Temporal and Spatial Evolution Characteristics and Influencing Factors Analysis of Green Production in China’s Dairy Industry: Based on the Perspective of Green Total Factor Productivity

Abstract

:1. Introduction

2. Review of Green Total Factor Productivity Assessment Research

3. Calculation and Analysis of Green Total Factor Productivity

3.1. Selection of Basic Data Sources and Variables

- (1)

- Expected input: Referring to Chen Yao et al. [23], assets, energy and agricultural resources are selected as the proxy variables of expected input. The investment of assets includes four items: medical and epidemic prevention fee, tool and material purchase fee, repair and maintenance fee and fixed asset fee. Energy input includes electricity input and coal input; agricultural resource input is the amount of feed grain consumption.

- (2)

- Expected output: In this paper, dairy output is selected as the proxy variable of expected output, so as to reflect the total value of economic activities in the dairy industry within a year.

- (3)

- Undesirable output: The negative impact of dairy farming on the environment is mainly caused by pollutants such as manure and greenhouse gas emissions. The carbon emissions of the dairy industry refer to the calculation methods of Bai Mei [25], Wang Xiaoqin [20], and Li Ting-yu [26] et al., based on the life cycle method from the perspective of the whole industrial chain [27], and methane and nitrous oxide are converted into carbon dioxide equivalent according to the greenhouse benefit potential (GWP) coefficient. The types of pollutants in the dairy industry mainly include three harmful substances, namely chemical oxygen demand (COD), total nitrogen (TN) and total phosphorus (TP).

