Modulus of Elasticity in Plywood Boards: Comparison between a Destructive and a Nondestructive Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

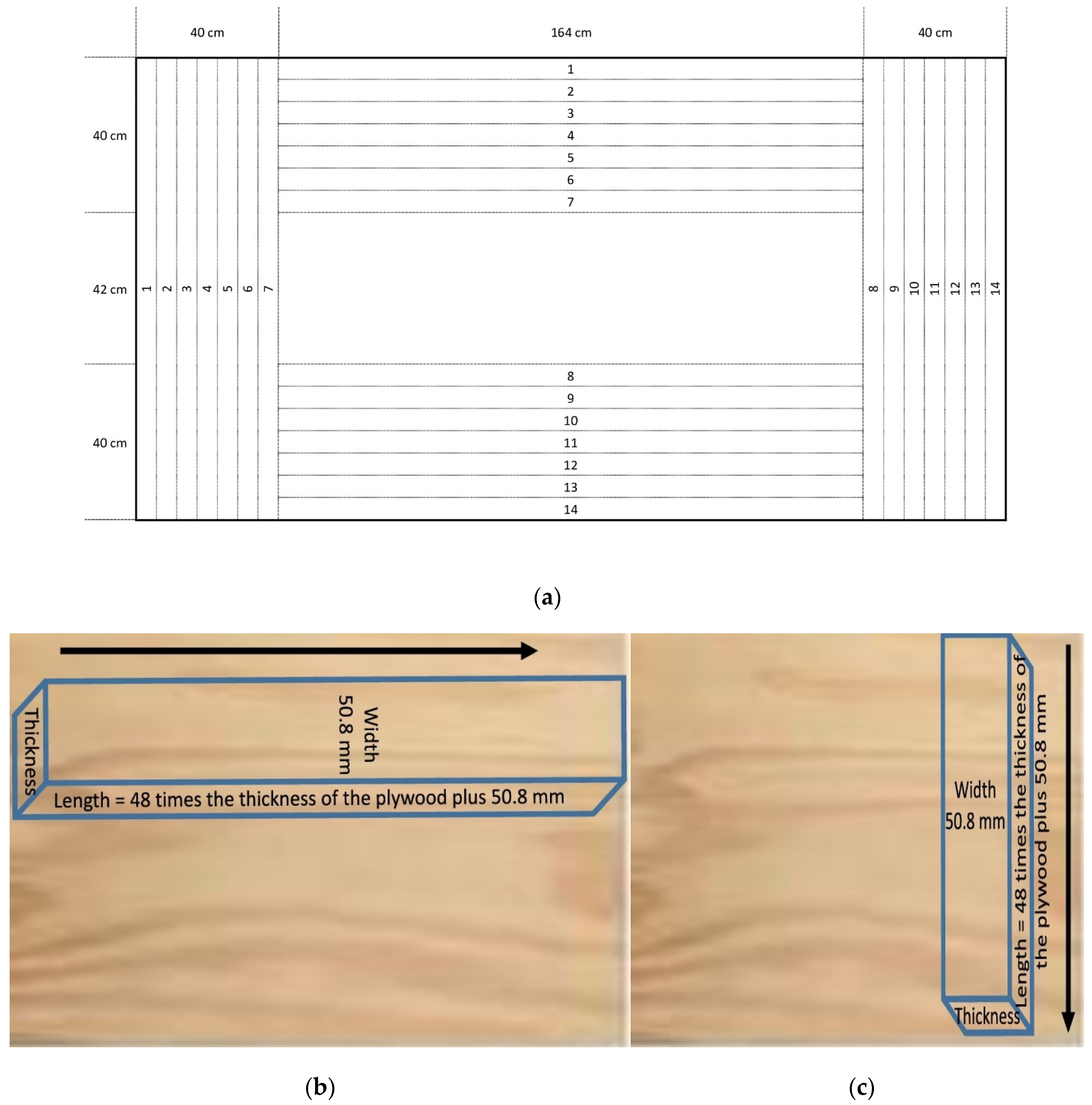

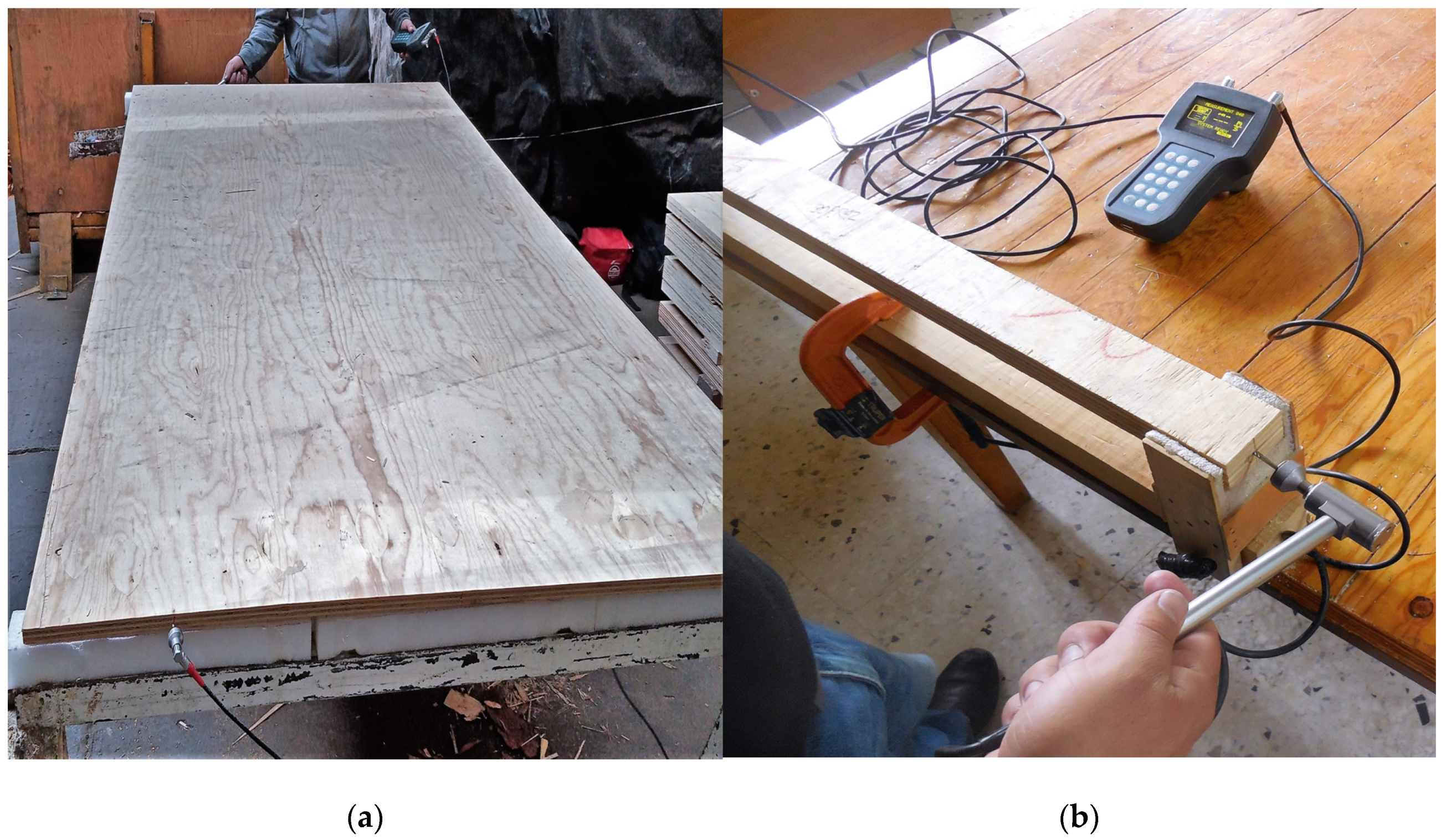

