Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience

Abstract

:1. Introduction

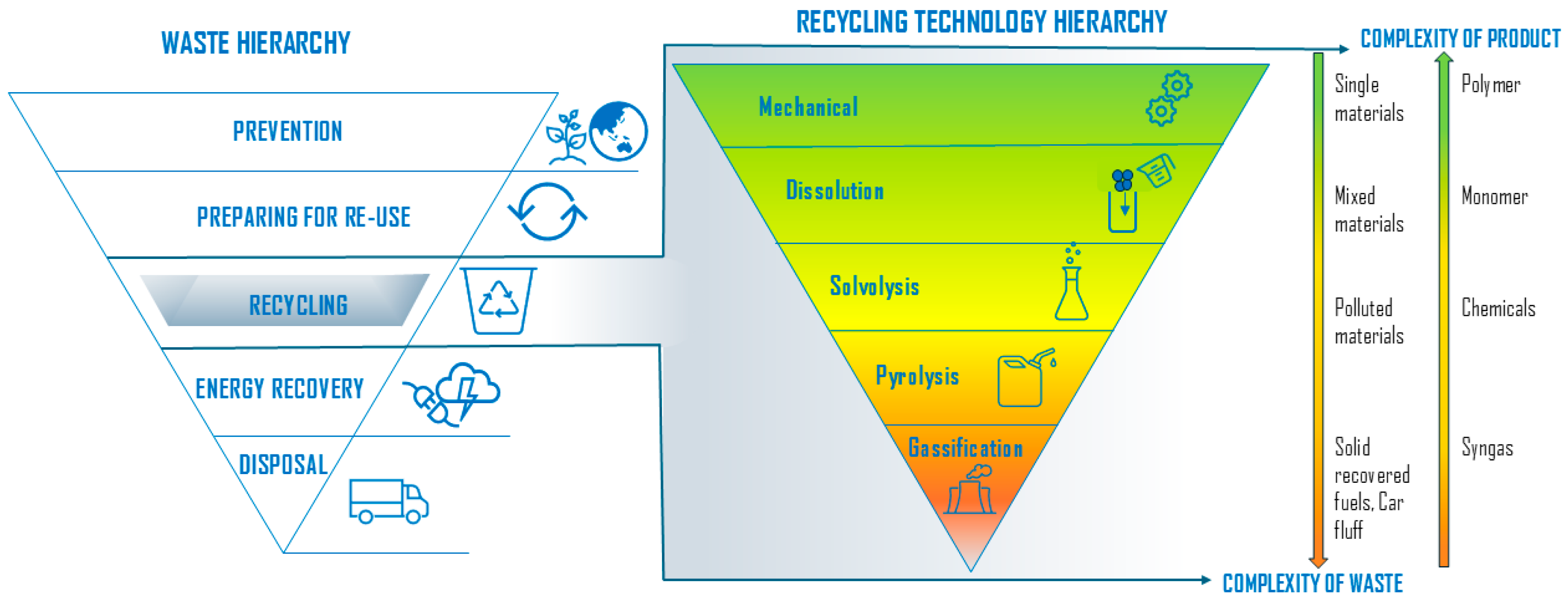

2. Mechanical Recycling

3. Chemical Recycling

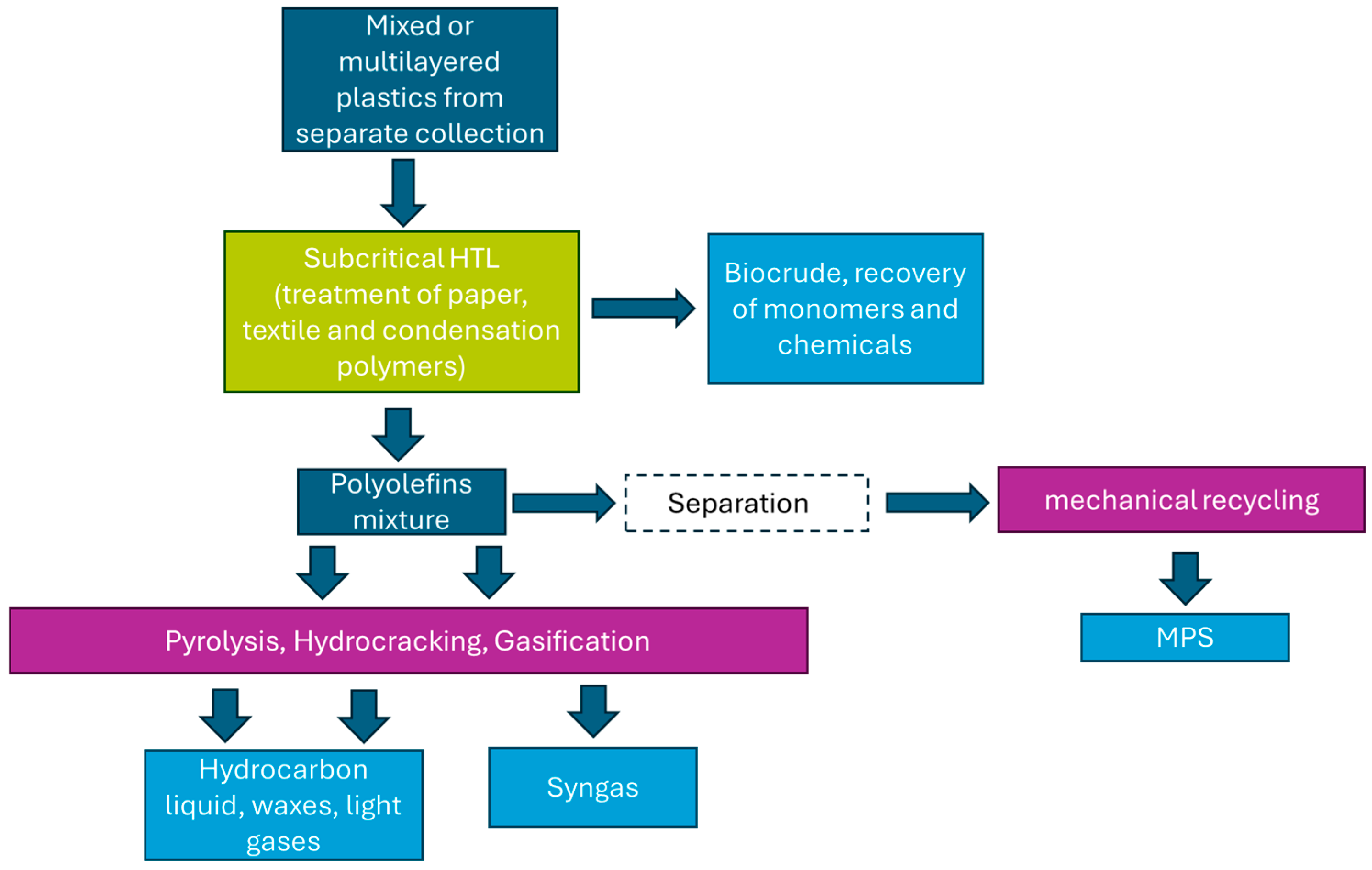

3.1. Overview

3.2. Focus on Pyrolysis

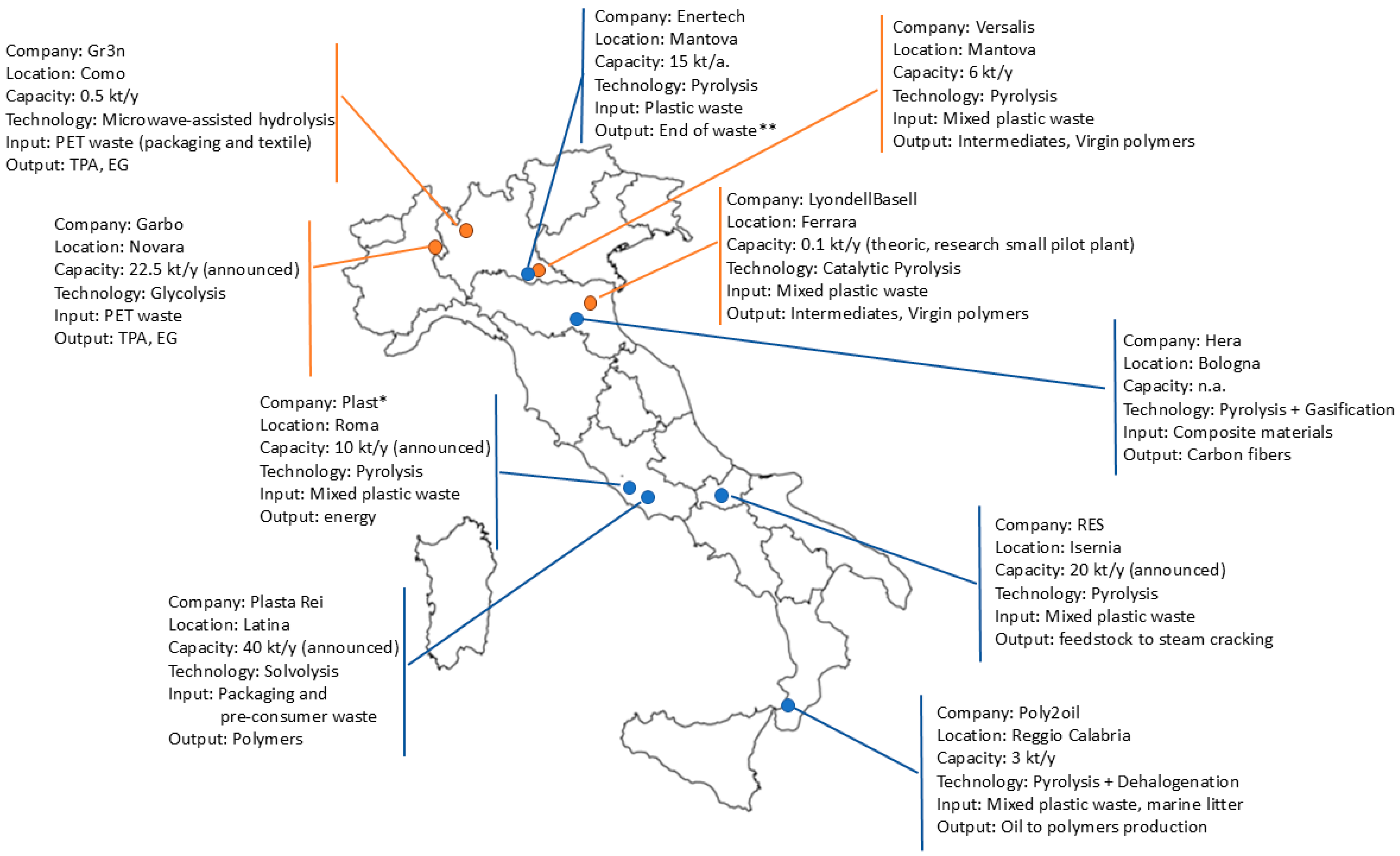

3.3. Present Situation of European Chemical Recycling

3.4. Solutions, Strategies, and Policies for the Scale-Up of Chemical Recycling Technologies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | acrylonitrile butadiene styrene |

| ASSORIMAP | (Italian) National Association of Recyclers and Regenerators of Plastic Materials |

| BAT | best available technology |

| BDM | Benzenedimethanol |

| BG | butyl glycol |

| BPA | bisphenol A |

| BTEX | benzene, toluene, ethylene, and xylene |

| BHET | bis(2-hydroxyethyl) terephthalate |

| BFR | brominated flame retardant |

| CA | crotonic acid |

| CEFIC | European Chemical Industry Council |

| COREPLA | (Italian) National Consortium for the Collection and Recycling of Plastic packages |

