Approaching a Zero-Waste Strategy in Rapeseed (Brassica napus) Exploitation: Sustainably Approaching Bio-Based Polyethylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Compound Generation

2.2. Composite Characterization

3. Results

3.1. Rapeseed Fibers Analysis

3.2. Coupling Agent Dosage Study

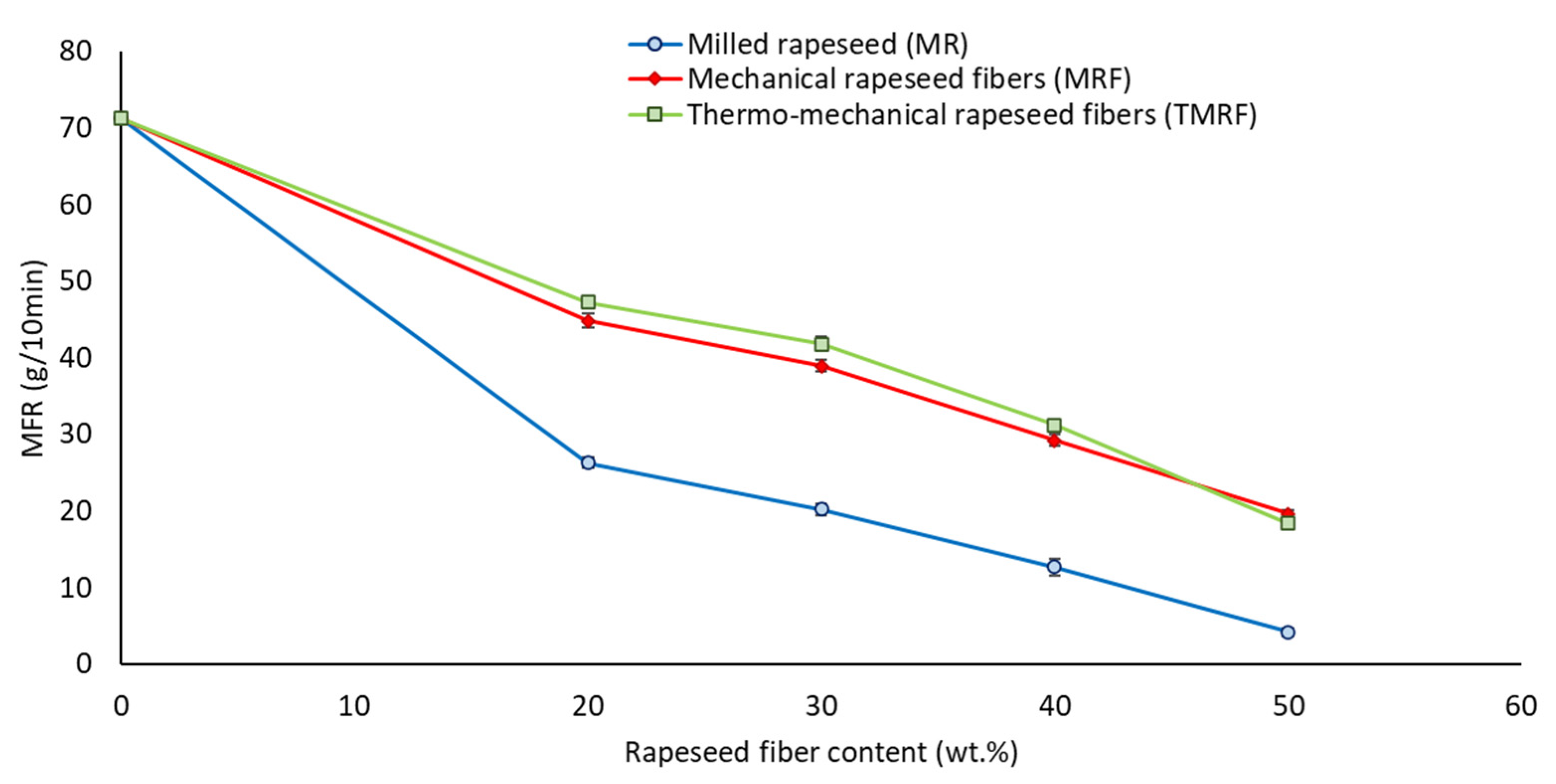

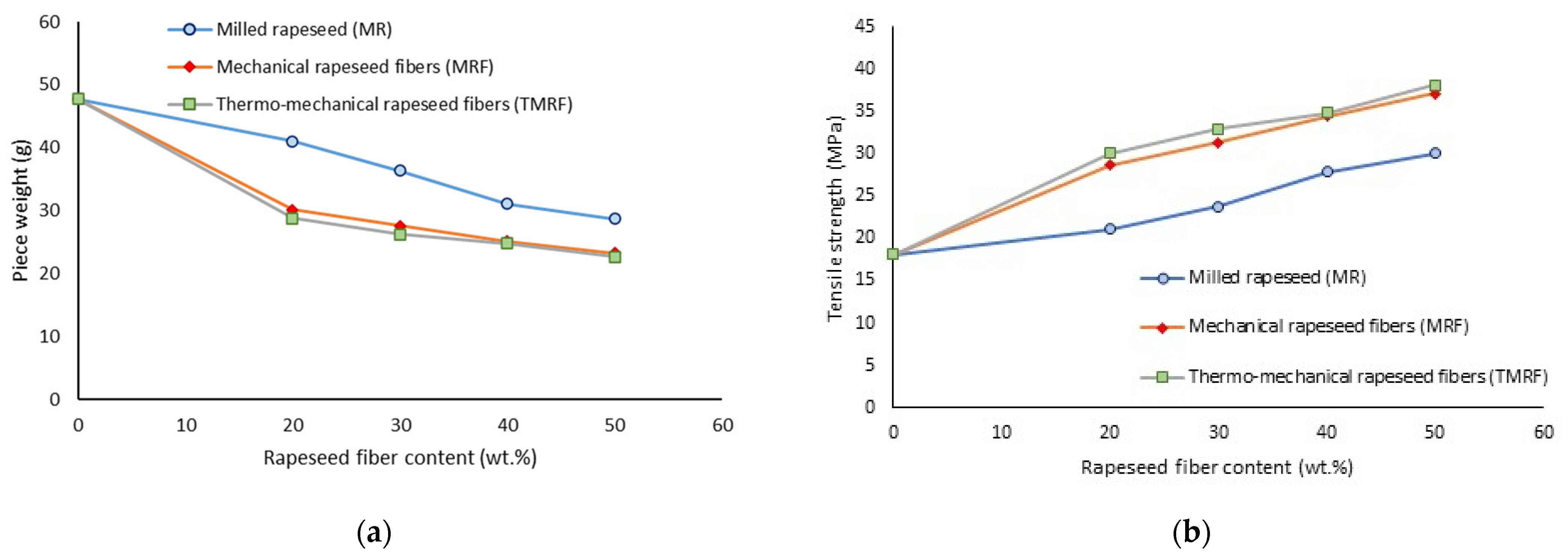

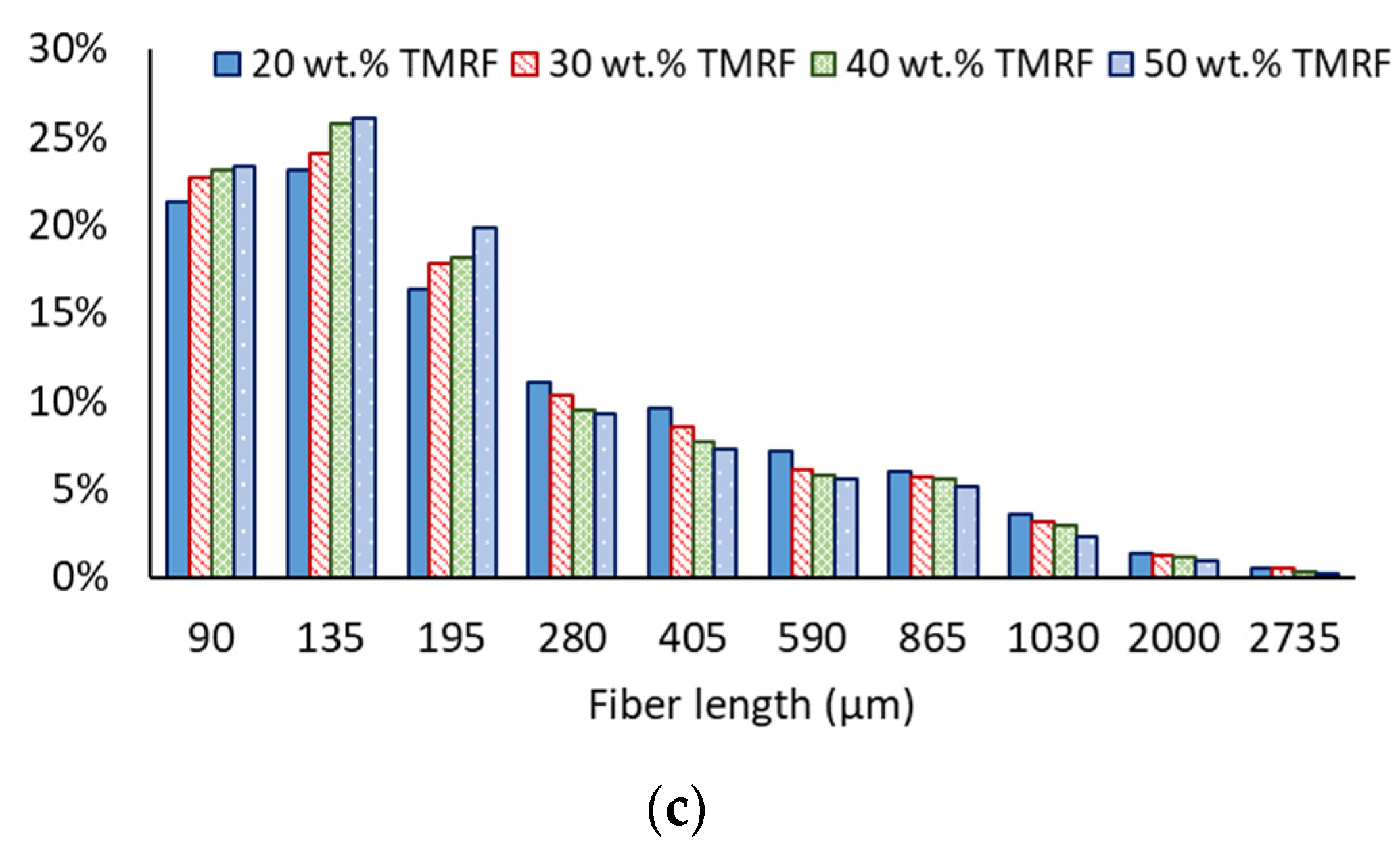

3.3. Physical Properties of Composites

3.4. Composite Macromechanical Analysis

3.5. Composite Micromechanical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gareiou, Z.; Chroni, C.; Kontoleon, K.; El