1. Introduction

The share of renewables in global electricity generation reached almost 29% in 2020 [

1], and the renewable installed capacity amounted to 2.79 TW in the same year [

2]. The predominant renewable resources in electricity generation are hydropower, wind, and solar power, which correspond to a share of renewable installed capacity of about 43%, 26%, and 25%, respectively [

2]. Among solar energy technologies, concentrating solar power (CSP) systems efficiently generate electricity from solar energy using a thermodynamic cycle, such as Rankine, Brayton, or Stirling [

3]. These technologies are very promising and are increasingly deployed worldwide, especially in countries located in the Sunbelt region (including countries in the Mediterranean, North and South Africa, China, India, Latin America, and Australia), as they are characterized by very high levels of direct normal irradiance (DNI) [

4,

5]. CSP systems mainly consist of a collector, which can be of different shapes and is designed to capture and subsequently concentrate the sun’s rays onto a receiving system, a solar tracking system and a power conversion unit (PCU). These technologies can be classified into four further types, namely: parabolic troughs and Fresnel linear reflectors, which are defined as line-focusing technologies as their collectors linearly concentrate the solar radiation onto a receiver tube; and central towers and parabolic dish systems which are point-focusing technologies that have a collector that concentrates the solar radiation on a single point receiver [

6].

Among these technologies, parabolic trough systems, solar towers and Fresnel linear reflectors are the most commercially mature, as they are characterized by high conversion efficiencies, can be coupled with thermal storage systems to generate electricity even during the hours when direct solar irradiation is not available, and do not emit greenhouse gases during their operation.

Dish-Stirling concentrators mainly comprise the paraboloidal shaped reflector that concentrates the sun’s rays on a focal point where the receiver and the entire PCU are fixed, the biaxial tracking system, and the cooling system of the engine. The high-temperature thermal energy obtained is transferred to the Stirling engine for the production of mechanical energy, and this is finally converted into electricity by means of an electric generator [

7]. When compared to other CSP technologies, dish-Stirling systems have the lowest commercial penetration although they feature the highest solar-to-electric conversion efficiency and geometric concentration ratios [

8,

9,

10,

11,

12,

13]. Indeed, some factors limit the competitiveness of dish-Stirling systems, and essentially these consist of the high installation cost [

10,

12] and the difficulty of coupling such systems to thermal storage systems [

11].

In order to improve the market penetration of dish-Stirling systems, several theoretical and experimental studies have been conducted on both system optimization and the investigation of applications in various fields such as cogeneration, drinking water production, off-grid electrification, water pumping, thermal and electrical energy storage, and hybridization [

13,

14]. The hybridization of renewable electricity generation technologies, such as dish-Stirling systems, by exploiting different primary energy sources in addition to solar energy, would make it possible to extend the operating period and solve the problem of the aleatory and intermittent nature of the solar source. In this way, the hybridization of the CSP dish-Stirling systems would ensure more stable production, and therefore greater flexibility in meeting electricity demands, which do not always match the period of availability of solar radiation [

15]. Furthermore, if the solar source is combined with another renewable energy source, it would be possible to achieve not only an increase in electricity production, but also a significant environmental benefit in terms of avoided CO

2 equivalent emissions.

Both theoretical and experimental studies have been carried out on the hybridization of dish-Stirling systems. Monné et al. carried out an energy analysis and life cycle assessment on two possible configurations of a 10 kW

e hybrid dish-Stirling system using natural gas and biogas considering Seville (Spain) as the climatic location. The data analysed showed that hybridization can be advantageous depending on the nature of the fuel used, and biogas is the best performing [

16,

17]. Hartenstine et al. studied the operation of a hybrid receiver by means of numerical simulations and demonstrated its technological feasibility through small-scale tests. The hybrid receiver was designed to achieve an overall thermal efficiency of at least 80%. The main objective of this development was to design, fabricate and demonstrate that a heat pipe receiver can operate using different energy sources, even simultaneously. A full-scale hybrid receiver was then fabricated, demonstrating the possibility of ensuring maximum and continuous electrical output from the system [

