Landscape Restoration Using Individual Tree Harvest Strategies

Abstract

1. Introduction

2. Materials and Methods

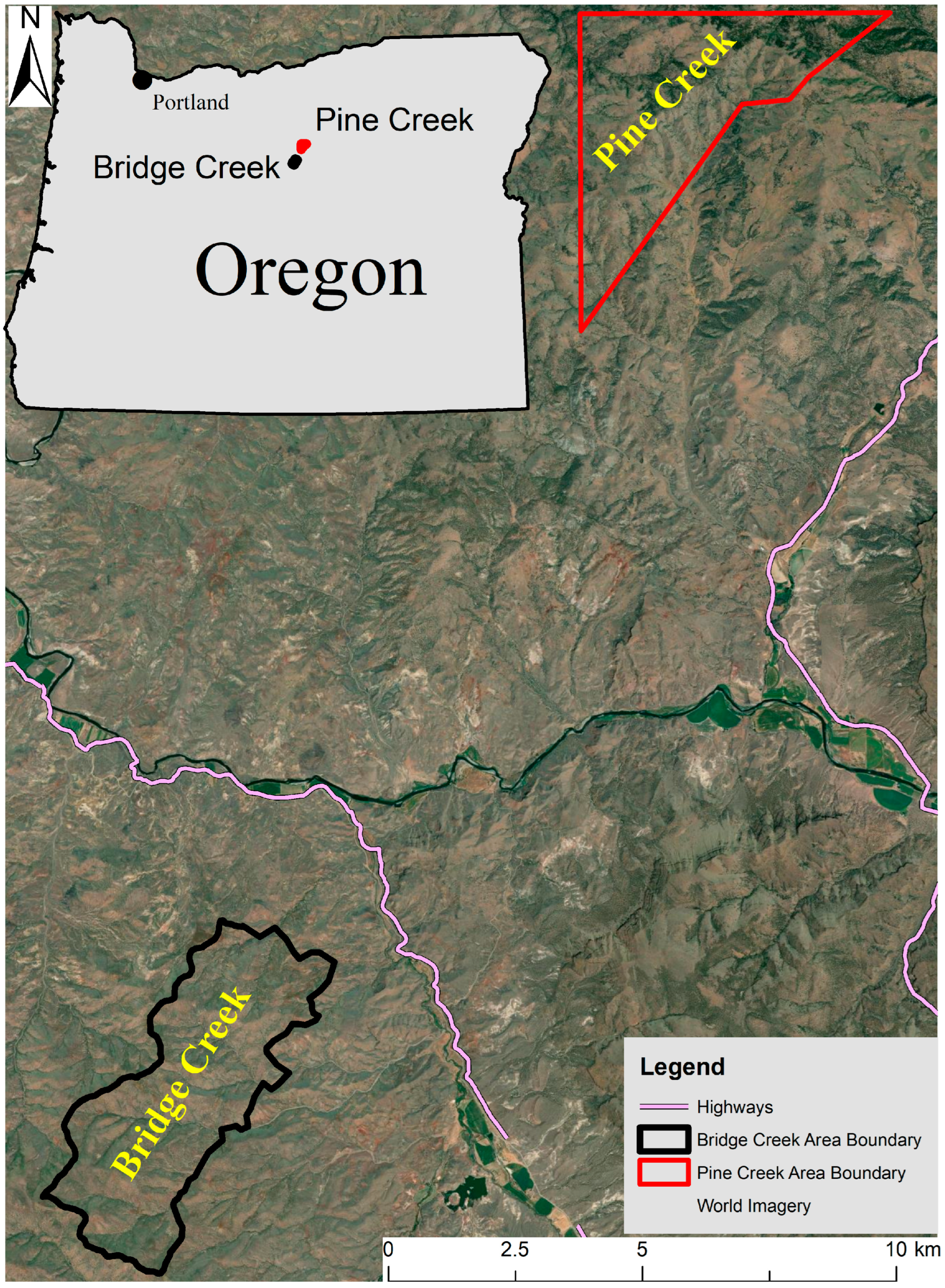

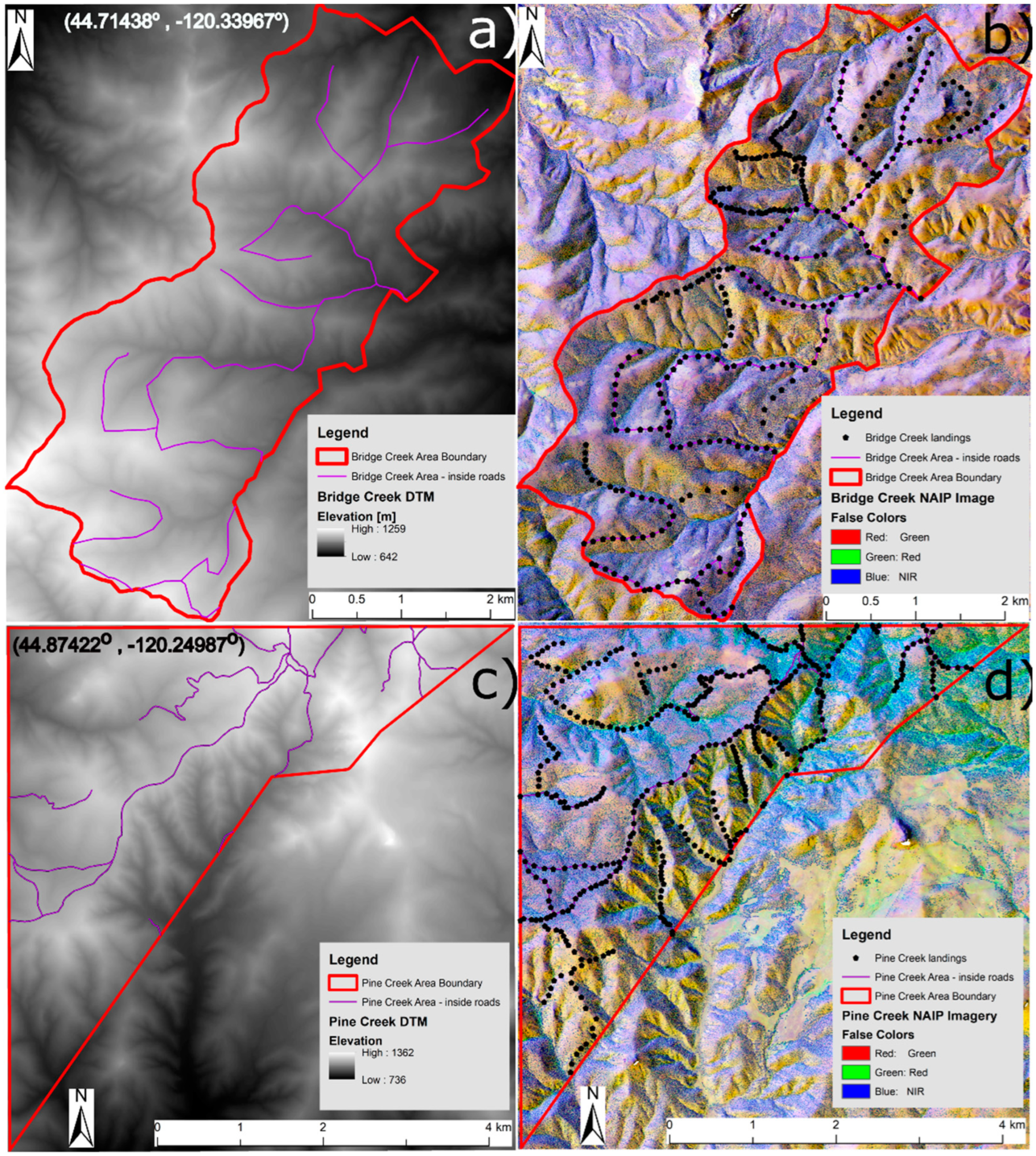

2.1. Study Areas

2.2. Input Data

2.2.1. Individual Tree Location and Value

2.2.2. Landing Locations

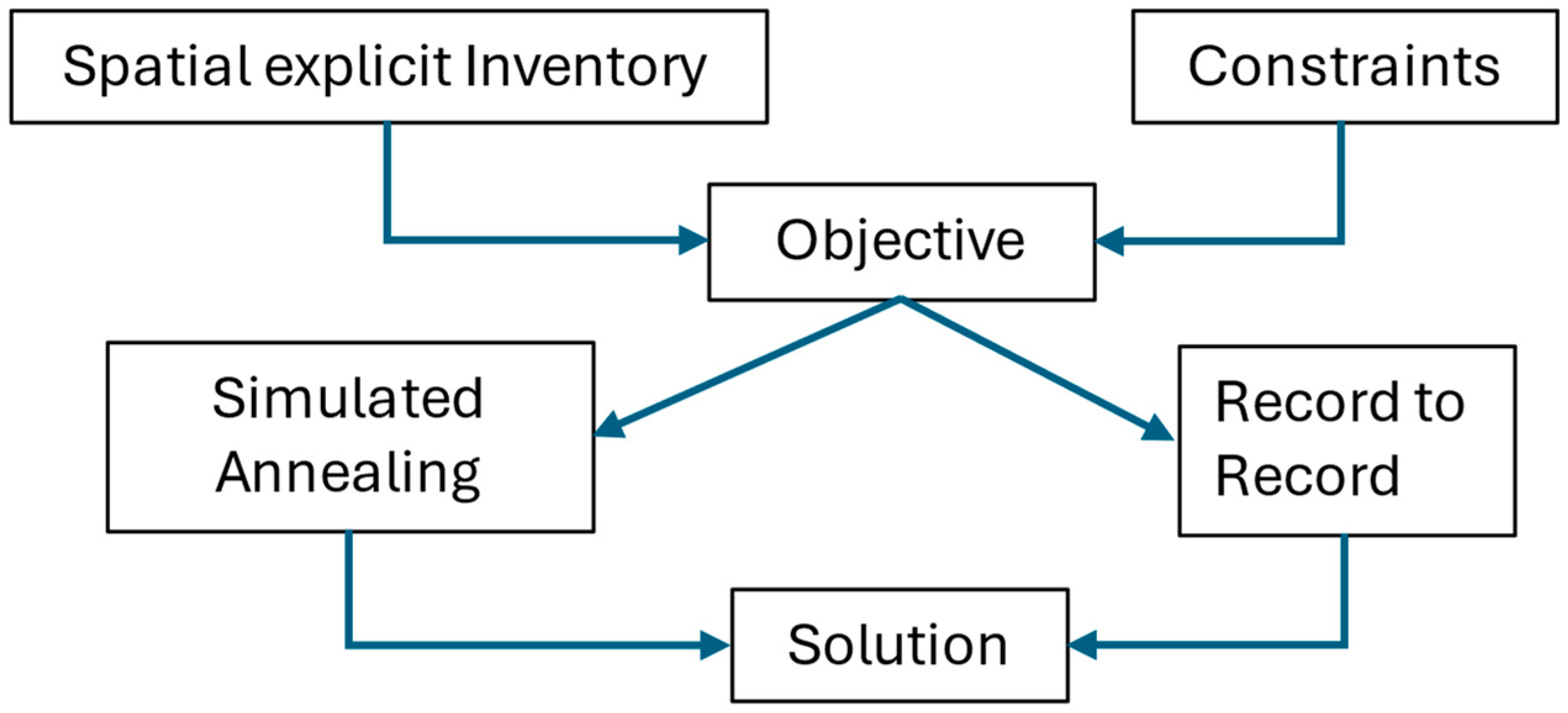

2.3. Individual Tree Harvest Scheduling

2.3.1. Harvest Costs

2.3.2. Spatial Implementation of the Harvests

2.3.3. Formulation of the Harvest Problem

- Harvest weight = sum of weights of trees with weight > 0.3 tons;

- Non-harvest weight = sum of weights of trees with weight ≤ 0.3 tons;

- Distance to closest active landing = Euclidean distance from the centroid of harvest unit to landing;

- The monetary values of the attributes used to compute the net revenue of each harvest unit are presented in Table 4.

| Attribute | Value | Units | Short Description and Source |

|---|---|---|---|

| Felling subsidy | 2.0 | USD/tree | Estimated USDA remediation value [45] |

| Value of merchantable tree | 65 | USD/ton | Estimated value of a tree [46] |

| Feller-buncher and processor moving cost | 0.03 | USD/m | Estimated cost of moving the feller-buncher and processor within the harvested area (authors) |

| Non-merchantable tree felling cost | 12 | USD/green ton | Cost of felling a non-merchantable tree [6] |

| Merchantable tree felling cost | 10 | USD/green ton | Cost of felling a merchantable tree [6] |

| Merchantable tree processing cost | 15 | USD/green ton | Cost of processing a merchantable tree [6] |

| Skidding distance coefficient | 0.18 | USD/m/green ton | Distance-related cost of moving merchantable juniper to the landing [6] |

| Skidding coefficient | 20 | USD/green ton | Non-distance related skidding activities [6] |