Bachawati, M.; Saba, M.; Martin, R.H.; Zervas, E. Awareness of Citizens for the Single-Use Plastics: Comparison between a High-Income and an Upper-Middle-Income Economy of the Easter Mediterranean Region, Greece and Lebanon. Sustainability 2022, 14, 1912. [Google Scholar] [CrossRef]

- Herberz, T.; Barlow, C.Y.; Finkbeiner, M. Sustainability assessment of a single-use plastics ban. Sustainability 2020, 12, 3746. [Google Scholar] [CrossRef]

- Otoni, C.G.; Azeredo, H.M.C.; Mattos, B.D.; Beaumont, M.; Correa, D.S.; Rojas, O.J. The Food–Materials Nexus: Next Generation Bioplastics and Advanced Materials from Agri-Food Residues. Adv. Mater. 2021, 33, 2102520. [Google Scholar] [CrossRef] [PubMed]

- Melchor-Martínez, E.M.; Macías-Garbett, R.; Alvarado-Ramírez, L.; Araújo, R.G.; Sosa-Hernández, J.E.; Ramírez-Gamboa, D.; Parra-Arroyo, L.; Alvarez, A.G.; Monteverde, R.P.B.; Cazares, K.A.S.; et al. Towards a Circular Economy of Plastics: An Evaluation of the Systematic Transition to a New Generation of Bioplastics. Polymers 2022, 14, 1203. [Google Scholar] [CrossRef]

- Van den Oever, M.; Molenveld, K.; van der Zee, M.; Bos, H. Bio-Based and Biodegradable Plastics: Facts and Figures; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2017; ISBN 978-94-6343-121-7. [Google Scholar]