18]. Within the same project, BIOSTIRLING-4SKA, Blázquez et al. performed the optimization of the concentrator geometry and receiver cavity according to the requirements of the flow distribution on the receiver walls set by the hybrid receiver designer [

19], and Barbosa et al. tested hybridization with syngas produced from biomass [

20]. Kang et al. experimentally investigated the heat transfer characteristics of the hybrid solar receiver for a concentrated dish system in order to achieve an improvement in energy and economic efficiency [

21]. Laing et al. developed a hybrid sodium heat pipe receiver as part of the HYHPIRE project. The hybrid receiver was designed for the SBP/LCS 10-kWel dish/Stirling system with the SOLO-161 Stirling engine. The system was successfully tested in all operating modes reaching generation efficiencies of 16% in solar-only mode, 17% in gas-only mode, and 15% in hybrid-mode with a maximum gross output power of 7.8 kW. A market-ready combustion system was developed for the SOLO 161 CHP engine, also demonstrating a reduced environmental impact [

22]. Moreno et al. designed and tested a prototype of a hybrid dish-Stirling combustion system. The system consisted of a pre-mixed natural gas burner that heats a finned sodium heat pipe. The experimentally validated design emphasised simplicity, low cost and robustness [

23].

In this paper, a theoretical and parametric study is presented, aimed at evaluating and verifying the energy and environmental benefits that could be obtained by modifying the operating set-up of the dish-Stirling system installed at the university campus of Palermo, in Southern Italy, from solar to hybrid. The hybridization of this system, which already mounts a suitable engine for that purpose, will be the subject of future projects and experiments. The dish-Stirling system of Palermo, which was manufactured by the Swedish company Ripasso Energy, has a peak electrical power of 31.5 kW

e with a DNI of 960 W/m², and holds the current worldwide record for solar-to-electric conversion efficiency of 32% (a record set at the test site in Upington, South Africa) [

11]. In this work, energy and environmental analyses were carried out by varying certain factors, such as: the operating strategy of the hybrid power plant, i.e., the number of hours per day during which the system operates in solar or hybrid mode; the installation site (with different levels of DNI); and the type of fuel gas used to supply the combustion unit. Specifically, the operation of the dish-Stirling system in hybrid configuration was investigated assuming the use of natural gas or biogas and syngas, both derived from lignocellulosic biomass. In addition to Palermo, the other two installation sites considered in this study already host two large CSP plants: the first, to the west of Abu Dhabi (United Arab Emirates), hosts Shams, which is the largest renewable energy project in operation in the Middle East, with a capacity of 100 MW [

24]; and the second, in the Mojave Desert (California, United States), where the Mojave Solar Project (MSP), with a total power capacity of 250 MW, is installed [

25]. To carry out the environmental analysis in the aforementioned locations, the energy and technological context of each country was taken into account to find a solution that can potentially push the system towards widespread use.

The paper is structured as follows:

The second section defines and describes the energy model of the hybrid dish-Stirling system and the methodology used to carry out the environmental analysis of the same system.

In the third section, the reference dish-Stirling system is described, and an overview of the different case studies investigated is illustrated, varying the installation location and the specific fuel gas used.

The fourth section shows the results obtained in terms of both energy performance and achievable environmental benefits.

Finally, in the fifth section, the conclusions of this research are drawn.

2. Materials and Methods

As mentioned above, dish-Stirling systems efficiently convert direct solar radiation into electrical energy. However, the intermittent and aleatory nature of the solar energy source makes the energy generation discontinuous and, therefore, it may not meet the energy demand of the end-user. Among the various CSP technologies, one of the advantages of solar concentrators driven by Stirling engines is that it can be powered by high-temperature thermal energy obtained from any type of energy source, whether renewable or not. The hybridization of Stirling engines would allow the solar plant to operate even in the absence of direct solar radiation; for example, at night or on days when the sky is not clear. Thus, the Stirling engine could be powered by thermal energy obtained from the concentration of direct solar radiation, or alternatively by thermal energy obtained from the combustion of fuel gases in an external combustion unit.

