Designing Environmentally Sustainable Furniture Products: Furniture-Specific Life Cycle Design Guidelines and a Toolkit to Promote Environmental Performance

Abstract

1. Introduction

1.1. The Environmental Impact of Furniture

1.2. The Role of Design for Sustainable Development

1.3. The Current Situation of Sustainable Furniture Design

1.4. The Research Considerations, Questions, Objectives

2. Materials and Methods

2.1. Preliminary Research Phase: Analysis of the (Un)sustainable Characteristics of Furniture

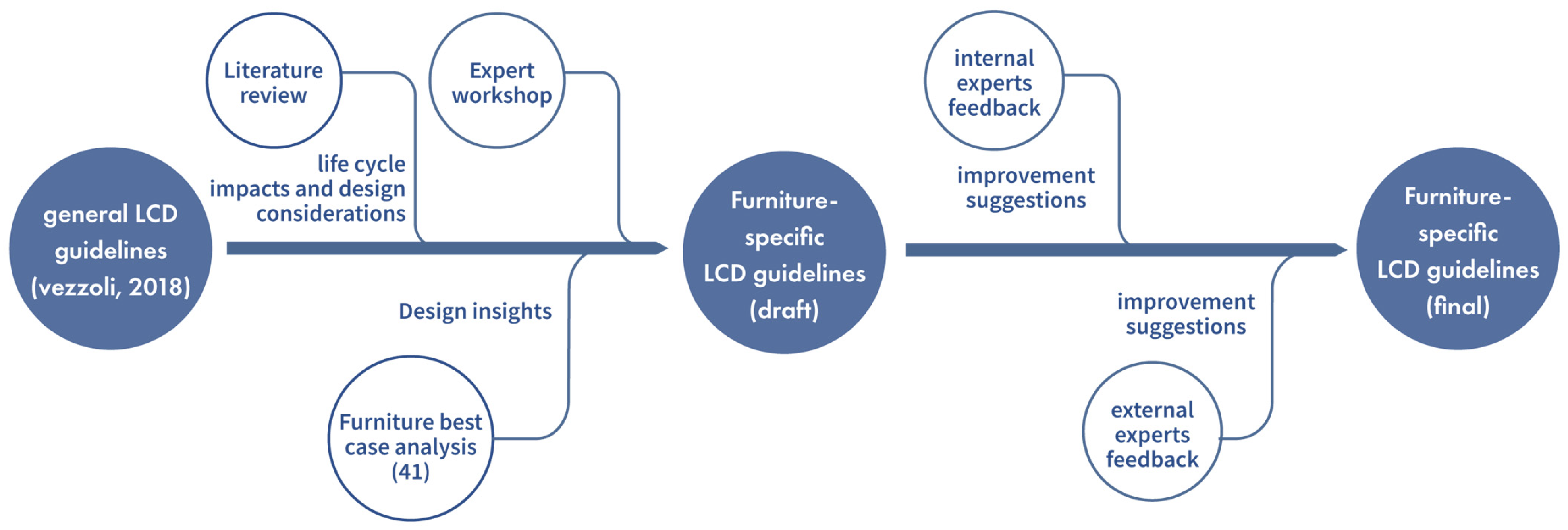

2.2. Development: The Development of Furniture-Specific LCD Guidelines and a Toolkit

2.3. Design and Iterative Evaluation and Improvement of the ICS × Furniture Toolkit

2.3.1. The Design of Furniture LCD Tools

- The general ICS toolkit was developed as part of European Union-funded projects and the Lens Network. They have undergone verification by collaborators from approximately 150 universities.

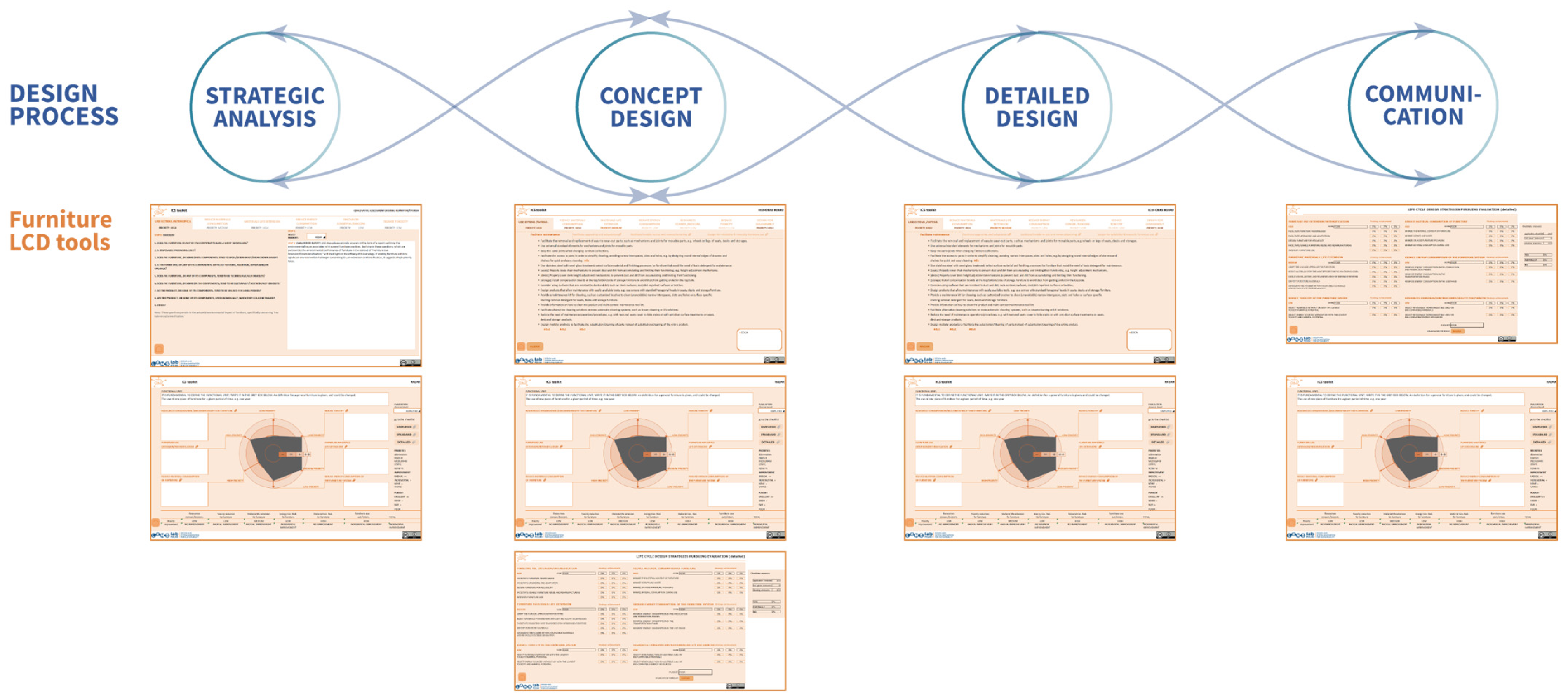

- The general ICS toolkit integrates functions crucial for qualitative assessment, sustainability design orientation, and improvement comparison. These functionalities are significant in the development of sustainable projects and can support the entire design process from strategic analysis to concept design, detailed design, and communication.

- The new knowledge developed within this research, including the environmental impact, the developed guidelines, and the cases, can be seamlessly integrated into the toolkit to support furniture LCD.

2.3.2. The Iterative Improvement of These Furniture Tools

- (1)

- Tools Evaluation within the Course

- (2)

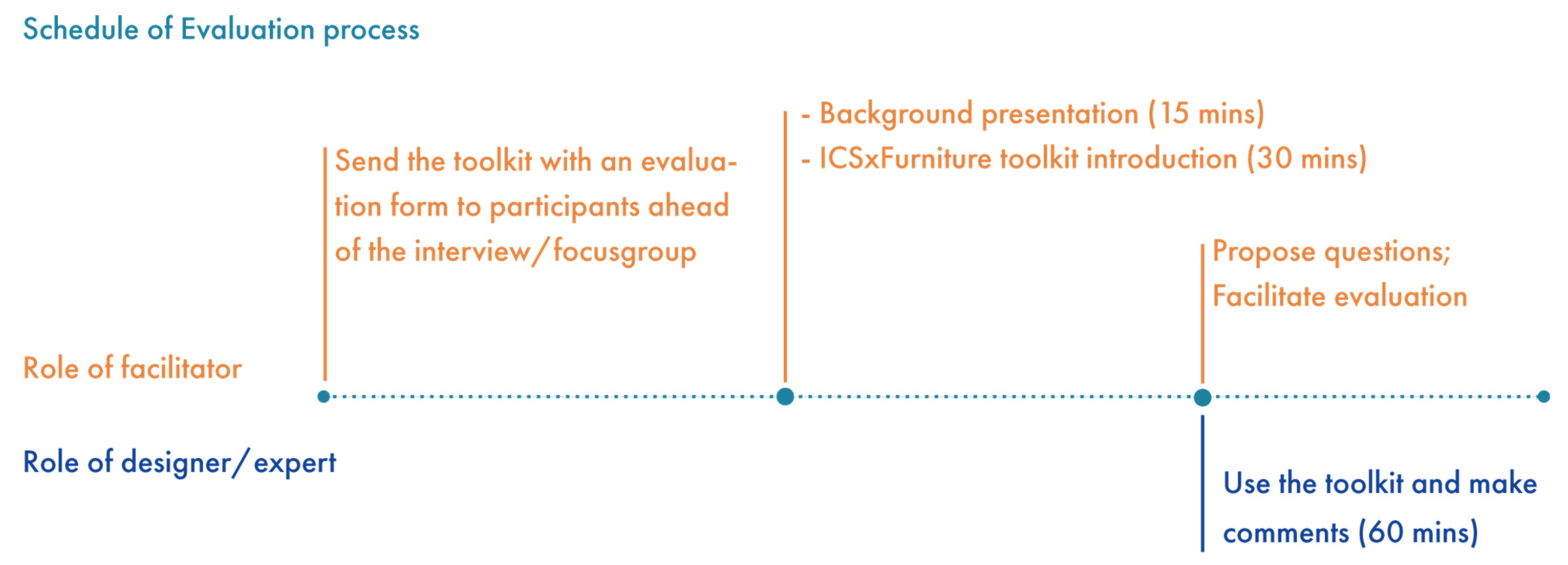

- Tools Evaluation with Experts

- The process initiated with the distribution of the toolkit to designers or experts participating in the process;

