Degradation of Ibuprofen by the Electro/Fe3+/Peroxydisulfate Process: Reactive Kinetics, Degradation Products and Mechanism

Abstract

:1. Introduction

2. Results and Discussion

2.1. Comparative Study of Different Processes

2.2. Impact Factors

2.2.1. The Effect of PDS Concentration

2.2.2. The Effect of the Initial Fe3+ Concentration

2.2.3. The Effect of Current Density

2.2.4. The Effect of the Initial IBU Concentration

2.2.5. The Effect of the Initial pH

2.2.6. Effect of Co-Existing Components

2.3. Comparison with Other Technologies

2.4. Determination of Reactive Species

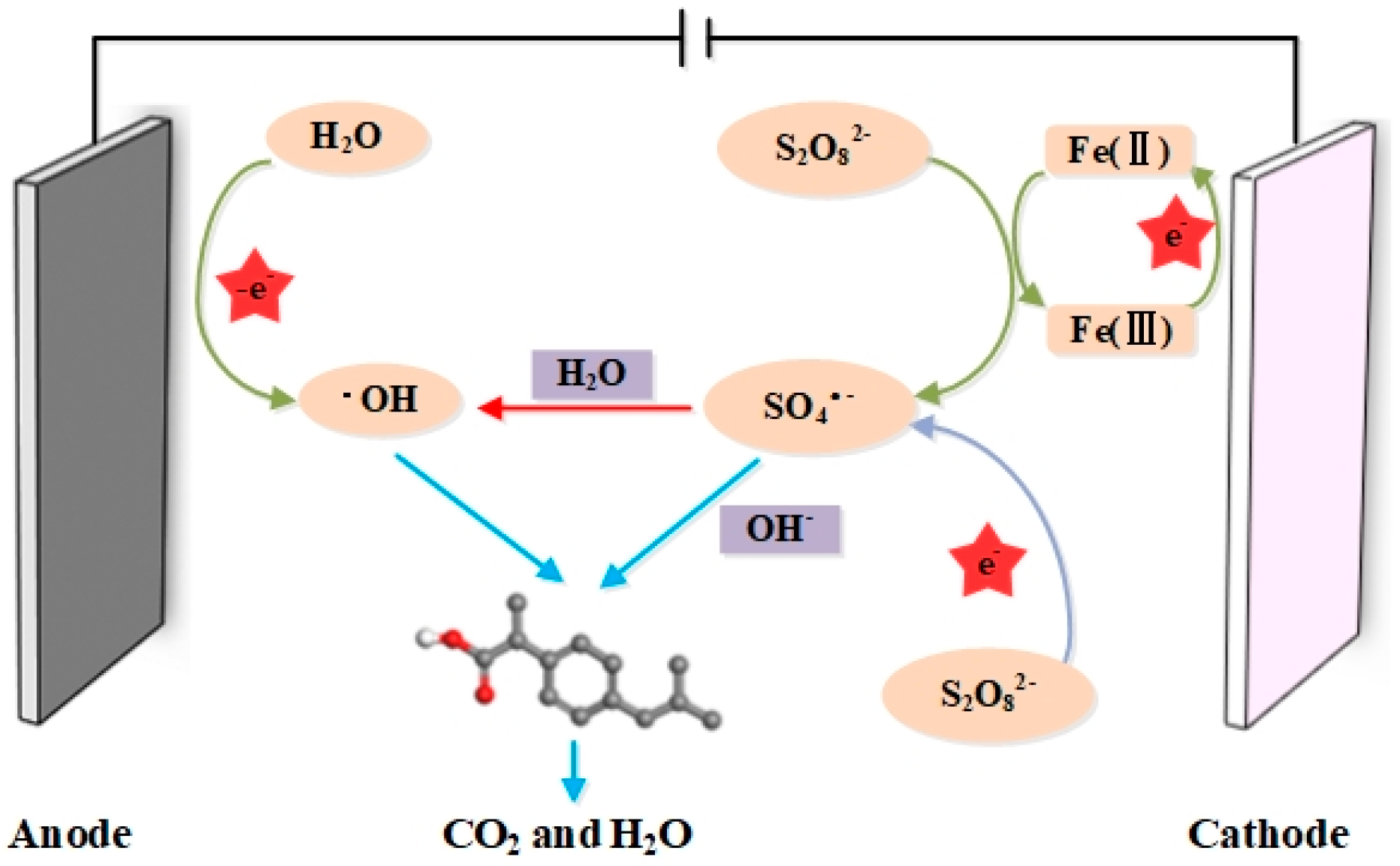

2.5. Proposed Mechanism of the EC/Fe3+/PDS Process

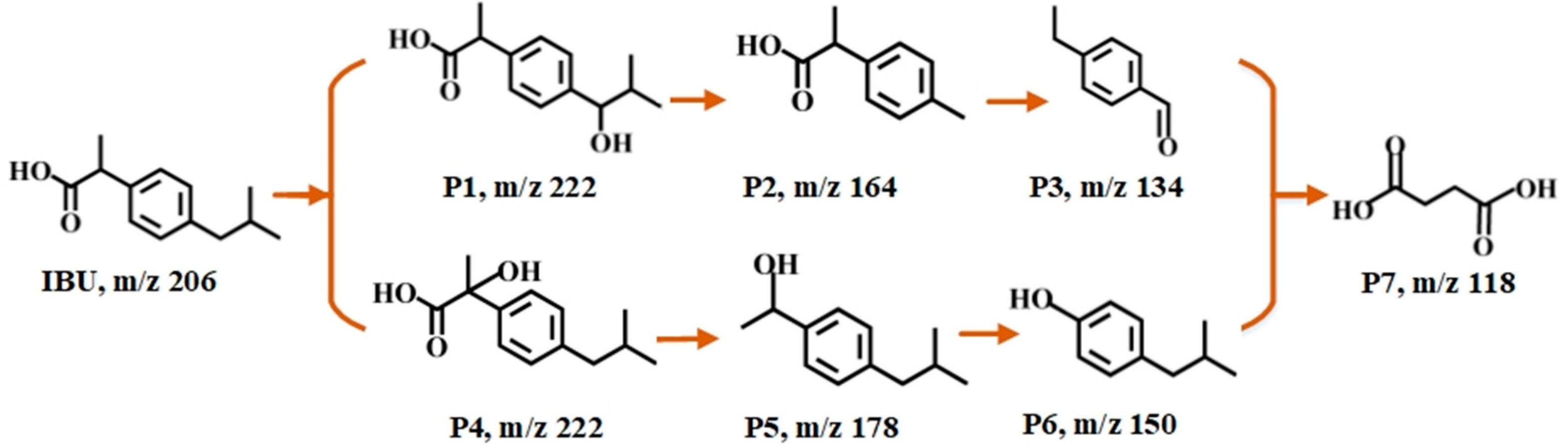

2.6. Oxidation Products and Proposed Pathway of IBU Degradation

3. Materials and Methods

3.1. Materials

3.2. Analytical Methods

3.3. Experimental Procedure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Parolini, M. Toxicity of the Non-Steroidal Anti-Inflammatory Drugs (NSAIDs) acetylsalicylic acid, paracetamol, diclofenac, ibuprofen and naproxen towards freshwater invertebrates: A review. Sci. Total Environ. 2020, 740, 140043. [Google Scholar] [CrossRef]

- Wang, C.; Yu, Y.; Yin, L.; Niu, J.; Hou, L.-A. Insights of ibuprofen electro-oxidation on metal-oxide-coated Ti anodes: Kinetics, energy consumption and reaction mechanisms. Chemosphere 2016, 163, 584–591. [Google Scholar] [CrossRef] [PubMed]

- Brillas, E. A critical review on ibuprofen removal from synthetic waters, natural waters, and real wastewaters by advanced oxidation processes. Chemosphere 2022, 286, 131849. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, H.; Ma, F.; Cheng, S.; Shen, Z.; Zhang, J.; Min, J.; Wang, Y.; Liu, G.; Yao, H. Electro-catazone treatment of ozone-resistant drug ibuprofen: Interfacial reaction kinetics, influencing mechanisms, and degradation sites. J. Hazard. Mater. Adv. 2021, 4, 100023. [Google Scholar] [CrossRef]

- Ding, H.; Hu, J. Degradation of ibuprofen by UVA-LED/TiO2/persulfate process: Kinetics, mechanism, water matrix effects, intermediates and energy consumption. Chem. Eng. J. 2020, 397, 125462. [Google Scholar] [CrossRef]

