A Novel Bamboo–Wood Composite Utilizing High-Utilization, Easy-to-Manufacture Bamboo Units: Optimization of Mechanical Properties and Bonding Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bamboo–Wood Composites

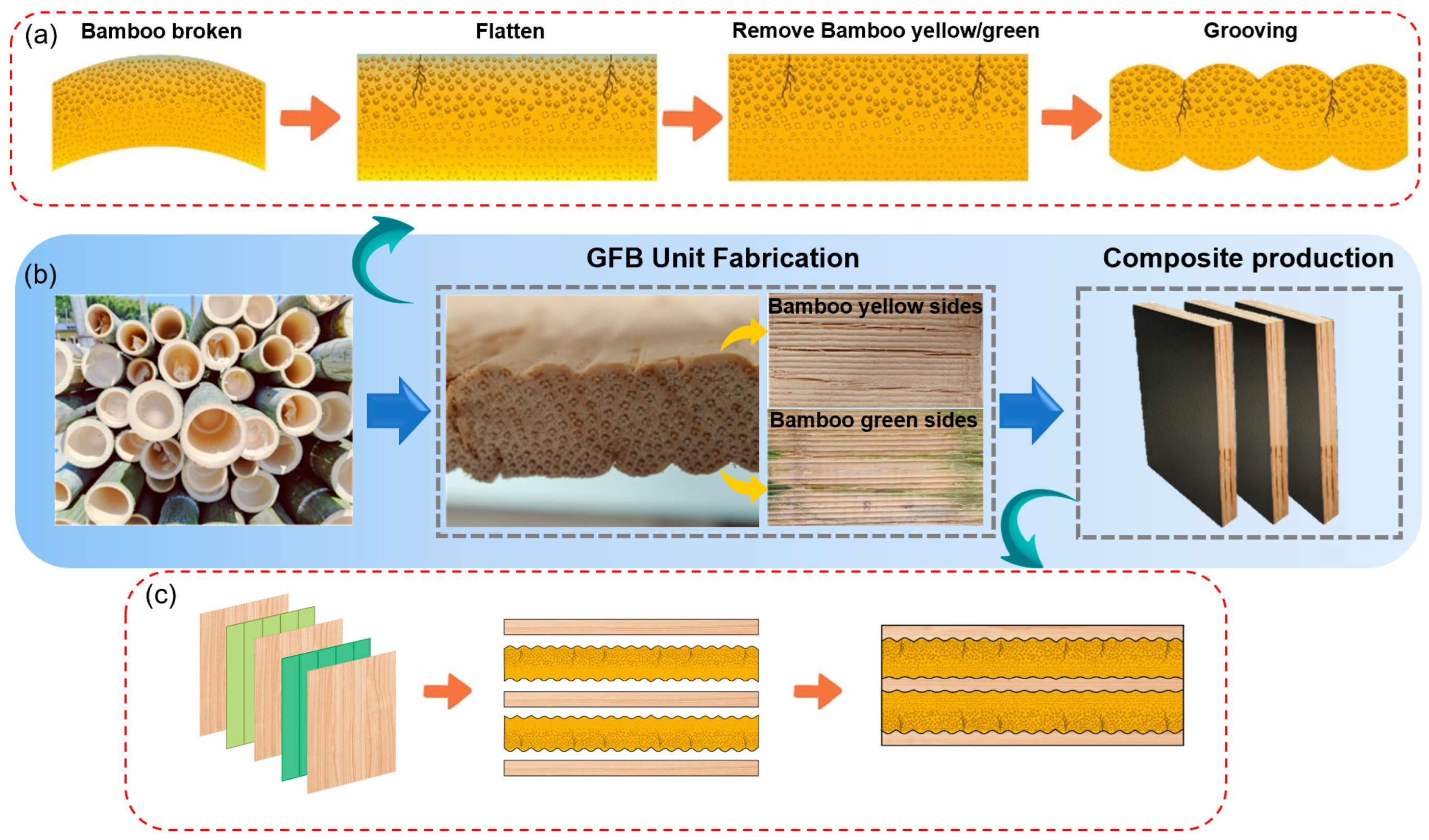

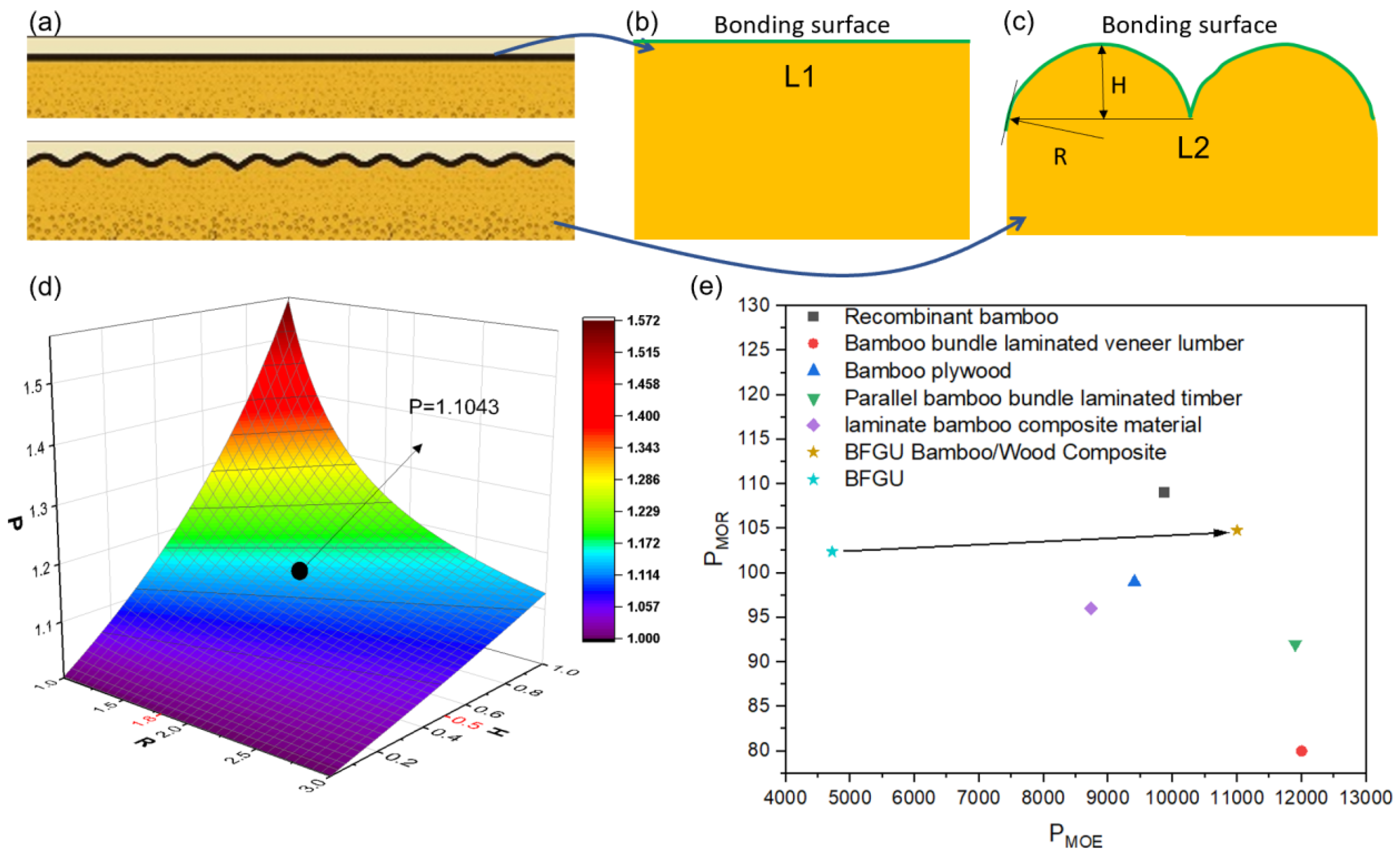

2.2.1. Preparation of Grooved-Flattened Bamboo (GFB) Units

2.2.2. Structural Design of Bamboo–Wood Composites

2.3. Optimization of Process Parameters for Bamboo–Wood Composite Production

