Multilayer Granular Recycled Rubber for Its Application to Technical Flooring

Abstract

:1. Introduction

2. Materials

2.1. Recycled Rubber

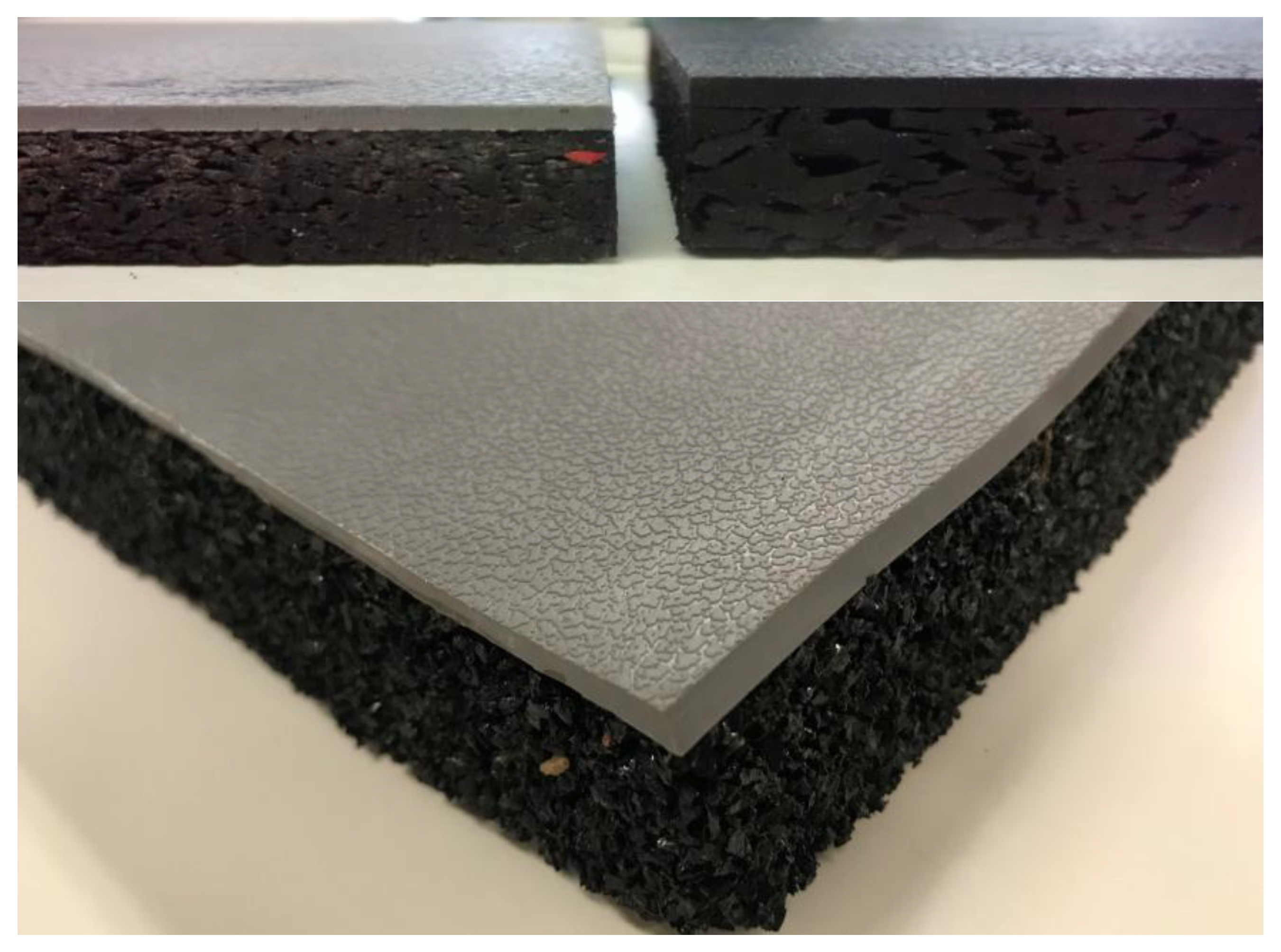

2.2. Test Specimen Preparation

3. Experimental Methods

3.1. Physical Properties

3.1.1. Specific Gravity

3.1.2. Porosity

3.2. Cantilever Bending Static Test

3.3. Dynamic Modulus of Elasticity: Ultrasound Test

- Signal generator.

