Towards Sustainable Viscose-to-Viscose Production: Strategies for Recycling of Viscose Fibres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pretreatment of Pre-Consumer Undyed Viscose Fabric

2.3. Viscose Dope Preparation and Spinning

2.4. Filtration Test

2.5. Gamma Number

2.6. Determination of Caustic

2.7. Determination of Cellulose in the Alkali Cellulose and Viscose Dope

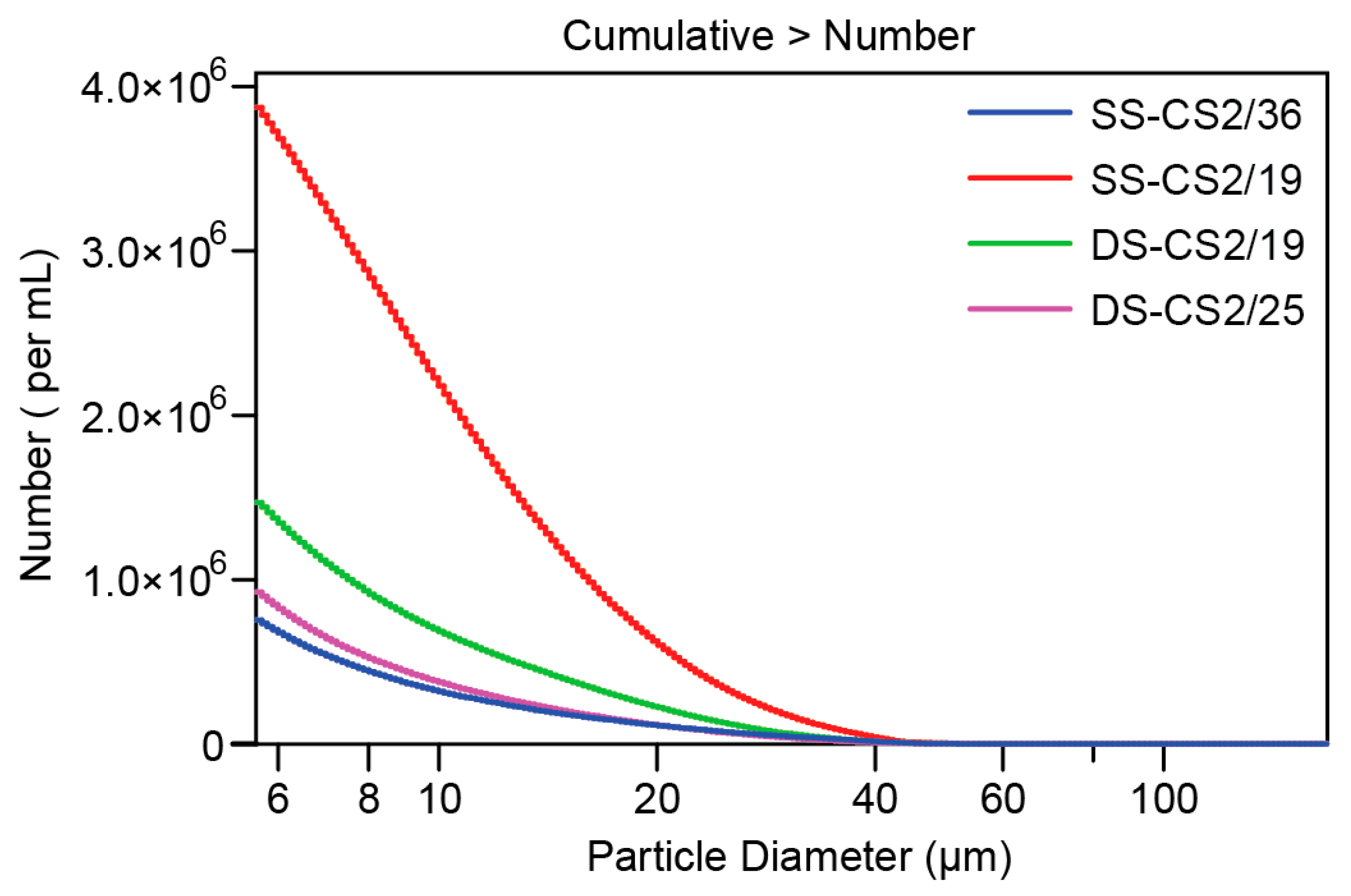

2.8. Particle Distribution in Viscose Dope

2.9. Intrinsic Viscosity

2.10. Chemical Oxygen Demand

2.11. Molecular Weight Distribution

3. Results and Discussion

3.1. Viscose Production via Single-Steeping

3.2. Viscose Production via Double-Steeping

3.3. Properties of Viscose Fibres

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leal Filho, W.; Perry, P.; Heim, H.; Dinis, M.A.P.; Moda, H.; Ebhuoma, E.; Paço, A. An Overview of the Contribution of the Textiles Sector to Climate Change. Front. Environ. Sci. 2022, 10, 973102. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future; Ellen MacArthur Foundation: Isle of Wight, UK, 2017. [Google Scholar]

- Textile Exchange. Materials Market Report; Textile Exchange: Lamesa, TX, USA, 2023. [Google Scholar]

- Orfanidou, T.; Hassegawa, M.; Leskinen, P.; Sixta, H.; Oinas, P.; Cardellini, G. Wood-Based Textiles & Modern Wood Buildings; European Forest Institute: Joensuu, Finland, 2023. [Google Scholar]

- Fechter, C.; Brelid, H.; Fischer, S. Possibilities for Optimization of Industrial Alkaline Steeping of Wood-Based Cellulose Fibers. Molecules 2020, 25, 5834. [Google Scholar] [CrossRef]