- At the outset of each interview/focus group, the facilitator provided background information and introduced the ICS × Furniture toolkit;

- Following the presentation, the facilitator guided the evaluation by proposing questions as needed, while designers or experts utilized the toolkit and offered feedback.

- (3)

- Online questionnaire

3. Results

3.1. Furniture’s Environmental Impact and Innovation Approaches

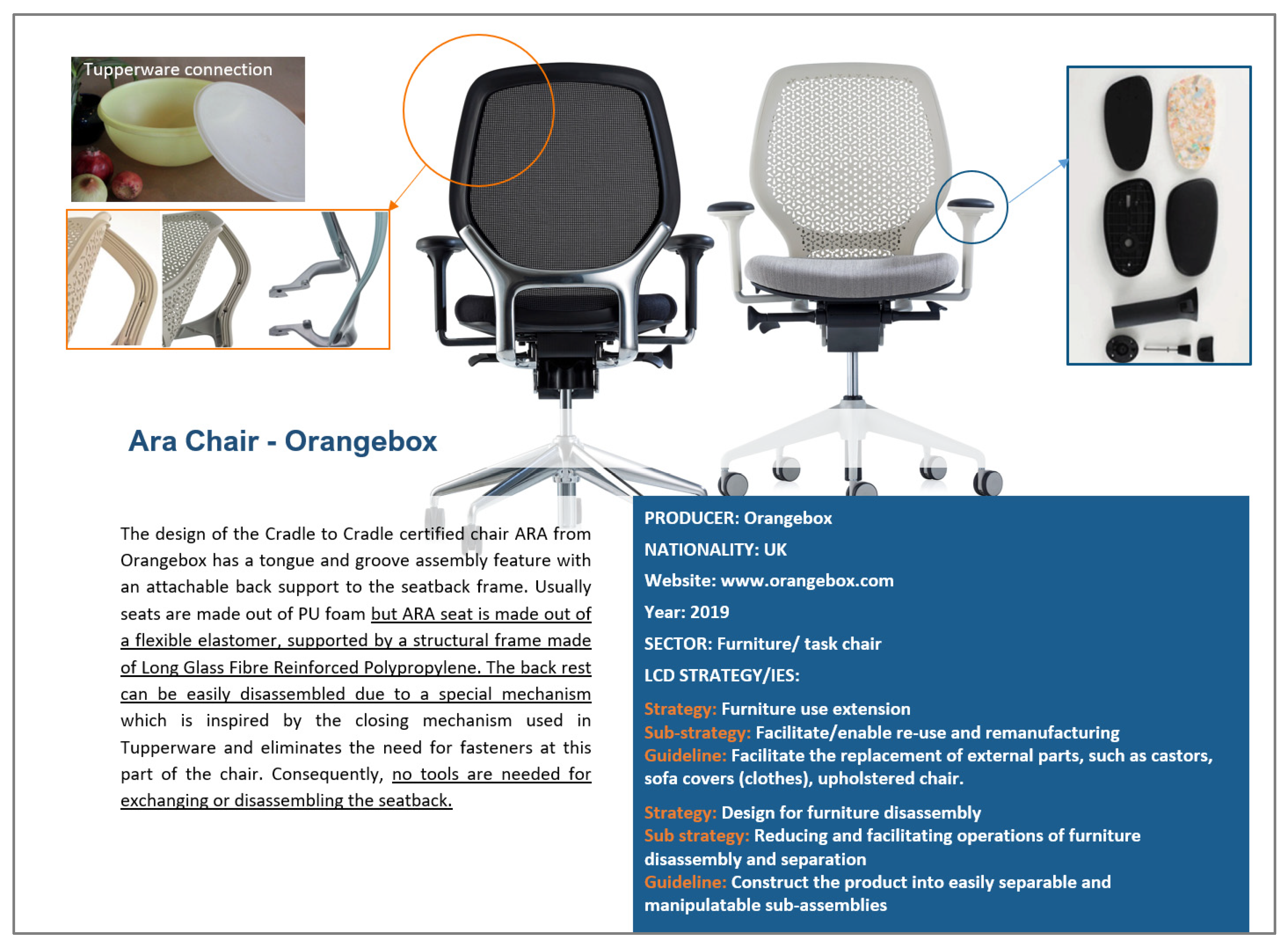

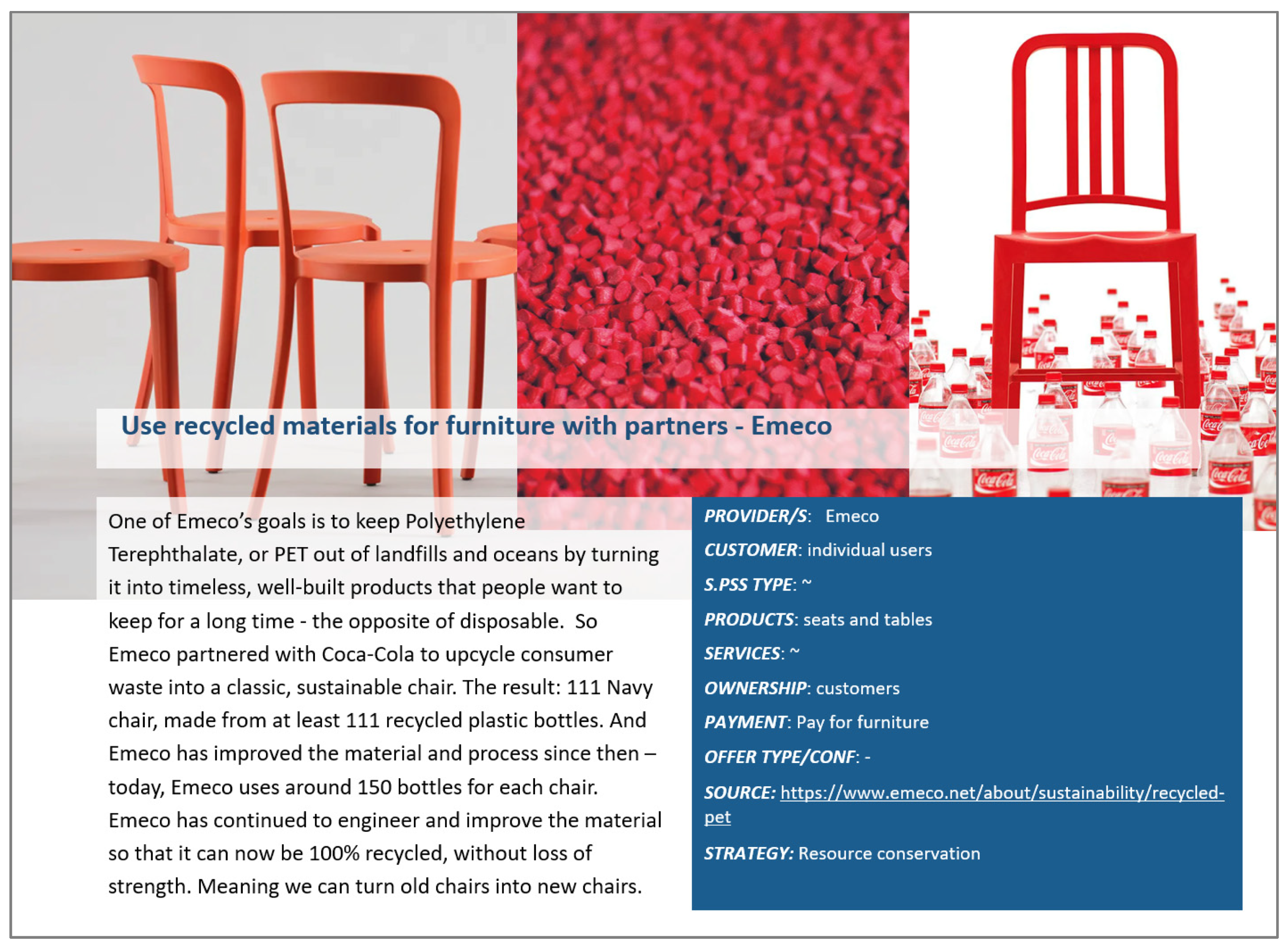

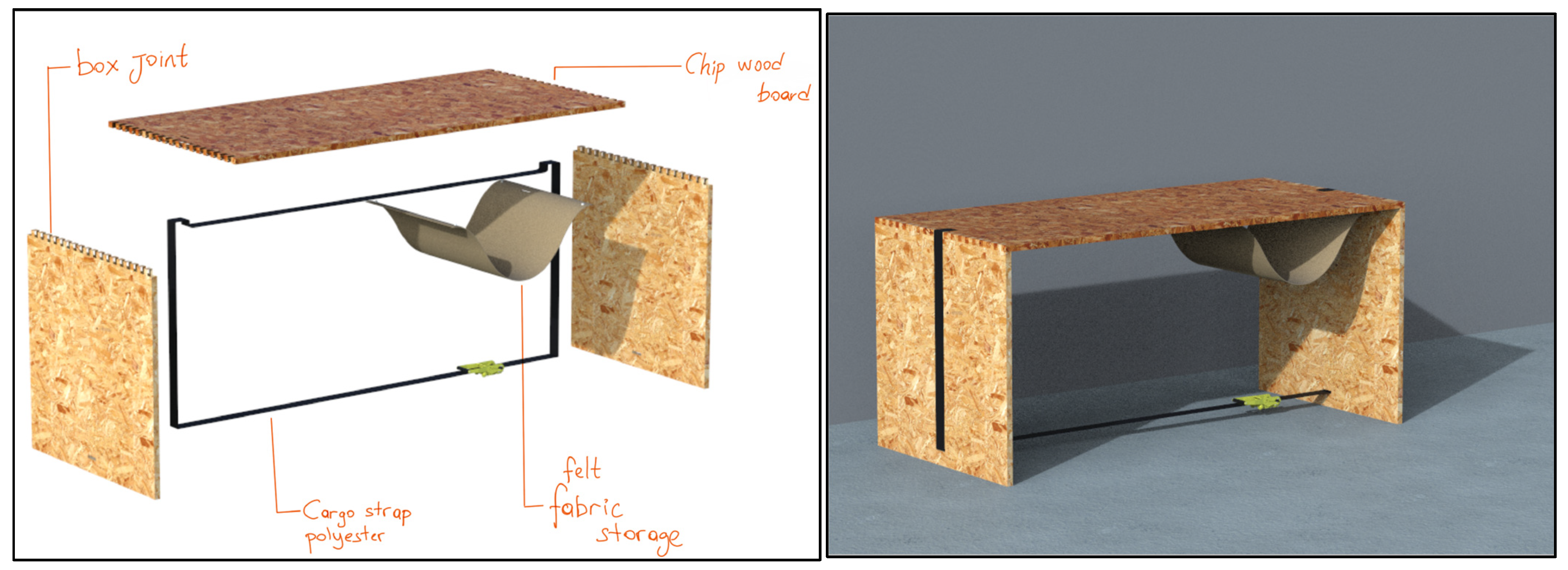

3.2. Furniture Best Practice Analysis

3.3. Furniture-Specific LCD Strategies, Sub-Strategies and Guidelines

- Furniture Use Extension/Intensification: focuses on reducing the environmental impact of furniture and its components by extending or intensifying its lifespan.

- Reducing Material Consumption of Furniture: aims to minimize material use throughout its life cycle, from extraction and processing to transportation and disposal.

- Furniture Materials Life Extension: seeks to prolong the lifespan of furniture materials through recycling or composting.

- Resources Conservation/Bio-compatibility: emphasizes the use of renewable or inexhaustible resources, including both energy and materials.

- Reducing Toxicity of the Furniture System: focuses on selecting materials or processes that minimize the emission of harmful substances throughout the furniture’s life cycle.

- Reducing Energy Consumption of the Furniture System: aims to decrease energy use across all stages of the furniture’s life cycle.

- Design for Furniture Disassembly: encourages designing furniture that is easily disassembly, promoting materials recycling and furniture reuse.

