Technosol Development Based on Residual Fraction of Coal Tailings Processing, Agro-Industrial Waste, and Paper Industry Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Waste Characterization

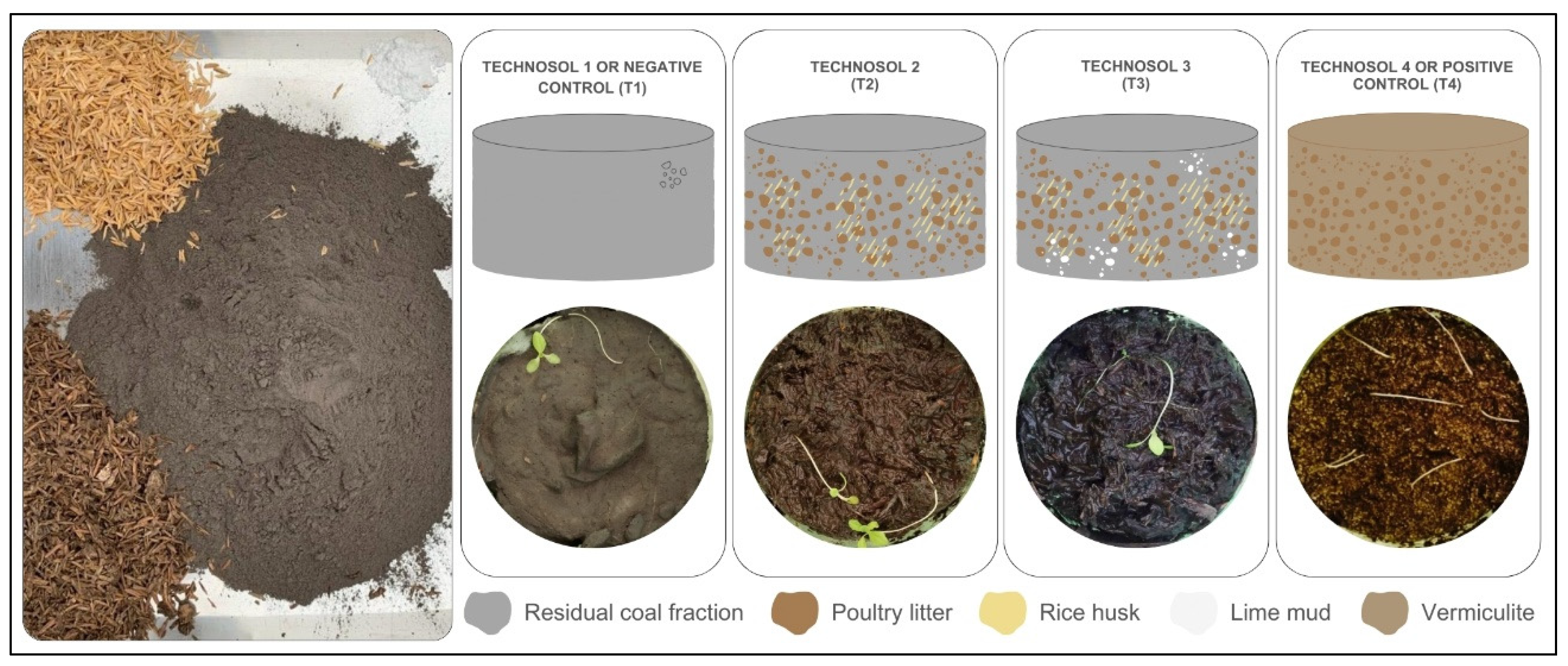

2.3. Technosols Formulations

2.4. Ecotoxicity Tests with Allium cepa L. as a Bioindicator

2.5. Germination and Growth Tests of Lactuca sativa L.

2.6. Chemical Fertility Analyses of Technosols

3. Results and Discussion

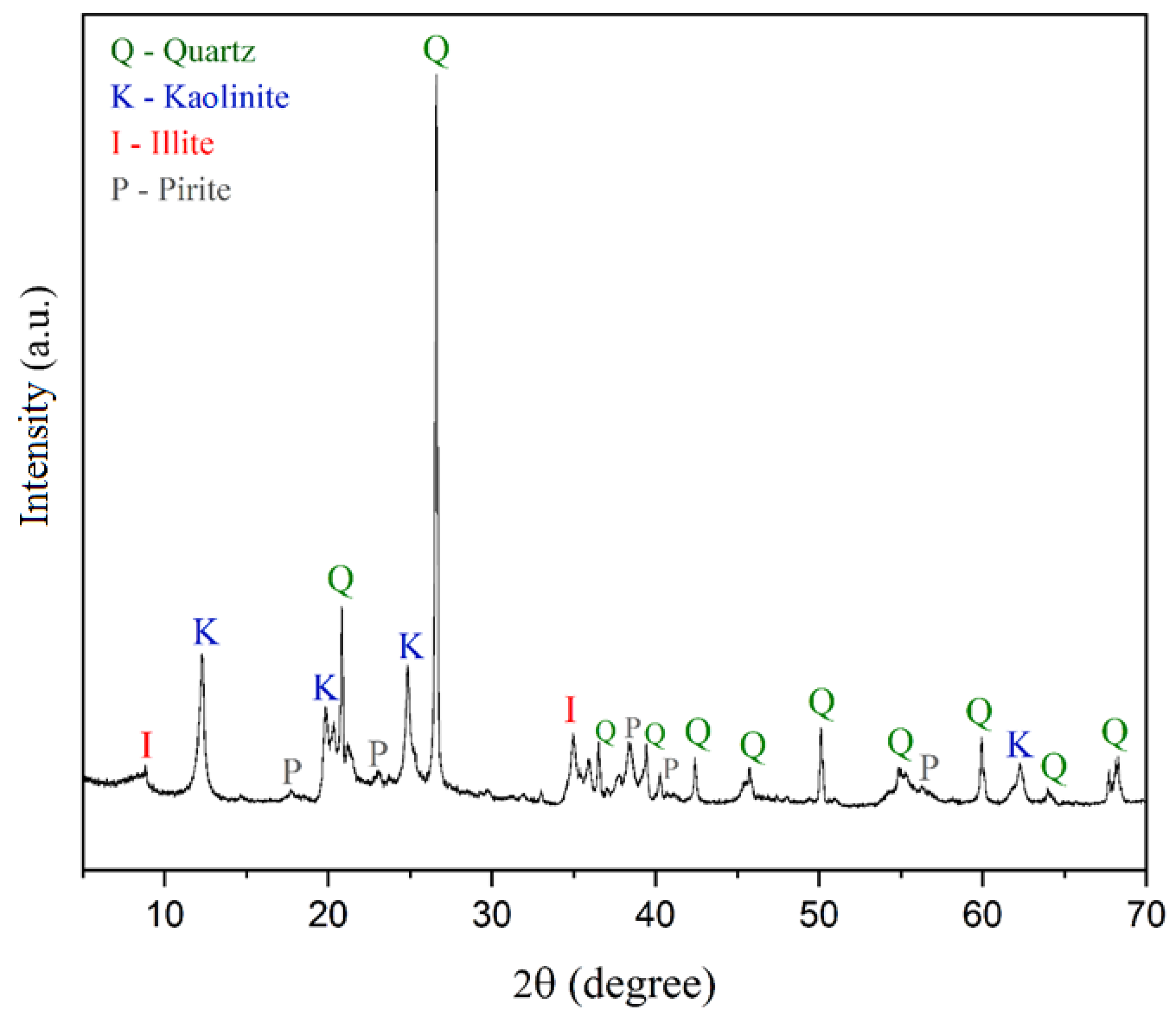

3.1. Waste Characterization

| Elements | Waste (mg dm−3) | Reference Values NBR 10004/2004 (mg dm−3) | SWM (mg dm−3) | |||

