Cr | Ti | B | C | Al |

|---|---|---|---|---|---|---|---|---|---|

| Al-Mg-Si | 1.1 | 0.6 | 0.25 | 0.14 | 0.15 | / | / | / | Bal. |

| TB | 1.1 | 0.6 | 0.25 | 0.14 | 0.15 | 0.87 | 0.39 | / | Bal. |

| TC | 1.1 | 0.6 | 0.25 | 0.14 | 0.15 | 0.87 | / | 0.22 | Bal. |

| Designation | WAAM Deposition Parameters |

|---|---|

| Wire feed speed (m/min) | 6.5 |

| Current (A) | 144 |

| Voltage (V) | 18 |

| Shileding gas flow rate (L/min) | 25 |

| Filling speed (mm/s) | 10 |

| Alloys | Ultimate Tensile Strength Rm /MPa(Stedv) | Yield Strength RP0.2/MPa (Stedv) | Elongation A5/(%) (Stedv) |

|---|---|---|---|

| Al-0.48Mg-0.54Si-0.25Ti-0.04B [21] | 283.5 ± 2.6 | 262.8 ± 1.7 | 5.9 ± 0.8 |

| Al-0.87Mg-1.05Si [22] | 344 ± 43 | 189 ± 38 | / |

| Al-0.96Mg-0.58Si-0.23Cu-0.02Fe [24] | 336 | 314 | 13 |

| T6-TB (this work) | 300.8 ± 2.7 | 256.2 ± 2.8 | 8.2 ± 0.4 |

| T6-TC (this work) | 353.7 ± 2.7 | 309.7 ± 1.9 | 5.3 ± 0.4 |

| Samples | C | m | R | ΔKth |

|---|---|---|---|---|

| T6-TB | 7.943 × 10−10 | 4.75746 | 0.926 | 2.76 |

| T6-TC | 1.245 × 10−11 | 6.20116 | 0.934 | 4.262 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Chen, J.; Zeng, L.; Tuo, Z.; Ren, J.; Zheng, Z.; Wu, H. Microstructure and Mechanical Properties of TiB2/TiC Particle Modified Al-Mg-Si Alloys Fabricated by Wire-Arc Additive Manufacturing. Materials 2025, 18, 1978. https://doi.org/10.3390/ma18091978

Li T, Chen J, Zeng L, Tuo Z, Ren J, Zheng Z, Wu H. Microstructure and Mechanical Properties of TiB2/TiC Particle Modified Al-Mg-Si Alloys Fabricated by Wire-Arc Additive Manufacturing. Materials. 2025; 18(9):1978. https://doi.org/10.3390/ma18091978

Chicago/Turabian StyleLi, Tao, Jiqiang Chen, Lingpeng Zeng, Zhanglong Tuo, Jieke Ren, Zuming Zheng, and Hanlin Wu. 2025. "Microstructure and Mechanical Properties of TiB2/TiC Particle Modified Al-Mg-Si Alloys Fabricated by Wire-Arc Additive Manufacturing" Materials 18, no. 9: 1978. https://doi.org/10.3390/ma18091978

APA StyleLi, T., Chen, J., Zeng, L., Tuo, Z., Ren, J., Zheng, Z., & Wu, H. (2025). Microstructure and Mechanical Properties of TiB2/TiC Particle Modified Al-Mg-Si Alloys Fabricated by Wire-Arc Additive Manufacturing. Materials, 18(9), 1978. https://doi.org/10.3390/ma18091978