- Cao, J.; Lai, L.; Lai, B.; Yao, G.; Chen, X.; Song, L. Degradation of tetracycline by peroxymonosulfate activated with zero-valent iron: Performance, intermediates, toxicity and mechanism. Chem. Eng. J. 2019, 364, 45–56. [Google Scholar] [CrossRef]

- Peng, F.; Yin, R.; Liao, Y.; Xie, X.; Sun, J.; Xia, D.; He, C. Kinetics and mechanisms of enhanced degradation of ibuprofen by piezo-catalytic activation of persulfate. Chem. Eng. J. 2020, 392, 123818. [Google Scholar] [CrossRef]

- Zhang, G.; Ding, Y.; Nie, W.; Tang, H. Efficient degradation of drug ibuprofen through catalytic activation of peroxymonosulfate by Fe3C embedded on carbon. J. Environ. Sci. 2019, 78, 1–12. [Google Scholar] [CrossRef]

- Shen, C.; Wang, Y.; Fu, J. Urchin-like Co3O4 anchored on reduced graphene oxide with enhanced performance for peroxymonosulfate activation in ibuprofen degradation. J. Environ. Manag. 2022, 307, 114572. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, M.; Yuan, Y.; Zhang, P.; Du, S.; Ya, T.; Chen, D.; Wang, X.; Zhang, T. Responses of microbial communities and their interactions to ibuprofen in a bio-electrochemical system. J. Environ. Manag. 2021, 289, 112473. [Google Scholar] [CrossRef]

- Kristensen, D.M.; Desdoits-Lethimonier, C.; Mackey, A.L.; Dalgaard, M.D.; De Masi, F.; Munkbøl, C.H.; Styrishave, B.; Antignac, J.-P.; Le Bizec, B.; Platel, C.; et al. Ibuprofen alters human testicular physiology to produce a state of compensated hypogonadism. Proc. Natl. Acad. Sci. USA 2018, 115, E715. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leverrier-Penna, S.; Mitchell, R.T.; Becker, E.; Lecante, L.; Ben Maamar, M.; Homer, N.; Lavoué, V.; Kristensen, D.M.; Dejucq-Rainsford, N.; Jégou, B.; et al. Ibuprofen is deleterious for the development of first trimester human fetal ovary ex vivo. Hum. Reprod. 2018, 33, 482–493. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geiger, E.; Hornek-Gausterer, R.; Saçan, M.T. Single and mixture toxicity of pharmaceuticals and chlorophenols to freshwater algae Chlorella vulgaris. Ecotoxicol. Environ. Saf. 2016, 129, 189–198. [Google Scholar] [CrossRef]

- Ding, T.; Yang, M.; Zhang, J.; Yang, B.; Lin, K.; Li, J.; Gan, J. Toxicity, degradation and metabolic fate of ibuprofen on freshwater diatom Navicula sp. J. Hazard. Mater. 2017, 330, 127–134. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Chu, W.; Huang, Y.; Xu, L.; Chen, M.; Yan, M. Solar photocatalytic degradation of ibuprofen with a magnetic catalyst: Effects of parameters, efficiency in effluent, mechanism and toxicity evolution. Environ. Pollut. 2021, 276, 116691. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Shen, C.; Li, L.; Li, H.; Zhang, M. Electrocatalytic degradation of ibuprofen in aqueous solution by a cobalt-doped modified lead dioxide electrode: Influencing factors and energy demand. RSC Adv. 2016, 6, 30598–30610. [Google Scholar] [CrossRef]

- Yang, Z.; Su, R.; Luo, S.; Spinney, R.; Cai, M.; Xiao, R.; Wei, Z. Comparison of the reactivity of ibuprofen with sulfate and hydroxyl radicals: An experimental and theoretical study. Sci. Total Environ. 2017, 590–591, 751–760. [Google Scholar] [CrossRef]

- Shen, X.; Zhu, Z.; Zhang, H.; Di, G.; Chen, T.; Qiu, Y.; Yin, D. Carbonaceous composite materials from calcination of azo dye-adsorbed layered double hydroxide with enhanced photocatalytic efficiency for removal of Ibuprofen in water. Environ. Sci. Eur. 2020, 32, 77. [Google Scholar] [CrossRef]