2.2. Preparation of Plywood Boards

2.3. Mechanical Properties

2.3.1. Bending Test Nondestructive Method

2.3.2. Static Bending Destructive Method

Test Speed

2.4. Physical Properties

2.5. Statistical Analysis

3. Results and Discussion

3.1. Modulus of Rupture

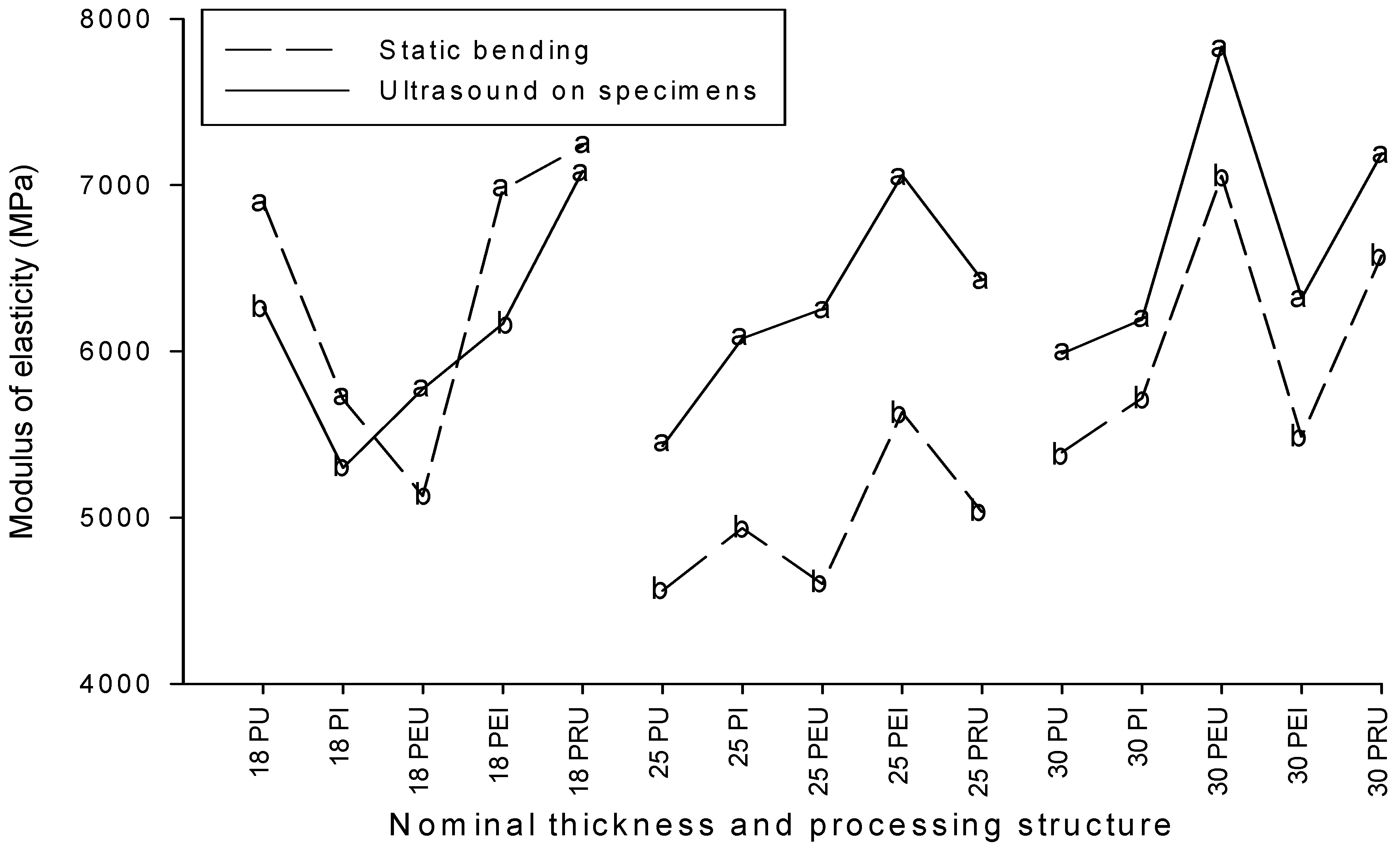

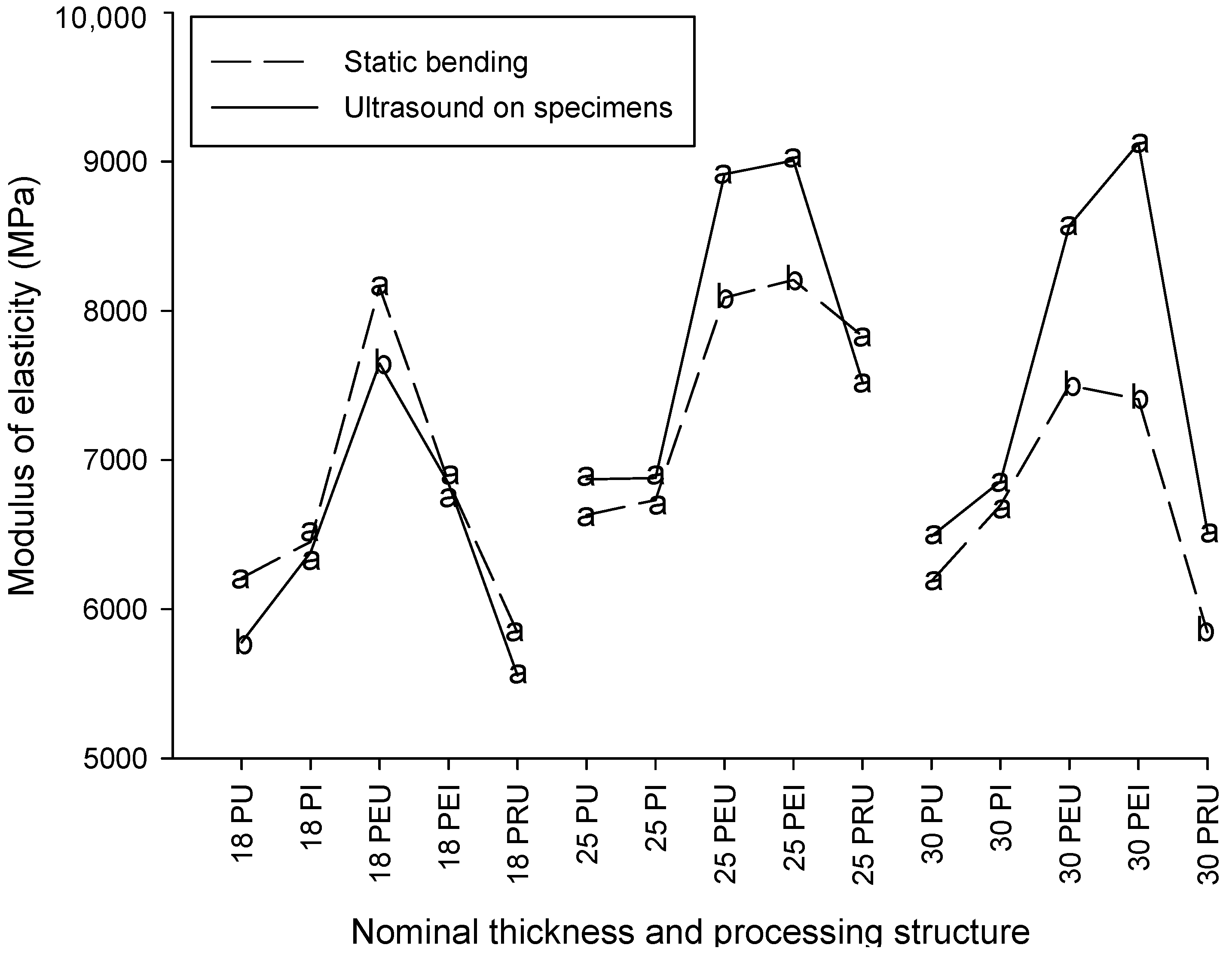

3.2. Modulus of Elasticity

3.2.1. Comparison between Methods

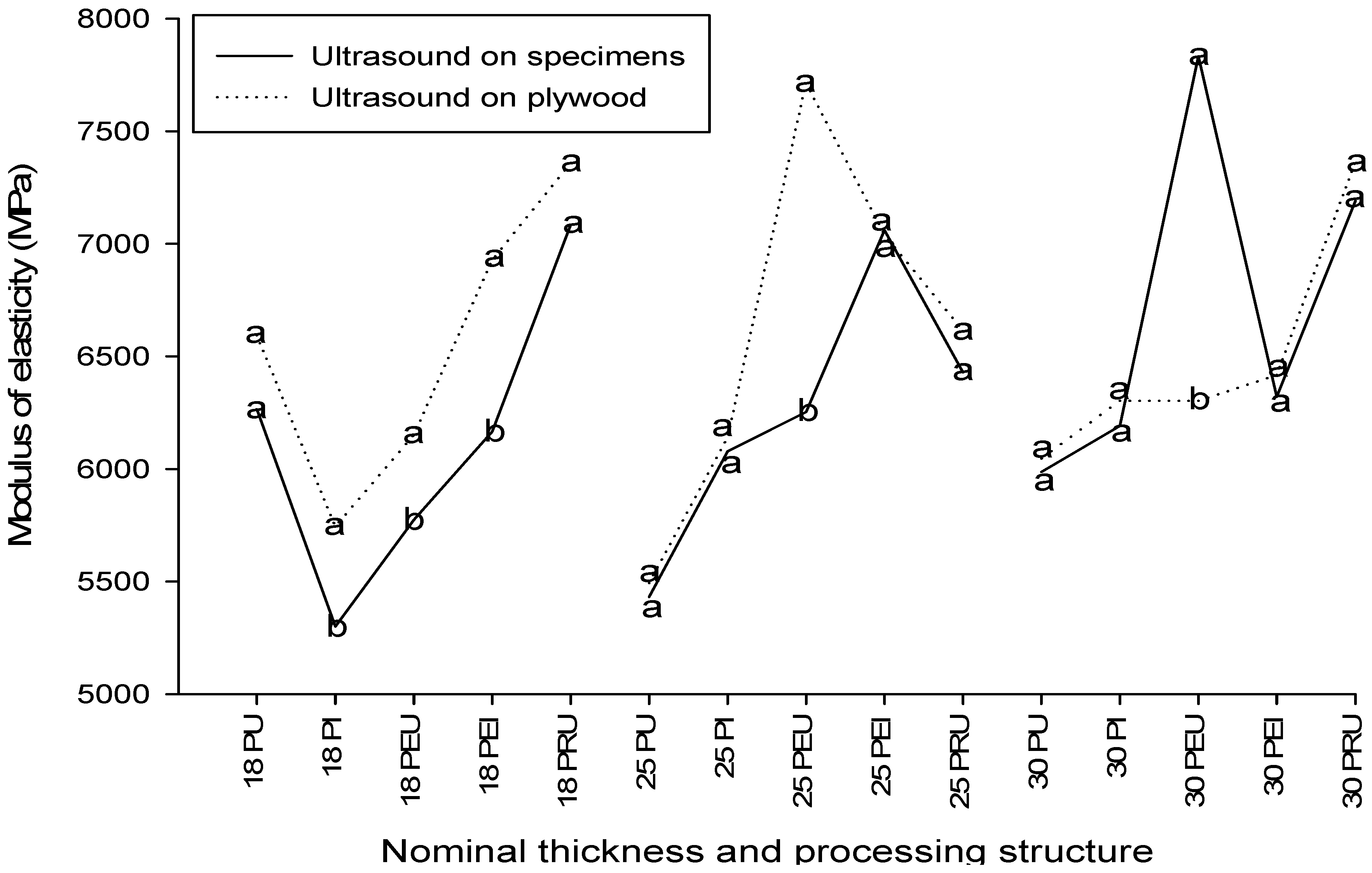

3.2.2. Comparison between Specimens and Complete Boards for Nondestructive Testing

3.3. Correlation between Variables

4. Conclusions

- The plywood panels that included eucalyptus veneers in their processing structure had a higher modulus of rupture.