| Landing cost | 500 | USD/landing | Cost of preparing a landing area [39] |

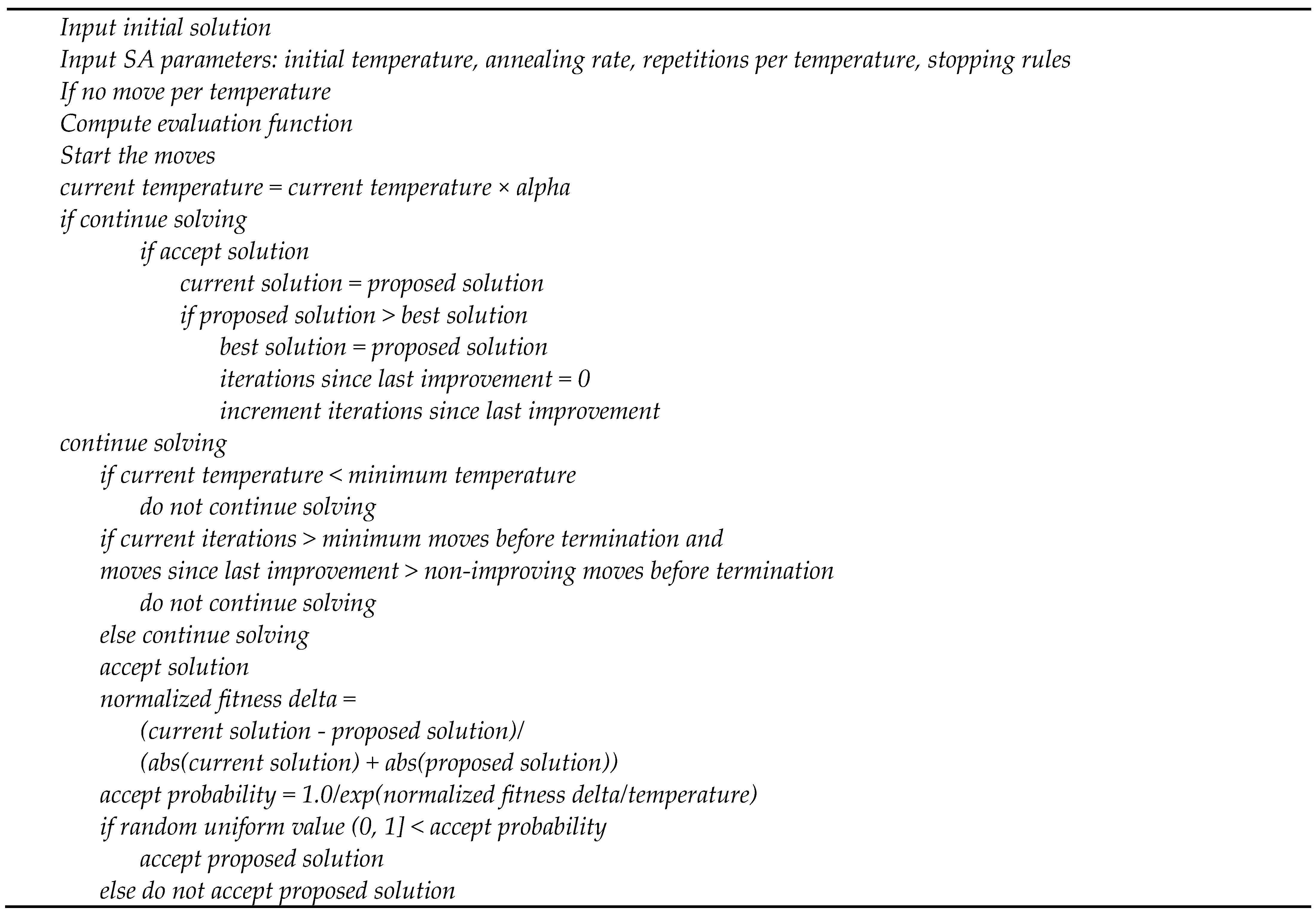

2.3.4. Simulated Annealing

| Annealing rate: | 0.99 |

| Initial temperature: | 0.25 |

| Number of moves/temperature: | 200 |

2.3.5. Record-to-Record Travel

3. Results

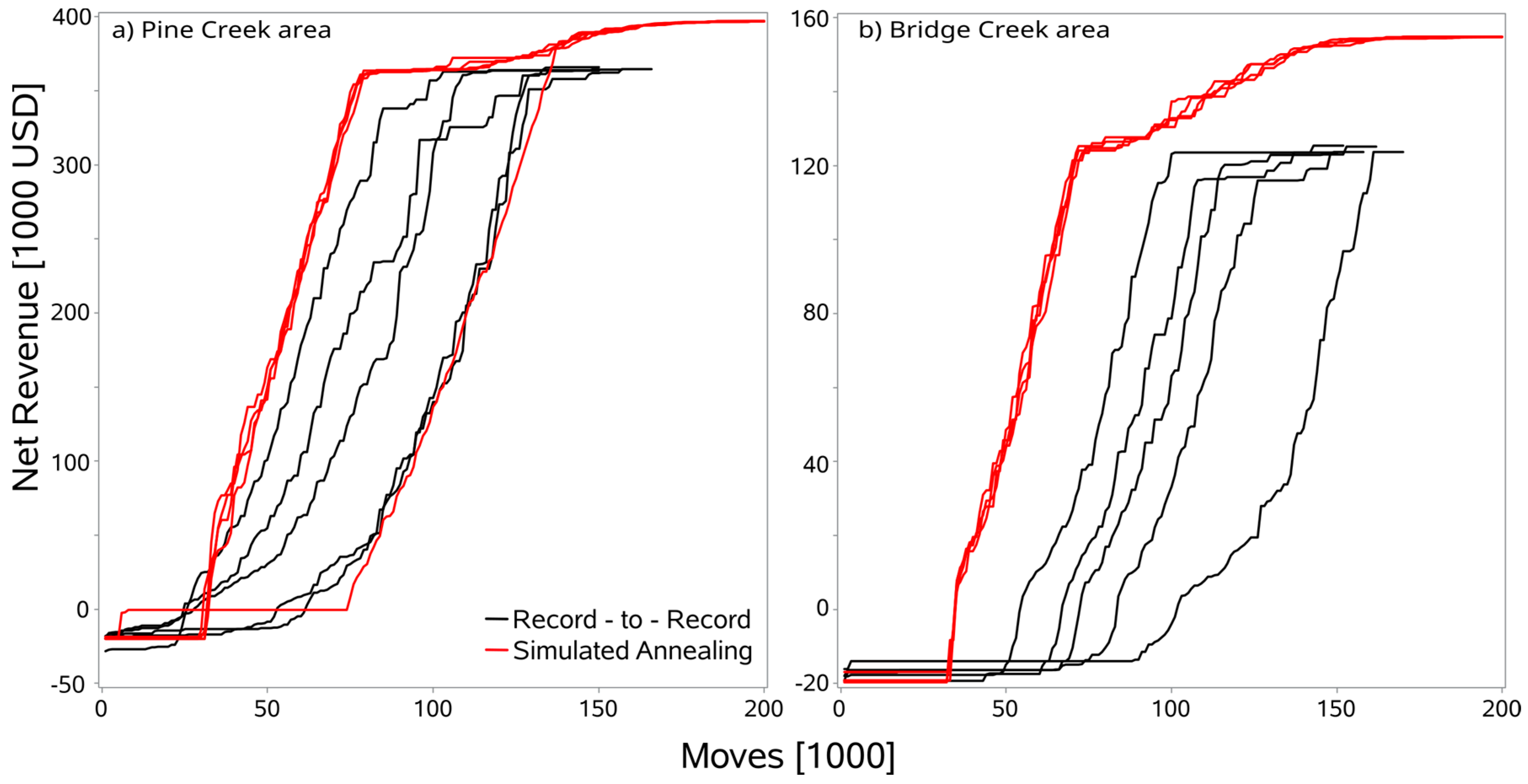

3.1. Price at 65 USD/ton at the Landing

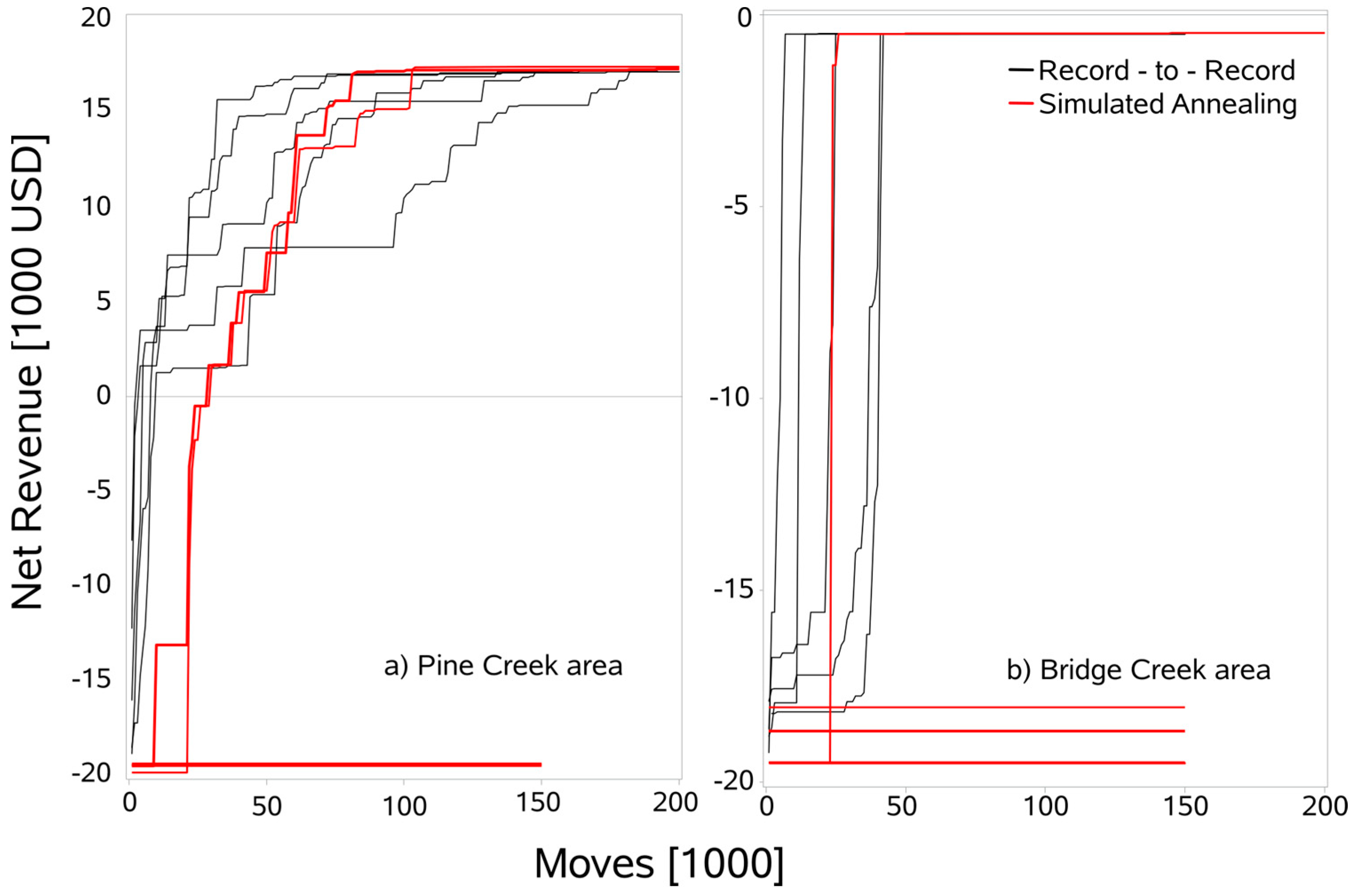

3.2. Price at 45 USD/ton at the Landing

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Durfee, N.; Ochoa, C.G.; Mata-Gonzalez, R. The Use of Low-Altitude UAV Imagery to Assess Western Juniper Density and Canopy Cover in Treated and Untreated Stands. Forests 2019, 10, 296. [Google Scholar] [CrossRef]

- Knapp, P.A.; Soulé, P.T. Recent Juniperus occidentalis (Western Juniper) Expansion on a Protected Site in Central Oregon. Glob. Chang. Biol. 1998, 4, 347–357. [Google Scholar] [CrossRef]

- Miller, R.F.; Bates, J.D.; Svejcar, T.J.; Pierson, F.B.; Eddleman, L.E. Biology, Ecology, and Management of Western Juniper (Juniperus occidentalis); Oregon State University: Corvallis, OR, USA, 2005; p. 82. [Google Scholar]

- Miller, R.F.; Rose, J.A. Historic Expansion of Juniperus occidentalis (Western Juniper) in Southeastern Oregon. Great Basin Nat. 1995, 55, 37–45. [Google Scholar]

- Swan, L. Western Juniper Furniture Market Research and Design Project; US Forest Service: Klamath Falls, OR, USA, 1998; p. 17.