- Bortolatto, R.; Bittencourt, P.R.S.; Yamashita, F. Biodegradable composites of starch/polyvinyl alcohol/soybean hull (Glycine max L.) produced by thermoplastic injection. J. Appl. Polym. Sci. 2022, 139, 52288. [Google Scholar] [CrossRef]

- Lekrine, A.; Belaadi, A.; Makhlouf, A.; Amroune, S.; Bourchak, M.; Satha, H.; Jawaid, M. Structural, thermal, mechanical and physical properties of Washingtonia filifera Fibres Reinforced Thermoplastic Biocomposites. Mater. Today Commun. 2022, 31, 103574. [Google Scholar] [CrossRef]

- Fourati, Y.; Tarrés, Q.; Mutjé, P.; Boufi, S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr. Polym. 2018, 199, 51–57. [Google Scholar] [CrossRef]

- Kiliç, E.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, X.; Fullana-I.-palmer, P.; Puig, R. Leather waste to enhance mechanical performance of high-density polyethylene. Polymers 2020, 12, 2016. [Google Scholar] [CrossRef]

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of Natural Fiber-Reinforced Plastics (NFRP) Based on Biobased Polyethylene and Waste Fibers From Posidonia oceanica Seaweed. Polym. Polym. Compos. 2008, 36, 1378–1385. [Google Scholar] [CrossRef]

- Shah, N.; Fehrenbach, J.; Ulven, C.A. Hybridization of hemp fiber and recycled-carbon fiber in polypropylene composites. Sustainability 2019, 11, 3163. [Google Scholar] [CrossRef] [Green Version]

- Reixach, R.; Espinach, F.X.; Arbat, G.; Julián, F.; Delgado-Aguilar, M.; Puig, J.; Mutjé, P. Tensile properties of polypropylene composites reinforced with mechanical, thermomechanical, and chemi-thermomechanical pulps from orange pruning. BioResources 2015, 10, 4544–4556. [Google Scholar] [CrossRef] [Green Version]

- Serra, A.; Tarrés, Q.; Llop, M.; Reixach, R.; Mutjé, P.; Espinach, F.X. Recycling dyed cotton textile byproduct fibers as polypropylene reinforcement. Text. Res. J. 2019, 89, 2113–2125. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.S.; Wolcott, M.P.; Kim, H.S.; Kim, H.J. Thermal properties of lignocellulosic filler-thermoplastic polymer bio-composites. J. Therm. Anal. Calorim. 2005, 82, 157–160. [Google Scholar] [CrossRef]

- Deng, Y.; Tian, Y. Assessing the environmental impact of flax fibre reinforced polymer composite from a consequential life cycle assessment perspective. Sustainability 2015, 7, 11462–11483. [Google Scholar] [CrossRef] [Green Version]

- Rajput, P.; Sarin, M.; Sharma, D.; Singh, D. Characteristics and emission budget of carbonaceous species from post-harvest agricultural-waste burning in source region of the Indo-Gangetic plain. Tellus Ser. B Chem. Phys. Meteorol. 2014, 66, 21026. [Google Scholar] [CrossRef] [Green Version]

- Jannat, A.; Ishikawa-ishiwata, Y. Does Climate Change Affect Rapeseed Production in Exporting and Importing Countries? Evidence from Market Dynamics Syntheses. Sustainability 2022, 14, 6051. [Google Scholar] [CrossRef]

- D’Odorico, P.; Davis, K.F.; Rosa, L.; Carr, J.A.; Chiarelli, D.; Dell’Angelo, J.; Gephart, J.; MacDonald, G.K.; Seekell, D.A.; Suweis, S.; et al. The Global Food-Energy-Water Nexus. Rev. Geophys. 2018, 56, 456–531. [Google Scholar] [CrossRef]

- Jiang, S.; Li, B.; Shen, Y. The influence of pulp and paper industry on environment. Web Conf. 2021, 308, 02007. [Google Scholar] [CrossRef]

- Anastas, P.; Warner, J. Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Mboowa, D. A review of the traditional pulping methods and the recent improvements in the pulping processes. Biomass Convers. Biorefin. 2021, 1, 1–12. [Google Scholar] [CrossRef]

- Biermann, C. Handbook of Pulping and Papermaking, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 1996; ISBN 9780120973620. [Google Scholar]

- Das, T.K.; Houtman, C. Evaluating chemical-, Mechanical-, and bio-pulping processes and their sustainability characterization using life-cycle assessment. Environ. Prog. 2004, 23, 347–357. [Google Scholar] [CrossRef]

