Mechanical and Thermal Insulation Properties of rGFRP Fiber-Reinforced Lightweight Fly-Ash-Slag-Based Geopolymer Mortar

Abstract

1. Introduction

2. Material and Methods

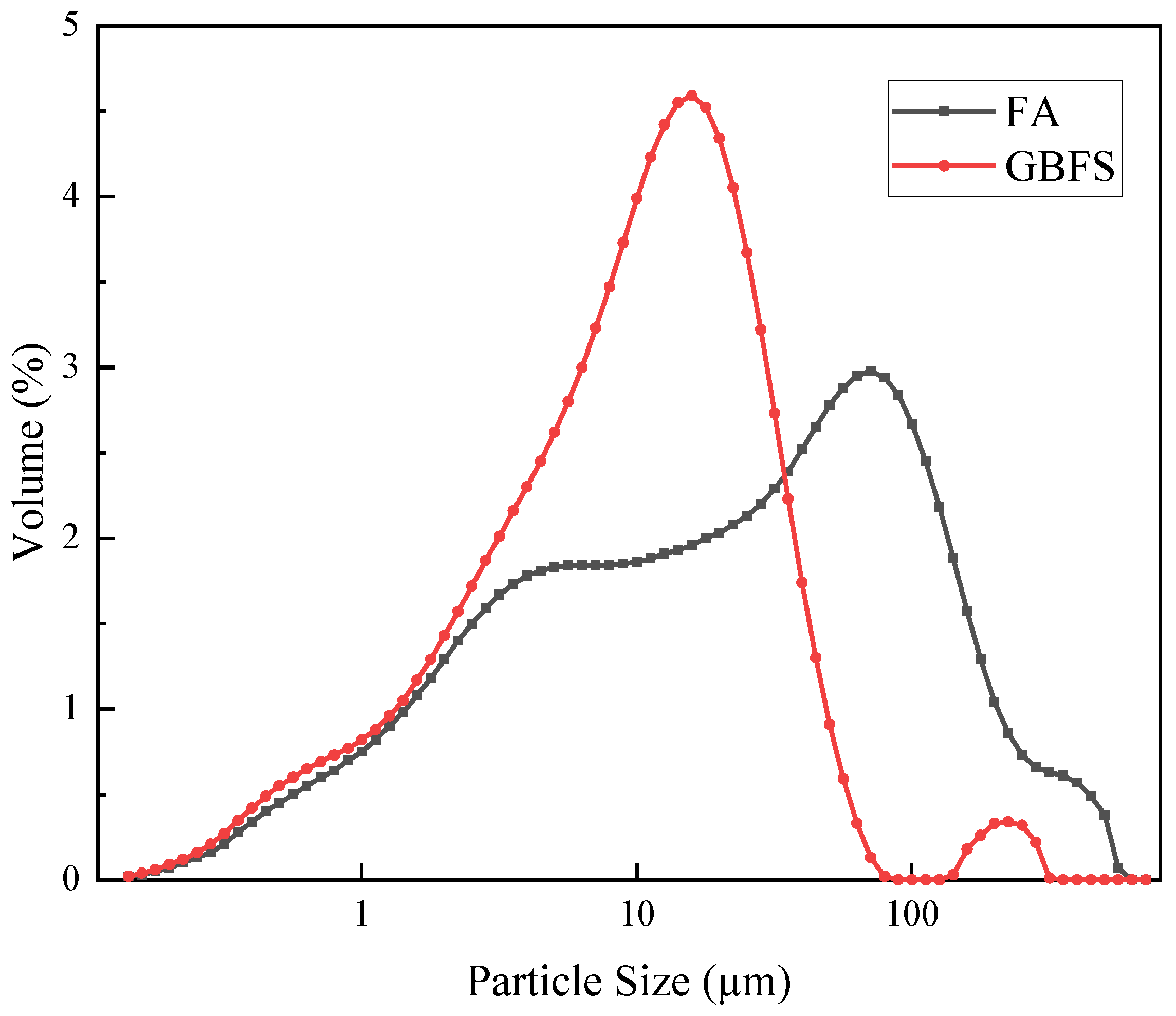

2.1. Materials

2.2. Mixture Design and Sample Preparation

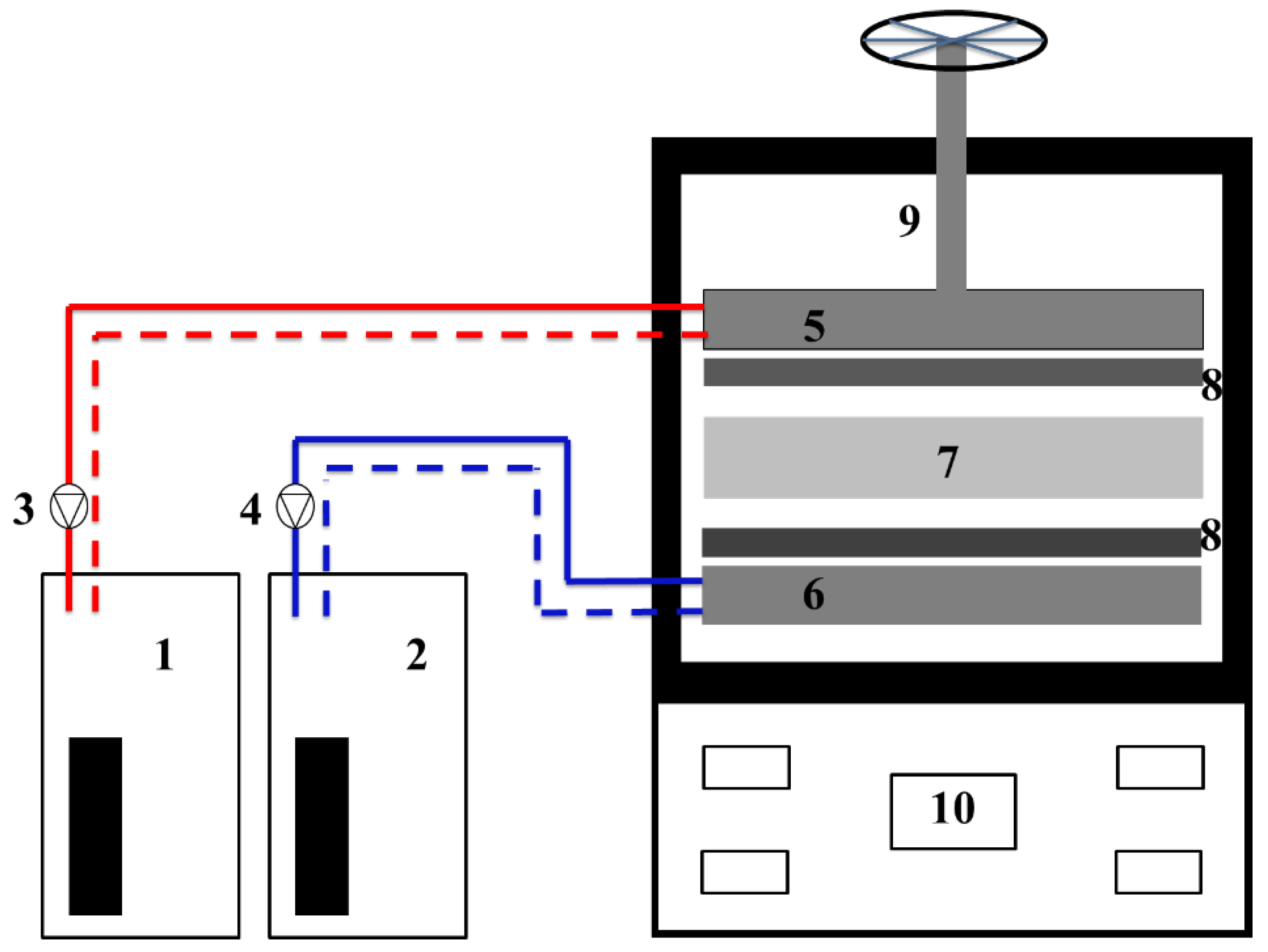

2.3. Test Methods

2.3.1. Workability and UCS

2.3.2. Density and Drying Shrinkage

2.3.3. Thermal Conductivity

2.3.4. Porosity

3. Results and Discussion

3.1. Workability

3.1.1. Spread Diameter

3.1.2. Setting Time

3.2. Density

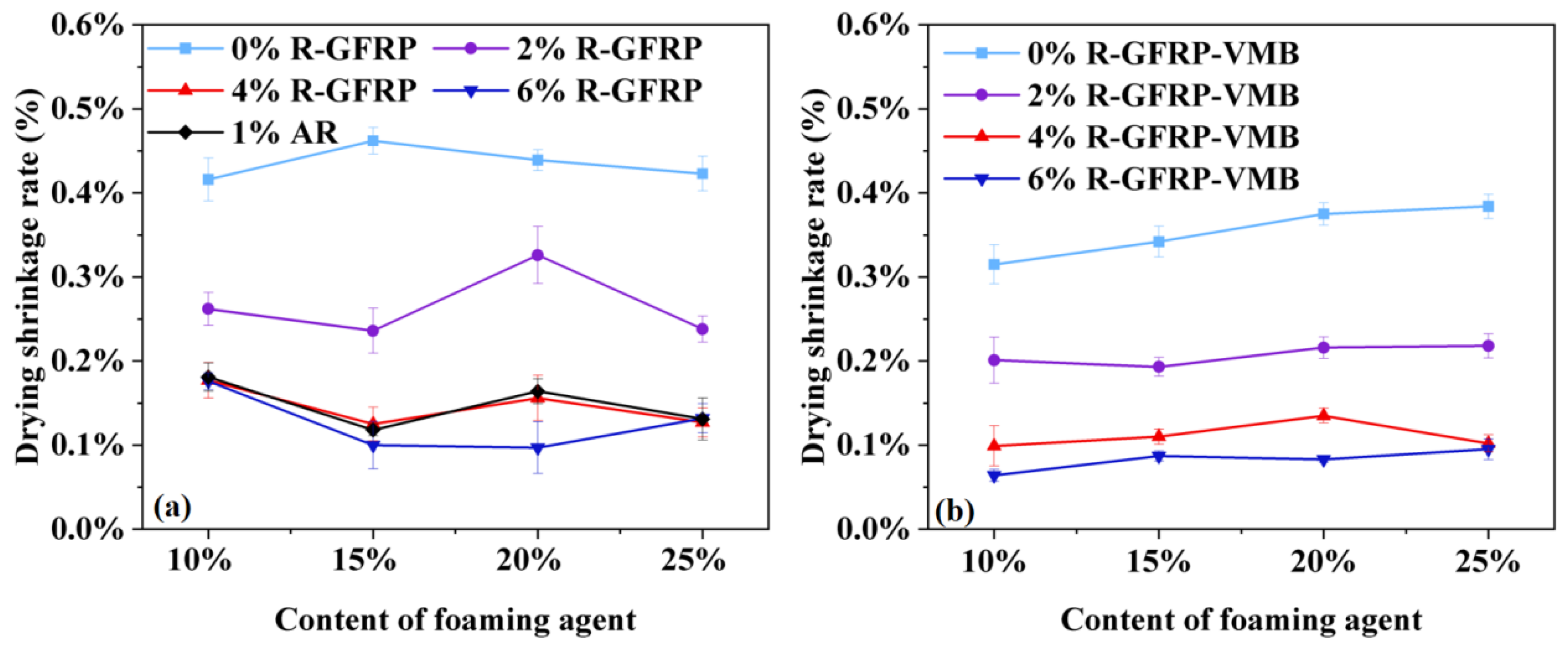

3.3. Drying Shrinkage

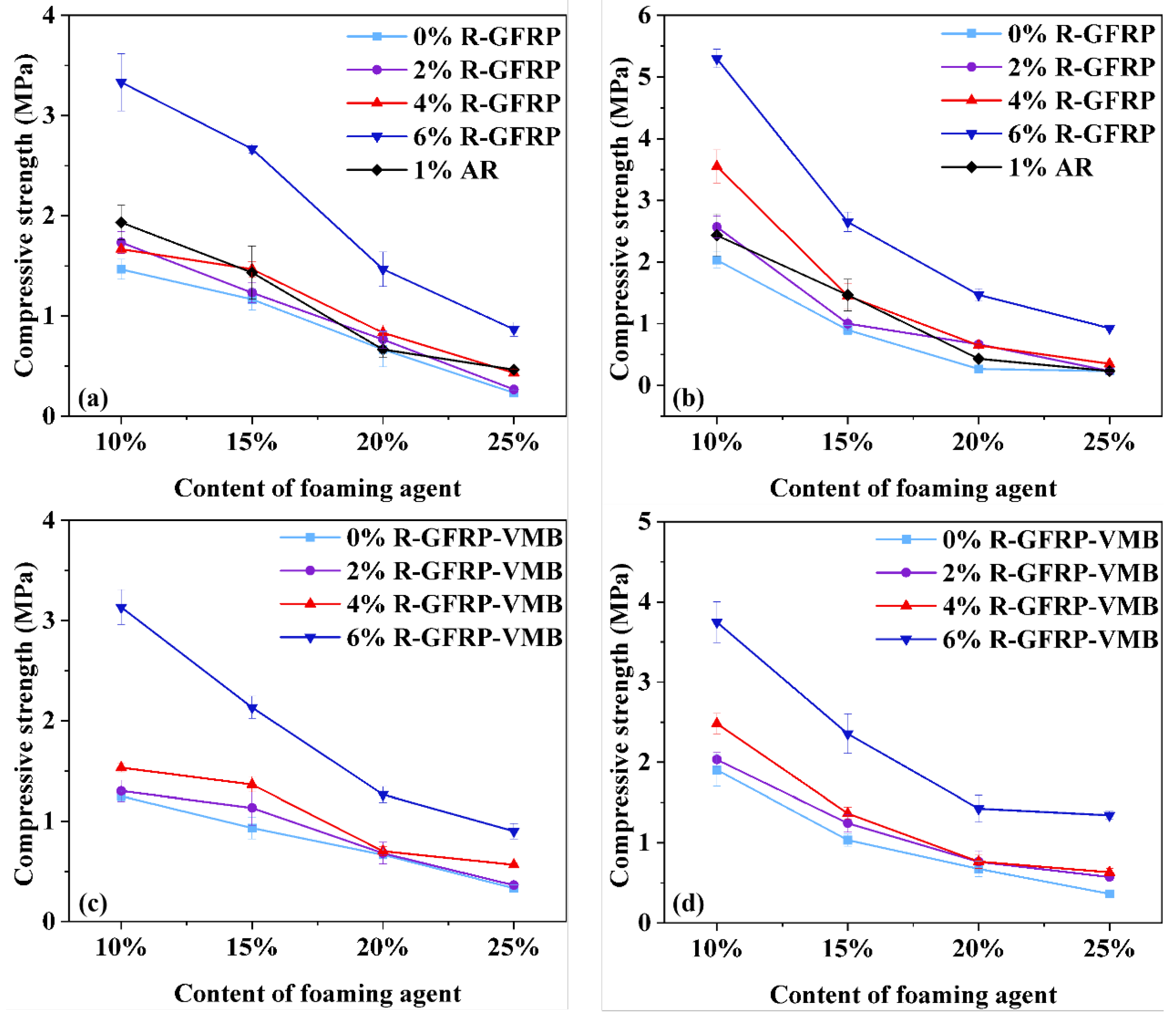

3.4. Unconfined Compressive Strength

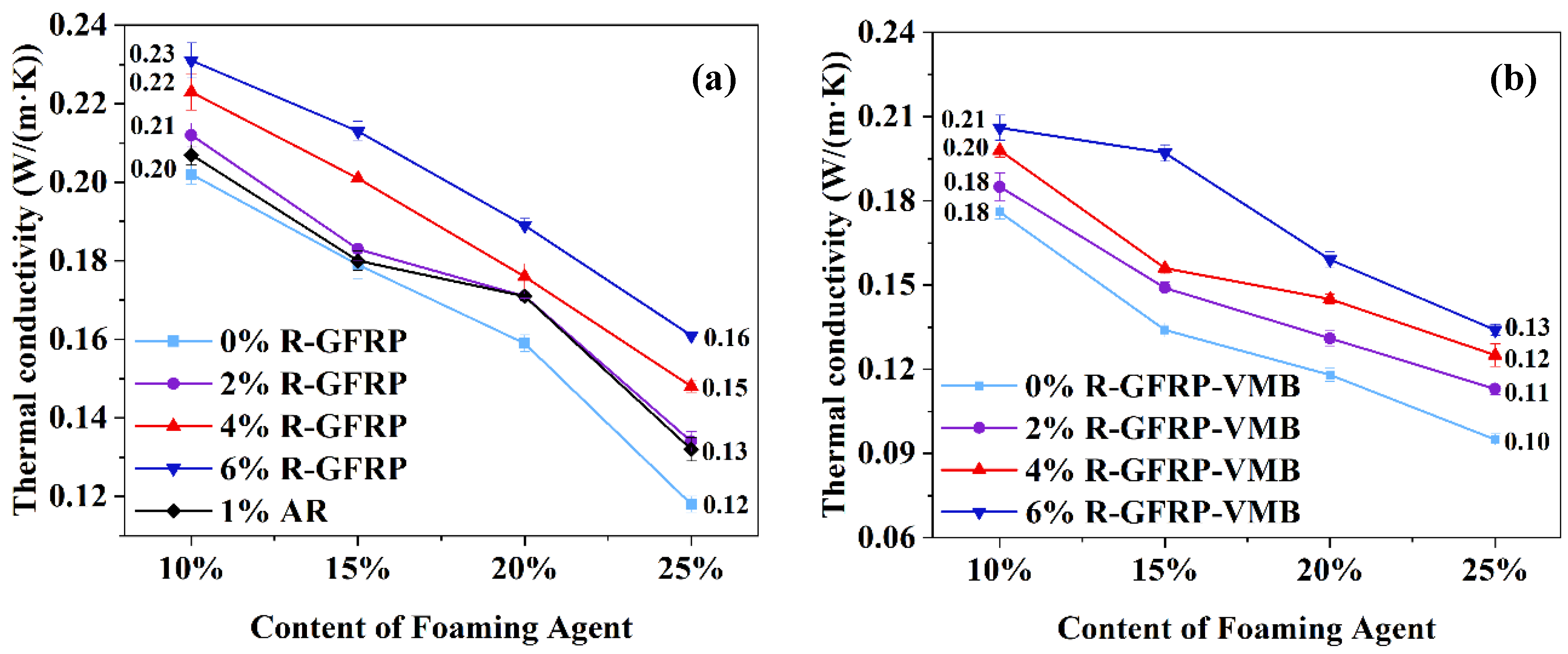

3.5. Thermal Conductivity

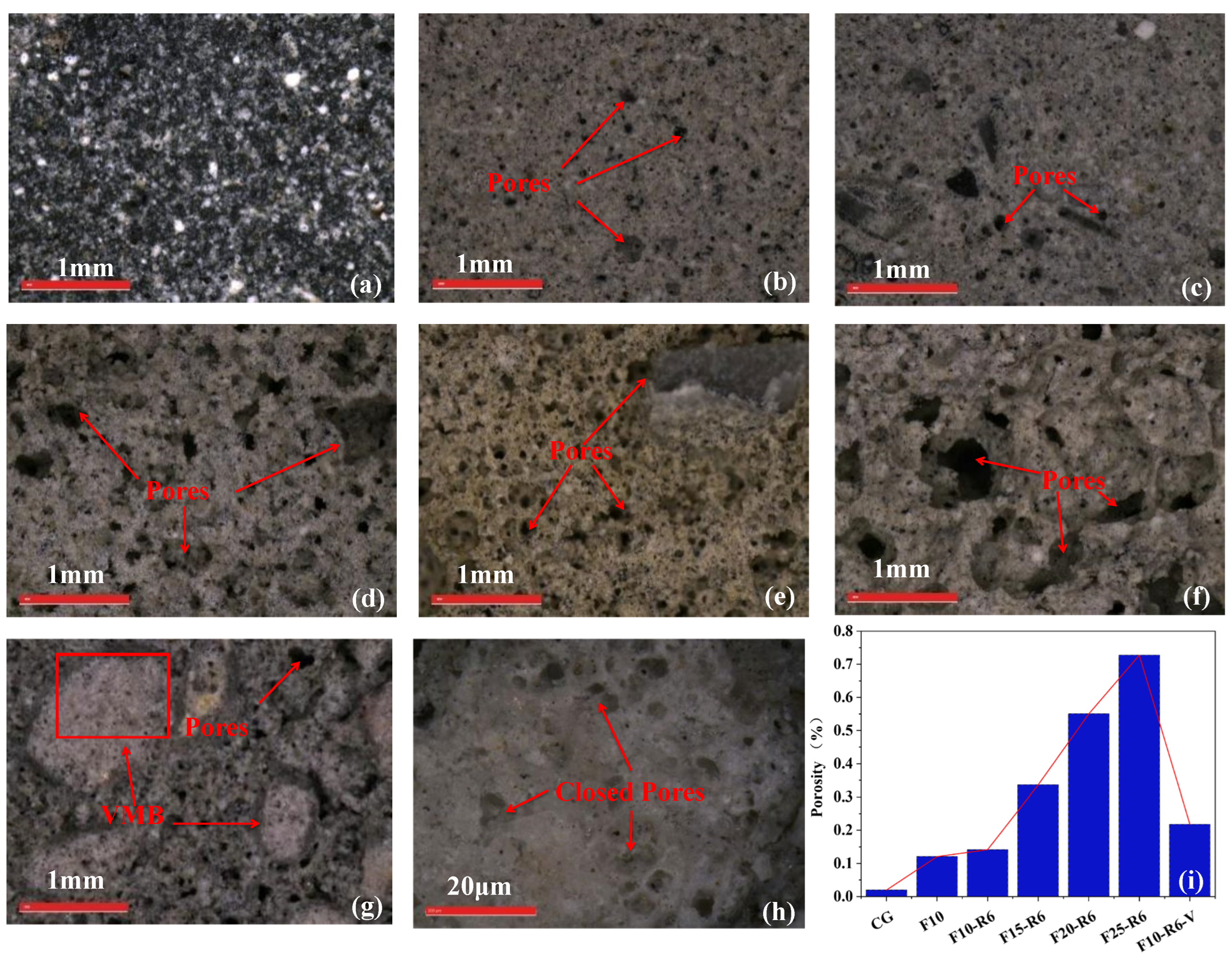

