Mechanical Performance and Bond Integrity of Finger Jointed High-Density Sub-Tropical Hardwoods for Residential Decking

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacture

2.3. Conditioning and Treatment

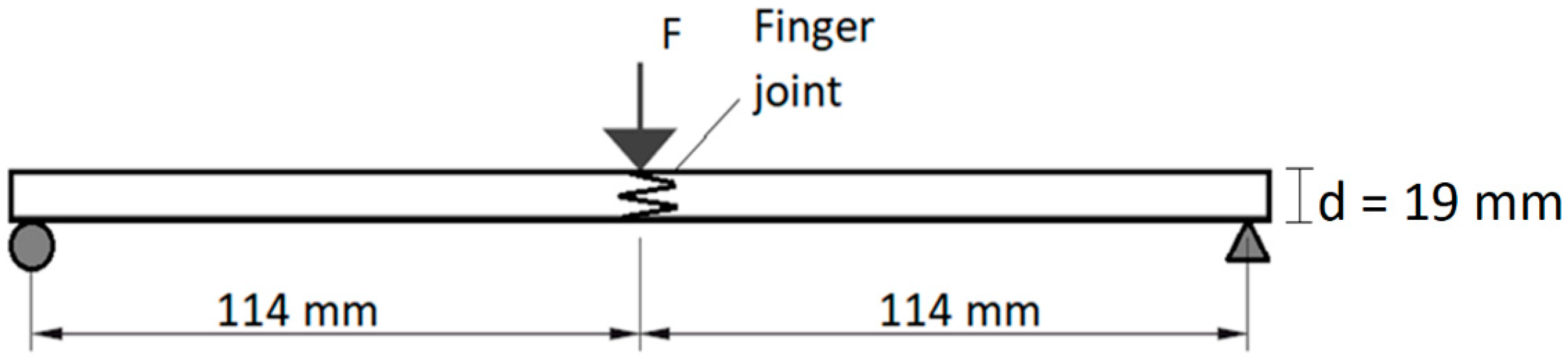

2.4. Bending Strength (MOR) and Stiffness (MOE) Testing

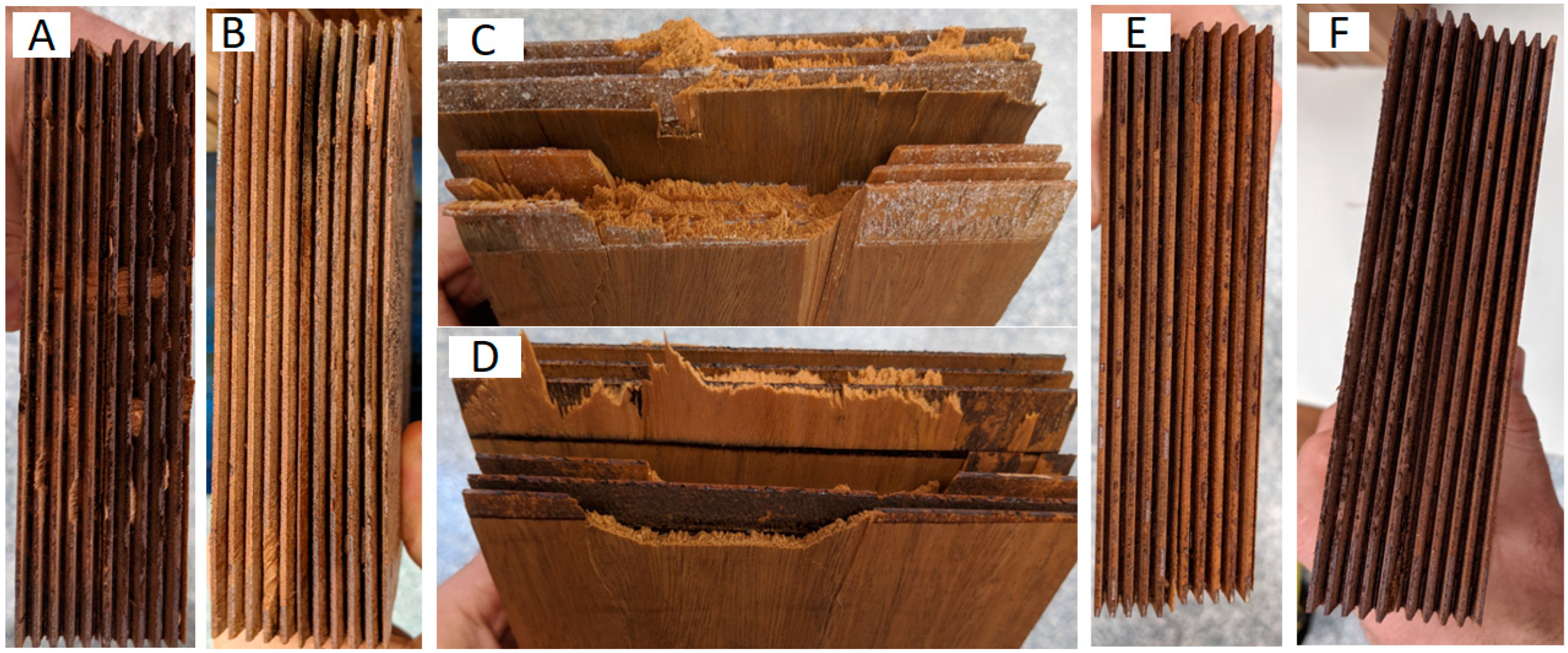

2.5. Wood Fibre Amount (WFA)

2.6. Analysis of Results

3. Results and Discussion

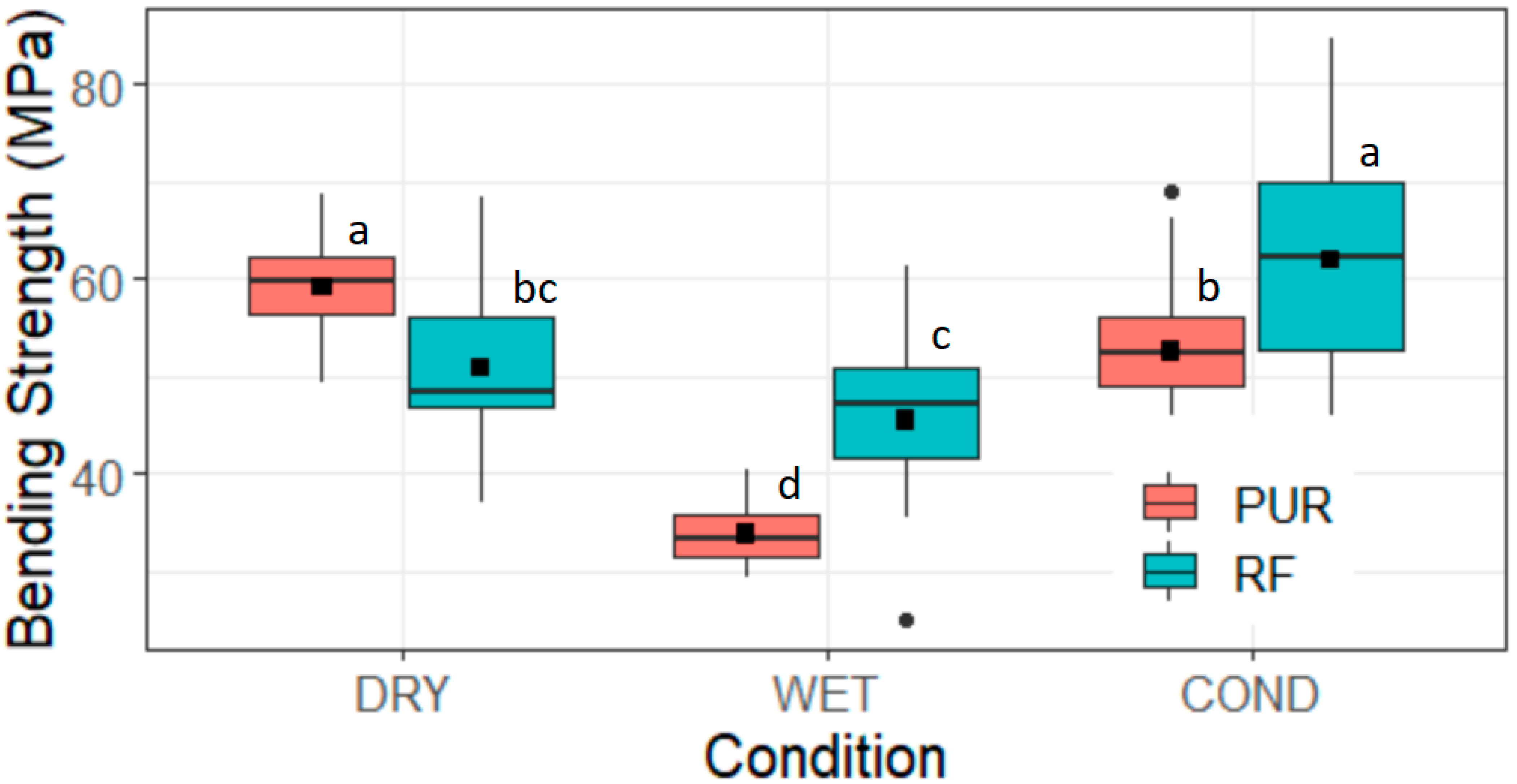

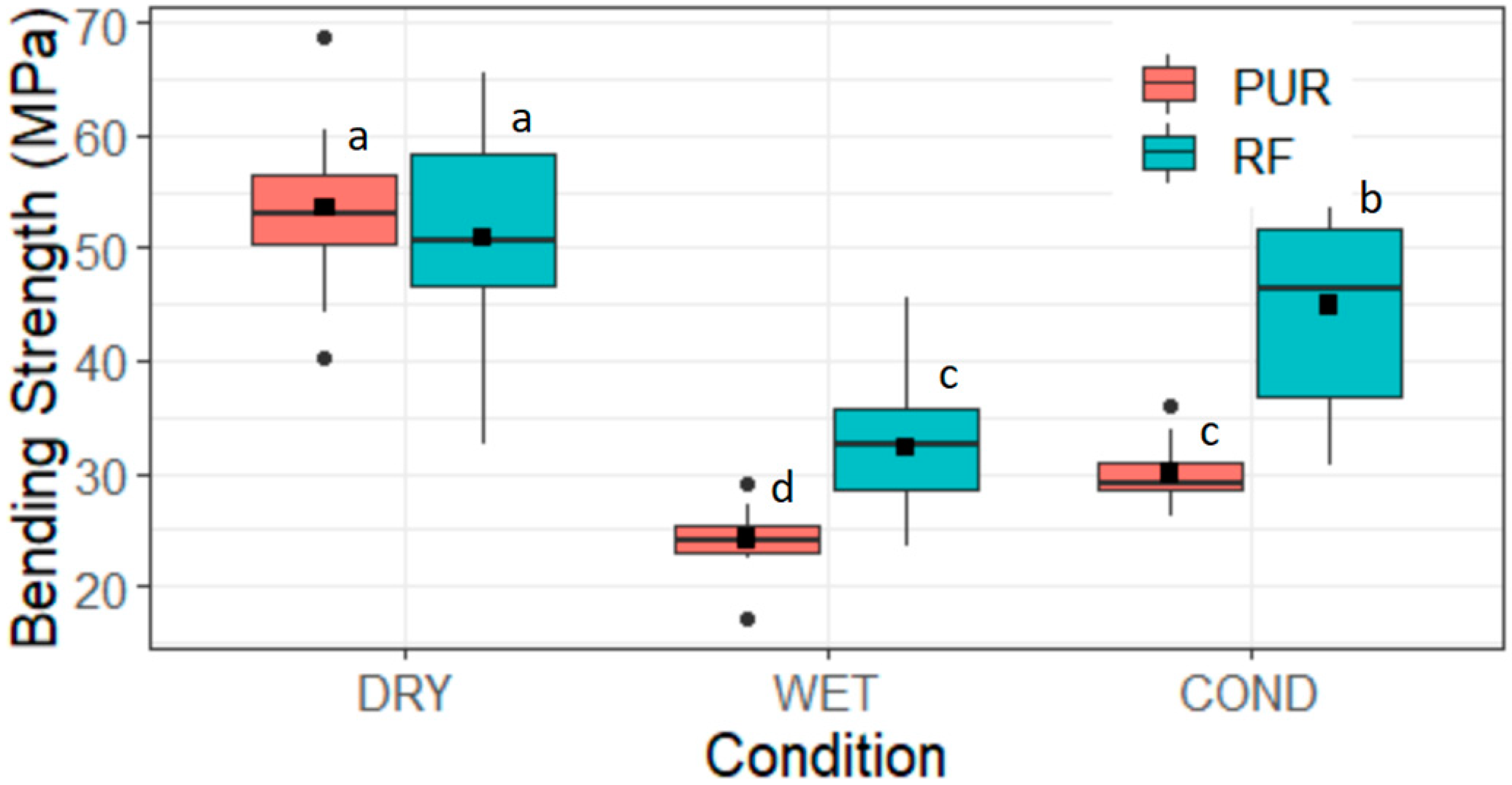