- Li, Y. Effect of coupling agent concentration, fiber content, and size on mechanical properties of wood/HDPE composites. Int. J. Polym. Mater. Polym. Biomater. 2012, 61, 882–890. [Google Scholar] [CrossRef] [Green Version]

- El-Sabbagh, A. Effect of coupling agent on natural fibre in natural fibre/polypropylene composites on mechanical and thermal behaviour. Compos. Part B Eng. 2014, 57, 126–135. [Google Scholar] [CrossRef]

- Kakou, C.A.; Arrakhiz, F.Z.; Trokourey, A.; Bouhfid, R.; Qaiss, A.; Rodrigue, D. Influence of coupling agent content on the properties of high density polyethylene composites reinforced with oil palm fibers. Mater. Des. 2014, 63, 641–649. [Google Scholar] [CrossRef]

- Rao, J.; Zhou, Y.; Fan, M. Revealing the interface structure and bonding mechanism of coupling agent treated WPC. Polymers 2018, 10, 266. [Google Scholar] [CrossRef] [Green Version]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Ismadi; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M.; Clemons, C.M. Effect of processing method on surface and weathering characteristics of wood-flour/HDPE composites. J. Appl. Polym. Sci. 2004, 93, 1021–1030. [Google Scholar] [CrossRef] [Green Version]

- Teuber, L.; Militz, H.; Krause, A. Processing of wood plastic composites: The influence of feeding method and polymer melt flow rate on particle degradation. J. Appl. Polym. Sci. 2016, 133, 43231. [Google Scholar] [CrossRef]

- Anand Raj, M.K.; Muthusamy, S.; Panchal, H.; Mahmoud Ibrahim, A.M.; Alsoufi, M.S.; Elsheikh, A.H. Investigation of mechanical properties of dual-fiber reinforcement in polymer composite. J. Mater. Res. Technol. 2022, 18, 3908–3915. [Google Scholar] [CrossRef]

- Haque, M.E.; Khan, M.W.; Rani, M. Studies on morphological, physico-chemical and mechanical properties of wheat straw reinforced polyester resin composite. Polym. Bull. 2022, 79, 2933–2952. [Google Scholar] [CrossRef]

- Thabah, W.; Kumar Singh, A.; Bedi, R. Tensile properties of urea treated rice straw reinforced recycled polyethylene terephthalate composite materials. Mater. Today Proc. 2022, 56, 2151–2157. [Google Scholar] [CrossRef]

- Kusić, D.; Božič, U.; Monzón, M.; Paz, R.; Bordón, P. Thermal and Mechanical Characterization of Banana Fiber Reinforced Composites for Its Application in Injection Molding. Materials 2020, 13, 3581. [Google Scholar] [CrossRef] [PubMed]

- Ehman, N.V.; Ita-Nagy, D.; Felissia, F.E.; Vallejos, M.E.; Quispe, I.; Area, M.C.; Chinga-Carrasco, G. Hydrothermal-Alkaline Sugarcane Bagasse Pulp and Coupled with a Bio-Based Compatibilizer. Molecules 2020, 25, 2158. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, F.; Choi, H.S.; Park, M.K. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Mulinari, D.R.; Voorwald, H.J.C.; Cioffi, M.O.H.; da Silva, M.L.C.P.; da Cruz, T.G.; Saron, C. Sugarcane bagasse cellulose/HDPE composites obtained by extrusion. Compos. Sci. Technol. 2009, 69, 214–219. [Google Scholar] [CrossRef]

- Tarrés, Q.; Hernández-díaz, D.; Ardanuy, M. Interface strength and fiber content influence on corn stover fibers reinforced bio-polyethylene composites stiffness. Polymers 2021, 13, 768. [Google Scholar] [CrossRef]

- López, J.P.; Gironès, J.; Mendez, J.A.; Pèlach, M.A.; Vilaseca, F.; Mutjé, P. Impact and flexural properties of stone-ground wood pulp-reinforced polypropylene composites. Polym. Compos. 2013, 34, 842–848. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M.; Méndez, J.A.; Espinach, F.X. Impact strength and water uptake behavior of bleached kraft softwood-reinforced PLA composites as alternative to PP-based materials. Polymers 2020, 12, 2144. [Google Scholar] [CrossRef]