3.6. Porosity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karalar, M. Experimental and Numerical Investigation on Flexural and Crack Failure of Reinforced Concrete Beams with Bottom Ash and Fly Ash. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44 (Suppl. S1), 331–354. [Google Scholar] [CrossRef]

- Lin, H.; Liu, H.; Li, Y.; Kong, X. Properties and reaction mechanism of phosphoric acid activated metakaolin geopolymer at varied curing temperatures. Cem. Concr. Res. 2021, 144, 106425. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated cementitious materials and concretes–Steps towards standardization. Spec. Publ. 2017, 320, 37.0–37.6. [Google Scholar] [CrossRef]

- Nodehi, M. A comparative review on foam-based versus lightweight aggregate-based alkali-activated materials and geopoly-mer. Innov. Infrastruct. Solut. 2021, 6, 231. [Google Scholar] [CrossRef]

- Novais, R.M.; Pullar, R.; Labrincha, J.A. Geopolymer foams: An overview of recent advancements. Prog. Mater. Sci. 2020, 109, 100621. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in compar-ison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Gu, G.; Xu, F.; Huang, X.; Ruan, S.; Peng, C.; Lin, J. Foamed geopolymer: The relationship between rheological properties of geo-polymer paste and pore-formation mechanism. J. Clean. Prod. 2020, 277, 123238. [Google Scholar] [CrossRef]

- Liang, G.; Liu, T.; Li, H.; Dong, B.; Shi, T. A novel synthesis of lightweight and high-strength green geopolymer foamed material by rice husk ash and ground-granulated blast-furnace slag. Resour. Conserv. Recycl. 2022, 176, 105922. [Google Scholar] [CrossRef]