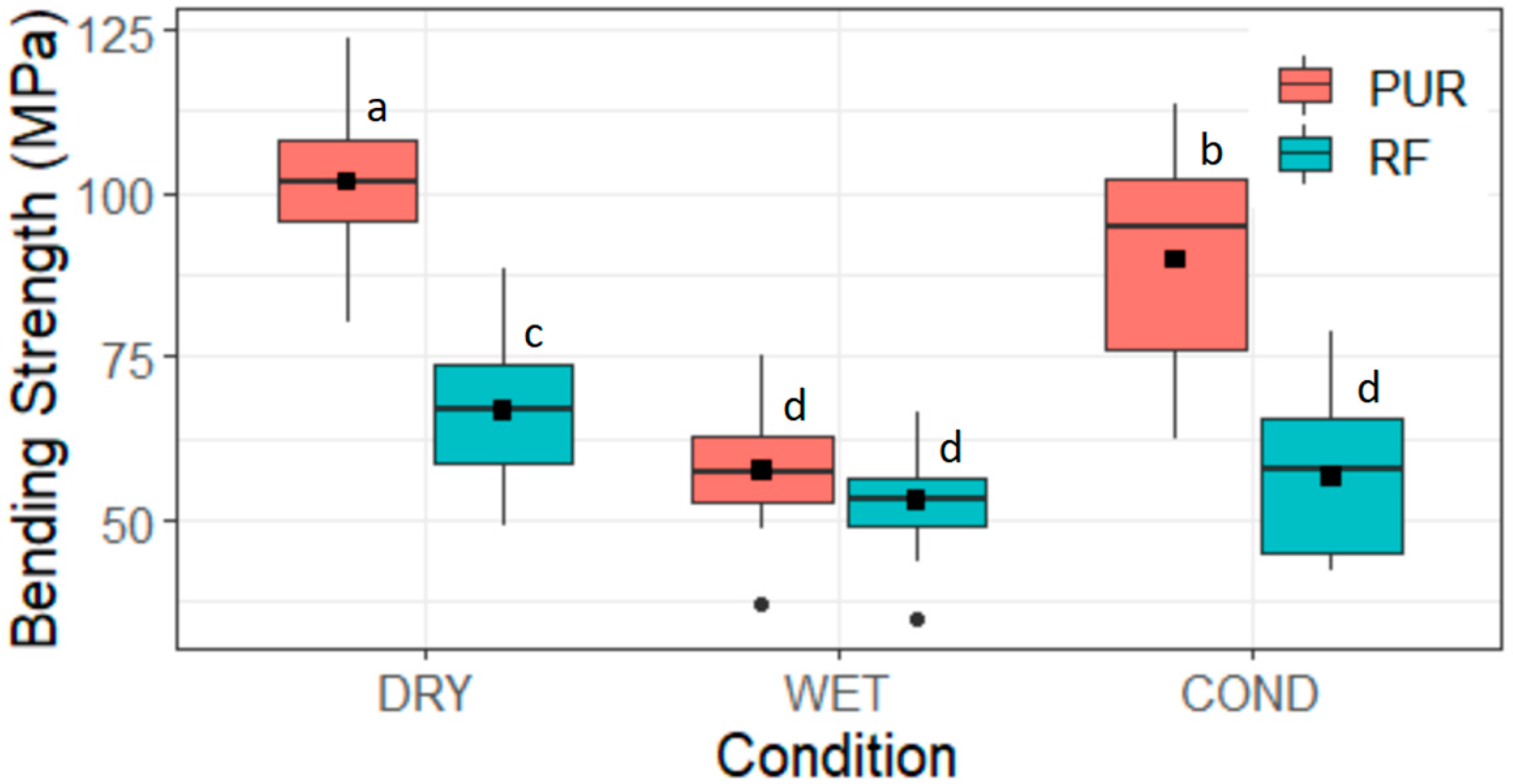

3.1. Bending Strength

- On the impact of FJ length, the 20 mm PUR DRY samples produced a significantly higher mean MOR value (p-value < 2.2 × 10−12) with an increase of 43% (SPG) and 47% (DSK) when compared to the 10 mm FJs. FJ length had a similar impact on the RF DRY samples with a mean MOR increase of 29% (SPG) and 24% (DSK) for the 20 mm joints when compared to the 10 mm. This observation was consistent across all testing conditions for the two species, adhesives, and joint types.

