Open-Cell Rigid Polyurethane Foams from Peanut Shell-Derived Polyols Prepared under Different Post-Processing Conditions

Abstract

:1. Introduction

2. Experimental

2.1. Materials

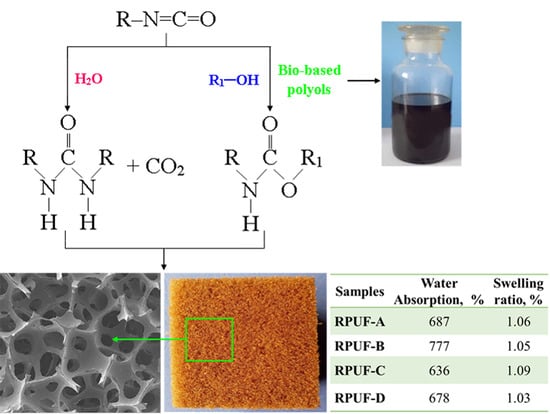

2.2. Preparation of Open-Cell RPUFs

2.3. Characterization and Property Testing of RPUFs

3. Results and Discussion

3.1. Foaming Behaviors

3.2. Apparent Density

3.3. Dimensional Stability and Water Absorption

3.4. Mechanical Properties

3.5. Cell Morphology

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tu, Y.C.; Kiatsimkul, P.; Suppes, G.; Hsieh, F. Physical properties of water-blown rigid polyurethane foams from vegetable oil-based polyols. J. Appl. Polym. Sci. 2007, 105, 453–459. [Google Scholar] [CrossRef]

- Wang, C.; Wu, Y.; Li, Y.; Shao, Q.; Yan, X.; Han, C.; Wang, Z.; Liu, Z.; Guo, Z. Flame-retardant rigid polyurethane foam with a phosphorus-nitrogen single intumescent flame retardant. Polym. Adv. Technol. 2018, 29, 668–676. [Google Scholar] [CrossRef]

- Chen, X.; Huo, L. TG-FTIR characterization of volatile compounds from flame retardant polyurethane foams materials. J. Anal. Appl. Pyrol. 2013, 100, 186–191. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Kurańska, M.; Prociak, A.; Malewska, E.; Bujok, S. The effect of different palm oil based bio-polyols on foaming process and selected properties of porous polyurethanes. Polym. Int. 2017, 66, 1522–1529. [Google Scholar] [CrossRef]

- Huang, G.; Wang, P. Effects of preparation conditions on properties of rigid polyurethane foam composites based on liquefied bagasse and jute fibre. Polym. Test. 2017, 60, 266–273. [Google Scholar] [CrossRef]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C.C. Depolymerization of lignins and their applications for the preparation of polyols and rigid polyurethane foams: a review. Renew. Sustain. Energy Rev. 2016, 60, 317–329. [Google Scholar] [CrossRef]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Tymchyshyn, M.; Xu, C.C. Hydrolytic liquefaction of hydrolysis lignin for the preparation of bio-based rigid polyurethane foam. Green Chem. 2016, 18, 2385–2398. [Google Scholar] [CrossRef]

- Carriço, C.S.; Fraga, T.; Pasa, V.M.D. Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur. Polym. J. 2016, 85, 53–61. [Google Scholar] [CrossRef]

- Hu, Y.H.; Gao, Y.; Wang, D.N.; Hu, C.P.; Zu, S.; Vanoverloop, L.; Randall, D. Rigid polyurethane foam prepared from a rape seed oil based polyol. J. Appl. Polym. Sci. 2002, 84, 591–597. [Google Scholar] [CrossRef]

- Campanella, A.; Bonnaillie, L.M.; Wool, R.P. Polyurethane foams from soyoil-based polyols. J. Appl. Polym. Sci. 2010, 112, 2567–2578. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, L.; Li, D.; Yin, J.; Wu, S.; Mao, Z. Mechanical properties of polyurethane foams prepared from liquefied corn stover with PAPI. Bioresour. Technol. 2008, 99, 2265–2268. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.T.; Zhao, C.S.; Dai, C.L.; Fu, Y.; Lin, S. Thermal and mechanical properties of polyurethane rigid foam based on epoxidized soybean oil. J. Polym. Environ. 2012, 20, 230–236. [Google Scholar] [CrossRef]

- Ji, D.; Fang, Z.; He, W.; Luo, Z.; Jiang, X.; Wang, T.; Guo, K. Polyurethane rigid foams formed from different soy-based polyols by the ring opening of epoxidised soybean oil with methanol, phenol, and cyclohexanol. Ind. Crops Prod. 2015, 74, 76–82. [Google Scholar] [CrossRef]