- Hu, Y.; Shao, Z.; Wang, J.; Zang, J.; Tang, L.; Ma, F.; Qian, B.; Ma, B.; Wang, L. Investigation into the influence of calcium compounds on the properties of micropore-foamed geopolymer. J. Build. Eng. 2022, 45, 103521. [Google Scholar] [CrossRef]

- Boetes, R. Heat Transfer Reduction in Closed Cell Polyurethane Foams. 1986. Available online: https://www.researchgate.net/profile/Ruud-Boetes/publication/27349229_Heat_transfer_reduction_in_closed_cell_polyurethane_foams/links/56c1af3108aeedba056682d5/Heat-transfer-reduction-in-closed-cell-polyurethane-foams.pdf (accessed on 22 March 2023).

- Su, L.; Fu, G.; Liang, B.; Sun, Q.; Zhang, X. Mechanical properties and microstructure evaluation of fly ash-Slag geopolymer foaming materials. Ceram. Int. 2022, 48, 18224–18237. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Kioupis, D.; Zisimopoulou, A.; Tsivilis, S.; Kakali, G. Development of porous geopolymers foamed by aluminum and zinc pow-ders. Ceram. Int. 2021, 47, 26280–26292. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, current thinking and challenges in geopolymer foam concrete technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. Expanded glass as light-weight aggregate in concrete–A review. J. Clean. Prod. 2021, 313, 127848. [Google Scholar] [CrossRef]

- Aziz, A.; Bellil, A.; El Hassani, I.-E.E.A.; Fekhaoui, M.; Achab, M.; Dahrouch, A.; Benzaouak, A. Geopolymers based on natural per-lite and kaolinic clay from Morocco: Synthesis, characterization, properties, and applications. Ceram. Int. 2021, 47, 24683–24692. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Real, S.; Bogas, J.A.; Gomes, M.D.G.; Ferrer, B. Thermal conductivity of structural lightweight aggregate concrete. Mag. Concr. Res. 2016, 68, 798–808. [Google Scholar] [CrossRef]

