Barriers to Visibility in Supply Chains: Challenges and Opportunities of Artificial Intelligence Driven by Industry 4.0 Technologies

Abstract

1. Introduction

- What is the state of the art on barriers to visibility in supply chains?

- What are the main barriers to visibility identified in literature?

- What are the key avenues for future research on barriers to visibility in supply chains?

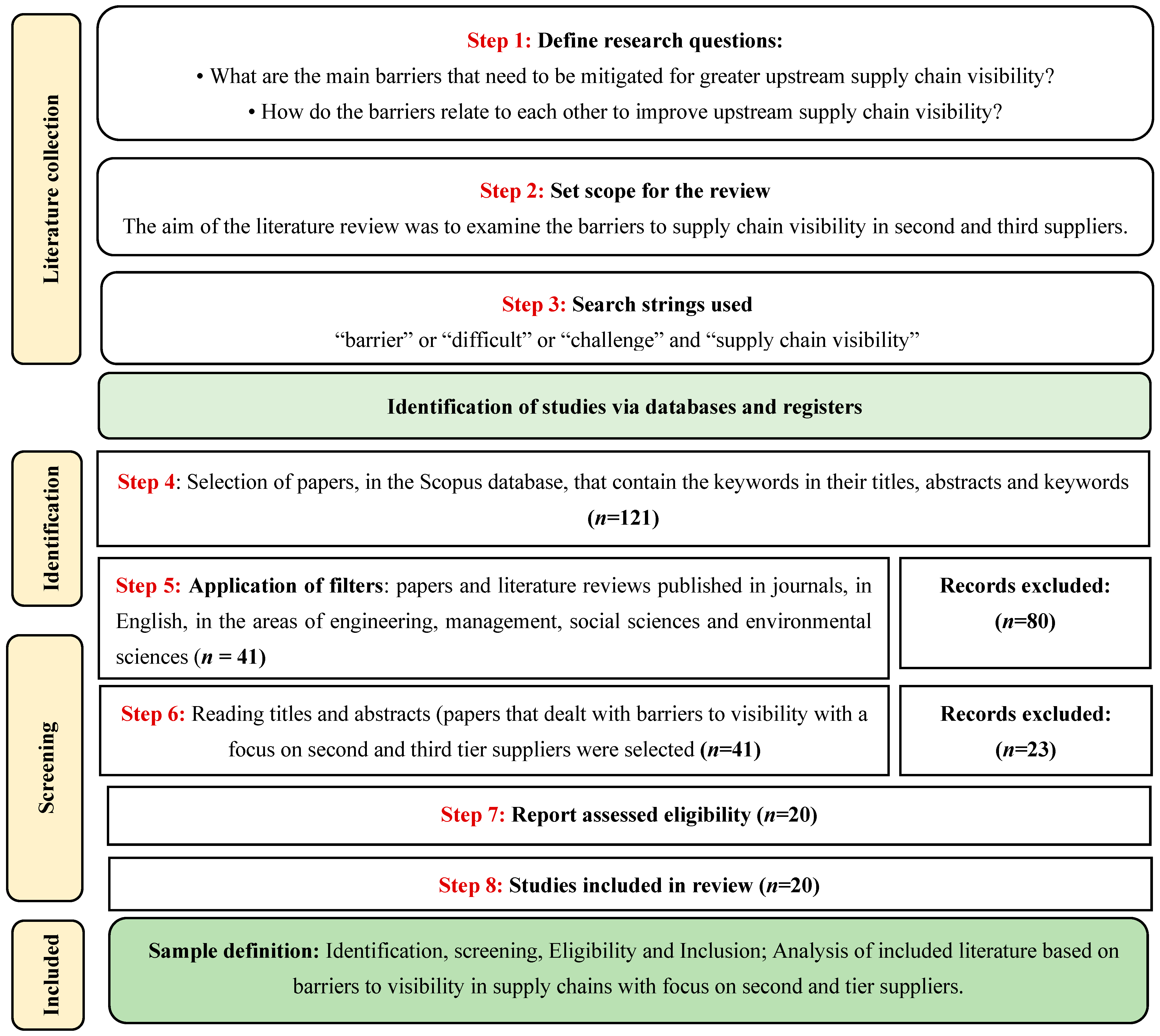

2. Materials and Methods

Systematic Literature Review

3. Background

3.1. Visibility in Supply Chains

3.2. Identifying Barriers to Visibility in Supply Chains

3.3. Main Barriers and the View of the Resource-Based View Theory and the Dynamic Capabilities Theory

3.4. Classification of Barriers

4. Results and Discussion

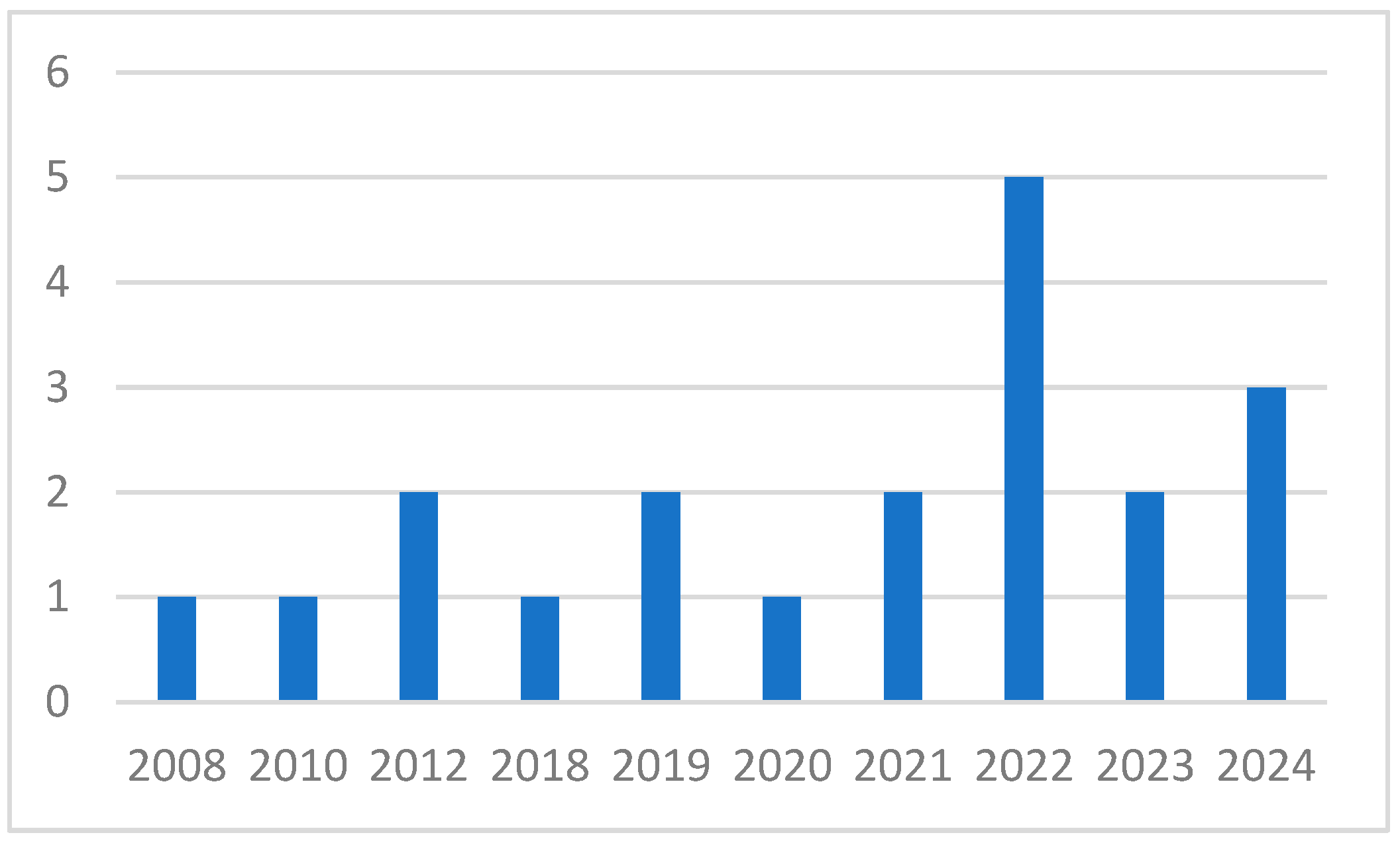