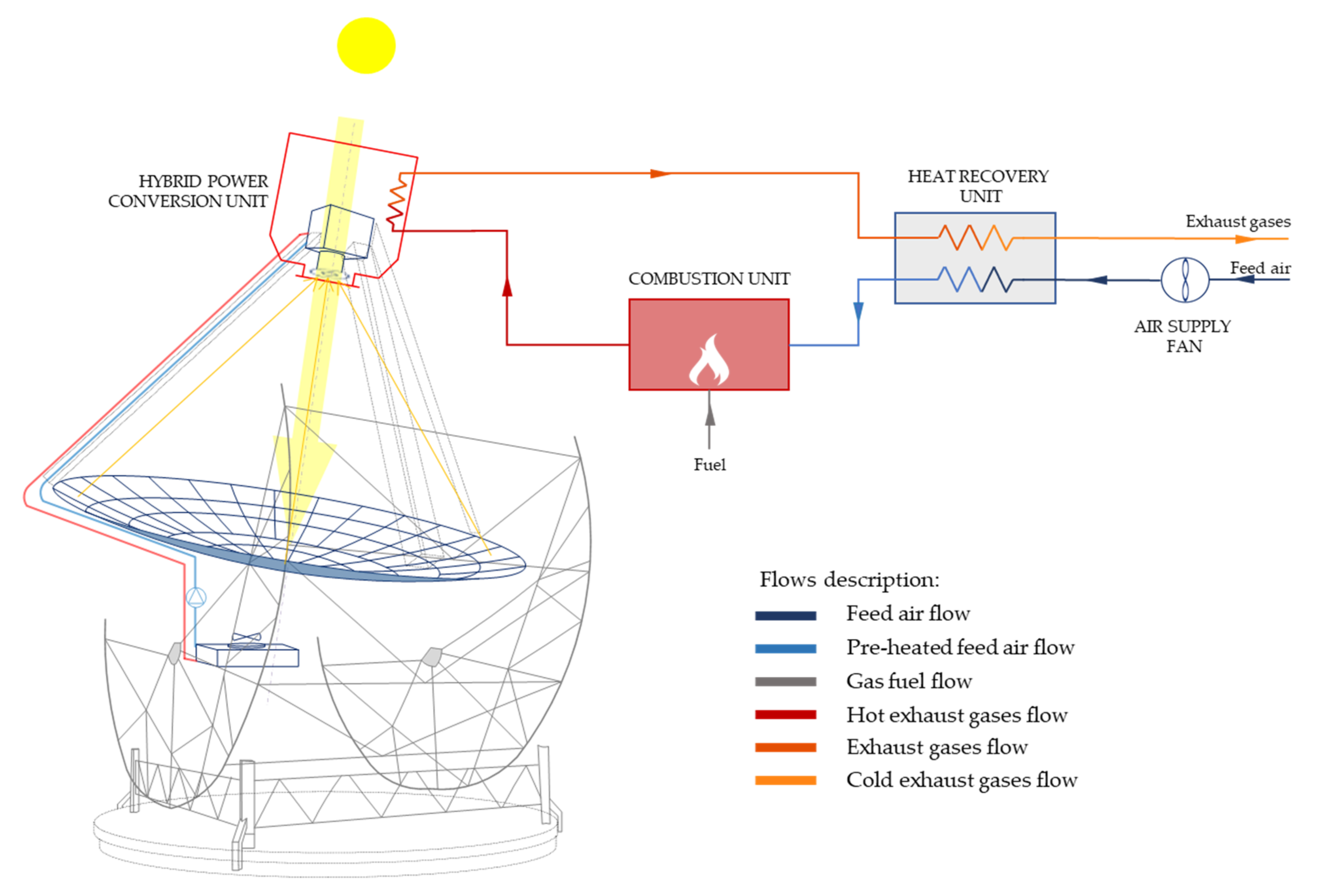

For this purpose, as shown in

Figure 1 below, the hybrid dish-Stirling solar concentrator system layout should include the following additional components:

The combustion unit including the combustion chamber, the ignition device, the fuel controller, and the burner.