- Gong, J.Q.; Liu, S.L.; Hu, X.; Sun, K.Q. Laboratory Research on Vitrified Microsphere Insulation Mortar. Appl. Mech. Mater. 2014, 694, 251–255. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the mechanical and thermal properties of aerated geopolymer concrete using porous lightweight aggregates. Constr. Build. Mater. 2020, 264, 120713. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; Liu, Y.; Wang, E.; He, Z.; Xu, H.; Ren, X. Preparation and characterization of lightweight aggregate foamed geopol-ymer concretes aerated using hydrogen peroxide. Constr. Build. Mater. 2020, 256, 119442. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Narayanan, N. Influence of composition and curing on drying shrinkage of aerated concrete. Mater. Struct. 2000, 33, 243–250. [Google Scholar] [CrossRef]

- Selvi, M.T.; Dasarathy, A.; Ilango, S.P. Mechanical properties on light weight aggregate concrete using high density polyethylene granules. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Walbrück, K.; Maeting, F.; Witzleben, S.; Stephan, D. Natural Fiber-Stabilized Geopolymer Foams—A Review. Materials 2020, 13, 3198. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Zhang, Z.; Wang, H.; Mastali, M. Comparative study on the drying shrinkage and mechanical properties of geopolymer foam concrete incorporating different dosages of fiber, sand and foam agents. In High Tech Concrete: Where Technology and Engineering Meet, Proceedings of the 2017 fib Symposium, Maastricht, The Netherlands, 12–14 June 2017; Hordijk, D., Luković, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 42–48. [Google Scholar] [CrossRef]

- Senff, L.; Novais, R.; Carvalheiras, J.; Labrincha, J. Eco-friendly approach to enhance the mechanical performance of geopolymer foams: Using glass fibre waste coming from wind blade production. Constr. Build. Mater. 2020, 239, 117805. [Google Scholar] [CrossRef]

- Dawood, E.T.; Hamad, A.J. Toughness behaviour of high-performance lightweight foamed concrete reinforced with hybrid fibres. Struct. Concr. 2015, 16, 496–507. [Google Scholar] [CrossRef]

- Triwulan; Dwijayanti, L.Y.; Ekaputri, J.J.; Bayuaji, R. Lightweight Geopolymer Binder with Abaca Fiber in Different Curing. Mater. Sci. Forum 2016, 841, 140–147. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, T.; Zheng, X.; Liu, Y.; Darkwa, J.; Zhou, G. Thermo-mechanical and moisture absorption properties of fly ash-based lightweight geopolymer concrete reinforced by polypropylene fibers. Constr. Build. Mater. 2020, 251, 118960. [Google Scholar] [CrossRef]

- Moradnouri, A.; Vakilian, M.; Hekmati, A.; Fardmanesh, M. The end part of cryogenic HV bushing insulation design in a 230/20 kV HTS transformer. Cryogenics 2020, 108, 103090. [Google Scholar] [CrossRef]

- Moradnouri, A.; Vakilian, M.; Hekmati, A.; Fardmanesh, M. Inductance Calculation of HTS Transformers with Multi-segment Windings Considering Insulation Constraints. J. Supercond. Nov. Magn. 2021, 34, 1329–1339. [Google Scholar] [CrossRef]

- Correia, J.R.; Almeida, N.M.; Figueira, J.R. Recycling of FRP composites: Reusing fine GFRP waste in concrete mixtures. J. Clean. Prod. 2011, 19, 1745–1753. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-Art Review of Capabilities and Limitations of Polymer and Glass Fibers Used for Fiber-Reinforced Concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef]

- Suganya, M.; Sathyan, D.; Mini, K. Performance of concrete using waste fiber reinforced polymer powder as a partial replace-ment for fine aggregate. Mater. Today Proc. 2018, 5, 24114–24123. [Google Scholar] [CrossRef]

- Sakulich, A.R.; Li, V.C. Nanoscale characterization of engineered cementitious composites (ECC). Cem. Concr. Res. 2011, 41, 169–175. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Lee, Y.H.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, M.; Wang, L.; Ma, G. Experimental study on mechanical property and microstructure of cement mortar rein-forced with elaborately recycled GFRP fiber. Cem. Concr. Compos. 2021, 117, 103908. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Provis, J.; Kim, T.; Vongsvivut, J. High strength/density ratio in a syntactic foam made from one-part mix geopolymer and cenospheres. Compos. Part B Eng. 2019, 173, 106908. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Sustainable one-part geopolymer foams with glass fines versus sand as aggregates. Constr. Build. Mater. 2018, 171, 223–231. [Google Scholar] [CrossRef]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Standards Press of China: Beijing, China, 2005.

- GB/T 1346-2001; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Ce-ments. Standards Press of China: Beijing, China, 2001.

- JGJT 2009-2009; Standard for Test Method of Performance on Building Mortar. Standards Press of China: Beijing, China, 2009.

- G.T. 9966.3-2020; Test Methods for Natural Stone—Part 3: Determination of Water Absorption, Bulk Density, True Density and True Porosity. Ministry of Construction: Beijing, China, 2020.