|---|---|---|---|---|---|---|

| RFC | PL | RH | LM | |||

| Aluminum (Al) | 1.3 | <0.1 | <0.1 | <0.1 | NA | 100–2000 |

| Barium (Ba) | 0.04 | 0.01 | <0.10 | <0.10 | 70 | 500 * |

| Boron (B) | <0.1 | 0.2 | <0.1 | <0.1 | NA | 0.2–5 |

| Calcium (Ca) | 14.1 | 16.1 | 0.75 | 501.1 | NA | 100–2000 |

| Copper (Cu) | <0.01 | 1.13 | <0.009 | <0.009 | NA | 0.1–3 |

| Iron (Fe) | 0.12 | 0.41 | <0.10 | <0.10 | NA | 50–1000 |

| Magnesium (Mg) | 4.455 | 22.245 | 0.49 | <0.10 | NA | 40–500 |

| Manganese (Mn) | <0.01 | 0.375 | <0.10 | <0.10 | NA | 5–500 |

| Molybdenum (Mo) | <0.01 | 0.03 | <0.01 | <0.01 | NA | 0.01–0.2 |

| Phosphorus (P) | <0.02 | 37.955 | 2.185 | <0.05 | NA | NA |

| Potassium (K) | 0.5 | 61.4 | 10.7 | 1.1 | NA | 50–500 |

| Silver (Ag) | <0.01 | <0.01 | <0.01 | 0.115 | 5 | NA |

| Selenium (Se) | <0.01 | <0.01 | <0.01 | 0.03 | 1 | 10 * |

| Sodium (Na) | 3.35 | 34.45 | 2.3 | 3.8 | NA | 20–200 |

| Vanadium (V) | <0.01 | 0.01 | <0.01 | <0.01 | NA | 100 * |

| Zinc (Zn) | <0.01 | 0.175 | <0.10 | <0.10 | NA | 1–40 * |

3.2. Ecotoxicity of Technosols

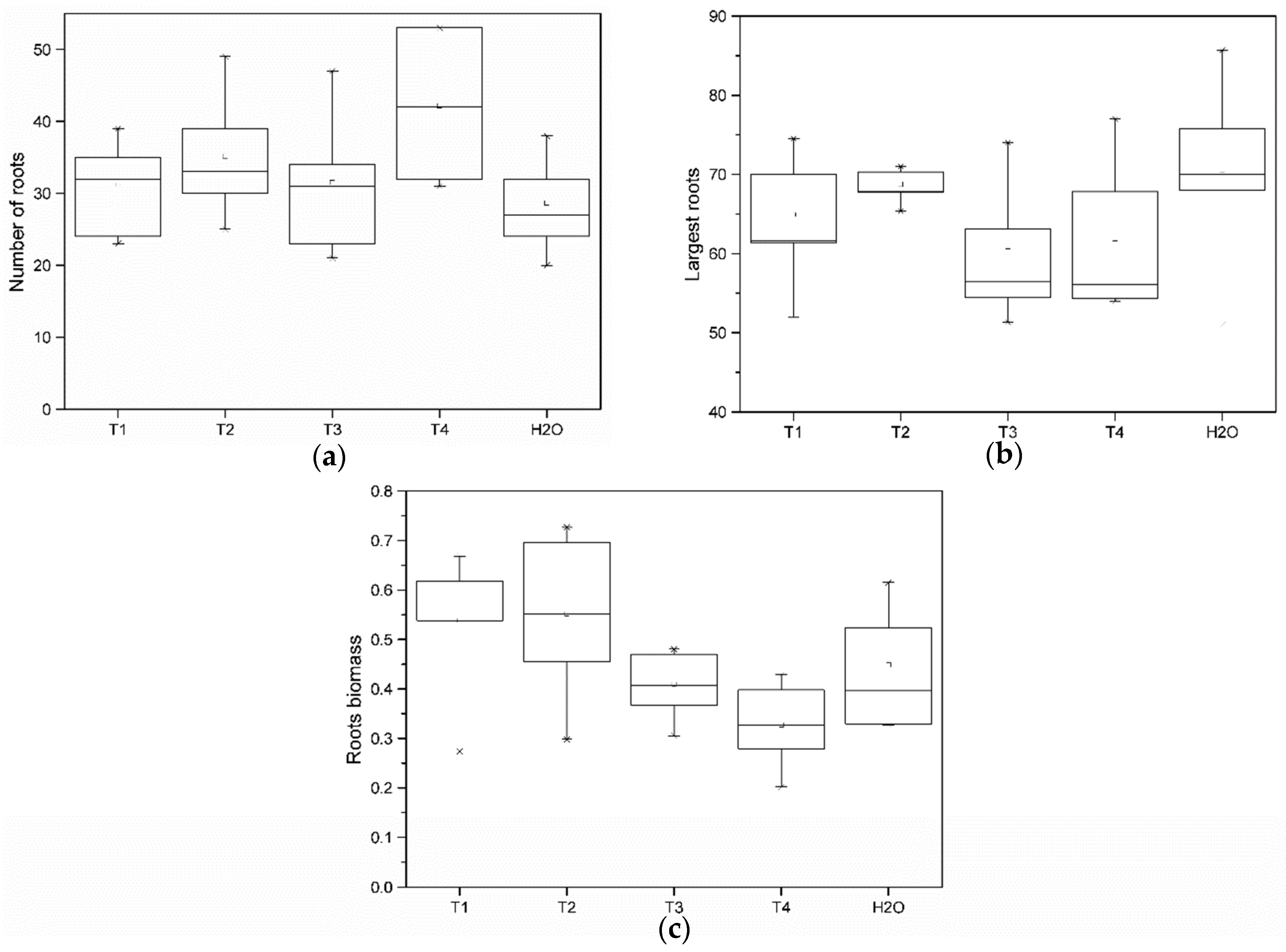

3.3. Germination and Growth of Lactuca sativa L.

3.4. Fertility of the Technosols

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalkreuth, W.; Holz, M.; Mexias, A.; Balbinot, M.; Levandowski, J.; Willett, J.; Finkelman, R.; Burger, H. Depositional Setting, Petrology and Chemistry of Permian Coals from the Paraná Basin: 2. South Santa Catarina Coalfield, Brazil. Int. J. Coal Geol. 2010, 84, 213–236. [Google Scholar] [CrossRef]

