Sustainable Solid Biofuel Production: Transforming Sewage Sludge and Pinus sp. Sawdust into Resources for the Circular Economy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biological Material

2.2. Biomass Characterization

2.3. Briquette Production

2.4. Statistical Analysis

3. Results

3.1. Characterization of Sewage Sludge and Pinus sp. Sawdust

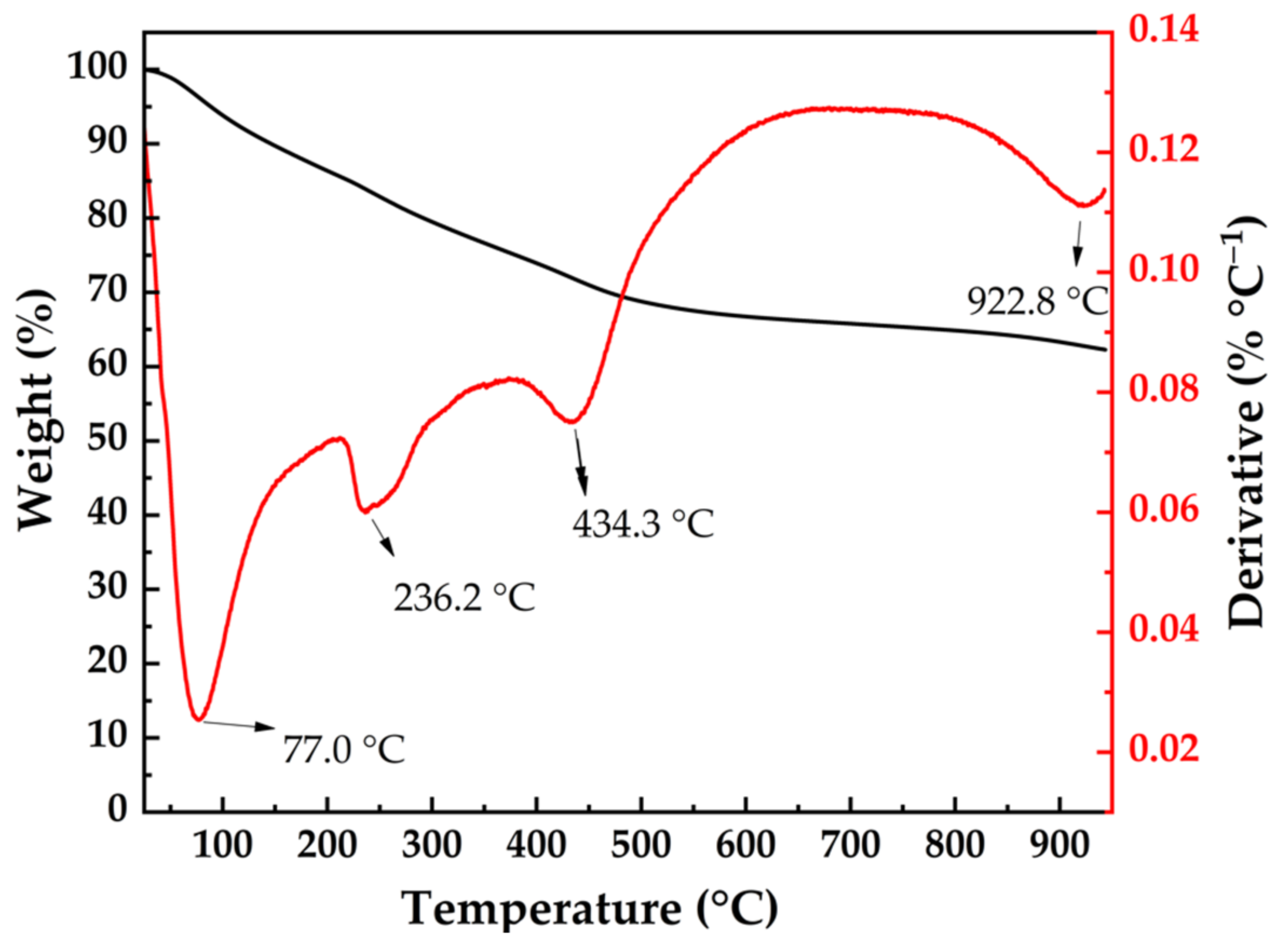

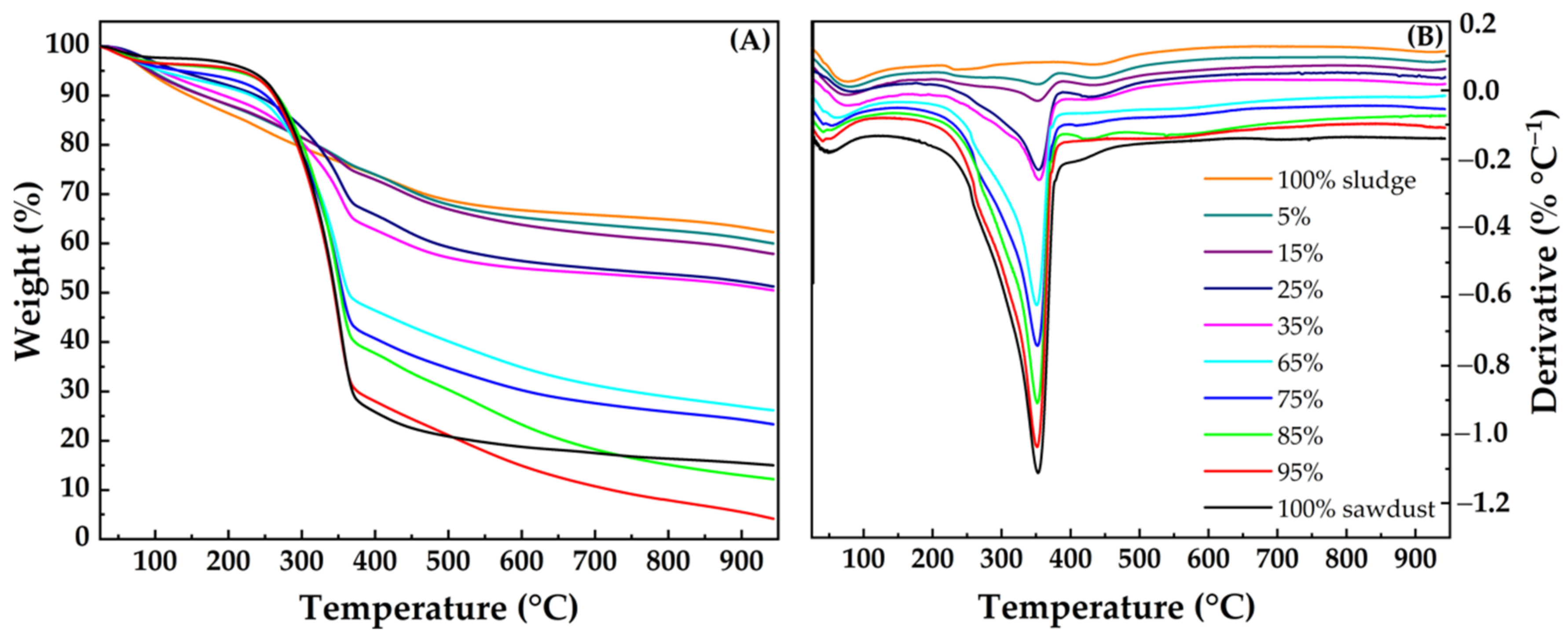

3.2. Thermogravimetric Analysis

3.3. Briquette Evaluation

4. Discussion

4.1. Characterization of Sewage Sludge and Pinus sp. Sawdust

4.2. Thermogravimetric Analysis

4.3. Briquette Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tabelini, D.B.; Lima, J.P.P.; Borges, A.C.; Aguiar, A. A Review on the Characteristics and Methods of Dairy Industry Wastewater Treatment in the State of Minas Gerais, Brazil. J. Water Process Eng. 2023, 53, 103779. [Google Scholar] [CrossRef]