- The modulus of elasticity in a parallel direction can be obtained by the ultrasonic method on 18 mm thick boards with a PRU structure. While in the perpendicular direction, it is feasible to use in a PI structure in the three studied board thicknesses 18, 25 and 30 mm.

- The modulus of elasticity in the parallel direction can be obtained in full boards using the ultrasonic method in PU and PRU structures with a thickness of 18 mm; while for boards with thicknesses of 25 and 30 mm, the modulus can be obtained in PU, PI, PEI, PRU structures.

- The modulus of elasticity in the perpendicular direction can be obtained in complete boards by means of the ultrasonic method, in boards with a PEU structure of 25 mm thickness, and in the PRU structure of 30 mm thickness.

- There is a significant correlation (r = 0.75) between the modulus of elasticity determined on specimens using the nondestructive method and the destructive method, as well as between the ultrasonic modulus of elasticity in specimens and the ultrasonic modulus of elasticity obtained from complete boards (r = 0.80); therefore, there is the possibility of predicting static values from the ultrasonic test.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, W.; Zhang, Z.; Zhou, G.; Leng, W.; Mei, C. Understanding the interaction between bonding strength and strain distribution of plywood. Int. J. Adhes. Adhes. 2020, 98, 102506. [Google Scholar] [CrossRef]

- Chang, L.; Tang, Q.; Gao, L.; Fang, L.; Wang, Z.; Guo, W. Fabrication and characterization of HDPE resins as adhesives in plywood. Eur. J. Wood Wood Prod. 2018, 76, 325–335. [Google Scholar] [CrossRef]

- Fateh, T.; Rogaume, T.; Luche, J.; Richard, F.; Jabouille, F. Kinetic and mechanism of the thermal degradation of a plywood by using thermogravimetry and Fourier-transformed infrared spectroscopy analysis in nitrogen and air atmosphere. Fire Saf. J. 2013, 58, 25–37. [Google Scholar] [CrossRef]

- Xu, X.; Yang, X.; Lyu, J.; Chen, L.; Sun, Y.; Xu, S. Dynamic mechanical characteristics of poplar veneers painted with damping coatings. J. Nanjing For. Univ. 2016, 59, 125–130. [Google Scholar]

- Camero, A.Á.; Castellón, D.G.; Lazo, D.Á.; Terrero, B.R. Análisis de la estructura físico-mecánica de muebles a base de tablero de fibras de densidad media y madera contrachapada. Cienc. For. Y Ambient. 2019, 4, 55–65. [Google Scholar]

- Bekhta, P.; Salca, E.A. Influence of veneer densification on the shear strength and temperature behavior inside the plywood during hot press. Constr. Build. Mater. 2018, 162, 20–26. [Google Scholar] [CrossRef]

- Tannert, T.; Antonio, R.; Kasal, B.; Kloiber, M.; Plaza, M.; Riggio, M.; Rinn, F.; Widmann, R.; Yamaguchi, N. In situ assessment of structural timber using semi-destructive techniques. Mater. Struct. 2014, 47, 767–785. [Google Scholar] [CrossRef]

- Virgen-Cobos, G.H.; Olvera-Licona, G.; Hermoso, E.; Esteban, M. Nondestructive Techniques for Determination of Wood Mechanical Properties of Urban Trees in Madrid. Forests 2022, 13, 1381. [Google Scholar] [CrossRef]

- Ross, R.J. Nondestructive Evaluation of Wood, 3rd ed.; Government Printing Office: Madison, WI, USA, 2015; p. 176.

- Shull, P.J. Nondestructive Evaluation: Theory, Techniques, and Applications; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Kawamoto, S.; Williams, R.S. Acoustic Emission and Acoustic-Ultrasonic Techniques for Wood and Wood-Based Composites: A Review; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2002; p. 16.