- Albán Reyes, D.C.; Skoglund, N.; Svedberg, A.; Eliasson, B.; Sundman, O. The Influence of Different Parameters on the Mercerisation of Cellulose for Viscose Production. Cellulose 2016, 23, 1061–1072. [Google Scholar] [CrossRef]

- Wilkes, A.G. The Viscose Process; Woodhead Publishing Ltd.: Sawston, UK, 2001. [Google Scholar]

- Mendes, I.S.F.; Prates, A.; Evtuguin, D.V. Production of Rayon Fibres from Cellulosic Pulps: State of the Art and Current Developments. Carbohydr. Polym. 2021, 273, 118466. [Google Scholar] [CrossRef]

- Asaadi, S.; Hummel, M.; Hellsten, S.; Härkäsalmi, T.; Ma, Y.; Michud, A.; Sixta, H. Renewable High-Performance Fibers from the Chemical Recycling of Cotton Waste Utilizing an Ionic Liquid. ChemSusChem 2016, 9, 3250–3258. [Google Scholar] [CrossRef]

- Ma, Y.; Zeng, B.; Wang, X.; Byrne, N. Circular Textiles: Closed Loop Fiber to Fiber Wet Spun Process for Recycling Cotton from Denim. ACS Sustain. Chem. Eng. 2019, 7, 11937–11943. [Google Scholar] [CrossRef]

- Liu, W.; Liu, S.; Liu, T.; Liu, T.; Zhang, J.; Liu, H. Eco-Friendly Post-Consumer Cotton Waste Recycling for Regenerated Cellulose Fibers. Carbohydr. Polym. 2018, 206, 141–148. [Google Scholar] [CrossRef]

- Harnesk, T. Ny Teknik; Ny Teknik Group: Stockholm, Sweden, 2023. [Google Scholar]

- Infinna-Infinited Fiber. Available online: https://infinitedfiber.com/about-infinna/fashion/ (accessed on 28 March 2024).

- Spinnova Sustainability|Spinnova. Available online: https://spinnova.com/sustainability/ (accessed on 28 March 2024).

