Identification of Aggregates Quarries via Computer Vision Analysis as a Tool for Sustainable Aggregates Management and Land Planning

Abstract

1. Introduction

1.1. Aggregates as an Industry

1.2. Aggregates Quarries Inventories

1.3. Use of Artificial Intelligence to Improve Quarries Inventories

2. Materials and Methods

2.1. Materials and Environments

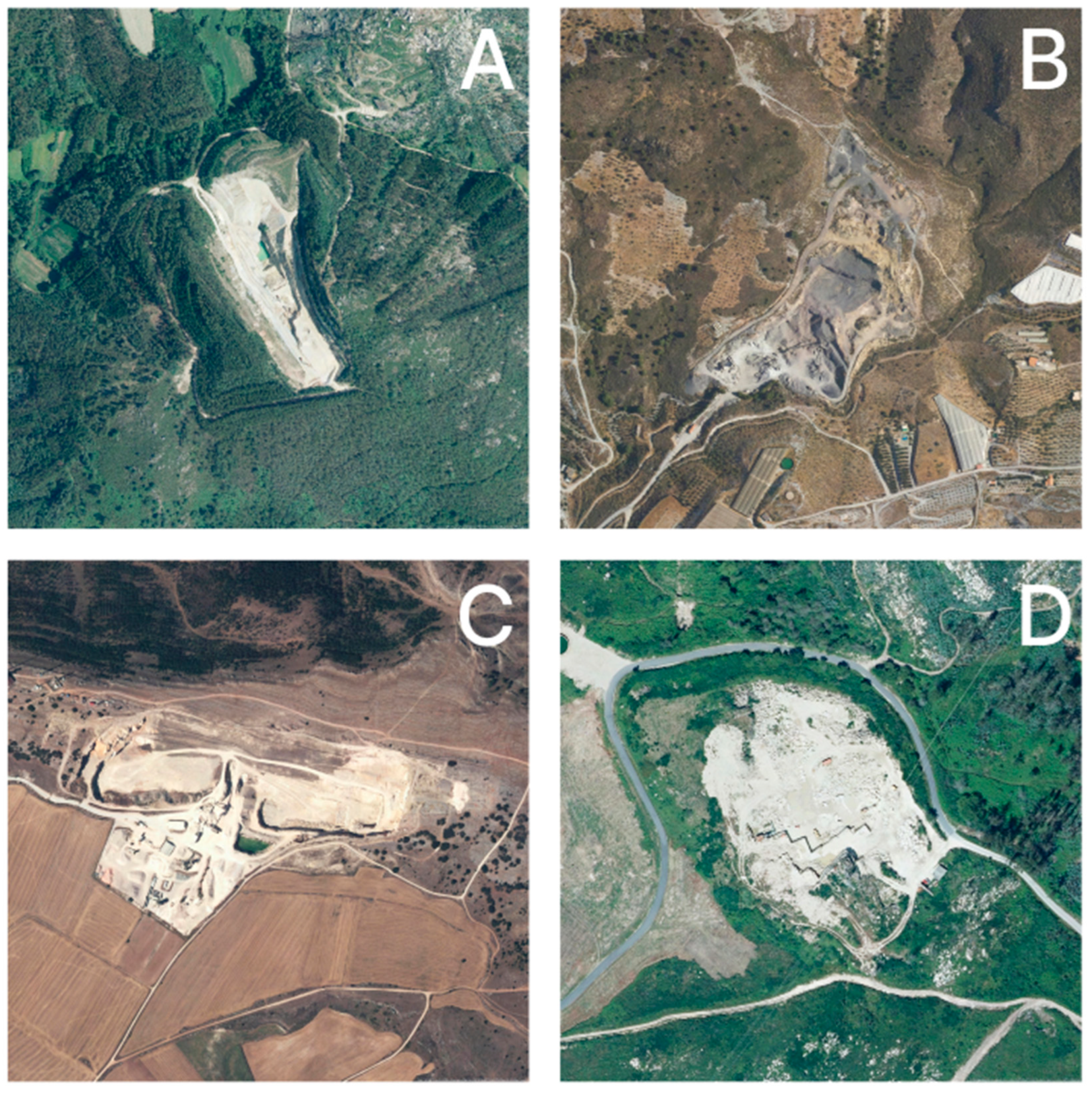

2.2. Images Dataset

2.3. Image Classification Training

2.4. Image Segmentation Training

2.5. Object Detection Training

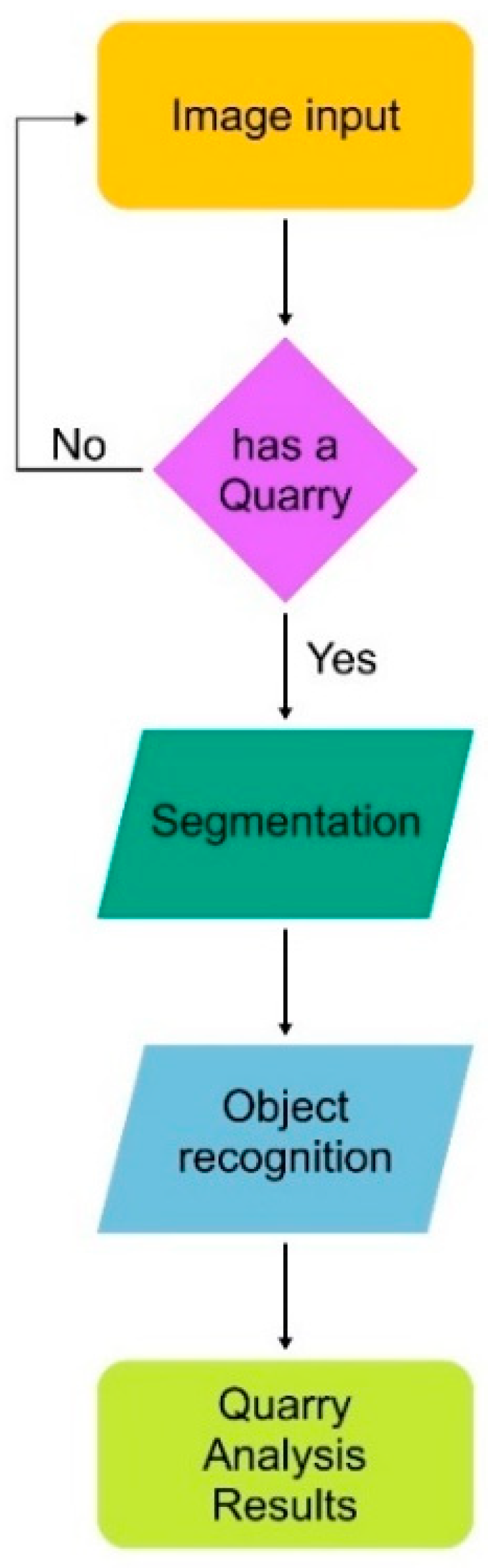