- Urban, R.C.; Nakada, L.Y.K.; de Lima Isaac, R. A System Dynamics Approach for Large-Scale Water Treatment Plant Sludge Management: A Case Study in Brazil. J. Clean. Prod. 2023, 419, 138105. [Google Scholar] [CrossRef]

- Wu, X.; Nawaz, S.; Li, Y.; Zhang, H. Environmental Health Hazards of Untreated Livestock Wastewater: Potential Risks and Future Perspectives. Environ. Sci. Pollut. Res. 2024, 31, 24745–24767. [Google Scholar] [CrossRef] [PubMed]

- Ding, A.; Zhang, R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life Cycle Assessment of Sewage Sludge Treatment and Disposal Based on Nutrient and Energy Recovery: A Review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [CrossRef]

- Hušek, M.; Moško, J.; Pohořelý, M. Sewage Sludge Treatment Methods and P-Recovery Possibilities: Current State-of-the-Art. J. Environ. Manag. 2022, 315, 115090. [Google Scholar] [CrossRef]

- Alejandra Ramírez-Ramírez, M.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Fernando Pintor-Ibarra, L.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Luján-Álvarez, C.; Rutiaga-Quiñones, J.G. Evaluation of Selected Physical and Thermal Properties of Briquette Hardwood Biomass Biofuel. BioEnergy Res. 2022, 15, 1407–1414. [Google Scholar] [CrossRef]

- Solayman, H.M.; Hossen, M.A.; Abd Aziz, A.; Yahya, N.Y.; Leong, K.H.; Sim, L.C.; Monir, M.U.; Zoh, K.D. Performance Evaluation of Dye Wastewater Treatment Technologies: A Review. J. Environ. Chem. Eng. 2023, 11, 109610. [Google Scholar] [CrossRef]

- Sanka, P.M.; Snv, L.K.; Komakech, H.; Mandela, N.; Magambo, H. Production of Low Emission Briquettes from Faecal Sludge as an Alternative Source of Cooking Energy. Energy Sustain. Soc. 2023. [Google Scholar] [CrossRef]

- De Oliveira Brotto, J.; Cruz, T.A.; de Oliveira Pereira, I.; Ienczak, J.L.; Peralta, R.A.; Lázaro-Martínez, J.M.; José, H.J.; Rodríguez-Castellón, E.; Moreira, R.d.F.P.M. Mechanistic Insights and Kinetics of Torrefaction of Pine Wood Biomasses Using Solid-State NMR. J. Anal. Appl. Pyrolysis 2023, 172, 106019. [Google Scholar] [CrossRef]

- Gupta, A.; Dutt, B.; Sharma, S. Analysis of Chemical Properties of Thermally Treated Pinus Roxburghii Sargent Wood. Bioresources 2023, 18, 4598–4609. [Google Scholar] [CrossRef]

- Vieira, T.A.S.; Trugilho, P.F.; Carabineiro, S.A.C.; Zanuncio, A.J.V.; Carvalho, A.G.; Branco-Vieira, M. Impact of Chemical Composition on Eucalyptus Wood Clones for Sustainable Energy Production. Forests 2023, 14, 2240. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Wang, Y.; Qu, L. Predicting Higher Heating Value of Sewage Sludges via Artificial Neural Network Based on Proximate and Ultimate Analyses. Water 2023, 15, 674. [Google Scholar] [CrossRef]

- Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Junior, P.R. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Montiano, M.G.; Díaz-Faes, E.; Barriocanal, C. Effect of Briquette Composition and Size on the Quality of the Resulting Coke. Fuel Process. Technol. 2016, 148, 155–162. [Google Scholar] [CrossRef]