- Pillai, P.K.S.; Li, S.; Bouzidi, L.; Narine, S.S. Metathesized palm oil polyol for the preparation of improved bio-based rigid and flexible polyurethane foams. Ind. Crops Prod. 2016, 83, 568–576. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A. The influence of rapeseed oil-based polyols on the foaming process of rigid polyurethane foams. Ind. Crops Prod. 2016, 89, 182–187. [Google Scholar] [CrossRef]

- Kairytė, A.; Vėjelis, S. Evaluation of forming mixture composition impact on properties of water blown rigid polyurethane (PUR) foam from rapeseed oil polyol. Ind. Crops Prod. 2015, 66, 210–215. [Google Scholar] [CrossRef]

- Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Oleic and undecylenic acids as renewable Feedstocks in the synthesis of polyols and polyurethanes. Polymers 2010, 2, 440–453. [Google Scholar] [CrossRef]

- Bähr, M.; Mülhaupt, R. Linseed and soybean oil-based polyurethanes prepared via the non-isocyanate route and catalytic carbon dioxide conversion. Green Chem. 2012, 14, 483–489. [Google Scholar] [CrossRef]

- Palanisamy, A.; Rao, B.S.; Mehazabeen, S. Diethanolamides of castor oil as polyols for the development of water-blown polyurethane foam. J. Polym. Environ. 2011, 19, 698–705. [Google Scholar] [CrossRef]

- Silva, V.R.D.; Mosiewicki, M.A.; Yoshida, M.I.; Silva, M.C.D.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash II: Mechanical characterization. Polym. Test. 2013, 32, 665–672. [Google Scholar] [CrossRef]

- Soto, G.D.; Marcovich, N.E.; Mosiewicki, M.A. Flexible polyurethane foams modified with biobased polyols: Synthesis and physical-chemical characterization. J. Appl. Polym. Sci. 2016, 133, 43833. [Google Scholar] [CrossRef]

- Zhou, W.; Bo, C.; Jia, P.; Zhou, Y.; Zhang, M. Effects of tung oil-based polyols on the thermal stability, flame retardancy, and mechanical properties of rigid polyurethane foam. Polymers 2019, 11, 45. [Google Scholar] [CrossRef] [PubMed]

- Maldas, D.; Shiraishi, N. Liquefaction of wood in the presence of polyol using NaOH as a Catalyst and its application to polyurethane foams. Int. J. Polymer. Mater. 1996, 33, 61–71. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, J.; Hse, C.Y.; Shupe, T.F. Preparation of polyurethane foams using fractionated products in liquefied wood. J. Appl. Polym. Sci. 2014, 131, 2113–2124. [Google Scholar] [CrossRef]

- Mori, R. Inorganic-organic hybrid biodegradable polyurethane resin derived from liquefied Sakura wood. Wood Sci. Technol. 2015, 49, 507–516. [Google Scholar] [CrossRef]

- Čuk, N.; Fabjan, E.; Grželj, P.; Kunaver, M. Water-blown polyurethane/polyisocyanurate foams made from recycled polyethylene terephthalate and liquefied wood-based polyester polyol. J. Appl. Polym. Sci. 2015, 132, 41522. [Google Scholar] [CrossRef]

- Chen, F.; Lu, Z. Liquefaction of wheat straw and preparation of rigid polyurethane foam from the liquefaction products. J. Appl. Polym. Sci. 2010, 111, 508–516. [Google Scholar] [CrossRef]

- Xie, J.; Zhai, X.; Hse, C.; Hse, C.Y.; Shupe, T.F.; Pan, H. Polyols from microwave liquefied bagasse and its application to rigid polyurethane foam. Materials 2015, 8, 8496–8509. [Google Scholar] [CrossRef]

- Lee, S.H.; Teramoto, Y.; Shiraishi, N. Biodegradable polyurethane foam from liquefied waste paper and its thermal stability, biodegradability, and genotoxicity. J. Appl. Polym. Sci. 2010, 83, 1482–1489. [Google Scholar] [CrossRef]

- Liu, Y.J. Handbook of Raw Materials and Additives for Polyurethanes, 2nd ed.; Chemical Industry Press: Beijing, China, 2012; pp. 71–124. [Google Scholar]

- Zhang, Q.; Zhang, G.; Han, D.; Wu, Y. Renewable chemical feedstocks from peanut shell liquefaction: Preparation and characterization of liquefied products and residue. J. Appl. Polym. Sci. 2016, 133, 44162. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Qu, G.; Lin, X.; Han, D.; Yan, X.; Zhang, H. Liquefaction of peanut shells with cation exchange resin and sulfuric acid as dual catalyst for the subsequent synthesis of rigid polyurethane foam. Polymers 2019, 11, 993. [Google Scholar] [CrossRef] [PubMed]

- Narine, S.S.; Kong, X.; Bouzidi, L.; Sporns, P. Physical properties of polyurethanes produced from polyols from seed oils: II. Foams. J. Am. Oil Chem. Soc. 2007, 84, 65–72. [Google Scholar] [CrossRef]