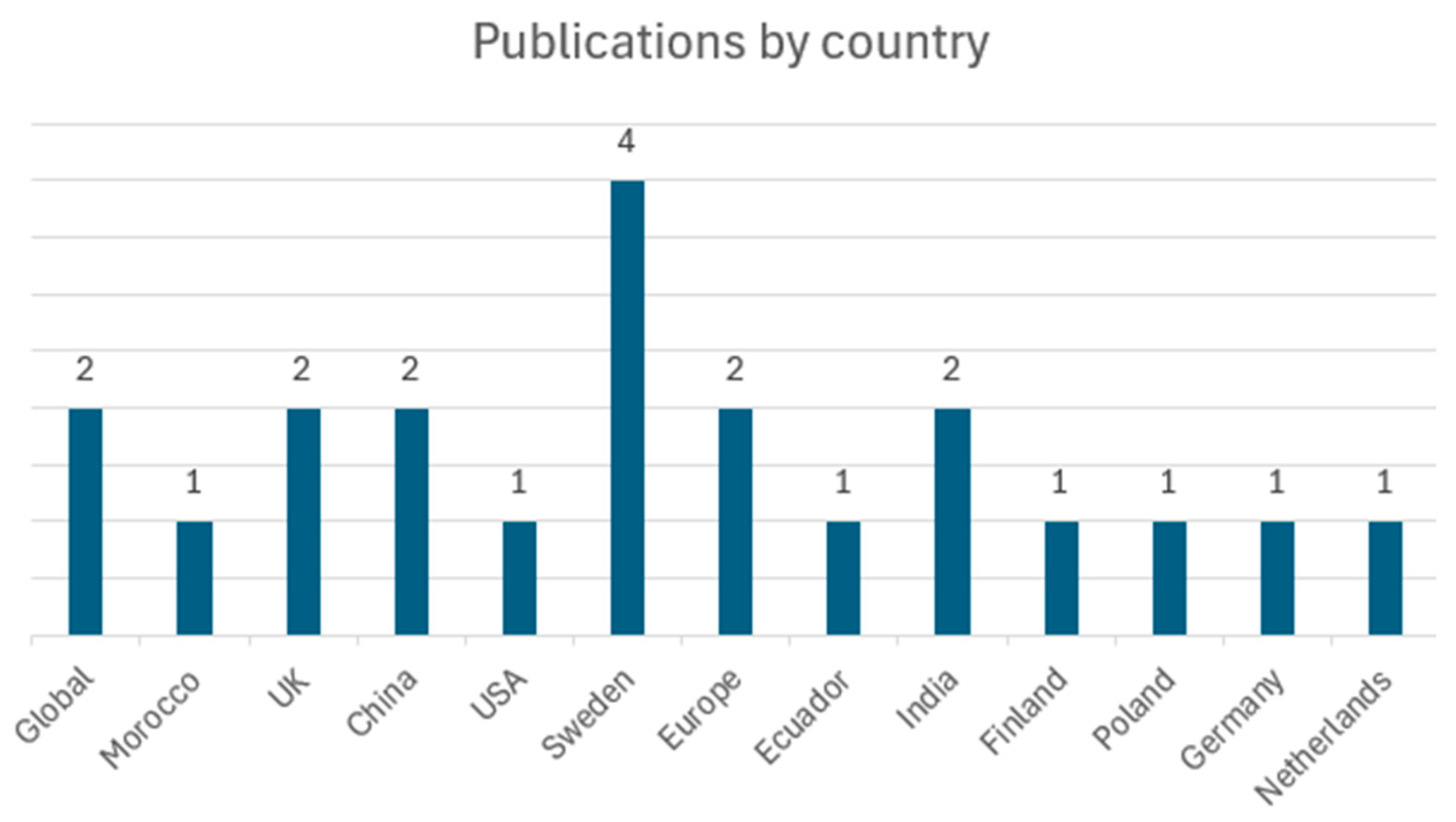

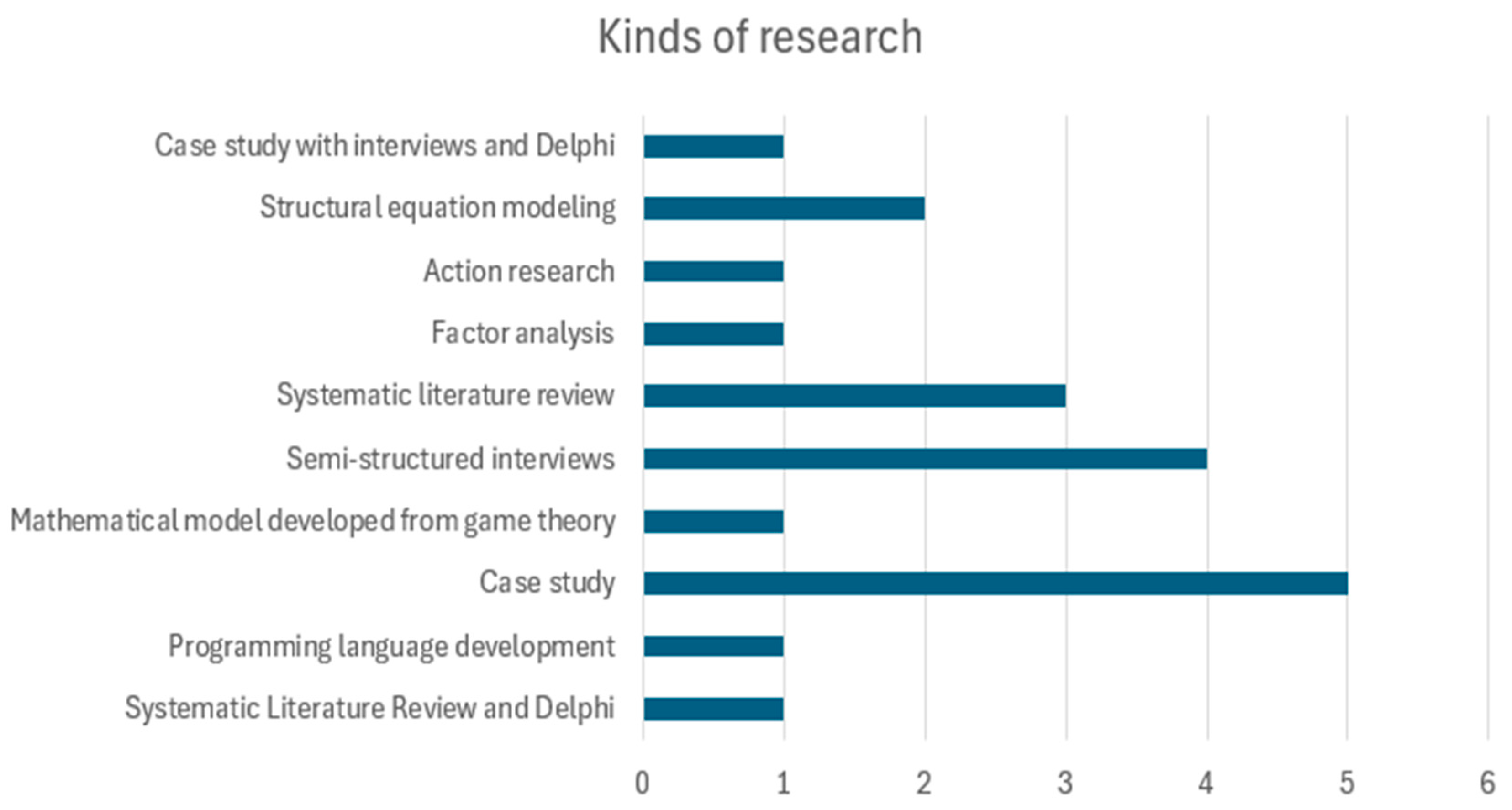

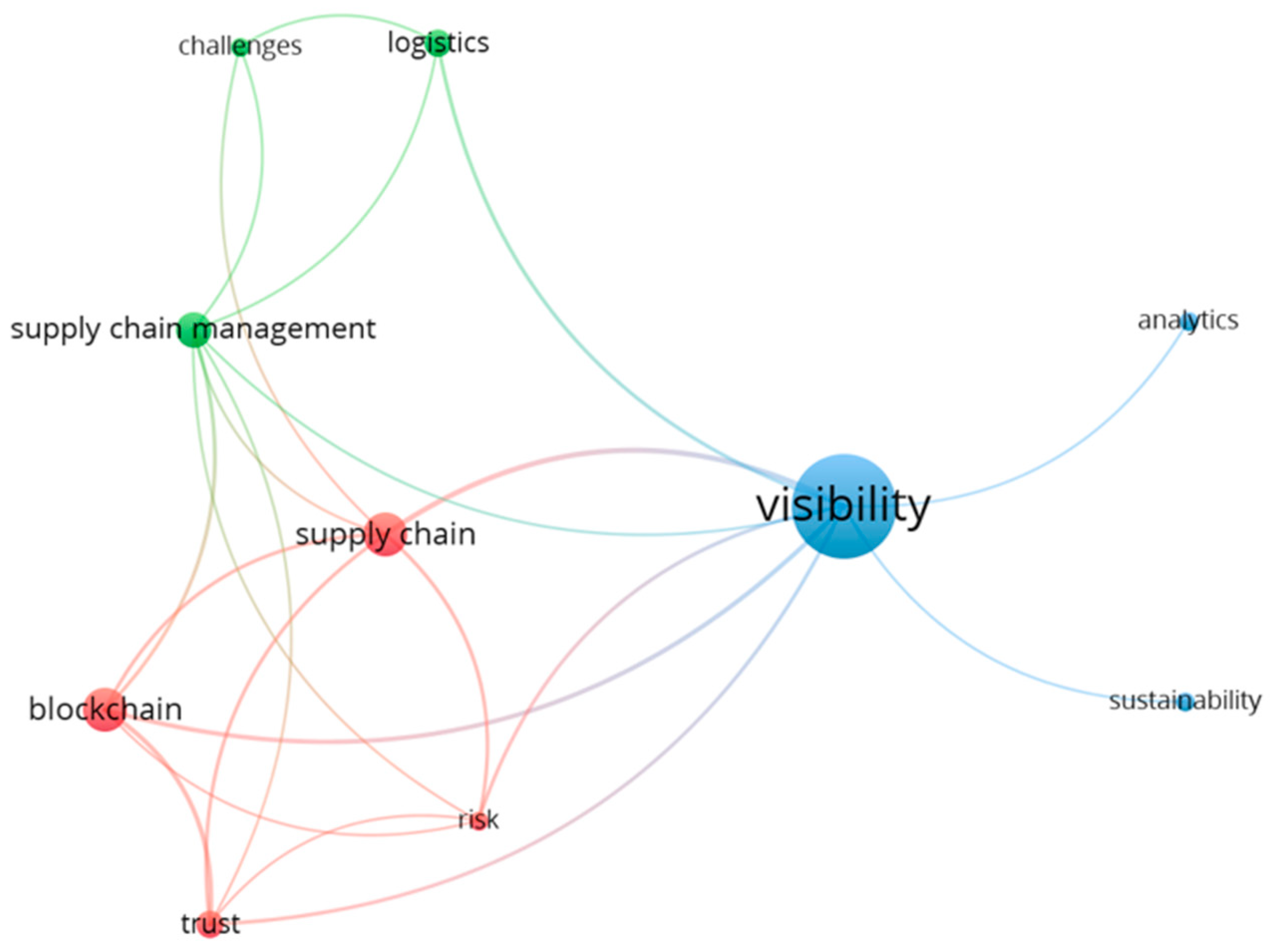

4.1. State-of-the-Art Bibliometric Results

4.2. Discussion

4.2.1. Barriers to Visibility: Classification and Insights

- Resource-Related Barriers

- Dynamic Capabilities-Related Barriers

- Strategic and Cultural Barriers

4.2.2. Interrelationships Between Barriers

4.2.3. The Role of Artificial Intelligence Driven by Industry 4.0 Technologies (AI-IT4.0)

4.2.4. Sector-Specific Insights

4.2.5. Implications for Future Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agrawal, T.K.; Kalaiarasan, R.; Olhager, J.; Wiktorsson, M. Supply chain visibility: A Delphi study on managerial perspectives and priorities. Int. J. Prod. Res. 2024, 62, 2927–2942. [Google Scholar] [CrossRef]