- Two transductors, transmitter and receptor.

- One oscilloscope.

3.4. Dynamic Stiffness Test

4. Results

4.1. Static Modulus of Elasticity (Cantilever Bending Static Test)

4.2. Dynamic Modulus of Elasticity (Ultrasound)

4.3. Dynamic Stiffness

4.4. Impact Sound Reduction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maderuelo-Sanz, R.; Nadal-Gisbert, A.V.; Crespo-Amorós, J.E.; Parres-García, F. A novel sound absorber with recycled fibers coming from end of life tires (ELTs). Appl. Acoust. 2012, 73, 402–408. [Google Scholar] [CrossRef]

- Yehia, A.A. Recycling of rubber waste. Polym. Plast. Technol. Eng. 2004, 43, 1735–1754. [Google Scholar] [CrossRef]

- Myhre, M.; Saiwari, S.; Dierkes, W.; Noordermeer, J. Rubber recycling: Chemistry, processing, and applications. Rubber Chem. Technol. 2012, 85, 408–449. [Google Scholar] [CrossRef]

- Tasalloti, A.; Chiaro, G.; Murali, A.; Banasiak, L. Physical and mechanical properties of granulated rubber mixed with granular soils—A literature review. Sustainability 2021, 13, 4309. [Google Scholar] [CrossRef]

- Adhikari, B. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Holmes, N.; Browne, A.; Montague, C. Acoustic properties of concrete panels with crumb rubber as a fine aggregate replacement. Constr. Build. Mater. 2014, 73, 195–204. [Google Scholar] [CrossRef] [Green Version]

- Chettah, A.; Chedly, S.; Ichchou, M.; Bareille, O.; Onteniente, J.P. Experimental and numerical investigation of flexural vibration damping by recycled rubber granulates. Int. J. Veh. Noise Vib. 2008, 4, 70–92. [Google Scholar] [CrossRef]

- Kuczmarski, M.A.; Johnston, J.C. Acoustic Absorption in Porous Materials. In Nasa/Tm—2011-216995; National Aeronautics and Space Administration: Washington, DC, USA, 2011; pp. 1–20. [Google Scholar]

- Oliva, D.; Hongisto, V. Sound absorption of porous materials—Accuracy of prediction methods. Appl. Acoust. 2013, 74, 1473–1479. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. Sound absorbing properties of materials made of rubber crumbs. J. Acoust. Soc. Am. 2008, 123, 3037. [Google Scholar] [CrossRef]

- Bérengier, M.C. Porous road pavements: Acoustical characterization and propagation effects. J. Acoust. Soc. Am. 1997, 101, 155. [Google Scholar] [CrossRef]

- Chiaro, G.; Tasalloti, A.; Palermo, A.; Granello, G.; Banasiak, L. Reuse of Waste Tires to Develop Eco-rubber Seismic-Isolation Foundation Systems: Preliminary Results. In Lecture Notes in Civil Engineering; Springer: Singapore, 2021; Volume 144, LNCE. [Google Scholar] [CrossRef]

- Janajreh, I.; Hussain, M.; Elagroudy, S.; Moustakas, K. Recycled tire granular for playground in hot regions: Technical assessment. J. Mater. Cycles Waste Manag. 2021, 23, 107–120. [Google Scholar] [CrossRef]

- Hong, Z.; Bo, L.; Guangsu, H.; Jia, H. A novel composite sound absorber with recycled rubber particles. J. Sound Vib. 2007, 304, 400–406. [Google Scholar] [CrossRef]

- Swift, M.J.; Briš, P.; Horoshenkov, K.V. Acoustic absorption in re-cycled rubber granulate. Appl. Acoust. 1999, 57, 203–212. [Google Scholar] [CrossRef]

- Soto, P.F.; Herráez, M.; González, A.; de Saja, J.A. Acoustic impedance and absorption coefficient measurements of porous materials used in the automotive industry. Polym. Test. 1994, 13, 77–88. [Google Scholar] [CrossRef]

- Sookprasert, P.; Hinchiranan, N. Morphology, mechanical and thermal properties of poly(lactic acid) (PLA)/natural rubber (NR) blends compatibilized by NR-graft-PLA. J. Mater. Res. 2017, 32, 788–800. [Google Scholar] [CrossRef]