3.2. Model Selection

3.2.1. Super-Efficiency EBM Model

3.2.2. Global Malmquist–Luenberger Index

3.2.3. Dagum Gini Coefficient and Its Decomposition

3.2.4. Kernel Density Estimation Function

4. Analysis of GTFP Development Characteristics of Chinese Dairy Industry

4.1. Analysis of the Temporal Evolution Characteristics of GTFP in the Chinese Dairy Industry

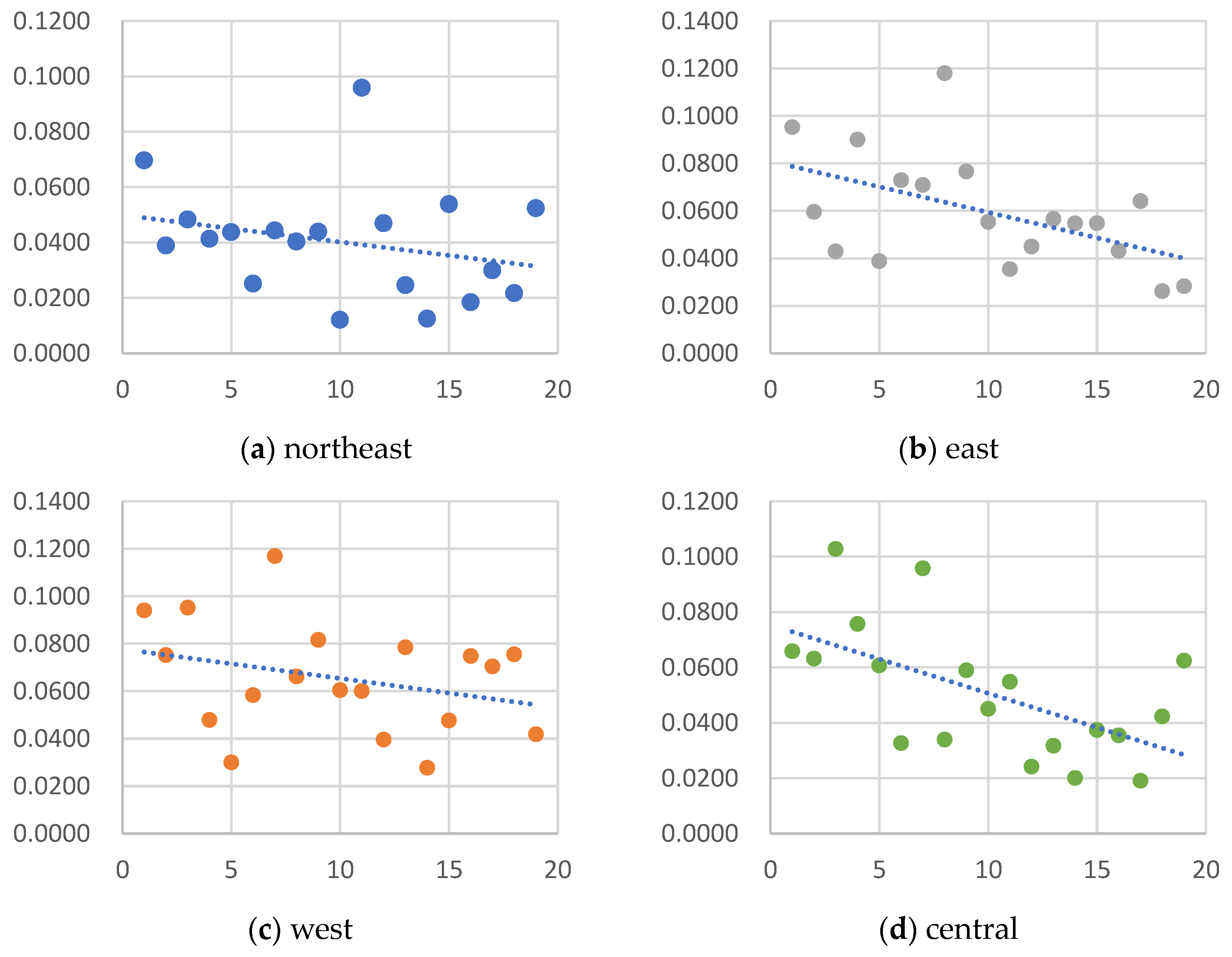

4.2. Regional Analysis of GTFP in the Chinese Dairy Industry

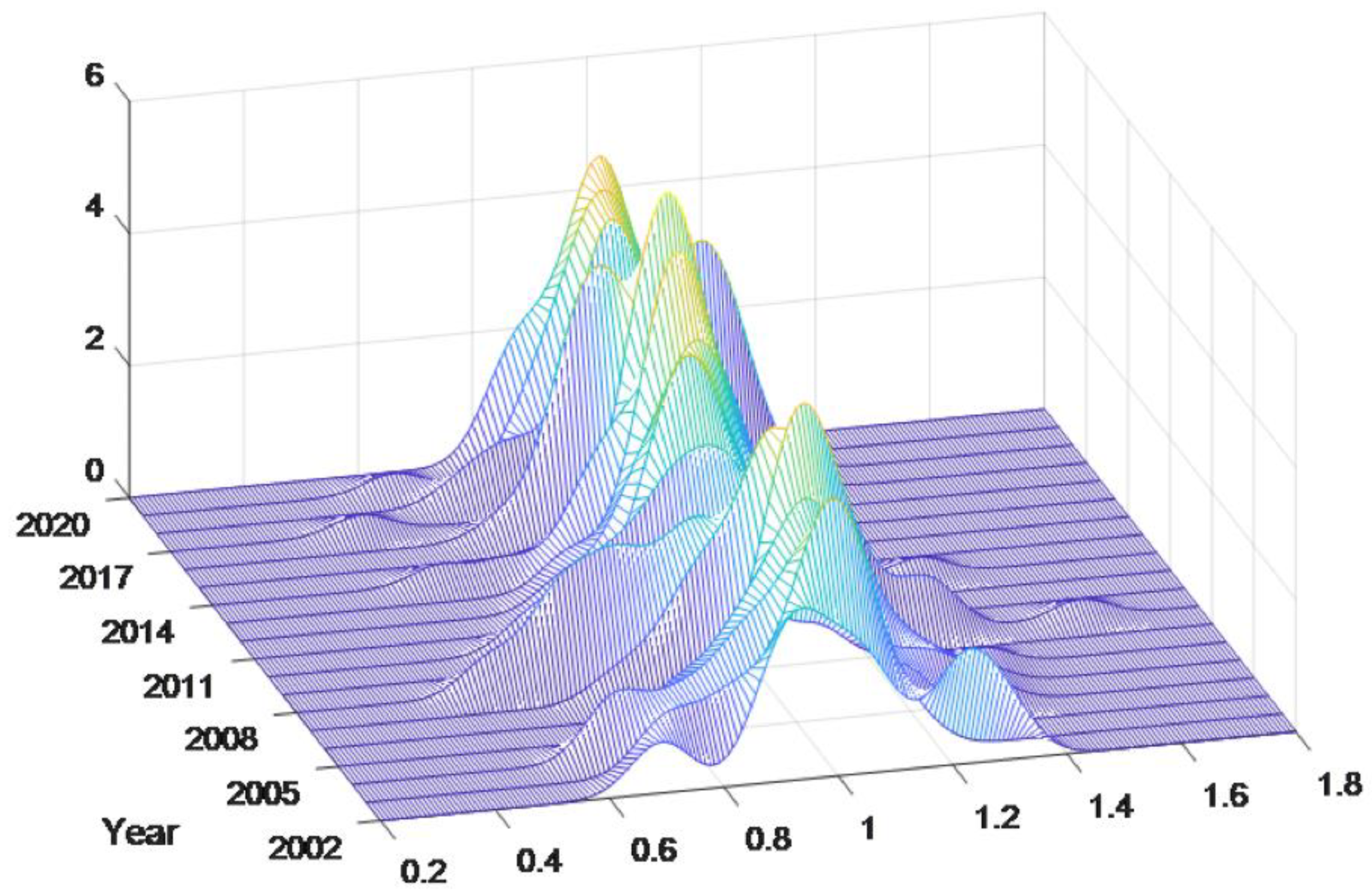

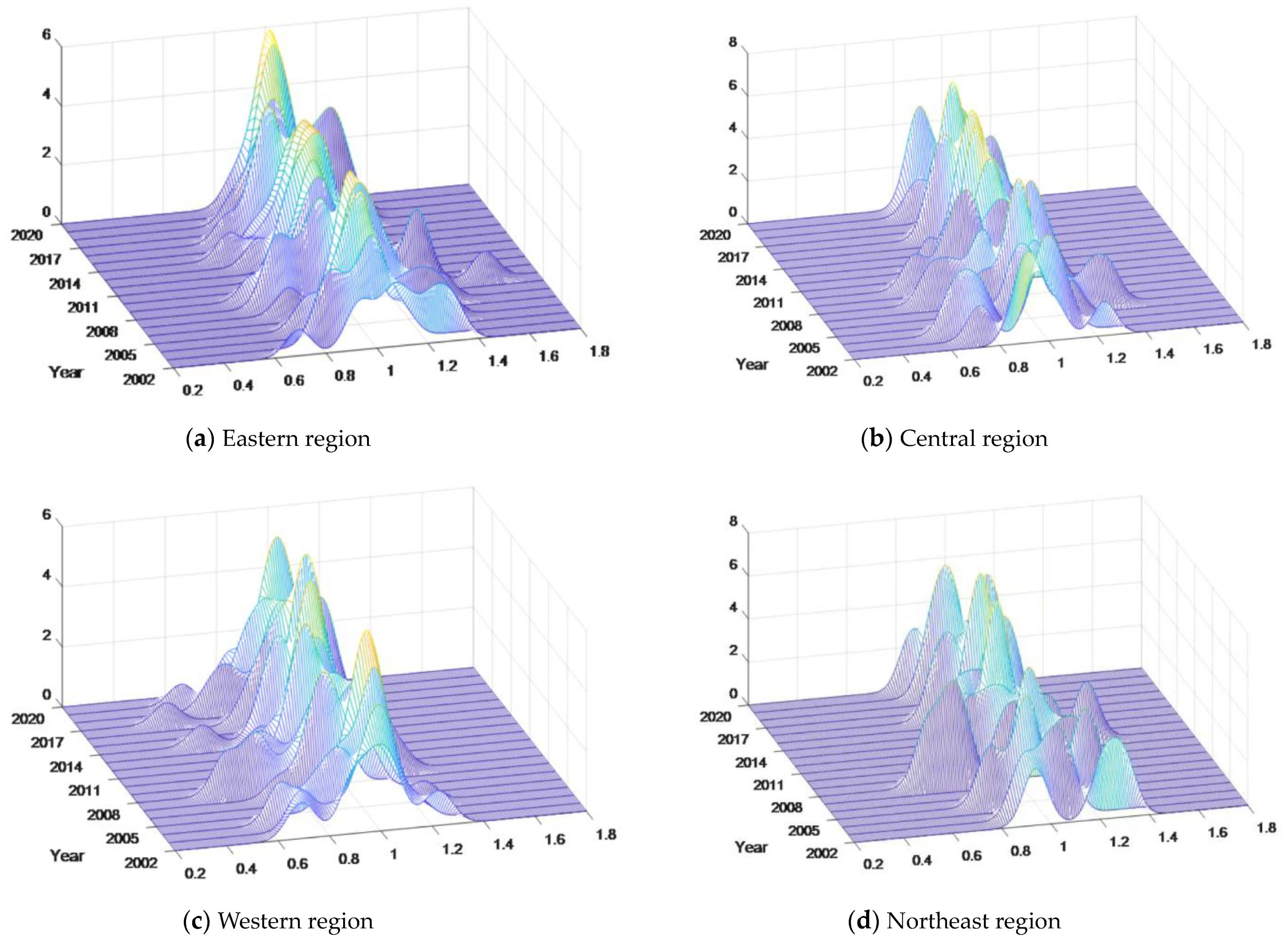

4.3. The Dynamic Evolution of China’s Dairy Industry GTFP

5. Factors Influencing China’s Dairy Industry GTFP

5.1. Selection of Indicators

5.2. Model Specification

5.3. Empirical Tests and Results Analysis

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Opinions of the CPC Central Committee and The State Council on Comprehensively Promoting Rural Revitalization and Accelerating Agricultural and Rural Modernization. Qinghai Agric. Technol. Ext. 2021, 3–9.

- Chen, J.; Zhong, F. The Role of Income and Food Prices in Diet-Related Greenhouse Gas Emissions in China: A Path towards a Sustainable Diet. Foods 2022, 11, 4051. [Google Scholar] [CrossRef]

- Dong, H.; Li, Y.; Tao, X. Agricultural greenhouse gas emissions and mitigation technologies in China. Trans. Chin. Soc. Agric. Eng. 2008, 24, 269–273. [Google Scholar]