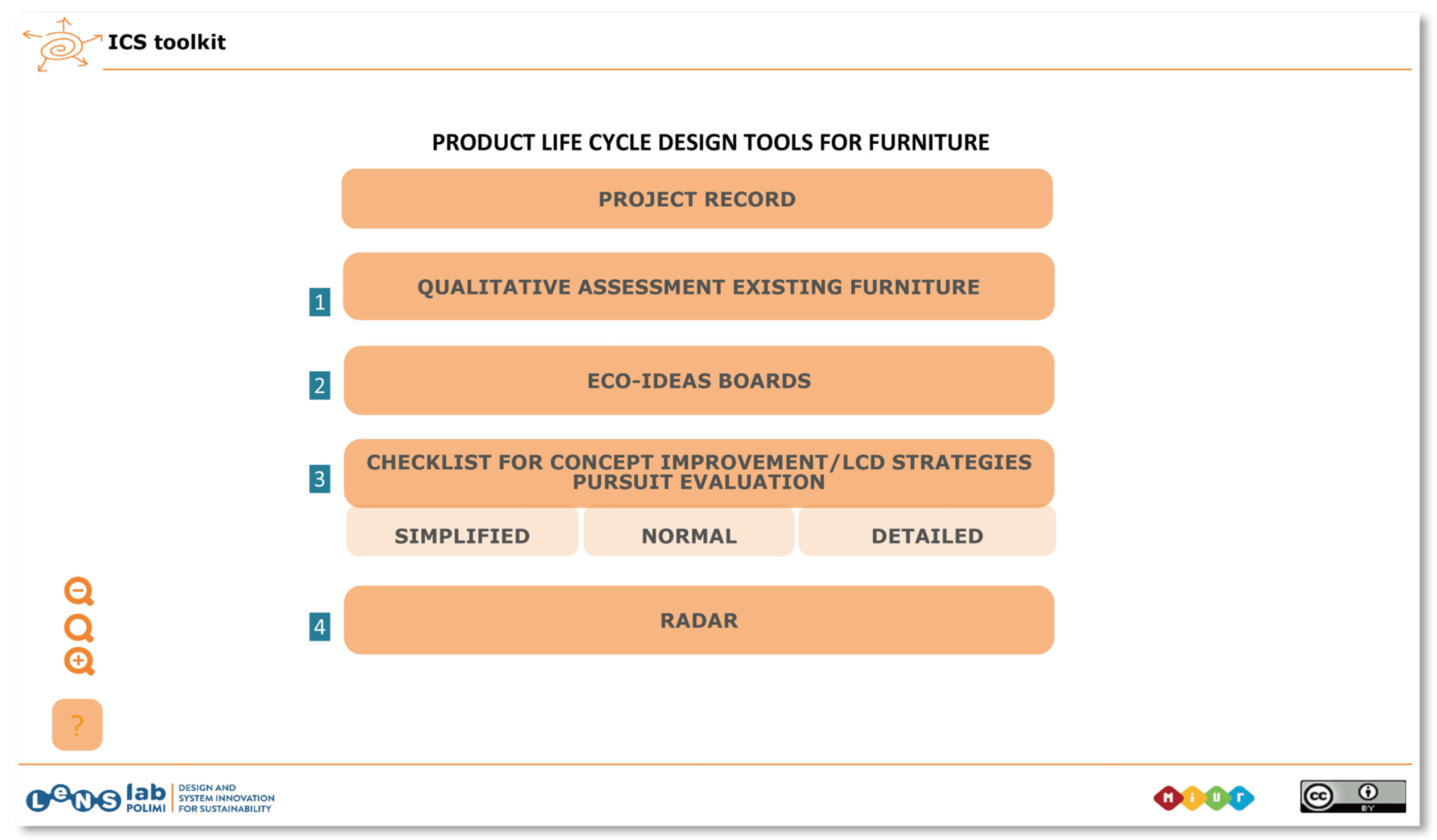

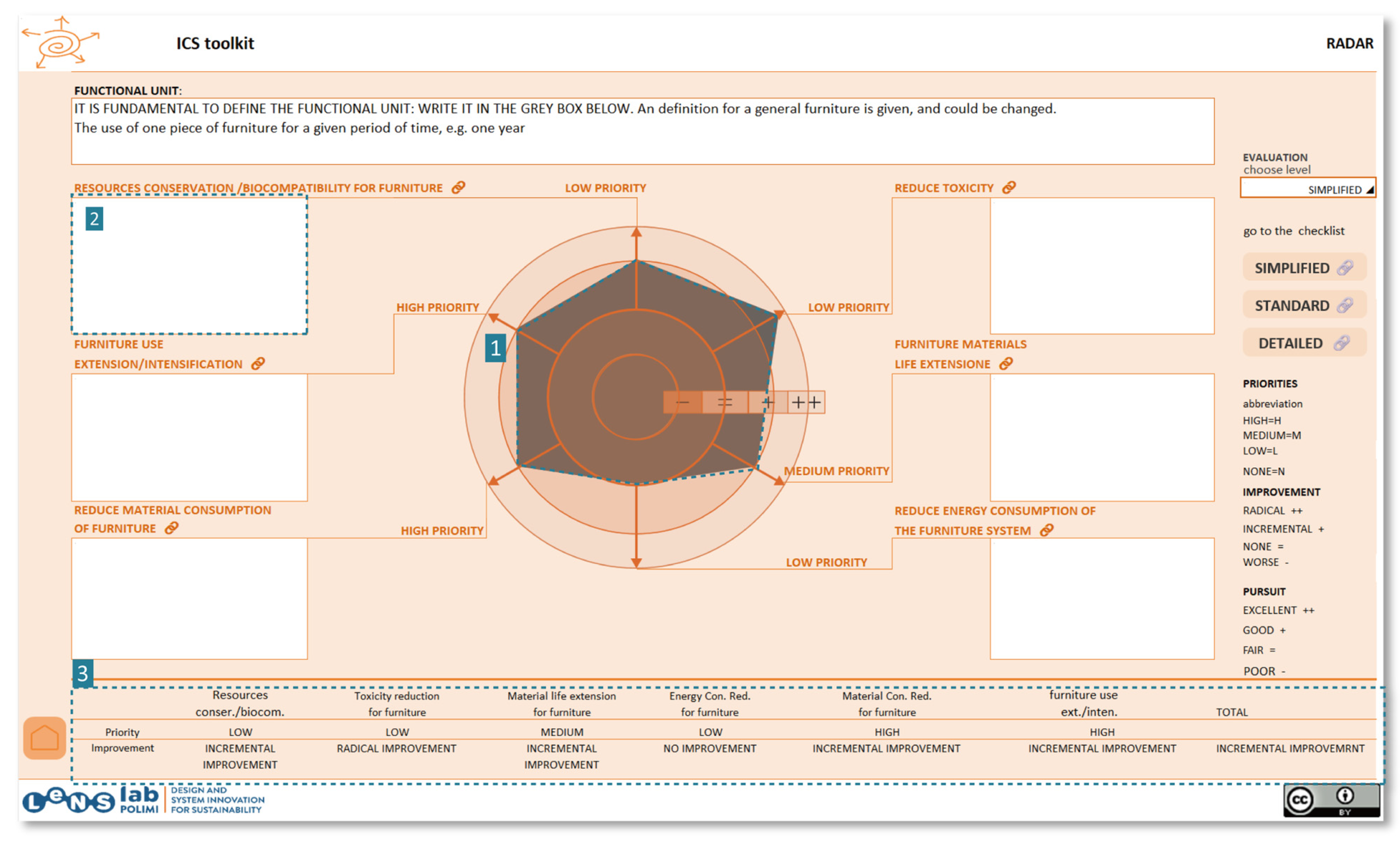

3.4. The ICS × Furniture Toolkit: Objectives, Functions and Integration in the Design Process

- Checklist for Existing Furniture Evaluation: this consists of six checklists, one tailored to each strategy, designed to assess the design priorities for the existing furniture items.

- ECO-Idea Boards: there are six sets of boards, again, one for each strategy, intended to foster the generation and visualization of eco-friendly design concepts.

- Checklist for Concept Improvement/Furniture LCD Strategy Pursuit Evaluation: this tool is divided into three levels of detail for evaluating and enhancing design concepts according to LCD strategies—simplified (strategy level), normal (sub-strategy level), and deep (guideline level).