| DMT | dimethyl ester of terephthalic acid |

| EEE | electric and electronic equipment |

| EG | ethylene glycol |

| ELV | end-of-life vehicles |

| EoL | end of life |

| EoW | end of waste |

| EPS | expanded polystyrene |

| EVOH | ethylene vinyl alcohol |

| GHG | greenhouse gas |

| HTL | hydrothermal liquefaction |

| JRC | Joint Research Centre |

| HCl | hydrogen chloride |

| MDA | methylene diphenyl diamine |

| MEG | mono-ethylene-glycol |

| MMA | methyl methacrylate |

| MPO | mixed polyolefins |

| MRFs | mechanical recovery facilities |

| PA, PA6, PA66, PA12 | polyamide, polyamide 6, polyamide 66, polyamide 12 |

| PBT | polybutylene terephthalate |

| PHB | poly(3-hydroxybutyrate) |

| PC | polycarbonate |

| PC + ABS | polycarbonate/acrylonitrile butadiene styrene blend |

| PAH | poly aromatic hydrocarbons |

| PE, LDPE, HDPE | polyethylene, low-density polyethylene, high-density polyethylene |

| PET | polyethylene terephthalate |

| PIP | polyisoprene |

| PLA | poly lactic acid |

| PMMA | polymethylmethacrylate (acrylic) |

| PP | polypropylene |

| PS | polystyrene |

| PTMT | polytetramethylene terephthalate |

| PU | polyurethane |

| PUs | polyurethanes |

| PVC | polyvinyl chloride |

| REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals |

| SRA | secondary reduce agent |

| SRM | secondary raw materials |

| TAM | terephthalamide |

| TDA | 2,4- and 2,6-toluenediamine |

| TPA | terephthalic acid |

| XPS | expanded extruded polystyrene |

| WEEE | waste electrical and electronic equipment |

References

- Plastics Europe. Plasticsthefastfacts2023-1. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2023/ (accessed on 12 April 2024).

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Handbook of Recycling, State-Of-the-art for Practitioners, Analysts, and Scientists, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 723–738. [CrossRef]

- The Circular Economy for Plastics A European Analysis. 2024. Available online: https://plasticseurope.org/knowledge-hub/the-circular-economy-for-plastics-a-european-analysis-2024/ (accessed on 9 December 2024).

- Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2018/852/oj/eng (accessed on 9 December 2024).

- CPA Roadmap to 10 Mt—Untapped Potential Report. Available online: https://ec.europa.eu/docsroom/documents/46956 (accessed on 9 December 2024).

- Commission Implementing Decision (EU) 2019/665—Of 17 April 2019—Amending Decision 2005/270/EC Establishing the Formats Relating to the Database System Pursuant to European Parliament and Council Directive 94/62/EC on Packaging and Packaging Waste—(Notified Under Document C(2019) 2805). Available online: https://eur-lex.europa.eu/eli/dec_impl/2019/665/oj/eng (accessed on 9 December 2024).

- ISPRA. Rapporto Rifiuti Urbani n. 380. 2022; ISBN 978-88-448-1145-7. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2022 (accessed on 9 December 2024).

- ISPRA. Rapporto Rifiuti Urbani n. 393. 2023; ISBN 978-88-448-1200-3. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2023 (accessed on 9 December 2024).

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 9 December 2024).

- Squitieri, G.; Cancelli, D.; Leoni, S.; Galli, L.; Cipriano, V.; Pacilli, A.; Di Mario, V. (Edited by Edo Ronchi) IL Riciclo in Italia|Rapporto. 2023. Available online: https://www.ricicloinitalia.it/il-rapporto-2023/ (accessed on 9 December 2024).

- A European Strategy for Plastics in a Circular Economy. Available online: https://www.europarc.org/wp-content/uploads/2018/01/Eu-plastics-strategy-brochure.pdf (accessed on 9 December 2024).

- European Commission. Commitments and Deliverables of the Circular Plastics Alliance. Available online: https://single-market-economy.ec.europa.eu/industry/industrial-alliances/circular-plastics-alliance/commitments-and-deliverables-circular-plastics-alliance_en (accessed on 7 October 2024).

- Maris, J.; Bourdon, S.; Brossard, J.M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- U.S. Food & Drug Administration. Use of Recycled Plastics in Food Packaging (Chemistry Considerations): Guidance for Industry. Available online: https://www.fda.gov/FoodGuidances (accessed on 9 December 2024).

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Paletta, A.; Filho, W.L.; Balogun, A.-L.; Foschi, E.; Bonoli, A. Barriers and challenges to plastics valorisation in the context of a circular economy: Case studies from Italy. J. Clean. Prod. 2019, 241, 118149. [Google Scholar] [CrossRef]

- Malik, N.; Kumar, P.; Shrivastava, S.; Ghosh, S.B. An overview on PET waste recycling for application in packaging. Int. J. Plast. Technol. 2017, 21, 1–24. [Google Scholar] [CrossRef]

- Plastics Recyclers Europe. Plastics Recycling Industry Figures. 2022. Available online: https://www.plasticsrecyclers.eu/publications/ (accessed on 3 September 2024).

- ASSORIMAP. Il Riciclo Meccanico Delle Materie Plastiche REPORT 2023. 2024. Available online: www.plasticconsult.it (accessed on 9 December 2024).

- Plastic Finder. Available online: https://www.plasticfinder.it/web/guest (accessed on 4 September 2024).