- The Writing Committee of the Third National Climate Change Assessment Report. In The Third National Climate Change Assessment Report; Science Press: Beijing, China, 2015.

- Liu, C.; Shi, X.; Li, C. Digital Technology, Factor Allocation and Environmental Efficiency of Dairy Farms in China: Based on Carbon Emission Constraint Perspective. Sustainability 2023, 15, 15455. [Google Scholar] [CrossRef]

- Milić, D.; Novaković, T.; Tekić, D.; Matkovski, B.; Đokić, D.; Zekić, S. Economic Sustainability of the Milk and Dairy Supply Chain: Evidence from Serbia. Sustainability 2023, 15, 15234. [Google Scholar] [CrossRef]

- Lu, Z.; Shao, C.; Wang, F.; Dong, R. Evaluation of Green and Low-Carbon Development Level of Chinese Provinces Based on Sustainable Development Goals. Sustainability 2023, 15, 15449. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, W. Spatial econometric study on convergence of total factor productivity among provinces in China. J. Shandong Univ. (Philos. Soc. Sci.) 2017, 43–49. [Google Scholar]

- Yao, C.; Qian, S.; Li, Z.; Liang, L. Measurement and spatiotemporal evolution mechanism of carbon emissions from livestock industry among provinces in China. Resour. Sci. 2017, 39, 698–712. [Google Scholar]

- Wu, Q.; Zhang, Y.; Zhang, M. Quantitative evaluation, spatio-temporal characteristics and dynamic evolution of carbon emissions from China’s animal husbandry: 2001–2020. J. Arid. Land Resour. Environ. 2022, 36, 65–71. [Google Scholar] [CrossRef]

