An Experimental Study Focusing on the Filling Process and Consolidation Characteristics of Geotextile Tubes Filled with Fine-Grained Tungsten Tailings

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

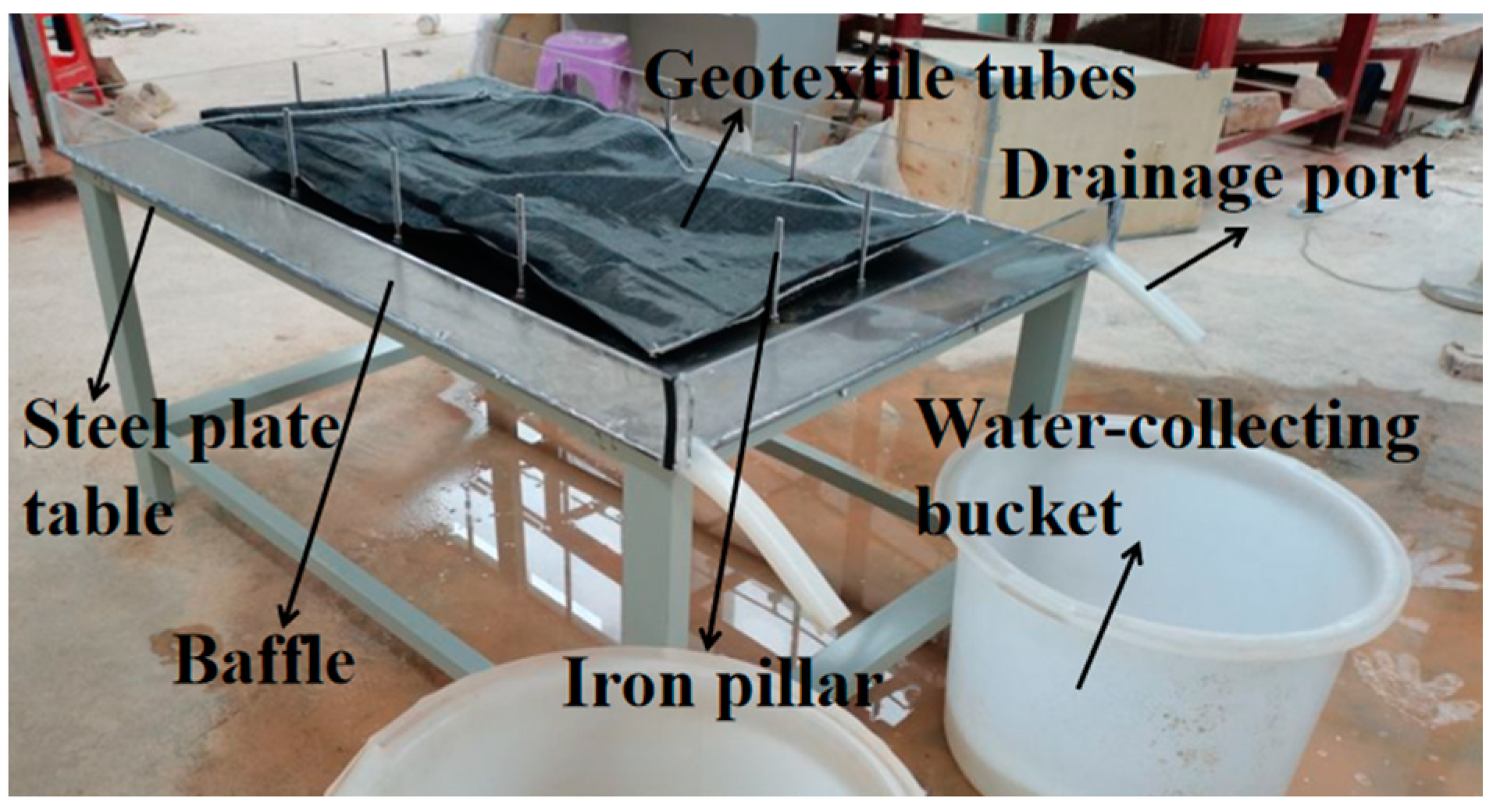

2.2. Testing Instruments

2.3. Experimental Design

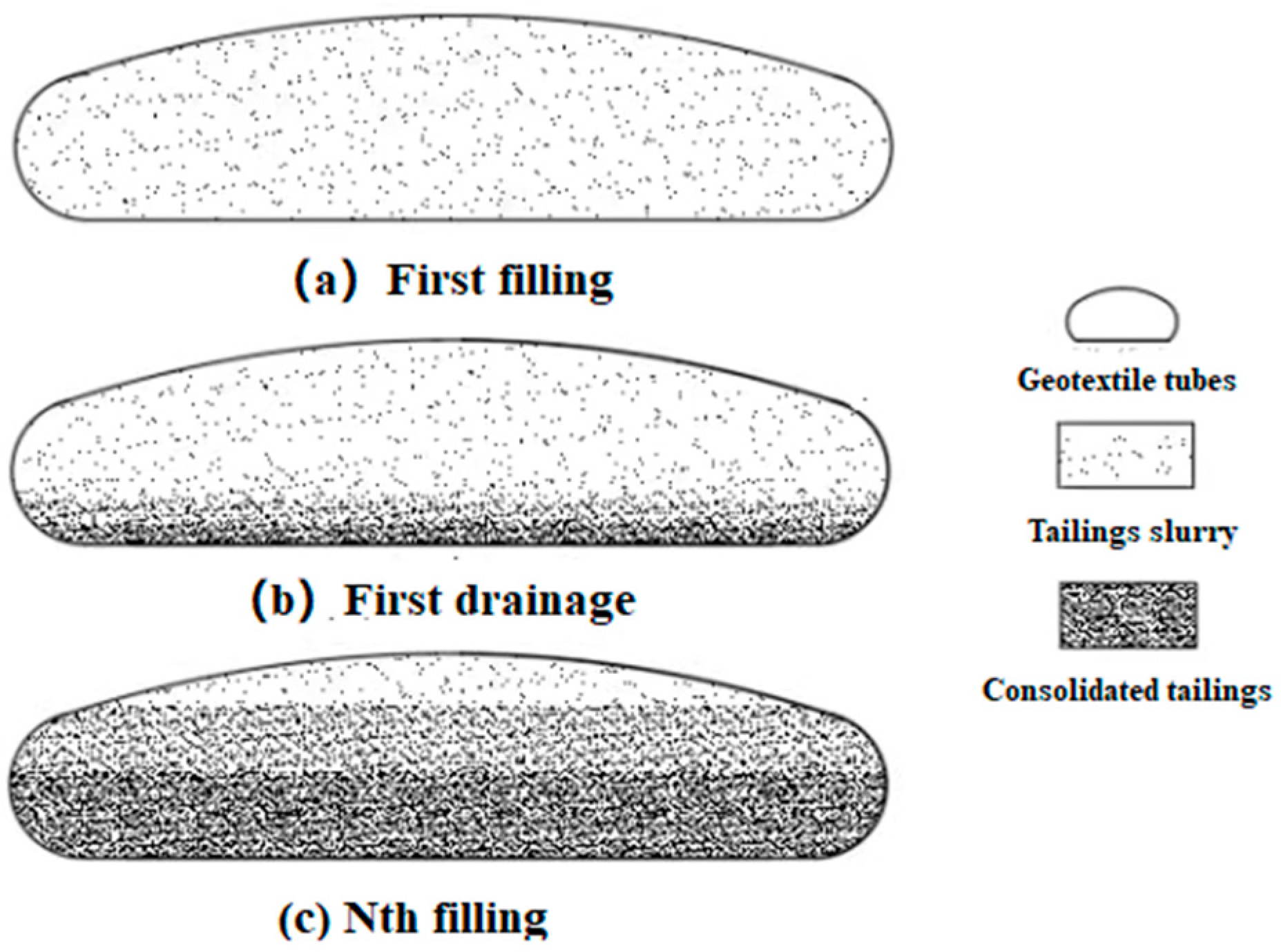

2.4. Test Methods

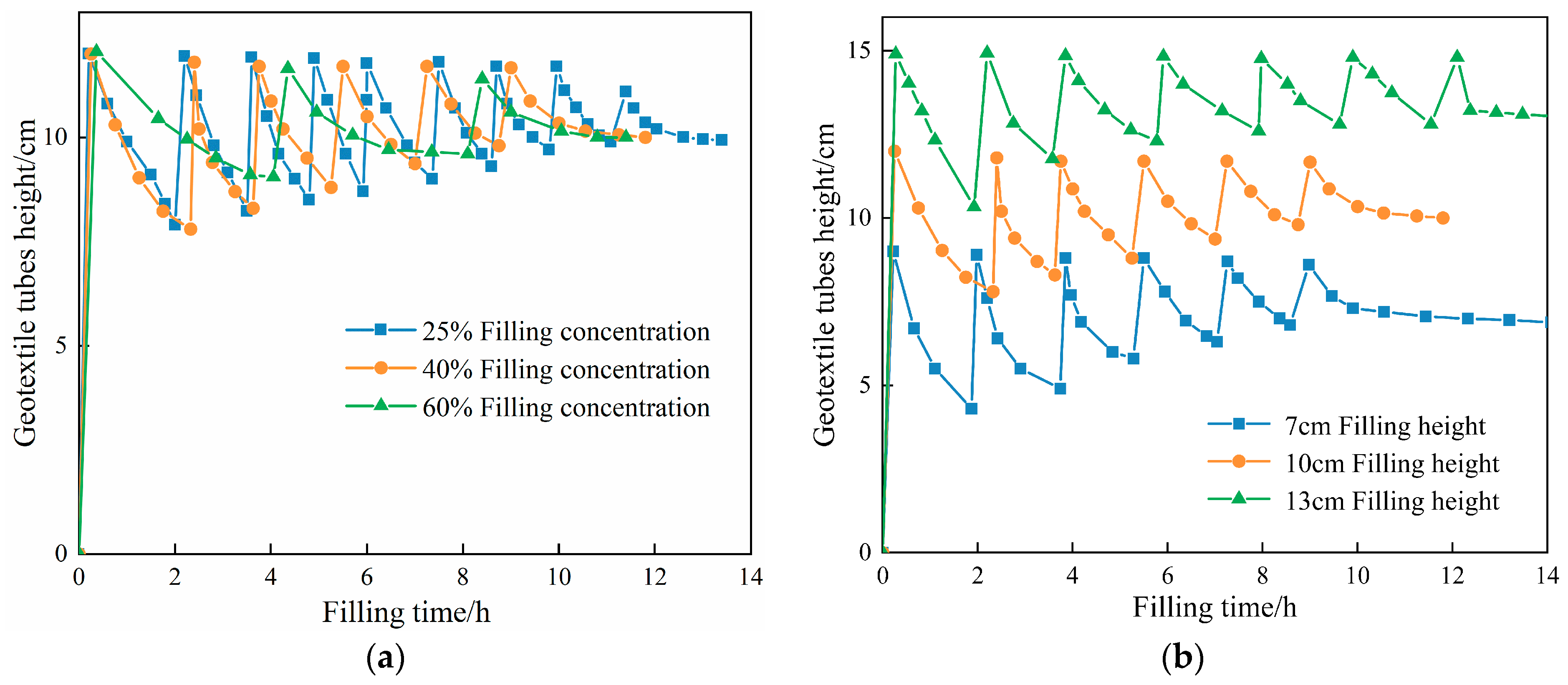

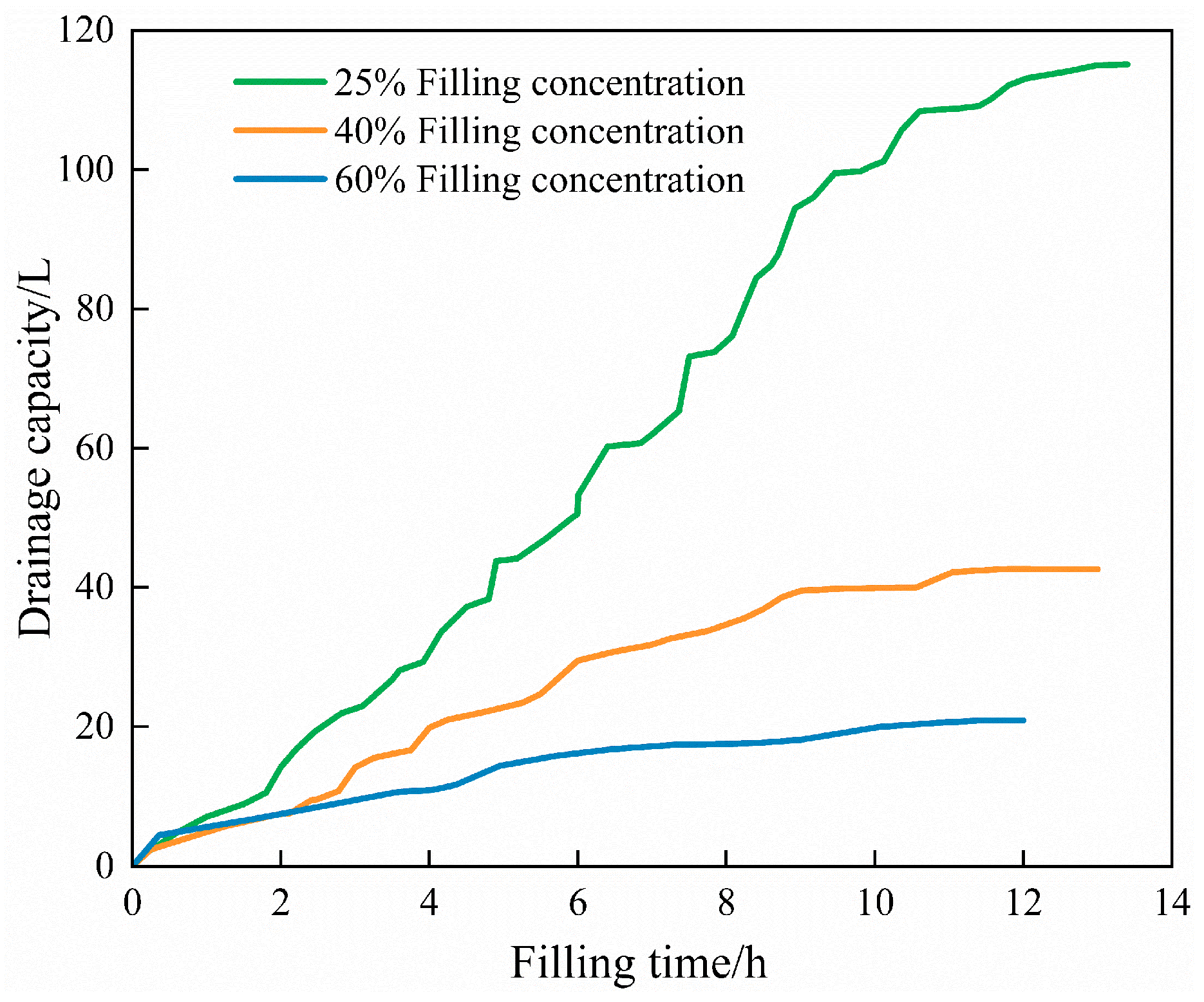

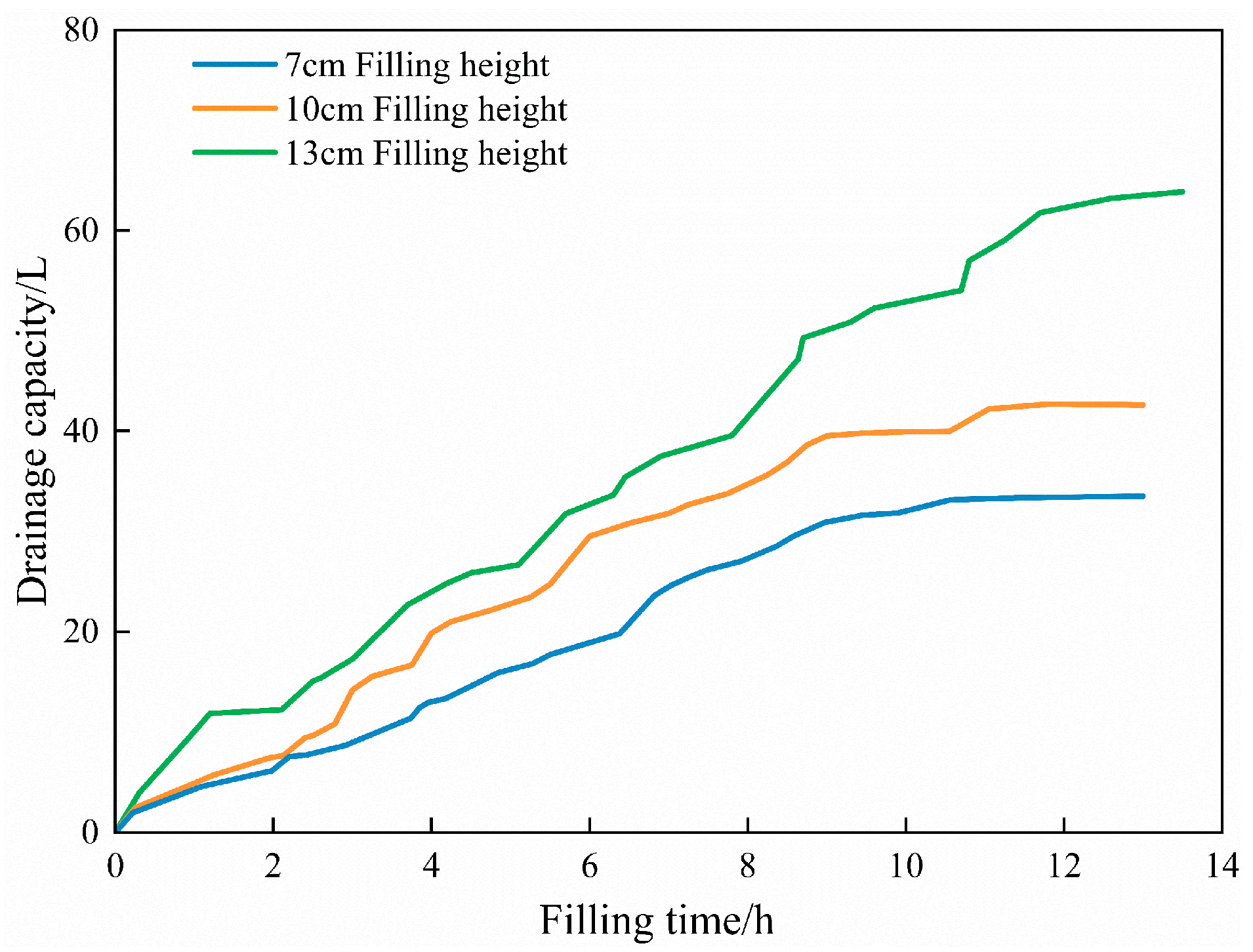

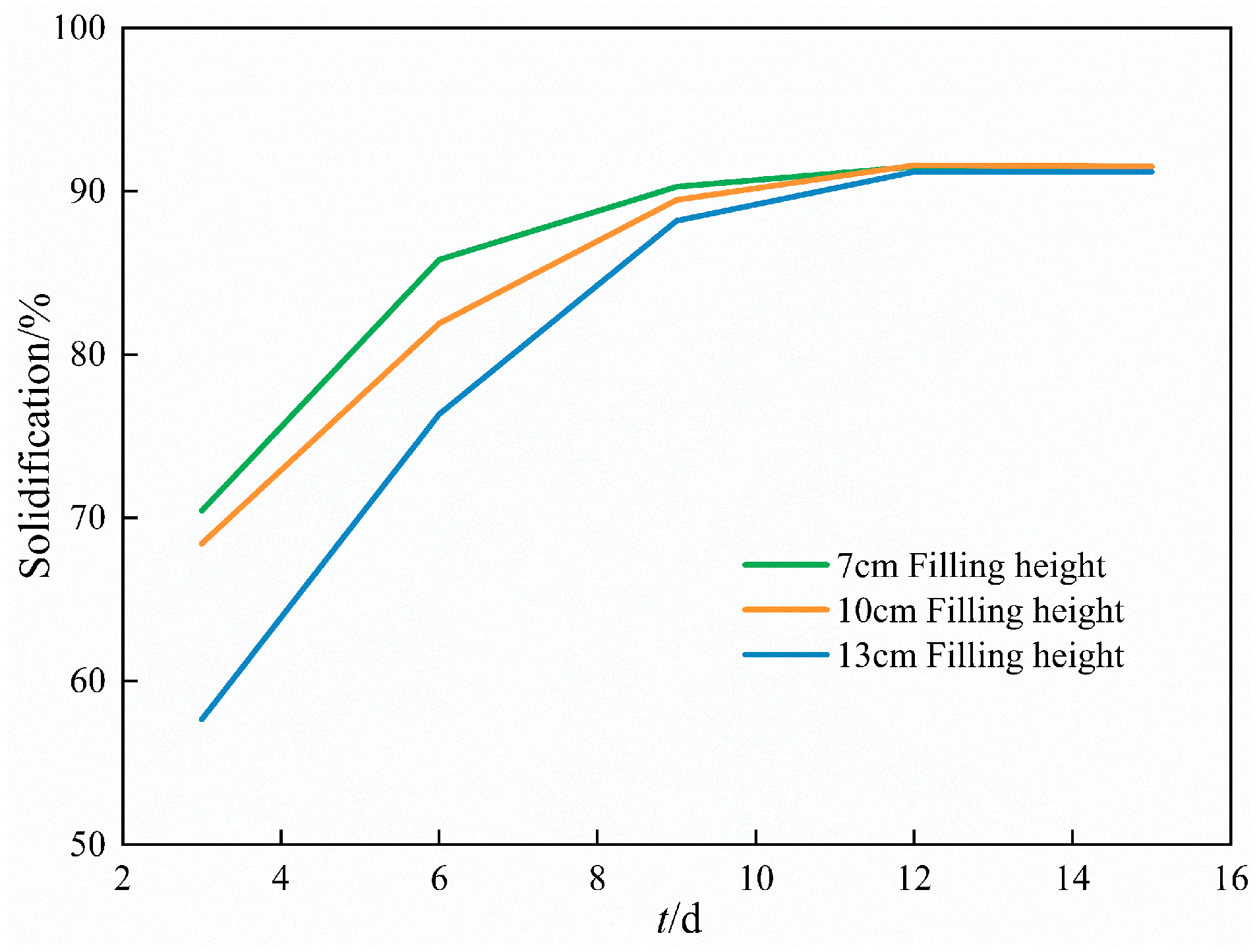

3. Analysis of the Results of the Geotextile Tube-Filling Stage

4. Analysis of the Results of the Geotextile Tubes Consolidation Phase

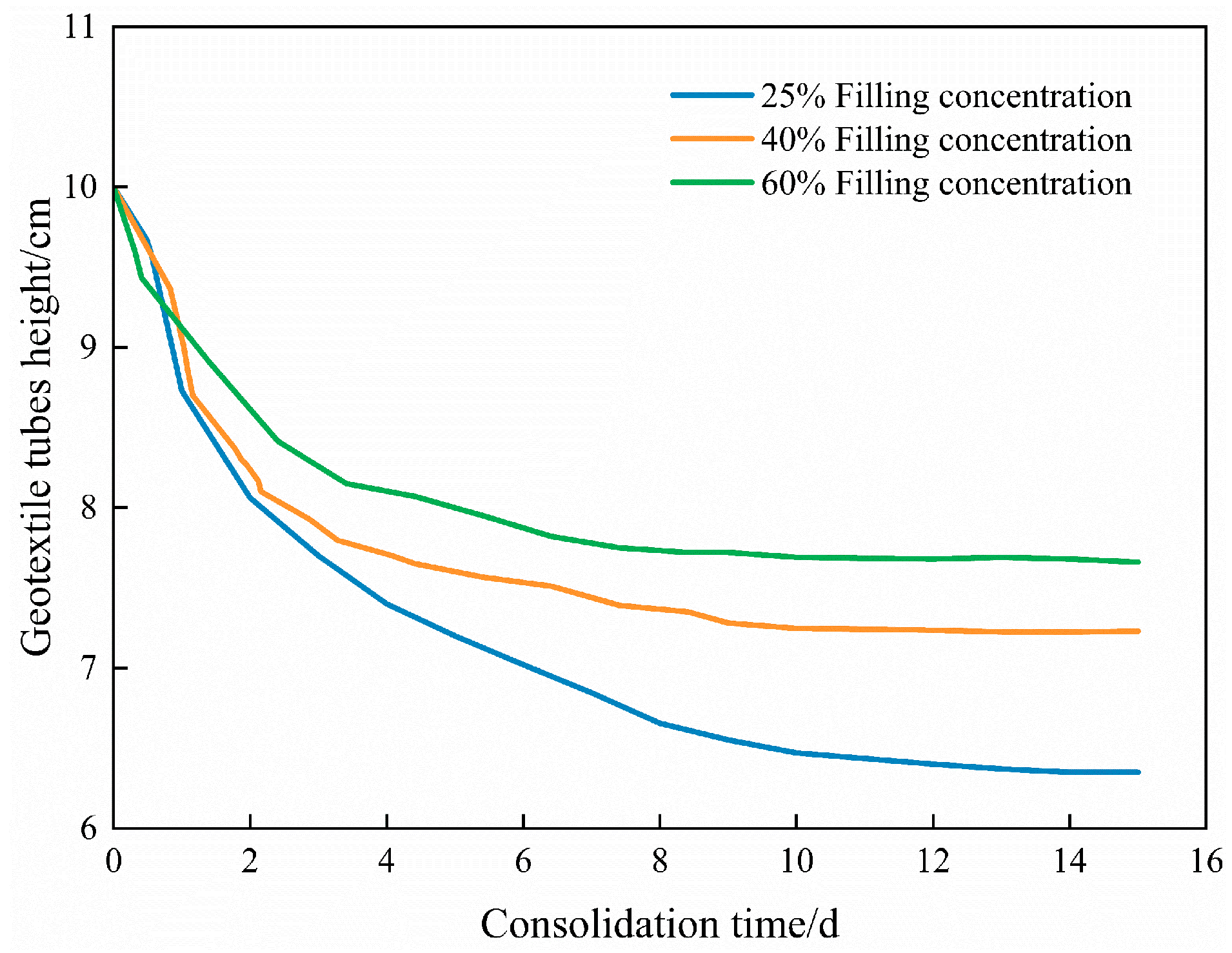

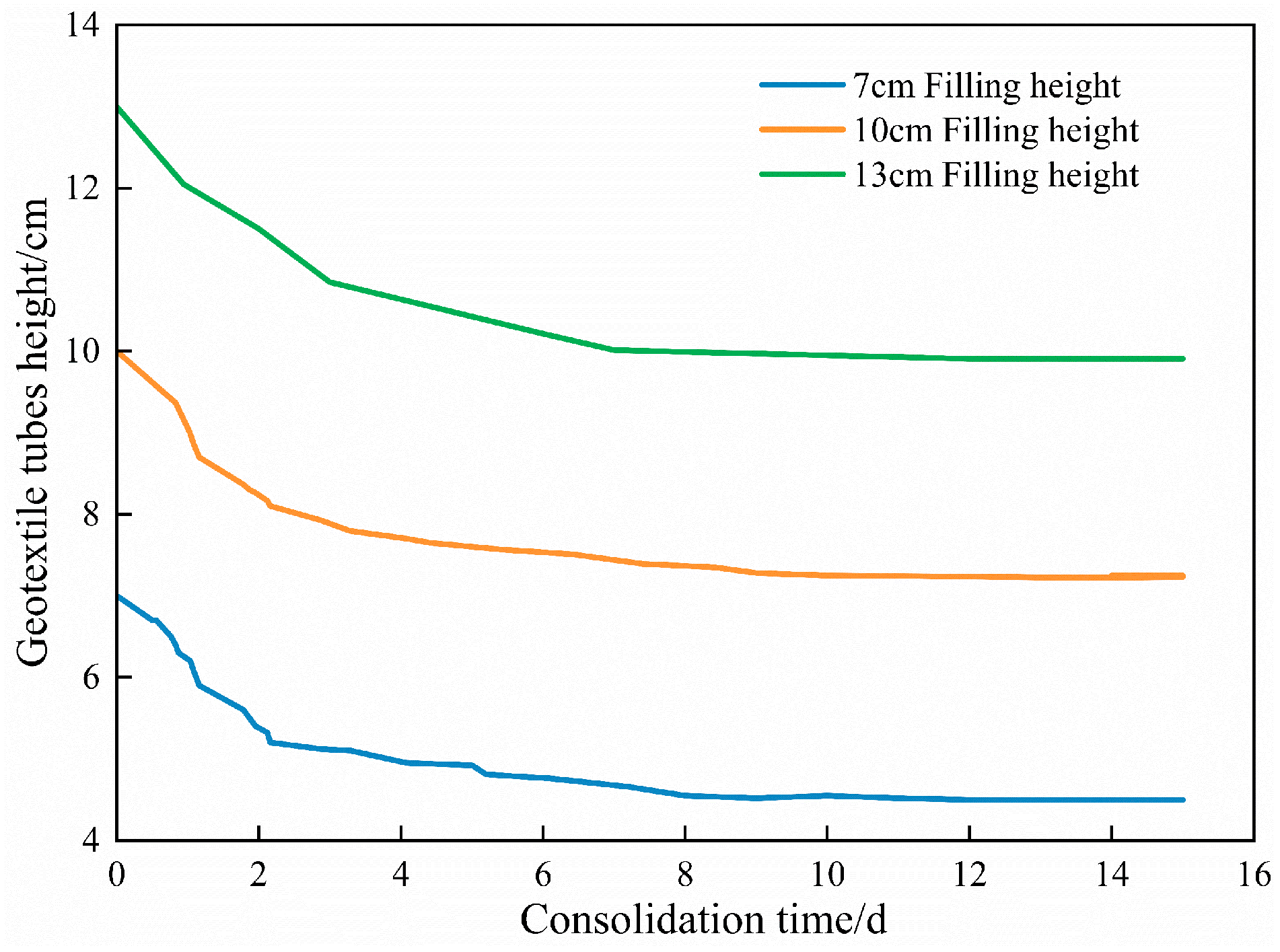

4.1. Analysis of Geotextile Tubes Consolidation Settlement

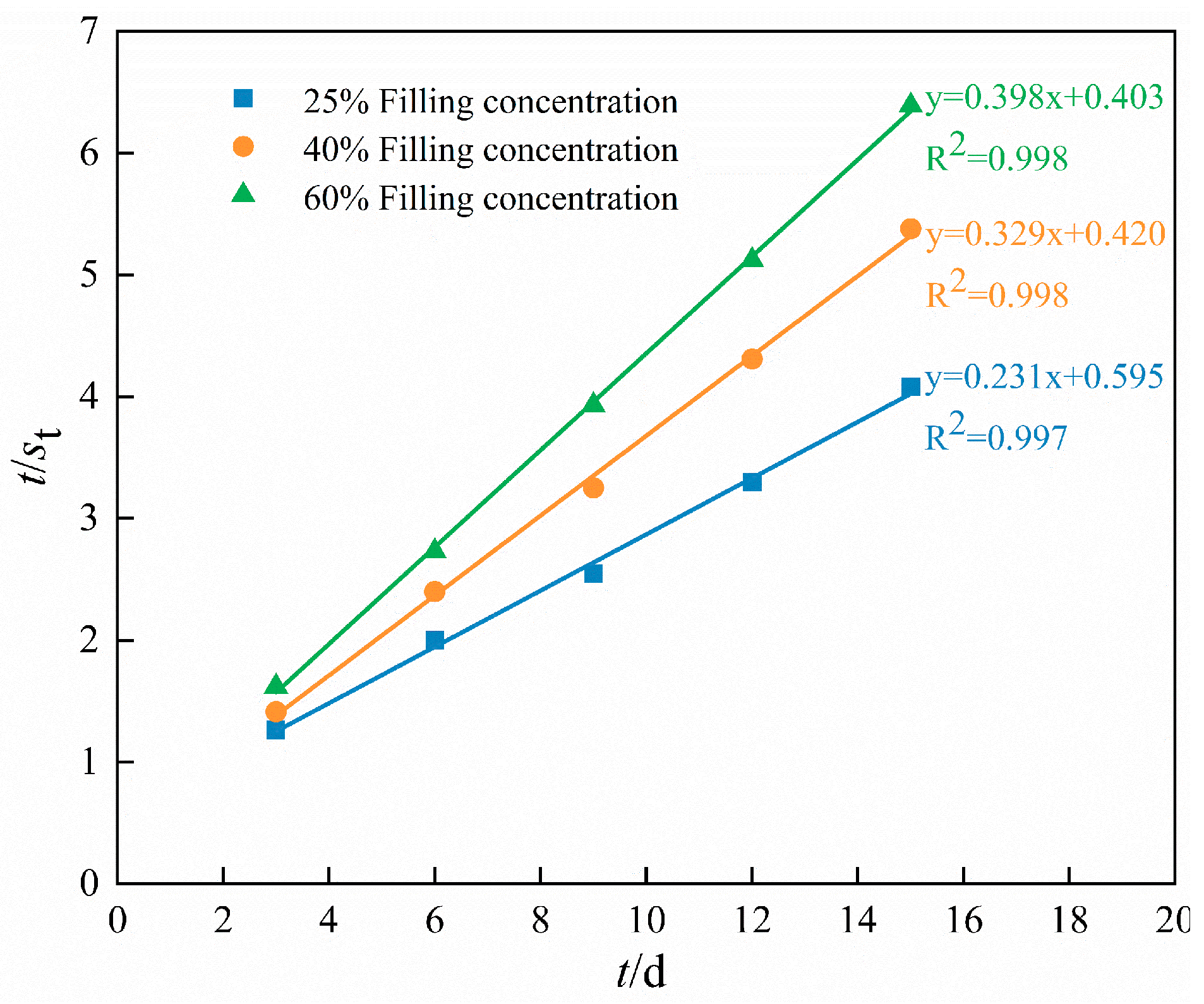

4.2. Hyperbolic Analysis of Geotextile Tubes Consolidation Settlement