- The 20 mm PUR FJs produced significantly higher MOR values (p-value < 2.0 × 10−16) with an increase of 34% and 19% (DSK) and 37% and 15% (SPG) for both DRY and COND, respectively, when compared with corresponding RF samples. The 10 mm PUR DRY results produced slight increases in MOR compared to RF DRY samples for SPG. The same comparison for PUR and RF DRY samples for DSK produced no significant difference (p-value > 0.05) for the 10 mm FJs. The 10 mm RF COND samples produced higher (p-value < 0.001) MOR values with an increase of 5% and 33% (DSK) and 14% and 15% (SPG) when compared to PUR COND.

- In all treatment conditions, with the exception of the 20 mm DSK FJ, the variation in the distribution plots is lower for the PUR samples when compared to RF.

- The impact of the COND phase of testing was measured by comparing the reversal in MOR loss from the WET phase. The reversal was largest for the PUR samples with SPG presenting a 36% and 42% (10 and 20 mm) increase and DSK presenting a 19 and 36% (10 and 20 mm) increase. RF samples showed a minimal reversal in MOR loss for the 10 mm FJs (for both SPG and DSK) and no significant difference in MOR for the 20 mm FJs.

3.2. Bending Stiffness (MOE) Results

3.3. Wood Fibre Amount (WFA) Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bootle, K. Wood in Australia; McGraw-Hill Book Company: Sydney, Australia, 1983; Volume 1, p. 443. [Google Scholar]

- Jokerst, R.W. Finger-Jointed Wood Products; Forest Products Laboratory—USDA Forest Services: Madison, WI, USA, 1981; pp. 1–24.