- Xu, L.; Qu, J.; Wu, J.; Wei, Q.; Bai, J.; Li, H. Spatial-temporal changes and prediction of carbon emissions in China’s agriculture and animal husbandry. J. Ecol. Rural Environ. 2019, 35, 1232–1241. [Google Scholar] [CrossRef]

- Chen, Y.; Shang, J. Estimation of greenhouse gas emissions from livestock industry in the four major pastoral areas of China and decomposition of influencing factors. China Popul. Resour. Environ. 2014, 24, 89–95. [Google Scholar]

- Tang, H.; Su, Y.; Ma, H.; Wang, J. Pattern and equity of carbon emissions from animal husbandry in Xinjiang. Arid Land Geogr. 2017, 40, 1338–1345. [Google Scholar] [CrossRef]

- Yi, Q.; Li, B.; Geng, N. Analysis of total factor productivity of China’s animal husbandry based on environmental adjustment. China Popul. Resour. Environ. 2014, 24, 121–125. [Google Scholar]

- Zou, J.; Xiang, C. Measurement of environmental efficiency in China’s animal husbandry and analysis of influencing factors. Environ. Pollut. Control 2016, 38, 90–96. [Google Scholar] [CrossRef]

- Xu, B.; Shen, Z.; Lin, G. Evolution of Green Total Factor Productivity and Regional Disparity in China’s Husbandry. Chin. J. Eco-Agric. 2019, 27, 613–622. [Google Scholar]

- Cui, Z.; Wang, M.; Shi, Z. Analysis of total factor productivity of China’s herbivorous animal husbandry under greenhouse gas emissions constraints. J. Agrotech. Econ. 2018, 66–78. [Google Scholar] [CrossRef]

