Improving the Performance of the Reverse Osmosis Process with Fiber Filter and Ultrafiltration: Promoting Municipal Sewage Reclamation and Reuse for Industrial Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of WRRF and Reclaimed Water Source

2.2. Analytical Methods

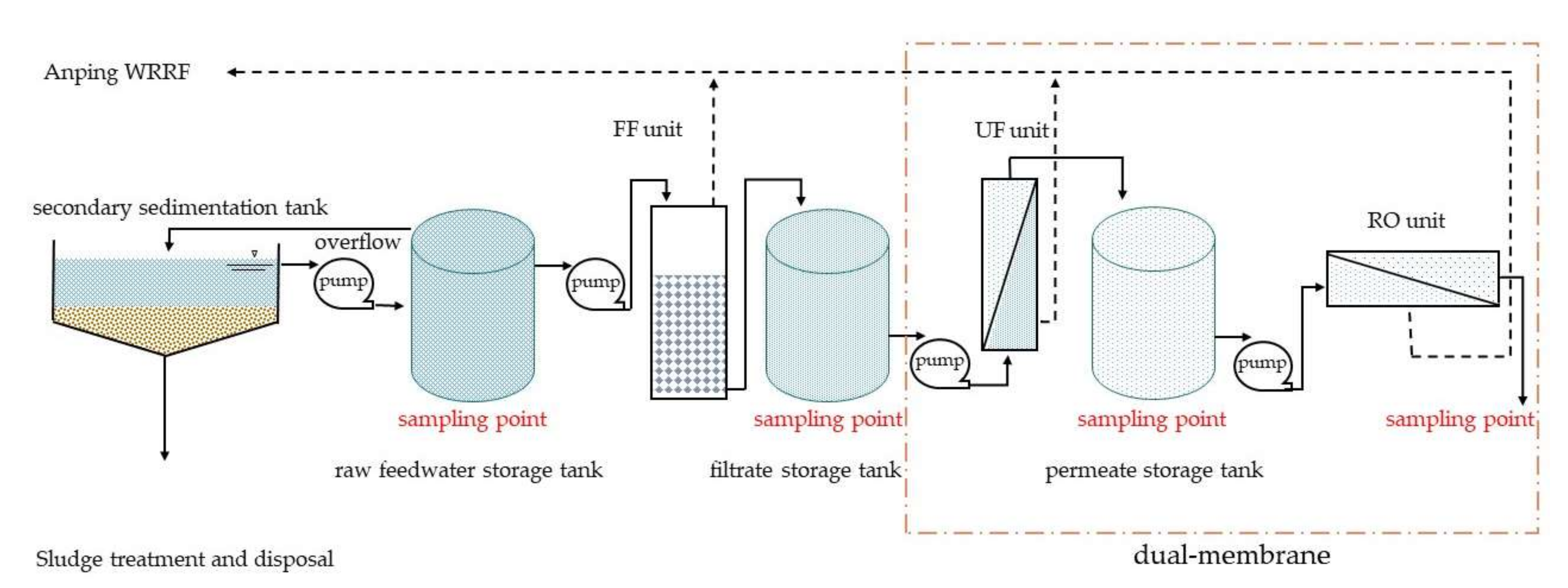

2.3. Description of Pilot Plant Test System and Membrane Selection

- 1.

- FF unit

- 2.

- UF unit

- 3.