- Ramorino, G.; Vetturi, D.; Cambiaghi, D.; Pegoretti, A.; Ricco, T. Developments in dynamic testing of rubber compounds: Assessment of non-linear effects. Polym. Test. 2003, 22, 681–687. [Google Scholar] [CrossRef]

- Thaijaroen, W.; Harrison, A.J.L. Nonlinear dynamic modelling of rubber isolators using six parameters based on parabolic spring, springpot, and smooth-slip friction element. Polym. Test. 2010, 29, 857–865. [Google Scholar] [CrossRef]

- Digilov, R.M.; Abramovich, H. Flexural vibration test of a beam elastically restrained at one end: A new approach for Young’s modulus determination. Adv. Mater. Sci. Eng. 2013, 2013, 329530. [Google Scholar] [CrossRef] [Green Version]

- Allard, J.; Champoux, Y. New empirical equations for sound propagation in rigid frame fibrous materials. J. Acoust. Soc. Am. 1992, 91, 3346–3353. [Google Scholar] [CrossRef]

- Allard, J.F.; Castagnede, B.; Henry, M.; Lauriks, W. Evaluation of tortuosity in acoustic porous materials saturated by air. Rev. Sci. Instrum. 1994, 65, 754–755. [Google Scholar] [CrossRef] [Green Version]

- Champoux, Y.; Stinson, M.R. On acoustical models for sound propagation in rigid frame porous materials and the influence of shape factors. J. Acoust. Soc. Am. 1992, 92, 1120–1131. [Google Scholar] [CrossRef]

- Delany, M.E.; Bazley, E.N. Acoustical properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Miki, Y. Acoustical properties of porous materials. Modifications of Delany-Bazley models. J. Acoust. Soc. Jpn. (E) 1990, 11, 19–24. [Google Scholar] [CrossRef]

- Qunli, W. Empirical relations between acoustical properties and flow resistivity of porous plastic open-cell foam. Appl. Acoust. 1988, 25, 141–148. [Google Scholar] [CrossRef]

- del Rey, R.; Alba, J.; Arenas, J.P.; Sanchis, V.J. An empirical modelling of porous sound absorbing materials made of recycled foam. Appl. Acoust. 2012, 73, 604–609. [Google Scholar] [CrossRef]

- Onokpise, O.U. Natural Rubber, Hevea Brasiliensis (Willd. Ex A. Juss.) MüLl. Arg., Germplasm Collection In The Amazon Basin, Brazil: A Retrospective. Econ. Bot. 2004, 58, 544–555. [Google Scholar] [CrossRef]

- Billmeyer, F.W. Ciencia De Los Polimeros; Editorial Reverté: Barcelona, Spain, 2004; pp. 493–514. [Google Scholar]

- ASTM D 792-08; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008; pp. 1–6. [CrossRef]

- Gadea, J.M.; Juliá, E.; Montava, I.; Segura, J.; Nadal, A. Evaluation of acoustic and dynamic behaviour of ethylene vinyl acetate panels. Materwiss Werksttech 2019, 50, 14–24. [Google Scholar] [CrossRef]

| Properties | Raw Rubber | Vulcanized Rubber |

|---|---|---|

| Behaviour | Thermoplastic | Thermostable |

| Surface aspect | Sticky | Non-sticky |

| Tensile strength | Low | High |

| Elasticity | Low | High |

| Deformability | Low | Nonexistent |

| Thickness (mm) | Density (g/cm3) | Granulometry (mm) |

|---|---|---|

| T1 = 20 | D1 = 0.85 | G1 = 1–3 |

| T2 = 22 | D2 = 0.90 | G2 = 4–8 |

| D3 = 0.95 |

| Samples | Container Mass with Air (g) | Container Mass with Water (g) | Container Mass and Sample (g) | Container Mass and Saturated Sample (g) | SG |