- Francis, V. Supply chain visibility: Lost in translation? Supply Chain Manag. Int. J. 2008, 13, 180–184. [Google Scholar] [CrossRef]

- Kalaiarasan, R.; Olhager, J.; Agrawal, T.K.; Wiktorsson, M. The ABCDE of supply chain visibility: A systematic literature review and framework. Int. J. Prod. Econ. 2022, 248, 108464. [Google Scholar] [CrossRef]

- Goh, M.K.H.; Garg, M. ChangAn Automotive Co.—Making Supply Chains Work. Asian J. Manag. Cases 2008, 5, 57–71. [Google Scholar] [CrossRef]

- Xu, X.; Tatge, L.; Xu, X.; Liu, Y. Blockchain applications in the supply chain management in German automotive industry. Prod. Plan. Control 2024, 35, 917–931. [Google Scholar] [CrossRef]

- Lafargue, P.; Rogerson, M.; Parry, G.C.; Allainguillaume, J. Broken chocolate: Biomarkers as a method for delivering cocoa supply chain visibility. Supply Chain Manag. Int. J. 2022, 27, 728–741. [Google Scholar] [CrossRef]

- Rogerson, M.; Parry, G.C. Blockchain: Case studies in food supply chain visibility. Supply Chain Manag. Int. J. 2020, 25, 601–614. [Google Scholar] [CrossRef]

- Knol, A.; Tan, Y. The Cultivation of Information Infrastructures for International Trade: Stakeholder Challenges and Engagement Reasons. J. Theor. Appl. Electron. Commer. Res. 2018, 13, 106–117. [Google Scholar] [CrossRef]

- Mehrotra, A. Implementing IT in SCM—Understanding the Challenges. Glob. Bus. Rev. 2010, 11, 167–184. [Google Scholar] [CrossRef]

- Al-Khatib, A.W. The impact of industrial Internet of things on sustainable performance: The indirect effect of supply chain visibility. Bus. Process Manag. J. 2023, 29, 1607–1629. [Google Scholar] [CrossRef]

- Brookbanks, M.; Parry, G. The impact of a blockchain platform on trust in established relationships: A case study of wine supply chains. Supply Chain Manag. Int. J. 2022, 27, 128–146. [Google Scholar] [CrossRef]

- Cao, Y.; Yi, C.; Wan, G.; Hu, H.; Li, Q.; Wang, S. An analysis on the role of blockchain-based platforms in agricultural supply chains. Transp. Res. Part E Logist. Transp. Rev. 2022, 163, 102731. [Google Scholar] [CrossRef]

- Caridi, M.; Perego, A.; Tumino, A. Measuring supply chain visibility in the apparel industry. Benchmarking Int. J. 2013, 20, 25–44. [Google Scholar] [CrossRef]

- Hilletofth, P.; Lättilä, L. Agent based decision support in the supply chain context. Ind. Manag. Data Syst. 2012, 112, 1217–1235. [Google Scholar] [CrossRef]