The fuel feeding system, i.e., the set of pipes and components required to transport the fuel used into the combustion unit.

The fan supplying the air that is used as a comburent to the combustion chamber.

The heat recovery unit, i.e., a heat exchanger capable of pre-heating the air delivered to the combustion chamber by recovering part of the residual heat from the exhaust gases.

A control system that allows the switching of the operation mode of the dish-Stirling system from solar to hybrid.

The operation of the hybrid dish-Stirling system (see

Figure 1) employs high-temperature gases produced by the oxidation reaction of the fuel gas in the presence of air in the combustion chamber. These gases flow towards the power conversion unit (PCU) providing the high-temperature thermal power required for running the Stirling engine. In this way, the working fluid (hydrogen, air, or helium) reaches its nominal temperature and pressure conditions necessary to evolve inside the Stirling engine and perform the thermodynamic transformations of the homonymous cycle. Downstream of the heat exchange in the PCU, the still hot exhaust gases are sent to a heat recuperator in order to preheat the countercurrent feed airflow.

2.1. Energy Model of a Hybrid Dish-Stirling Concentrating Solar Power Plant

The heart of the hypothesized hybrid solar plant layout is undoubtedly the dish-Stirling solar concentrator, whose engine can be powered by the high-temperature thermal energy obtained from either concentrating solar radiation or the combustion of various types of fuels. In order to assess the energy producibility of the hybrid dish-Stirling system, it is necessary to update the reference energy model of the solar power plant [

26], which was calibrated and validated on the basis of experimentally collected data. To this aim, new terms relating to the energy input and losses characterizing the operation of the system in hybrid set-up were added. The reference energy model, based on the energy balance of the system, approximates the dependence between the mechanical output power

and the thermal input power

of the engine with a linear correlation, as shown in Equation (1) below:

where

and

are two fitting parameters characterizing the linear correlation, and

is an ambient temperature correction factor defined as the ratio between the ambient temperature reference value (set at 25 °C) and the actual temperature, both expressed in Kelvin degrees.