- RO unit

3. Results

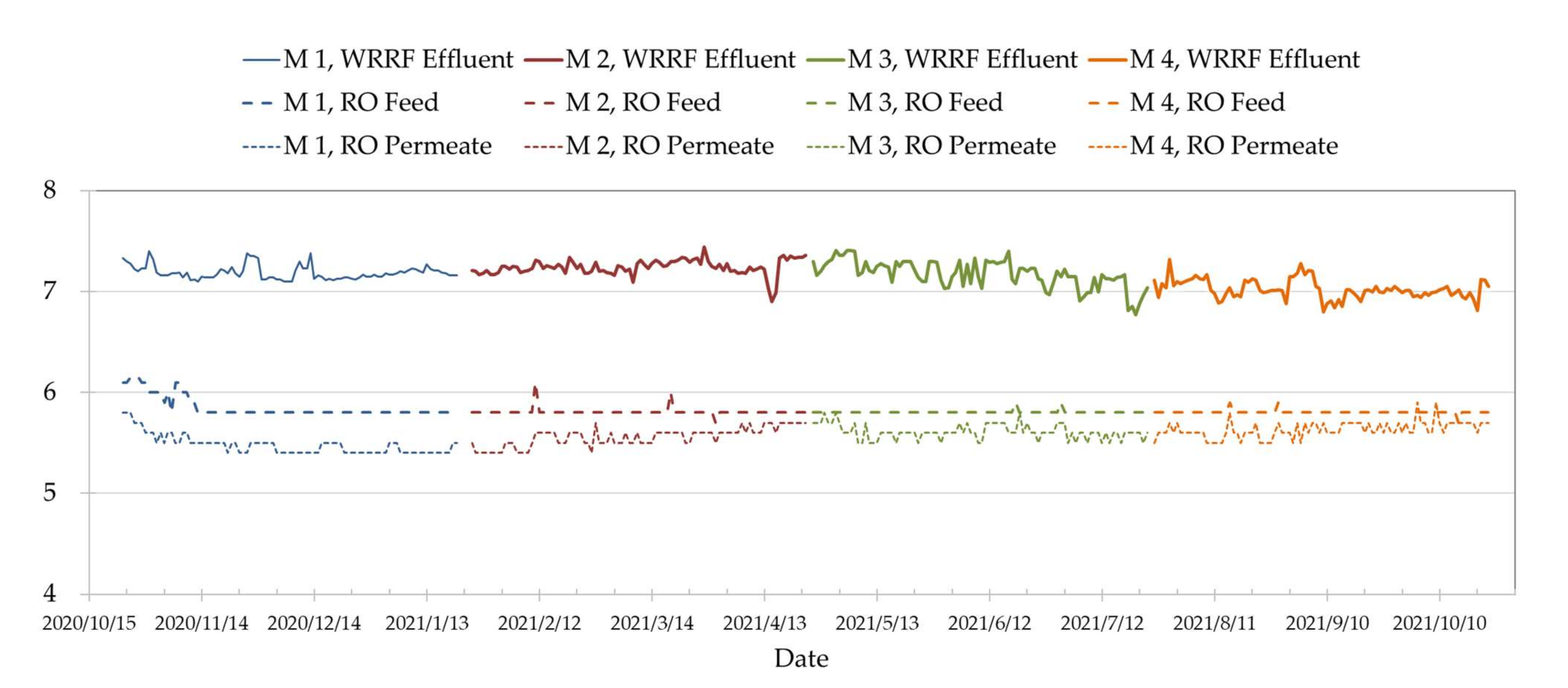

3.1. Characterization of WRRF Effluent

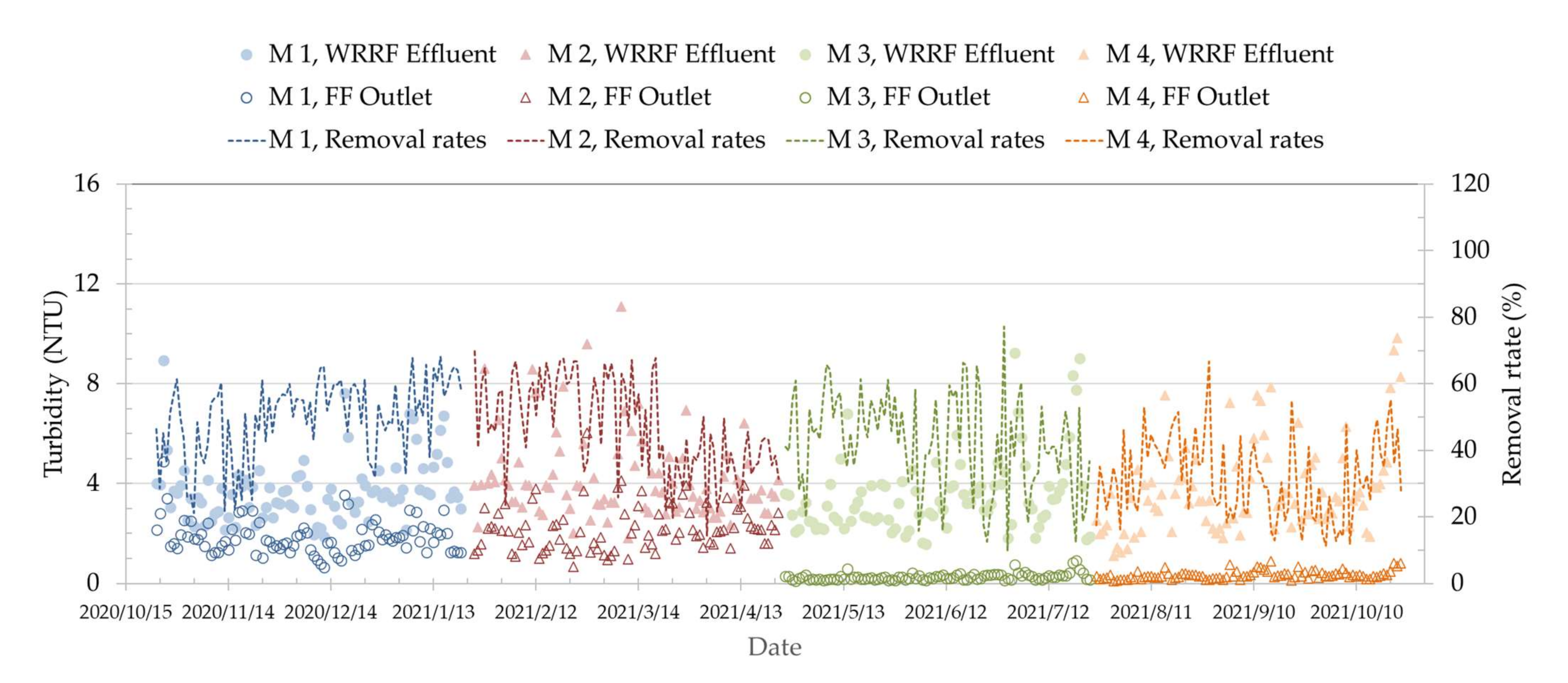

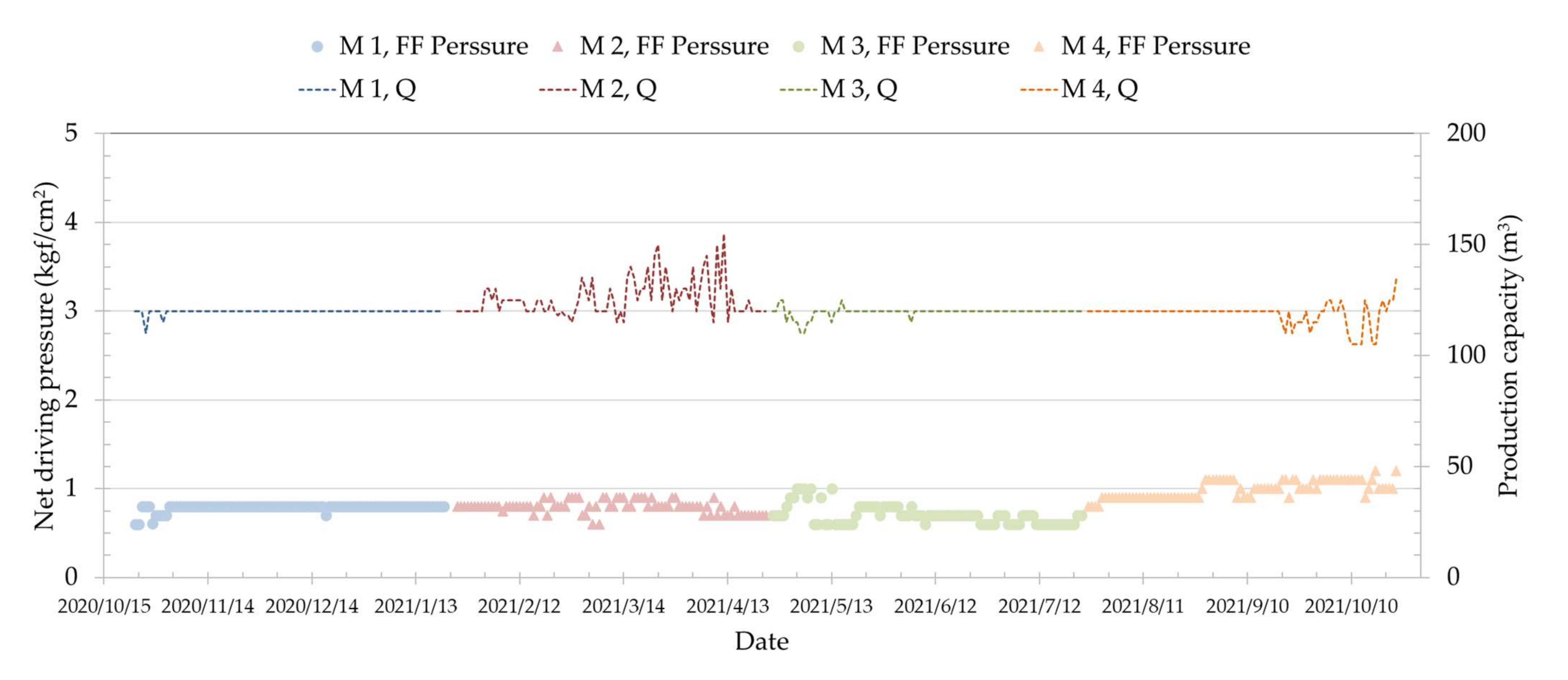

3.2. Filter Efficiency of Selected FF Unit

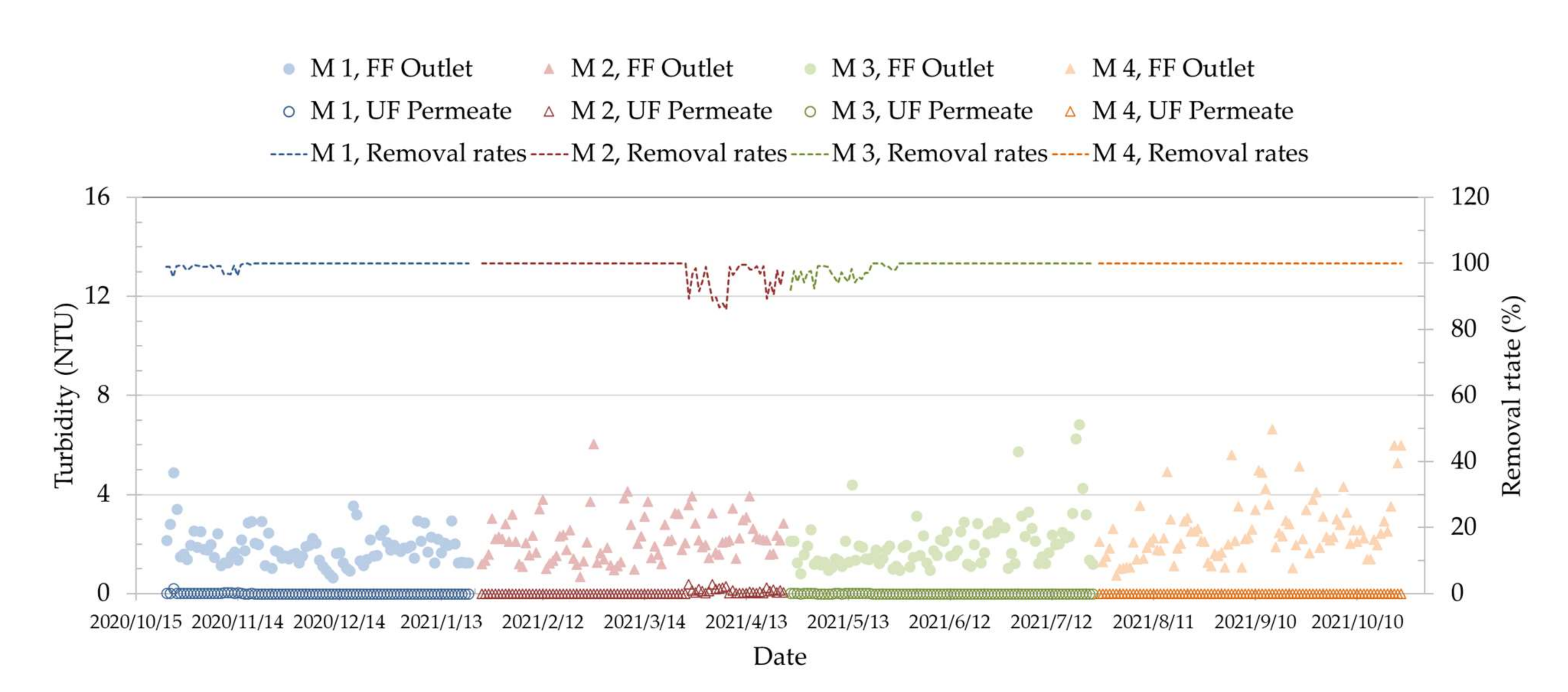

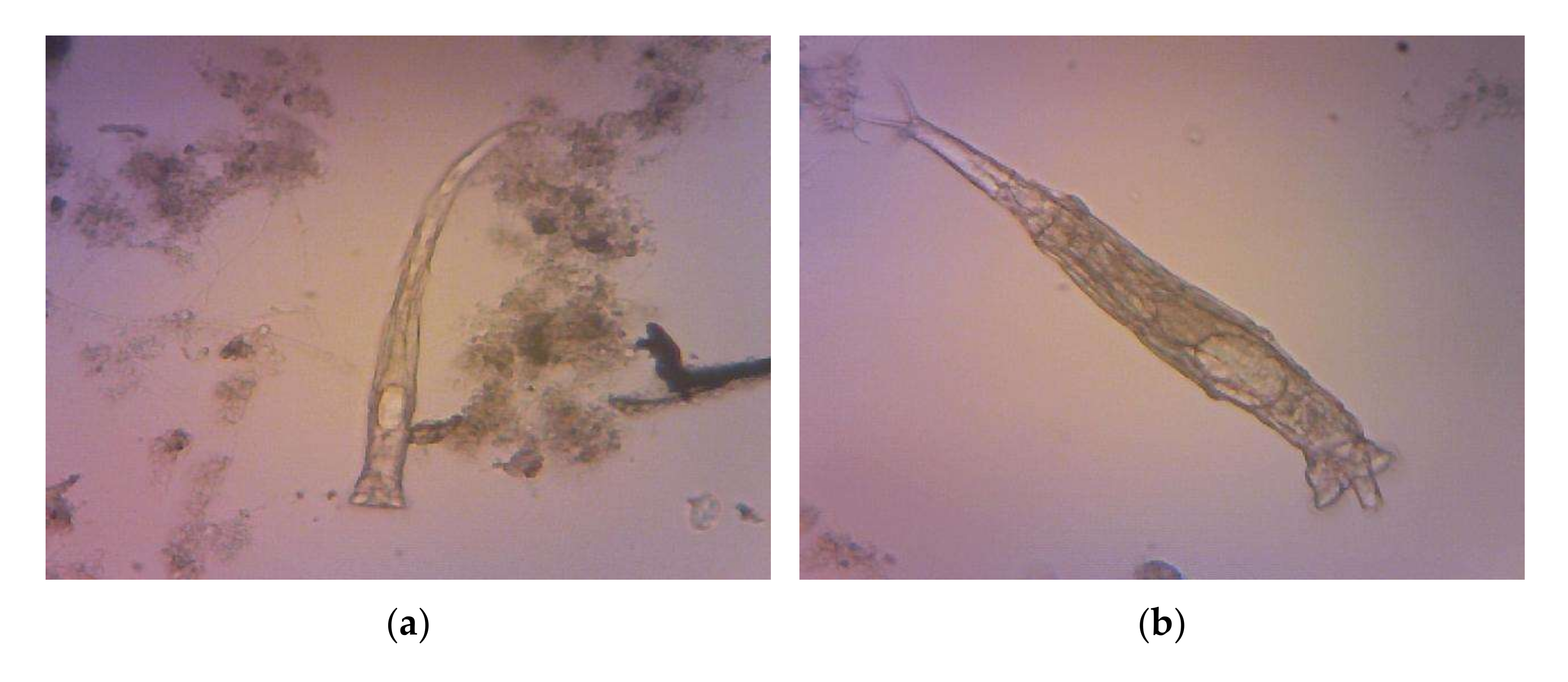

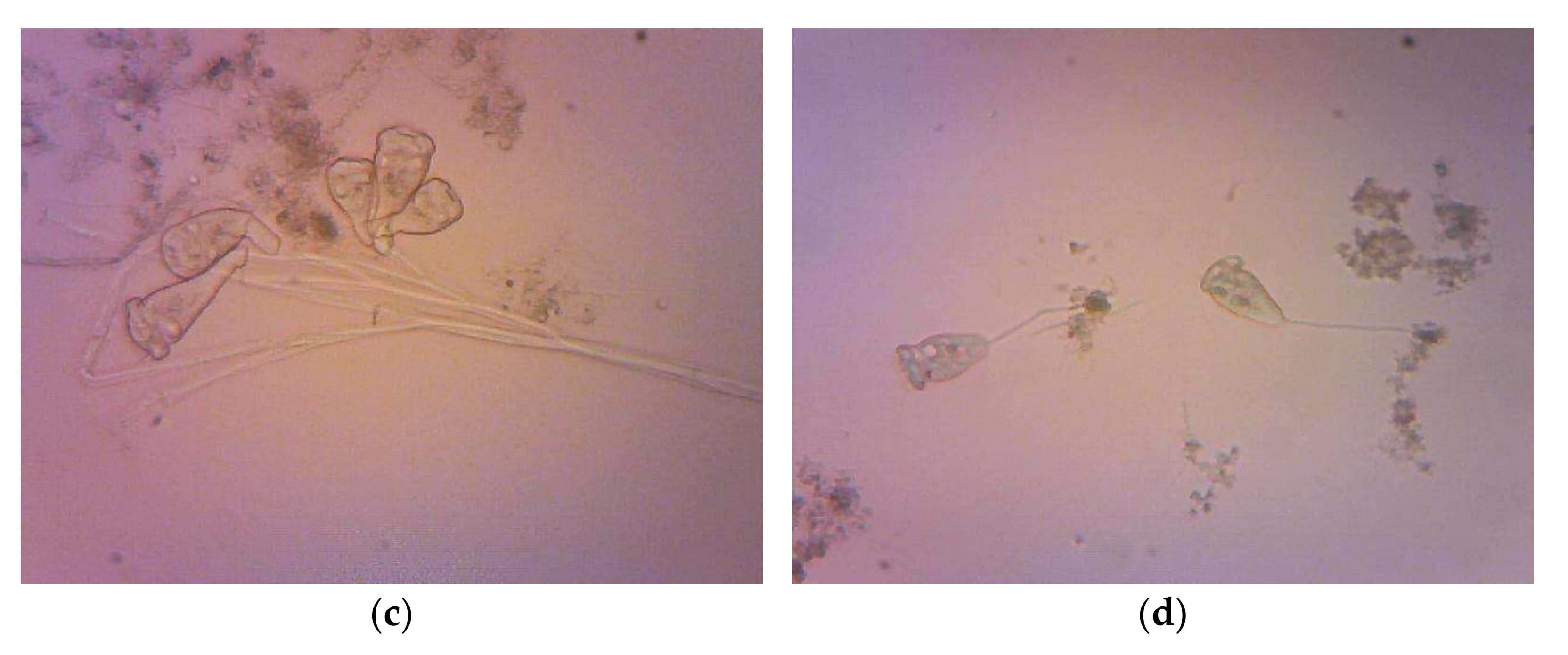

3.3. Filter Efficiency of UF Unit

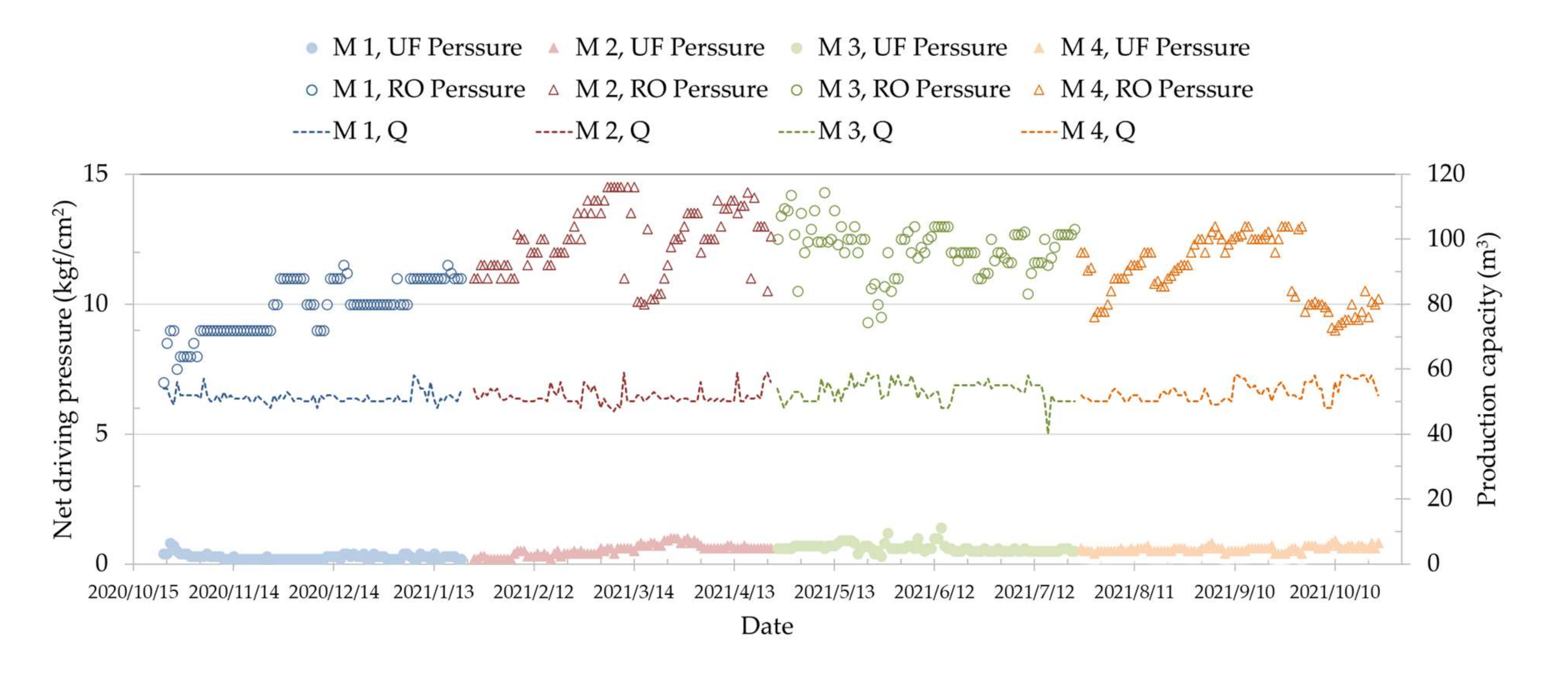

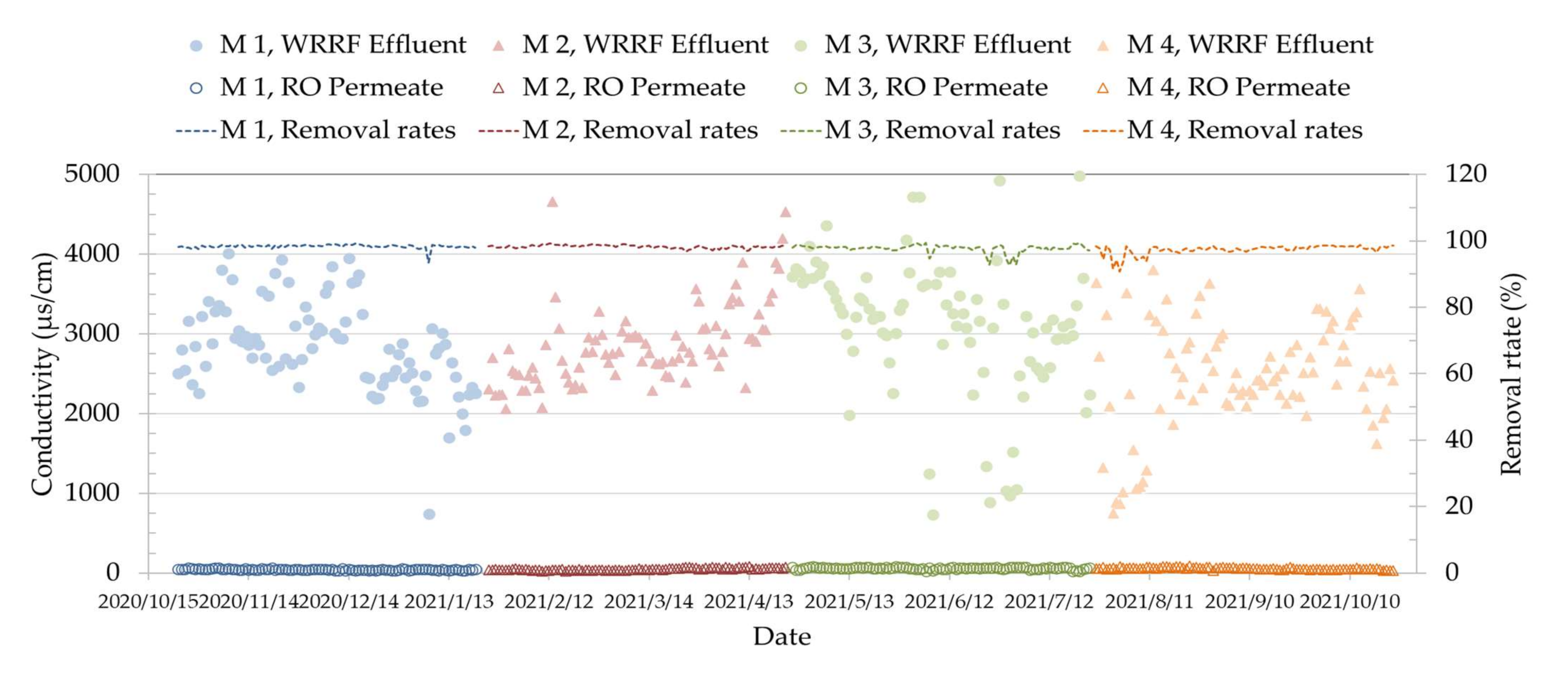

3.4. Water-Quality Performance of RO System

4. Discussion

5. Conclusions

- The pretreatment unit consists of FF and UF. The filtrate of FF never exceeded 6.82 NTU, and the permeate of UF never exceeded 0.38 NTU. The average turbidity removal rates were 42.7 and 99.2%, respectively. Therefore, the proposed pretreatment process is suitable for RO;