- Sarasini, F.; Santulli, C. Non-destructive testing (NDT) of natural fibre composites: Acoustic emission technique. In Natural Fibre Composites; Hodzic, A., Thule, A., Shanks, R., Eds.; Woodhead Publishing: Philadelphia, PA, USA, 2014; pp. 273–302. [Google Scholar]

- Ramos, H.M.; Cuellar, J.E. Módulo de elasticidad de Cedrelinga cateniformis d. de plantaciones empleando técnicas no destructivas. Rev. For. Venez. 2018, 62, 59–68. [Google Scholar]

- Wu, S.J.; Xu, J.M.; Li, G.Y.; Risto, V.; Lu, Z.H.; Li, B.Q.; Wang, W. Estimation of basic density and modulus of elasticity of Eucalypt clones in Southern China using non-destructive methods. J. Trop. For. Sci. 2011, 23, 51–56. [Google Scholar]

- De Alcantara, P.G.; Rodrigo, M.; Calil, C.; José, A.; Alves, A.; Calil, C. Avaliaçao do módulo de elasticidade de peças de madeira laminada colada (MLC) obtido por meio do ensaio de vibraçao transversal. Ambiente Construido 2013, 13, 7–14. [Google Scholar]

- Mantilla, E.V.; Costa, R.; Von, P.G.; Penido, M.A.; Dordenoni, V.; Rodo, J.; Smits, M. Determination of constant elastic of pequi wood using ultrasound. Mix Sustentável. Florianópolis 2020, 6, 139–144. [Google Scholar] [CrossRef]

- Sotomayor-Castellanos, J.R.; Villaseñor-Aguilar, J.M.; Aoi, I. Módulos de elasticidad evaluados por métodos no destructivos y ruptura de la madera de Pinus douglasiana: Vibraciones transversales, ultrasonido, ondas de esfuerzo y flexión estática. Investig. E Ing. De La Madera 2007, 3, 3–17. [Google Scholar]

- ASTM D 3043-17; Standard Test Methods for Structural Panels in Flexure. American Society for Testing and Materials: Philadelphia, PA, USA, 2017.

- ASTM D 44442 20; Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based MaterialsAmerican Society for Testing and Materials. Intertek: Philadelphia, PA, USA, 2020.

- ASTM D 2395-17; Standard Test Methods for Specific Gravity (Relative Density) of Wood and Wood-Base Materials. American Society for Testing and Materials. Intertek: Philadelphia, PA, USA, 2017.

- Di Rienzo, J.A.; Casanoves, F.; Balzarini, M.G.; González, L.; Tablada, M.; Robledo, C.W. InfoStat Versión 2018; Grupo InfoStat, FCA, Universidad Nacional de Córdoba: Córdoba, Argentina, 2018; Available online: http://www.infostat.com.ar (accessed on 7 March 2024).

- Reis, A.H.S.; Silva, D.W.; Vilela, A.P.; Mendes, R.F.; Mendes, L.M. Physical-mechanical Properties of Plywood Produced with Acrocarpus fraxinifolius and Pinus oocarpa. Floresta e Ambiente 2019, 26, e20170157. [Google Scholar] [CrossRef]

- Ugolev, B.N. Drevesinovedenie i Lesnoe Tovarovedenie [Wood Science and Forest Commodity Science]; GOU VPO MGUL: Moscow, Russia, 2007; 351p. [Google Scholar]

- Bekhta, P.; Salca, E.A.; Lunguleasa, A. Some properties of plywood panels manufactured from combinations of thermally densified and non-densified veneers of different thicknesses in one structure. J. Build. Eng. 2020, 29, 101116. [Google Scholar] [CrossRef]

- Salca, E.A.; Bekhta, P.; Seblii, Y. The effect of veneer densification temperature and wood species on the plywood properties made from alternate layers of densified and non-densified veneers. Forests 2020, 11, 700. [Google Scholar] [CrossRef]

- Bekhta, P.; Chernetskyi, O.; Kusniak, I.; Bekhta, N.; Bryn, O. Selected properties of plywood bonded with low-density polyethylene film from different wood species. Polymers 2021, 14, 51. [Google Scholar] [CrossRef]

- Sotomayor-Castellanos, J.R. Influencia de las dimensiones de las probetas en el cálculo de características dinámicas de madera determinadas por métodos no destructivos. Investig. E Ing. De La Madera 2017, 13, 22–45. [Google Scholar]

- Sotomayor-Castellanos, J.R.; Correa-Jurado, S. Retención de sales de boro en tres maderas mexicanas y su efecto en el módulo de elasticidad dinámico. Rev. Científica 2016, 24, 90–99. [Google Scholar] [CrossRef]

- Gonçalves, R.; Trinca, A.J.; Cerri, D.G.P. Comparison of elastic constants of wood determined by ultrasonic wave propagation and static compression testing. Wood Fiber Sci. 2011, 43, 64–75. [Google Scholar]

- Ozyhar, T.; Hering, S.; Sanabria, S.J.; Niemz, P. Determining moisture-dependent elastic characteristics of beech wood by means of ultrasonic waves. Wood Sci. Technol. 2013, 47, 329–341. [Google Scholar] [CrossRef]

