Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies

Abstract

:1. Introduction

2. Review Process and Studies Reviewed

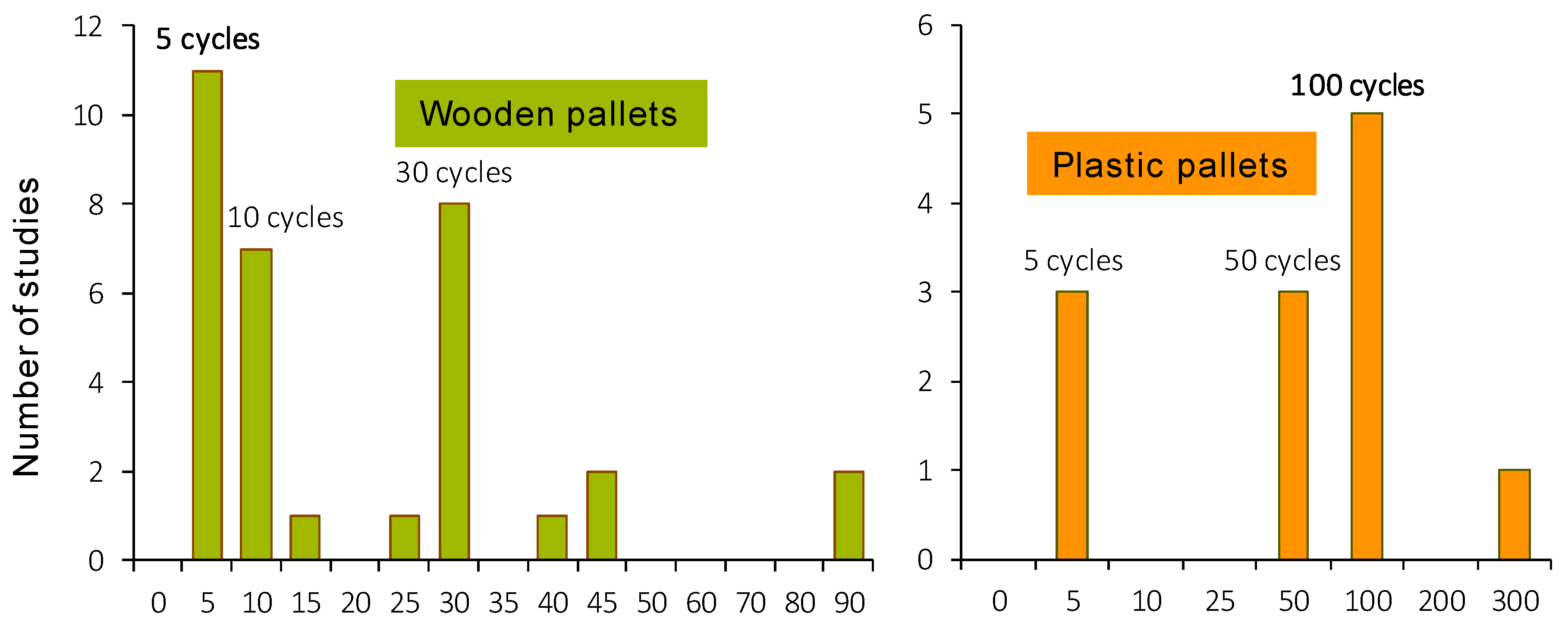

2.1. Review Process

2.2. Studies Reviewed

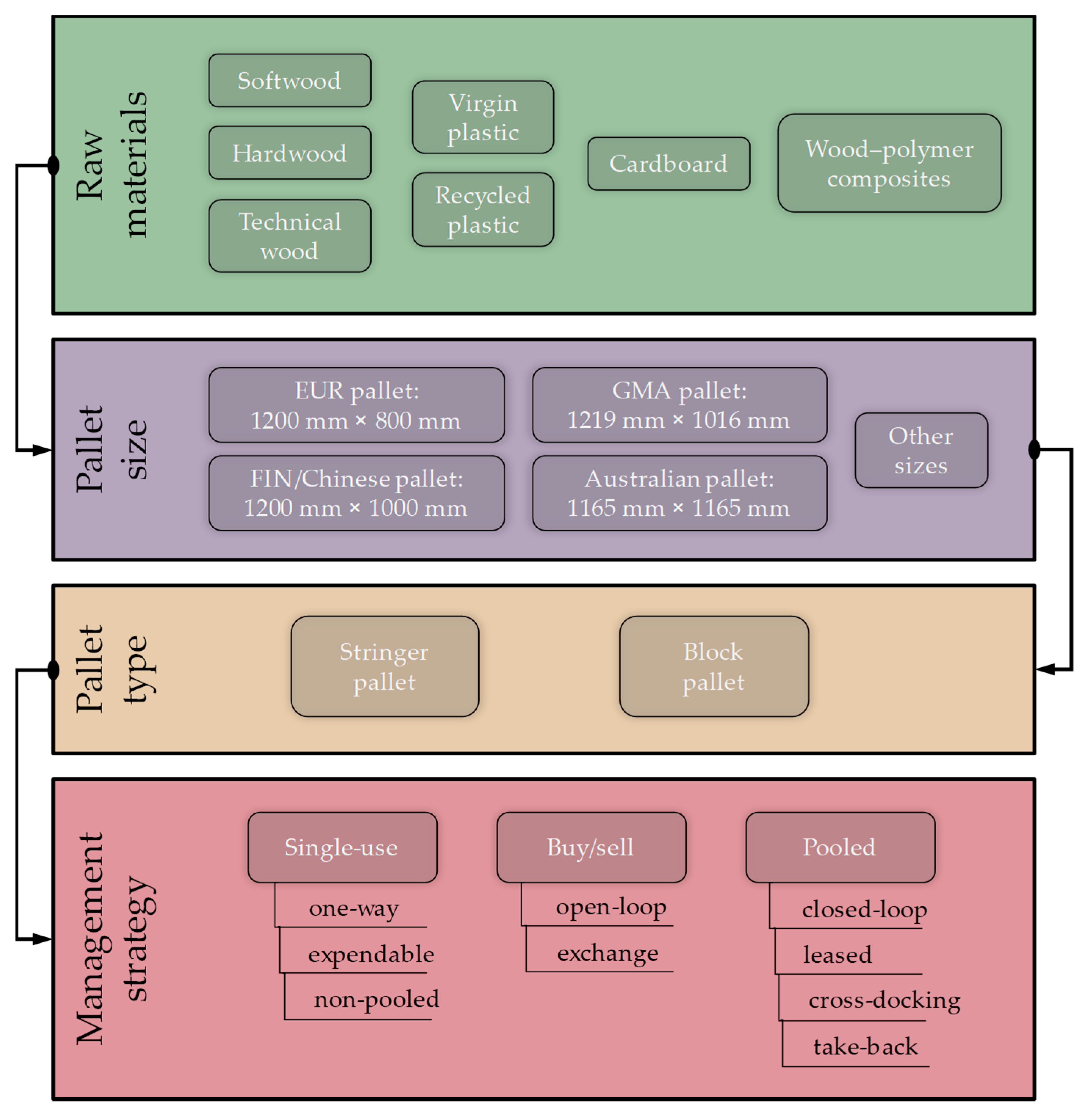

3. Pallets Classification

4. Methodological Choices

4.1. Geographical Scope