- Our Technology-TreeToTextile. Available online: https://treetotextile.com/our-technology/ (accessed on 28 March 2024).

- Peterson, A.; Wallinder, J.; Bengtsson, J.; Idström, A.; Bialik, M.; Jedvert, K.; de la Motte, H. Chemical Recycling of a Textile Blend from Polyester and Viscose, Part I: Process Description, Characterization, and Utilization of the Recycled Cellulose. Sustainability 2022, 14, 7272. [Google Scholar] [CrossRef]

- Liebert, T. Cellulose Solvents—Remarkable History and Bright Future. In Cellulose Solvents: For Analysis, Shaping and Chemical Modification; American Chemical Society: Washington, DC, USA, 2010; pp. 3–52. [Google Scholar]

- Dieter, V. Cellulosic Man-Made Fibers. In Fibers: History, Production, Properties, Market; Springer: Cham, Switzerland, 2022; pp. 831–880. [Google Scholar]

- Dyer, J.; Daul, C.G. Viscose Rayon: Recent Developments and Future Prospects. Ind. Eng. Chem. Prod. Res. Dev. 1981, 20, 222–230. [Google Scholar] [CrossRef]

- Shaikh, T.; Chaudhari, S.; Varma, A. Viscose Rayon: A Legendary Development in the Manmade Textile. Int. J. Eng. Res. Appl. 2012, 2, 675–680. [Google Scholar]

- Sayyed, A.J.; Deshmukh, N.A.; Pinjari, D.V. A Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibres: Viscose, Cellulose Acetate, Cuprammonium, LiCl/DMAc, Ionic Liquids, and NMMO Based Lyocell. Cellulose 2019, 26, 2913–2940. [Google Scholar] [CrossRef]

- Engström, A.C.; Ek, M.; Henriksson, G. Improved Accessibility and Reactivity of Dissolving Pulp for the Viscose Process: Pretreatment with Monocomponent Edoglucanase. Biomacromolecules 2006, 7, 2027–2031. [Google Scholar] [CrossRef]

- Gondhalekar, S.C.; Pawar, P.J.; Dhumal, S.S. Use of Electron Beam Irradiation for Improving Reactivity of Dissolving Pulp in Viscose Process. J. Radioanal. Nucl. Chem. 2019, 322, 67–72. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, S.; Zhao, C.; Wang, D. Improved Reactivity of Bamboo Dissolving Pulp for the Viscose Process: Post-Treatment with Beating. Bioresources 2014, 9, 3449–3455. [Google Scholar] [CrossRef]

- Sixta, H. Comparative Evaluation of TCF Bleached Harwood Dissolving Pulps. Lenzing. Berichte 2000, 79, 119–128. [Google Scholar]

- Duan, C.; Li, J.; Ma, X.; Chen, C.; Liu, Y.; Stavik, J.; Ni, Y. Comparison of Acid Sulfite (AS)- and Prehydrolysis Kraft (PHK)-Based Dissolving Pulps. Cellulose 2015, 22, 4017–4026. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Kunttu, J.; Heinonen, T.; Pukkala, T.; Peltola, H. Does Expanding Wood Use in Construction and Textile Markets Contribute to Climate Change Mitigation? Renew. Sustain. Energy Rev. 2023, 174, 113152. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Environmental Impact Assessment of Man-Made Cellulose Fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Hammar, T.; Peñaloza, D.; Hanning, A.-C.; Haatanen, N.; Pakkasmaa, J. Life Cycle Assessment of Textile Fibre-to-Fibre Recycling by Cellulose Carbamate Technology. J. Clean. Prod. 2023, 426, 139189. [Google Scholar] [CrossRef]

- Sihtola, H.; Nizovsky, B. Preparation of High-Quality Viscose from Low Alpha-Cellulose Pulp by a Modified Steeping-Aging Procedure. TAPPI Tech. Assoc. Pulp Pap. Ind. 1969, 52, 501–504. [Google Scholar]

- ISO 5351:2010; Pulps—Determination of Limiting Viscosity Number in Cupri-Ethylenediamine (CED) Solution. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO 692:1982; Pulps—Determination of Alkali Solubility. International Organization for Standardization: Geneva, Switzerland, 1982.