- Multi-Strategy Radar: a visual tool that depicts how a furniture design or concept aligns with various LCD strategies, providing a holistic view of its sustainability aspects.

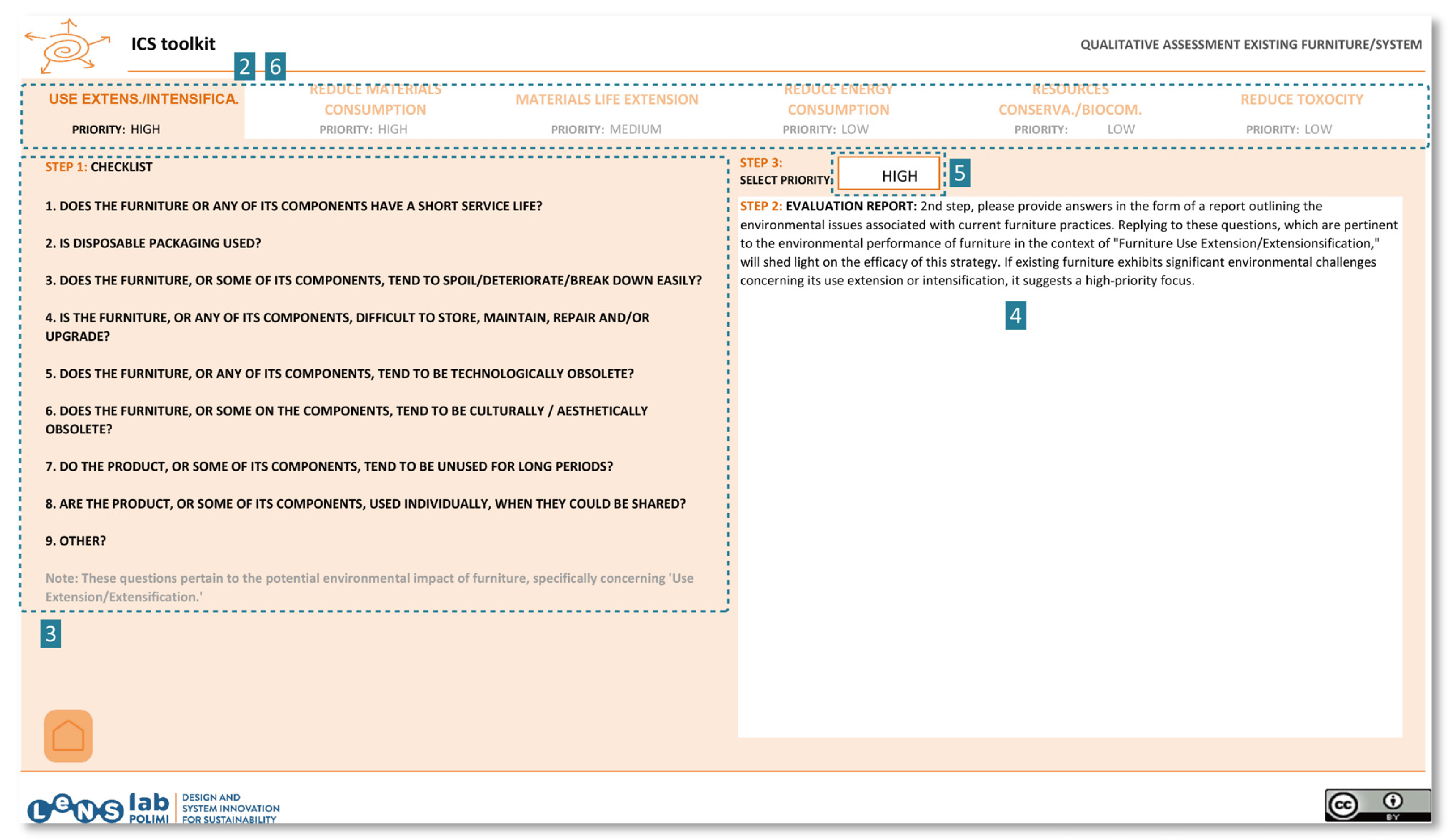

3.4.1. Checklist for the Existing Furniture Evaluation

- Six checklists, each one related to one specific furniture LCD strategy;

- A navigator to move between different checklists;

- A list of environmentally focused questions associated with each strategy;

- Space for environmental analysis results for reference furniture;

- A drop-down menu for users to assign priority levels to each strategy;

- Visual representation of assigned priorities assigned to each design strategy.