- JGJ/T-2009; Standard for Test Method of Basic Properties of Construction Mortar. China Architecture & Building Press: Beijing, China, 2009.

- GB/T 10294-2008; Thermal Insulation-Determination of Steady-State Thermal Resistance and Related Properties-Guarded Hot Plate Apparatus. China Architecture & Building Press: Beijing, China, 2008.

- Vaisman, L.; Wagner, H.D.; Marom, G. The role of surfactants in dispersion of carbon nanotubes. Adv. Colloid Interface Sci. 2006, 128, 37–46. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Zhang, H.; Sarker, P.K.; Wang, Q.; He, B.; Jiang, Z. Strength and toughness of ambient-cured geopolymer concrete containing virgin and recycled fibres in mono and hybrid combinations. Constr. Build. Mater. 2021, 304, 124649. [Google Scholar] [CrossRef]

- Kumar, G.S. Influence of fluidity on mechanical and permeation performances of recycled aggregate mortar. Constr. Build. Mater. 2019, 213, 404–412. [Google Scholar] [CrossRef]

- Yaowarat, T.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M.; Rashid, A.S.A. Compressive and flexural strength of polyvinyl al-cohol–modified pavement concrete using recycled concrete aggregates. J. Mater. Civ. Eng. 2018, 30, 04018046. [Google Scholar] [CrossRef]

- Duan, P.; Song, L.; Yan, C.; Ren, D.; Li, Z. Novel thermal insulating and lightweight composites from metakaolin geopolymer and polystyrene particles. Ceram. Int. 2017, 43, 5115–5120. [Google Scholar] [CrossRef]

- Novais, R.M.; Buruberri, L.; Ascensão, G.; Seabra, M.; Labrincha, J. Porous biomass fly ash-based geopolymers with tailored thermal conductivity. J. Clean. Prod. 2016, 119, 99–107. [Google Scholar] [CrossRef]

- Rickard, W.D.; Vickers, L.; Van Riessen, A. Performance of fibre reinforced, low density metakaolin geopolymers under simu-lated fire conditions. Appl. Clay Sci. 2013, 73, 71–77. [Google Scholar] [CrossRef]

- Hou, L.; Li, J.; Lu, Z.; Niu, Y. Influence of foaming agent on cement and foam concrete. Constr. Build. Mater. 2021, 280, 122399. [Google Scholar] [CrossRef]

- Cheng, Z.; Liu, Z.; Hao, H.; Lu, Y.; Li, S. Multi-scale effects of tensile properties of lightweight engineered geopolymer composites reinforced with MWCNTs and steel-PVA hybrid fibers. Constr. Build. Mater. 2022, 342, 128090. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Aghaee, K.; Khayat, K.H. Effect of shrinkage-mitigating materials on performance of fiber-reinforced concrete—An overview. Constr. Build. Mater. 2021, 305, 124586. [Google Scholar] [CrossRef]

- Hayase, G.; Kugimiya, K.; Ogawa, M.; Kodera, Y.; Kanamori, K.; Nakanishi, K. The thermal conductivity of polymethylsilsesqui-oxane aerogels and xerogels with varied pore sizes for practical application as thermal superinsulators. J. Mater. Chem. A 2014, 2, 6525–6531. [Google Scholar] [CrossRef]

- Agustini, N.K.A.; Triwiyono, A.; Sulistyo, D.; Suyitno, S. Mechanical properties and thermal conductivity of fly ash-based geo-polymer foams with polypropylene fibers. Appl. Sci. 2021, 11, 4886. [Google Scholar] [CrossRef]

- Shao, N.-N.; Liu, Z.; Xu, Y.-Y.; Kong, F.-L.; Wang, D.-M. Fabrication of hollow microspheres filled fly ash geopolymer composites with excellent strength and low density. Mater. Lett. 2015, 161, 451–454. [Google Scholar] [CrossRef]

- Mao, Y.; Liu, J.; Shi, C. Autogenous shrinkage and drying shrinkage of recycled aggregate concrete: A review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Batool, F.; Bindiganavile, V. Fresh Properties of Fiber Reinforced Cement-Based Foam with Pozzolans. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 253–264. [Google Scholar] [CrossRef]

| No. | References | Materials | 28 d Compressive Strength (MPa) | Density (g/cm3) | Thermal Conductivity (W/m·K) | Porosity (%) |

|---|---|---|---|---|---|---|

| 1 | G. Gu et al. [7] | FA, GBFS, and Na2SiO3 | N/A | 1.71–1.87 | N/A | N/A |

| 2 | Y. Hu et al. [9] | FA, ZSM-5 waste, and Ca(OH)2 | 6.80–12.90 | 0.74–1.39 | N/A | 29.4–41.8 |

| 3 | G. Liang et al. [8] | GBFS, RHA Na2SiO3, and NaOH | 59.67–74.64 | 0.75–1.92 | 0.11–0.29 | 29.1–75.2 |

| 4 | L. Su et al. [11] | FA, GBFS, and Na2SiO3 | 1.2–2.2 | N/A | N/A | 60.2–65.1 |

| 5 | A. Aziz et al. [16] | EP, MK, Na2SiO3, and NaOH | 10.9–36.2 | 1.48–1.73 | N/A | 17.6–33.7 |

| 6 | O. Sengul et al. [17] | EP, OPC, and sand | 0.1–28.8 | 0.70–2.02 | 0.13–0.6 | N/A |