4.2. Functional Unit

4.3. System Boundary

4.4. Life Cycle Inventory

4.5. Life Cycle Impact Assessment

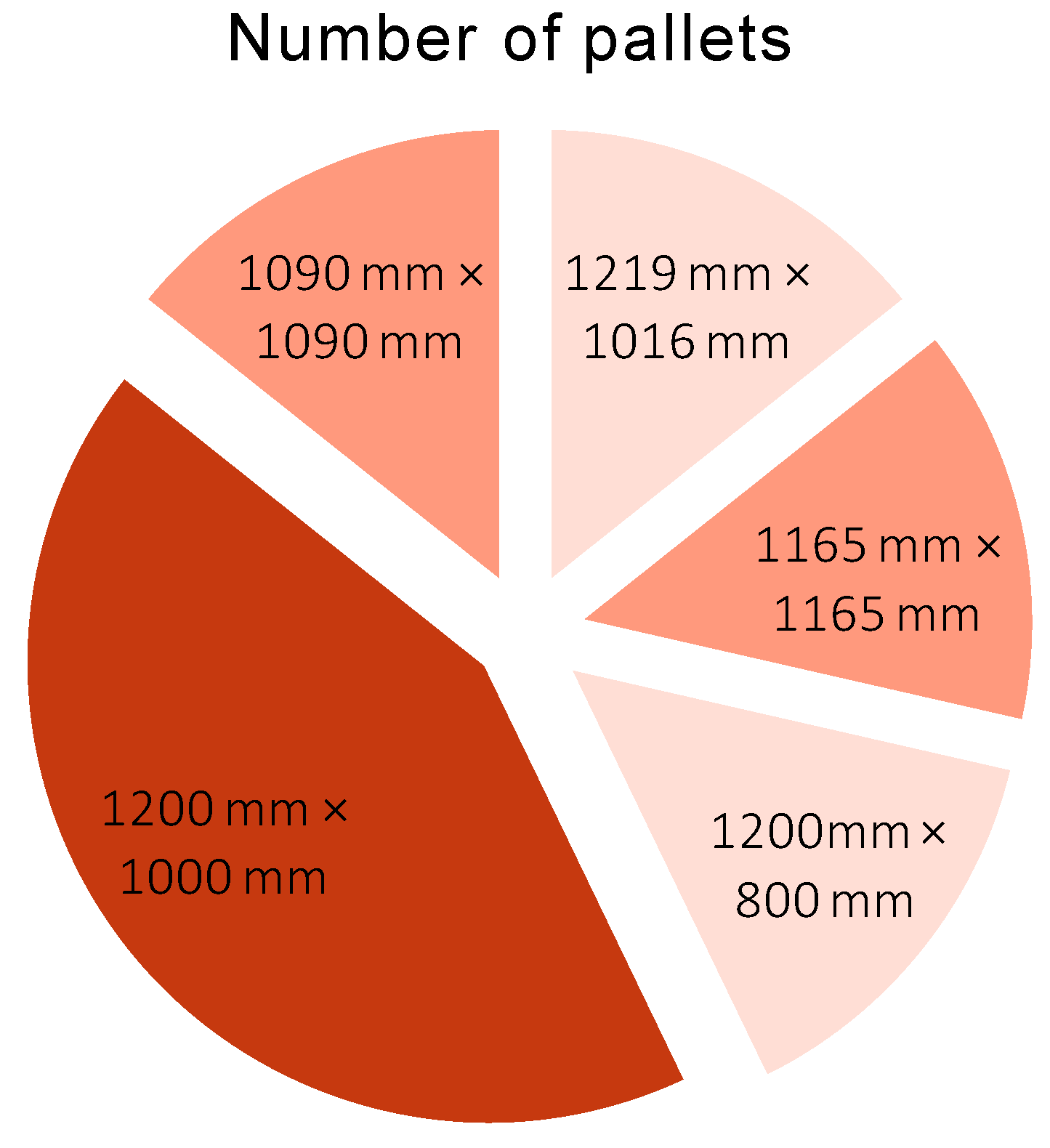

5. Pallets Studied

6. Life Cycle Inventory

6.1. Wooden Pallets

6.2. Plastic Pallets

7. Life Cycle Impact Assessment

7.1. Carbon Footprint

7.2. Other Impact Categories by Studies

7.2.1. Reuse Intensity

7.2.2. GMA-Sized Wooden and Plastic Pallets

7.2.3. Pallets in Australia and China

7.2.4. Pallets Made of Waste Plastic or Tropical Wood

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Freedonia World Pallets. 2014. Available online: https://www.freedoniagroup.com/industry-study/world-pallets-3126.htm (accessed on 16 October 2019).