- UNI Ente Italiano di Normazione. UNI 10667-1:2010 Plastic Raw-Secondary Materials—Part 1: General. 2010. Available online: https://www.intertekinform.com/en-gb/standards/uni-10667-1-2010-1075509_saig_uni_uni_2506092/?srsltid=AfmBOoqfxN4IoyjkrCkEL4-gIGDwRsXCYgoBs65MWlRuMVV2KZtdF_WU (accessed on 15 January 2025).

- Gazzotti, S.; De Felice, B.; Ortenzi, M.A.; Parolini, M. Approaches for Management and Valorization of Non-Homogeneous, Non-Recyclable Plastic Waste. Int. J. Environ. Res. Public Health 2022, 19, 10088. [Google Scholar] [CrossRef]

- Genuino, H.C.; Ruiz, M.P.; Heeres, H.J.; Kersten, S.R.A. Pyrolysis of mixed plastic waste (DKR-350): Effect of washing pre-treatment and fate of chlorine. Fuel Process. Technol. 2022, 233, 107304. [Google Scholar] [CrossRef]

- Corepla. Relazione sulla gestione. 2023. Available online: https://www.corepla.it/wp-content/uploads/2024/06/relazione_sulla_gestione_2023_corepla.pdf (accessed on 9 December 2024).

- Colantonio, S.; Cafiero, L.; De Angelis, D.; Ippolito, N.M.; Tuffi, R.; Ciprioti, S.V. Thermal and catalytic pyrolysis of a synthetic mixture representative of packaging plastics residue. Front. Chem. Sci. Eng. 2020, 14, 288–303. [Google Scholar] [CrossRef]

- Senato della Repubblica Italiana, DDL S. 635. 2022. Available online: https://parlamento18.openpolis.it/atto/documento/id/180879 (accessed on 9 December 2024).

- Virginia Racioppi, A.G. Studio di Fattibilità nell’ambito dell’Economia Circolare Mirato al Riciclo Delle Plastiche Miste. Available online: https://www.mimit.gov.it/images/stories/documenti/allegati/coop/SF_Riciclo_PlasticheMiste.pdf (accessed on 10 October 2024).

- EcoRevive. Applicazioni EcoRevive. Available online: https://www.ecorevive.world/blog (accessed on 21 August 2024).

- iblu. Prodotti. Available online: https://www.iblu.it/it/prodotti.html (accessed on 21 August 2024).

- Corepla. Iren Rileva I.Blu e Diventa Leader nel Trattamento Della Plastica. Available online: https://www.corepla.it/news/iren-rileva-iblu-e-diventa-leader-nel-trattamento-della-plastica (accessed on 10 October 2024).

- Il Sole 24 Ore. Acciaio: La Plastica Rimpiazza il Carbone. Available online: https://seitoscana.it/parlano-di-noi/14102021-acciaio-la-plastica-rimpiazza-carbone (accessed on 10 October 2024).

- Fiore, E.; Tamborrini, P. PHOENIX: Towards a circular economy of plasmix waste—A systemic design approach. Circ. Econ. 2024, 3, 100075. [Google Scholar] [CrossRef]

- Harscoet, E.; Chouvenc, S.; Faugeras, A.-C.; Ammenti-Deloitte, F. Chemical and Physico-Chemical Recycling of Plastic Waste Final Report. 2022. Available online: www.record-net.org (accessed on 9 December 2024).

- Closed Loop Partners. Accelerating Circular Supply Chains for Plastics; Closed Loop Partners: New York, NY, USA, 2019; Available online: https://www.closedlooppartners.com/ (accessed on 12 April 2024).

- Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2014; pp. 563–581. [CrossRef]

- Cafiero, L.; Fabbri, D.; Trinca, E.; Tuffi, R.; Ciprioti, S.V. Thermal and spectroscopic (TG/DSC–FTIR) characterization of mixed plastics for materials and energy recovery under pyrolytic conditions. J. Therm. Anal. Calorim 2015, 121, 1111–1119. [Google Scholar] [CrossRef]

- Roy, P.S.; Garnier, G.; Allais, F.; Saito, K. Strategic Approach Towards Plastic Waste Valorization: Challenges and Promising Chemical Upcycling Possibilities. ChemSusChem 2021, 14, 4007–4027. [Google Scholar] [CrossRef] [PubMed]

- Bozkurt, O.D.; Okonsky, S.T.; Alexopoulos, K.; Toraman, H.E. Catalytic conversion of SPW and products upgrading. Adv. Chem. Eng. 2022, 60, 117–168. [Google Scholar] [CrossRef]

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Expanding plastics recycling technologies: Chemical aspects, technology status and challenges. Green Chem. 2022, 24, 8899–9002. [Google Scholar] [CrossRef]

- PlasticsEurope. Plastics Convert Iron ore to Steel Feedstock Recycling in Blast Furnaces. Available online: https://legacy.plasticseurope.org/download_file/force/1108/181 (accessed on 9 December 2024).

- Mirabile, D.; Pistelli, M.I.; Marchesini, M.; Falciani, R.; Chiappelli, L. Thermal valorisation of automobile shredder residue: Injection in blast furnace. Waste Manag. 2002, 22, 841–851. [Google Scholar] [CrossRef] [PubMed]

- Lotfian, S.; Vikström, T.; Lennartsson, A.; Björkman, B.; Ahmed, H.; Samuelsson, C. Plastic-containing materials as alternative reductants for base metal production. Can. Metall. Q. 2019, 58, 164–176. [Google Scholar] [CrossRef]

- Caro, D.; Albizzati, P.F.; Cristóbal Garcia, J.; Saputra Lase, I.; Garcia-Gutierrez, P.; Juchtmans, R.; Garbarino, E.; Blengini, G.; Manfredi, S.; De Meester, S.; et al. Towards a Better Definition and Calculation of Recycling. In JRC Science for Policy Report; Publications Office of the European Union: Luxembourg, 2023; Available online: https://data.europa.eu/doi/10.2760/636900 (accessed on 9 December 2024).