- Naderi, M.; Soltani, R.D.C. Hybrid of ZnFe layered double hydroxide/nano-scale carbon for activation of peroxymonosulfate to decompose ibuprofen: Thermodynamic and reaction pathways investigation. Environ. Technol. Innov. 2021, 24, 101951. [Google Scholar] [CrossRef]

- Wojnárovits, L.; Takács, E. Rate constants of sulfate radical anion reactions with organic molecules: A review. Chemosphere 2019, 220, 1014–1032. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, X.; Sun, K.; Lin, C.; Ma, J.; He, M.; Ouyang, W. Persulfate-based advanced oxidation processes (AOPs) for organic-contaminated soil remediation: A review. Chem. Eng. J. 2019, 372, 836–851. [Google Scholar] [CrossRef]

- Wang, Z.; Qiu, W.; Pang, S.; Gao, Y.; Zhou, Y.; Cao, Y.; Jiang, J. Relative contribution of ferryl ion species (Fe(IV)) and sulfate radical formed in nanoscale zero valent iron activated peroxydisulfate and peroxymonosulfate processes. Water Res. 2020, 172, 115504. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Wu, J.; Zhang, H. Degradation of clofibric acid in aqueous solution by an EC/Fe3+/PMS process. Chem. Eng. J. 2014, 244, 514–521. [Google Scholar] [CrossRef]

- Cui, Y.-H.; Lv, X.-D.; Lei, J.-X.; Liu, Z.-Q. Synergistic Effect of Cathode/peroxymonosulfate/Fe3+ on Phenol Degradation. Electrochim. Acta 2017, 245, 201–210. [Google Scholar] [CrossRef]

- Lin, H.; Zhong, X.; Ciotonea, C.; Fan, X.; Mao, X.; Li, Y.; Deng, B.; Zhang, H.; Royer, S. Efficient degradation of clofibric acid by electro-enhanced peroxydisulfate activation with Fe-Cu/SBA-15 catalyst. Appl. Catal. B Environ. 2018, 230, 1–10. [Google Scholar] [CrossRef]

- Gong, H.; Chu, W.; Lam, S.H.; Lin, A.Y.-C. Ibuprofen degradation and toxicity evolution during Fe2+/Oxone/UV process. Chemosphere 2017, 167, 415–421. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Wang, B.; Wang, S.; Liu, M.; Wu, Y.; Lu, L.; Ren, H.; Li, H.; Dong, W.; et al. Degradation of ibuprofen in soil systems by persulfate activated with pyrophosphate chelated Fe(II). Chem. Eng. J. 2020, 379, 122145. [Google Scholar] [CrossRef]

- Tran, N.; Drogui, P.; Nguyen, L.; Brar, S.K. Optimization of sono-electrochemical oxidation of ibuprofen in wastewater. J. Environ. Chem. Eng. 2015, 3, 2637–2646. [Google Scholar] [CrossRef]

- Hunge, Y.M.; Uchida, A.; Tominaga, Y.; Fujii, Y.; Yadav, A.A.; Kang, S.-W.; Suzuki, N.; Shitanda, I.; Kondo, T.; Itagaki, M.; et al. Visible Light-Assisted Photocatalysis Using Spherical-Shaped BiVO4 Photocatalyst. Catalysts 2021, 11, 460. [Google Scholar] [CrossRef]

- Matzek, L.W.; Carter, K.E. Activated persulfate for organic chemical degradation: A review. Chemosphere 2016, 151, 178–188. [Google Scholar] [CrossRef]

- Lv, X.-D.; Yang, S.-Q.; Xue, W.-J.; Cui, Y.-H.; Liu, Z.-Q. Performance of Cu-cathode/Fe3+/peroxymonosulfate process on iohexol degradation. J. Hazard. Mater. 2019, 366, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhong, S.; Song, Y.; Wang, B.; Zhang, F. Degradation of tetracycline hydrochloride by electro-activated persulfate oxidation. J. Electroanal. Chem. 2018, 809, 74–79. [Google Scholar] [CrossRef]