- Tucker, C.L.; Liang, E. Stiffness predictions for unidirectional short-fiber composites: Review and evaluation. Compos. Sci. Technol. 1999, 59, 655–671. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W. Tensile porperties of fibre-reinforced metals-copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–338. [Google Scholar] [CrossRef]

- Bowyer, W.H.; Bader, H.G. On the reinforcement of thermoplastics by imperfectly aligned discontinuous fibres. J. Mater. Sci. 1972, 7, 1315–1321. [Google Scholar] [CrossRef]

- Hirsch, T.J. Modulus of Elasticity of Concrete Affected by Elastic Moduli of Cement Paste Matrix and Aggregate. J. Proc. 1962, 59, 427–452. [Google Scholar]

- Salem, S.; Oliver-ortega, H.; Espinach, F.X.; Hamed, K.B.; Nasri, N.; Alcalà, M.; Mutjé, P. Study on the Tensile Strength and Micromechanical Analysis of Alfa Fibers Reinforced High Density Polyethylene Composites. Fibers Polym. 2019, 20, 602–610. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Julian, F.; Del Rey, R.; Mendez, J.A.; Mutje, P. Estimation of the interfacial shears strength, orientation factor and mean equivalent intrinsic tensile strength in old newspaper fiber/polypropylene composites. Compos. Part B Eng. 2013, 50, 232–238. [Google Scholar] [CrossRef]

- Thomason, J.L. Interfacial strength in thermoplastic composites—At last an industry friendly measurement method? Compos. Part A Appl. Sci. Manuf. 2002, 33, 1283–1288. [Google Scholar] [CrossRef] [Green Version]

- Pegoretti, A.; Della Volpe, C.; Detassis, M.; Migliaresi, C.; Wagner, H.D. Thermomechanical behaviour of interfacial region in carbon fibre/epoxy composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1067–1074. [Google Scholar] [CrossRef]

- Kompella, M.K.; Lambros, J. Micromechanical characterization of cellulose fibers. Polym. Test. 2002, 21, 523–530. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose_Bledzki_1999.pdf. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Espinach, F.X.; Granda, L.A.; Tarrés, Q.; Duran, J.; Fullana-I-Palmer, P.; Mutjé, P. Mechanical and micromechanical tensile strength of eucalyptus bleached fi bers reinforced polyoxymethylene composites. Compos. Part B Eng. 2016, 116, 333–339. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Llop, M.F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Study of the flexural modulus of lignocellulosic fibers reinforced bio-based polyamide11 green composites. Compos. Part B Eng. 2018, 152, 126–132. [Google Scholar] [CrossRef]

| Fiber | Yield (%) | Chemical Composition | Morphology | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cellulose 1 (%) | Lignin (%) | Pentosans (%) | Ash (%) | Length (µm) | Width (µm) | Fines (%) | Aspect Ratio 2 | ||

| Milled rapeseed (MR) | 99.7 ± 0.2 | 50.6 | 19.8 ± 1.7 | 23.8 ± 1.6 | 5.8 ± 0.4 | 1354 ± 78 | 31.7 ± 0.2 | 8.0 ± 2.4 | 42.7 |

| Mechanical rapeseed fibers (MRF) | 98.1 ± 0.4 | 51.7 | 19.3 ± 1.5 | 24.1 ± 1.8 | 4.9 ± 0.6 | 412 ± 22 | 22.4 ± 0.1 | 46.7 ± 7.8 | 18.4 |

| Thermomechanical rapeseed fibers (TMRF) | 95.3 ± 0.3 | 53.4 | 17.3 ± 1.1 | 26.6 ± 1.4 | 2.7 ± 0.5 | 528 ± 23 | 22.0 ± 0.2 | 37.2 ± 8.3 | 24.0 |

| Fiber | Content (wt.%) | Density (g/cm3) | VF | (µm) | (µm) | Width (µm) | Aspect Ratio 1 |

|---|---|---|---|---|---|---|---|

| MR | 20 | 1.002 ± 0.005 | 0.154 | 303.82 ± 8.33 | 707.82 ± 7.42 | 29.6 ± 0.2 | 10.26 |

| 30 | 1.027 ± 0.001 | 0.238 | 293.51 ± 11.24 | 686.64 ± 9.56 | 29.3 ± 0.1 | 10.02 | |