- Cabrales, H.; Arzola, N.; Araque, O. The Effects of Moisture Content, Fiber Length and Compaction Time on African Oil Palm Empty Fruit Bunches Briquette Quality Parameters. Heliyon 2020, 6, e05607. [Google Scholar] [CrossRef] [PubMed]

- Obi, O.F.; Pecenka, R.; Clifford, M.J. A Review of Biomass Briquette Binders and Quality Parameters. Energies 2022, 15, 2426. [Google Scholar] [CrossRef]

- Ferronato, N.; Calle Mendoza, I.J.; Gorritty Portillo, M.A.; Conti, F.; Torretta, V. Are Waste-Based Briquettes Alternative Fuels in Developing Countries? A Critical Review. Energy Sustain. Dev. 2022, 68, 220–241. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Filleti, R.A.P.; Musule, R.; Matheus, T.T.; Freire, F. A Systematic Review and Life Cycle Assessment of Biomass Pellets and Briquettes Production in Latin America. Renew. Sustain. Energy Rev. 2022, 157, 112042. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating Values of Wood Pellets from Different Species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Rocha, S.; Soares, P.; Maia, L. Briquettes from Sludge in Sewage Treatment Plant: Calorific Power. Environ. Sci. Pollut. Res. 2022, 29, 91096–91104. [Google Scholar] [CrossRef]

- NBR8112; Carvão Vegetal Análise Imediata. ABNT: Rio do Janeiro, Brazil, 1986.

- NBR8633; Carvão Vegetal Determinação Do Poder Calorífico. ABNT: Rio do Janeiro, Brazil, 1984.

- Barzegar, R.; Yozgatligil, A.; Olgun, H.; Atimtay, A.T. TGA and Kinetic Study of Different Torrefaction Conditions of Wood Biomass under Air and Oxy-Fuel Combustion Atmospheres. J. Energy Inst. 2020, 93, 889–898. [Google Scholar] [CrossRef]

- Huang, Y.F.; Lo, S.L. Predicting Heating Value of Lignocellulosic Biomass Based on Elemental Analysis. Energy 2020, 191, 116501. [Google Scholar] [CrossRef]

- Güleç, F.; Pekaslan, D.; Williams, O.; Lester, E. Predictability of Higher Heating Value of Biomass Feedstocks via Proximate and Ultimate Analyses—A Comprehensive Study of Artificial Neural Network Applications. Fuel 2022, 320, 123944. [Google Scholar] [CrossRef]

- Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies 2021, 14, 6529. [Google Scholar] [CrossRef]

- Wang, T.; Rong, H.; Chen, S.; Zhou, Y.; Li, J.; Xiao, Y.; Xue, Y. TG- MS Study on in-Situ Sulfur Retention during the Co-Combustion of Reclaimed Asphalt Binder and Wood Sawdust. J. Hazard. Mater. 2021, 403, 123911. [Google Scholar] [CrossRef] [PubMed]

- Greco, G.; Videgain, M.; Di Stasi, C.; Pires, E.; Manyà, J.J. Importance of Pyrolysis Temperature and Pressure in the Concentration of Polycyclic Aromatic Hydrocarbons in Wood Waste-Derived Biochars. J. Anal. Appl. Pyrolysis 2021, 159, 105337. [Google Scholar] [CrossRef]

- Riaz, S.; Al-Abdeli, Y.M.; Oluwoye, I. Partially Oxidative Torrefaction of Woody Biomass Pellets: Burning Behaviour and Emission Analysis. Bioenergy Res. 2023, 16, 2331–2341. [Google Scholar] [CrossRef]

- De Souza, E.C.; Gomes, J.P.S.; Pimenta, A.S.; de Azevedo, T.K.B.; Pereira, A.K.S.; Gomes, R.M.; Brito, J.O.; Dias Júnior, A.F. Briquette Production as a Sustainable Alternative for Waste Management in the Tannin Extraction Industry. Environ. Sci. Pollut. Res. 2023, 30, 18078–18090. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Phuleria, H.C.; Chandel, M.K. Estimation of Energy Recovery Potential of Sewage Sludge in India: Waste to Watt Approach. J. Clean. Prod. 2020, 276, 122538. [Google Scholar] [CrossRef]