- SFS-EN ISO 445 Pallets for Materials Handling. Vocabulary. 2013. Available online: https://www.iso.org/standard/61915.html (accessed on 16 October 2019).

- Bilbao, A.M.; Carrano, A.; Hewitt, M.; Thorn, B. On the environmental impacts of pallet management operations. Manag. Res. Rev. 2011, 34, 1222–1236. [Google Scholar] [CrossRef]

- Roy, D.; Carrano, A.L.; Pazour, J.A.; Gupta, A. Cost-effective pallet management strategies. Transp. Res. Part E Logist. Transp. Rev. 2016, 93, 358–371. [Google Scholar] [CrossRef]

- Ustundag, A.; Satoglu, S.I. Cost-Benefit Analysis for RFID Based Pallet Pooling Systems. 2016. Available online: https://www.researchgate.net/publication/299484863_Cost-Benefit_Analysis_for_RFID_Based_Pallet_Pooling_Systems (accessed on 16 October 2019).

- Park, J.; Horvath, L.; Bush, R.J. Life Cycle Inventory Analysis of the Wood Pallet Repair Process in the United States. J. Ind. Ecol. 2018, 22, 1117–1126. [Google Scholar] [CrossRef]

- Product Category Rule (PCR) Guidance on Wooden Pallets, EPD Requirements. 2019. Available online: https://www.shopulstandards.com/ProductDetail.aspx?UniqueKey=35976 (accessed on 16 October 2019).

- Elsevier, B.V. Document Search. Available online: https://www.scopus.com/ (accessed on 16 October 2019).

- Clavirate. Web of Science. Available online: https://apps.webofknowledge.com (accessed on 16 October 2019).

- Anil, S.K.; Ray, C.D.; Okudan Kremer, G.E. Comparison of treatment methods for pallets using LCA and dynamic programming. In Proceedings of the IIE Annual Conference and Expo 2010 Proceedings, Cancun, Mexico, 5–9 June 2010. [Google Scholar]

- Anil, S.K.; Ray, C.D.; Kremer, G.E.O. Pallet life cycle comparison using LCA and multiobjective dynamic programming. In Proceedings of the ASEM 2010 31st Annual National Conference of the American Society for Engineering Management, Fayetteville, AR, USA, 13–16 October 2010. [Google Scholar]

- Choi, B.; Yoo, S.; Lee, K.-D.; Park, S.-I. An environmental impact comparison of disposable wood pallets and reusable steel cradles: A case study on rolled steel coils in container shipping in South Korea. Int. J. Sustain. Transp. 2019, 1–8. [Google Scholar] [CrossRef]

- Lee, S.G.; Xu, X. A simplified life cycle assessment of re-usable and single-use bulk transit packaging. Packag. Technol. Sci. 2004, 17, 67–83. [Google Scholar] [CrossRef]

- Alvarez, S.; Rubio, A. Compound method based on financial accounts versus process-based analysis in product carbon footprint: A comparison using wood pallets. Ecol. Indic. 2015, 49, 88–94. [Google Scholar] [CrossRef]

- Alanya-Rosenbaum, S.; Bergman, R.; Gething, B. Developing procedures and guidance for performing an environmental assessment of us wooden pallets. WIT Trans. Ecol. Environ. 2018, 215, 37–45. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. J. Clin. Epidemiol. 2009, 62, 1006–1012. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO 6780-Flat Pallets for Intercontinental Materials Handling—Principal Dimensions and Tolerances. 2003. Available online: https://www.iso.org/standard/30524.html (accessed on 16 October 2019).

- Franklin Associates. Life Cycle Inventory of Wood Pallet Systems; Final Summary Report; Franklin Associates: Prairie Village, KS, USA, 2007. [Google Scholar]

- Gasol, C.M.; Farreny, R.; Gabarrell, X.; Rieradevall, J. Life cycle assessment comparison among different reuse intensities for industrial wooden containers. Int. J. Life Cycle Assess. 2008, 13, 421–431. [Google Scholar] [CrossRef]

- Kurisunkal, S. Environmental Analysis of Pallets Using Life Cycle Analysis and Multi-Objective Dynamic Programming; The Pennsylvania State University: State College, PA, USA, 2010. [Google Scholar]

- Bilbao, A.M. Environmental Impact Analysis of Alternative Pallet Management Systems. 2011, p. 147. Available online: https://scholarworks.rit.edu/cgi/viewcontent.cgi?referer=https://www.google.com/&httpsredir=1&article=6707&context=theses (accessed on 16 October 2019).