|---|---|---|---|---|---|

| T1D1G1 | 141.03 | 123.35 | 162.47 | 126.6 | 1.18 |

| T1D1G2 | 141.03 | 123.35 | 162.86 | 126.89 | 1.19 |

| T1D2G1 | 141.03 | 123.35 | 160.49 | 126.63 | 1.20 |

| T1D2G2 | 141.03 | 123.35 | 161.42 | 126.2 | 1.16 |

| T1D3G1 | 141.03 | 123.35 | 162.34 | 127.28 | 1.23 |

| T1D3G2 | 141.03 | 123.35 | 162.78 | 126.72 | 1.18 |

| T2D1G1 | 141.03 | 123.35 | 164.18 | 127.52 | 1.22 |

| T2D1G2 | 141.03 | 123.35 | 163.56 | 126.71 | 1.18 |

| T2D2G1 | 141.03 | 123.35 | 165.5 | 127.28 | 1.19 |

| T2D2G2 | 141.03 | 123.35 | 162.22 | 126.64 | 1.18 |

| T2D3G1 | 141.03 | 123.35 | 164.43 | 124.2 | 1.04 |

| T2D3G2 | 141.03 | 123.35 | 163.7 | 126.47 | 1.16 |

| Samples | Apparent Density (kg/m3) | Water Density (kg/m3) | SG | Porosity (%) |

|---|---|---|---|---|

| T1D1G1 | 850 | 1000 | 1.18 | 28 |

| T1D1G2 | 850 | 1000 | 1.19 | 29 |

| T1D2G1 | 900 | 1000 | 1.20 | 25 |

| T1D2G2 | 900 | 1000 | 1.16 | 23 |

| T1D3G1 | 950 | 1000 | 1.23 | 23 |

| T1D3G2 | 950 | 1000 | 1.18 | 20 |

| T2D1G1 | 850 | 1000 | 1.22 | 30 |

| T2D1G2 | 850 | 1000 | 1.18 | 28 |

| T2D2G1 | 900 | 1000 | 1.19 | 24 |

| T2D2G2 | 900 | 1000 | 1.18 | 24 |

| T2D3G1 | 950 | 1000 | 1.04 | 8 |

| T2D3G2 | 950 | 1000 | 1.16 | 18 |

| Samples | Density (kg/m3) | E (MPa) |

|---|---|---|

| T1D1G1 | 850 | 49.55 |

| T1D1G2 | 850 | 53.05 |

| T1D2G1 | 900 | 54.99 |

| T1D2G2 | 900 | 57.81 |

| T1D3G1 | 950 | 53.68 |

| T1D3G2 | 950 | 67.30 |

| T2D1G1 | 850 | 48.39 |

| T2D1G2 | 850 | 45.78 |

| T2D2G1 | 900 | 47.71 |

| T2D2G2 | 900 | 56.46 |

| T2D3G1 | 950 | 48.39 |

| T2D3G2 | 950 | 48.39 |

| Samples | Density (kg/m3) | Edynamic (MPa) |

|---|---|---|

| T1D1G1 | 850 | 42.93 |

| T1D1G2 | 850 | 54.66 |

| T1D2G1 | 900 | 49.91 |

| T1D2G2 | 900 | 59.04 |

| T1D3G1 | 950 | 51.00 |

| T1D3G2 | 950 | 72.96 |

| T2D1G1 | 850 | 42.40 |

| T2D1G2 | 850 | 45.12 |

| T2D2G1 | 900 | 48.12 |

| T2D2G2 | 900 | 52.65 |

| T2D3G1 | 950 | 48.76 |

| T2D3G2 | 950 | 46.18 |

| Samples | Density (kg/m3) | S’ (MN/m3) |

|---|---|---|

| T1D1G1 | 850 | 36.93 |

| T1D1G2 | 850 | 41.48 |

| T1D2G1 | 900 | 48.10 |

| T1D2G2 | 900 | 37.74 |

| T1D3G1 | 950 | 41.05 |

| T1D3G2 | 950 | 30.06 |

| T2D1G1 | 850 | 37.53 |

| T2D1G2 | 850 | 29.16 |

| T2D2G1 | 900 | 30.06 |

| T2D2G2 | 900 | 42.76 |

| T2D3G1 | 950 | 36.33 |

| T2D3G2 | 950 | 47.19 |

| Samples | Density (kg/m3) | Thickness (m) | m’ (kg/m2) | S’ (MN/m3) | ΔLw (dB) |