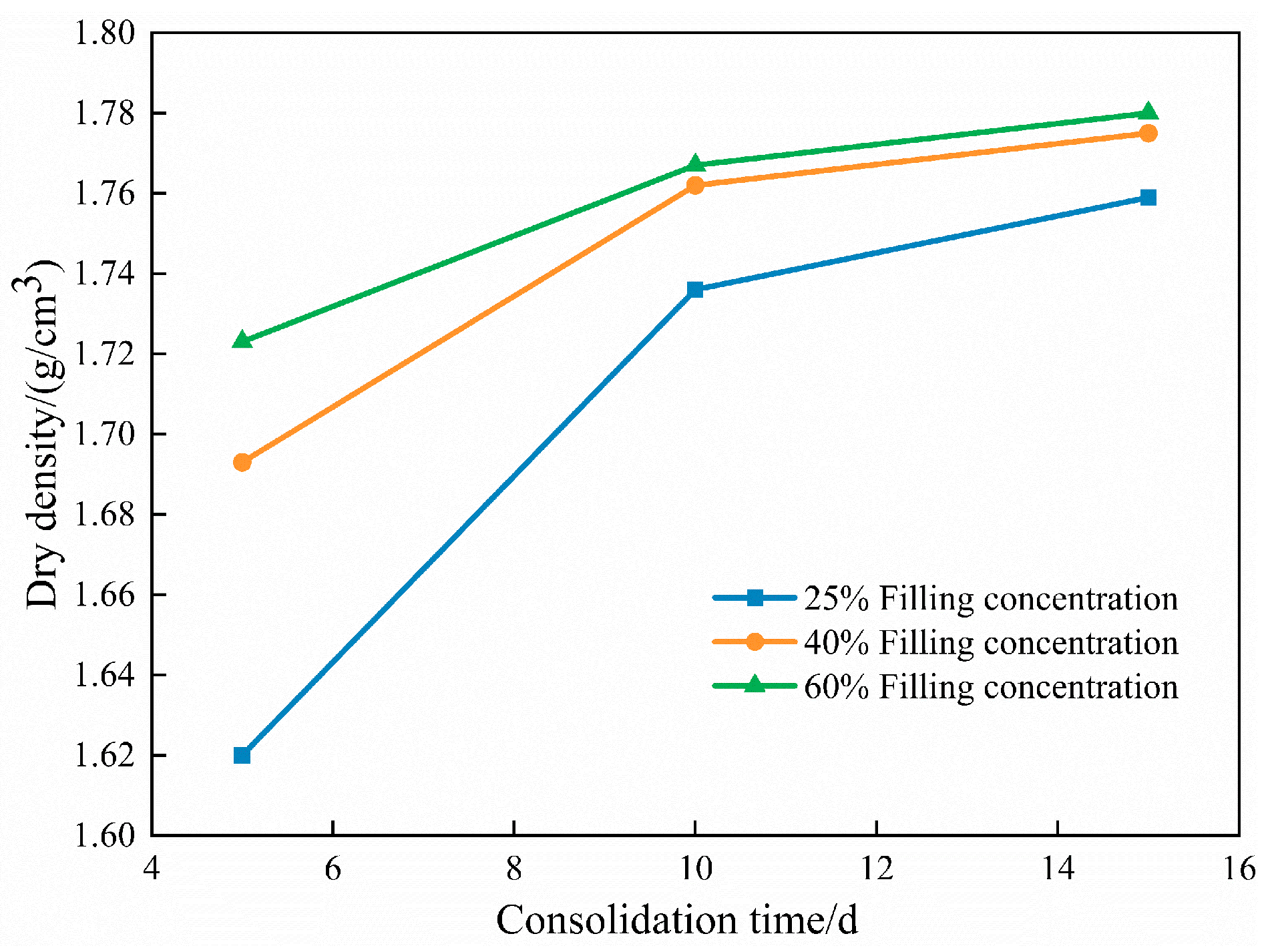

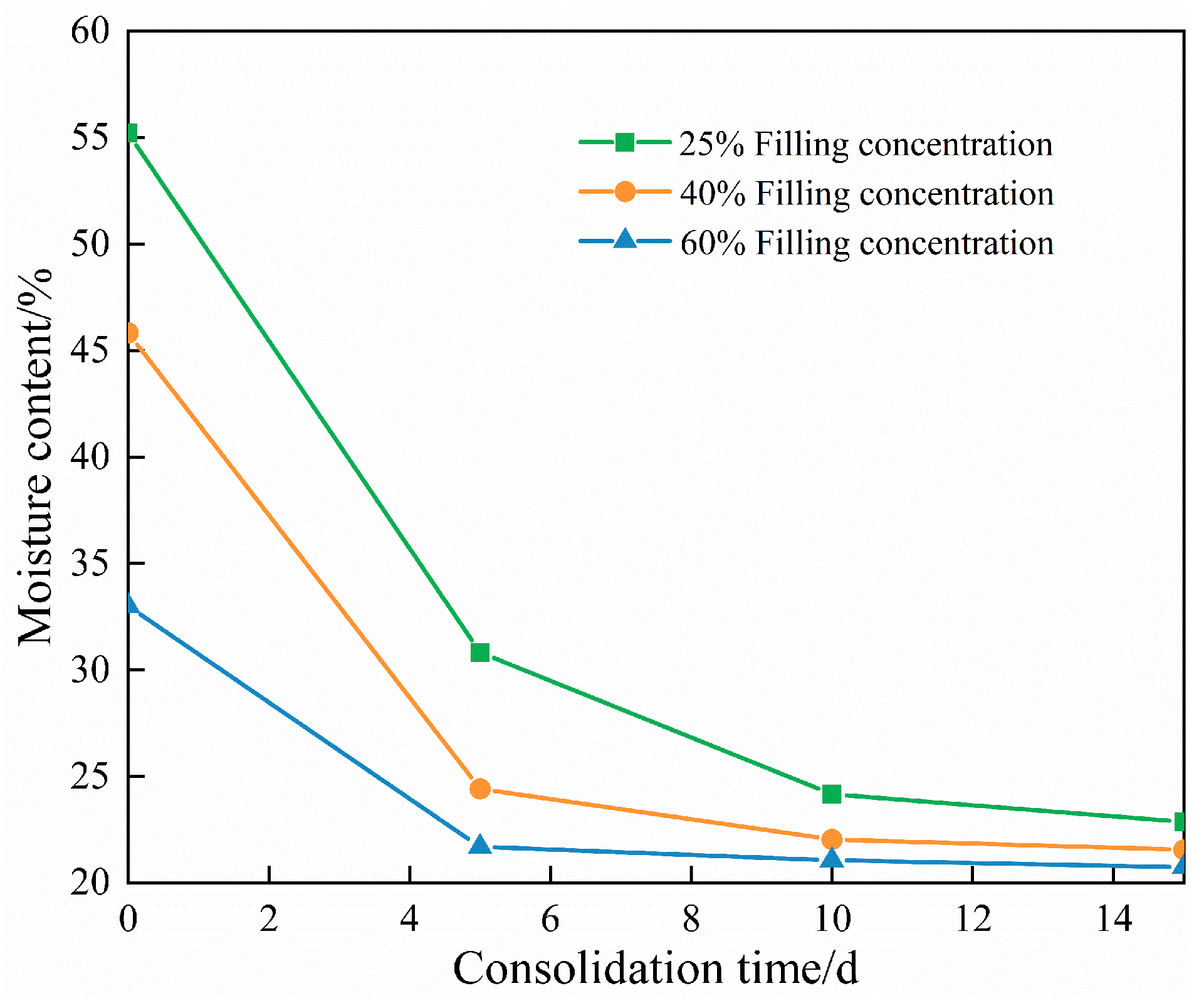

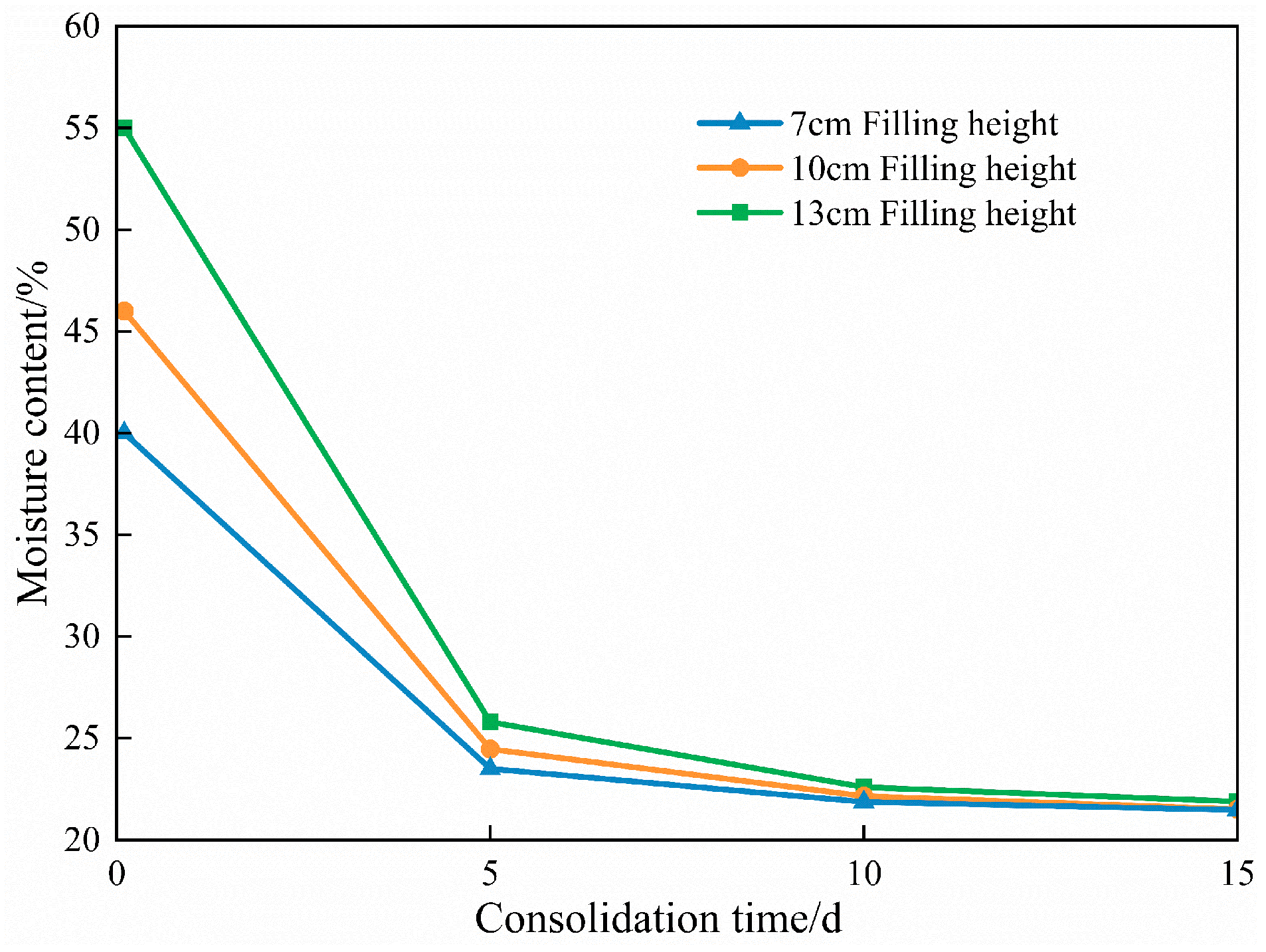

4.3. Analysis of Physical Properties of Geotextile Tube Consolidation

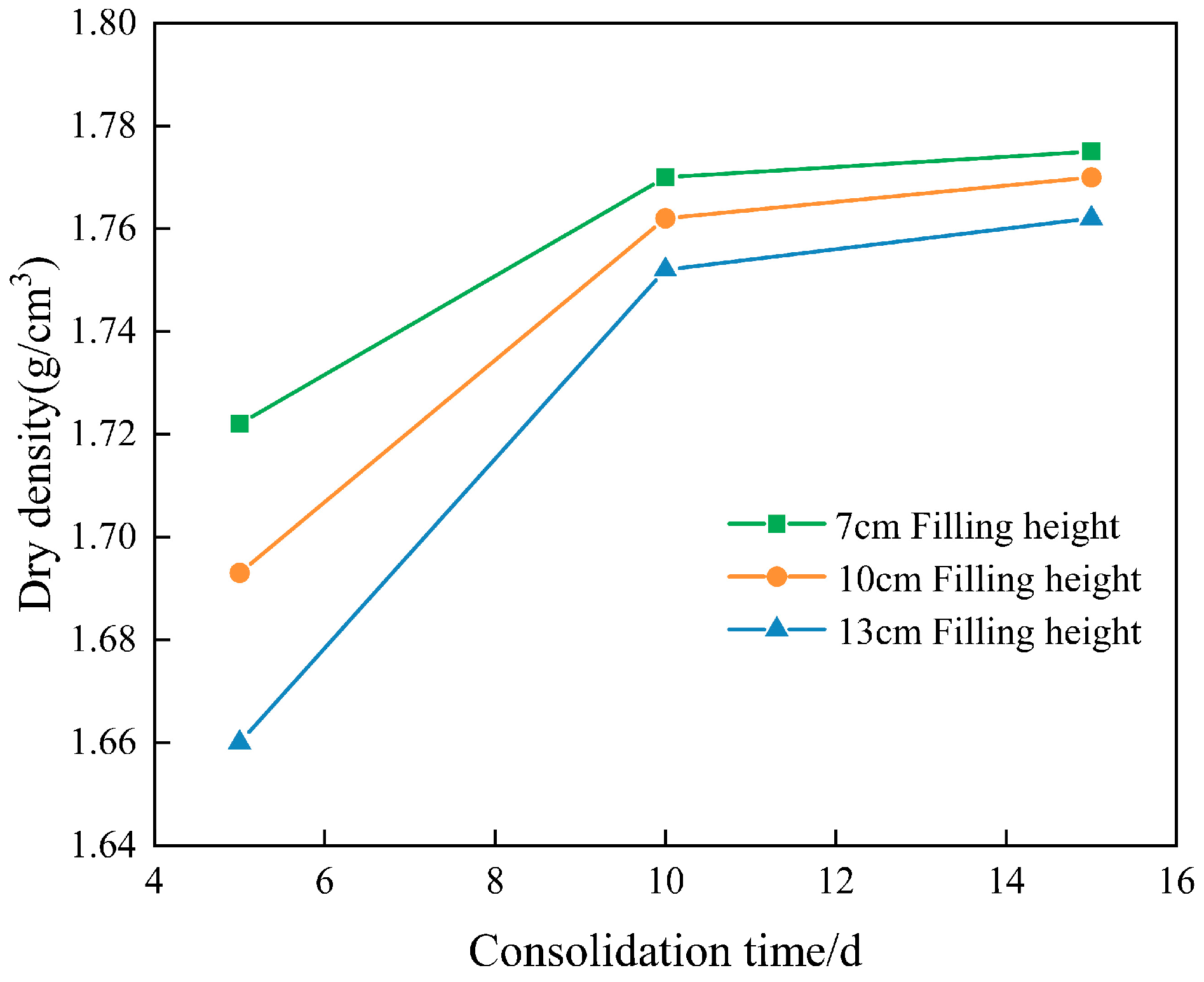

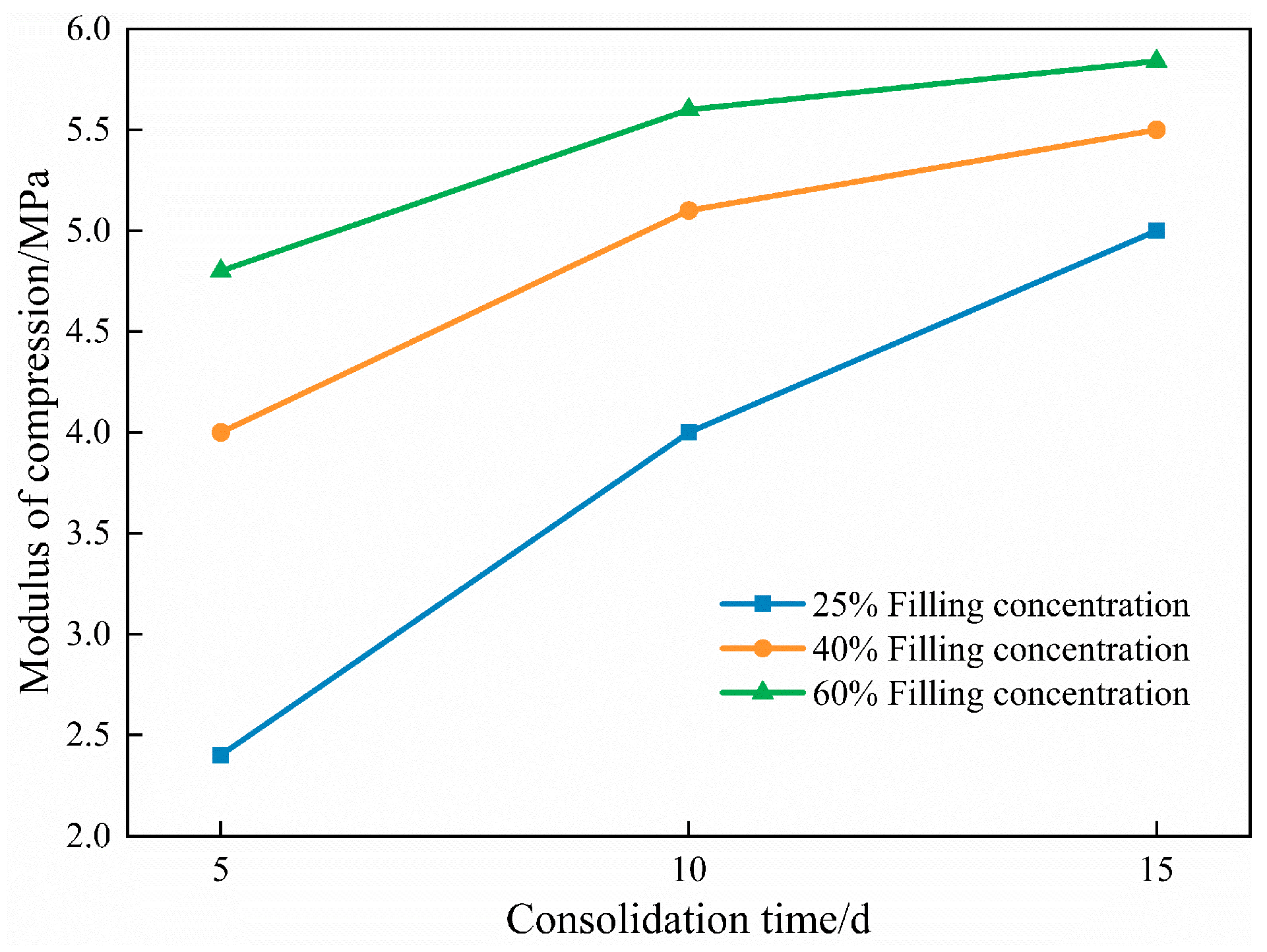

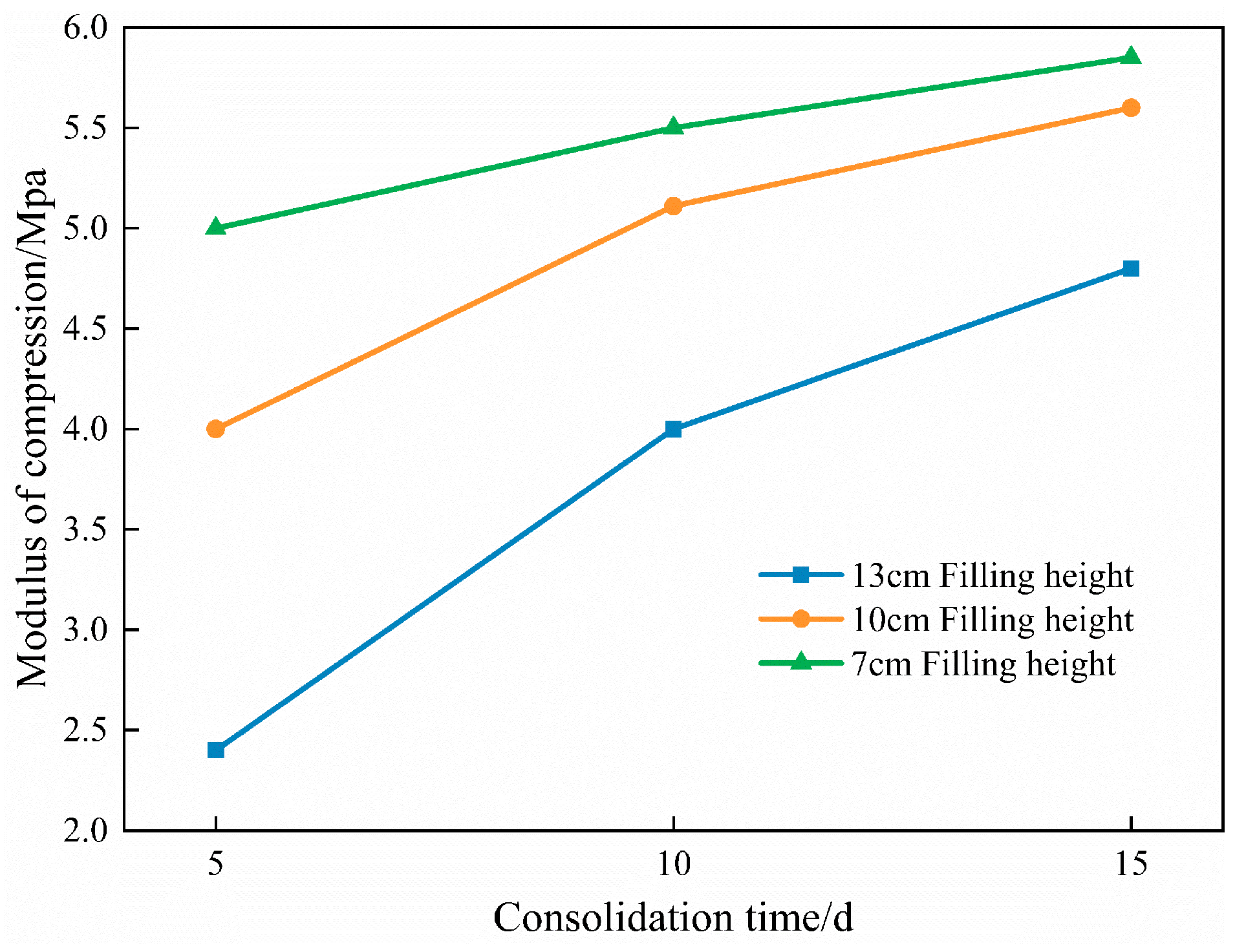

4.4. Analysis of Mechanical Properties of Geotextile Tube Consolidation

5. Discussion

6. Conclusions

- (1)

- In terms of filling efficiency, the filling efficiency at a 25% concentration is relatively poor, whereas at a 60% concentration, the efficiency is relatively high. The impact of filling height on the filling efficiency of the geotextile tube is minimal.

- (2)

- Concerning settlement during consolidation, higher filling concentrations result in faster stabilization during the consolidation phase. After 15 days of