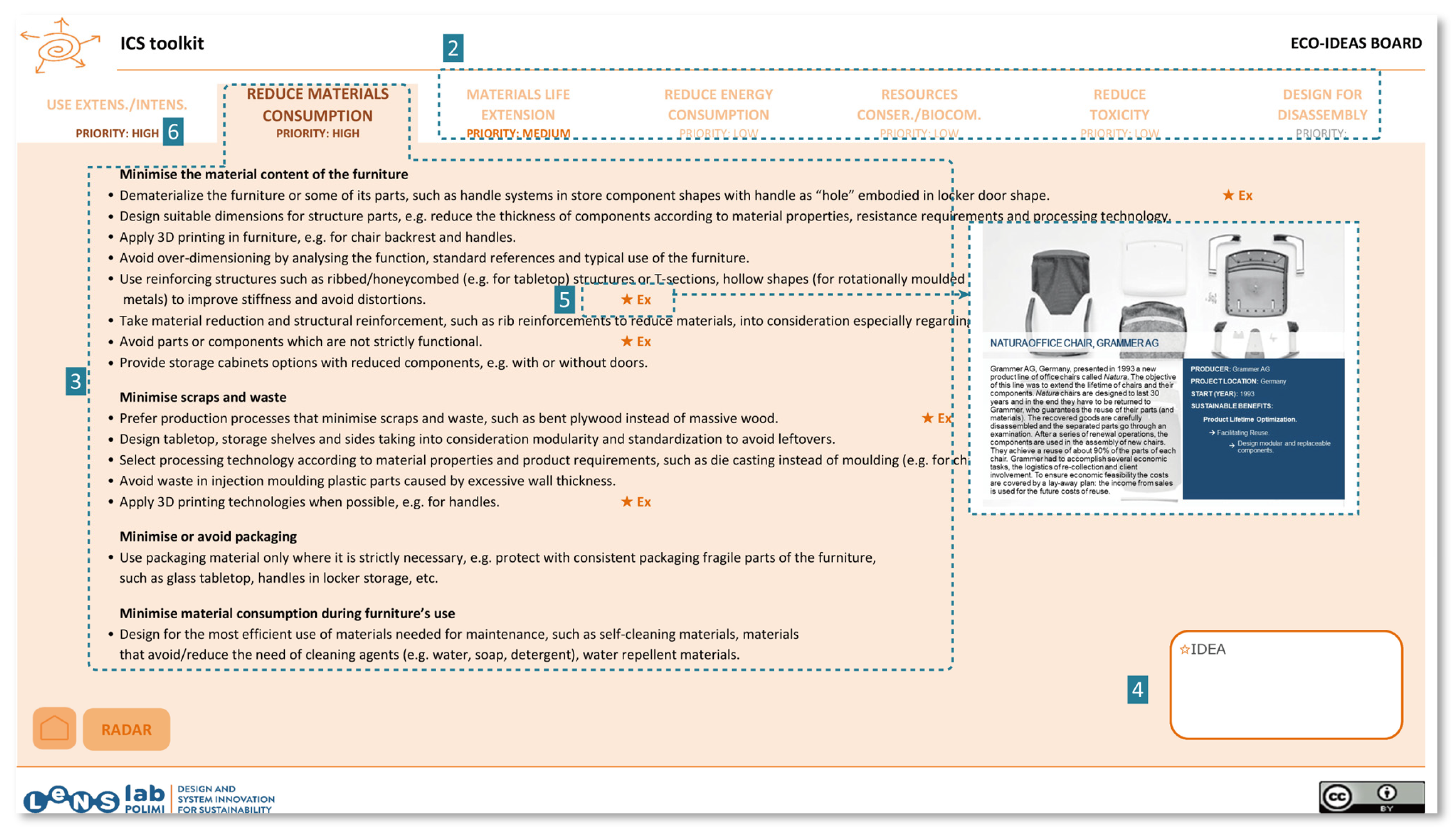

3.4.2. ECO-Idea Boards (Integrating Furniture Product LCD Guidelines and Cases)

- Eleven idea boards for 7 furniture LCD strategies;

- A navigator enables seamless transition between different idea boards;

- A list of design guidelines for each strategy;

- e-post-its allow users to write down promising new ideas during brainstorm;

- Best practices linked to certain guidelines, to illustrate successful implementations and inspire new ideas;

- Visualization of priorities for each strategy to indicate where to start and the importance of each strategy for the project.

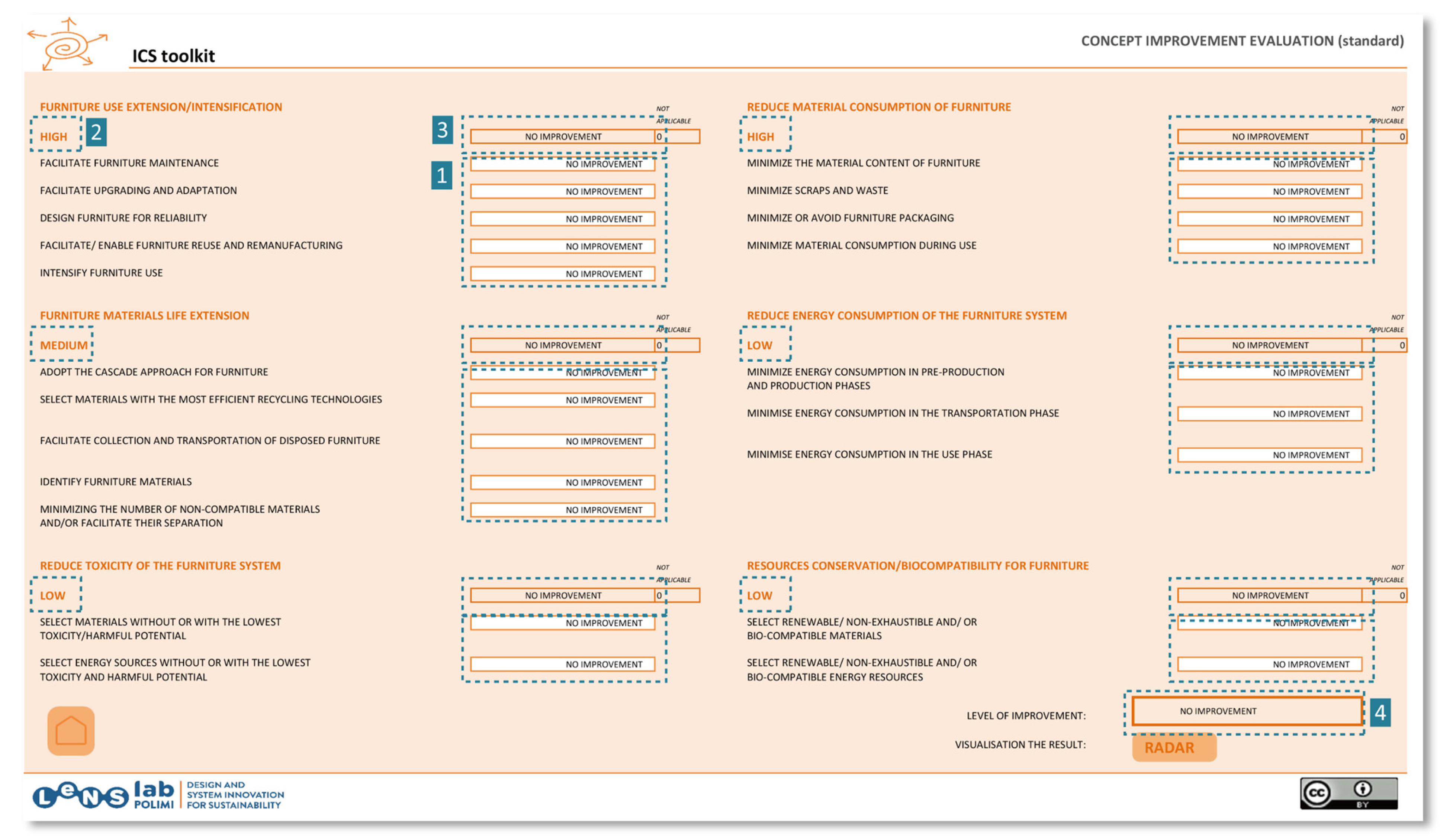

3.4.3. Checklist for Concept Improvement/LCD Strategies Pursuit Evaluation

- A Drop-down List: This component allows users to assess the level of improvement achieved for each sub-strategy. The options available range from “worse” to “no improvement”, “incremental improvement”, and “radical improvement”;

- Identified Priority for Each Strategy;

- A Score and Level of Improvement for the Pursuit of Sub-strategies;

- A Final Score and Level of Improvement for the Pursuit of Strategies.

3.4.4. Multi-Strategy Radar

- A radar map to visualize the potential improvement of the furniture product concept over the existing furniture product for each of six strategies;

- A space for each strategy to summarize and highlight the promising ideas identified for the new concept;

- Text to keep users informed about the level of priorities and the degree of improvement for each strategy.

3.5. The ICS × Furniture Toolkit: Evaluation

3.5.1. The Result of Tools Evaluation within the Course

- A tool guide video presentation has been made for users to understand the function of each tool and how to use each tool.

- Since the ECO-idea boards and the Checklist for Existing Furniture Evaluation contain many pages, we redeveloped the title bar for better navigation to avoid missing some strategies.

- Color differentiation was used to guide the operation of tools.

3.5.2. Tools Evaluation with Experts

3.5.3. Online Questionnaire

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Circular Economy Action Plan: For a Cleaner and More Competitive Europe; Publications Office of the European Union: Brussels, Belgium, 2020; Available online: https://data.europa.eu/doi/10.2779/05068 (accessed on 5 October 2021).

- Joint Research Center of the European Commission. Ecodesign for Sustainable Products Regulation—Preliminary Study on New Product Priorities (Draft); Technical Report; Joint Research Center of the European Commission: Seville, Spanish, 2023. [Google Scholar]

- CSIL; CNFA. World Furniture Outlook 2020; Centre for Industry Studies, China National Furniture Association: Beijing, China, 2020. [Google Scholar]

- CSIL. “The World Furniture Market in 2022”, Design Diffusion. Available online: https://www.designdiffusion.com/en/2021/12/13/the-world-furniture-market-in-2022/ (accessed on 15 September 2023).

- Forrest, A.; Hilton, M.; Ballinger, A.; Whittaker, D. Circular Economy Opportunities in the Furniture Sector; European Environment Bureau: Brussels, Belgium, 2017. [Google Scholar]

- European Commission. Consumption Footprint Platform|EPLCA. Consumption Footprint Platform. Available online: https://eplca.jrc.ec.europa.eu/ConsumptionFootprintPlatform.html (accessed on 17 September 2023).