2.4. The Tensile Shear Properties of Bamboo–Wood Composites

2.5. Bonding Interface and Mechanism

2.6. Penetration of Water

3. Results

3.1. Numerical Modeling and Effectiveness Assessment

3.2. Effects of Process Parameters on Responses

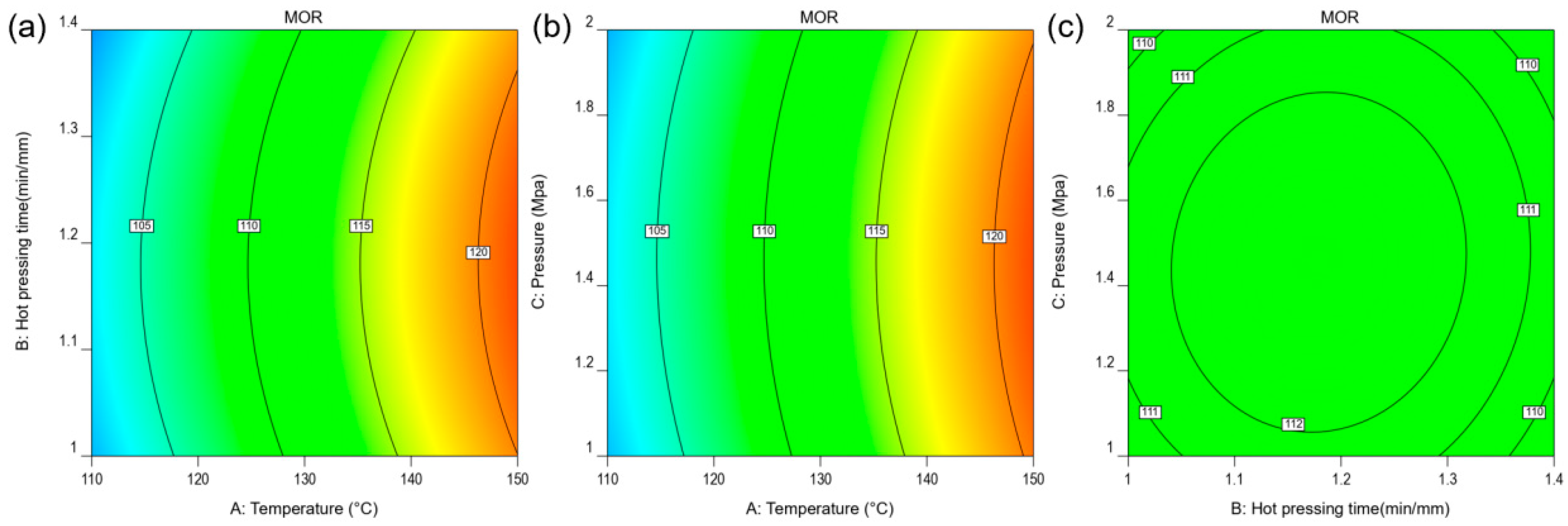

3.2.1. The Response of MOR

3.2.2. The Response of the MOE

3.2.3. Optimization and Verification of the Effects of the Process Parameters on the Responses

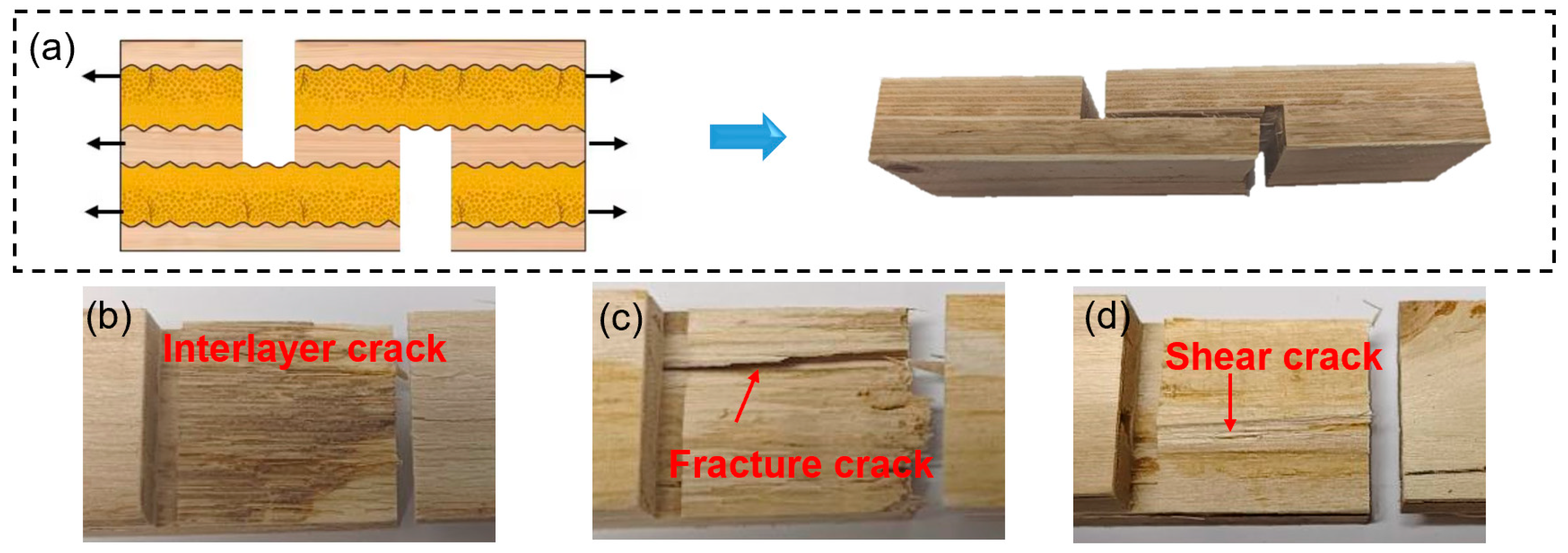

3.3. The Tensile Shear Properties of Bamboo–Wood Composites