- Weiler, J.; Schneider, I.A.H. Pyrite Utilization in the Carboniferous Region of Santa Catarina, Brazil: Potentials, Challenges, and Environmental Advantages. REM Int. Eng. J. 2019, 72, 515–522. [Google Scholar] [CrossRef]

- Faraco, M.N.S. Valorização de Frações Residuais Geradas No Beneficiamento de Carvão Mineral Da Região Sul de Santa Catarina; Universidade Federal de Santa Catarina: Florianópolis, Brasil, 2022. [Google Scholar]

- Weiler, J.; do Amaral Filho, J.R.; Schneider, I.A.H. Processamento de Rejeito de Carvão Visando a Redução de Custos No Tratamento Da Drenagem Ácida de Minas—Estudo de Caso Na Região Carbonífera de Santa Catarina. Eng. Sanit. Ambient. 2016, 21, 337–345. [Google Scholar] [CrossRef][Green Version]

- Brasil Resolução No 2, de 18 de Junho de 2021. Define a Relação de Minerais Estratégicos Para o País, de Acordo Com Os Critérios de Que Trata o Art. 2o Do Decreto No 10.657, de 24 de Março de 2021. Diário Oficial da União 2021, Edição 115, Seção 1, p. 103. Available online: https://www.gov.br/mme/pt-br/assuntos/noticias/mme-lanca-relatorio-anual-do-comite-interministerial-de-analise-de-projetos-de-minerais-estrategicos/resolucao2CTAPME.pdf (accessed on 1 July 2024).