- Devasahayam, S.; Raju, G.B.; Hussain, C.M. Utilization and recycling of end-of-life plastics for sustainable and clean industrial processes including the iron and steel industry. Mater. Sci. Energy Technol. 2019, 2, 634–646. [Google Scholar] [CrossRef]

- Munir, D.; Irfan, M.F.; Usman, M.R. Hydrocracking of virgin and waste plastics: A detailed review. Renew. Sustain. Energy Rev. 2018, 90, 490–515. [Google Scholar] [CrossRef]

- Vidal, F.; van der Marel, E.R.; Kerr, R.W.; McElroy, C.; Schroeder, N.; Mitchell, C.; Rosetto, G.; Chen, T.T.; Bailey, R.M.; Hepburn, C.; et al. Designing a circular carbon and plastics economy for a sustainable future. Nature 2024, 626, 7997. [Google Scholar] [CrossRef] [PubMed]

- Arena, U.; Ardolino, F. Technical and environmental performances of alternative treatments for challenging plastics waste. Resour. Conserv. Recycl. 2022, 183, 106379. [Google Scholar] [CrossRef]

- Castagnoli, A.; Salem, A.M.; Desideri, U.; Pecorini, I. Environmental assessment of gasification and green hydrogen potential role in waste management decarbonization. J. Clean. Prod. 2024, 482, 144174. [Google Scholar] [CrossRef]

- Gutierrez, G.; Amadei, P.; Klenert, A.M.; Nessi; Tonini, S. Environmental and economic assessment of plastic waste recycling. In JRC Technical Report; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J.; Jin, H.; Guo, L. Chemical recycling methods for managing waste plastics: A review. Environ. Chem. Lett. 2024, 22, 149–169. [Google Scholar] [CrossRef]

- Krause, L.; Özgen, A.; Kern, J.; Das, S.; Carus, M.; Raschka, A. Mapping of Advanced Plastic Waste Recycling Technologies and Their Global Capacities-Short Version. 2024. Available online: https://renewable-carbon.eu/publications/product/mapping-of-advanced-plastic-waste-recycling-technologies-and-their-global-capacities-short-version-pdf/ (accessed on 9 December 2024).

- Moussa, K.; Awad, S.; Krawczak, P.; Al Takash, A.; Faraj, J.; Khaled, M. An Overview of the Non-Energetic Valorization Possibilities of Plastic Waste via Thermochemical Processes. Materials 2024, 17, 1460. [Google Scholar] [CrossRef]

- Scheirs, J.; Kaminsky, W. Feedstock Recycling and Pyrolysis of Waste Plastics: Converting Waste Plastics into Diesel and Other Fuels; John Wiley & Sons Ltd.: Chichester, UK, 2006. [Google Scholar] [CrossRef]

- Martínez-Narro, G.; Hassan, S.; Phan, A.N. Chemical recycling of plastic waste for sustainable polymer manufacturing—A critical review. J. Environ. Chem. Eng. 2024, 12, 112323. [Google Scholar] [CrossRef]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Tariq, R.; Gul, K.; Ahmad, W. Pyrolysis Study of Polypropylene and Polyethylene Into Premium Oil Products. Int. J. Green Energy 2015, 12, 663–671. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P.; Escola, J.M. Catalytic Upgrading of Plastic Wastes. In Feedstock Recycling and Pyrolysis of Waste Plastics; John Wiley & Sons Ltd.: Chichester, UK, 2006; pp. 73–110. [Google Scholar] [CrossRef]

- Calero, M.; Solís, R.R.; Muñoz-Batista, M.J.; Pérez, A.; Blázquez, G.; Martín-Lara, M.Á. Oil and gas production from the pyrolytic transformation of recycled plastic waste: An integral study by polymer families. Chem. Eng. Sci. 2023, 271, 118569. [Google Scholar] [CrossRef]

- Esposito, L.; Cafiero, L.; De Angelis, D.; Tuffi, R.; Ciprioti, S.V. Valorization of the plastic residue from a WEEE treatment plant by pyrolysis. Waste Manag. 2020, 112, 1–10. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Y.; Ke, L.; Dai, L.; Wu, Q.; Cobb, K.; Zeng, Y.; Zou, R.; Liu, Y.; Ruan, R. A review on catalytic pyrolysis of plastic wastes to high-value products. Energy Convers Manag 2022, 254, 115243. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Olazar, M.; Bilbao, J. Operating Conditions for the Pyrolysis of Poly-(ethylene terephthalate) in a Conical Spouted-Bed Reactor. Ind. Eng. Chem. Res. 2010, 49, 2064–2069. [Google Scholar] [CrossRef]

- Wan, H.; Huang, Z. Pyrolysis Evaluation of Tennis String Polyurethane and Water-Borne Polyurethane Wastes through Isoconversional Kinetic Analysis. Polymers 2022, 14, 1501. [Google Scholar] [CrossRef] [PubMed]

- Garrido, M.A.; Font, R. Pyrolysis and combustion study of flexible polyurethane foam. J. Anal. Appl. Pyrolysis 2015, 113, 202–215. [Google Scholar] [CrossRef]

- Takamoto, D.Y.; Petrich, M.A. Effect of Heterogeneous Secondary Pyrolysis Reactions on the Thermal Decomposition of Polyurethane Scrap. Ind. Eng. Chem. Res. 1994, 33, 3004–3009. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Oasmaa, A.; Pihkola, H.; Deviatkin, I.; Tenhunen, A.; Mannila, J.; Minkkinen, H.; Pohjakallio, M.; Laine-Ylijoki, J. Pyrolysis of plastic waste: Opportunities and challenges. J. Anal. Appl. Pyrolysis 2020, 152, 104804. [Google Scholar] [CrossRef]