- Serrano, E.; Gustafsson, J.; Larsen, H. Modelling of finger-joint failure in glued-laminated timber beams. J. Struct. Eng. 2001, 127, 914–921. [Google Scholar] [CrossRef]

- Milner, H.; Yeoh, E. Finite element analysis of glued timber finger joints. J. Struct. Eng. 1991, 117, 755–766. [Google Scholar] [CrossRef]

- Smardzewski, J. Distribution of stresses in finger joints. Wood Sci. Technol. 1996, 30, 477–489. [Google Scholar] [CrossRef]

- Lara-Bocanegra, A.; Majano-Majano, A.; Crespo, J.; Guaita, M. Finger-jointed Eucalyptus globulus with 1C-PUR adhesive for high performance engineered laminated products. Constr. Build. Mater. 2017, 135, 529–537. [Google Scholar] [CrossRef]

- Ahmad, Z.; Lum, W.; Lee, S.; Razlan, M.; Mohamad, W. Mechanical properties of finger jointed beams fabricated from eight Malaysian hardwood species. Constr. Build. Mater. 2017, 145, 464–473. [Google Scholar] [CrossRef]

- Rao, S.; Gong, M.; Chui, Y.H.; Mohammad, M. Effect of Geometric Parameters of Finger Joint Profile on Ultimate Tensile Strength of Single Finger-Jointed Boards. Wood Fiber Sci. 2012, 44, 263–270. [Google Scholar]

- Kretschmann, D.E. Wood Handbook—Mechanical Properties of Wood; Forest Products Laboratory—USDA Forest Services: Madison, WI, USA, 2010; pp. 100–145.

- Ayarkwa, J.; Hirashima, Y.; Sasaki, Y. Effect of finger geometry and end pressure on the flexural properties of finger-jointed tropical african hardwoods. For. Prod. J. 2000, 50, 53–63. [Google Scholar]

- Habipi, B.; Ajdinaj, D. Wood Finger-Joint Strength as Function of Finger Length and Slope Positioning of Tips. Int. J. Eng. Appl. Sci. (IJEAS) 2015, 2, 128–132. [Google Scholar]

- Sterley, M.; Serrano, E.; Enquist, B.; Hornatowska, J. Finger jointing of freshly sawn Norway spruce side boards—A comparative study of fracture properties of joints glued with phenol-resorcinol and one-component polyurethane adhesive. In Materials and Joints in Timber Structures; RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2014; Volume 9. [Google Scholar]

- Dziurka, D.; Kulinski, M.; Trocinski, A.; Radoslaw, M. Posibility to use short sawn timber in the product of glued laminated beams. Materials 2022, 15, 2992. [Google Scholar] [CrossRef]

- AS/NZS8008; Timber—Finger-Jointed Structural Timber—Performance Requirements. Standards Australia/Standards New Zealand: Sydney, Australia, 2022.

- AS5068; Timber—Finger Joints in Structural Products—Production Requirements. Standards Australia: Sydney, Australia, 2006.

- Leggate, W.; McGavin, R.; Outhwaite, A.; Gilbert, B.; Gunalan, S. Barriers to the Effective Adhesion of High-Density Hardwood Timbers for Glue-Laminated Beams in Australia. Forests 2022, 13, 1038. [Google Scholar] [CrossRef]

- Leggate, W.; McGavin, R.; Miao, C.; Outhwaite, A.; Chandra, K.; Dorries, J.; Kumar, C.; Knackstedt, M. The influence of mechanical surface preparation methods on southern pine and spotted gum wood properties: Wettability and permeability. BioResources 2020, 15, 8554–8576. [Google Scholar] [CrossRef]

- Leggate, W.; McGavin, R.; Outhwaite, A.; Kumar, C.; Faircloth, A.; Knackstedt, M. Influence of mechanical surface preparation methods on the bonding of southern pine and spotted gum: Tensile shear strength of lap joints. BioResources 2021, 16, 46–61. [Google Scholar] [CrossRef]