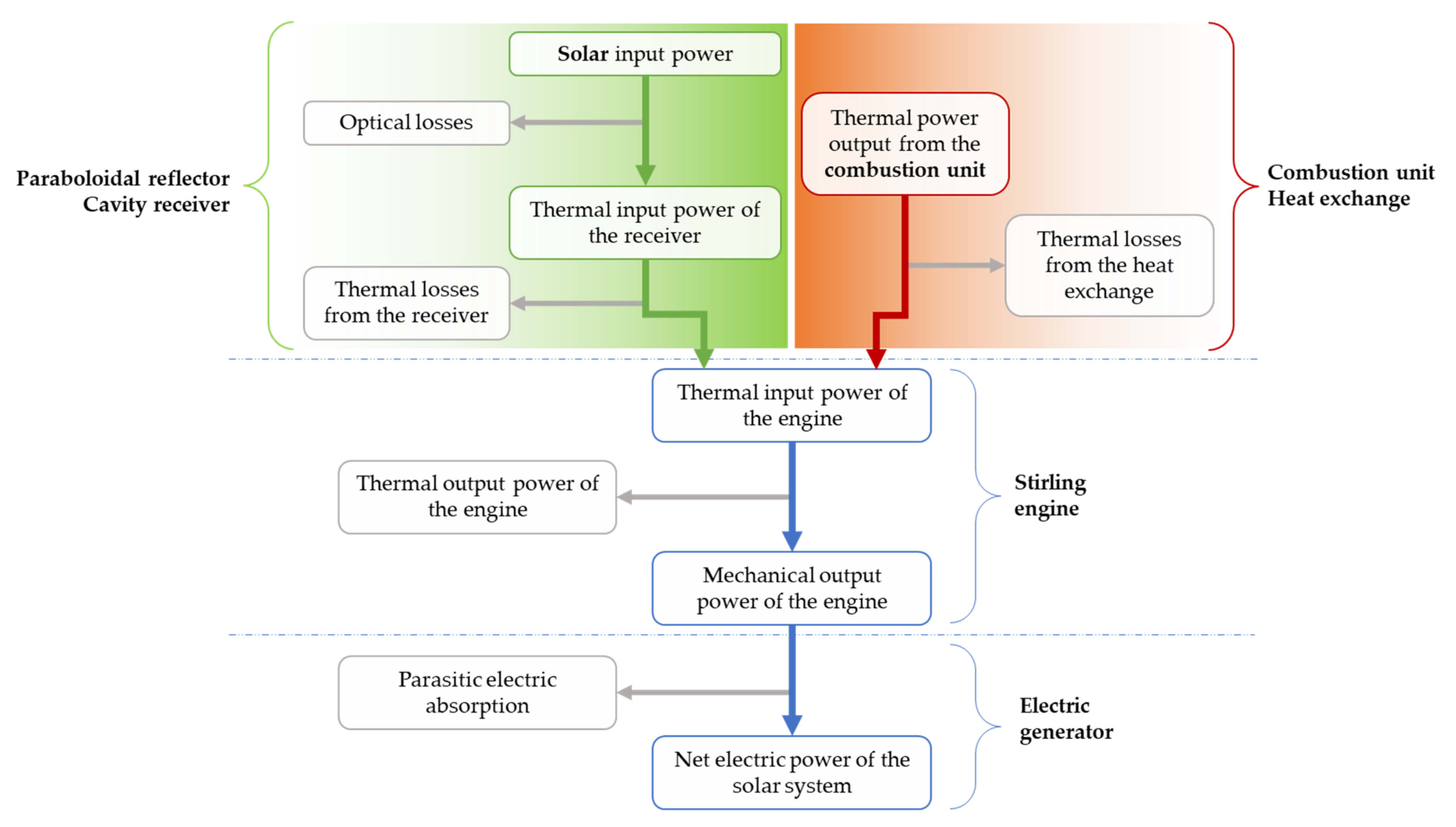

As shown in

Figure 2, according to the hybridization hypothesis to be investigated,

represents the engine input thermal power that will be obtained from the available DNI or, alternatively, from the products of gas combustion. In both cases, it is necessary to take into account the upper operating limit of the Stirling engine in terms of the maximum thermal power input to the engine.

When the dish-Stirling concentrator operates in solar mode (see

Figure 2), the thermal power delivered to the Stirling engine

is obtained as the difference between the solar power concentrated at the receiver and the amount of power lost because of thermal and optical inefficiencies. Starting from the paraboloidal reflector, the collected solar power

is defined as the product of the solar beam radiation

, and the net mirror area

as described in Equation (2) below:

Considering the optical inefficiencies of both reflector and receiver surfaces, the power absorbed by the receiver cavity

can be evaluated as follows:

where

indicates the cleanness level of mirrors,

is the optical efficiency of the concentrator obtained as a product of the reflectivity of mirrors

, the intercept factor

which takes into account the tracking errors, the focusing inaccuracy and the wind effect, etc., and the absorption coefficient of the receiver cavity

. Additionally, due to the differences in temperature between the receiver and the surrounding environment, the receiver energy balance is also affected by thermal losses, which can be divided into convective

and radiative thermal losses

, as defined in the equations below:

The following variables are included in these last equations:

the average temperature of the receiver cavity ;

the external air temperature ;

the effective sky temperature

that was derived by the following empirical expression [

27,

28,

29]:

the aperture area of the receiver ;

the emissivity of the receiver cavity ; and

the Stefan–Boltzmann constant .