- Niero, M.; Di Felice, F.; Ren, J.; Manzardo, A.; Scipioni, A. How can a life cycle inventory parametric model streamline life cycle assessment in the wooden pallet sector? Int. J. Life Cycle Assess. 2014, 19, 901–918. [Google Scholar] [CrossRef]

- Carrano, A.L.; Thorn, B.K.; Woltag, H. Characterizing the Carbon Footprint of Wood Pallet Logistics. For. Prod. J. 2014, 64, 232–241. [Google Scholar] [CrossRef]

- Ng, R.; Shi, C.W.P.; Tan, H.X.; Song, B. Avoided impact quantification from recycling of wood waste in Singapore: An assessment of pallet made from technical wood versus virgin softwood. J. Clean. Prod. 2014, 65, 447–457. [Google Scholar] [CrossRef]

- Bengtsson, J.; Logie, J. Life Cycle Assessment of One-way and Pooled Pallet Alternatives. Procedia CIRP 2015, 29, 414–419. [Google Scholar] [CrossRef]

- Carrano, A.L.; Pazour, J.A.; Roy, D.; Thorn, B.K. Selection of pallet management strategies based on carbon emissions impact. Int. J. Prod. Econ. 2015, 164, 258–270. [Google Scholar] [CrossRef]

- Tornese, F.; Carrano, A.L.; Thorn, B.K.; Pazour, J.A.; Roy, D. Carbon footprint analysis of pallet remanufacturing. J. Clean. Prod. 2016, 126, 630–642. [Google Scholar] [CrossRef]

- Edge Environment Pty Ltd Pallet Life Cycle Assessment and Benchmark. 2017. Available online: https://re-pal.com/wp-content/uploads/2019/03/Edge-Environment-Pallet-Life-Cycle-Assessment-and-Benchmark-Report.pdf (accessed on 16 October 2019).

- Tornese, F.; Pazour, J.A.; Thorn, B.K.; Roy, D.; Carrano, A.L. Investigating the environmental and economic impact of loading conditions and repositioning strategies for pallet pooling providers. J. Clean. Prod. 2018, 172, 155–168. [Google Scholar] [CrossRef]

- Kočí, V. Comparisons of environmental impacts between wood and plastic transport pallets. Sci. Total Environ. 2019, 686, 514–528. [Google Scholar] [CrossRef] [PubMed]

- SFS-EN ISO 14040 Environmental Management. Life Cycle Assessment. Principles and Framework. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 16 October 2019).

- SFS-EN ISO 14067 Greenhouse Gases. Carbon Footprint of Products. Requirements and Guidelines for Quantification. 2018. Available online: https://www.iso.org/standard/71206.html (accessed on 16 October 2019).

- Ellen MacArthur Foundation Circularity Indicators: An Approach to Measuring Circularity. Ellen MacArthur Found, 2015. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/insight/Circularity-Indicators_Methodology_May2015.pdf (accessed on 16 October 2019).

- Modern Materials Handling the Pallet Report: Users Want More Service and Support. Available online: https://www.mmh.com/article/the_pallet_report_users_want_more_service_support (accessed on 6 August 2019).

- Modern Materials Handling Pallet Market Evaluation Study. 2017. Available online: https://www.mmh.com/article/2017_pallet_market_evaluation_study_free_43_page_report (accessed on 16 October 2019).

- European Pallet Association EPAL: Record Result of 115.8m EPAL Pallets in 2017. 2018. Available online: https://pt.epal-pallets.org/news/details/article/record-result-of-1158m-epal-pallets-in-2017-1/?no_cache=1 (accessed on 16 October 2019).