- Liao, S.; Zhen, D.; Song, Y.; Yin, Y. Synthesis of biodegradable polyurethane flower mud. Chin. J. Colloid Polym. 2009, 27, 10–12. [Google Scholar]

- Tiuc, A.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved sound absorption properties of polyurethane foam mixed with textile waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef]

- Ahn, W.S. Open-cell rigid polyurethane foam using reactive cell opening agents. J. Korea Acad.-Ind. Coop. Soc. 2013, 14, 2524–2528. [Google Scholar]

- Zhang, G.; Zhang, Q.; Wu, Y.; Zhang, H.; Cao, J.; Han, D. Effect of auxiliary blowing agents on properties of rigid polyurethane foams based on liquefied products from peanut shell. J. Appl. Polym. Sci. 2017, 134, 45582. [Google Scholar] [CrossRef]

- Tondi, G.; Pizzi, A. Tannin-based rigid foams: characterization and modification. Ind. Crops Prod. 2009, 29, 356–363. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Effect of expandable graphite on the properties of intumescent flame-retardant polyurethane foam. J. Appl. Polym. Sci. 2008, 110, 2586–2594. [Google Scholar] [CrossRef]

| Sample | OH Number, mgKOH·g−1 | Acid Number, mgKOH·g−1 | Viscosity(25°C), mPa·s | Color |

|---|---|---|---|---|

| A | 451.9 | 1.0 | 47 | black |

| B | 473.3 | 1.0 | 143 | black |

| C | 451.9 | 8.9 | 47 | black |

| D | 473.3 | 8.9 | 143 | black |

| Samples | Gel Time, s | Free Rise Time, s |

|---|---|---|

| RPUF-A | 24 | 39 |

| RPUF-B | 28 | 41 |

| RPUF-C | 449 | 578 |

| RPUF-D | 480 | 593 |

| Samples | −25 °C | 85 °C | ||||

|---|---|---|---|---|---|---|

| Length, % | Width, % | Height, % | Length, % | Width, % | Height, % | |

| RPUF-A | −0.13 | −0.07 | −0.03 | 0.02 | 0.08 | 0.07 |

| RPUF-B | −0.12 | −0.05 | −0.16 | 0.13 | 0.26 | 0.18 |

| RPUF-C | −0.35 | −0.07 | −0.15 | 0.07 | 0.50 | 0.15 |

| RPUF-D | −0.34 | −0.10 | −0.27 | 0.06 | 0.27 | 0.20 |

| Samples | Water Absorption, % | Swelling Ratio, % |

|---|---|---|

| RPUF-A | 687 | 1.06 |

| RPUF-B | 777 | 1.05 |

| RPUF-C | 636 | 1.09 |

| RPUF-D | 678 | 1.03 |

| Samples | Maximum Pressure, N | Compression Strength, KPa | Stress-Strain | ||

|---|---|---|---|---|---|

| 10%, KPa | 20%, KPa | 25%, KPa | |||

| RPUF-A | 63.4 | 248.5 | 221.9 | 278.6 | 307.5 |

| RPUF-B | 89.5 | 350.7 | 326.4 | 337.7 | 349.6 |

| RPUF-C | 51.0 | 200.1 | 171.4 | 189.0 | 197.9 |

| RPUF-D | 59.2 | 231.7 | 204.4 | 215.1 | 218.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Wu, Y.; Chen, W.; Han, D.; Lin, X.; Xu, G.; Zhang, Q. Open-Cell Rigid Polyurethane Foams from Peanut Shell-Derived Polyols Prepared under Different Post-Processing Conditions. Polymers 2019, 11, 1392. https://doi.org/10.3390/polym11091392

Zhang G, Wu Y, Chen W, Han D, Lin X, Xu G, Zhang Q. Open-Cell Rigid Polyurethane Foams from Peanut Shell-Derived Polyols Prepared under Different Post-Processing Conditions. Polymers. 2019; 11(9):1392. https://doi.org/10.3390/polym11091392

Chicago/Turabian StyleZhang, Guangyu, Yumin Wu, Weisheng Chen, Dezhi Han, Xiaoqi Lin, Gongchen Xu, and Qinqin Zhang. 2019. "Open-Cell Rigid Polyurethane Foams from Peanut Shell-Derived Polyols Prepared under Different Post-Processing Conditions" Polymers 11, no. 9: 1392. https://doi.org/10.3390/polym11091392

APA StyleZhang, G., Wu, Y., Chen, W., Han, D., Lin, X., Xu, G., & Zhang, Q. (2019). Open-Cell Rigid Polyurethane Foams from Peanut Shell-Derived Polyols Prepared under Different Post-Processing Conditions. Polymers, 11(9), 1392. https://doi.org/10.3390/polym11091392