consolidation, the settlement of the geotextile tube decreases significantly with an increasing filling concentration. Although settlement increases with a greater filling height, the time required to reach a relatively stable consolidation stage is approximately 12 days across the different heights.

- (3)

- Regarding settlement prediction, by plotting the relationship between ttt and t/stt/s_tt/st for different filling concentrations and heights, it was determined that the hyperbolic method effectively reflects settlement changes over the consolidation time. The final settlement of the geotextile tube under various conditions can be predicted using the hyperbolic formula, which, in turn, provides insights into the degree of the consolidation of the tube over time.

- (4)

- In terms of physical and mechanical properties, the study of the physical and mechanical properties of the tailings within the tubes at different consolidation times shows that, with an increasing consolidation time and filling concentration, the dry density, internal friction angle, cohesion, and compression modulus of the tailings all increase. Conversely, for a given consolidation time, as the filling height of the geotextile tube increases, the consolidation effect worsens, resulting in a decreased dry density, cohesion, internal friction angle, and compression modulus, thereby reducing the deformation resistance of the tailings within the tube.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Wang, C.; Harbottle, D.; Liu, Q.X.; Xu, Z.H. Current state of fine mineral tailings treatment: A critical review on theory and practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Azizli, K.M.; Tan Chee, Y.; Birrel, J. Design of the Lohan Tailings Dam, Mamut Copper Mining Sdn. Bhd., Malaysia. Miner. Eng. 1995, 8, 705–712. [Google Scholar] [CrossRef]