- ISO 3696:1987; Water for Analytical Laboratory Use—Specification and Test Methods. International Organization for Standardization: Geneva, Switzerland, 1987.

- Treiber, E.; Rehnström, J.; Ameen, C.; Kolos, F. Using a Laboratory Viscose Small-Scale Plant to Test Chemical Conversion Pulps. Das Pap. 1962, 16, 85–94. [Google Scholar]

- Gondhalekar, S.C.; Pawar, P.J.; Dhumal, S.S.; Thakre, S.S. Mechanism of Xanthation Reaction in Viscose Process. Cellulose 2019, 26, 1595–1604. [Google Scholar] [CrossRef]

- Gondhalekar, S.C.; Pawar, P.J.; Dhumal, S.S.; Thakre, S. Fate of CS2 in Viscose Process: A Chemistry Perspective. Cellulose 2022, 29, 1451–1461. [Google Scholar] [CrossRef]

- Porro, F.; Bédué, O.; Chanzy, H.; Heux, L. Solid-State 13C NMR Study of Na-Cellulose Complexes. Biomacromolecules 2007, 8, 2586–2593. [Google Scholar] [CrossRef]

- Strunk, P.; Eliasson, B.; Hägglund, C.; Agnemo, R. The Influence of Properties in Cellulose Pulps on the Reactivity in Viscose Manufacturing. In Proceedings of the 16th International Symposium on Wood, Fiber and Pulping Chemistry, Tianjin, China, 8–10 June 2011; Volume 1, pp. 377–383. [Google Scholar]

- ISO 5079:2020; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres. International Organization for Standardization: Geneva, Switzerland, 2020.

- Strunk, P. Characterization of Cellulose Pulps and the Influence of Their Properties on the Process and Production of Viscose and Cellulose Ethers. Ph.D. Thesis, Umeå Universitet, Umeå, Sweden, 2012. [Google Scholar]

- Siller, M.; Ahn, K.; Pircher, N.; Rosenau, T.; Potthast, A. Dissolution of Rayon Fibers for Size Exclusion Chromatography: A Challenge. Cellulose 2014, 21, 3291–3301. [Google Scholar] [CrossRef]

- Wedin, H.; Lopes, M.; Sixta, H.; Hummel, M. Evaluation of Post-Consumer Cellulosic Textile Waste for Chemical Recycling Based on Cellulose Degree of Polymerization and Molar Mass Distribution. Text. Res. J. 2019, 89, 5067–5075. [Google Scholar] [CrossRef]

- Sixta, H. Handbook of Pulp; Wiley-VCH: Weinheim, Germany, 2006; ISBN 9783527309993. [Google Scholar]

- Strunk, P.; Lindgren, Å.; Eliasson, B.; Agnemo, R. Chemical Changes of Cellulose Pulps in the Processing to Viscose Dope. Cellul. Chem. Technol. 2012, 46, 559–569. [Google Scholar]

- Östberg, L.; Germgård, U. Some Aspects on the Activation of Dissolving Pulps and the Influence on the Reactivity in a Following Viscose Stage. Cellul. Chem. Technol. 2013, 47, 165–169. [Google Scholar]

- Östberg, L.; Håkansson, H.; Germgård, U. Some Aspects of the Reactivity of Pulp Intended for High-Viscosity Viscose. Bioresources 2012, 7, 743–755. [Google Scholar] [CrossRef]