- In practice, FF followed by UF produced stable RO feedwater of an SDI15 lower than 4.1, which indicates a robust protective effect on the subsequent RO process;

- When UF provided a stable filtration performance, the RO unit exhibited a stable performance and production capacity. Indeed, the RO membranes rejected 97.9% of the EC, which meets the requirements for industrial reuse and government regulations;

- The quality of the UF permeate was close to general water standards, while the RO permeate could be categorized as extremely pure water;

- The fouling of the UF and RO membranes can be controlled and reduced through the application of BW, CEB, and CIP.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balfaqih, H.; Al-Nory, M.T.; Nopiah, Z.M.; Saibani, N. Environmental and economic performance assessment of desalination supply chain. Desalination 2017, 406, 2–9. [Google Scholar] [CrossRef]

- Mancosu, N.; Snyder, R.L.; Kyriakakis, G.; Spano, D. Water Scarcity and Future Challenges for Food Production. Water 2015, 7, 975–992. [Google Scholar] [CrossRef]

- Giannoccaro, G.; Arborea, S.; de Gennaro, B.C.; Iacobellis, V.; Piccinni, A.F. Assessing Reclaimed Urban Wastewater for Reuse in Agriculture: Technical and Economic Concerns for Mediterranean Regions. Water 2019, 11, 1511. Available online: https://www.mdpi.com/2073-4441/11/7/1511 (accessed on 5 December 2020). [CrossRef] [Green Version]

- Ponce-Robles, L.; Masdemont-Hernández, B.; Munuera-Pérez, T.; Pagán-Muñoz, A.; Lara-Guillén, A.J.; García-García, A.J.; Alarcón-Cabañero, J.J. WWTP Effluent Quality Improvement for Agricultural Reuse Using an Autonomous Prototype. Water 2020, 12, 2240. Available online: https://www.mdpi.com/2073-4441/12/8/2240 (accessed on 5 December 2020). [CrossRef]

- Chang, D.; Ma, Z. Wastewater reclamation and reuse in Beijing: Influence factors and policy implications. Desalination 2012, 297, 72–78. [Google Scholar] [CrossRef]

- Sewage System Office Construction and Planning Agency Ministry of the Interior. Public Sewage Treatment Plant. 2022. Available online: https://www.cpami.gov.tw/home.html (accessed on 12 March 2022).