- Salam, S.; Xiao, M.; Khosravifar, A.; Ziotopoulou, K. Seismic stability of coal tailings dams with spatially variable and liquefiable coal tailings using pore pressure plasticity models. Comput. Geotech. 2021, 132, 104017. [Google Scholar] [CrossRef]

- He, Y.; Chen, Q.S.; Qi, C.C.; Zhang, Q.L.; Xiao, C.C. Lithium slag and fly ash-based binder for cemented fine tailings backfill. J. Environ. Manag. 2019, 248, 109282. [Google Scholar] [CrossRef] [PubMed]

- Motta, F.L.; Gaikwad, R.; Botha, L.; Soares, J.B.P. Quantifying the effect of polyacrylamide dosage, Na+ and Ca2+ concentrations, and clay particle size on the flocculation of mature fine tailings with robust statistical methods. Chemosphere 2018, 208, 263–272. [Google Scholar] [CrossRef]

- Wu, S.; Yang, C.; Zhang, C.; Mao, H.; Du, Y.; Zhang, X. Particle size distribution of fine-grained tailings based on Weibull distribution. J. Chongqing Univ. 2016, 39, 1–12. [Google Scholar]

- Yin, G.; Zhang, D.; Wei, Z.; Wan, L.; Huang, G. Testing study on interaction characteristics between fine grained tailings and geosynthetics. Chin. J. Rock Mech. Eng. 2004, 23, 426–429. [Google Scholar]

- Chu, J.; Yan, S.W.; Li, W. Innovative methods for dike construction—An overview. Geotext. Geomembr. 2012, 30, 35–42. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, Z.; Cao, G.; Yang, Y.; Wang, H.; Zhuang, S.; Lu, T. A case study on utilizing geotextile tubes for tailings dams construction in China. Geotext. Geomembr. 2019, 47, 187–192. [Google Scholar] [CrossRef]

- Li, Q.Y.; Ma, G.W.; Li, P.; Su, Z.D. Dynamic characteristics of tailings dam with geotextile tubes under seismic load. Rev. Adv. Mater. Sci. 2021, 60, 599–614. [Google Scholar] [CrossRef]

- Fatema, N.; Bhatia, S.K. Sediment Retention and Clogging of Geotextile with High Water Content Slurries. Int. J. Geosynth. Ground Eng. 2018, 4, 13. [Google Scholar] [CrossRef]

- Moo-Young, H.K.; Tucker, W.R. Evaluation of vacuum filtration testing for geotextile tubes. Geotext. Geomembr. 2002, 20, 191–212. [Google Scholar] [CrossRef]

- Chow, R.W. Dewatering fine-grained soils using geotextile tubes—An Australian case study. In Proceedings of the 8th International Conference on Geosynthetics (8ICG), Yokohama, Japan, 18–22 September 2006; pp. 511–514. [Google Scholar]

- Kutay, M.E.; Aydilek, A.H. Retention performance of geotextile containers confining geomaterials. Geosynth. Int. 2004, 11, 100–113. [Google Scholar] [CrossRef]

- Zhu, Y.S. Geopipe bags and their application prospects. China Text. Lead. 2005, 12, 75–76+78+92. [Google Scholar] [CrossRef]