|---|---|---|---|---|---|

| T1D1G1 | 850 | 0.02 | 17 | 36.93 | 12.95 |

| T1D1G2 | 850 | 0.02 | 17 | 41.48 | 12.19 |

| T1D2G1 | 900 | 0.02 | 18 | 48.10 | 11.6 |

| T1D2G2 | 900 | 0.02 | 18 | 37.74 | 13.18 |

| T1D3G1 | 950 | 0.02 | 19 | 41.05 | 12.98 |

| T1D3G2 | 950 | 0.02 | 19 | 30.06 | 15.01 |

| T2D1G1 | 850 | 0.022 | 18.7 | 37.53 | 13.46 |

| T2D1G2 | 850 | 0.022 | 18.7 | 29.16 | 15.11 |

| T2D2G1 | 900 | 0.022 | 19.8 | 30.06 | 15.28 |

| T2D2G2 | 900 | 0.022 | 19.8 | 42.76 | 12.98 |

| T2D3G1 | 950 | 0.022 | 20.9 | 36.33 | 14.4 |

| T2D3G2 | 950 | 0.022 | 20.9 | 47.19 | 12.69 |

| Samples | Estatic (MPa) | Edynamic (MPa) | S’ (MN/m3) | ΔLw (dB) |

|---|---|---|---|---|

| T1D1G1 | 49.55 | 42.93 | 36.93 | 12.95 |

| T1D1G2 | 53.05 | 54.66 | 41.48 | 12.19 |

| T1D2G1 | 54.99 | 49.91 | 48.10 | 11.6 |

| T1D2G2 | 57.81 | 59.04 | 37.74 | 13.18 |

| T1D3G1 | 53.68 | 51.00 | 41.05 | 12.98 |

| T1D3G2 | 67.30 | 72.96 | 30.06 | 15.01 |

| T2D1G1 | 48.39 | 42.40 | 37.53 | 13.46 |

| T2D1G2 | 45.78 | 45.12 | 29.16 | 15.11 |

| T2D2G1 | 47.71 | 48.12 | 30.06 | 15.28 |

| T2D2G2 | 56.46 | 52.65 | 42.76 | 12.98 |

| T2D3G1 | 48.39 | 48.76 | 36.33 | 14.4 |

| T2D3G2 | 48.39 | 46.18 | 47.19 | 12.69 |

| Samples | Estatic (MPa) | Edynamic (MPa) | Ratio Estatic/Edynamic |

|---|---|---|---|

| T1D1G1 | 49.55 | 42.93 | 1.154 |

| T1D1G2 | 53.05 | 54.66 | 0.971 |

| T1D2G1 | 54.99 | 49.91 | 1.102 |

| T1D2G2 | 57.81 | 59.04 | 0.979 |

| T1D3G1 | 53.68 | 51.00 | 1.053 |

| T1D3G2 | 67.30 | 72.96 | 0.922 |

| T2D1G1 | 48.39 | 42.40 | 1.141 |

| T2D1G2 | 45.78 | 45.12 | 1.015 |

| T2D2G1 | 47.71 | 48.12 | 0.991 |

| T2D2G2 | 56.46 | 52.65 | 1.072 |

| T2D3G1 | 48.39 | 48.76 | 0.992 |

| T2D3G2 | 48.39 | 46.18 | 1.048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanz Buades, V.; Juliá Sanchis, E.; Segura Alcaraz, J.; Montava Belda, I.; Gadea Borrell, J.M. Multilayer Granular Recycled Rubber for Its Application to Technical Flooring. Sustainability 2022, 14, 16372. https://doi.org/10.3390/su142416372

Sanz Buades V, Juliá Sanchis E, Segura Alcaraz J, Montava Belda I, Gadea Borrell JM. Multilayer Granular Recycled Rubber for Its Application to Technical Flooring. Sustainability. 2022; 14(24):16372. https://doi.org/10.3390/su142416372

Chicago/Turabian StyleSanz Buades, Victoria, Ernesto Juliá Sanchis, Jorge Segura Alcaraz, Isaac Montava Belda, and José María Gadea Borrell. 2022. "Multilayer Granular Recycled Rubber for Its Application to Technical Flooring" Sustainability 14, no. 24: 16372. https://doi.org/10.3390/su142416372

APA StyleSanz Buades, V., Juliá Sanchis, E., Segura Alcaraz, J., Montava Belda, I., & Gadea Borrell, J. M. (2022). Multilayer Granular Recycled Rubber for Its Application to Technical Flooring. Sustainability, 14(24), 16372. https://doi.org/10.3390/su142416372