- Maryam, B.; Büyükgüngör, H. Wastewater reclamation and reuse trends in Turkey: Opportunities and challenges. J. Water Process Eng. 2019, 30, 100501. [Google Scholar] [CrossRef]

- Alsarayreh, A.A.; Al-Obaidi, M.A.; Farag, S.K.; Patel, R.; Mujtaba, I.M. Performance evaluation of a medium-scale industrial reverse osmosis brackish water desalination plant with different brands of membranes. A simulation study. Desalination 2021, 503, 114927. [Google Scholar] [CrossRef]

- Al-Obaidi, M.A.; Alsarayreh, A.A.; Al-Hroub, A.M.; Alsadaie, S.; Mujtaba, I.M. Performance analysis of a medium-sized industrial reverse osmosis brackish water desalination plant. Desalination 2018, 443, 272–284. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.; Jepson, W. Drivers and barriers to urban water reuse: A systematic review. Water Secur. 2020, 11, 100073. [Google Scholar] [CrossRef]

- Lefebvre, O. Beyond NEWater: An insight into Singapore’s water reuse prospects. Curr. Opin. Environ. Sci. Health 2018, 2, 26–31. [Google Scholar] [CrossRef]

- Pintilie, L.; Torres, C.M.; Teodosiu, C.; Castells, F. Urban wastewater reclamation for industrial reuse: An LCA case study. J. Clean. Prod. 2016, 139, 1–14. [Google Scholar] [CrossRef]

- Touati, K.; Gzara, L.; Mahfoudhi, S.; Bourezgui, S.; Hafiane, A.; Elfil, H. Treatment of coastal well water using ultrafiltration-nanofiltration-reverse osmosis to produce isotonic solutions and drinking water: Fouling behavior and energy efficiency. J. Clean. Prod. 2018, 200, 1053–1064. [Google Scholar] [CrossRef]

- Tang, F.; Hu, H.-Y.; Sun, L.-J.; Sun, Y.-X.; Shi, N.; Crittenden, J.C. Fouling characteristics of reverse osmosis membranes at different positions of a full-scale plant for municipal wastewater reclamation. Water Res. 2016, 90, 329–336. [Google Scholar] [CrossRef]

- Barbagallo, S.; Cirelli, G.L.; Consoli, S.; Licciardello, F.; Marzo, A.; Toscano, A. Analysis of treated wastewater reuse potential for irrigation in Sicily. Water Sci. Technol. 2012, 65, 2024–2033. [Google Scholar] [CrossRef] [Green Version]

- Nejati, S.; Mirbagheri, S.A.; Warsinger, D.M.; Fazeli, M. Biofouling in seawater reverse osmosis (SWRO): Impact of module geometry and mitigation with ultrafiltration. J. Water Process Eng. 2019, 29, 100782. [Google Scholar] [CrossRef]

- Corbatón-Báguena, M.J.; Álvarez-Blanco, S.; Vincent-Vela, M.C. Evaluation of fouling resistances during the ultrafiltration of whey model solutions. J. Clean. Prod. 2018, 172, 358–367. [Google Scholar] [CrossRef]

- Sim, L.N.; Chong, T.H.; Taheri, A.H.; Sim, S.T.V.; Lai, L.; Krantz, W.B.; Fane, A.G. A review of fouling indices and monitoring techniques for reverse osmosis. Desalination 2018, 434, 169–188. [Google Scholar] [CrossRef]

- Brover, S.; Lester, Y.; Brenner, A.; Sahar-Hadar, E. Optimization of ultrafiltration as pre-treatment for seawater RO desalination. Desalination 2022, 524, 115478. [Google Scholar] [CrossRef]

- Jamaly, S.; Darwish, N.N.; Ahmed, I.; Hasan, S.W. A short review on reverse osmosis pretreatment technologies. Desalination 2014, 354, 30–38. [Google Scholar] [CrossRef]

- Voutchkov, N. Considerations for selection of seawater filtration pretreatment system. Desalination 2010, 261, 354–364. [Google Scholar] [CrossRef]

- American Public Health Association. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Water Works Association & Water Environment Federation: Washington, DC, USA, 2017. [Google Scholar]

- Environmental Protection Administration. Environmental Analysis Laboratory. 2020. Available online: https://www.epa.gov.tw/niea/A048BA729D1F7D58 (accessed on 8 March 2022).

- Kim, J.J.; Yoon, H.; Hong, J.; Lee, T.; Wilf, M. Evaluation of new compact pretreatment system for high turbidity seawater: Fiber filter and ultrafiltration. Desalination 2013, 313, 28–35. [Google Scholar] [CrossRef]

- Lee, J.J.; Cha, J.H.; Ben Aim, R.; Han, K.B.; Kim, C.W. Fiber filter as an alternative to the process of flocculation–sedimentation for water treatment. Desalination 2008, 231, 323–331. [Google Scholar] [CrossRef]

- Lee, J.J.; Johir, M.A.H.; Chinu, K.H.; Shon, H.K.; Vigneswaran, S.; Kandasamy, J.; Shaw, K. Hybrid filtration method for pre-treatment of seawater reverse osmosis (SWRO). Desalination 2009, 247, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Jeanmaire, J.-P.; Suty, H.; Marteil, P.; Breant, P.; Pedenaud, P. Application of the flexible fiber filter module (3FM) filter to sea water filtration. Water Sci. Technol. 2007, 56, 157–165. [Google Scholar] [CrossRef]

- Qin, J.-J.; Wai, M.N.; Oo, M.H.; Kekre, K.A.; Seah, H. Feasibility study for reclamation of a secondary treated sewage effluent mainly from industrial sources using a dual membrane process. Sep. Purif. Technol. 2006, 50, 380–387. [Google Scholar] [CrossRef]

- Qin, J.-J.; Kekre, K.A.; Tao, G.; Oo, M.H.; Wai, M.N.; Lee, T.C.; Seah, H. New option of MBR-RO process for production of NEWater from domestic sewage. J. Membr. Sci. 2006, 272, 70–77. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, L.; Ong, S.L. Fouling behavior and foulant characteristics of reverse osmosis membranes for treated secondary effluent reclamation. J. Membr. Sci. 2010, 349, 65–74. [Google Scholar] [CrossRef]

- PENTAIR. Product Selection Tools. 2020. Available online: https://xflow.pentair.com/en (accessed on 28 December 2020).