- González-García, S.; Ferro, F.S.; Silva, D.A.L.; Feijoo, G.; Lahr, F.A.R.; Moreira, M.T. Cross-country comparison on environmental impacts of particleboard production in Brazil and Spain. Resour. Conserv. Recycl. 2019, 150, 104434. [Google Scholar] [CrossRef]

- Ceschin, F.; Gaziulusoy, İ. Design for Sustainability: A Multi-Level Framework from Products to Socio-Technical Systems, 1st ed.; Routledge: London, UK; New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- ISO/TR 14062; Environmental Management, Integrating Environmental Aspects into Product Design and Development. The International Organization for Standardization: Geneva, Switzerland, 2002.

- Boks, C.; McAloone, T. The design of eco board games as an umbrella approach to sustainable product design education. Presented at the 17th International Conference on Engineering Design. In Proceedings of the International Conference on Engineering and Product Design Education, Vol. Sustainable Design, Palo Alto, CA, USA, 24–27 August 2009; Design Society: Stanford, CA, USA, 2009; pp. 390–395. Available online: https://orbit.dtu.dk/en/publications/the-design-of-eco-board-games-as-an-umbrella-approach-to-sustaina (accessed on 5 May 2022).

- Brezet, H.; van Hemel, C. Ecodesign: A Promising Approach to Sustainable Production and Consumption; United Nations Environment Programme, Industry and Environment, Cleaner Production: Paris, France; Rathenau Institute: The Hague, The Netherlands; Delft University of Technology: Delft, The Netherlands, 1997. [Google Scholar]

- Charter, M.; Tischner, U. (Eds.) Sustainable Solutions: Developing Products and Services for the Future, 1st ed.; Greenleaf Publishing Limited: Sheffield, UK, 2001; Available online: https://www.taylorfrancis.com/books/9781351282475 (accessed on 18 November 2021).

- Giudice, F.; Rosa, G.L.; Risitano, A. Product Design for the Environment: A Life Cycle Approach; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Keoleian, G.A.; Menerey, D. Life Cycle Design Guidance Manual. Environmental Requirements and the Product System; Final Report; PB-93-164507/XAB; National Pollution Prevention Center: Ann Arbor, MI, USA, 1993. Available online: https://www.osti.gov/biblio/5886794 (accessed on 27 September 2023).

- Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Characterization of the State-of-the-art and Identification of Main Trends for Ecodesign Tools and Methods: Classifying Three Decades of Research and Implementation. Indian Inst. Sci. J. 2015, 95, 405–427. [Google Scholar]

- Tischner, U. (Ed.) Tools for ecodesign and sustainable product design. In Sustainable Solutions: Developing Products and Services for the Future, 1st ed.; Greenleaf Publishing Limited: Sheffield, UK, 2001; pp. 263–274. [Google Scholar]

- Vezzoli, C.; Manzini, E. Design for Environmental Sustainability, 2008th ed.; Springer: Berlin, Germany; London, UK, 2008. [Google Scholar]

- Chaves, L.I. Design for sustainability: A methodological approach for the introduction of environmental requirements in the furniture sector. Prod. Manag. Dev. 2008, 6, 167–171. [Google Scholar]

- Ljungberg, L.Y. Materials selection and design for development of sustainable products. Mater. Des. 2007, 28, 466–479. [Google Scholar] [CrossRef]

- Vezzoli, C. Design for Environmental Sustainability, 2nd ed.; Springer: London, UK, 2018; Available online: http://link.springer.com/10.1007/978-1-4471-7364-9 (accessed on 6 March 2021).

- Iritani, D.R.; Silva, D.A.L.; Saavedra, Y.M.B.; Grael, P.F.F.; Ometto, A.R. Sustainable strategies analysis through Life Cycle Assessment: A case study in a furniture industry. J. Clean. Prod. 2015, 96, 308–318. [Google Scholar] [CrossRef]

- Sun, Y.; Yen, C.-C.; Chen, T.-L. Designing ‘Forest’ into Daily Lives for Sustainability: A Case Study of Taiwanese Wooden Furniture Design. Sustainability 2023, 15, 7311. [Google Scholar] [CrossRef]

- Şatiroğlu, E.; Dinçer, D.; Korgavuş, B. Urban Furniture İn The Context Of Sustanainable Materials. Kent Akad. 2023, 16, 566–576. [Google Scholar] [CrossRef]

- Deng, W.; Lin, H.; Jiang, M. Research on Bamboo Furniture Design Based on D4S (Design for Sustainability). Sustainability 2023, 15, 8832. [Google Scholar] [CrossRef]

- Suhaily, S.S.; Jawaid, M.; Khalil, H.P.S.A.; Mohamed, A.R.; Ibrahim, F. A review of oil palm biocomposites for furniture design and applications: Potential and challenges. BioResources 2012, 7, 4400–4423. [Google Scholar] [CrossRef]

- Badiu, A.; Badiu, I.; Dragomir, M. Studies regarding the use of reclaimed wood in the manufacture of modern furniture–Part II. Acta Tech. Napoc.-Ser. Appl. Math. Mech. Eng. 2015, 58, 231–238. [Google Scholar]

- Bovea, M.D.; Vidal, R. Materials selection for sustainable product design: A case study of wood based furniture eco-design. Mater. Des. 2004, 25, 111–116. [Google Scholar] [CrossRef]

- Estrada, R.D.; Wyller, M.; Dahy, H. Aerochair Integrative design methodologies for lightweight carbon fiber furniture design. In Proceedings of the 37th Conference on Education and Research in Computer Aided Architectural Design in Europe and 23rd Conference of the Iberoamerican Society Digital Graphics, eCAADe SIGraDi 2019, Porto, Portugal, 11–13 September 2019; Architecture in the Age of the 4th Industrial Revolutio. pp. 691–700. [Google Scholar] [CrossRef]

- Kumar, R.; Ayshwarya, B.; Muslihudin, M.; Nguyen, P.T.; Alfian, F.Y.; Hashim, W.; Shankar, K.; Hafizah, S.; Mukodimah, S.; Odarich, I.N.; et al. Into the Furniture Woods: Analytical Hierarchy Process Method. Int. J. Recent Technol. Eng. 2019, 8, 1562–1567. [Google Scholar] [CrossRef]

- Li, S.; Yuan, Y.; Wang, J.; Guo, M. Do novel wooden composites provide an environmentally favorable alternative for panel-type furniture? BioResources 2019, 14, 2740–2758. [Google Scholar] [CrossRef]

- Lovarelli, D.; Fusi, A.; Pretolani, R.; Bacenetti, J. Delving the environmental impact of roundwood production from poplar plantations. Sci. Total Environ. 2018, 645, 646–654. [Google Scholar] [CrossRef]

- Montagna, G.; Carvalho, C. Textiles, identity and innovation: Design the future. In Proceedings of the 1st International Textile Design Conference (D_TEX 2017), Lisbon, Portugal, 2–4 November 2017; CRC Press: London, UK, 2018. [Google Scholar]

- Wever, R. Design for volume optimization of packaging for durable goods. Packag. Technol. Sci. 2011, 24, 211–222. [Google Scholar] [CrossRef]

- Rinawati, D.I.; Sriyanto; Sari, D.P.; Prayodha, A.C. Eco-efficiency Analysis of Furniture Product Using Life Cycle Assessment. E3S Web Conf. 2018, 31, 08005. [Google Scholar] [CrossRef]

- Santos, G.; Rebelo, M.; Barros, S.; Pereira, M. Certification and integration of environment with quality and safety—A path to sustained success. In Sustainable Development—Authoritative and Leading Edge Content for Environmental Management; InTech: Rijeka, Croatia, 2012; Volume 1, pp. 193–218. [Google Scholar]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Zhang, X.; Zeng, S. Research on Sustainable Furniture Design Based on Waste Textiles Recycling. Sustainability 2023, 15, 3601. [Google Scholar] [CrossRef]

- Borchardt, M.; Poltosi, L.A.C.; Sellitto, M.A.; Pereira, G.M. Adopting ecodesign practices: Case study of a midsized automotive supplier. Environ. Qual. Manag. 2009, 19, 7–22. [Google Scholar] [CrossRef]

- Krystofik, M.; Luccitti, A.; Parnell, K.; Thurston, M. Adaptive remanufacturing for multiple lifecycles: A case study in office furniture. Resour. Conserv. Recycl. 2018, 135, 14–23. [Google Scholar] [CrossRef]

- Lähtinen, K.; Vivanco, D.A.S.; Toppinen, A. Designers’ wooden furniture ecodesign implementation in Scandinavian country-of-origin (COO) branding. J. Prod. Brand Manag. 2014, 23, 180–191. [Google Scholar] [CrossRef]

- Chaves, L.I. Design for Environmental Sustainability: Design Strategies, Methods and Tools in the Furniture Sector; Politecnico di Milano: Milan, France, 2007. [Google Scholar]

- Michelsen, O.; Fet, A.M.; Dahlsrud, A. Eco-efficiency in extended supply chains: A case study of furniture production. J. Environ. Manage. 2006, 79, 290–297. [Google Scholar] [CrossRef]

- Yurtay, Y.; Yurtay, N.; Demirci, H.; Zaimoglu, E.A.; Göksu, A. Improvement and Implementation of Sustainable Key Performance Indicators in Supply Chain Management: The Case of a Furniture Firm. IEEE Access 2023, 11, 41913–41927. [Google Scholar] [CrossRef]

- Orangebox. ARA—Orangebox, ARA Cradle-to-Cradle Task Chair. Available online: https://www.orangebox.com/products/ARA (accessed on 19 November 2023).