- Weiler, J.; Firpo, B.A.; Schneider, I.A.H. Coal Waste Derived Soil-like Substrate: An Opportunity for Coal Waste in a Sustainable Mineral Scenario. J. Clean. Prod. 2018, 174, 739–745. [Google Scholar] [CrossRef]

- Adami, L.; Schiavon, M. From Circular Economy to Circular Ecology: A Review on the Solution of Environmental Problems through Circular Waste Management Approaches. Sustainability 2021, 13, 925. [Google Scholar] [CrossRef]

- Rossiter, D.G. Classification of Urban and Industrial Soils in the World Reference Base for Soil Resources (5 Pp). J. Soils Sediments 2007, 7, 96–100. [Google Scholar] [CrossRef]

- Ruiz, F.; Perlatti, F.; Oliveira, D.P.; Ferreira, T.O. Revealing Tropical Technosols as an Alternative for Mine Reclamation and Waste Management. Minerals 2020, 10, 110. [Google Scholar] [CrossRef]

- Zocche, J.J.; Sehn, L.M.; Pillon, J.G.; Schneider, C.H.; Olivo, E.F.; Raupp-Pereira, F. Technosols in Coal Mining Areas: Viability of Combined Use of Agro-Industry Waste and Synthetic Gypsum in the Restoration of Areas Degraded. Clean. Eng. Technol. 2023, 13, 100618. [Google Scholar] [CrossRef]

- Scotti, R.; Bonanomi, G.; Scelza, R.; Zoina, A.; Rao, M. Organic Amendments as Sustainable Tool to Recovery Fertility in Intensive Agricultural Systems. J. Soil Sci. Plant Nutr. 2015, 15, 333–352. [Google Scholar] [CrossRef]

- Tejada, M.; Hernandez, M.T.; Garcia, C. Application of Two Organic Amendments on Soil Restoration: Effects on the Soil Biological Properties. J. Environ. Qual. 2006, 35, 1010–1017. [Google Scholar] [CrossRef]

- dos Santos, H.G.; Coelho, M.R.; Baca, J.F.M.; Áglio, M.L.D.; Fidalgo, E.C.C. Sistema Brasileiro de Classificação de Solos, 5th ed.; Embrapa: Rio de Janeiro, Brasil, 2018; Volume 5, ISBN 9788570358004. [Google Scholar]

- Gonçalves, J.O.; Fruto, C.M.; Barranco, M.J.; Oliveira, M.L.S.; Ramos, C.G. Recovery of Degraded Areas through Technosols and Mineral Nanoparticles: A Review. Sustainability 2022, 14, 993. [Google Scholar] [CrossRef]

- Kozłowski, M.; Otremba, K.; Pająk, M.; Pietrzykowski, M. Changes in Physical and Water Retention Properties of Technosols by Agricultural Reclamation with Wheat–Rapeseed Rotation in a Post-Mining Area of Central Poland. Sustainability 2023, 15, 7131. [Google Scholar] [CrossRef]

- Michaeli, E.; Solár, V.; Maxin, M.; Vilček, J.; Boltižiar, M. The Nature of the Technosols on the Waste from Nickel Production. Sustainability 2021, 13, 406. [Google Scholar] [CrossRef]

- Fabbri, D.; Pizzol, R.; Calza, P.; Malandrino, M.; Gaggero, E.; Padoan, E.; Ajmone-Marsan, F. Constructed Technosols: A Strategy toward a Circular Economy. Appl. Sci. 2021, 11, 3432. [Google Scholar] [CrossRef]

- Napoletano, P.; Colombo, C.; Di Iorio, E.; Memoli, V.; Panico, S.C.; Ruggiero, A.G.; Santorufo, L.; Maisto, G.; De Marco, A. Integrated Approach for Quality Assessment of Technosols in Experimental Mesocosms. Sustainability 2021, 13, 9101. [Google Scholar] [CrossRef]

- Ruiz, F.; Cherubin, M.R.; Ferreira, T.O. Soil Quality Assessment of Constructed Technosols: Towards the Validation of a Promising Strategy for Land Reclamation, Waste Management and the Recovery of Soil Functions. J. Environ. Manag. 2020, 276, 111344. [Google Scholar] [CrossRef]

- Santos, E.S.; Abreu, M.M.; Macías, F. Rehabilitation of Mining Areas through Integrated Biotechnological Approach: Technosols Derived from Organic/Inorganic Wastes and Autochthonous Plant Development. Chemosphere 2019, 224, 765–775. [Google Scholar] [CrossRef]

- ERDF Instrução Técnica de Resíduos ITR/01/08, de 8 de Janeiro de 2008 Referente à Elaboración de Solos (Tecnosolos) Derivados de Residuos. Available online: https://gaia.xunta.es/plataforma/ambilex/searchByCode?id=a01aef53-5fda-4a7a-a00d-8bbee54b9fea (accessed on 15 May 2024).