- Dahhou, M.; El Moussaouiti, M.; Benlalla, A.; El Hamidi, A.; Taibi, M.; Arshad, M.A. Structural Aspects and Thermal Degradation Kinetics of Water Treatment Plant Sludge of Moroccan Capital. Waste Biomass Valorization 2016, 7, 1177–1187. [Google Scholar] [CrossRef]

- Yaras, A.; Demirel, B.; Akkurt, F.; Arslanoglu, H. Thermal Conversion Behavior of Paper Mill Sludge: Characterization, Kinetic, and Thermodynamic Analyses. Biomass Convers. Bioref. 2023, 13, 2007–2016. [Google Scholar] [CrossRef]

- Xu, X.; Pan, R.; Chen, R. Combustion Characteristics, Kinetics, and Thermodynamics of Pine Wood Through Thermogravimetric Analysis. Appl. Biochem. Biotechnol. 2021, 193, 1427–1446. [Google Scholar] [CrossRef] [PubMed]

- Hameed, Z.; Naqvi, S.R.; Naqvi, M.; Ali, I.; Taqvi, S.A.A.; Gao, N.; Hussain, S.A.; Hussain, S. A Comprehensive Review on Thermal Coconversion of Biomass, Sludge, Coal, and Their Blends Using Thermogravimetric Analysis. J. Chem. 2020, 2020, 5024369. [Google Scholar] [CrossRef]

- Apaydın Varol, E.; Mutlu, Ü. TGA-FTIR Analysis of Biomass Samples Based on the Thermal Decomposition Behavior of Hemicellulose, Cellulose, and Lignin. Energies 2023, 16, 3674. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M. Thermogravimetric Study of Biomass, Sewage Sludge and Coal Combustion. Energy Convers. Manag. 2013, 75, 425–430. [Google Scholar] [CrossRef]

- De Sousa Oliveira, R.; Santos, L.T.V.; Melo, S.C.; Chagas, M.P.; Ribeiro, D.; Reis, C.A.F.; Novaes, E.; Sette, C.R. Wood Energy Yield for Eucalyptus Clones Growing under Seasonal Drought-Stress in Brazil. Biomass Bioenergy 2021, 154, 106264. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of Species, Particle Size and Compacting Pressure on Relaxed Density and Compressive Strength of Fuel Briquettes. Int. J. Energy Environ. Eng. 2013, 4, 30. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Acheampong, B.B. Strength Properties and Calorific Values of Sawdust-Briquettes as Wood-Residue Energy Generation Source from Tropical Hardwoods of Different Densities. Biomass Bioenergy 2016, 85, 144–152. [Google Scholar] [CrossRef]

- Granado, M.P.P.; Suhogusoff, Y.V.M.; Santos, L.R.O.; Yamaji, F.M.; De Conti, A.C. Effects of Pressure Densification on Strength and Properties of Cassava Waste Briquettes. Renew. Energy 2021, 167, 306–312. [Google Scholar] [CrossRef]