- SFS-EN 13698-1 Pallet Production Specification. Part 1: Construction Specification for 800 mm × 1200 mm Flat Wooden Pallets. 2004. Available online: https://sales.sfs.fi/en/index/tuotteet/SFS/CEN/ID2/1/6888.html.stx (accessed on 16 October 2019).

- National Wooden Pallet and Container Association Uniform Standard for Wood Pallets. 2014. Available online: https://cdn.ymaws.com/www.palletcentral.com/resource/collection/E8AADDDE-7CBA-4298-8341-C7F29D0C14FF/Uniform-Standard-for-Wood-Pallets-2014(REV).pdf (accessed on 16 October 2019).

- European Pallet Association e.V. EPAL Euro Pallet. Available online: https://www.epal-pallets.org/eu-en/load-carriers/epal-euro-pallet/ (accessed on 7 August 2019).

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method. 2019. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC115959/jrc115959_pef_method-online.pdf (accessed on 16 October 2019).

| No. | Reference | Publication Type 1 | The Main Goal of the Study |

|---|---|---|---|

| (1) | [18] | R | To provide a life cycle inventory (LCI) that quantifies resource and energy use, waste, and emissions associated with three pallet systems with different reuse, repair, and recycling rates. |

| (2) | [19] | J | To develop a life cycle inventory analysis and to analyze the environmental impacts of the current management system by means of a life cycle inventory assessment. |

| (3) | [20] | T | To address a void in the studies by presenting an unbiased comparative life cycle analysis (LCA) study comparing plastic and wooden pallets through investigation of their environmental impacts and carbon footprints. |

| (4) | [21] | J | To frame and model the environmental issues and impacts associated with the management of pallets throughout the entire life cycle. |

| (5) | [22] | J | To develop a parametric model describing LCI of a range of wooden pallets used as tertiary packaging. |

| (6) | [23] | J | To help increase the understanding of the impacts of decisions at each life-cycle phase of pallets and, by extension, returnable containers and other forms of packaging. |

| (7) | [24] | J | To assess, quantify, and compare the carbon emissions of recycled wood waste (technical wood) with virgin softwood in the application of wooden pallets using comparative carbon footprint assessment methodology. |

| (8) | [14] | J | To assess the potential of the compound method based on accounting for product carbon footprints. To evaluate the differences between this method and product carbon footprint. |

| (9) | [25] | C | To calculate the environmental impact of softwood (structural grade pine), hardwood, and plastic pallets compared to their key market alternatives: simple/one-way pallets of softwood or cardboard. |

| (10) | [26] | J | To provide a detailed comparison of the environmental impacts of the three pallet management strategies (single-use expendable, reusable buy/sell, and reusable leased pool) in each of the phases of the pallet lifecycle. |

| (11) | [27] | J | To explore and quantify the carbon equivalent (CO2 eq.) emissions associated with the remanufacturing operations of wood pallets while considering loading and service environment conditions. |

| (12) | [28] | R | To undertake a comparative study of the environmental credentials of various pallet options using life cycle assessment (LCA). |

| (13) | [15] | C | To provide guidance to the wooden pallet sector for environmental performance assessment and to enhance knowledge for developing environmental product declarations (EPDs) in the wood pallet manufacturing industry. |

| (14) | [6] | J | To develop an LCI for the repair process of 48 × 40 in. (1219 × 1016 mm) stringer-class in the United States. |

| (15) | [29] | J | To determine the maximum distance at which a repair facility can be located so that a closed-loop pallet system is both environmentally and economically sustainable. |

| (16) | [30] | J | To build a life cycle model for both wood and plastic pallets. |

| No. | Pallet Size (mm) | Stated Pallet Mass (kg) | Inputs | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wood (kg) | Plastic (kg) | Nails (kg) | Paint (kg) | Electricity (kWh) | Heat (MJ) | Fuel | |||

| (2)a | 1200 × 800 | 24.5 | 25.2 | - | 0.430 | 0.042 | 0.70 | 6.1 | 0.017 L, LFO o |