- Dodson, E. A Comparison of Harvesting Systems for Western Juniper. Int. J. For. Eng. 2010, 21, 40–47. [Google Scholar] [CrossRef]

- Dodson, E.M.; Deboodt, T.; Hudspeth, G. Production, Cost, and Soil Compaction Estimates for Two Western Juniper Extraction Systems. West. J. Appl. For. 2006, 21, 185–194. [Google Scholar] [CrossRef]

- Hyyppa, J.; Kelle, O.; Lehikoinen, M.; Inkinen, M. A Segmentation-Based Method to Retrieve Stem Volume Estimates from 3-D Tree Height Models Produced by Laser Scanners. IEEE Trans. Geosci. Remote Sens. 2001, 39, 969–975. [Google Scholar] [CrossRef]

- Gatziolis, D.; Andersen, H.-E. A Guide to LiDAR Data Acquisition and Processing for the Forests of the Pacific Northwest; USDA—Forest Service, Pacific Northwest Reserach Station: Portland, OR, USA, 2008; p. 32.

- Liu, S.; Cieszewski, C.J. Impacts of Management Intensity and Harvesting Practices on Long-Term Forest Resource Sustainability in Georgia. Math. Comput. For. Nat.-Resour. Sci. 2009, 1, 52–66. [Google Scholar]

- Wang, H.; Yang, T.-R.; Waldy, J.; Jr, J.A.K. Estimating Individual Tree Heights and Dbhs from Vertically Displaced Spherical Image Pairs. Math. Comput. For. Nat.-Resour. Sci. 2021, 13, 1–14. [Google Scholar]

- Hao, Z.; Lin, L.; Post, C.J.; Mikhailova, E.A.; Li, M.; Chen, Y.; Yu, K.; Liu, J. Automated Tree-Crown and Height Detection in a Young Forest Plantation Using Mask Region-Based Convolutional Neural Network (Mask R-CNN). ISPRS J. Photogramm. Remote Sens. 2021, 178, 112–123. [Google Scholar] [CrossRef]

- Parsakhoo, A.; Mostafa, M.; Shataee, S.; Lotfalian, M. Decision Support System to Find a Skid Trail Network for Extracting Marked Trees. J. For. Sci. 2017, 63, 62–69. [Google Scholar] [CrossRef]

- Philippart, J.; Sun, M.; Doucet, J.-L.; Lejeune, P. Mathematical Formulation and Exact Solution for Landing Location Problem in Tropical Forest Selective Logging, a Case Study in Southeast Cameroon. J. For. Econ. 2012, 18, 113–122. [Google Scholar] [CrossRef]

- Pukkala, T.; Lähde, E.; Laiho, O. Which Trees Should Be Removed in Thinning Treatments? For. Ecosyst. 2015, 2, 32. [Google Scholar] [CrossRef]

- Pukkala, T.; Miina, J. Tree-Selection Algorithms for Optimizing Thinning Using a Distance-Dependent Growth Model. Can. J. For. Res. 1998, 28, 693–702. [Google Scholar] [CrossRef]

- Vauhkonen, J.; Pukkala, T. Selecting the Trees to Be Harvested Based on the Relative Value Growth of the Remaining Trees. Eur. J. For. Res. 2016, 135, 581–592. [Google Scholar] [CrossRef]

- Wing, B.M.; Boston, K.; Ritchie, M.W. A Technique for Implementing Group Selection Treatments with Multiple Objectives Using an Airborne Lidar-Derived Stem Map in a Heuristic Environment. For. Sci. 2019, 65, 211–222. [Google Scholar] [CrossRef]

- Contreras, M.A.; Chung, W. Developing a Computerized Approach for Optimizing Individual Tree Removal to Efficiently Reduce Crown Fire Potential. For. Ecol. Manag. 2013, 289, 219–233. [Google Scholar] [CrossRef]

- Soil Survey Staff. Soil Taxonomy, a Basic System of Soil Classification for Making and Interpreting Soil Surveys; USDA—NRCS: Alexandria, LA, USA, 1999; p. 886.

- Millison, A. Climate Classification Systems. In Permaculture Design Tools for Climate Resilience; Oregon State University: Corvallis, OR, USA, 2018; pp. 28–38. [Google Scholar]

- Archuleta, C.-A.M.; Constance, E.W.; Arundel, S.T.; Lowe, A.J.; Mantey, K.S.; Phillips, L.A. The National Map Seamless Digital Elevation Model Specifications; US Geological Service: Reston, VA, USA, 2017; p. 50.

- O’Callaghan, J.F.; Mark, D.M. The Extraction of Drainage Networks from Digital Elevation Data. Comput. Vis. Graph. Image Process. 1984, 28, 323–344. [Google Scholar] [CrossRef]

- Schriver, R. Landscape Inventory and Harvest Strategies for Individual Western Juniper in Eastern Oregon. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2018. [Google Scholar]

- Goodfellow, I.J.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative Adversarial Networks. arXiv 2014, arXiv:1406.2661. [Google Scholar] [CrossRef]

- Isola, P.; Zhu, J.-Y.; Zhou, T.; Efros, A.A. Image-to-Image Translation with Conditional Adversarial Networks; IEEE: Honolulu, HA, USA, 2017. [Google Scholar]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. Tensor Flow: Large-Scale Machine Learning on Heterogeneous Systems. 2015. Available online: https://www.tensorflow.org (accessed on 8 June 2024).