Finally, the thermal power delivered to the Stirling engine

can be expressed as follows:

On the other hand, when the dish-Stirling concentrator is operating in non-solar-mode (see

Figure 2), it is assumed that the maximum thermal input power that can be processed by the Stirling engine is obtained through heat exchange with the hot gases coming from the combustion chamber. More specifically, in this case, the thermal power fed into the Stirling engine

is equal to the nominal thermal power of the combustor reduced by the thermal losses due to its inefficiencies

and the heat exchange between the hot gases coming from the combustor and the working fluid of the engine

. Thus, it is possible to derive the volumetric flow rate of the fuel gas

supplied to the combustor inlet as follows:

where

is the lower heating value of the used fuel gas.

To summarize, the mechanical power delivered by the engine (defined by Equation (1)) can be recast as follows, depending on the operating mode of the system:

For both modes of operation explored, the net electrical power generated by the system under consideration can be defined as the difference between the gross electric output power and the electric power absorbed by the auxiliary components

. Among them, the cooling system of the Stirling engine and the solar tracking system were considered. Moreover, taking into account the mechanical-to-electric power conversion efficiency of the electric generator

, the gross electric output power of the system

can be written as in the following equation:

In conclusion, the net electrical power generated by the system

can be defined as follows:

Therefore, knowing the annual energy producibility of the hybrid system

obtained by integrating the instantaneous electric output power of the system (see Equation (10)) over time, the annual generation efficiency of the system

can be assessed as follows:

where

and

are the annual amounts of electricity produced by solar energy source and fuel, respectively, in the

t-th year; and

and

are the annual energy input to the hybrid dish-Stirling system when it operates in solar mode and non-solar-mode, respectively, during the same year.

In this study, the energy performance of the dish-Stirling system analysed in the hybrid-operating configuration was measured on the basis of the annual electricity production efficiency value calculated as in Equation (11).

2.2. Environmental Analysis

In this study, the environmental analysis of the proposed hybrid dish-Stirling system was carried out by assessing the amount of CO2 equivalent avoided emissions, as well as the amount of CO2 that would be emitted annually if the same amount of electricity produced from renewable sources had instead been produced using technologies powered by fossil fuels such as natural gas, oil, or coal. The conversion factor of electricity to CO2 e emissions depends essentially on two factors, which are the fossil fuel mix typical of the selected country and the categories of technologies for electricity generation that are considered.

Technologies for generating electricity from renewable sources can make a significant contribution to the reduction of greenhouse gas emissions into the atmosphere. Indeed, a life cycle assessment of the various renewable (biopower, photovoltaics, concentrating solar power, geothermal energy, hydropower, ocean energy, and wind energy) and non-renewable electricity generation technologies (nuclear energy, natural gas, oil, and coal) shows that the environmental impact of the former is considerably lower than that of the latter [

30]. Specifically, according to the Special Report of the Intergovernmental Panel on Climate Change (IPCC) on Renewable Energy Sources and Climate Change Mitigation (SRREN), it can be observed that the estimated median values of lifecycle Greenhouse Gases (GHG) emissions for renewable energy technologies do not exceed 0.046 kgCO

2 e/kWh with photovoltaics [

30]. On the other hand, these median values for technologies fuelled by non-renewable sources reach 0.469, 0.84, and 1.001 kgCO

2 e/kWh for natural gas, oil, and coal, respectively [

30].

The fossil fuel energy mix of a specific country has been extrapolated from data and statistics published by the International Energy Agency (IEA), which provide the annual electricity generation for each country in the world, from 1990 to 2020, and the share of energy produced from fossil and renewable sources [

31].

The amount of equivalent CO

2 avoided emissions

, expressed in tonnes per year, was assessed using the following equation:

where

is the total renewable electricity generated by the investigated hybrid power plant during the

t-th year (expressed in kWh per year), and

is the median value of lifecycle GHG emissions referring to the fossil fuel energy mix (natural gas, oil, coal) that characterized the selected country, expressed in kgCO

2 e/kWh.

4. Results and Discussion

In accordance with the energy model described and detailed in

Section 2.1, it was possible to estimate the electrical energy production of the investigated hybrid dish-Stirling system in both solar and non-solar operating modes.