2.6. Assembly of the Code

3. Results

3.1. Quarry Classification

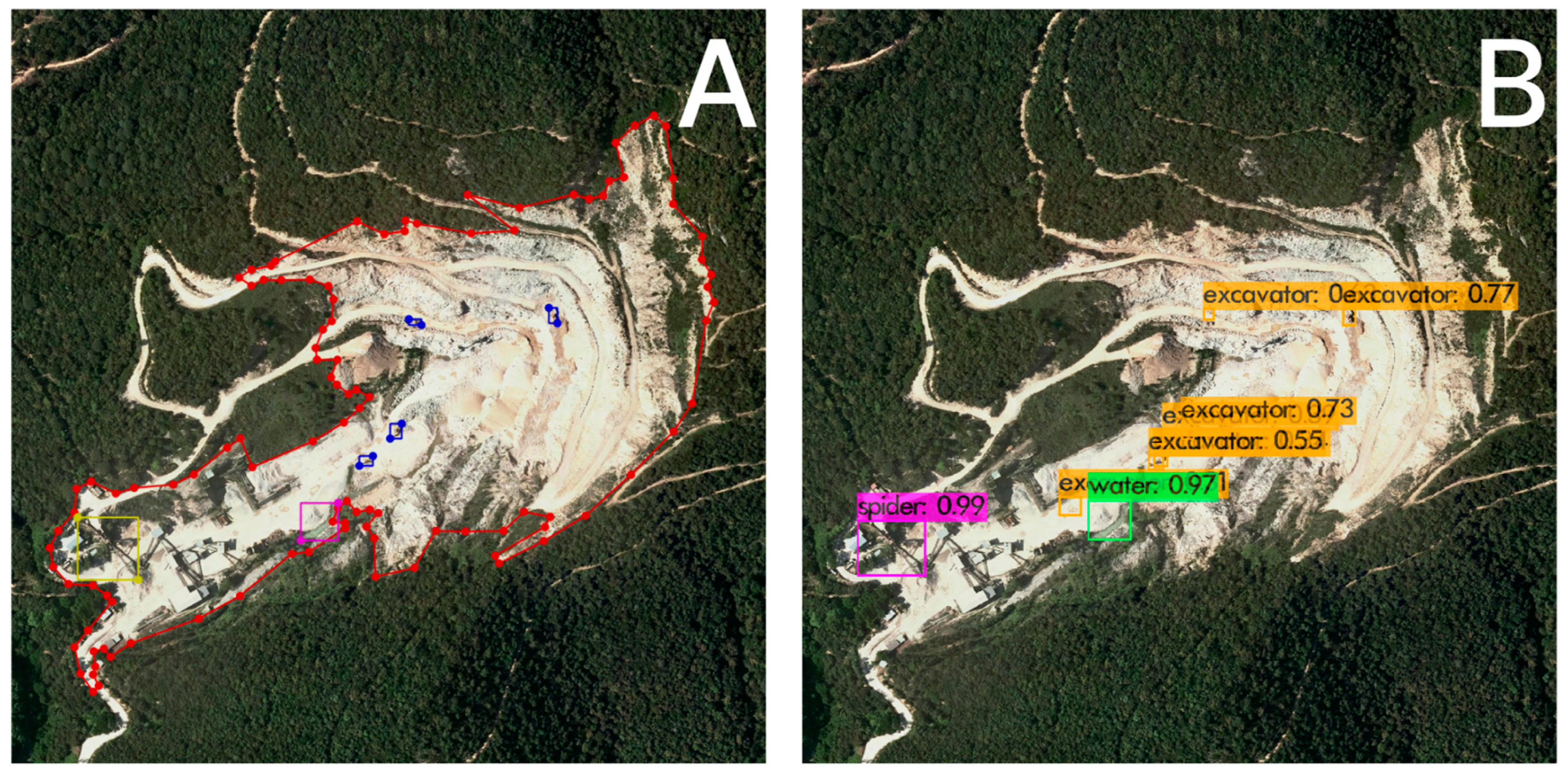

3.2. Quarry Segmentation

3.3. Quarry Object Detection

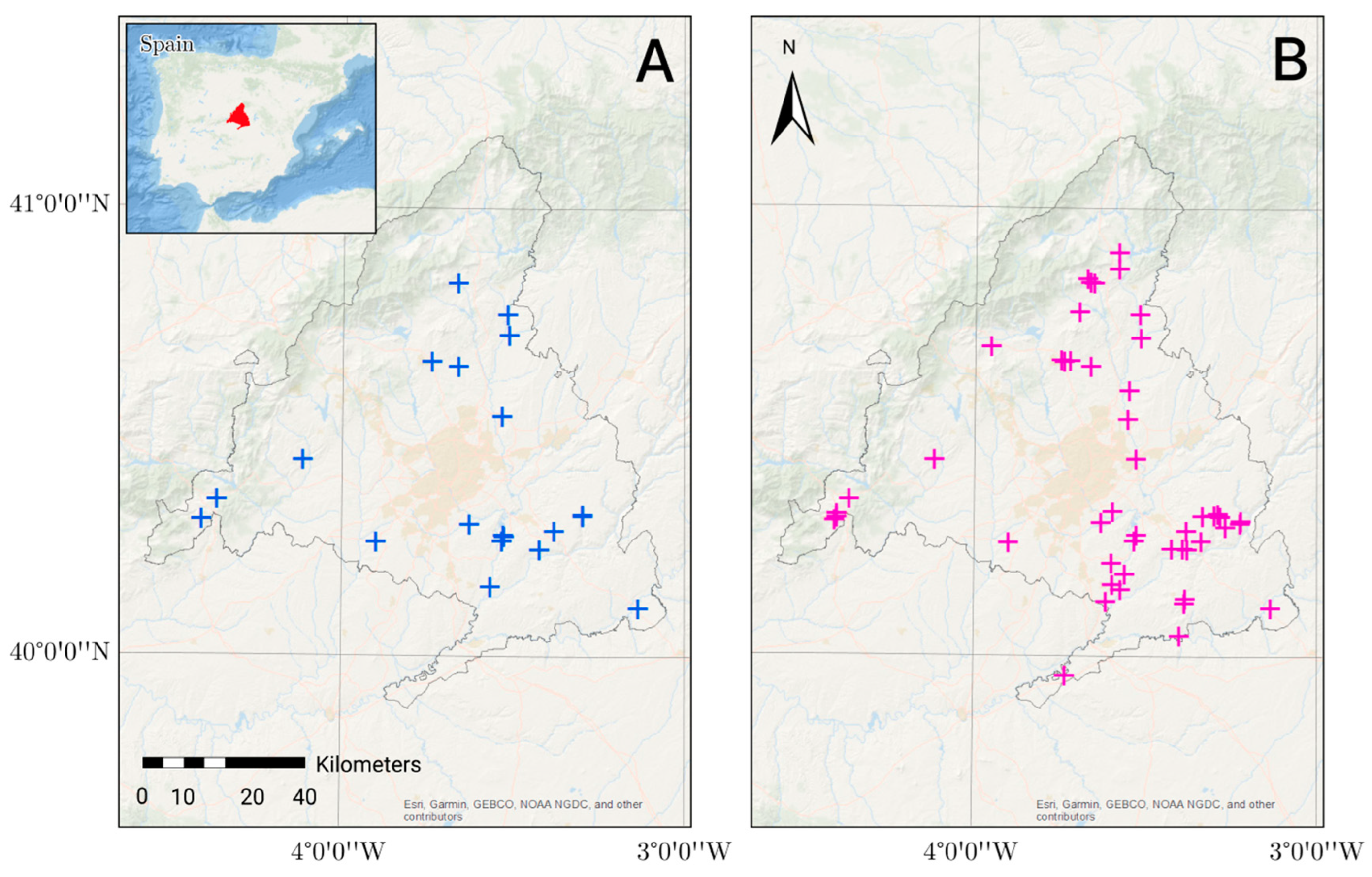

3.4. Validation of the Methodological Approach: Additional Case Study

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- GAIN. Global Aggregates Information Network. Available online: https://www.gain.ie/ (accessed on 12 January 2023).

- López-Acevedo, F.J.; Escavy, J.I.; Herrero, M.J. Application of Spatial Data Mining to national mines inventories for exploration and land planning of high place-value mineral resources. The case of aggregates in Spain. Resour. Policy 2022, 79, 103096. [Google Scholar] [CrossRef]

- Union Européenne des Producteurs de Granulats (UEPG). Available online: https://uepg.eu/ (accessed on 12 January 2023).

- Gherman, I.-E.; Lakatos, E.-S.; Clinci, S.D.; Lungu, F.; Constandoiu, V.V.; Cioca, L.I.; Rada, E.C. Circularity Outlines in the Construction and Demolition Waste Management: A Literature Review. Recycling 2023, 8, 69. [Google Scholar] [CrossRef]

- Aquino, C.; Inoue, M.; Miura, H.; Mizuta, M.; Okamoto, T. The effects of limestone aggregate on concrete properties. Constr. Build. Mater. 2010, 24, 2363–2368. [Google Scholar] [CrossRef]

- Bustillo Revuelta, M. Construction Materials: Geology, Production and Applications; Springer: Cham, Switzerland, 2021; Volume IX, p. 602. [Google Scholar] [CrossRef]

- UNEP Global Environmental Alert Service. Sand, Rarer Than One Thinks; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2014; p. 15. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/8665/GEAS_Mar2014_Sand_Mining.pdf (accessed on 12 January 2023).