- Strimbu, V.F.; Strimbu, B.M. A Graph-Based Segmentation Algorithm for Tree Crown Extraction Using Airborne LiDAR Data. ISPRS J. Photogramm. Remote Sens. 2015, 104, 30–43. [Google Scholar] [CrossRef]

- Noone, M.; Kagan, J.S.; Nielsen, E. Western Juniper (Juniperus occidentalis) and Invasive Annual Grass Mapping in Eastern Oregon; Portland State University: Portland, OR, USA, 2013; p. 57. [Google Scholar]

- Swan, L.; Connolly, M. Processing and Finishing Western Juniper; Oregon State University: Portland, OR, USA, 1998; p. 13. [Google Scholar]

- Gedney, D.R.; Azuma, D.L.; Bolsinger, C.L.; McKay, N. Western Juniper in Eastern Oregon; U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station: Portland, OR, USA, 1999.

- Environmental Systems Research Institute, ArcMap 10.8.2.; Environmental Systems Research Institute: Redland, CA, USA, 2022.

- Bettinger, P.; Graetz, D.; Boston, K.; Sessions, J.; Chung, W.D. Eight Heuristic Planning Techniques Applied to Three Increasingly Difficult Wildlife Planning Problems. Silva Fenn. 2002, 36, 561–584. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by Simulated Annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Metropolis, N.; Rosenbluth, A.W.; Rosenbluth, M.N.; Teller, A.H.; Teller, E. Equations of State Calculations by Fast Computing Machines. J. Chem. Phys. 1953, 21, 1087–1092. [Google Scholar] [CrossRef]

- Dueck, G. New Optimization Heuristics: The Great Deluge Algorithm and the Record-to-Record Travel. J. Comput. Phys. 1993, 104, 86–92. [Google Scholar] [CrossRef]

- Pukkala, T.; Kurttila, M. Examining the Performance of Six Heuristic Optimisation Techniques in Different Forest Planning Problems. Silva Fenn. 2005, 39, 67–80. [Google Scholar] [CrossRef]

- Borges, P.; Bergseng, E.; Eid, T. Adjacency Constraints in Forestry—A Simulated Annealing Approach Comparing Different Candidate Solution Generators. Math. Comput. For. Nat.-Resour. Sci. 2014, 6, 11–25. [Google Scholar]

- Winter, H. Western Juniper in East Oregon. Presented at the JUBoP Field Visit; Oral Presentation: Fossil, OR, USA, 2017. [Google Scholar]

- Murray, A.T. Spatial Restrictions in Harvest Scheduling. For. Sci. 1999, 45, 45–52. [Google Scholar] [CrossRef]

- St. John, R.; Tóth, S. Spatially Explicit Forest Harvest Scheduling with Difference Equations. Ann. Oper. Res. 2015, 232, 235–257. [Google Scholar] [CrossRef]

- Anderson, A.E.; Nelson, J. Projecting Vector-Based Road Networks with a Shortest Path Algorithm. Can. J. For. Res. 2004, 34, 1444–1457. [Google Scholar] [CrossRef]

- Hoos, H.; Stutzle, T. Stochastic Local Search; Morgan Kaufmann Publishers: New York, NY, USA, 2005. [Google Scholar]

- Marti, R.; Pardalos, P.M.; Resende, M.G.C. Handbook of Heuristics; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- US Department of Agriculture. Sage Grouse Initiative. Available online: https://www.nrcs.usda.gov/programs-initiatives/sage-grouse-initiative (accessed on 10 June 2024).

- Derby, K. In The Stiks Mill. Presented at the JuBOP Field Visit; Oral Presentation: Fossil, OR, USA, 2017. [Google Scholar]

- Van Deusen, P.C. Multiple Solution Harvest Scheduling. Silva Fenn. 1999, 33, 207–216. [Google Scholar] [CrossRef][Green Version]

- Baskent, E.Z.; Jordan, G.A. Forest Landscape Management Modeling Using Simulated Annealing. For. Ecol. Manag. 2002, 165, 29–45. [Google Scholar] [CrossRef]

- Nourani, Y.; Andresen, B. A Comparison of Simulated Annealing Cooling Strategies. J. Phys. A Math. Gen. 1998, 31, 8373–8385. [Google Scholar] [CrossRef]

- Strimbu, B.M.; Paun, M. Sensitivity of Forest Plan Value to Parameters of Simulated Annealing. Can. J. For. Res. 2013, 43, 28–38. [Google Scholar] [CrossRef]

- Zomaya, A.Y.; Kazman, R.; Atallah, M.J. Simulated Annealing Techniques. In Handbook on Algorithms and Theory of Computation; CRC Press: Boca Raton, FL, USA, 1999; pp. 37-1–37-19. [Google Scholar]

- Peters, P.A. Spacing of Roads and Landings to Minimize Timber Harvest Cost. For. Sci. 1978, 24, 209–217. [Google Scholar] [CrossRef]