- Ávila, M.R.; Braccini, A.d.L.e.; Scapim, C.A.; Albrecht, L.P.; Tonin, T.A.; Stülp, M. Bioregulator Application, Agronomic Efficiency, and Quality of Soybean Seeds. Sci. Agric. 2008, 65, 604–612. [Google Scholar] [CrossRef][Green Version]

- Kordi, M.; Farrokhi, N.; Pech-Canul, M.I.; Ahmadikhah, A. Rice Husk at a Glance: From Agro-Industrial to Modern Applications. Rice Sci. 2024, 31, 14–32. [Google Scholar] [CrossRef]

- SBCS. Manual de Calagem e Adubação Para Os Estados Do Rio Grande Do Sul e de Santa Catarina; Sociedade Brasileira de Ciência do Solo: Porto Alegre, Brasil, 2016. [Google Scholar]

- Gaskin, J.; Miller, W.; Morris, L.A. Land Application of Pulp Mill Lime Mud. 2009. Available online: https://www.researchgate.net/publication/277772121 (accessed on 1 July 2024).

- Firpo, B.A.; do Amaral Filho, J.R.; Schneider, I.A.H. A Brief Procedure to Fabricate Soils from Coal Mine Wastes Based on Mineral Processing, Agricultural, and Environmental Concepts. Miner. Eng. 2015, 76, 81–86. [Google Scholar] [CrossRef]

- CONAMA. Resolução N° 357; Conselho Nacional do Meio Ambiente: Brasília, Brasil, 2005. [Google Scholar]

- Bratti, F.C. Uso Da Cama de Aviário Como Fertilizante Orgânico Na Produção de Aveia Preta e Milho; Universidade Tecnológica Federal do Paraná: Dois Vizinhos, Brasil, 2013. [Google Scholar]

- ABPA. Relatório Anual 2023; Associação Brasileira de Proteína Animal: São Paulo, Brasil, 2024. [Google Scholar]

- Reis, A.d.S.; Silva, N.C.; Neves, U.M. Produção de Carvão Ativado a Partir de Casca de Arroz. Desafios Rev. Interdiscip. Univ. Fed. Tocantins 2015, 2, 89–103. [Google Scholar] [CrossRef]

- Benedet, G.A.; Zaccaron, A.; Inocente, J.M.; de Souza Nandi, V.; Arcaro, S.; Raupp-Pereira, F.; Gorini Neto, D. Development of Eco-Friendly Clay Ceramics Using Rice Husk Ash as a Secondary Mineral Source of Quartz. Mater. Today Commun. 2024, 38, 108103. [Google Scholar] [CrossRef]

- Della, V.P.; Kühn, I.; Hotza, D. Caracterização de Cinza de Casca de Arroz Para Uso Como Matéria-Prima Na Fabricação de Refratários de Sílica. Quim. Nova 2001, 24, 778–782. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 10 March 2021).

- IBÁ (Indústria Brasileira de Árvores). Relatório Anual IBÁ 2021; FGV: São Paulo, SP, Brasil, 2021; 175p. [Google Scholar]

- ABNT NBR 10004; Resíduos Sólidos—Classificação. Associação Brasileira de Cerâmica: Rio de Janeiro, Brasil, 2004; 18p.

- Almeida, H.C.; da Silveira, C.B.; Ernani, P.R.; Campos, M.L.; Almeida, D. Composição Química de Um Resíduo Alcalino Da Indústria de Papel e Celulose (DREGS). Quim. Nova 2007, 30, 1669–1672. [Google Scholar] [CrossRef]

- Kossmann, C.H.; de Zottich, F.S.; Borgert, C.H.; Neto, L.R.; Junca, E.; de Oliveira, J.R.; Telles, V.B.; Grillo, F.F. Caracterização Da Lama de Cal Da Indústria de Celulose Visando Sua Aplicação Na Indústria Siderúrgica. In 18° ENEMET; Encontro Nacional de Estudantes de Engenharia Metalúrgica, de Materiais e de Minas: São Paulo, Brasil, 2018; p. 6. [Google Scholar]

- ASTM D7348-21; Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ABNT NBR 10005; Procedimento Para Obtenção de Extrato Lixiviado de Resíduos Sólidos. Associação Brasileira de Cerâmica: Rio de Janeiro, Brasil, 2004.

- Hugen, C. Valores de Referência Para Teores de Cr, Cu, Ni, Pb e Zn Em Solos Do Estado de Santa Catarina; Universidade do Estado de Santa Catarina-UDESC: Lages, Brasil, 2010. [Google Scholar]

- USDA. Soil Survey Manual; Handbook No. 18; USDA: Washington, DC, USA, 2017.

- USEPA-SW 846; Hazardous Waste Test Methods. United States Environmental Protection Agency: Washington, DC, USA, 2022.