- Crespo, J.; Aira, J.R.; Vázquez, C.; Majano-Majano, A.; Guaita, M. Determination of the elastic constants in Eucalyptus globulus by ultrasound and mechanical tests. In Proceedings of the WCTE 2016 World Conference on Timber Engineering, Vienna, Austria, 25 August 2016. [Google Scholar]

- Jiang, J.; Bachtiar, E.V.; Lu, J.; Niemz, P. Comparison of moisture-dependent orthotropic Young’s moduli of Chinese fir wood determined by ultrasonic wave method and static compression or tension tests. Eur. J. Wood Wood Prod. 2018, 76, 953–964. [Google Scholar] [CrossRef]

- Halabe, U.B.; Bidigalu, G.M.; GangaRao, H.V.; Ross, R.J. Nondestructive evaluation of green wood using stress wave and transverse vibration techniques. Mater. Eval. 1997, 55, 1013–1018. [Google Scholar]

- Divo´s, F.; Tanaka, T. Effects of creep on modulus of elasticity determination of wood. J. Vib. Acoust. 2000, 122, 90–92. [Google Scholar] [CrossRef]

- Iñiguez-González, G. Clasificación Mediante Técnicas no Destructivas y Evaluación de las Propiedades Mecánicas de la Madera Aserrada de Conífera de gran Escuadría Para uso Estructural. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2007. [Google Scholar]

- Senalik, C.A.; Schueneman, G.; Ross, R.J. Ultrasonic-Based Nondestructive Evaluation Methods for Wood. In Nondestructive Evaluation of Wood, 2nd ed.; Ross, R.J., Ed.; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2015; Volume 2, pp. 21–52. [Google Scholar]

- Baradit, E.; Niemz, P.; Fernández-Pérez, A. Propiedades físico-mecánicas de algunas maderas nativas chilenas coníferas y latifoliadas por ultrasonido. Maderas. Cienc. Y Tecnol. 2013, 15, 235–244. [Google Scholar] [CrossRef][Green Version]

- Cobas, A.C.; Area, M.C.; Monteoliva, S. Patrones de variación de la densidad de la madera y morfometría celular de Salix babylonica para la determinación de la edad de transición entre madera juvenil y madura. Maderas. Cienc. Y Tecnol. 2014, 16, 343–354. [Google Scholar] [CrossRef][Green Version]

- Chauhan, S.; Sethy, A. Differences in dynamic modulus of elasticity determined by three vibration methods and their relationship with static modulus of elasticity. Maderas. Cienc. Y Tecnol. 2016, 18, 373–382. [Google Scholar] [CrossRef]

- Leon, J.L.H. Anatomía y densidad o peso específico de la madera. Rev. For. Venez. 2010, 54, 67–76. [Google Scholar]

- López, I.A. El nuevo enfoque en los ensayos mecánicos de la madera aserrada para uso estructural en la normativa europea. Madera Y Bosques 2002, 8, 3–16. [Google Scholar] [CrossRef][Green Version]

- Nope, P.; Cristini, V.; Tippner, J.; Zlámal, J.; Vand, M.H.; Šeda, V. Dynamic Properties of Wood Obtained by Frequency Resonance Technique and Dynamic Mechanical Analysis. Wood Fiber Sci. 2023, 55, 131–142. [Google Scholar] [CrossRef]

- Nisgoski, S.; Trianoski, R.; Muñiz, G.I.B.; Matos, J.L.M.; Stygar, M. Variação Radial das Estruturas da Madeira de Acrocarpus fraxinifolius Wight and Arn. Floresta e Ambiente 2012, 19, 316–324. [Google Scholar] [CrossRef]

- Hassan, K.T.; Horacek, P.; Tippnera, J. Evaluation of Stiffness and Strength of Scots Pine Wood Using Resonance Frequency and Ultrasonic Techniques. BioResources 2013, 8, 1634–1645. [Google Scholar] [CrossRef]

- Nope, P.; Cristini, V.; Zlámal, J.; Vand, M.H.; Šeda, V.; Tippner, J. Determination of the Static BendingProperties of Green Beech and OakWood by the Frequency ResonanceTechnique. Forests 2024, 15, 150. [Google Scholar] [CrossRef]

- Baar, J.; Tippner, J.; Rademacher, P. Prediction of mechanical properties-modulus of rupture and modulus of elasticity-of five tropical species by nondestructive methods. Maderas. Cienc. Y Tecnol. 2015, 17, 239–252. [Google Scholar] [CrossRef]