- Zhen, J.; Zhang, S.; Zhuang, X.; Ahmad, S.; Lee, T.; Si, H.; Cao, C.; Ni, S.-Q. Sulfate radicals based heterogeneous peroxymonosulfate system catalyzed by CuO-Fe3O4-Biochar nanocomposite for bisphenol A degradation. J. Water Process Eng. 2021, 41, 102078. [Google Scholar] [CrossRef]

- Chen, X.-L.; Li, F.; Zhang, M.; Liu, B.; Chen, H.; Wang, H. Highly dispersed and stabilized Co3O4/C anchored on porous biochar for bisphenol A degradation by sulfate radical advanced oxidation process. Sci. Total Environ. 2021, 777, 145794. [Google Scholar] [CrossRef]

- Li, G.; Cao, X.-Q.; Meng, N.; Huang, Y.-M.; Wang, X.-D.; Gao, Y.-Y.; Li, X.; Yang, T.-S.; Li, B.-L.; Zhang, Y.-Z.; et al. Fe3O4 supported on water caltrop-derived biochar toward peroxymonosulfate activation for urea degradation: The key role of sulfate radical. Chem. Eng. J. 2021, 433, 133595. [Google Scholar] [CrossRef]

- Babaei, A.A.; Golshan, M.; Kakavandi, B. A heterogeneous photocatalytic sulfate radical-based oxidation process for efficient degradation of 4-chlorophenol using TiO2 anchored on Fe oxides@carbon. Process Saf. Environ. Prot. 2021, 149, 35–47. [Google Scholar] [CrossRef]

- Chanikya, P.; Nidheesh, P.V.; Syam Babu, D.; Gopinath, A.; Suresh Kumar, M. Treatment of dyeing wastewater by combined sulfate radical based electrochemical advanced oxidation and electrocoagulation processes. Sep. Purif. Technol. 2021, 254, 117570. [Google Scholar] [CrossRef]

- Qi, F.; Zeng, Z.; Wen, Q.; Huang, Z. Enhanced organics degradation by three-dimensional (3D) electrochemical activation of persulfate using sulfur-doped carbon particle electrode: The role of thiophene sulfur functional group and specific capacitance. J. Hazard. Mater. 2021, 416, 125810. [Google Scholar] [CrossRef]

- Sun, X.; Liu, Z.; Sun, Z. Electro-enhanced degradation of atrazine via Co-Fe oxide modified graphite felt composite cathode for persulfate activation. Chem. Eng. J. 2021, 433, 133789. [Google Scholar] [CrossRef]

- Bu, L.; Zhou, S.; Shi, Z.; Bi, C.; Zhu, S.; Gao, N. Iron electrode as efficient persulfate activator for oxcarbazepine degradation: Performance, mechanism, and kinetic modeling. Sep. Purif. Technol. 2017, 178, 66–74. [Google Scholar] [CrossRef]

- Aseman-Bashiz, E.; Sayyaf, H. Metformin degradation in aqueous solutions by electro-activation of persulfate and hydrogen peroxide using natural and synthetic ferrous ion sources. J. Mol. Liq. 2020, 300, 112285. [Google Scholar] [CrossRef]

- Akbari, S.; Ghanbari, F.; Moradi, M. Bisphenol A degradation in aqueous solutions by electrogenerated ferrous ion activated ozone, hydrogen peroxide and persulfate: Applying low current density for oxidation mechanism. Chem. Eng. J. 2016, 294, 298–307. [Google Scholar] [CrossRef]

- Wang, Y.R.; Chu, W. Degradation of 2,4,5-trichlorophenoxyacetic acid by a novel Electro-Fe(II)/Oxone process using iron sheet as the sacrificial anode. Water Res. 2011, 45, 3883–3889. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhou, N. Removal of carbamazepine from aqueous solution using sono-activated persulfate process. Ultrason. Sonochem. 2016, 29, 156–162. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Qi, J.; Kang, J.; Shen, J.; Yan, P.; Wang, W.; Bi, L.; Zhang, X.; Zhu, X. Degradation of bisphenol S by peroxymonosulfate activation through monodispersed CoFe2O4 nanoparticles anchored on natural palygorskite. Sep. Purif. Technol. 2021, 277, 119492. [Google Scholar] [CrossRef]