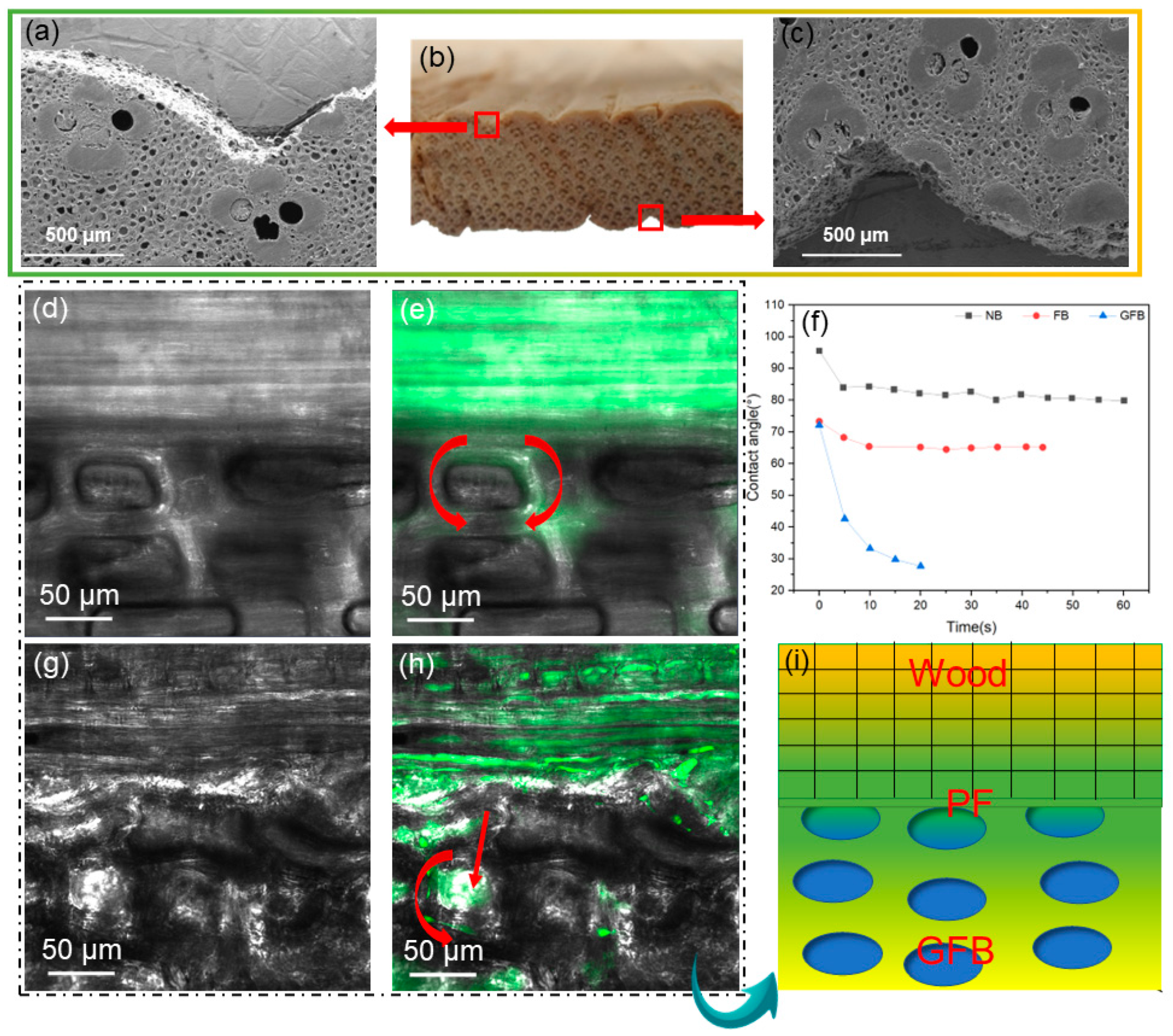

3.4. Bonding Mechanism

4. Application

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hong, C.; Li, H.; Xiong, Z.; Lorenzo, R.; Corbi, I.; Corbi, O.; Wei, D.; Yuan, C.; Yang, D.; Zhang, H. Review of connections for engineered bamboo structures. J. Build. Eng. 2020, 30, 101324. [Google Scholar] [CrossRef]

- Hailemariam, E.K.; Hailemariam, L.M.; Amede, E.A.; Nuramo, D.A. Identification of barriers, benefits and opportunities of using bamboo materials for structural purposes. Eng. Constr. Archit. Manag. 2023, 30, 2716–2738. [Google Scholar] [CrossRef]

- Chen, J.; Guagliano, M.; Shi, M.; Jiang, X.; Zhou, H. A comprehensive overview of bamboo scrimber and its new development in China. Eur. J. Wood Wood Prod. 2021, 79, 363–379. [Google Scholar] [CrossRef]

- Bala, A.; Gupta, S. Engineered bamboo and bamboo-reinforced concrete elements as sustainable building materials: A review. Constr. Build. Mater. 2023, 394, 132116. [Google Scholar] [CrossRef]

- Khajouei-Nezhad, M.; Semple, K.; Nasir, V.; Marggraf, G.; Hauptman, J.; Dai, C. Advances in engineered bamboo processing: Material conversion and structure. Adv. Bamboo Sci. 2023, 5, 100045. [Google Scholar] [CrossRef]

- Wang, J.; Shi, D.; Zhou, C.; Zhang, Q.; Li, Z.; Marmo, F.; Demartino, C. An active-bending sheltered pathway based on bamboo strips for indoor temporary applications: Design and construction. Eng. Struct. 2024, 307, 117863. [Google Scholar] [CrossRef]