Table 5 shows the annual electricity productions that were evaluated for all the considered scenarios: the electricity production indicated for Scenario 0

is calculated considering the system operating always and only in solar operation mode, while the electricity production indicated for Scenarios I, II, and III is strictly related to the period in which the same system operates in non-solar mode

. Therefore, to these latter quantities

, the production from solar sources

must be added to obtain the total annual production of the hybrid system

.

From

Table 5, it can be observed that electricity production evaluated for Scenario 0 clearly increases by considering Palermo, Abu Dhabi and the Mojave Desert, in that order, as they are characterized by progressively higher levels of DNI (see Scenario 0 in

Table 5). On the other hand, the electricity generated by the combustion of fuel does not reflect this same trend as the location varies. Indeed, the conversion efficiency of the Stirling engine is affected by the effectiveness of the heat exchange with the environment on the cold side, and this is worse in Abu Dhabi, being the warmest location (see

Figure 5). Specifically in Palermo, annual simulations show that the hybridization of the dish-Stirling system would increase solar electricity production by 63%, 74%, and 78% for scenarios I, II, and III, respectively.

Furthermore, from

Table 6, which shows the generation efficiency values calculated in accordance with Equation (11), it emerges that the increase in annual electricity production of the hybrid system would also be accompanied by an improvement in its generation efficiency, which is greater the longer the period of non-solar operation of the system (it becomes maximum for Scenario III).

Concerning the operation of the dish-Stirling system in solar mode (Scenario 0), the results obtained from the annual simulations show that the system could achieve an annual generation efficiency of 35.7% if it was installed at the Mojave Desert location. This efficiency value is higher than those obtained for the other two installation locations investigated. This result is supported by the fact that, from the hourly-frequency distribution of DNI for the Mojave Desert on an annual basis (see

Figure 4), approximately 50% of the hours with DNI greater than 250 W/m² fall within the DNI range between 850 and 1000 W/m², and of these, approximately 45% of the hours correspond to DNI values between 900 and 950 W/m². This would mean that if the dish-Stirling pilot plant installed in Palermo, having been sized for a nominal DNI level of 960 W/m², was installed in the Mojave Desert, it could exhibit the best conversion efficiency when operating in solar mode, achieving a generation efficiency on an annual basis of 35.7.

Table 7,

Table 8 and

Table 9 below show results obtained from the environmental analysis in terms of avoided CO

2 equivalent emissions expressed in tons per year, as explained in

Section 2.2 above. To this aim, the median value of lifecycle GHG emissions referring to the fossil fuel energy mix of each selected country was used (see

Table 4).

Specifically,

Table 7 shows the equivalent avoided CO

2 emissions

that could be achieved through the generation of renewable electricity by the dish-Stirling system operating in solar mode. From these results, it can be seen that the expected environmental benefits change significantly depending on the assumed location of the renewable energy plant, because the energy mix on which each country’s energy production is based differs. Of the three possible locations considered, the avoided CO

2 equivalent emissions would be higher if the dish-Stirling system were installed in the Mojave Desert, as coal currently accounts for 39% of total electricity production in the United States.

Furthermore, referring to the hybrid dish Stirling system fed with syngas or biogas, the avoided quantities of CO

2 equivalent emissions obtained for Scenario 0 (see

Table 7) should be increased by the quantities calculated for Scenarios I, II and III (see

Table 8). Indeed, in this case, the dish Stirling would operate in hybrid mode using not only the solar source, but also heat obtained from the combustion of syngas or biogas, which can be considered renewable and CO

2-neutral if derived from lignocellulosic biomass.

It would be different if the Stirling engine in the hybrid configuration were powered by natural gas instead of biogas or syngas. In this case, the CO2 avoided emissions were evaluated as the difference between those calculated considering the emission factor characteristic of the country of interest and those calculated considering the emission factor related to the use of only natural gas. These results are reported in the following table.