| 40 | 1.054 ± 0.009 | 0.327 | 280.44 ± 14.33 | 642.70 ± 11.21 | 29.2 ± 0.1 | 9.60 | |

| 50 | 1.085 ± 0.003 | 0.421 | 268.19 ± 9.42 | 598.08 ± 8.16 | 28.9 ± 0.2 | 9.28 | |

| MRF | 20 | 1.004 ± 0.002 | 0.150 | 280.60 ± 15.64 | 599.94 ± 12.21 | 20.7 ± 0.1 | 13.56 |

| 30 | 1.030 ± 0.007 | 0.232 | 251.09 ± 8.21 | 556.16 ± 7.45 | 20.1 ± 0.2 | 12.49 | |

| 40 | 1.060 ± 0.004 | 0.320 | 232.16 ± 9.74 | 487.34 ± 8.76 | 19.7 ± 0.2 | 11.78 | |

| 50 | 1.093 ± 0.008 | 0.414 | 219.91 ± 16.21 | 463.77 ± 13.42 | 19.5 ± 0.1 | 11.28 | |

| TMRF | 20 | 1.005 ± 0.001 | 0.148 | 323.24 ± 7.94 | 724.34 ± 6.37 | 19.9 ± 0.1 | 16.24 |

| 30 | 1.032 ± 0.007 | 0.230 | 305.84 ± 5.11 | 710.14 ± 5.88 | 19.7 ± 0.1 | 15.52 | |

| 40 | 1.062 ± 0.006 | 0.317 | 291.63 ± 6.89 | 661.35 ± 6.91 | 19.4 ± 0.2 | 15.03 | |

| 50 | 1.097 ± 0.009 | 0.410 | 275.60 ± 8.36 | 606.68 ± 7.77 | 19.3 ± 0.1 | 14.27 |

| Fiber | Content (wt.%) | Tensile Properties | Flexural Properties | Impact Properties | |||||

|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Deformation (mm) | Charpy Unnotched (kJ/m2) | Charpy Notched (kJ/m2) | ||

| - | 0 | 18.12 ± 0.32 | 1.04 ± 0.02 | 12.23 ± 0.67 | 21.25 ± 0.24 | 0.84 ± 0.03 | 9.80 ± 0.12 | Not break | 7.57 ± 0.09 |

| MR | 20 | 22.13 ± 0.17 | 2.06 ± 0.03 | 3.31 ± 0.32 | 26.34 ± 0.38 | 1.28 ± 0.07 | 6.66 ± 0.22 | 12.09 ±0.18 | 4.73 ± 0.02 |

| 30 | 25.57 ± 0.29 | 3.29 ± 0.05 | 1.24 ± 0.24 | 31.23 ± 0.41 | 1.76 ± 0.06 | 5.09 ± 0.34 | 10.62 ±0.16 | 4.34 ± 0.06 | |

| 40 | 30.74 ± 0.31 | 4.08 ± 0.02 | 0.72 ± 0.18 | 38.77 ± 0.26 | 2.27 ± 0.02 | 3.90 ± 0.21 | 9.95 ±0.09 | 4.10 ± 0.01 | |

| 50 | 34.18 ± 0.26 | 5.07 ± 0.06 | 0.57 ± 0.09 | 42.18 ± 0.31 | 3.18 ± 0.05 | 3.50 ± 0.16 | 8.84 ±0.14 | 3.89 ± 0.05 | |

| MRF | 20 | 30.18 ± 0.12 | 3.51 ± 0.02 | 3.47 ± 0.21 | 30.44 ± 0.26 | 1.67 ± 0.03 | 7.07 ± 0.34 | Not break | 6.01 ± 0.03 |

| 30 | 33.82 ± 0.18 | 4.05 ± 0.03 | 1.31 ± 0.12 | 37.51 ± 0.19 | 2.00 ± 0.03 | 5.62 ± 0.28 | Not break | 5.49 ± 0.03 | |

| 40 | 38.18 ± 0.21 | 4.88 ± 0.06 | 0.80 ± 0.09 | 42.44 ± 0.23 | 2.50 ± 0.06 | 4.08 ± 0.21 | Not break | 4.95 ± 0.06 | |

| 50 | 42.54 ± 0.35 | 5.77 ± 0.08 | 0.68 ± 0.07 | 48.02 ± 0.35 | 3.04 ± 0.05 | 3.46 ± 0.12 | Not break | 4.77 ± 0.04 | |