| Treatment | Sludge/Wood Ratio | Treatment | Sludge/Wood Ratio |

|---|---|---|---|

| 1 | 0/100 | 6 | 65/35 |

| 2 | 5/95 | 7 | 75/25 |

| 3 | 15/85 | 8 | 85/15 |

| 4 | 25/75 | 9 | 95/5 |

| 5 | 35/65 | 10 | 100/0 |

| Material | Elemental Composition (%) | |||

|---|---|---|---|---|

| C (%) | H (%) | N (%) | S (%) | |

| Sewage sludge | 9.922.4 a | 3.511.8 a | 0.7272.2 a | 0.3782.3 a |

| Pinus sp. sawdust | 50.42.1 b | 5.892.3 b | 0.1181.3 b | 0.0382.2 b |

| O (%) | C/H | C/N | ||

| Sewage sludge | 21.922.7 a | 2.802.5 a | 13.73.1 a | |

| Pinus sp. sawdust | 43.552.8 b | 8.573.4 b | 427.12.2 b | |

| Material | Proximate Analysis (%) | HCV MJ/Kg | ||

|---|---|---|---|---|

| Fixed Carbon (%) | Volatile Matter (%) | Ash (%) | ||

| Sewage sludge | 8.13.5 a | 48.44.6 a | 55.514.5 a | 14.642.5 a |

| Pinus sp. sawdust | 15.85.5 b | 83.75.1 b | 0.5315.6 b | 20.352.6 b |

| Sample | % H2O | Tmáx H2O | Tonset | %mass Loss | T máx | T máx2 | Tendset | %Residue (at 950 °C) |

|---|---|---|---|---|---|---|---|---|

| 100% sawdust | 2.4 | 49.4 | 275.9 | 71.1 | 352.6 | -- | 367.9 | 15.0 |

| 95 | 3.4 | 45.4 | 263.8 | 66.6 | 351.9 | -- | 364.8 | 4.1 |

| 85 | 3.4 | 51.3 | 278.2 | 56.1 | 351.4 | 423.2 | 363.9 | 12.2 |

| 75 | 4.3 | 53.6 | 270.9 | 50.3 | 352.2 | 408.6 | 365.4 | 23.3 |

| 65 | 5.4 | 60.6 | 272.5 | 44.2 | 351.1 | -- | 363.7 | 26.2 |

| 35 | 6.9 | 75.8 | 275.3 | 27.3 | 354.3 | 420.9 | 367.7 | 50.5 |

| 25 | 4.2 | 84.5 | 267.9 | 24.5 | 353.5 | 425.7 | 365.8 | 51.3 |

| 15 | 6.8 | 76.2 | -- | -- | 351.9 | 433.5 | 367.4 | 57.9 |

| 5 | 5.7 | 79.6 | 274.9 | -- | 352.2 | 433.1 | -- | 60.0 |

| 100% sludge | 3.7 | 77.0 | -- | -- | 434.3 | -- | 62.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, A.B.; Zanuncio, A.J.V.; Carvalho, A.G.; de Cassia Oliveira Carneiro, A.; de Castro, V.R.; Carvalho, A.M.M.L.; Lopes, O.P.; Branco-Vieira, M.; Ferreira, M.V.; de Assunção, R.M.N.; et al. Sustainable Solid Biofuel Production: Transforming Sewage Sludge and Pinus sp. Sawdust into Resources for the Circular Economy. Sustainability 2024, 16, 4554. https://doi.org/10.3390/su16114554

Pereira AB, Zanuncio AJV, Carvalho AG, de Cassia Oliveira Carneiro A, de Castro VR, Carvalho AMML, Lopes OP, Branco-Vieira M, Ferreira MV, de Assunção RMN, et al. Sustainable Solid Biofuel Production: Transforming Sewage Sludge and Pinus sp. Sawdust into Resources for the Circular Economy. Sustainability. 2024; 16(11):4554. https://doi.org/10.3390/su16114554

Chicago/Turabian StylePereira, Alex Borges, Antonio José Vinha Zanuncio, Amélia Guimarães Carvalho, Angélica de Cassia Oliveira Carneiro, Vinícius Resende de Castro, Ana Marcia Macedo Ladeira Carvalho, Olivia Pereira Lopes, Monique Branco-Vieira, Marcos Vinícius Ferreira, Rosana Maria Nascimento de Assunção, and et al. 2024. "Sustainable Solid Biofuel Production: Transforming Sewage Sludge and Pinus sp. Sawdust into Resources for the Circular Economy" Sustainability 16, no. 11: 4554. https://doi.org/10.3390/su16114554