- Kauppila, O.; Valikangas, K.; Majava, J. Improving supply chain transparency between a manufacturer and suppliers: A triadic case study. Manag. Prod. Eng. Rev. 2020, 11, 84–91. [Google Scholar] [CrossRef]

- Wyciślak, S.; Akhtar, A. Real-Time Visibility as a Catalyst for Operational Enhancements. Logforum 2024, 20, 161–174. [Google Scholar] [CrossRef]

- Lopez-Torres, G.C.; Schiuma, G.; Muñoz-Arteaga, J.; Alvarez-Torres, F.J. Unveiling the relationships between visibility, information technologies and innovation management for sustainability performance: An empirical study. Eur. J. Innov. Manag. 2024. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. A declaração PRISMA 2020: Diretriz atualizada para relatar revisões sistemáticas. Rev. Panam. De Salud Pública 2022, 46, 1. [Google Scholar] [CrossRef] [PubMed]

- Brun, A.; Karaosman, H.; Barresi, T. Supply Chain Collaboration for Transparency. Sustainability 2020, 12, 4429. [Google Scholar] [CrossRef]

- Sunmola, F.T.; Apeji, U.D. Modelling supply chain visibility: A framework with considerations for manufacturing and business. J. Manufac. Technol. Manag. 2024. [Google Scholar] [CrossRef]

- Oubrahim, I.; Sefiani, N.; Happonen, A. The Influence of Digital Transformation and Supply Chain Integration on Overall Sustainable Supply Chain Performance: An Empirical Analysis from Manufacturing Companies in Morocco. Energies 2023, 16, 1004. [Google Scholar] [CrossRef]

- Barratt, M.; Oke, A. Antecedents of supply chain visibility in retail supply chains: A resource-based theory perspective. J. Oper. Manag. 2007, 25, 1217–1233. [Google Scholar] [CrossRef]

- Tiwari, M.; Bryde, D.J.; Stavropoulou, F.; Dubey, R.; Kumari, S.; Foropon, C. Modelling supply chain Visibility, digital Technologies, environmental dynamism and healthcare supply chain Resilience: An organisation information processing theory perspective. Transp. Res. Part E Logist. Transp. Rev. 2024, 188, 103613. [Google Scholar] [CrossRef]

- Jain, N.K.; Chakraborty, K.; Choudhary, P. Building supply chain resilience through industry 4.0 base technologies: Role of supply chain visibility and environmental dynamism. J. Bus. Ind. Mark. 2024, 39, 1750–1763. [Google Scholar] [CrossRef]

- Sharma, R.; Kamble, S.; Mani, V.; Belhadi, A. An Empirical Investigation of the Influence of Industry 4.0 Technology Capabilities on Agriculture Supply Chain Integration and Sustainable Performance. IEEE Trans. Eng. Manag. 2024, 71, 12364–12384. [Google Scholar] [CrossRef]

- Yavuz, O.; Uner, M.M.; Okumus, F.; Karatepe, O.M. Industry 4.0 technologies, sustainable operations practices and their impacts on sustainable performance. J. Clean. Prod. 2023, 387, 135951. [Google Scholar] [CrossRef]

- Ali, Z.; Gongbing, B.; Mehreen, A.; Ghani, U. Predicting firm performance through supply chain finance: A moderated and mediated model link. Int. J. Logist. Res. Appl. 2020, 23, 121–138. [Google Scholar] [CrossRef]

- Bowen, F.; Siegler, J. The role of visibility in supply chain resiliency: Applying the Nexus supplier index to unveil hidden critical suppliers in deep supply networks. Decis. Support Syst. 2024, 176, 114063. [Google Scholar] [CrossRef]

- Shi, H.; Feng, T.; Zhu, Z. The impact of big data analytics capability on green supply chain integration: An organizational information processing theory perspective. Bus. Process Manag. J. 2023, 29, 550–577. [Google Scholar] [CrossRef]

- Klueber, R.; O’Keefe, R.M. Defining and assessing requisite supply chain visibility in regulated industries. J. Enterp. Inf. Manag. 2013, 26, 295–315. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Ngai, E.W.T. Virtual supply-chain management. Prod. Plan. Control 2004, 15, 584–595. [Google Scholar] [CrossRef]

- Finkenstadt, D.J.; Handfield, R. Blurry vision: Supply chain visibility for personal protective equipment during COVID-19. J. Purch. Supply Manag. 2021, 27, 100689. [Google Scholar] [CrossRef]

- Panigrahi, R.R.; Shrivastava, A.K.; Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Almuflih, A.S.; Qureshi, M.R.N. AI Chatbot Adoption in SMEs for Sustainable Manufacturing Supply Chain Performance: A Mediational Research in an Emerging Country. Sustainability 2023, 15, 13743. [Google Scholar] [CrossRef]