- Ratnayesuraj, C.R.; Bhatia, S.K. Testing and analytical modeling of two-dimensional geotextile tube dewatering process. Geosynth. Int. 2018, 25, 132–149. [Google Scholar] [CrossRef]

- Guo, W.; Chu, J.; Zhou, B. Model tests on methods to improve dewatering efficiency for sludge-inflated geotextile tubes. Geosynth. Int. 2015, 22, 380–392. [Google Scholar] [CrossRef]

- Lawson, C.R. Geotextile containment for hydraulic and environmental engineering. In Proceedings of the 8th International Conference on Geosynthetics (8ICG), Yokohama, Japan, 18–22 September 2006; pp. 7–48. [Google Scholar]

- Middleton, G.V. The Tukey Chi-Square Test. J. Geol. 1965, 73, 547–549. [Google Scholar] [CrossRef]

- Shu, Y. Technical progress of geotextile tubes dam engineering in China. Adv. Sci. Technol. Water Resour. 2018, 38, 1–11+18. [Google Scholar]

- Alvarez, I.E.; Rubio, R.; Ricalde, H. Beach restoration with geotextile tubes as submerged breakwaters in Yucatan, Mexico. Geotext. Geomembr. 2007, 25, 233–241. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, J.; Zhu, X.; Zhang, B.; Gao, M. Key technology research and application of cofferdam construction in large-area reclamation project. Port Waterw. Eng. 2013, 5, 168–175. [Google Scholar] [CrossRef]

- Yan, S.W.; Chu, J. Construction of an offshore dike using slurry filled geotextile mats. Geotext. Geomembr. 2010, 28, 422–433. [Google Scholar] [CrossRef]

- Kim, H.; Kim, H. Consolidation Analysis of Geotextile Tubes Filled with Highly Compressible Sludge Using Variable Coefficients of Consolidation. J. Korean Geoenviron. Soc. 2021, 22, 25–32. [Google Scholar]

- Liu, W.; Zhang, Y.; Yang, G. Model experimental study of filling property of geotextile tube. Chin. J. Rock Mech. Eng. 2013, 32, 2544–2549. [Google Scholar]

- Koerner, G.R.; Koerner, R.M. Geotextile tube assessment using a hanging bag test. Geotext. Geomembr. 2006, 24, 129–137. [Google Scholar] [CrossRef]

- Cui, X.; Zhou, H.; Qie, Y.; Wu, P. Experimental Study on the Characteristics of Geofabriform Filling Body with Fine Tailings. Nonferrous Met. (Miner. Process. Sect.) 2016, 198, 60–64. [Google Scholar]

- Han, Y.; Cui, X.; Qie, Y. Industrial test of damming using different kinds of geofabriform filled with grade tailings. Nonferrous Met. (Min. Sect.) 2019, 71, 41–46. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, T.W.; Dinoy, P.R.; Kim, H.S.; Kim, H.J. Design and consolidation analysis of geotextile tubes for the Saemangeum project in Korea. Geosynth. Int. 2018, 25, 507–524. [Google Scholar] [CrossRef]

- Kim, H.J.; Dinoy, P.R. Two-dimensional consolidation analysis of geotextile tubes filled with fine-grained material. Geotext. Geomembr. 2021, 49, 1149–1164. [Google Scholar] [CrossRef]

- Kim, H.J.; Won, M.S.; Jamin, J.C.; Joo, J.H. Numerical and field test verifications for the deformation behavior of geotextile tubes considering 1D and areal strain. Geotext. Geomembr. 2016, 44, 209–218. [Google Scholar] [CrossRef]

- Leshchinsky, D.; Leshchinsky, O.; Ling, H.I.; Gilbert, P.A. Geosynthetic tubes for confining pressurized slurry: Some design aspects. J. Geotech. Eng. 1996, 122, 682–690. [Google Scholar] [CrossRef]

- Muthukumaran, A.E.; Ilamparuthi, K. Laboratory studies on geotextile filters as used in geotextile tube dewatering. Geotext. Geomembr. 2006, 24, 210–219. [Google Scholar] [CrossRef]

- Yee, T.W.; Lawson, C.R. Modelling the geotextile tube dewatering process. Geosynth. Int. 2012, 19, 339–353. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.J.; Liu, S.J.; Chu, J.; Sun, H.L.; Geng, X.Y.; Cai, Y.Q. Consolidation of Sludge Dewatered in Geotextile Tubes under Combined Fill and Vacuum Preloading. J. Geotech. Geoenviron. Eng. 2022, 148, 17. [Google Scholar] [CrossRef]

- Zhang, H.; Geng, X.Y.; Sun, H.L.; Deng, Y.F.; Liu, S.J.; Cai, Y.Q. Consolidation theory of slurry dewatered by permeable geotextile tube with distributed prefabricated drains. Can. Geotech. J. 2023, 60, 213–229. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, H.-l.; Liu, S.-j.; Chu, J.; Shi, L.; Geng, X.-y.; Deng, Y.-f.; Cai, Y.-q. Large-Strain Consolidation of Sludge in Multiple-Drainage Geotextile Tubes. J. Geotech. Geoenviron. Eng. 2023, 149, 04023037. [Google Scholar] [CrossRef]

- Cao, B.; Tian, Y.; Gui, R.; Liu, Y. Experimental Study on the Effect of Key Factors on the Soil–Water Characteristic Curves of Fine-Grained Tailings. Front. Environ. Sci. 2021, 9, 710986. [Google Scholar] [CrossRef]

- Fu, S.; Liu, X.; Liu, X.; Chen, M.; Deng, Z. An experimental study of the mechanical properties of tailings filling mold bag. Hydrogeol. Eng. Geol. 2018, 45, 83–88. [Google Scholar]

- Zhou, H. Study on the Stability of Tailings Dam Based on the Geotextile Tubes Method. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2017. [Google Scholar]

- Haeri, S.M.; Noorzad, R.; Oskoorouchi, A.M. Effect of geotextile reinforcement on the mechanical behavior of sand. Geotext. Geomembr. 2000, 18, 385–402. [Google Scholar] [CrossRef]

- Tan, T.S.; Inoue, T.; Lee, S.L. Hyperbolic method for consolidation analysis. J. Geotech. Eng. 1991, 117, 1723–1737. [Google Scholar] [CrossRef]

- Arulrajah, A.; Nikraz, H.; Bo, M.W. Factors affecting field instrumentation assessment of marine clay treated with prefabricated vertical drains. Geotext. Geomembr. 2004, 22, 415–437. [Google Scholar] [CrossRef]

- Han, Y. Experimental Study on Filling Characteristics of Geofabriform with Fine Tailings of Different Concentration and Particle Size Distribution. Mod. Min. 2019, 35, 127–130+137. [Google Scholar]

| Unit Thicknesses/mm | Mass per Unit Area/(g/m2) | Tensile Strength/(kN/m) | Elongation/% | Tearing Force/N | Vertical Permeability Coefficient/(cm/s) | Equivalent Pore Size O95/mm | ||

|---|---|---|---|---|---|---|---|---|

| Warp | Woof | Warp | Woof | |||||

| 0.5 | 180 | 35.2 | 25.1 | 20 | 21 | 291 | 1.1 × 10−3 | 0.105 |

| Serial Number | Geotextile Tube Number | Concentration of Filling and Irrigation/% | Filling Height/cm | Consolidation Time/d |

|---|---|---|---|---|

| 1 | 1~3 | 25 | 10 | 5, 10, 15 |

| 2 | 4~6 | 60 | 10 | 5, 10, 15 |

| 3 | 7~9 | 40 | 10 | 5, 10, 15 |

| 4 | 10~12 | 40 | 7 | 5, 10, 15 |

| 5 | 13~15 | 40 | 13 | 5, 10, 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wu, Z.; He, H.; Xu, Q. An Experimental Study Focusing on the Filling Process and Consolidation Characteristics of Geotextile Tubes Filled with Fine-Grained Tungsten Tailings. Sustainability 2024, 16, 5270. https://doi.org/10.3390/su16125270

Liu X, Wu Z, He H, Xu Q. An Experimental Study Focusing on the Filling Process and Consolidation Characteristics of Geotextile Tubes Filled with Fine-Grained Tungsten Tailings. Sustainability. 2024; 16(12):5270. https://doi.org/10.3390/su16125270

Chicago/Turabian StyleLiu, Xiaowen, Zeming Wu, Haisong He, and Qing Xu. 2024. "An Experimental Study Focusing on the Filling Process and Consolidation Characteristics of Geotextile Tubes Filled with Fine-Grained Tungsten Tailings" Sustainability 16, no. 12: 5270. https://doi.org/10.3390/su16125270

APA StyleLiu, X., Wu, Z., He, H., & Xu, Q. (2024). An Experimental Study Focusing on the Filling Process and Consolidation Characteristics of Geotextile Tubes Filled with Fine-Grained Tungsten Tailings. Sustainability, 16(12), 5270. https://doi.org/10.3390/su16125270