- Nyam, T.T.; Ayeleru, O.O.; Ramatsa, I.M.; Olubambi, P.A. Conversion of Waste Plastics into Value-added Materials: A Global Perspective. In Plastic Waste Management; Wiley-VCH GmbH: Weinheim, Germany, 2024; pp. 227–258. [Google Scholar] [CrossRef]

- Stefano, L.S.; Cafiero, L.; De Angelis, D.; Pavoni, S.; Tuffi, R.; Scarsella, M. Thermal pyrolysis of a real plastic sample from small WEEE and characterization of the produced oil in view of fuel or feedstock uses. Therm. Sci. Eng. Prog. 2024, 48, 102403. [Google Scholar] [CrossRef]

- Papari, S.; Bamdad, H.; Berruti, F. Pyrolytic Conversion of Plastic Waste to Value-Added Products and Fuels: A Review. Materials 2021, 14, 2586. [Google Scholar] [CrossRef] [PubMed]

- Hussin, F.; Aroua, M.K.; Kassim, M.A.; Ali, U.F.M. Transforming plastic waste into porous carbon for capturing carbon dioxide: A review. Energies 2021, 14, 8421. [Google Scholar] [CrossRef]

- Cocchi, M.; Cafiero, L.; De Angelis, D.; Falasconi, M.B.; Piemonte, V.; Tuffi, R.; Ciprioti, S.V. Conversion of Marine Plastic Litter into Chemicals and Fuels through Catalytic Pyrolysis Using Commercial and Coal Fly Ash-Synthesized Zeolites. ACS Sustain. Chem. Eng. 2023, 11, 3644–3656. [Google Scholar] [CrossRef]

- Cocchi, M.; De Angelis, D.; Mazzeo, L.; Nardozi, P.; Piemonte, V.; Tuffi, R.; Ciprioti, S.V. Catalytic pyrolysis of a residual plastic waste using zeolites produced by coal fly ash. Catalysts 2020, 10, 1113. [Google Scholar] [CrossRef]

- Benedetti, M.; Cafiero, L.; De Angelis, D.; Dell’Era, A.; Pasquali, M.; Stendardo, S.; Tuffi, R.; Ciprioti, S.V. Pyrolysis of WEEE plastics using catalysts produced from fly ash of coal gasification. Front. Environ. Sci. Eng. 2017, 11, 11. [Google Scholar] [CrossRef]

- Eldahshory, A.I.; Emara, K.; Abd-Elhady, M.S.; Ismail, M.A. Catalytic pyrolysis of waste polypropylene using low-cost natural catalysts. Sci. Rep. 2023, 13, 11766. [Google Scholar] [CrossRef]

- An, L.; Kou, Z.; Li, R.; Zhao, Z. Research Progress in Fuel Oil Production by Catalytic Pyrolysis Technologies of Waste Plastics. Catalysts 2024, 14, 212. [Google Scholar] [CrossRef]

- EU. CELEX_32006R1907_EN_TXT—REACH. 2006. Available online: https://eur-lex.europa.eu/eli/reg/2006/1907/oj/eng (accessed on 9 December 2024).

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.; D’Hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Dai, L.; Zhou, N.; Lv, Y.; Cheng, Y.; Wang, Y.; Liu, Y.; Cobb, K.; Chen, P.; Lei, H.; Ruan, R. Pyrolysis technology for plastic waste recycling: A state-of-the-art review. Prog. Energy Combust. Sci. 2022, 93, 101021. [Google Scholar] [CrossRef]

- Kodera, Y.; Yamamoto, T.; Ishikawa, E. Energy-and economic-balance estimation of pyrolysis plant for fuel-gas production from plastic waste based on bench-scale plant operations. Fuel Commun. 2021, 7, 16. [Google Scholar] [CrossRef]

- Plastic Europe. Plastic Europe Chemical Recycling. Available online: https://plasticseurope.org/sustainability/circularity/recycling/chemical-recycling/ (accessed on 12 April 2024).

- Quantafuel. Quantafuels Plants & Projects. Available online: https://www.quantafuel.com/search?q=Quantafuels+Plants# (accessed on 12 April 2024).

- BASF. BASF ChemCycling. Available online: https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach/chemcycling.html (accessed on 12 April 2024).

- Plastic Energy. Plastic Energy Projects. Available online: https://plasticenergy.com/projects/ (accessed on 12 April 2024).

- Polimerica. Parte Impianto di Pirolisi a Rotterdam. Available online: https://www.polimerica.it/articolo.asp?id=31171 (accessed on 3 December 2024).

- ENI Versalis. ENI Hoop. Available online: https://www.eni.com/en-IT/media/press-release/2023/10/pr-versalis-mantua-hoop-31-10-2023.html (accessed on 12 April 2024).

- The European House Ambrosetti. La Circolarità della Plastica—Opportunità Industriali, Innovazione e Ricadute Economico-Occupazionali per l’Italia. 2022. Available online: https://www.ambrosetti.eu/site/get-media/?type=doc&id=16458&doc_player=1 (accessed on 9 December 2024).

- Plast Magazine. LyondellBasell, Impianto di Riciclo con Tecnologia MoReTec in Germania. Available online: https://www.plastmagazine.it/lyondellbasell-impianto-di-riciclo-chimico-con-tecnologia-moretec-in-germania/ (accessed on 4 June 2024).

- Polimerica. NextChem si Rafforza nel Riciclo Chimico. Available online: https://www.polimerica.it/articolo.asp?id=29722 (accessed on 6 December 2024).

- Enerkem. Enerkem Ecoplanta. Available online: https://enerkem.com/projects/ecoplanta (accessed on 12 April 2024).

- SUEZ. Infinite Loop Technologies. Available online: https://www.suez.com/en/news/press-releases/selection-saint-avold-grand-est-region-france-site-infinite-loop-technology (accessed on 12 April 2024).