- Tedesco, M.J.; Gianello, C.; Bissani, C.A.; Bohnen, H.; Volkweiss, S.J. Análises de Solo, Plantas e Outros Materiais; Departamento de Solos da Universidade Federal do Rio Grande do Sul: Porto Alegre, Brasil, 1995; p. 2. [Google Scholar]

- Li, J.; Wang, J. Comprehensive Utilization and Environmental Risks of Coal Gangue: A Review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Acordi, J.; Simão, L.; Faraco, M.N.S.; Borgert, C.H.; Olivo, E.; Montedo, O.R.K.; Raupp-Pereira, F. Waste Valorization of Coal Mining Waste from a Circular Economy Perspective: A Brazilian Case Study Based on Environmental and Physicochemical Features. Resour. Policy 2023, 80, 103243. [Google Scholar] [CrossRef]

- Ulsenheimer, A.M.; Sordi, A.; Cericato, A.; Lajús, C. Formulação de Fertilizantes Organominerais e Ensaio de Produtividade. Unoesc Ciência ACET Joaçaba 2016, 7, 195–202. [Google Scholar]

- Firpo, B.A.; Weiler, J.; Schneider, I.A.H. Technosol Made from Coal Waste as a Strategy to Plant Growth and Environmental Control. Energy Geosci. 2021, 2, 160–166. [Google Scholar] [CrossRef]

- Oliveira, M.L.S.; Ward, C.R.; Sampaio, C.H.; Querol, X.; Cutruneo, C.M.N.L.; Taffarel, S.R.; Silva, L.F.O. Partitioning of Mineralogical and Inorganic Geochemical Components of Coals from Santa Catarina, Brazil, by Industrial Beneficiation Processes. Int. J. Coal Geol. 2013, 116–117, 75–92. [Google Scholar] [CrossRef]

- ASTM D2492-02; Standard Test Method for Forms of Sulfur in Coal. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Fallavena, V.L.V.; de Abreu, C.S.; Inácio, T.D.; Pires, M.; Azevedo, C.M.N.; Fernandes, I.D.; Ferret, L.S.; Martinez Tarazona, M.R. Caracterização Detalhada de Material de Referência Certificado de Carvão Brasileiro. Quim. Nova 2013, 36, 859–864. [Google Scholar] [CrossRef][Green Version]

- Korndörfer, G.H.; de Souza, S.R. Elementos Benéficos. In Nutrição Mineral de Plantas; Fernandes, M.S., de Souza, S.R., Santos, L.A., Eds.; Sociedade Brasileira de Ciência do Solo: Viçosa, Brasil, 2006; pp. 355–374. [Google Scholar]

- Moses, C.O.; Kirk Nordstrom, D.; Herman, J.S.; Mills, A.L. Aqueous Pyrite Oxidation by Dissolved Oxygen and by Ferric Iron. Geochim. Cosmochim. Acta 1987, 51, 1561–1571. [Google Scholar] [CrossRef]

- Allen, S.E. Chemical Analysis of Ecological Materials, 2nd ed.; Blackwell Scientific Publications: Oxford, UK; London, UK, 1989. [Google Scholar]

- Scherer, E.E.; Nadal, R.d; de Castilhos, E.G. Utilização de Esterco de Aves e Adubo Fosfatado Na Cultura Do Milho; EMPASC: Florianópolis, Brasil, 1968. [Google Scholar]

- Rogeri, D.A.; Ernani, P.R.; Mantovani, A.; Lourenço, K.S. Composition of Poultry Litter in Southern Brazil. Rev. Bras. Ciência Solo 2016, 40, e0140697. [Google Scholar] [CrossRef]

- Bolan, N.S.; Szogi, A.A.; Chuasavathi, T.; Seshadri, B.; Rothrock, M.J.; Panneerselvam, P. Uses and Management of Poultry Litter. Worlds Poult. Sci. J. 2010, 66, 673–698. [Google Scholar] [CrossRef]

- Brooks, R.R. Biological Methods of Prospecting for Minerals; John Wiley & Sons: New York, NY, USA, 1983. [Google Scholar]

- He, J.; Lange, C.R.; Dougherty, M. Laboratory Study Using Paper Mill Lime Mud for Agronomic Benefit. Process Saf. Environ. Prot. 2009, 87, 401–405. [Google Scholar] [CrossRef]

- McBride, M.B.; Spiers, G. Trace Element Content of Selected Fertilizers and Dairy Manures as Determined by ICP–MS. In Communications in Soil Science and Plant Analysis; 2001; Volume 32, pp. 139–156. Available online: https://www.tandfonline.com/toc/lcss20/32/19-20?nav=tocList (accessed on 1 July 2024).