- Villaseñor-Aguilar, J.M.; Sotomayor-Castellanos, J.R. Caracterización dinámica de la madera de Fraxinus americana y Fraxinus uhdei. Rev. De Apl. Científica Y Técnica 2015, 1, 43–53. [Google Scholar]

| Thickness Nominal (mm) | Species and Resin | Board Structure * | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18 | PU | P |  | P |  | P |  | P | ||||

| PI | P |  | P |  | P |  | P | |||||

| PEU | P |  | P |  | P |  | P | |||||

| PEI | P |  | P |  | P |  | P | |||||

| PRU | P |  | P |  | R |  | P | |||||

| 25 | PU | P |  |  | P |  | P |  | P |  | P | |

| PI | P |  |  | P |  | P |  | P |  | P | ||

| PEU | P |  |  | P |  | P |  | P |  | P | ||

| PEI | P |  |  | P |  | P |  | P |  | P | ||

| PRU | P |  |  | P |  | R |  | R |  | P | ||

| 30 | PU | P |  | P |  | P |  | P |  | P |  | P |

| PI | P |  | P |  | P |  | P |  | P |  | P | |

| PEU | P |  | P |  | P |  | P |  | P |  | P | |

| PEI | P |  | P |  | P |  | P |  | P |  | P | |

| PRU | P |  | P |  | R |  | P |  | R |  | P | |

| Species and Resin | 18 mm | 25 mm | 30 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| MOR (MPa) | MC (%) | Density (kg/m3) | MOR (MPa) | MC (%) | Density (kg/m3) | MOR (MPa) | MC (%) | Density (kg/m3) | |

| PU | 39.8 (11.96) b | 8.3 (0.42) a | 618 (29.9) b | 34.6 (14.53) a | 8.3 (3.12) a | 589 (28.0) b | 32.4 (10.46) b | 16.4 (9.88) a | 619 (59.2) c |

| PI | 35.6 (14.02) b | 7.6 (1.57) b | 575 (20.8) c | 35.8 (12.90) a | 7.4 (0.29) ab | 567 (26.4) c | 38.5 (10.85) a | 6.9 (1.00) b | 572 (19.8) e |

| PEU | 46.5 (19.43) a | 5.7 (0.92) c | 654 (36.4) a | 35.4 (15.21) a | 6.4 (1.85) c | 674 (31.7) a | 42.0 (8.33) a | 5.9 (0.36) b | 670 (37.7) a |

| PEI | 38.5 (9.42) b | 7.2 (0.46) b | 663 (23.1) a | 35.8 (10.63) a | 7.1 (3.54) bc | 684 (33.7) a | 32.6 (9.19) b | 5.7 (2.67) b | 650 (27.6) b |

| PRU | 39.4 (9.59) b | 5.6 (1.00) c | 557 (24.9) d | 38.2 (16.94) a | 6.5 (0.74) bc | 598 (29.0) b | 34.1 (8.43) b | 5.7 (0.58) b | 599 (26.9) d |

| MC | DTT | MOR | MOE | MOEUP | MOEUT | |

|---|---|---|---|---|---|---|

| MC | 1 | −0.18 (0.0031) | −0.15 (0.0141) | −0.19 (0.0020) | −0.20 (0.0007) | −0.21 (0.0005) |

| DTT | 1 | 0.13 (0.0299) | 0.34 (<0.0001) | 0.50 (<0.0001) | 0.45 (<0.0001) | |

| MOR | 1 | 0.80 (<0.0001) | 0.48 (<0.0001) | 0.56 (<0.0001) | ||

| MOE | 1 | 0.75 (<0.0001) | 0.73 (<0.0001) | |||

| MOEUP | 1 | 0.80 (<0.0001) | ||||

| MOEUT | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de la Cruz-Carrera, R.; Carrillo-Parra, A.; Prieto-Ruíz, J.Á.; Fuentes-Talavera, F.J.; Ruiz-Aquino, F.; Goche-Télles, J.R. Modulus of Elasticity in Plywood Boards: Comparison between a Destructive and a Nondestructive Method. Forests 2024, 15, 1596. https://doi.org/10.3390/f15091596

de la Cruz-Carrera R, Carrillo-Parra A, Prieto-Ruíz JÁ, Fuentes-Talavera FJ, Ruiz-Aquino F, Goche-Télles JR. Modulus of Elasticity in Plywood Boards: Comparison between a Destructive and a Nondestructive Method. Forests. 2024; 15(9):1596. https://doi.org/10.3390/f15091596

Chicago/Turabian Stylede la Cruz-Carrera, Ricardo, Artemio Carrillo-Parra, José Ángel Prieto-Ruíz, Francisco Javier Fuentes-Talavera, Faustino Ruiz-Aquino, and José Rodolfo Goche-Télles. 2024. "Modulus of Elasticity in Plywood Boards: Comparison between a Destructive and a Nondestructive Method" Forests 15, no. 9: 1596. https://doi.org/10.3390/f15091596

APA Stylede la Cruz-Carrera, R., Carrillo-Parra, A., Prieto-Ruíz, J. Á., Fuentes-Talavera, F. J., Ruiz-Aquino, F., & Goche-Télles, J. R. (2024). Modulus of Elasticity in Plywood Boards: Comparison between a Destructive and a Nondestructive Method. Forests, 15(9), 1596. https://doi.org/10.3390/f15091596