| 1200 × 800 | 24.3 | 25.5 | - | 0.430 | - | 0.70 | 5.7 | 0.017 L, LFO | |

| (3) | 1219 × 1016 | - | 22.5 | - | 0.360 b | - | 0.95 | - | 0.18 L, diesel |

| 1219 × 1016 | 20.4 | - | 20.5 | - | - | 8.5 | - | - | |

| (5) | 1200 × 800 | 8.55 | 8.37 | - | 0.180 | - | - c | - | - |

| (6) | 1219 × 1016 | - | 13.8 | - | 0.324 b | - | 0.12 | 10.0 | - |

| 1219 × 1016 | - | 29.7 | - | 0.378 b | - | 0.093 | 10.0 | - | |

| 1219 × 1016 | - | 31.6 | - | 0.459 b | - | 0.062 | 10.0 | - | |

| (7) | 1200 × 800 | - | 17.1 | - | 0.272 | - | 0.20 | 0.60 | - |

| 1200 × 800 | - | 11.9 d | - | 0.272 | - | 0.20 | - | - | |

| (8)e | 1200 × 800 | - | 9.10 | - | 0.490 | - | 2.2 | - | 0.16 L, gas oil |

| (9) | 1165 × 1165 | - | 20.9–31.3 f | - | 0.390 | 0.14–0.15 | 0.47–1.00 | 0.39–1.56 | - |

| 1200 × 1000 | - | 14.2–18.5 f | - | 0.530 | 0.083 | 0.50–1.00 | 1.04–1.56 | - | |

| 1165 × 1165 | 34.0 | - | 35.7 g | - | 0.36 h | 35.7 | - | - | |

| 1200 × 1000 | 19.4 | - | 19.4 | - | 0.20 i | 25.0 | - | - | |

| (12) | 1200 × 1000 | 13.8 | - | 16.2 j | - | - | 190 | - | 0.0040–0.0060 L, diesel |

| 1090 × 1090 | 15.5 | - | 18.3 j | - | - | 170 | - | 0.0036–0.0053 L, diesel | |

| 1200 × 1000 | 35.0 | - | 41.3 j | - | - | 430 | - | 0.0091–0.0136 L, diesel | |

| - | 13.0 | 13.0 | - | 0.310 | - | 0.29–0.58 | 0.60–0.90 | ||

| - | 17.0 | 17.0 | - | 0.290 | - | 0.27–0.55 | 0.57–0.81 | ||

| - | 37.5 | 35.0–40.0 | - | 0.690 | - | 0.61–1.40 | 0.85–1.45 | ||

| - | 6.50 | - | 6.5 k | - | 0.070 h | 8.38 | - | - | |

| - | 34.0 | - | 34.4 k | - | 0.39 h | 48.3 | - | - | |

| (16) | 1200 × 800 m | - | 20.0–25.0 | - | - n | - | 0.10–0.13 | - | 0.032–0.039 L, diesel |

| 1200 × 800 | 25.0 | - | 25 l | - | - | 14.1 | - | 0.63 L, diesel | |

| Component | Number of Components | Length (mm) | Width (mm) | Thickness (mm) | Volume (m3) | Density (kg/m3) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| Bottom deck lead board | 2 | 1200 | 100 | 22 | 0.0053 | 474 | 2.50 |

| Top deck lead board | 2 | 1200 | 145 | 22 | 0.0077 | 3.63 | |

| Central bottom deck board | 1 | 1200 | 145 | 22 | 0.0038 | 1.81 | |

| Stringer board | 3 | 800 | 145 | 22 | 0.0077 | 3.63 | |

| Central top deck board | 1 | 1200 | 145 | 22 | 0.0038 | 1.81 | |

| Intermediate top deck board | 2 | 1200 | 100 | 22 | 0.0053 | 2.50 | |

| Outer skid block | 6 | 145 | 100 | 78 | 0.0068 | 3.22 | |

| Center skid block | 3 | 145 | 145 | 78 | 0.0049 | 2.33 | |

| Nails | 78 | - | - | - | - | - | 0.38 |

| Total | 21.82 | ||||||

| No. | Material | Pallet Size (mm) | GWP Per Pallet (kg CO2-eq.) | GWP Per Cycle (kg CO2-eq.) | Life Cycle Stage 1 | ||||