- Klausler, O.; Rehm, K.; Elstermann, F.; Niemz, P. Influence of wood machining on tensile shear strength and wood failure percentage of one-component polyurethane bonded wooden joints after wetting. Int. Wood Prod. J. 2013, 5, 18–26. [Google Scholar] [CrossRef]

- Serrano, E. Adhesive Joints in Timber Engineering. Modelling and Testing of Fracture Properties. Ph.D. Thesis, Lund University, Lund, Sweden, 2000. [Google Scholar]

- ASTMD4688; Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber. ASTM International: West Conshohocken, PA, USA, 2005.

- Muller, U.; Veigel, S.; Follrich, J.; Gabriel, J. Performance of One-Component Polyurethane in Comparison to Other Wood Adhesives. In Proceedings of the International Conference on Wood Adhesives 2009, Lake Tahoe, NV, USA, 28–30 September 2009. [Google Scholar]

- AS1720.1; Timber Structures—Design Methods. Standards Australia: Sydney, Australia, 2010.

- AS/NZS1328.1; Glued Laminated Structural Timber, Part 1, Performance Requirements and Minimum Production Requirements. Standards Australia/Standards New Zealand: Sydney, Australia, 1998.

- Klausler, O. Improvement of One-Component Polyurethane Bonded Wooden Joints Under Wet Conditions; ETH Zurich DISS ETH NO 22157; ETH Zurich: Zurich, Switzerland, 2014. [Google Scholar]

- AS/NZS4063.2; Characterisation of Structural Timber, Part 2, Determination of Characteristic Values. Standards Australia/Standards New Zealand: Sydney, Australia, 2010.

- AS/NZS4063.1; Characterisation of Structural Timber, Part 1, Test Methods. Standards Australia: Sydney, Australia, 2010.