- De Laat, J.; Le, G.T.; Legube, B. A comparative study of the effects of chloride, sulfate and nitrate ions on the rates of decomposition of H2O2 and organic compounds by Fe(II)/H2O2 and Fe(III)/H2O2. Chemosphere 2004, 55, 715–723. [Google Scholar] [CrossRef]

- Li, J.; Xu, M.; Yao, G.; Lai, B. Enhancement of the degradation of atrazine through CoFe2O4 activated peroxymonosulfate (PMS) process: Kinetic, degradation intermediates, and toxicity evaluation. Chem. Eng. J. 2018, 348, 1012–1024. [Google Scholar] [CrossRef]

- Li, J.; Yan, J.; Yao, G.; Zhang, Y.; Li, X.; Lai, B. Improving the degradation of atrazine in the three-dimensional (3D) electrochemical process using CuFe2O4 as both particle electrode and catalyst for persulfate activation. Chem. Eng. J. 2019, 361, 1317–1332. [Google Scholar] [CrossRef]

- Liu, L.; Mi, H.; Zhang, M.; Sun, F.; Zhan, R.; Zhao, H.; He, S.; Zhou, L. Efficient moxifloxacin degradation by CoFe2O4 magnetic nanoparticles activated peroxymonosulfate: Kinetics, pathways and mechanisms. Chem. Eng. J. 2021, 407, 127201. [Google Scholar] [CrossRef]

- Feng, Y.; Song, Q.; Lv, W.; Liu, G. Degradation of ketoprofen by sulfate radical-based advanced oxidation processes: Kinetics, mechanisms, and effects of natural water matrices. Chemosphere 2017, 189, 643–651. [Google Scholar] [CrossRef]

- Giannakis, S.; Lin, K.-Y.A.; Ghanbari, F. A review of the recent advances on the treatment of industrial wastewaters by Sulfate Radical-based Advanced Oxidation Processes (SR-AOPs). Chem. Eng. J. 2021, 406, 127083. [Google Scholar] [CrossRef]

- Gu, M.; Sui, Q.; Farooq, U.; Zhang, X.; Qiu, Z.; Lyu, S. Degradation of phenanthrene in sulfate radical based oxidative environment by nZVI-PDA functionalized rGO catalyst. Chem. Eng. J. 2018, 354, 541–552. [Google Scholar] [CrossRef]

- Bian, X.; Xia, Y.; Zhan, T.; Wang, L.; Zhou, W.; Dai, Q.; Chen, J. Electrochemical removal of amoxicillin using a Cu doped PbO2 electrode: Electrode characterization, operational parameters optimization and degradation mechanism. Chemosphere 2019, 233, 762–770. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Zhang, M.; Zhang, B.-T.; Yu, Y.-G. The electrochemical degradation of ciprofloxacin using a SnO2-Sb/Ti anode: Influencing factors, reaction pathways and energy demand. Chem. Eng. J. 2016, 296, 79–89. [Google Scholar] [CrossRef]

- Hama Aziz, K.H.; Miessner, H.; Mueller, S.; Kalass, D.; Moeller, D.; Khorshid, I.; Rashid, M.A.M. Degradation of pharmaceutical diclofenac and ibuprofen in aqueous solution, a direct comparison of ozonation, photocatalysis, and non-thermal plasma. Chem. Eng. J. 2017, 313, 1033–1041. [Google Scholar] [CrossRef]

- Shi, K.; Wang, Y.; Xu, A.; Zhou, X.; Zhu, H.; Wei, K.; Liu, X.; Shen, J.; Han, W. Efficient degradation of ibuprofen by electro-Fenton with microtubular gas- diffusion electrodes synthesized by wet-spinning method. J. Electroanal. Chem. 2021, 897, 115615. [Google Scholar] [CrossRef]

- Wang, P.; Bu, L.; Wu, Y.; Ma, W.; Zhu, S.; Zhou, S. Mechanistic insight into the degradation of ibuprofen in UV/H2O2 process via a combined experimental and DFT study. Chemosphere 2021, 267, 128883. [Google Scholar] [CrossRef]

- Sun, S.; Hu, Y.; Xu, M.; Cheng, F.; Zhang, H.; Li, Z. Photo-Fenton degradation of carbamazepine and ibuprofen by iron-based metal-organic framework under alkaline condition. J. Hazard. Mater. 2022, 424, 127698. [Google Scholar] [CrossRef]