- Bettinger, P.; Sessions, J.; Boston, K. A Review of the Status and Use of Validation Procedures for Heuristics Used in Forest Planning. Math. Comput. For. Nat.-Resour. Sci. 2009, 1, 26–37. [Google Scholar]

- Bettinger, P.; Boston, K. Forest Planning Heuristics—Current Recommendations and Research Opportunities for s-Metaheuristics. Forests 2017, 8, 476. [Google Scholar] [CrossRef]

- Lockwood, C.; Moore, T. Harvest Scheduling with Spatial Constraints: A Simulated Annealing Approach. Can. J. For. Res. 1993, 23, 468–478. [Google Scholar] [CrossRef]

- Moriguchi, K.; Ueki, T.; Saito, M. Identification of Effective Implementations of Simulated Annealing for Optimizing Thinning Schedules for Single Forest Stands. Eur. J. Oper. Res. 2017, 262, 1094–1108. [Google Scholar] [CrossRef]

- Pascual, A.; Pukkala, T.; de-Miguel, S.; Pesonen, A.; Packalen, P. Influence of Timber Harvesting Costs on the Layout of Cuttings and Economic Return in Forest Planning Based on Dynamic Treatment Units. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=6494911 (accessed on 24 November 2018).

| Study Area | Surface | Elevation Mean/Min ↔ Max/Std. Dev. | Roads Length | Number of Sub-Basins |

|---|---|---|---|---|

| [ha] | [m] | [km] | [count] | |

| Bridge Creek | 1667.9 | 950/642 ↔ 1259/178.4 | 21.9 | 12 |

| Pine Creek | 1597.1 | 1133/833 ↔ 1358/95.7 | 19.4 | 14 |

| Study Area | Number of Trees | Height Mean/Min–Max/Std. Dev. |

|---|---|---|

| [count] | [m] | |

| Pine Creek | 178,515 | 8.3/1.8–36.3/4.48 |

| Bridge Creek | 162,941 | 5.8/1.8–24.4/2.53 |

| Study Area | No. Potential Landings | Average Area/Potential Landing [ha] |

|---|---|---|

| Bridge Creek | 344 | 4.8 |

| Pine Creek | 399 | 4.0 |

| Study Area | Algorithm | Upper Bound | Lower Bound | Maximum Net Revenue | Number of Solutions above/below Lower Bound | Terminating Criteria for Best Solution |

|---|---|---|---|---|---|---|

| Bridge Creek | SA | USD 289,752 | USD 117,752 | USD 154,943 | 23/6 | freezing |

| R2R | USD 289,752 | USD 117,752 | USD 125,464 | 23/6 | non-improvement | |

| Pine Creek | SA | USD 559,281 | USD 359,781 | USD 397,219 | 12/17 | freezing |

| R2R | USD 559,281 | USD 359,781 | USD 365,836 | 19/10 | non-improvement |

| Study Area | Heuristic | Number of Landings | Average Weight/Landing | Average Distance from Cell to Landing | Average Number of Cells/Landing | Average Number of Trees Harvested/Landing | Net Revenue at Landing |

|---|---|---|---|---|---|---|---|

| [count] | [ton] | [m] | [count] | [count] | [USD/Merchantable Green ton] | ||

| Bridge Creek | SA | 223 | 90 | 71.1 | 94 | 228 | 7.72/ton |

| R2R | 308 | 65 | 65.2 | 68 | 201 | 6.27/ton | |

| Pine Creek | SA | 261 | 147 | 71.9 | 86 | 276 | 10.35/ton |

| R2R | 354 | 108 | 68.3 | 63 | 203 | 9.56/ton |

| Study Area | Algorithm | Upper Bound | Lower Bound | Maximum Net Revenue | Number of Solutions above/below Lower Bound | Terminating Criteria of Best Solution |

|---|---|---|---|---|---|---|

| Bridge Creek | SA | USD 9861 | −USD 162,139 | −USD 461 | 10/0 | Freezing |

| R2R | USD 9861 | −USD 162,139 | −USD 486 | 10/0 | Non-improving | |

| Pine Creek | SA | USD 37,049 | −USD 162,451 | USD 17,468 | 10/0 | Freezing |

| R2R | USD 37,049 | −USD 162,451 | USD 17,315 | 10/0 | Freezing |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schriver, R.; Sessions, J.; Strimbu, B.M. Landscape Restoration Using Individual Tree Harvest Strategies. Sustainability 2024, 16, 5124. https://doi.org/10.3390/su16125124

Schriver R, Sessions J, Strimbu BM. Landscape Restoration Using Individual Tree Harvest Strategies. Sustainability. 2024; 16(12):5124. https://doi.org/10.3390/su16125124

Chicago/Turabian StyleSchriver, Robert, John Sessions, and Bogdan M. Strimbu. 2024. "Landscape Restoration Using Individual Tree Harvest Strategies" Sustainability 16, no. 12: 5124. https://doi.org/10.3390/su16125124

APA StyleSchriver, R., Sessions, J., & Strimbu, B. M. (2024). Landscape Restoration Using Individual Tree Harvest Strategies. Sustainability, 16(12), 5124. https://doi.org/10.3390/su16125124