- Huang, Y.; Qi, Y.; Zhang, Y.; Yu, W. Progress of bamboo recombination technology in China. Adv. Polym. Technol. 2019, 2019, 2723191. [Google Scholar] [CrossRef]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Lou, Z.; Li, Y.; Zhao, Y. Bamboo Flattening Technique. In Bamboo and Sustainable Construction; Springer: Berlin/Heidelberg, Germany, 2023; pp. 185–210. [Google Scholar]

- Chen, L.; Luo, X.; Huang, B.; Ma, Y.; Fang, C.; Liu, H.; Fei, B. Properties and bonding interface characteristics of an innovative bamboo flattening and grooving unit (BFGU) for laminated bamboo lumber. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132185. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Fu, W.; Zhang, B.; Chang, F.; Jiang, P. Study on the effect of cutting parameters on bamboo surface quality using response surface methodology. Measurement 2021, 174, 109002. [Google Scholar] [CrossRef]

- Adamu, M.; Rahman, M.R.; Bakri, M.K.B.; Md Yusof, F.A.B.; Khan, A. Characterization and optimization of mechanical properties of bamboo/nanoclay/polyvinyl alcohol/styrene nanocomposites using response surface methodology. J. Vinyl Addit. Technol. 2021, 27, 147–160. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, J.; Wang, X.; Huang, B.; Ma, X.; Fang, C.; Zhang, X.; Sun, F.; Fei, B. Fine gluing of bamboo skin and bamboo pith ring based on sanding. Ind. Crops Prod. 2022, 188, 115555. [Google Scholar] [CrossRef]

- GB/T17657-2013; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. National Standards of the People’s Republic of China: Beijing, China, 2013.

- Uzcategui, M.G.; Franca, F.J.; Seale, R.D.; Senalik, C.A.; Ross, R.J. Flexural and tensile properties of 2 × 6 and 2 × 10 southern pine lumber: Southenr pine lumber properties. Wood Fiber Sci. 2022, 54, 257–269. [Google Scholar] [CrossRef]

- Baltic, S.; Magnien, J.; Gänser, H.P.; Antretter, T.; Hammer, R. Coupled damage variable based on fracture locus: Prediction of ductile failure in a complex structure. Int. J. Solids Struct. 2020, 207, 132–144. [Google Scholar] [CrossRef]

- Das, A.; Mohanty, K. Optimization of lignin extraction from bamboo by ultrasound-assisted organosolv pretreatment. Bioresour. Technol. 2023, 376, 128884. [Google Scholar] [CrossRef] [PubMed]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. Part B Eng. 2022, 235, 109776. [Google Scholar] [CrossRef]

- Veza, I.; Spraggon, M.; Fattah, I.R.; Idris, M. Response surface methodology (RSM) for optimizing engine performance and emissions fueled with biofuel: Review of RSM for sustainability energy transition. Results Eng. 2023, 18, 101213. [Google Scholar] [CrossRef]

- Garg, S.; Nayyar, A.; Buradi, A.; Shadangi, K.P.; Sharma, P.; Bora, B.J.; Jain, A.; Shah, M.A. A novel investigation using thermal modeling and optimization of waste pyrolysis reactor using finite element analysis and response surface methodology. Sci. Rep. 2023, 13, 10931. [Google Scholar] [CrossRef] [PubMed]

- Mo, T.; Chen, Z.; Zhou, D.; Lu, G.; Huang, Y.; Liu, Q. Effect of lamellar structural parameters on the bending fracture behavior of AA1100/AA7075 laminated metal composites. J. Mater. Sci. Technol. 2022, 99, 28–38. [Google Scholar] [CrossRef]

- Shi, J.; Liang, Y.; Yu, H.; Ban, Z.; Zhang, Y.; Yang, W.; Yu, W. A new strategy for bamboo ultra-long radial slice preparation and novel composite fabrication. Ind. Crops Prod. 2023, 203, 117232. [Google Scholar] [CrossRef]