- Bågenholm-Ruuth, E.; Sanchis-Sebastiá, M.; Hollinger, N.; Teleman, A.; Larsson, P.T.; Wallberg, O. Transforming Post-Consumer Cotton Waste Textiles into Viscose Staple Fiber Using Hydrated Zinc Chloride. Cellulose 2024, 31, 737–748. [Google Scholar] [CrossRef]

- Carolina, D.; Forsberg, R.; Stridh, K.; De Wit, P.P.; Sundman, O. Is There a Diffusion of Alkali in the Activation of Dissolving Cellulose Pulp at Low NAOH Stoichiometric Excess? Cellulose 2018, 9, 1297–1308. [Google Scholar] [CrossRef]

- Schild, G.; Sixta, H. Sulfur-Free Dissolving Pulps and Their Application for Viscose and Lyocell. Cellulose 2011, 18, 1113–1128. [Google Scholar] [CrossRef]

- Schild, G.; Opietnik, M. Lyocell Fibers from Pulps with High and Xylan Content—Part 2: Mechanical Properties. Lenzing. Berichte 2022, 97, 38–44. [Google Scholar]

| Samples | Label | CS2 (%) |

|---|---|---|

| Single-steeping | SS-CS2/36 | 36 |

| SS-CS2/19 | 19 | |

| Double-steeping | DS-CS2/25 | 25 |

| DS-CS2/19 | 19 |

| Samples | Intrinsic Viscosity, mL/g | Alkali Cellulose | Viscose Dope | ||||

|---|---|---|---|---|---|---|---|

| NaOH, % | Cellulose, % | Kr | NaOH, % | Cellulose, % | Gamma Number, % | ||

| SS-CS2/36 | 166 | 15 | 27 | 1111 | 5 | 10 | 40 |

| DS-CS2/25 | 15 * | 27 * | |||||

| 12 | 25 | 1025 | 5 | 9 | 33 | ||

| SS-CS2/19 | 15 | 26 | 4516 | 5 | 10 | 23 | |

| DS-CS2/19 | 15 * | 27 * | |||||

| 12 | 23 | 2176 | 5 | 10 | 24 | ||

| Typical range, dissolving cellulose pulp | 400–600 | 15–16 | 29–36 | 100–1200 | 4.0–4.5 | 9.4–10.5 | 30–45 |

| Sample | Titer (Dry), Dtex | Elongation (Dry), % | Tenacity (Dry), cN/tex |

|---|---|---|---|

| SS-CS2/36 | 2.12 (0.20) | 16.39 (3.68) | 15.51 (2.07) |

| DS-CS2/25 | 1.99 (0.24) | 11.66 (2.19) | 14.76 (2.47) |

| Typical range of viscose staple fibre (unbleached) [47] | ~2.0–2.2 | ~15 | ~15–19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forsberg, D.C.R.; Bengtsson, J.; Hollinger, N.; Kaldéus, T. Towards Sustainable Viscose-to-Viscose Production: Strategies for Recycling of Viscose Fibres. Sustainability 2024, 16, 4127. https://doi.org/10.3390/su16104127

Forsberg DCR, Bengtsson J, Hollinger N, Kaldéus T. Towards Sustainable Viscose-to-Viscose Production: Strategies for Recycling of Viscose Fibres. Sustainability. 2024; 16(10):4127. https://doi.org/10.3390/su16104127

Chicago/Turabian StyleForsberg, Diana Carolina Reyes, Jenny Bengtsson, Nadine Hollinger, and Tahani Kaldéus. 2024. "Towards Sustainable Viscose-to-Viscose Production: Strategies for Recycling of Viscose Fibres" Sustainability 16, no. 10: 4127. https://doi.org/10.3390/su16104127

APA StyleForsberg, D. C. R., Bengtsson, J., Hollinger, N., & Kaldéus, T. (2024). Towards Sustainable Viscose-to-Viscose Production: Strategies for Recycling of Viscose Fibres. Sustainability, 16(10), 4127. https://doi.org/10.3390/su16104127