- Hydrocarbon Technologies. Technip Announces Successful Launch of Carbios Industrial Demonstration Plant. Available online: https://www.hydrocarbonprocessing.com/news/2021/11/technip-announces-successful-launch-of-carbios-industrial-demonstration-plant (accessed on 26 April 2024).

- petnology.com. GR3N Launches Industrial Demonstration Plant for its Microwave Assisted DEpolymerization (MADE) Recycling Technology. Available online: https://www.petnology.com/online/news-detail/gr3n-launches-industrial-demonstration-plant-for-its-microwave-assisted-depolymerization-made-recycling-technology (accessed on 26 April 2024).

- Saipem. Saipem e Garbo Insieme per lo Sviluppo di una Nuova Tecnologia per il Riciclo Delle Plastiche. Available online: https://www.saipem.com/it/media/comunicati-stampa/2023-03-15/saipem-e-garbo-insieme-lo-sviluppo-di-una-nuova-tecnologia-il (accessed on 26 April 2024).

- Zheng, L.; Wang, M.; Li, Y.; Xiong, Y.; Wu, C. Recycling and Degradation of Polyamides. Molecules 2024, 29, 1742. [Google Scholar] [CrossRef] [PubMed]

- Plasteurope.com. RETOURMATRAS. Available online: https://www.plasteurope.com/news/RETOURMATRAS_t254622/ (accessed on 26 August 2024).

- Creasolv. CreaSolv® Demonstration Plant for Research and Industry Partners. Available online: https://www.creasolv.de/en/plants-projects/loemi-creasolv-demonstration-plant.html (accessed on 26 April 2024).

- CreaSolv. CreaCycle GmbH. Available online: https://www.creasolv.de/en/our-partners/creacycle-gmbh.html (accessed on 26 April 2024).

- Bioplastics Magazine. APK New Large-Scale Newcycling Plant Will Start Construction in 2024. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20231219-apk.php (accessed on 26 April 2024).

- Mura Tecnology. SCALING WORLDWIDE. Available online: https://muratechnology.com/global-development/ (accessed on 26 April 2024).

- The European Chemical Industry Council. Position paper on Chemical Recycling. 2022. Available online: https://cefic.org/app/uploads/2022/04/Cefic-position-paper-on-Chemical-Recycling.pdf (accessed on 9 December 2024).

- Zero Waste Europe. Recycled Content in Plastics. 2021. Available online: https://zerowasteeurope.eu/wp-content/uploads/2021/05/rpa_2021_mass_balance_booklet-2.pdf (accessed on 4 June 2024).

- The European Chemical Industry Council. Chemical Recycling: Greenhouse Gas Emission Reduction Potential of an Emerging Waste Management Route. 2020. Available online: https://cefic.org/app/uploads/2020/12/CEFIC_Quantis_report_final.pdf (accessed on 9 December 2024).

- OMV Group. ReOil: Getting Crude Oil Back out of Plastic. Available online: https://www.omv.com/en (accessed on 27 August 2024).

- Rizos, V.; Urban, P.; Righetti, E.; Kassab, A. Chemical Recycling of Plastics. Technologies, Trends and Policy Implications. Ceps In-Depth Analysis. 2023. Available online: https://www.ceps.eu/download/publication/?id=40124&pdf=CEPS-In-depth-analysis-2023-11_Chemical-recycling-of-plastics.pdf (accessed on 9 December 2024).

- European Commission. Plastics in a Circular Economy. Available online: https://research-and-innovation.ec.europa.eu/research-area/environment/circular-economy/plastics-circular-economy_en (accessed on 10 January 2024).

- Ministero Dell’ambiente e Della Sicurezza Energetica. Investimento 1.2: Progetti ‘Faro’ di Economia Circolare. Available online: https://www.mase.gov.it/pagina/investimento-1-2-progetti-faro-di-economia-circolare-0 (accessed on 29 August 2024).

| Chemical | Thermo-Chemical Processes | |||||

|---|---|---|---|---|---|---|

| Sub-Categories | Solvent/Reagent | Range of Application | Sub-Categories | Operating Conditions | Range of Application | |

| Glycolysis | EG | Limited | Pyrolysis | 400–900 °C, inert atmosphere | Wide | |

| Methanolysis | Methanol | Limited | Gasification | 700–1700 °C, partial oxidative atmosphere | Very wide | |

| Aminolysis | Amine solution | Limited | Hydrocracking | 300–500 °C, 30–100 bar | Wide | |

| Hydrolysis | Acid | H2SO4, H3PO4, HCl, etc. | Limited | Liquefaction * | Subcritical water: 200–300 °C and 10–40 bar | Medium |