- Ewen, D. Gispen’s Environmentally sustainable furniture design approaches, strategies and tools. In A Workbook for Developing Circular Business Models; OCF 2.0 Foundation: Doetinchem, The Netherlands, 2022. [Google Scholar]

- Herrington, J.; McKenney, S.; Reeves, T.; Oliver, R. Design-based research and doctoral students: Guidelines for preparing a dissertation proposal. In Proceedings of the ED-MEDIA 2007—World Conference on Educational Multimedia, Hypermedia & Telecommunications, Vancouver, BC, Canada, 25 June 2007; Association for the Advancement of Computing in Education (AACE): Vancouver, BC, Canada, 2007; pp. 4089–4097. Available online: https://www.learntechlib.org/primary/p/25967/ (accessed on 3 May 2022).

- Vezzoli, C.; Sciama, D. Life Cycle Design: From general methods to product type specific guidelines and checklists: A method adopted to develop a set of guidelines/checklist handbook for the eco-efficient design of NECTA vending machines. J. Clean. Prod. 2006, 14, 1319–1325. [Google Scholar] [CrossRef]

- Cobb, P. Supporting the improvement of learning and teaching in social and institutional context. In Cognition and Instruction: Twenty-Five Years of Progress; Lawrence Erlbaum Associates Publishers: Mahwah, NJ, USA, 2001; pp. 455–478. [Google Scholar]

- Cobb, P.; Confrey, J.; Disessa, A.; Lehrer, R.; Schauble, L. Design Experiments in Educational Research. Educ. Res. 2003, 32, 9–13. [Google Scholar] [CrossRef]

- Baumgartner, E.; Bell, P. What will we do with design principles? Design principles and principled design practice. In Proceedings of the Annual Conference of the American Educational Research Association, New Orleans, LA, USA, 1–5 April 2002. [Google Scholar]

- Laemlaksakul, V.; Sangsai, N. A Study of Ecological Products by Life Cycle Assessment in Thai Furniture Industry. Applied Mechanics and Materials. Available online: https://www.scientific.net/AMM.431.344 (accessed on 9 February 2021).

- Wang, S.; Su, D.; Zhu, S. A comparative study on life cycle assessment of typical wood base furniture. In Proceedings of the2016 5th International Conference on Sustainable Energy and Environment Engineering (ICSEEE 2016), Zhuhai, China, 4–6 November 2016. [Google Scholar]

- Mirabella, N.; Castellani, V.; Sala, S. LCA for assessing environmental benefit of eco-design strategies and forest wood short supply chain: A furniture case study. Int. J. Life Cycle Assess. 2014, 19, 1536–1550. [Google Scholar] [CrossRef]

- González-García, S.; Lozano, R.G.; Moreira, M.T.; Gabarrell, X.; i Pons, J.R.; Feijoo, G.; Murphy, R.J. Eco-innovation of a wooden childhood furniture set: An example of environmental solutions in the wood sector. Sci. Total Environ. 2012, 426, 318–326. [Google Scholar] [CrossRef]

- Medeiros, D.L.; Tavares, A.O.D.C.; Rapôso, Á.L.Q.R.e.S.; Kiperstok, A. Life cycle assessment in the furniture industry: The case study of an office cabinet. Int. J. Life Cycle Assess. 2017, 22, 1823–1836. [Google Scholar] [CrossRef]

- Gamage, G.B.; Boyle, C.; McLaren, S.J.; McLaren, J. Life cycle assessment of commercial furniture: A case study of Formway LIFE chair. Int. J. Life Cycle Assess. 2008, 13, 401–411. [Google Scholar] [CrossRef]

- Höglmeier, K.; Weber-Blaschke, G.; Richter, K. Utilization of recovered wood in cascades versus utilization of primary wood—A comparison with life cycle assessment using system expansion. Int. J. Life Cycle Assess. 2014, 19, 1755–1766. [Google Scholar] [CrossRef]

- Phungrassami, H.; Usubharatana, P. Life cycle assessment and Eco-efficiency of Para-rubber wood production in Thailand. Pol. J. Environ. Stud. 2015, 24, 2113–2126. [Google Scholar]

- González-García, S.; Gasol, C.M.; Lozano, R.G.; Moreira, M.T.; Gabarrell, X.; i Pons, J.R.; Feijoo, G. Assessing the global warming potential of wooden products from the furniture sector to improve their ecodesign. Sci. Total Environ. 2011, 410–411, 16–25. [Google Scholar] [CrossRef]

- Smoca, A. Hemp fibres reinforced bio-composites for sustainable design. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, Sofia, Bulgaria, 30 June–6 July 2019; pp. 471–478. [Google Scholar] [CrossRef]

- Linkosalmi, L.; Husgafvel, R.; Fomkin, A.; Junnikkala, H.; Witikkala, T.; Kairi, M.; Dahl, O. Main factors influencing greenhouse gas emissions of wood-based furniture industry in Finland. J. Clean. Prod. 2016, 113, 596–605. [Google Scholar] [CrossRef]

- Cambria, D.; Pierangeli, D. Application of a life cycle assessment to walnut tree (Juglans regia L.) high quality wood production: A case study in southern Italy. J. Clean. Prod. 2012, 23, 37–46. [Google Scholar] [CrossRef]

- Müller, K.; Sonderegger, W.; Kläusler, O.; Klippel, M.; Escamilla, E.Z. Mechanical characterisation of densified hardwood with regard to structural applications. J. Renew. Mater. 2020, 8, 1091–1109. [Google Scholar] [CrossRef]

- Hartini, S.; Wicaksono, P.A.; Prastawa, H.; Hadyan, A.F.; Sriyanto. The Environmental Impact Assessment of Furniture Production Process Using the Life Cycle Assessment. IOP Conf. Ser. Mater. Sci. Eng. 2019, 598, 012078. [Google Scholar] [CrossRef]

- Kutnar, A.; Tavzes, Č. Sustainable development in wood industry. In Proceedings of the 22nd International Scientific Conference: Wood is Good—EU Preaccession Challenges of the Sector, Zagreb, Croatia, 21 October 2011; pp. 83–88. [Google Scholar]

- Castellani, V.; Sala, S.; Mirabella, N. Beyond the throwaway society: A life cycle-based assessment of the environmental benefit of reuse. Integr. Environ. Assess. Manag. 2015, 11, 373–382. [Google Scholar] [CrossRef] [PubMed]

- Gassmann, O.; Enkel, E.; Chesbrough, H. The future of open innovation: The future of open innovation. RD Manag. 2010, 40, 213–221. [Google Scholar] [CrossRef]

| General Guidelines | Actions/Insights Sources | Furniture-Specific LCD Guidelines |

|---|---|---|

| Design modular and dynamically configured products to facilitate their adaptability for changing environments | Adding characteristics relevant to specific furniture products or types/Insightples from case study | Design reconfigurable furniture that can adapt to different spaces and situations, such as modular desks and storage that can be used for both transforming a given office space or accommodating new function (e.g., an individual working station that can be transformed into a collective one, and that can also be rearranged if the office moves to a new location). |

| Design products that can be upgraded and adapted on-site | Adding characteristics relevant to specific furniture products or types/Insights from case study and expert knowledge | [Office seats] Design modular and on-site upgradable seats, allowing the user to substitute (with standard tools) fixed feet with wheels and/or fixed components with adjustable ones. |

| Adding new guidelines/Insights from experts’ knowledge or case study | Design a family of furniture instead of single ones, with different properties and functions that enable adaptation. | |

| Enable and facilitate software upgrade | Erase if irrelevant |

| Design Strategies | Design Approaches | Detailed Design Sub-Approaches | Case Number |

|---|---|---|---|

| Furniture Use Extension or intensification | A6 modular system | B10 modularity with different functions | #5, #13 |

| B35 modularity with different sizes | #16 | ||

| B36 changeable shapes (e.g., bed, sofa) | #15 | ||

| A7 disassemble and assembly connections | B11 embedded nuts | #6 | |

| B14 zipper connections | #8, #12, #19 | ||

| B15 reduction in the number of components/connections | #8, #9, #10 | ||

| B18 tupperware-like connections | #17 | ||

| B19 wedge dowel connections | #20 | ||

| B31 buckle connections | #30 | ||

| B34 special brackets and cut-outs | #41 | ||

| A8 multi-functions | B12 changeable dimensions (e.g., beds) | #7 | |

| B36 changeable shapes (e.g., beds, closets) | #11 | ||

| A9 standardization | B13 universal components | #8 | |

| A15 uses strong materials | B9 incorporation of metal as raw materials | #37 | |

| Reducing energy consumption of the furniture system | A2 reduced packaging volume | B3 stackable design | #3, #21 |

| B22 flat packaging | #23, #30, #42 | ||

| B25 vacuum packaging | #25 | ||

| B32 inflation assembly/disassembly | #31 | ||

| A3 distributed economy | B4 use of local raw materials | #3, #4 | |

| B17 on-site assembly | #16, #39 | ||

| A12 enhancing environmental benefits rather than reducing impacts | B24 integration of energy generation mechanisms | #24 | |