| Species * | Joint Type | Adhesive | Test Condition | ||

|---|---|---|---|---|---|

| DRY | WET | COND | |||

| SPG | 10 mm | PUR | 15 | 15 | 15 |

| 20 mm | PUR | 15 | 15 | 15 | |

| 10 mm | RF | 15 | 15 | 15 | |

| 20 mm | RF | 15 | 15 | 15 | |

| DSK | 10 mm | PUR | 15 | 15 | 15 |

| 20 mm | PUR | 15 | 15 | 15 | |

| 10 mm | RF | 15 | 15 | 15 | |

| 20 mm | RF | 15 | 15 | 15 | |

| Finger Configurations | Values | |

|---|---|---|

| Cutter Size | 10 mm | 20 mm |

| Length (L)—mm | 7.77 | 17.91 |

| Pitch (p)—mm | 3.67 | 6.02 |

| Fingertip (b)—mm | 1.15 | 1.42 |

| Slope (s)—mm/mm | 0.088 (~1:12) | 0.089 (~1:12) |

| Properties | SPG | DSK | ||||||

|---|---|---|---|---|---|---|---|---|

| PUR | RF | PUR | RF | |||||

| 10 mm | 20 mm | 10 mm | 20 mm | 10 mm | 20 mm | 10 mm | 20 mm | |

| Dry Conditions (DRY) | ||||||||

| Mean (MPa) | 59.1 | 102.8 | 50.9 | 84.0 | 53.6 | 101.7 | 50.9 | 66.7 |

| COV (%) | 8.1 | 23.3 | 14.9 | 26.5 | 13.0 | 11.7 | 19.8 | 15.6 |

| Wet Conditions (WET) | ||||||||

| Mean (MPa) | 33.9 | 50.3 | 45.4 | 71.5 | 24.2 | 57.6 | 32.3 | 53.0 |

| COV (%) | 9.5 | 18.9 | 22.2 | 31.9 | 12.0 | 16.4 | 17.0 | 16.4 |

| Re-Dry Conditions (COND) | ||||||||

| Mean (MPa) | 52.6 | 86.1 | 61.9 | 73.1 | 30.0 | 89.5 | 44.9 | 56.8 |

| COV (%) | 17.8 | 11.3 | 22.7 | 35.2 | 8.5 | 18.5 | 22.7 | 21.2 |

| Properties | SPG | DSK | ||||||

|---|---|---|---|---|---|---|---|---|

| PUR | RF | PUR | RF | |||||

| 10 mm | 20 mm | 10 mm | 20 mm | 10 mm | 20 mm | 10 mm | 20 mm | |

| Dry Conditions (DRY) | ||||||||

| Mean (MPa) | 14,761 c | 15,750 b | 17,269 a | 16,909 a | 15,254 b | 16,718 a | 17,470 a | 17,304 a |

| COV (%) | 14% | 14% | 8% | 15% | 11% | 9% | 7% | 6% |

| Wet Conditions (WET) | ||||||||

| Mean (MPa) | 10,211 d | 13,311 c | 15,088 bc | 11,621 d | 13,447 c | 11,757 c | 11,307 d | 11,732 c |

| COV (%) | 25% | 14% | 16% | 18% | 8% | 22% | 24% | 11% |

| Re-Dry Conditions (COND) | ||||||||

| Mean (MPa) | 14,227 bc | 15,273 b | 16,586 ab | 16,356 ab | 15,243 b | 16,358 ab | 13,632 bc | 16,375 ab |

| COV (%) | 13% | 17% | 7% | 10% | 16% | 9% | 24% | 8% |

| Properties | SPG | DSK | ||||||

|---|---|---|---|---|---|---|---|---|

| PUR | RF | PUR | RF | |||||

| 10 mm | 20 mm | 10 mm | 20 mm | 10 mm | 20 mm | 10 mm | 20 mm | |

| Dry Conditions (DRY) | ||||||||

| Mean (%) | 2 | 6 | 36 | 15 | 6 | 33 | 45 | 24 |

| Maximum (%) | 10 | 25 | 70 | 35 | 20 | 60 | 60 | 70 |

| Wet Conditions (WET) | ||||||||

| Mean (%) | 0 | 5 | 7 | 15 | 0 | 18 | 2 | 17 |

| Maximum (%) | 5 | 5 | 25 | 50 | 0 | 50 | 5 | 80 |

| Re-Dry Conditions (COND) | ||||||||

| Mean (%) | 4 | 12 | 10 | 19 | 10 | 25 | 4 | 14 |

| Maximum (%) | 5 | 60 | 25 | 50 | 25 | 50 | 5 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faircloth, A.; Kumar, C.; McGavin, R.L.; Gilbert, B.P.; Leggate, W. Mechanical Performance and Bond Integrity of Finger Jointed High-Density Sub-Tropical Hardwoods for Residential Decking. Forests 2023, 14, 956. https://doi.org/10.3390/f14050956

Faircloth A, Kumar C, McGavin RL, Gilbert BP, Leggate W. Mechanical Performance and Bond Integrity of Finger Jointed High-Density Sub-Tropical Hardwoods for Residential Decking. Forests. 2023; 14(5):956. https://doi.org/10.3390/f14050956

Chicago/Turabian StyleFaircloth, Adam, Chandan Kumar, Robert L. McGavin, Benoit P. Gilbert, and William Leggate. 2023. "Mechanical Performance and Bond Integrity of Finger Jointed High-Density Sub-Tropical Hardwoods for Residential Decking" Forests 14, no. 5: 956. https://doi.org/10.3390/f14050956

APA StyleFaircloth, A., Kumar, C., McGavin, R. L., Gilbert, B. P., & Leggate, W. (2023). Mechanical Performance and Bond Integrity of Finger Jointed High-Density Sub-Tropical Hardwoods for Residential Decking. Forests, 14(5), 956. https://doi.org/10.3390/f14050956