- da Torezani, Y.L.S. Estudo Espacial e Multivariado Da Média Regional Das Concentrações de Elementos-Traço Da Micro Bacia Do Rio Corumbiara-Ro; Universidade Federal de Rondônia: Porto Velho, RO, Brasil, 2006. [Google Scholar]

- Chaves, E.V. Absorção de Metais Pesados de Solos Contaminados Do Aterro Sanitário e Pólo Industrial de Manaus Pelas Espécies de Plantas Senna Multijuga, Schizolobium Amazonicum e Caesalpinia Echinata; Universidade Federal do Amazonas: Manaus, AM, Brasil, 2008. [Google Scholar]

- Echart, C.L.; Cavalli-Molina, S. Fitotoxicidade Do Alumínio: Efeitos, Mecanismo de Tolerância e Seu Controle Genético. Ciência Rural 2001, 31, 531–541. [Google Scholar] [CrossRef]

- Menezes, C.E.G.; Pereira, M.G.; Correia, M.E.F.; dos Anjos, L.H.C.; Paula, R.R.; de Souza, M.E. Aporte e Decomposição Da Serapilheira e Produção de Biomassa Radicular Em Florestas Com Diferentes Estágios Sucessionais Em Pinheiral, RJ. Ciência Florest. 2010, 20, 439–452. [Google Scholar] [CrossRef]

- da Silveira, A.N.; Silva, R.; Rubio, J. Treatment of Acid Mine Drainage (AMD) in South Brazil. Int. J. Miner. Process. 2009, 93, 103–109. [Google Scholar] [CrossRef]

- Kabata-Pendias, A.; Mukherjee, A.B. Trace Elements from Soil to Human; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-32713-4. [Google Scholar]

- Rebelo, W.B.; Zaccaron, A.; Saviatto, E.; Olivo, E.F.; Acordi, J.; Raupp-Pereira, F.; Ribeiro, M.J. Valorization of the Residual Fraction of Coal Tailings: A Mineral Circularity Strategy for the Clay Ceramic Industry in the Carboniferous Region of Santa Catarina, Southern Brazil. Materials 2024, 17, 2131. [Google Scholar] [CrossRef]

- de Mendes, I.C.; dos Reis Junior, F.B.; Hungria, M.; de Sousa, D.M.G.; Campo, R.J. Adubação Nitrogenada Suplementar Tardia Em Soja Cultivada Em Latossolos Do Cerrado; Embrapa: Brasília, Brasil, 2008. [Google Scholar]

- de Oliveira, T.S.; da Costa, L.M.; Cruz, C.D. Importancia Relativa Dos Metais Pesados Do Solo Na Identificacao e Separacao de Materiais de Origem. Rev. Ceres 1998, 45, 359–371. [Google Scholar]

- Matos, A.T.; Fontes, M.P.F.; da Costa, L.M.; Martinez, M.A. Mobility of Heavy Metals as Related to Soil Chemical and Mineralogical Characteristics of Brazilian Soils. Environ. Pollut. 2001, 111, 429–435. [Google Scholar] [CrossRef]

- Otto, R. Desenvolvimento Radicular e Produtividade Da Cana-de-Açúcar Relacionados à Mineralização Do N Do Solo e à Adubação Nitrogenada; Universidade de São Paulo: Piracicaba, Brasil, 2012. [Google Scholar]

- Das, B.M.; Sobhan, K. Fundamentos de Engenharia Geotécnica; Cengage: São Paulo, SP, Brasil, 2019. [Google Scholar]

- Kodama, H.; Grim, R.E. Clay Mineral. Encyclopedia Britannica. 2022. Available online: https://www.britannica.com/science/clay-mineral (accessed on 10 March 2021).

- Pejon, O.J.; Rodrigues, V.G.S.; Zuquette, L.V. Impactos Ambientais Sobre o Solo. In Engenharia Ambiental: Conceitos, Tecnologia e Gestão; Calijuri, M.d.C., Cunha, D.G.F., Eds.; Elsevier: Rio de Janeiro, Brasil, 2013; pp. 741–765. [Google Scholar]

- Amaral Filho, J.R.; Firpo, B.A.; Broadhurst, J.L.; Harrison, S.T.L. On the Feasibility of South African Coal Waste for Production of ‘FabSoil’, a Technosol. Miner. Eng. 2020, 146, 106059. [Google Scholar] [CrossRef]

- Weiler, J.; Firpo, B.A.; Schneider, I.A.H. Technosol as an Integrated Management Tool for Turning Urban and Coal Mining Waste into a Resource. Miner. Eng. 2020, 147, 106179. [Google Scholar] [CrossRef]

- Robinson, D.A.; Fraser, I.; Dominati, E.J.; Davíðsdóttir, B.; Jónsson, J.O.G.; Jones, L.; Jones, S.B.; Tuller, M.; Lebron, I.; Bristow, K.L.; et al. On the Value of Soil Resources in the Context of Natural Capital and Ecosystem Service Delivery. Soil Sci. Soc. Am. J. 2014, 78, 685–700. [Google Scholar] [CrossRef]

- Brasil Decreto n. 7.983, de 8 de Abril de 2013. Estabelece Regras e Critérios Para Elaboração Do Orçamento de Referência de Obras e Serviços de Engenharia, Contratados e Executados Com Recursos Dos Orçamentos Da União. DOU de 9.4.213, Brasília. 2013. Available online: http://www.planalto.gov.br/ccivil_03/_ato2011-2014/2013/decreto/d7983.htm (accessed on 10 March 2021).