- Liu, H.; Nkundabose, J.P.; Chen, H.; Yang, L.; Meng, C.; Ding, N. Decontamination of ibuprofen micropollutants from water based on visible-light-responsive hybrid photocatalyst. J. Environ. Chem. Eng. 2022, 10, 107154. [Google Scholar] [CrossRef]

- Li, C.; Lin, H.; Armutlulu, A.; Xie, R.; Zhang, Y.; Meng, X. Hydroxylamine-assisted catalytic degradation of ciprofloxacin in ferrate/persulfate system. Chem. Eng. J. 2019, 360, 612–620. [Google Scholar] [CrossRef]

- Tsitonaki, A.; Petri, B.; Crimi, M.; Mosbæk, H.; Siegrist, R.; Bjerg, P. In Situ Chemical Oxidation of Contaminated Soil and Groundwater Using Persulfate: A Review. Crit. Rev. Environ. Sci. Technol. 2010, 40, 55–91. [Google Scholar] [CrossRef]

- Jaafarzadeh, N.; Ghanbari, F.; Zahedi, A. Coupling electrooxidation and Oxone for degradation of 2,4-Dichlorophenoxyacetic acid (2,4-D) from aqueous solutions. J. Water Process Eng. 2018, 22, 203–209. [Google Scholar] [CrossRef]

- Jin, Y.; Sun, S.-P.; Yang, X.; Chen, X.D. Degradation of ibuprofen in water by FeII-NTA complex-activated persulfate with hydroxylamine at neutral pH. Chem. Eng. J. 2018, 337, 152–160. [Google Scholar] [CrossRef]

- Liu, S.-H.; Tang, W.-T.; Chou, P.-H. Microwave-assisted synthesis of triple 2D g-C3N4/Bi2WO6/rGO composites for ibuprofen photodegradation: Kinetics, mechanism and toxicity evaluation of degradation products. Chem. Eng. J. 2020, 387, 124098. [Google Scholar] [CrossRef]

- Ma, M.; Chen, L.; Zhao, J.; Liu, W.; Ji, H. Efficient activation of peroxymonosulfate by hollow cobalt hydroxide for degradation of ibuprofen and theoretical study. Chin. Chem. Lett. 2019, 30, 2191–2195. [Google Scholar] [CrossRef]

- Marković, M.; Jović, M.; Stanković, D.; Kovačević, V.; Roglić, G.; Gojgić-Cvijović, G.; Manojlović, D. Application of non-thermal plasma reactor and Fenton reaction for degradation of ibuprofen. Sci. Total Environ. 2015, 505, 1148–1155. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.A.; Hunge, Y.M.; Kulkarni, S.B. Synthesis of multifunctional FeCo2O4 electrode using ultrasonic treatment for photocatalysis and energy storage applications. Ultrason. Sonochem. 2019, 58, 104663. [Google Scholar] [CrossRef]