- Meyer-Larsen, N.; Lyridis, D.; Müller, R.; Zacharioudakis, P. Improving intermodal container logistics and security by RFID. Int. J. RF Technol. 2012, 3, 15–38. [Google Scholar] [CrossRef]

- Allouch, S.A.; Amecluioue, K.; Achatbi, I. An Ontological Approach to Model Outbound Logistics based on Internet of Things (OLP-IOT). Int. J. Supply Oper. Manag. 2023, 10, 456–484. [Google Scholar]

- Njualem, L.A. Leveraging Blockchain Technology in Supply Chain Sustainability: A Provenance Perspective. Sustainability 2022, 14, 10533. [Google Scholar] [CrossRef]

- Oliveira, M.P.V.d.; Handfield, R. Analytical foundations for development of real-time supply chain capabilities. Int. J. Prod. Res. 2019, 57, 1571–1589. [Google Scholar] [CrossRef]

- Vilko, J.; Ritala, P.; Hallikas, J. Risk management abilities in multimodal maritime supply chains: Visibility and control perspectives. Accid. Anal. Prev. 2019, 123, 469–481. [Google Scholar] [CrossRef]

- Moshood, T.; Nawanir, G.; Sorooshian, S.; Okfalisa, O. Digital Twins Driven Supply Chain Visibility within Logistics: A New Paradigm for Future Logistics. Appl. Syst. Innov. 2021, 4, 29. [Google Scholar] [CrossRef]

- Maria Grazia, A.; Demosthenes, I.; Laura, L.; Richard, M. Global production and supply chain risks: Insights from a survey of leading companies. ECB Econ. Bull. 2023, 7. [Google Scholar]

- Saqib, Z.A.; Zhang, Q. Impact of sustainable practices on sustainable performance: The moderating role of supply chain visibility. J. Manuf. Technol. Manag. 2021, 32, 1421–1443. [Google Scholar] [CrossRef]

- Suh, C.; Lee, I. An Empirical Study on the Manufacturing Firm’s Strategic Choice for Sustainability in SMEs. Sustainability 2018, 10, 572. [Google Scholar] [CrossRef]

- Yuen, K.F.; Wang, X.; Wong, Y.D.; Ma, F. A contingency view of the effects of sustainable shipping exploitation and exploration on business performance. Transp. Policy 2019, 77, 90–103. [Google Scholar] [CrossRef]

- Wei, H.-L.; Wang, E.T.G. The strategic value of supply chain visibility: Increasing the ability to reconfigure. Eur. J. Inf. Syst. 2010, 19, 238–249. [Google Scholar] [CrossRef]

- Swedish Government. Ministry of the Environment and Energy. Sweden’s Climate Policy Framework. Available online: https://www.government.se (accessed on 1 January 2025).

- Montecchi, M.; Plangger, K.; West, D.C. Supply chain transparency: A bibliometric review and research agenda. Int. J. Prod. Econ. 2021, 238, 108152. [Google Scholar] [CrossRef]

| Barriers | Characterization | Authors |

|---|---|---|

| B1-Lack of data standardization. | The lack of data standardization for the implementation of SCV systems. | Agrawal et al. (2024) [1]; Aoulad et al. (2023) [35]; Brookbanks; Parry, (2022) [11]. |

| B2-Lack of adequate infrastructure. | Lack of an information infrastructure. The information infrastructure is an open and shared set capable of covering different types of data from different technology sources. | Knol & Tan (2018) [8]; Xu et al. (2024) [5]. |

| B3-Costs associated with the implementation of AI-IT4.0 technologies. | Cost of technologies and lack of balance between technology costs and business benefits | Finkenstadt & Handfield, (2021) [32]; Knol & Tan, (2018) [8] |

| B4-Distrust in sharing data. | Trust issues and concerns over data accuracy. | Cao et al. (2022) [12]; Wyciślak & Akhtar, (2024b) [16] |

| B5-Complexities in the supply chain. | Long distances between parties, budget disparities across SC partners, different levels of technological advancement, and different company sizes. | Goh & Garg (2008) [4]; Hilletofth & Lättilä (2012) [14]. |

| B6-Lack of collaboration. | Lack of collaboration in sharing data with supply chain partners. | Mehrotra, (2010) [9]; Wyciślak & Akhtar, (2024) [16]. |

| B7-Lack of technical knowledge and training for the use of AI-IT4.0. | The lack of technical knowledge and training to work with AI-IT4.0 technologies makes data sharing difficult. | Njualem (2022) [36]; Oliveira & Handfield (2019) [37]; Vilko et al. (2019) [38] Moshood et al. (2021) [39]; Panigrahi et al. (2023) [33] |

| B8-Data overload. | The data needs to be clear and concise to facilitate decision-making. Excessive data hinders data analysis and information flow. | Kalaiarasan et al. (2022) [3]; Meyer-Larsen et al. (2012) [34] |