- Hydranautics—A Nitto Group Company. Product Selection Tools. 2020. Available online: https://membranes.com/product-selection-tools/ (accessed on 9 February 2022).

- Henan Dingxinda Import & Export Co., Ltd. Product Selection Tools. 2022. Available online: https://www.dxdcarbon.com/ (accessed on 9 February 2022).

- Urgun-Demirtas, M.; Benda, P.L.; Gillenwater, P.S.; Negri, M.C.; Xiong, H.; Snyder, S.W. Achieving very low mercury levels in refinery wastewater by membrane filtration. J. Hazard. Mater. 2012, 215–216, 98–107. [Google Scholar] [CrossRef]

- Singapore’s National Water Agency. NEWater Technology. 2021. Available online: https://www.pub.gov.sg/ (accessed on 12 August 2021).

- Doederer, K.; Farré, M.J.; Pidou, M.; Weinberg, H.S.; Gernjak, W. Rejection of disinfection by-products by RO and NF membranes: Influence of solute properties and operational parameters. J. Membr. Sci. 2014, 467, 195–205. [Google Scholar] [CrossRef] [Green Version]

- Water Resources Agency, MOEA. Laws. 2021. Available online: https://eng.wra.gov.tw/Default.aspx (accessed on 5 March 2022).

- Panhwar, M.Y.; Panhwar, S.; Keerio, H.A.; Khokhar, N.H.; Shah, S.A.; Pathan, N. Water quality analysis of old and new Phuleli Canal for irrigation purpose in the vicinity of Hyderabad, Pakistan. Water Pract. Technol. 2022, 17, 529–536. [Google Scholar] [CrossRef]

- Stenstrom, M.K.; Song, S.S. Effects of oxygen transport limitation on nitrification in the activated sludge process. Res. J. Water Pollut. Control. Fed. 1991, 63, 208–219. Available online: https://www.jstor.org/stable/25043984 (accessed on 23 December 2020).

- Keerio, H.A.; Bae, W. Experimental investigation of substrate shock and environmental ammonium concentration on the stability of ammonia-oxidizing bacteria (AOB). Water 2020, 12, 223. [Google Scholar] [CrossRef] [Green Version]

- Neger, M.K. Literature Review on the Survival of Fecal Coliform in Fresh and Saline Waters, and Sediments; Agreement No. GA-97020501-0; Lummi Indian Business Council: Bellingham, WA, USA, 2002. [Google Scholar]

- Căilean, D.; Barjoveanu, G.; Teodosiu, C.; Pintilie, L.; Dăscălescu, I.G.; Păduraru, C. Technical performances of ultrafiltration applied to municipal wastewater treatment plant effluents. Desalination Water Treat. 2015, 56, 1476–1488. [Google Scholar] [CrossRef]

- Samudro, G.; Mangkoedihardjo, S. Review on BOD, COD and BOD/COD Ratio: A triangle zone for toxic, biodegradable and stable levels. Int. J. Acad. Res. 2010, 2, 235–239. [Google Scholar]

- Mutamim, N.S.A.; Noor, Z.Z.; Hassan, M.A.A.; Olsson, G. Application of membrane bioreactor technology in treating high strength industrial wastewater: A performance review. Desalination 2012, 305, 1–11. [Google Scholar] [CrossRef]

- Viero, A.F.; Sant’Anna, G.L. Is hydraulic retention time an essential parameter for MBR performance? J. Hazard. Mater. 2008, 150, 185–186. [Google Scholar] [CrossRef]

- Fried, J.; Lemmer, H. On the dynamics and function of ciliates in sequencing batch biofilm reactors. Water Sci. Technol. 2003, 47, 189–196. [Google Scholar] [CrossRef]

- Chan, H. High performance achieved by microbes to separate laundry effluents resulting in producing high water quality in a compact area. Sep. Purif. Technol. 2012, 90, 101–108. [Google Scholar] [CrossRef]

- Pérez-Uz, B.; Arregui, L.; Calvo, P.; Salvadó, H.; Fernández, N.; Rodríguez, E.; Serrano, S. Assessment of plausible bioindicators for plant performance in advanced wastewater treatment systems. Water Res. 2010, 44, 5059–5069. [Google Scholar] [CrossRef]

- Hernández Navarro, M.; Melián-Martel, N.; Ruiz-García, A.; Río-Gamero, B.D. Fouling characterization during initial stage of cross-flow ultrafiltration. J. Water Process Eng. 2020, 38, 101611. [Google Scholar] [CrossRef]

- Walker, J.T.; Phillips, D.V.; Melin, J.; Spradlin, D. Effects of intermittent acidic irrigations on soybean yields and frogeye leaf spot. Environ. Exp. Bot. 1994, 34, 311–318. [Google Scholar] [CrossRef]

- Ruiz-García, A.; de la Nuez-Pestana, I. A computational tool for designing BWRO systems with spiral wound modules. Desalination 2018, 426, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Lesjean, B.; Leiknes, T.O. Salient outcomes of the European R&D projects on MBR technology. In Final MBR-Network Workshop; Kompetenzzentrum Wasser Berlin GmbH: Berlin, Germany, 2009. [Google Scholar]

| Parameter | Dingxinda (Fiber Filter) | Parameter | Pentair, X-Flow Aquaflex 64 (UF Membrane) | Parameter | Hydranautics, Nitto Denko LFC3-LD (RO Membrane) |

|---|---|---|---|---|---|

| Density | 1.38 kg/m3 | Maximum System Pressure | 43 psi | Maximum Applied Pressure | 600 psig |

| Filtration Linear Velocity | From 30 to 80 m3/m2/h | Maximum Backflush Pressure | 43 psi | Maximum Chlorine Concentration | <0.1 ppm |

| Backwash Time | From 10 to 20 min | Temperature Range | 0 to 40 °C | Maximum Feedwater Turbidity | 1.0 NTU |

| Backwash Cycle | From 8 to 24 h | Effective Membrane Area | 64.0 m2 | Maximum Feedwater SDI15 | 5.0 |

| Filtration Pressure | 2.0 kg/cm2 or less | Module Length | 1537.5 mm | Permeate Flow | 41.6 m3/d |