- Escavy, J.I.; Herrero, M.J.; Trigos, L.; Sanz-Pérez, E. Demographic vs economic variables in the modelling and forecasting of the demand of aggregates: The case of the Spanish market (1995–2016). Resour. Policy 2020, 65, 101537. [Google Scholar] [CrossRef]

- Sverdrup, H.U.; Koca, D.; Schlyter, P. A Simple System Dynamics Model for the Global Production Rate of Sand, Gravel, Crushed Rock and Stone, Market Prices and Long-Term Supply Embedded into the WORLD6 Model. Biophys. Econ. Resour. Qual. 2017, 2, 8. [Google Scholar] [CrossRef]

- Escavy, J.I.; Herrero, M.J.; Lopez-Acevedo, F.; Trigos, L. The progressive distancing of aggregate quarries from the demand areas: Magnitude, causes, and impact on CO2 emissions in Madrid Region (1995–2018). Resour. Policy 2022, 75, 102506. [Google Scholar] [CrossRef]

- Herrero, M.J.; Escavy, J.I.; Bustillo, M. The Spanish building crisis and its effect in the gypsum quarry production (1998–2012). Resour. Policy 2013, 38, 123–129. [Google Scholar] [CrossRef]

- Ministerio para la Transición Ecológica y el Reto Demográfico. Spanish Mining Statistics Data. Available online: https://www.miteco.gob.es/es/energia/mineria-explosivos.html (accessed on 20 December 2023).

- Franks, D.M. Reclaiming the neglected minerals of development. Extr. Ind. Soc. 2020, 7, 453–460. [Google Scholar] [CrossRef]

- Torres, A.; Brandt, J.; Lear, K.; Liu, J. A looming tragedy of the sand commons. Science 2017, 357, 970–971. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, J. From here to human-level AI. Artif. Intell. 2007, 171, 1174–1182. [Google Scholar] [CrossRef]

- IBM. What is artificial intelligence (AI)? Available online: https://www.ibm.com/topics/artificial-intelligence (accessed on 12 January 2023).

- Herrero, M.J.; Pérez-Fortes, A.P.; Escavy, J.I.; Insua-Arévalo, J.M.; De la Horra, R.; López-Acevedo, F.; Trigos, L. 3D model generated from UAV photogrammetry and semi-automated rock mass characterization. Comput. Geosci. 2022, 163, 105121. [Google Scholar] [CrossRef]

- IBM. What Is Computer Vision? Available online: https://www.ibm.com/topics/computer-vision (accessed on 12 January 2023).

- Karn, A. Artificial Intelligence in Computer Vision. Int. J. Eng. Appl. Sci. Technol. 2021, 6, 249–254. [Google Scholar] [CrossRef]

- Mayer, H. Object extraction in photogrammetric computer vision. ISPRS J. Photogramm. Remote Sens. 2008, 63, 213–222. [Google Scholar] [CrossRef]

- Razeghi, O.; Solis-Lemus, J.A.; Lee, A.W.C.; Karim, R.; Corrado, C.; Roney, C.H.; de Vecchi, A.; Niederer, S.A. CemrgApp: An interactive medical imaging application with image processing, computer vision, and machine learning toolkits for cardiovascular research. SoftwareX 2020, 12, 100570. [Google Scholar] [CrossRef] [PubMed]

- Eyiokur, F.I.; Kantarci, A.; Erakin, M.E.; Damer, N.; Ofli, F.; Imran, M.; Krizaj, J.; Salah, A.A.; Waibel, A.; Struc, V.; et al. A survey on computer vision based human analysis in the COVID-19 era. Image Vis. Comput. 2023, 130, 104610. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Bischof, W.F.; Caelli, T. Road tracking in aerial images based on human–computer interaction and Bayesian filtering. ISPRS J. Photogramm. Remote Sens. 2006, 61, 108–124. [Google Scholar] [CrossRef]

- Wang, W.; Yang, N.; Zhang, Y.; Wang, F.; Cao, T.; Eklund, P. A review of road extraction from remote sensing images. J. Traffic Transp. Eng. (Engl. Ed.) 2016, 3, 271–282. [Google Scholar] [CrossRef]

- Weinstein, B.G. A computer vision for animal ecology. J. Anim. Ecol. 2018, 87, 533–545. [Google Scholar] [CrossRef] [PubMed]

- Onesait Platform. Early Fire Detection System. Available online: https://blog.onesaitplatform.com/en/2022/12/21/early-fire-detection-system/ (accessed on 12 January 2023).