- Wang, X.; Yao, Y.; Xie, X.; Yuan, Z.; Li, W.; Yuan, T.; Huang, Y.; Li, Y. Investigation of the microstructure, chemical structure, and bonding interfacial properties of thermal-treated bamboo. Int. J. Adhes. Adhes. 2023, 125, 103400. [Google Scholar] [CrossRef]

- Su, H.; Du, G.; Ren, X.; Liu, C.; Wu, Y.; Zhang, H.; Ni, K.; Yin, C.; Yang, H.; Ran, X. High-performance bamboo composites based on the chemical bonding of active bamboo interface and chitosan. Int. J. Biol. Macromol. 2023, 244, 125345. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wei, X.; Smith, L.M.; Wang, G.; Chen, F. Evaluation of uniformity of bamboo bundle veneer and bamboo bundle laminated veneer lumber (BLVL). Forests 2019, 10, 921. [Google Scholar] [CrossRef]

- Zhang, J.; Ren, H.; Zhong, Y.; Zhao, R. Analysis of compressive and tensile mechanical properties of recombinant bamboo. J. Nanjing For. Univ. 2012, 36, 107–111. [Google Scholar]

- Han, J.; Gao, X.T. A study on tensile mechanical properties of bamboo plywood. Adv. Mater. Res. 2011, 291, 1009–1014. [Google Scholar] [CrossRef]

- Qi, J.Q.; Xie, J.L.; Huang, X.Y.; Yu, W.J.; Chen, S.M. Influence of characteristic inhomogeneity of bamboo culm on mechanical properties of bamboo plywood: Effect of culm height. J. Wood Sci. 2014, 60, 396–402. [Google Scholar] [CrossRef]

- Chen, G.; Yu, Y.; Li, X.; He, B. Mechanical behavior of laminated bamboo lumber for structural application: An experimental investigation. Eur. J. Wood Wood Prod. 2020, 78, 53–63. [Google Scholar] [CrossRef]

- Jain, S.; Kumar, R.; Jindal, U. Mechanical behaviour of bamboo and bamboo composite. J. Mater. Sci. 1992, 27, 4598–4604. [Google Scholar]

- Lou, Z.; Zheng, Z.; Yan, N.; Jiang, X.; Zhang, X.; Chen, S.; Xu, R.; Liu, C.; Xu, L. Modification and Application of Bamboo-Based Materials: A Review—Part II: Application of Bamboo-Based Materials. Forests 2023, 14, 2266. [Google Scholar] [CrossRef]

| Level | A (Temperature, °C) | B (Hot-Pressing Time, min/mm) | C (Pressure, MPa) |