| A14 lightweight | #31 | ||

| Furniture materials life extension | A5 use of low-impact materials_renewable/non-exhaustible/biocompatible materials | B8 use of recyclable materials | #4 |

| A7 disassemble and assembly connections | B14 zipper connections | #19 | |

| B18 tupperware-like connections | #17 | ||

| B19 wedge dowel connections | #20 | ||

| B31 buckle connections | #18, #30 | ||

| B11 embedded nuts | #6 | ||

| B15 reduction in the number of components/connections | #8, #9, #10 | ||

| B34 special brackets and cut-outs | #41 | ||

| A10 mono-materials | B7 3D printing technology | #4 | |

| B20 plastic molding processes | #18, #30 | ||

| B37 aluminium extrusion | #21 | ||

| A11 easier recycling | B21 materials marking | #22 | |

| Resources conservation/biocompatibility for furniture | A5 use of low-impact materials_renewable/non-exhaustible/biocompatible materials | B6 utilization of waste plastic from other sectors | #4 |

| B8 use of recyclable materials | #4 | ||

| B16 utilization of waste components from other furniture within the same sector | #35, #42 | ||

| B23 use of sustainably sourced materials | #23, #38 | ||

| B33 utilization of renewable materials (e.g., bamboo, palm leaves, rattan) | #36, #39 | ||

| Reduce material consumption of furniture system | A1 reinforced structure | B1 corrugated plywood | #1 |

| B2 ribbed structure | #2, #29 | ||

| B27 cross inset structure | #27 | ||

| A4 one-piece molding | B5 incorporation of bent wood craft | #3 | |

| B7 3D printing technology | #4 | ||

| B30 compression molding | #30 | ||

| A13 avoids packaging waste | B28 packaging as component(s) | #28 | |

| Reducing toxicity | A5 use of low-impact materials_renewable/non-exhaustible/biocompatible materials | B23 use of sustainably sourced materials | #32 |

| B29 water-based glues | #38 |

| Strategy: 1. Furniture Use Extension/Intensification |

|---|

| Sub-strategies 1.1: Facilitate furniture maintenance; 1.2: Facilitate furniture upgrading and adaptation; 1.3: Design furniture for reliability; 1.4: Facilitate/enable furniture re-use and remanufacturing; 1.5: Intensify furniture use. |

| Guidelines_1.2: Facilitate furniture upgrading and adaptation. 1.2.1: Design reconfigurable furniture that is able to adapt to different spaces/situations, such as modular desk and storage structures that can be used for both the transformation of a given office space or for a new function (e.g., an individual working station that can be transformed into a collective one, and that can also be rearranged if the office moves to a new location). 1.2.2: Design a family of products instead of single ones, with different properties and functions that enable adaptation. 1.2.3: Include add-on parts to transform and/or upgrade the function and properties of the furniture. 1.2.4: Design for changeable ergonomic positions, e.g., a height-adjustable desk and chairs. 1.2.5: Avoid premature aesthetic obsolescence by designing furniture that can be customized (e.g., exchangeable seat covers) or personalized with a corporate identity via software to avoid add-on brand identification operations (printing, adhesive plates, etc.). 1.2.6: Consider designing multi-functional products that can adapt to the user’s development (physical and cultural). 1.2.7: [Office seats] Design modular and on-site upgradable seats, allowing the user to substitute (with standard tools) fixed feet with wheels and/or fixed components with adjustable ones. 1.2.8: [Office desks] Design modular and on-site upgradable desks, allowing the user to add (with standard tools) drawers, change drawer typology, add inner cabling cabinets, etc. 1.2.9: [Office storage] Design modular and on-site upgradable storage, allowing the user to add (with standard tools) shells, change drawer typology, etc. 1.2.10: Co-design furniture and connection platforms such as flooring, ceilings, and walls. 1.2.11: Include multiple connection possibilities on tables and storages, e.g., electricity cables, joints to combine table surfaces, etc. 1.2.12: Provide website and/or app with instructions and tools to enable maintenance and repair by the user, such as periodic maintenance procedures, e.g., cleaning of hard surfaces (desk, storage), inspection, repair, and lubrification (height-adjustable mechanism for office chairs or wheels). 1.2.13: [Office desks] If related to tech devices, enable upgrading and design reconfigurable desks according to forecastable technology development, e.g., Wi-Fi system/wireless system of automated desks. |

| Group | Result of Using the ECO-Idea Boards |

|---|---|

| 1 | 32 new ideas |

| 2 | 16 new ideas |

| 3 | 20 new ideas |

| 4 | 18 new ideas |

| Rating: 1 = very unsatisfied; 2 = unsatisfied; 3 = moderately satisfied; 4 = satisfied; 5 = very satisfied | ||||||

| Tool | 1 | 2 | 3 | 4 | 5 | 4 + 5 |

| Comprehensibility: Do you clearly understand the aim of the tool? | ||||||

| ECO-idea boards | 0% | 0% | 27% | 40% | 33% | 73% |

| Multi-strategy radar | 13% | 7% | 7% | 53% | 20% | 73% |

| Checklist for existing furniture evaluation | 0% | 13% | 13% | 20% | 53% | 73% |

| ESPI form | 7% | 7% | 20% | 27% | 40% | 67% |

| Checklist for LCD strategies pursuit evaluation | 0% | 7% | 27% | 27% | 40% | 67% |

| Usability: is it easy to understand how to use the tool | ||||||

| ECO-idea boards | 0% | 0% | 27% | 27% | 47% | 73% |

| Multi-strategy radar | 0% | 7% | 20% | 33% | 40% | 73% |

| Checklist for existing furniture evaluation | 0% | 0% | 27% | 27% | 47% | 73% |

| ESPI form | 0% | 7% | 27% | 27% | 40% | 67% |

| Checklist for LCD strategies pursuit evaluation | 0% | 0% | 33% | 60% | 7% | 67% |

| Success/Usefulness: do you think the tool is helpful to achieve its aim? | ||||||

| ECO-idea boards | 0% | 13% | 7% | 20% | 60% | 80% |

| Multi-strategy radar | 0% | 7% | 33% | 47% | 13% | 60% |

| Checklist for existing furniture evaluation | 0% | 13% | 53% | 20% | 13% | 33% |

| ESPI form | 0% | 0% | 21% | 43% | 36% | 79% |

| Checklist for LCD strategies pursuit evaluation | 0% | 0% | 27% | 53% | 20% | 73% |

| Rating: 1 = very unsatisfied; 2 = unsatisfied; 3 = moderately satisfied; 4 = satisfied; 5 = very satisfied | ||||||

| Tool | 1 | 2 | 3 | 4 | 5 | 4 + 5 |

| Comprehensibility: Are the ICS × Furniture toolkit (and integrated tools) easily understandable (for the function and aim)? | ||||||

| Checklist for existing furniture evaluation | 0% | 0% | 24% | 62% | 14% | 76% |

| ECO-idea board | 0% | 0% | 24% | 57% | 19% | 76% |

| Checklist for furniture product LCD strategies pursuit evaluation | 0% | 0% | 29% | 52% | 19% | 71% |

| Multi-strategic radar | 0% | 5% | 24% | 43% | 29% | 72% |

| Usability: Are the ICS × Furniture toolkit (and integrated tools) easily used? | ||||||

| Checklist for existing furniture evaluation | 0% | 0% | 24% | 48% | 29% | 76% |

| ECO-idea board | 0% | 5% | 24% | 52% | 19% | 71% |

| Checklist for furniture product LCD strategies pursuit evaluation | 0% | 5% | 14% | 52% | 29% | 81% |

| Multi-strategic radar | 0% | 0% | 10% | 62% | 29% | 90% |

| Success/Usefulness: To what extent do you think the ICS × Furniture toolkit is useful to fulfill its aims? | ||||||

| Checklist for existing furniture evaluation | 0% | 0% | 24% | 38% | 38% | 76% |

| ECO-idea board | 0% | 0% | 24% | 29% | 48% | 76% |

| Checklist for furniture product LCD strategies pursuit evaluation | 0% | 0% | 10% | 57% | 33% | 90% |

| Multi-strategic radar | 0% | 0% | 14% | 24% | 62% | 86% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Vezzoli, C. Designing Environmentally Sustainable Furniture Products: Furniture-Specific Life Cycle Design Guidelines and a Toolkit to Promote Environmental Performance. Sustainability 2024, 16, 2628. https://doi.org/10.3390/su16072628

Yang D, Vezzoli C. Designing Environmentally Sustainable Furniture Products: Furniture-Specific Life Cycle Design Guidelines and a Toolkit to Promote Environmental Performance. Sustainability. 2024; 16(7):2628. https://doi.org/10.3390/su16072628

Chicago/Turabian StyleYang, Dongfang, and Carlo Vezzoli. 2024. "Designing Environmentally Sustainable Furniture Products: Furniture-Specific Life Cycle Design Guidelines and a Toolkit to Promote Environmental Performance" Sustainability 16, no. 7: 2628. https://doi.org/10.3390/su16072628

APA StyleYang, D., & Vezzoli, C. (2024). Designing Environmentally Sustainable Furniture Products: Furniture-Specific Life Cycle Design Guidelines and a Toolkit to Promote Environmental Performance. Sustainability, 16(7), 2628. https://doi.org/10.3390/su16072628