| Basic | NaOH, KOH, etc. | |||||

| Enzymatic | Enzymes | Wide | ||||

| Supercritical water: T > 378 °C, P > 220 bar | ||||||

| Ammonolysis | Ammonia solution | Limited | ||||

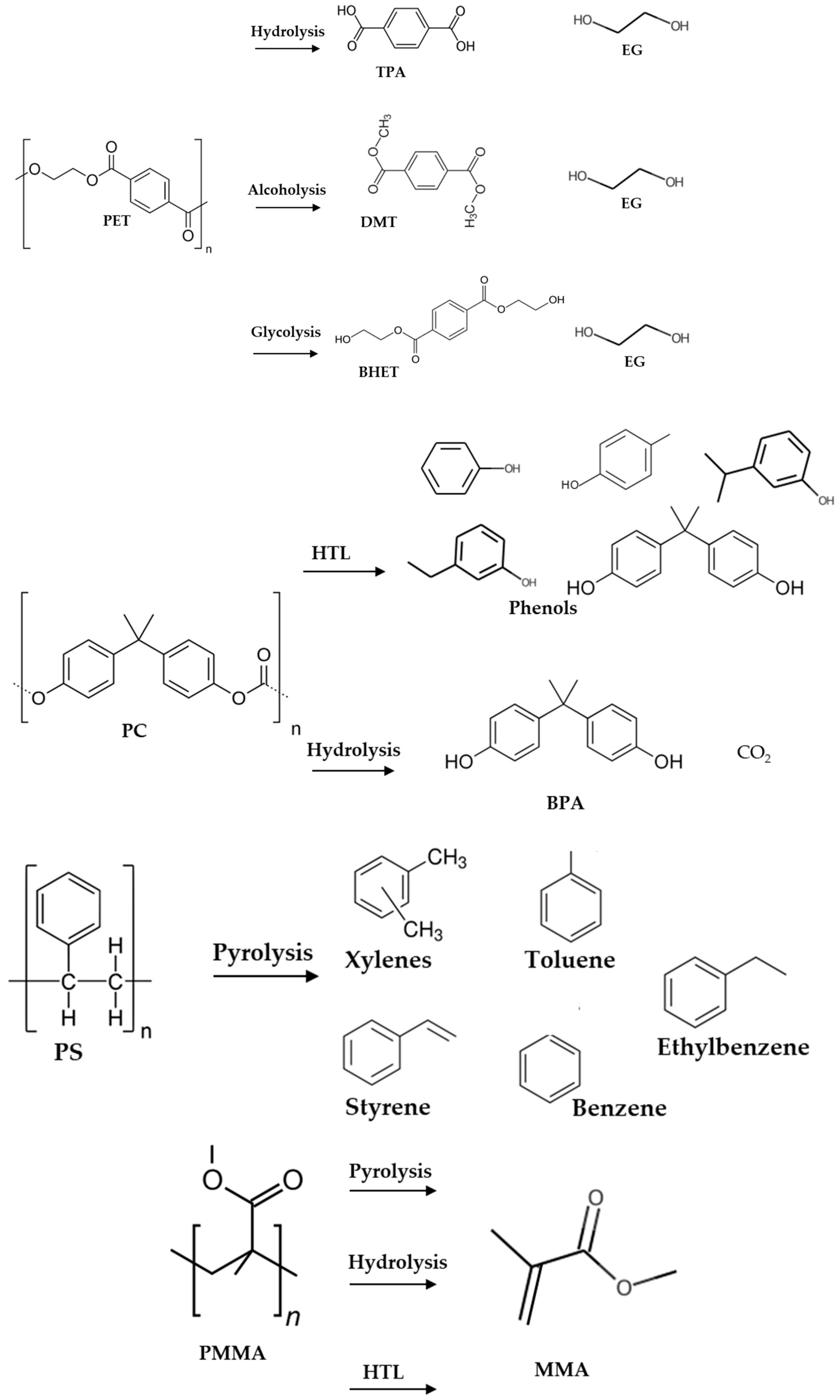

| Resin | Major Origin of Waste | More Suitable Processes and Main Products | Less or Not Suitable Processes | |

|---|---|---|---|---|

| Processes | Products | |||

| Mixed plastics | Multilayered plastics, residue of plastic selection (e.g., packaging) | Gasification | Syngas | Solvolysis |

| Pyrolysis | Crude oil | |||

| PE, PP, and MPO | Household, industrial plastic packaging, agricultural plastics, residue of plastic packaging selection, and automotive | Gasification | Syngas | Solvolysis, HTL |

| Pyrolysis | Hydrocarbon liquid, waxes, light gases | |||

| Hydrocracking | Liquid alkanes, light gases, and lubricants | |||

| Styrene-based polymers (e.g., PS, ABS, HIPS, SAN, and their mixtures) | WEEE, household and industrial plastic packaging, construction, and demolition | Pyrolysis | Styrene, styrene oligomers, BTEX, and PAH | Solvolysis |

| Hydrocracking | Monoaromatics | |||

| PET | Household plastic packaging | Hydrolysis | EG and TPA | Pyrolysis |

| Alcoholysis | DMT and EG | |||

| Glycolysis | BHET and EG | |||

| Aminolysis | TAM and EG | |||

| Hydrogenolysis | BDM and EG | |||

| Biocatalysis | BHET, EG, and TPA | |||

| PA6 | Automotive, textile waste, and WEEE | Hydrolysis, basic or acid | ε-Caprolactam, hexamethylene diamine | Pyrolysis |

| HTL | ε-Caprolactam | |||

| PC | WEEE | Hydrolysis, basic or acid | BPA | Pyrolysis |

| HTL | BPA, phenols | |||

| PIP | Medical, healthcare, and sport equipment | Hydrocracking | Oil with low content of olefins, aromatics, and coke | Solvolysis |

| PMMA | Automotive, construction, and demolition, WEEE | Pyrolysis | MMA | - |

| Hydrolysis | MMA | |||

| HTL | MMA | |||

| PU | Construction, demolition, and automotive | Solvolysis | Di-isocyanate, polyols | Pyrolysis |

| PVC * | Construction plastic waste | Hydrocracking | HCl, liquid fuel | Solvolysis |

| Pyrolysis, after a dechlorination step | HCl, aromatics | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cafiero, L.M.; De Angelis, D.; Tuccinardi, L.; Tuffi, R. Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience. Sustainability 2025, 17, 1293. https://doi.org/10.3390/su17031293

Cafiero LM, De Angelis D, Tuccinardi L, Tuffi R. Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience. Sustainability. 2025; 17(3):1293. https://doi.org/10.3390/su17031293

Chicago/Turabian StyleCafiero, Lorenzo Maria, Doina De Angelis, Letizia Tuccinardi, and Riccardo Tuffi. 2025. "Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience" Sustainability 17, no. 3: 1293. https://doi.org/10.3390/su17031293

APA StyleCafiero, L. M., De Angelis, D., Tuccinardi, L., & Tuffi, R. (2025). Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience. Sustainability, 17(3), 1293. https://doi.org/10.3390/su17031293