| B9-Lack of ability to combine data across a supply chain. | The data needs to be combined concisely and clearly to facilitate faster decision-making. | Moshood et al. (2021) [39]; Njualem (2022) [36]; Oliveira & Handfield (2019) [37]; Panigrahi et al. (2023) [33]; Vilko et al. (2019) [38]. |

| B10-Lack of uniform and international legal regulation | A clear and objective international standard on visibility helps prevent cybercrimes and addresses cultural challenges and communication barriers. | Lafargue et al. (2022) [6]. |

| B11-Lack of clear objectives for using AI-IT4.0 to generate data related to sustainability practices (environmental, social and economic). | There is a lack of awareness that using AI-IT4.0 for increasing visibility throughout the SC can contribute to improving its sustainability performance. | Wyciślak & Akhtar, (2024) [16] |

| B12-Disbelief in the benefits of visibility for supply chain performance (environmental, social, and economic). | Limited empirical results that prove the benefits of visibility for sustainability. | (Kalaiarasan et al., 2022) [3]. |

| Kinds of Barriers | Barriers |

|---|---|

| Resource-related barrier (Saqib & Zhang, 2021) [41] | B1-Lack of data standardization |

| B2-Lack of adequate infrastructure | |

| B3-Costs associated with the implementation of AI-IT4.0 | |

| B7-Lack of technical knowledge and training for the use of AI-IT4.0 | |

| B9-Lack of ability to combine data across a supply chain | |

| Dynamic capabilities-related barrier (Sunmola & Apeji, 2024) [20] | B4-Distrust in sharing data |

| B5-Complexities in the supply chain | |

| B6-Lack of collaboration | |

| B8-Data overload | |

| B10-Lack of uniform and international legal regulation | |

| Strategic or cultural barrier (Suh & Lee, 2018) [42] | B11-Lack of clear objectives for using AI-IT4.0 to generate data related to sustainability practices |

| B12—Disbelief in the benefits of visibility for supply chain performance |

| Authors | Title | Journal | Citations |

|---|---|---|---|

| Agrawal et al. (2024) [1] | Supply chain visibility: A Delphi study on managerial perspectives and priorities. | International Journal of Production Research | 23 |

| Brookbanks; Parry (2022) [11] | The impact of a blockchain platform on trust in established relationships: a case study of wine supply chains. | Supply Chain Management | 70 |

| Cao et al. (2022) [12] | An analysis on the role of blockchain-based platforms in agricultural supply chains. | Transportation Research Part E: Logistics and Transportation Review | 87 |

| Finkenstadt; Handfield. (2021) [32] | Blurry vision: Supply chain visibility for personal protective equipment during COVID-19. | Journal of Purchasing and Supply Management | 62 |

| Hilletofth; Lattila (2012) [14] | Agent based decision support in the supply chain context. | Industrial Management and Data Systems | 32 |

| Journals | Papers |

|---|---|

| Accident Analysis and Prevention | 1 |

| Applied System Innovation | 1 |

| Asian Journal of Management Cases | 1 |

| Global Business Review | 1 |

| Industrial Management and Data Systems | 1 |

| International Journal of Production Economics | 2 |

| International Journal of Production Research | 1 |

| International Journal of RF Technologies: Research and Applications | 1 |

| International Journal of Supply and Operations Management | 1 |

| Journal of Purchasing and Supply Management | 1 |

| Journal of Theoretical and Applied Electronic Commerce Research | 1 |

| Logforum | 1 |

| Production Planning and Control | 3 |

| Supply Chain Management | 2 |

| Sustainability | 1 |

| Transportation Research Part E: Logistics and Transportation Review | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado, F.; Garrido, S.; Bezerra, B.S. Barriers to Visibility in Supply Chains: Challenges and Opportunities of Artificial Intelligence Driven by Industry 4.0 Technologies. Sustainability 2025, 17, 2998. https://doi.org/10.3390/su17072998

Delgado F, Garrido S, Bezerra BS. Barriers to Visibility in Supply Chains: Challenges and Opportunities of Artificial Intelligence Driven by Industry 4.0 Technologies. Sustainability. 2025; 17(7):2998. https://doi.org/10.3390/su17072998

Chicago/Turabian StyleDelgado, Fernanda, Susana Garrido, and Barbara Stolte Bezerra. 2025. "Barriers to Visibility in Supply Chains: Challenges and Opportunities of Artificial Intelligence Driven by Industry 4.0 Technologies" Sustainability 17, no. 7: 2998. https://doi.org/10.3390/su17072998

APA StyleDelgado, F., Garrido, S., & Bezerra, B. S. (2025). Barriers to Visibility in Supply Chains: Challenges and Opportunities of Artificial Intelligence Driven by Industry 4.0 Technologies. Sustainability, 17(7), 2998. https://doi.org/10.3390/su17072998