- Du, H.; Wang, M.; Hu, M. Spatio-temporal differences of green total factor productivity in pig farming of different scales: Based on non-radial, non-angular SBM productivity index model. J. Hunan Agric. Univ. (Soc. Sci. Ed.) 2019, 20, 16–23. [Google Scholar] [CrossRef]

- Zhu, N.; Qin, F. Analysis of environmental efficiency and environmental total factor productivity in large-scale livestock and poultry farms: A case study of laying hens. J. Agrotech. Econ. 2015, 86–98. [Google Scholar] [CrossRef]

- Wang, X.; Liang, D.; Wang, X.; Peng, S.; Zheng, J. Evaluation of greenhouse gas emissions from a dairy farming system using a life cycle assessment. Trans. Chin. Soc. Agric. Eng. 2012, 28, 179–184. [Google Scholar]

- Huang, W. Method and Case Analysis of Carbon Footprint Assessment for Milk Production in Large-Scale Dairy Farms. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2015. [Google Scholar]

- Li, J.; Shi, Z.; Hu, X. Analysis of spatiotemporal differentiation characteristics of total factor productivity in China’s dairy industry. Chin. J. Agric. Resour. Reg. Plan. 2022, 43, 92–103. [Google Scholar]

- Chen, Y. Measurement of Carbon Emissions and Reduction Pathways in China’s Livestock Industry. Master’s Thesis, Northeast Forestry University, Harbin, China, 2016. [Google Scholar]

- Available online: http://www.stats.gov.cn/ (accessed on 10 November 2023).

- Bai, M.; Ma, W.; Wu, J.; Lu, Y.; Ren, K.; Kang, J. Estimation of greenhouse gas emissions from large-scale dairy farms in Beijing. J. Domest. Anim. Ecol. 2017, 38, 78–85. [Google Scholar]

- Li, T.; Xiong, H.; Wang, M. How should China’s dairy industry develop under the “dual carbon” target? A study on carbon emissions of the dairy industry from the perspective of the entire industry chain. Issues Agric. Econ. 2022, 15, 17–29. [Google Scholar] [CrossRef]

- Hoehn, D.; Laso, J.; Cristóbal, J.; Ruiz-Salmón, I.; Butnar, I.; Borrion, A.; Bala, A.; Fullana-i-Palmer, P.; Vázquez-Rowe, I.; Aldaco, R.; et al. Regionalized Strategies for Food Loss and Waste Management in Spain under a Life Cycle Thinking Approach. Foods 2020, 9, 1765. [Google Scholar] [CrossRef] [PubMed]

- Tone, K.; Tsutsui, M. An Epsilon-based Measure of Efficiency in DEA: A Third Pole of Technical Efficiency. Eur. J. Oper. Res. 2010, 207, 1554–1563. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, Y. Spatio-temporal differences and influencing factors of green total factor productivity in China’s animal husbandry. J. Ecol. Rural. Environ. 2023. [Google Scholar] [CrossRef]

- Wang, R. Regional differences and spatiotemporal evolution of green development level of China’s pig industry: An empirical study based on Dagum Gini coefficient decomposition and Kernal density estimation. Product. Res. Res. 2023, 74–79. [Google Scholar]

- Dagum, C. A New Approach to the Decomposition of the Gini Income Inequality Ratio. Empir. Econ. 1997, 22, 515–531. [Google Scholar] [CrossRef]

- Liu, S. Regional differences and stochastic convergence of economic growth quality in China. J. Quant. Tech. Econ. 2019, 36, 24–41. [Google Scholar] [CrossRef]

- Yu, G. Estimation and Influencing Factors of Carbon Emissions in China’s Dairy Industry; Northeast Agricultural University: Harbin, China, 2019. [Google Scholar]

- Guo, J. The impact of environmental regulation on green technology innovation: Evidence from China’s “Porter Effect”. Financ. Trade Econ. 2019, 40, 147–160. [Google Scholar]

- Zhang, T.; Yang, J.; Sheng, P. The influence of urbanization on carbon emissions in China and its channels of action. China Popul. Resour. Environ. 2016, 26, 47–57. [Google Scholar]