| Technosols Formulations | Composition | Amount (g) | Amount (%) |

|---|---|---|---|

| T1 | RFC | 554 | 100.00 |

| T2 | RFC | 464.17 | 83.79 |

| PL | 34.43 | 6.21 | |

| RH | 55.40 | 10.00 | |

| T3 | RFC | 463.40 | 83.65 |

| PL | 34.43 | 6.21 | |

| RH | 55.40 | 10.00 | |

| LM | 0.77 | 0.14 | |

| T4 | Vermiculite | 277 | 50.00 |

| PL | 277 | 50.00 |

| Parameters | Range | ||||

| Very Low | Low | Medium | High | Very High | |

| pH (H2O) | <5 | 5.1–5.4 | 5.5–6 | >6 | |

| Pexchangeable (mg dm−3) | 0–7 | 7–14 | 14–21 | 21–42 | >42 |

| K (mg dm−3) | 10–30 | 40–90 | 90–180 | >180 | |

| OM (g kg−1) | ≤25 | 26–50 | >50 | ||

| Ca (mmolc dm−3) | ≤20 | 21–40 | >40 | ||

| Mg (mmolc dm−3) | ≤5 | 6–10 | >10 | ||

| CEC (mmolc dm−3) | ≤750 | 760–1500 | 1510–3000 | >3000 | |

| V (%) | <45 | 45–64 | 65–80 | >80 | |

| Parameter | Textural Class | ||||

| I | II | III | IV | ||

| Clay (g kg−1) | >600 | 401–600 | 201–400 | ≤200 | |

| Sample | Oxides (%) | LOI | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | SO3 | Fe2O3 | CaO | K2O | TiO2 | MgO | MnO | P2O5 | ZrO2 | ||

| RFC | 47.87 | 22.03 | 1.19 | 3.20 | 0.97 | 2.25 | 1.37 | 0.72 | 0.01 | ND | 0.06 | 20.20 |

| Sample | Sulfur Forms and Content (%) | |||

|---|---|---|---|---|

| Pyritic | Sulfate | Organic | Total | |

| RFC | 60.0 | 10.0 | 30.0 | 100.0 |

| Variables | Technosols Formulations | |||

|---|---|---|---|---|

| T1 | T2 | T3 | T4 | |

| Extractable Aluminum (mmolc dm−3) | <0.01 | <0.01 | <0.01 | <0.01 |

| Extractable Calcium (mmolc dm−3) | 3.61 | 2.83 | 3.00 | 1.30 |

| Index in SMP | 8.07 | 7.82 | 7.82 | 5.70 |

| Extractable Magnesium (mmolc dm−3) | 7.83 | 8.99 | 8.81 | 5.47 |

| OM (g kg−1) | 18.20 | 24.80 | 21.10 | 26.00 |

| pH (H2O) | 8.10 | 7.70 | 7.80 | 7.14 |

| Extractable Potassium (mg dm−3) | 178.50 | 1814.40 | 1845.20 | 911.10 |

| Extractable Sodium (mg dm−3) | 60.10 | 444.50 | 459.40 | 22.40 |

| Extractable Phosphorus (mg dm−3) | <0.10 | 243.50 | 272.50 | 272.27 |

| Potential Acidity (mmolc dm−3) | 0.40 | 0.54 | 0.54 | 5.79 |

| Sum of Bases (mmolc dm−3) | 12.16 | 18.39 | 18.54 | 9.20 |

| CEC (mmolc dm−3) | 12.60 | 18.90 | 19.10 | 15.40 |

| V (%) | 96.77 | 97.15 | 97.17 | 59.93 |

| Clay content (g kg−1) | 8.00 | 20.00 | 24.00 | 6.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olivo, E.F.; Zaccaron, A.; Acordi, J.; Ribeiro, M.J.; Fernandes, É.M.R.; Zocche, J.J.; Raupp-Pereira, F. Technosol Development Based on Residual Fraction of Coal Tailings Processing, Agro-Industrial Waste, and Paper Industry Waste. Sustainability 2024, 16, 7471. https://doi.org/10.3390/su16177471

Olivo EF, Zaccaron A, Acordi J, Ribeiro MJ, Fernandes ÉMR, Zocche JJ, Raupp-Pereira F. Technosol Development Based on Residual Fraction of Coal Tailings Processing, Agro-Industrial Waste, and Paper Industry Waste. Sustainability. 2024; 16(17):7471. https://doi.org/10.3390/su16177471

Chicago/Turabian StyleOlivo, Eduarda Fraga, Alexandre Zaccaron, Juliana Acordi, Manuel Joaquim Ribeiro, Élia Maria Raposo Fernandes, Jairo José Zocche, and Fabiano Raupp-Pereira. 2024. "Technosol Development Based on Residual Fraction of Coal Tailings Processing, Agro-Industrial Waste, and Paper Industry Waste" Sustainability 16, no. 17: 7471. https://doi.org/10.3390/su16177471

APA StyleOlivo, E. F., Zaccaron, A., Acordi, J., Ribeiro, M. J., Fernandes, É. M. R., Zocche, J. J., & Raupp-Pereira, F. (2024). Technosol Development Based on Residual Fraction of Coal Tailings Processing, Agro-Industrial Waste, and Paper Industry Waste. Sustainability, 16(17), 7471. https://doi.org/10.3390/su16177471