| TMRF | 20 | 31.61 ± 0.28 | 3.61 ± 0.04 | 3.33 ± 0.11 | 32.27 ± 0.33 | 1.73 ± 0.04 | 6.94 ± 0.31 | Not break | 6.08 ± 0.04 |

| 30 | 35.57 ± 0.11 | 4.15 ± 0.03 | 1.11 ± 0.16 | 38.87 ± 0.46 | 2.10 ± 0.03 | 5.56 ± 0.27 | Not break | 5.69 ± 0.07 | |

| 40 | 38.79 ± 0.39 | 5.03 ± 0.01 | 0.76 ± 0.09 | 43.83 ± 0.26 | 2.64 ± 0.02 | 3.98 ± 0.22 | Not break | 5.37 ± 0.06 | |

| 50 | 43.77 ± 0.27 | 5.89 ± 0.05 | 0.61 ± 0.12 | 48.54 ± 0.33 | 3.18 ± 0.05 | 3.32 ± 0.09 | Not break | 5.12 ± 0.02 | |

| Fiber | Content (wt.%) | (MPa) | (µm) | (MPa) | (°) | |||

|---|---|---|---|---|---|---|---|---|

| MR | 20 | 9.73 | 565.51 | 371.68 | 0.27 | 0.66 | 0.18 | 61.19 |

| 30 | 10.10 | 685.01 | 472.38 | 0.29 | 0.60 | 0.17 | 60.98 | |

| 40 | 10.26 | 702.24 | 493.65 | 0.29 | 0.57 | 0.17 | 60.90 | |

| 50 | 10.00 | 598.61 | 414.36 | 0.31 | 0.59 | 0.18 | 60.74 | |

| MRF | 20 | 9.78 | 716.40 | 677.05 | 0.32 | 0.55 | 0.18 | 60.57 |

| 30 | 9.76 | 708.37 | 688.27 | 0.33 | 0.53 | 0.17 | 60.49 | |

| 40 | 10.41 | 544.84 | 576.07 | 0.34 | 0.55 | 0.19 | 60.31 | |

| 50 | 9.99 | 563.73 | 577.50 | 0.32 | 0.52 | 0.17 | 60.58 | |

| TMRF | 20 | 9.44 | 786.07 | 746.08 | 0.30 | 0.59 | 0.18 | 60.81 |

| 30 | 9.18 | 814.69 | 759.49 | 0.30 | 0.57 | 0.17 | 60.83 | |

| 40 | 9.73 | 627.15 | 629.25 | 0.29 | 0.62 | 0.18 | 60.99 | |

| 50 | 9.42 | 587.12 | 573.34 | 0.29 | 0.60 | 0.17 | 60.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguado, R.; Espinach, F.X.; Vilaseca, F.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M. Approaching a Zero-Waste Strategy in Rapeseed (Brassica napus) Exploitation: Sustainably Approaching Bio-Based Polyethylene Composites. Sustainability 2022, 14, 7942. https://doi.org/10.3390/su14137942

Aguado R, Espinach FX, Vilaseca F, Tarrés Q, Mutjé P, Delgado-Aguilar M. Approaching a Zero-Waste Strategy in Rapeseed (Brassica napus) Exploitation: Sustainably Approaching Bio-Based Polyethylene Composites. Sustainability. 2022; 14(13):7942. https://doi.org/10.3390/su14137942

Chicago/Turabian StyleAguado, Roberto, Francesc Xavier Espinach, Fabiola Vilaseca, Quim Tarrés, Pere Mutjé, and Marc Delgado-Aguilar. 2022. "Approaching a Zero-Waste Strategy in Rapeseed (Brassica napus) Exploitation: Sustainably Approaching Bio-Based Polyethylene Composites" Sustainability 14, no. 13: 7942. https://doi.org/10.3390/su14137942

APA StyleAguado, R., Espinach, F. X., Vilaseca, F., Tarrés, Q., Mutjé, P., & Delgado-Aguilar, M. (2022). Approaching a Zero-Waste Strategy in Rapeseed (Brassica napus) Exploitation: Sustainably Approaching Bio-Based Polyethylene Composites. Sustainability, 14(13), 7942. https://doi.org/10.3390/su14137942