- Qiu, B.; Yang, S.; Xin, P. FDI technology spillover channels and productivity growth in China’s manufacturing industry: An analysis based on panel data. J. World Econ. 2008, 20–31. [Google Scholar]

| Indicators | Variable | Variable Representation |

|---|---|---|

| input indicators | agricultural resource inputs | grain consumption (10,000 tons) |

| energy inputs | electricity input (kWh) | |

| coal input (tons) | ||

| medical and epidemic prevention expenses (CNY 10,000) | ||

| asset inputs | tools and materials purchase (CNY 10,000) repair and maintenance expenses (CNY 10,000) fixed assets (CNY 10,000) | |

| expected output | economic growth of the dairy industry | output value of dairy products (CNY 100 million) |

| undesirable output | carbon emissions of the dairy industry | carbon emissions of the dairy industry (10,000 tons) |

| pollutant emissions of the dairy industry | COD, TN, TP (tons) |

| Period | GTFP | GEC | GTC | Cumulative GTFP |

|---|---|---|---|---|

| 2001–2002 | 1.015 | 1.001 | 1.005 | 1.015 |

| 2002–2003 | 0.965 | 0.961 | 1.004 | 0.981 |

| 2003–2004 | 1.003 | 1.023 | 0.981 | 0.984 |

| 2004–2005 | 1.101 | 1.066 | 1.032 | 1.084 |

| mean of 10th Five-Year Plan period | 1.021 | 1.015 | 1.006 | —— |

| 2005–2006 | 1.132 | 0.979 | 1.156 | 1.216 |

| 2006–2007 | 0.971 | 1.046 | 0.928 | 1.187 |

| 2007–2008 | 0.834 | 1.002 | 0.832 | 1.020 |

| 2008–2009 | 1.186 | 1.019 | 1.164 | 1.206 |

| 2009–2010 | 0.950 | 1.026 | 0.926 | 1.157 |

| mean of 11th Five-Year Plan period | 1.016 | 1.014 | 1.001 | —— |

| 2010–2011 | 0.997 | 1.021 | 0.976 | 1.154 |

| 2011–2012 | 1.003 | 1.016 | 0.986 | 1.156 |

| 2012–2013 | 0.976 | 1.046 | 0.932 | 1.132 |

| 2013–2014 | 0.986 | 0.992 | 0.994 | 1.118 |

| 2014–2015 | 1.050 | 0.966 | 1.087 | 1.168 |

| mean of 12th Five-Year Plan period | 1.003 | 1.008 | 0.995 | —— |

| 2015–2016 | 0.964 | 1.005 | 0.959 | 1.132 |

| 2016–2017 | 1.109 | 1.010 | 1.098 | 1.241 |

| 2017–2018 | 0.996 | 0.979 | 1.017 | 1.237 |

| 2018–2019 | 0.996 | 1.0139 | 0.982 | 1.232 |

| 2019–2020 | 1.047 | 1.007 | 1.039 | 1.279 |

| mean of 13th Five-Year Plan period | 1.022 | 1.003 | 1.019 | —— |

| mean value of 2001–2020 | 1.016 | 1.010 | 1.005 | —— |

| Region | Province | Ranking | GTFP | GEC | GTC | Region | Province | Ranking | GTFP | GEC | GTC |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 2 | 1.043 | 1.022 | 1.021 | Northeast | Heilongjiang | 4 | 1.041 | 1.006 | 1.035 |

| Tianjin | 3 | 1.042 | 1.021 | 1.021 | Jilin | 8 | 1.025 | 1.021 | 1.004 | ||

| Shanghai | 5 | 1.039 | 1.028 | 1.011 | Liaoning | 10 | 1.017 | 1.013 | 1.004 | ||

| Guangdong | 6 | 1.026 | 1.037 | 0.989 | Western | Inner Mongolia | 1 | 1.045 | 1.020 | 1.025 | |

| Shandong | 12 | 1.013 | 1.017 | 0.997 | Shanxi | 11 | 1.013 | 1.013 | 1.000 | ||

| Jiangsu | 13 | 1.010 | 1.001 | 1.009 | Chongqing | 14 | 1.004 | 0.996 | 1.008 | ||

| Heibei | 15 | 1.001 | 1.008 | 0.993 | Ningxia | 17 | 0.997 | 1.000 | 0.997 | ||

| Fujian | 16 | 0.999 | 1.016 | 0.983 | Yunnan | 18 | 0.997 | 0.992 | 1.004 | ||

| Zhejiang | 20 | 0.992 | 1.002 | 0.990 | Xinjiang | 21 | 0.982 | 0.988 | 0.994 | ||

| Central | Hubei | 7 | 1.025 | 1.021 | 1.004 | Qinghai | 22 | 0.981 | 0.976 | 1.005 | |