| 7 | K. Pasupathy et al. [20] | FA, GBFS, and Na2SiO3 | 0.48–1.38 | 0.56–0.57 | 0.25–0.28 | 67.2–74.1 |

| 8 | J. Shi et al. [21] | MK, FA, and Na2SiO3 | 2.28–5.38 | 0.36–0.67 | 0.12–0.20 | 20.3–50.2 |

| 9 | L.Y. Dwijayanti et al. [29] | FA, abaca fiber, Na2SiO3, and NaOH | 44.65–65.5 | 0.19 | N/A | N/A |

| 10 | Y. Wang et al. [30] | FA, PP fiber, sand, Na2SiO3, and NaOH | 0.97–7.20 | 0.50–1.72 | 0.10–1.09 | N/A |

| Chemical Composition | SiO2 (wt.%) | Al2O3 (wt.%) | FexOy (wt.%) | CaO (wt.%) | MgO (wt.%) | SO3 (wt.%) | Other (wt.%) |

|---|---|---|---|---|---|---|---|

| FA | 52.1 | 34.3 | 5.42 | 2.77 | 0.49 | 1.45 | 3.47 |

| GBFS | 30.5 | 16.8 | 0.28 | 38.9 | 8.8 | 2.33 | 2.39 |

| Material | SDS | Water | SP | SPE | LA |

|---|---|---|---|---|---|

| Mass (g) | 12 | 228 | 4 | 1.2 | 1 |

| Sample Set | FOA | rGFRP Fiber | AR Fiber | VMB | FA | Slag | Ca(OH)2 | Na2SiO3 | NaOH |

|---|---|---|---|---|---|---|---|---|---|

| (g) | (g) | (g) | (g) | (g) | (g) | (g) | (g) | (g) | |

| CG | 0 | 0 | 0 | 0 | 50 | 50 | 0 | 13 | 4 |

| F10 | 10 | 0 | 0 | 0 | 45 | 45 | 10 | 13 | 4 |

| F10-AR | 0 | 1 | |||||||

| F10-R2 | 2 | 0 | |||||||

| F10-R4 | 4 | 0 | |||||||

| F10-R6 | 6 | 0 | |||||||

| F-15 | 15 | 0 | 0 | ||||||

| F15-AR | 0 | 1 | |||||||

| F15-R2 | 2 | 0 | |||||||

| F15-R4 | 4 | 0 | |||||||

| F15-R6 | 6 | 0 | |||||||

| F20 | 20 | 0 | 0 | ||||||

| F20-AR | 0 | 1 | |||||||

| F20-R2 | 2 | 0 | |||||||

| F20-R4 | 4 | 0 | |||||||

| F20-R6 | 6 | 0 | |||||||

| F-25 | 25 | 0 | 0 | ||||||

| F25-AR | 0 | 1 | |||||||

| F25-R2 | 2 | 0 | |||||||

| F25-R4 | 4 | 0 | |||||||

| F25-R6 | 6 | 0 | |||||||

| F10-V | 10 | 0 | 0 | 0 | 45 | 45 | |||

| F10-R2-V | 2 | 0 | 10 | 40 | 40 | ||||

| F10-R4-V | 4 | 0 | |||||||

| F10-R6-V | 6 | 0 | |||||||

| F-15-V | 15 | 0 | 0 | ||||||

| F15-R2-V | 2 | 0 | |||||||

| F15-R4-V | 4 | 0 | |||||||

| F15-R6-V | 6 | 0 | |||||||

| F20-V | 20 | 0 | 0 | ||||||

| F20-R2-V | 2 | 0 | |||||||

| F20-R4-V | 4 | 0 | |||||||

| F20-R6-V | 6 | 0 | |||||||

| F-25-V | 25 | 0 | 0 | ||||||

| F25-R2-V | 2 | 0 | |||||||

| F25-R4-V | 4 | 0 | |||||||

| F25-R6-V | 6 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Qiu, X.; Shen, S.; Wang, L.; Zang, Y. Mechanical and Thermal Insulation Properties of rGFRP Fiber-Reinforced Lightweight Fly-Ash-Slag-Based Geopolymer Mortar. Sustainability 2023, 15, 7200. https://doi.org/10.3390/su15097200

Zhang M, Qiu X, Shen S, Wang L, Zang Y. Mechanical and Thermal Insulation Properties of rGFRP Fiber-Reinforced Lightweight Fly-Ash-Slag-Based Geopolymer Mortar. Sustainability. 2023; 15(9):7200. https://doi.org/10.3390/su15097200

Chicago/Turabian StyleZhang, Mo, Xinxin Qiu, Si Shen, Ling Wang, and Yongquan Zang. 2023. "Mechanical and Thermal Insulation Properties of rGFRP Fiber-Reinforced Lightweight Fly-Ash-Slag-Based Geopolymer Mortar" Sustainability 15, no. 9: 7200. https://doi.org/10.3390/su15097200

APA StyleZhang, M., Qiu, X., Shen, S., Wang, L., & Zang, Y. (2023). Mechanical and Thermal Insulation Properties of rGFRP Fiber-Reinforced Lightweight Fly-Ash-Slag-Based Geopolymer Mortar. Sustainability, 15(9), 7200. https://doi.org/10.3390/su15097200