|---|---|---|---|---|---|---|---|---|---|

| RMA and PP | MAN | DIS | USE | EOL | |||||

| (1) | Wood 2 | 1219 × 1016 | 1.9 | 0.3 | 1.6 | ||||

| Wood 2 | 1219 × 1016 | 2.5 | 1.1 | 1.4 | |||||

| Wood 2,3 | 1219 × 1016 | 4.4 | 2.9 | 1.5 | 0.064 | ||||

| (2) | Wood | 1200 × 800 | 8.2 | −39 | 0.91 | 57 | −12 | 2.1 | |

| Wood | 1200 × 800 | −26 | −40 | 0.88 | 10 | −0.75 | 4.0 | ||

| (3) | Wood | 1219 × 1016 | 21 | 1.2 | 10 | 9 | 2.0 | ||

| Plastic | 1219 × 1016 | 166 | 1.3 | 50 | 110 | 5.8 | |||

| (4) | Wood | 17 | 0.67 | ||||||

| (5) | Wood 2 | 1200 × 800 | 2.3 | 3.1 | 0.18 | −1.0 | |||

| (6) | Wood 3 | 1219 × 1016 | −5.6–2.1 | 1.7 | 0.23 | 0.19 5 0.11 −7.6 | |||

| Wood | 1219 × 1016 | −13–6.5 | 3.0 | 0.21 | 3.0 4 | 0.42 5 0.27 −19 | |||

| Wood | 1219 × 1016 | −11–7.6 | 3.5 | 0.19 | 3.7 4 | 0.44 5 0.22 −18 | |||

| (7) | Wood | 1200 × 800 | 4.0 | 3.8 | 0.21 | ||||

| Composite | 1200 × 800 | 3.5 | 3.4 | 0.12 | |||||

| (8) | Wood 2 | 1200 × 800 | 9.9 c | ||||||

| Wood | 1200 × 800 | 8.1 | 6.2 | 1.3 | 0.57 | ||||

| (9) | Wood | 1200 × 1000 | 20–26 6 | 0.44–0.58 | |||||

| Wood | 1165 × 1165 | 50–61 6 | 0.60–0.73 | ||||||

| Plastic | 1200 × 1000 | 61 | 0.98 | ||||||

| 1165 × 1165 | 102 | 1.6 | |||||||

| Wood 2 | 1200 × 1000 | 3.1 | 1.6 | ||||||

| 1165 × 1165 | 2.2 | 1.1 | |||||||

| (11) | Wood | 1219 × 1016 | 3.7 | 3.7 7 | |||||

| (12) | Plastic | 1200 × 1000 | 3.7 | 1.4–4.1 | 3.7 | ||||

| Plastic | 1090 × 1090 | 4.1 | 2.0–6.1 | 4.1 | |||||

| Wood | 1200 × 1000 | 8.8 | 7.2–22 | 8.8 | |||||

| Plastic | 1200 × 1000 | 22 | 9.2–28 | 22 | |||||

| (14) | Wood | 1219 × 1016 | −0.20 | −0.20 8 | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deviatkin, I.; Khan, M.; Ernst, E.; Horttanainen, M. Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies. Sustainability 2019, 11, 5750. https://doi.org/10.3390/su11205750

Deviatkin I, Khan M, Ernst E, Horttanainen M. Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies. Sustainability. 2019; 11(20):5750. https://doi.org/10.3390/su11205750

Chicago/Turabian StyleDeviatkin, Ivan, Musharof Khan, Elizabeth Ernst, and Mika Horttanainen. 2019. "Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies" Sustainability 11, no. 20: 5750. https://doi.org/10.3390/su11205750

APA StyleDeviatkin, I., Khan, M., Ernst, E., & Horttanainen, M. (2019). Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies. Sustainability, 11(20), 5750. https://doi.org/10.3390/su11205750