| Henan | 9 | 1.024 | 1.016 | 1.008 | Gansu | 25 | 0.975 | 0.980 | 0.994 | ||

| Shanxi | 19 | 0.995 | 1.001 | 0.994 | Guangxi | 26 | 0.968 | 0.990 | 0.978 | ||

| Anhui | 23 | 0.979 | 0.979 | 1.000 | Guizhou | 27 | 0.958 | 0.967 | 0.99 | ||

| Hunan | 24 | 0.976 | 0.992 | 0.984 | Sichuan | 28 | 0.956 | 0.967 | 0.988 | ||

| - | - | - | - | - | Tibet | 29 | 0.916 | 0.945 | 0.970 |

| Year | General G | Inter-Regional Gini Coefficient | |||||

|---|---|---|---|---|---|---|---|

| East–Northeast | West–Northeast | West–East | Central–Northeast | Central–East | Central–West | ||

| 2002 | 0.096 | 0.0908 | 0.1129 | 0.1053 | 0.0961 | 0.0936 | 0.0838 |

| 2003 | 0.067 | 0.055 | 0.0624 | 0.0703 | 0.0559 | 0.0663 | 0.0709 |

| 2004 | 0.0911 | 0.0761 | 0.1182 | 0.0804 | 0.1502 | 0.1044 | 0.1075 |

| 2005 | 0.0743 | 0.0968 | 0.0652 | 0.0781 | 0.067 | 0.0961 | 0.0702 |

| 2006 | 0.0469 | 0.0485 | 0.0516 | 0.0364 | 0.0589 | 0.064 | 0.067 |

| 2007 | 0.0659 | 0.0543 | 0.0747 | 0.0844 | 0.0456 | 0.0617 | 0.0546 |

| 2008 | 0.1033 | 0.1111 | 0.1071 | 0.1071 | 0.107 | 0.0887 | 0.1149 |

| 2009 | 0.0855 | 0.1011 | 0.0574 | 0.1139 | 0.0389 | 0.0994 | 0.0551 |

| 2010 | 0.0851 | 0.0676 | 0.0695 | 0.0832 | 0.0841 | 0.1134 | 0.1053 |

| 2011 | 0.0578 | 0.0415 | 0.0499 | 0.0637 | 0.042 | 0.0554 | 0.0705 |

| 2012 | 0.0637 | 0.1036 | 0.105 | 0.0506 | 0.1167 | 0.0483 | 0.0608 |

| 2013 | 0.0411 | 0.0494 | 0.0474 | 0.0434 | 0.0408 | 0.0375 | 0.0345 |

| 2014 | 0.0669 | 0.0653 | 0.0801 | 0.0719 | 0.0321 | 0.0563 | 0.0732 |

| 2015 | 0.0359 | 0.0404 | 0.0229 | 0.0446 | 0.0192 | 0.0418 | 0.0278 |

| 2016 | 0.0517 | 0.0592 | 0.0554 | 0.0561 | 0.0509 | 0.048 | 0.0466 |

| 2017 | 0.0574 | 0.0396 | 0.0529 | 0.0696 | 0.0316 | 0.048 | 0.0576 |

| 2018 | 0.0607 | 0.0626 | 0.0669 | 0.0703 | 0.0391 | 0.0471 | 0.0527 |

| 2019 | 0.0527 | 0.0292 | 0.0554 | 0.0567 | 0.0438 | 0.0375 | 0.064 |

| 2020 | 0.0465 | 0.0467 | 0.051 | 0.037 | 0.0644 | 0.0563 | 0.0631 |

| mean | 0.0658 | 0.0652 | 0.0687 | 0.0696 | 0.0623 | 0.0665 | 0.0674 |

| year | intra-regional Gini coefficient | contribution rate | |||||

| Northeast | Eastern | Western | Central | intra-regional | inter-regional | super-variation density | |