| Parameters | k (min−1) | Half-Life (t1/2, min) | R2 | |

|---|---|---|---|---|

| Degradation under different systems | EC/Fe3+/PDS | 0.0408 | 16.99 | 0.994 |

| EC | 0.0120 | 57.76 | 0.998 | |

| EC/Fe3+ | 0.0143 | 48.47 | 0.997 | |

| EC/PDS | 0.0150 | 46.21 | 0.994 | |

| PDS concentration (mM) | 6 | 0.0215 | 32.24 | 0.996 |

| 8 | 0.0408 | 16.99 | 0.994 | |

| 10 | 0.0482 | 14.38 | 0.994 | |

| 12 | 0.0508 | 13.64 | 0.995 | |

| 14 | 0.0457 | 15.17 | 0.994 | |

| Fe3+ concentration (mM) | 0.5 | 0.0255 | 27.18 | 0.988 |

| 1.0 | 0.0508 | 13.64 | 0.995 | |

| 1.5 | 0.0598 | 11.59 | 0.997 | |

| 2.0 | 0.0851 | 8.15 | 0.983 | |

| 2.5 | 0.0657 | 10.55 | 0.995 | |

| Current density (mA/cm2) | 5 | 0.0193 | 35.91 | 0.993 |

| 10 | 0.0364 | 19.04 | 0.996 | |

| 15 | 0.0851 | 8.15 | 0.983 | |

| 20 | 0.0829 | 8.36 | 0.979 | |

| IBU concentration (mg/L) | 30 | 0.0851 | 8.15 | 0.983 |

| 40 | 0.0507 | 13.67 | 0.993 | |

| 50 | 0.0356 | 19.47 | 0.986 | |

| 60 | 0.0277 | 25.02 | 0.981 | |

| pH | 3 | 0.0851 | 8.15 | 0.983 |

| 5 | 0.0640 | 10.83 | 0.987 | |

| 7 | 0.0465 | 14.91 | 0.982 | |

| 9 | 0.0345 | 20.09 | 0.987 |

| Technology | Experimental Conditions | IBU Removal (%) | Reference |

|---|---|---|---|

| Electro-oxidation (Ti/SnO2-Sb/Ce-PbO2) | V = 30 mL; IBU = 20 mg/L; current density = 10 mA/cm2 | 90% removal in 60 min | [2] |

| BaTiO3/PDS under ultrasonic-wave | V = 25 mL, PS = 1.0 mM, IBU = 6.0 mg/L, BaTiO3 = 2.0 g/L | 99% removal in 60 min | [7] |

| Electro-Fenton | V = 200 mL, IBU = 10 mg/L, pH = 3.0, Fe2+ = 0.7 mM | 94.8% removal in 150 min | [56] |

| UV/H2O2 | IBU = 10 μM, H2O2 = 0.5 mM, pH = 5.2 | 95% removal in 240 min | [57] |

| Photo-Fenton (HSO3-MIL-53(Fe)) | V = 50 mL, IBU = 10 mg/L, H2O2 = 20 mM, HSO3-MIL-53(Fe) = 200 mg/L, pH0 = 8.0 | 100% removal in 90 min | [58] |

| Photocatalysis (phosphorus and sulfur co-doped graphitic carbon nitride (PSGCN) and AgBr particle) | Photocatalyst = 100 mg/100 mL, IBU = 15 mg/L | 90% removal in 100 min | [59] |

| EC/Fe3+/PDS | V = 200 mL; pH = 3; IBU = 30 mg/L; current density = 10 mA/cm2; Fe3+ = 2.0 mM; PDS = 12 mM | 99.37% removal in 60 min | this work |

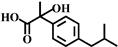

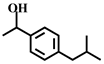

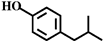

| Product | Reaction Time | Molecular Weight | Chemical Structure |

|---|---|---|---|

| IBU | 6.24 | 206 |  |

| P1 | 5.26 | 222 |  |

| P2 | 2.81 | 164 |  |

| P3 | 3.40 | 134 |  |

| P4 | 5.36 | 222 |  |

| P5 | 6.54 | 178 |  |

| P6 | 7.53 | 150 |  |

| P7 | 8.52 | 118 |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, N.; Shen, C.; Liu, Y.; Li, X.; Jia, G.; Qin, J.; Wang, X. Degradation of Ibuprofen by the Electro/Fe3+/Peroxydisulfate Process: Reactive Kinetics, Degradation Products and Mechanism. Catalysts 2022, 12, 329. https://doi.org/10.3390/catal12030329

Qiu N, Shen C, Liu Y, Li X, Jia G, Qin J, Wang X. Degradation of Ibuprofen by the Electro/Fe3+/Peroxydisulfate Process: Reactive Kinetics, Degradation Products and Mechanism. Catalysts. 2022; 12(3):329. https://doi.org/10.3390/catal12030329

Chicago/Turabian StyleQiu, Na, Chanchan Shen, Yongxia Liu, Xiuqing Li, Guangyin Jia, Jingping Qin, and Xinglei Wang. 2022. "Degradation of Ibuprofen by the Electro/Fe3+/Peroxydisulfate Process: Reactive Kinetics, Degradation Products and Mechanism" Catalysts 12, no. 3: 329. https://doi.org/10.3390/catal12030329

APA StyleQiu, N., Shen, C., Liu, Y., Li, X., Jia, G., Qin, J., & Wang, X. (2022). Degradation of Ibuprofen by the Electro/Fe3+/Peroxydisulfate Process: Reactive Kinetics, Degradation Products and Mechanism. Catalysts, 12(3), 329. https://doi.org/10.3390/catal12030329