- Thomas, G.; Gade, R.; Moeslund, T.B.; Carr, P.; Hilton, A. Computer vision for sports: Current applications and research topics. Comput. Vis. Image Underst. 2017, 159, 3–18. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Mehmood, M.; Shahzad, A.; Zafar, B.; Shabbir, A.; Ali, N.; Ahmad, A. Remote Sensing Image Classification: A Comprehensive Review and Applications. Math. Probl. Eng. 2022, 2022, 5880959. [Google Scholar] [CrossRef]

- Sowmya, A.; Trinder, J. Modelling and representation issues in automated feature extraction from aerial and satellite images. ISPRS J. Photogramm. Remote Sens. 2000, 55, 34–47. [Google Scholar] [CrossRef]

- Anaconda Inc. Anaconda Software Distribution. Available online: https://docs.anaconda.com/ (accessed on 12 January 2023).

- Python. Python Software Foundation. 2020. Available online: http://www.python.org/ (accessed on 12 January 2023).

- ESRI. ArcGIS Desktop ArcCatalog, 10.5; Environmental Systems Research Institute: Redlands, CA, USA, 2016; Available online: https://desktop.arcgis.com/en/arcmap/latest/manage-data/using-arccatalog/what-is-arccatalog-.htm/ (accessed on 12 January 2023).

- ESRI. ArcGIS Desktop ArcMap, 10.5; Environmental Systems Research Institute: Redlands, CA, USA, 2016; Available online: https://desktop.arcgis.com/en/arcmap/latest/map/main/what-is-arcmap-.htm/ (accessed on 12 January 2023).

- ESRI. ArcGIS Arcpy; Environmental Systems Research Institute: Redlands, CA, USA, 2016; Available online: https://desktop.arcgis.com/en/arcmap/10.5/analyze/arcpy/what-is-arcpy-.htm (accessed on 12 January 2023).

- ESRI. World Imagery; ESRI (ArcGIS Services): Redlands, CA, USA, 2023. [Google Scholar]

- Wada, K.; mpitid; Buijs, M.; Zhang, C.N.; Narumi; Kubovčík, M.; Myczko, A.; latentix; Zhu, L.; Yamaguchi, N.; et al. Labelme: Image Polygonal Annotation with Python, 4.6.0. 2021; Available online: https://zenodo.org/records/5711226 (accessed on 12 January 2023).

- Boesch, G. A Complete Guide to Image Classification in 2023. Available online: https://viso.ai/computer-vision/image-classification/ (accessed on 27 February 2023).

- Paszke, A.; Gross, S.; Massa, F.; Lerer, A.; Bradbury, J.; Chanan, G.; Killeen, T.; Lin, Z.; Gimelshein, N.; Antiga, L.; et al. PyTorch: An Imperative Style, High-Performance Deep Learning Library. In Proceedings of the 33rd Conference on Neural Information Processing Systems (NeurIPS 2019), Vancouver, BC, Canada, 8–14 December 2019. [Google Scholar]

- Sathyan, A. Anilsathyan7/Pytorch-Image-Classification: First Release of Pytorch Image Classification (v1.0.0). 2021. Available online: https://zenodo.org/record/4429503 (accessed on 12 January 2023).

- Google. TensorFlow, a Free and Open-Source Software Library for Machine Learning and Artificial Intelligence, 2.11th ed. 2022. Available online: https://www.tensorflow.org/ (accessed on 12 January 2023).

- Alyafeai, Z. The U-Net Model Is a Simple Fully Convolutional Neural Network That IS Used for Binary Segmentation i.e., Foreground and Background Pixel-Wise Classification. In This Notebook We Use It to Segment Cats and Dogs from Arbitrary Images. 2020. Available online: https://colab.research.google.com/github/zaidalyafeai/Notebooks/blob/master/unet.ipynb (accessed on 12 January 2023).