|---|---|---|---|

| −1 | 110 | 1 | 1 |

| 0 | 130 | 1.2 | 1.5 |

| 1 | 150 | 1.4 | 2 |

| Std Order | Run Order | Point (a) | Input Parameters | Output Parameters | |||

|---|---|---|---|---|---|---|---|

| A | B | C | MOR, MPa | MOE, GPa | |||

| 1 | 7 | F1 | 110 | 1 | 1 | 100.12 | 10.16 |

| 2 | 8 | F1 | 150 | 1 | 1 | 121.54 | 11.12 |

| 3 | 2 | F1 | 110 | 1.4 | 1 | 99.89 | 9.55 |

| 4 | 12 | F1 | 150 | 1.4 | 1 | 120.46 | 11.1 |

| 5 | 1 | F1 | 110 | 1 | 2 | 98.72 | 9.43 |

| 6 | 16 | F1 | 150 | 1 | 2 | 118.89 | 10.99 |

| 7 | 13 | F1 | 110 | 1.4 | 2 | 98.11 | 9.38 |

| 8 | 14 | F1 | 150 | 1.4 | 2 | 119.51 | 11.03 |

| 9 | 9 | A1 | 96.3641 | 1.2 | 1.5 | 96.21 | 9.22 |

| 10 | 11 | A1 | 163.636 | 1.2 | 1.5 | 123.56 | 11.2 |

| 11 | 4 | A1 | 130 | 0.863641 | 1.5 | 106.75 | 10.75 |

| 12 | 6 | A1 | 130 | 1.53636 | 1.5 | 104.28 | 10.1 |

| 13 | 3 | A1 | 130 | 1.2 | 0.659104 | 105.88 | 9.87 |

| 14 | 17 | A1 | 130 | 1.2 | 2.3409 | 107.89 | 9.95 |

| 15 | 10 | C1 | 130 | 1.2 | 1.5 | 113.1 | 10.89 |

| 16 | 15 | C1 | 130 | 1.2 | 1.5 | 112.44 | 10.91 |

| 17 | 5 | C1 | 130 | 1.2 | 1.5 | 112.56 | 10.92 |

| Terms | Responses | |

|---|---|---|

| MOR, MPa | MOE, Gpa | |

| Sum of squares | ||

| Regression | 1288.17 | 7.66 |

| Residual | 47.2 | 0.3503 |

| Lack of fit | 46.95 | 0.3498 |

| Pure error | 0.2472 | 0.0005 |

| Mean squares | ||

| Regression | 143.13 | 0.8511 |

| Residual | 6.74 | 0.05 |

| Lack of fit | 9.39 | 0.07 |

| Pure error | 0.1236 | 0.0002 |

| Degrees of freedom | ||

| Regression | 9 | 9 |

| Residual | 7 | 7 |

| Lack of fit | 5 | 5 |

| Pure error | 2 | 2 |

| Std. Dev | 2.6 | 0.2237 |

| Mean | 109.41 | 10.39 |

| C.V.% | 2.37 | 2.15 |

| PRESS | 357.17 | 2.7 |

| R2 | 0.9647 | 0.9563 |

| Adj R2 | 0.9192 | 0.9 |

| Adeq Precision | 16.0218 | 12.9913 |

| F-ratio (calculated) | 21.23 | 17.01 |

| Prob F | 0.0003 | 0.0006 |

| Remark | Significant | Significant |

| Name | Goal | Lower Limit | Upper Limit |

|---|---|---|---|

| A: Temperature | In range | 110 | 150 |

| B: Hot-pressing time | In range | 1 | 1.4 |

| C: Pressure | In range | 1 | 2 |

| MOR | Maximize | 96.21 | 123.56 |

| MOE | Maximize | 9.22 | 11.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Luan, Y.; Chen, L.; Huang, B.; Luo, X.; Miao, H.; Fang, C. A Novel Bamboo–Wood Composite Utilizing High-Utilization, Easy-to-Manufacture Bamboo Units: Optimization of Mechanical Properties and Bonding Performance. Forests 2024, 15, 716. https://doi.org/10.3390/f15040716

Ma Y, Luan Y, Chen L, Huang B, Luo X, Miao H, Fang C. A Novel Bamboo–Wood Composite Utilizing High-Utilization, Easy-to-Manufacture Bamboo Units: Optimization of Mechanical Properties and Bonding Performance. Forests. 2024; 15(4):716. https://doi.org/10.3390/f15040716

Chicago/Turabian StyleMa, Yifan, Yu Luan, Lin Chen, Bin Huang, Xun Luo, Hu Miao, and Changhua Fang. 2024. "A Novel Bamboo–Wood Composite Utilizing High-Utilization, Easy-to-Manufacture Bamboo Units: Optimization of Mechanical Properties and Bonding Performance" Forests 15, no. 4: 716. https://doi.org/10.3390/f15040716

APA StyleMa, Y., Luan, Y., Chen, L., Huang, B., Luo, X., Miao, H., & Fang, C. (2024). A Novel Bamboo–Wood Composite Utilizing High-Utilization, Easy-to-Manufacture Bamboo Units: Optimization of Mechanical Properties and Bonding Performance. Forests, 15(4), 716. https://doi.org/10.3390/f15040716