| Filter Material | Polyester fiber | Module Weight Water-Filled | 66 kg | Maximum Feed Flow | 17.0 m3/h |

| Specific Surface Area | 3000 m2/m3 | Membrane Diameter | 0.77 mm | Membrane Active Area | 37.1 m2 |

| Replacement Filter Media | None (10% supplement once a year) | Crossflow Flow Rate | 30.8 m3/h | Salt Rejection | 99.7% |

| Item | Mode 1 | Mode 2 | Mode 3 | Mode 4 |

|---|---|---|---|---|

| Production Capacity (m3) | 50.0 | 50.0 | 50.0 | 50.0 |

| FF Filtration Linear Velocity (m/h) | 80 | 80 | 80 | 80 |

| UF Filtrate Flux Rate (LMH) | 40 | 40 | 45 | 45 |

| RO Recovery (%) | 75 | 75 | 75 | 65 |

| RO Filtrate Flux Rate (LMH) | 16 | 18 | 18 | 18 |

| Running Period (days) | 90 | 90 | 90 | 90 |

| Unit | FF | UF | RO |

|---|---|---|---|

| CEB Cleaning Conditions | Monthly | Daily | N/A |

| CEB Cleaning Process | Chemicals: 100 mg/L NaOCl; Times: 4 h | Chemicals: 100 mg/L NaOCl; Times: 1 h | N/A |

| CIP Cleaning Conditions | Pressure differential (ΔP) exceeds 1.5 kg/cm2 or removal rate below 20% | Pressure differential (ΔP) exceeds 1.5 kg/cm2 | Pressure differential (ΔP) exceeds 3.0 kg/cm2 |

| CIP Cleaning Process | Chemicals: 0.05% NaOH, 100 mg/L NaOCl; Times: 8 h | Chemicals: 0.27% NaOH, 200 mg/L NaOCl; Times: 4 h | Chemicals: 0.01 N NaOH, 0.01 N HCl; Times: 4 h |

| Parameters | WRRF Effluent | ||

|---|---|---|---|

| Maximum | Mean Value ± SD | Minimum | |

| Coliform group 1 (CFU/100 mL) 2 | 1.5 × 105 | (3.3 ± 2.8) × 104 | 120 |

| BOD5 (mg/L) | 14.3 | 7.5 ± 2.4 | 2.4 |

| COD (mg/L) | 39.6 | 24.1 ± 3.6 | 13.5 |

| NH3-N (mg/L) | 9.20 | 1.83 ± 2.01 | 0.03 |

| TOC (mg/L) | 8.8 | 5.1 ± 1.4 | 2.8 |

| Cl− (mg/L) | 1340 | 603 ± 214 | 330 |

| SS (mg/L) | 16.8 | 6.3 ± 2.1 | 2.5 |

| TDS (mg/L) | 2503 | 1587 ± 388 | 498 |

| Turbidity (NTU) 3 | 11.1 | 3.8 ± 1.6 | 1.1 |

| pH | 7.3 | 6.8 ± 0.2 | 6.3 |

| EC (μs/cm) | 7860 | 2839 ± 757 | 735 |

| Item | Treated Water | Quality Standards of Reclaimed Water 1 |

|---|---|---|

| Temp (°C) | 21.1–33.4 | - |

| pH | 5.3–5.9 | 6.0–8.5 |

| Turbidity (NTU) | 0.1–1.2 | 5 |

| EC (μs/cm) | 30–105 | - |

| Boron (mg/L) | 0.05–0.25 | - |

| Ca2+ (mg/L) | 1.10–2.16 | - |

| Cl− (mg/L) | 1.5–16.1 | - |

| COD (mg/L) | ND (<3.2)–4.2 | - |

| Mg2+ (mg/L) | <0.1 | - |

| NH3-N (mg/L) | 0.04–1.42 | 10 |

| SiO2 (mg/L) | 0.11–1.34 | - |

| SS (mg/L) | <0.1 | - |

| TDS (mg/L) | 19.6–62.5 | - |

| SO42− (mg/L) | 0.10–2.73 | - |

| TOC (mg/L) | 0.3–0.6 | 10 |

| Minimum residual chlorine of combined residual chlorine (mg/L) | - | 0.4 |

| Minimum residual chlorine of free residual chlorine (mg/L) | - | 0.1 |

| Maximum allowable limit for coliform group (membrane filtration method) (CFU/100 mL) | <10 | 200 |

| Item 1 | Mode 1 | Mode 2 | Mode 3 | Mode 4 |

|---|---|---|---|---|

| Production capacity (m3) | 51.3 | 51.5 | 53.3 | 52.8 |

| UF filtrate flux rate (LMH) | 40 | 40 | 45 | 45 |

| RO recovery (%) | 75 | 75 | 75 | 65 |

| RO filtrate flux rate (LMH) | 16 | 18 | 18 | 18 |

| Chemical dosage cost (USD/m3) | 0.217 | 0.217 | 0.213 | 0.244 |

| Gross power (kWh) | 14,357 | 14,864 | 13,595 | 13,808 |

| Energy consumption rate (kWh/m3) | 3.11 | 3.21 | 2.84 | 2.91 |

| Energy cost per m3 (USD/m3) | 0.276 | 0.285 | 0.252 | 0.259 |

| Chemical dosage cost + energy cost 2 (USD/m3) | 0.493 | 0.502 | 0.465 | 0.503 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, S.-S.; Wu, J.-H. Improving the Performance of the Reverse Osmosis Process with Fiber Filter and Ultrafiltration: Promoting Municipal Sewage Reclamation and Reuse for Industrial Processes. Sustainability 2022, 14, 5443. https://doi.org/10.3390/su14095443

Chan S-S, Wu J-H. Improving the Performance of the Reverse Osmosis Process with Fiber Filter and Ultrafiltration: Promoting Municipal Sewage Reclamation and Reuse for Industrial Processes. Sustainability. 2022; 14(9):5443. https://doi.org/10.3390/su14095443

Chicago/Turabian StyleChan, Shih-Shuo, and Jung-Hua Wu. 2022. "Improving the Performance of the Reverse Osmosis Process with Fiber Filter and Ultrafiltration: Promoting Municipal Sewage Reclamation and Reuse for Industrial Processes" Sustainability 14, no. 9: 5443. https://doi.org/10.3390/su14095443

APA StyleChan, S.-S., & Wu, J.-H. (2022). Improving the Performance of the Reverse Osmosis Process with Fiber Filter and Ultrafiltration: Promoting Municipal Sewage Reclamation and Reuse for Industrial Processes. Sustainability, 14(9), 5443. https://doi.org/10.3390/su14095443