- Ronneberger, O.; Fischer, P.; Brox, T. U-net: Convolutional networks for biomedical image segmentation. In Proceedings of the Medical Image Computing and Computer-Assisted Intervention–MICCAI 2015: 18th International Conference, Munich, Germany, 5–9 October 2015; Proceedings, Part III 18. pp. 234–241. [Google Scholar]

- Clark, A. Pillow, 9.4.0. 2023. Available online: https://pillow.readthedocs.io/en/stable/ (accessed on 12 January 2023).

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 26 June–1 July 2016; pp. 779–788. [Google Scholar]

- O’Shea, K.; Nash, R. An introduction to convolutional neural networks. arXiv 2015, arXiv:1511.08458. [Google Scholar]

- Redmon, J. Darknet: Open Source Neural Networks in C. 2013. Available online: https://pjreddie.com/darknet/ (accessed on 12 January 2023).

- Oh, F. What Is CUDA? Available online: https://blogs.nvidia.com/blog/what-is-cuda-2/ (accessed on 27 February 2023).

- OpenCV. About OpenCV. Available online: https://opencv.org/about/ (accessed on 27 February 2023).

- Hasty.ai. Intersection over Union (IoU). Available online: https://hasty.ai/docs/mp-wiki/metrics/iou-intersection-over-union (accessed on 7 February 2023).

- Wu, Z. Computer Vision-Based Traffic Sign Detection and Extraction: A Hybrid Approach Using GIS And Machine Learning. Master’s Thesis, Georgia Southern University, Statesboro, GA, USA, 2019. [Google Scholar]

- Aleqabie, H.J. Recognition of Primary Geometric Shapes Using Image Segmentation and Blobs. Eur. Acad. Res. 2014, 2, 6067–6075. [Google Scholar]

- Bleischwitz, R.; Bahn-Walkowiak, B. Aggregates and Construction Markets in Europe: Towards a Sectoral Action Plan on Sustainable Resource Management. Miner. Energy-Raw Mater. Rep. 2007, 22, 159–176. [Google Scholar] [CrossRef]

- Neumayer, E. Does the “Resource Curse” hold for Growth in Genuine Income as Well? World Dev. 2004, 32, 1627–1640. [Google Scholar] [CrossRef]

- Escavy, J.; Herrero, M. The use of location–Allocation techniques for exploration targeting of high place-value industrial minerals: A market-based prospectivity study of the Spanish gypsum resources. Ore Geol. Rev. 2013, 53, 504–516. [Google Scholar] [CrossRef]

- Traeger, C.; Haski-Leventhal, D.; Alfes, K. Extending organizational socialization theory: Empirical evidence from volunteer work for refugees in France and Australia. Hum. Relat. 2021, 75, 1140–1166. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Acevedo, F.J.; Herrero, M.J.; Escavy, J.I.; Peláez Fernández, M.A. Identification of Aggregates Quarries via Computer Vision Analysis as a Tool for Sustainable Aggregates Management and Land Planning. Sustainability 2024, 16, 3099. https://doi.org/10.3390/su16083099

López-Acevedo FJ, Herrero MJ, Escavy JI, Peláez Fernández MA. Identification of Aggregates Quarries via Computer Vision Analysis as a Tool for Sustainable Aggregates Management and Land Planning. Sustainability. 2024; 16(8):3099. https://doi.org/10.3390/su16083099

Chicago/Turabian StyleLópez-Acevedo, Francisco J., María J. Herrero, José I. Escavy, and Miguel A. Peláez Fernández. 2024. "Identification of Aggregates Quarries via Computer Vision Analysis as a Tool for Sustainable Aggregates Management and Land Planning" Sustainability 16, no. 8: 3099. https://doi.org/10.3390/su16083099

APA StyleLópez-Acevedo, F. J., Herrero, M. J., Escavy, J. I., & Peláez Fernández, M. A. (2024). Identification of Aggregates Quarries via Computer Vision Analysis as a Tool for Sustainable Aggregates Management and Land Planning. Sustainability, 16(8), 3099. https://doi.org/10.3390/su16083099