| 2002 | 0.0696 | 0.0952 | 0.0941 | 0.0659 | 28.70% | 32.56% | 38.73% |

| 2003 | 0.0389 | 0.0595 | 0.0753 | 0.0632 | 31.08% | 8.91% | 60.01% |

| 2004 | 0.0483 | 0.0429 | 0.0952 | 0.1028 | 25.63% | 48.00% | 26.37% |

| 2005 | 0.0413 | 0.09 | 0.0479 | 0.0757 | 26.80% | 34.33% | 38.87% |

| 2006 | 0.0437 | 0.0388 | 0.03 | 0.0607 | 23.64% | 47.54% | 28.82% |

| 2007 | 0.0251 | 0.0729 | 0.0583 | 0.0327 | 27.43% | 46.48% | 26.09% |

| 2008 | 0.0443 | 0.0709 | 0.1169 | 0.0958 | 28.95% | 35.77% | 35.28% |

| 2009 | 0.0403 | 0.118 | 0.0662 | 0.0339 | 28.55% | 31.42% | 40.02% |

| 2010 | 0.0438 | 0.0766 | 0.0816 | 0.059 | 28.13% | 38.88% | 32.99% |

| 2011 | 0.0121 | 0.0554 | 0.0605 | 0.0451 | 29.22% | 35.74% | 35.03% |

| 2012 | 0.0959 | 0.0354 | 0.0601 | 0.0548 | 25.62% | 31.90% | 42.48% |

| 2013 | 0.0469 | 0.045 | 0.0396 | 0.0242 | 29.98% | 3.08% | 66.95% |

| 2014 | 0.0246 | 0.0566 | 0.0785 | 0.0317 | 29.17% | 41.03% | 29.80% |

| 2015 | 0.0124 | 0.0547 | 0.0277 | 0.0201 | 30.03% | 19.67% | 50.30% |

| 2016 | 0.0538 | 0.0548 | 0.0477 | 0.0374 | 29.27% | 21.04% | 49.68% |

| 2017 | 0.0184 | 0.0432 | 0.0749 | 0.0355 | 31.15% | 40.70% | 28.15% |

| 2018 | 0.0299 | 0.0641 | 0.0704 | 0.0191 | 30.99% | 28.12% | 40.88% |

| 2019 | 0.0217 | 0.0261 | 0.0755 | 0.0423 | 31.81% | 20.71% | 47.49% |

| 2020 | 0.0523 | 0.0282 | 0.0419 | 0.0625 | 26.55% | 9.27% | 64.19% |

| mean | 0.0402 | 0.0594 | 0.0654 | 0.0507 | 28.56% | 30.27% | 41.16% |

| Variable Name | Abbreviation | Number of Observations | Mean | Variance | Standard Deviation | Maximum | Minimum |

|---|---|---|---|---|---|---|---|

| industrial agglomeration | LQ | 551 | 1.834 | 6.764 | 2.603 | 16.578 | 0.045 |

| economic development | lnPergdp | 551 | 1.081 | 0.636 | 0.798 | 2.803 | −1.175 |

| environmental planning | ER | 551 | 0.012 | 0.000 | 0.009 | 0.135 | 0.001 |

| emission efficiency | GPT | 551 | 3.118 | 9.920 | 3.153 | 24.281 | 0.112 |

| urbanization rate | lnPU | 551 | −0.818 | 0.201 | 0.449 | −0.158 | −2.263 |

| Variable Name | Coefficient | Std. Err. | t | p > |t| | 95% Conf. Interval | |

|---|---|---|---|---|---|---|

| LQ | 7.92 *** | 2.05 | 3.85 | 0.000 | 3.87 | 11.97 |

| lnPergdp | 64.39 *** | 13.22 | 4.87 | 0.000 | 38.40 | 90.38 |

| ER | 936.64 | 306.13 | 3.06 | 0.002 | 335.17 | 1538.11 |

| GPT | 6.91 *** | 0.94 | 7.32 | 0.000 | 5.05 | 8.77 |

| LnPU | 75.50 | 41.75 | 1.81 | 0.071 | −6.53 | 157.54 |

| _cons | 3.96 | 68.03 | 0.06 | 0.955 | −129.80 | 137.52 |

| Province | YES | |||||

| Year | YES | |||||

| N | 551 | |||||

| R-squared | 0.8664 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, H. Temporal and Spatial Evolution Characteristics and Influencing Factors Analysis of Green Production in China’s Dairy Industry: Based on the Perspective of Green Total Factor Productivity. Sustainability 2023, 15, 16250. https://doi.org/10.3390/su152316250

Liu Y, Liu H. Temporal and Spatial Evolution Characteristics and Influencing Factors Analysis of Green Production in China’s Dairy Industry: Based on the Perspective of Green Total Factor Productivity. Sustainability. 2023; 15(23):16250. https://doi.org/10.3390/su152316250

Chicago/Turabian StyleLiu, Yashuo, and Huanan Liu. 2023. "Temporal and Spatial Evolution Characteristics and Influencing Factors Analysis of Green Production in China’s Dairy Industry: Based on the Perspective of Green Total Factor Productivity" Sustainability 15, no. 23: 16250. https://doi.org/10.3390/su152316250