A Multi-Rheology Design Method of Sheeting Polymer Extrusion Dies Based on Flow Network and the Winter–Fritz Design Equation

Abstract

:1. Introduction

2. Methodology

- Isothermal incompressible flow

- Streamlined flow

- Steady and fully-developed flows in both slit and manifold

- Uniform pressure at the exit of the slit

- Unidirectional flow in both manifold and slit network segments (ignoring traverse flow in the manifold)

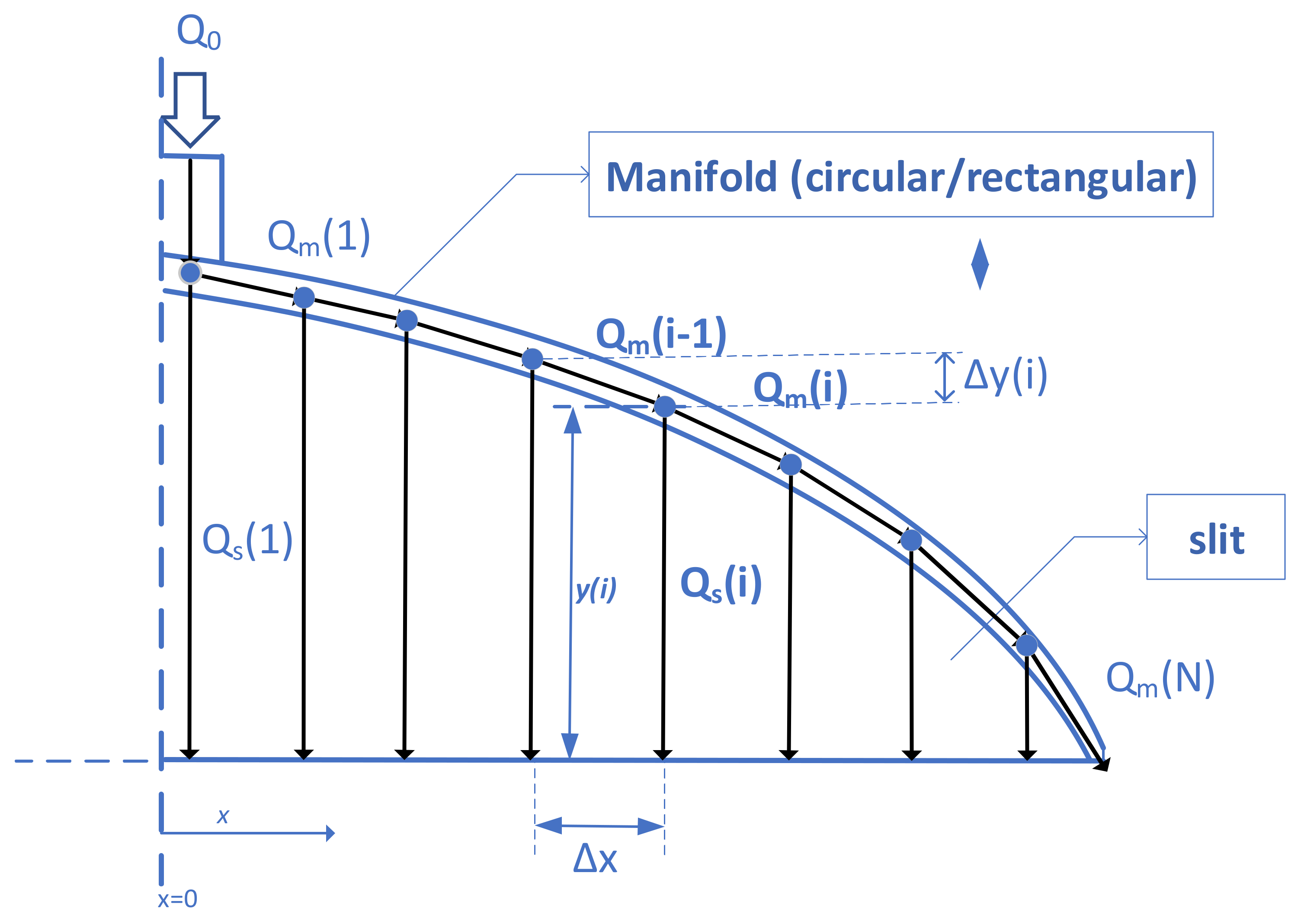

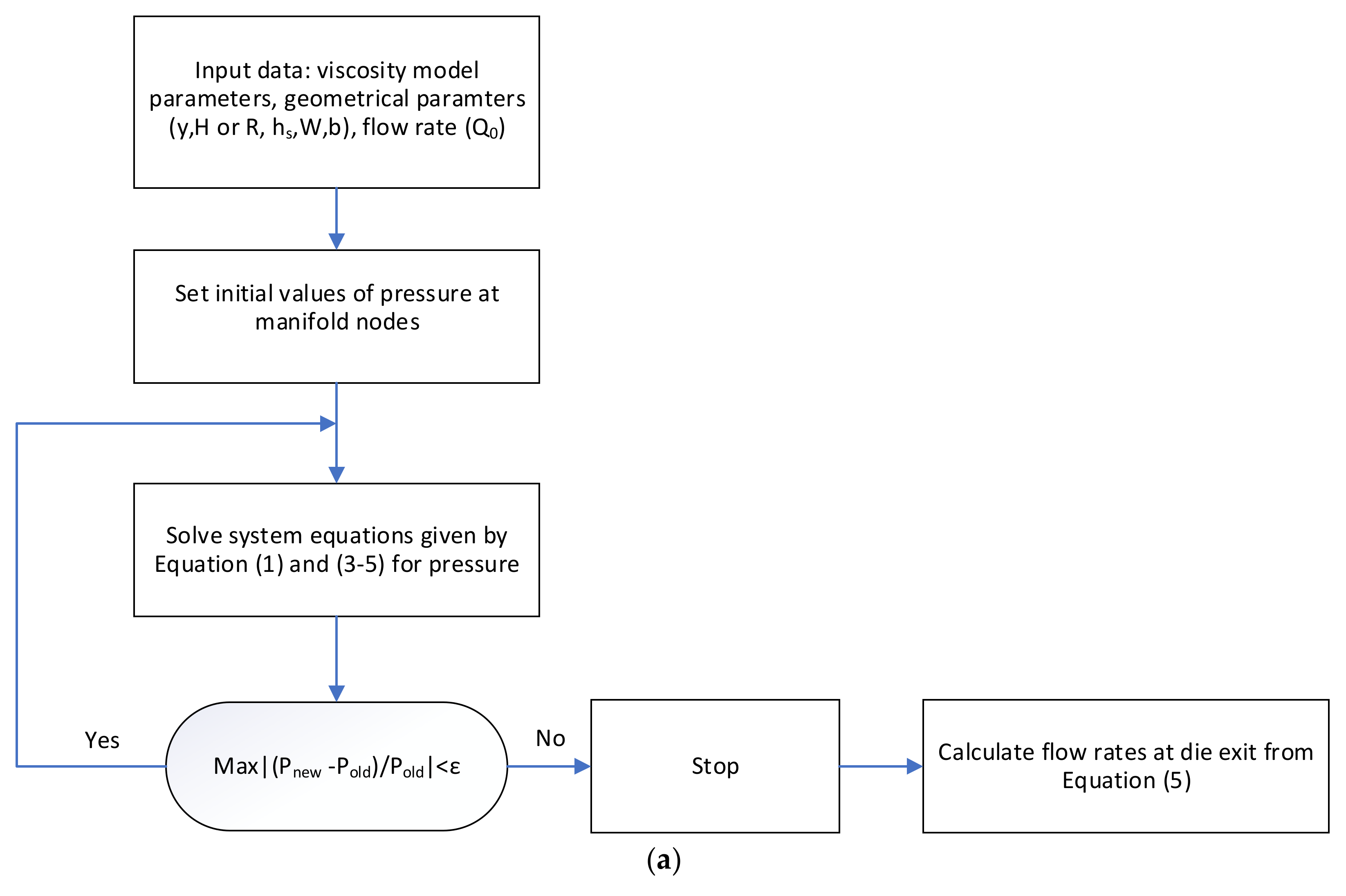

2.1. Calculation of the Flow Distribution

2.2. Design of the Manifold Curve

- Constant shear rates between the slit and the manifold and

- Uniform velocity distribution at the exit of the slit.

2.3. Calculation of Wall Shear Rates and Pressure Gradients

3. Results and Discussion

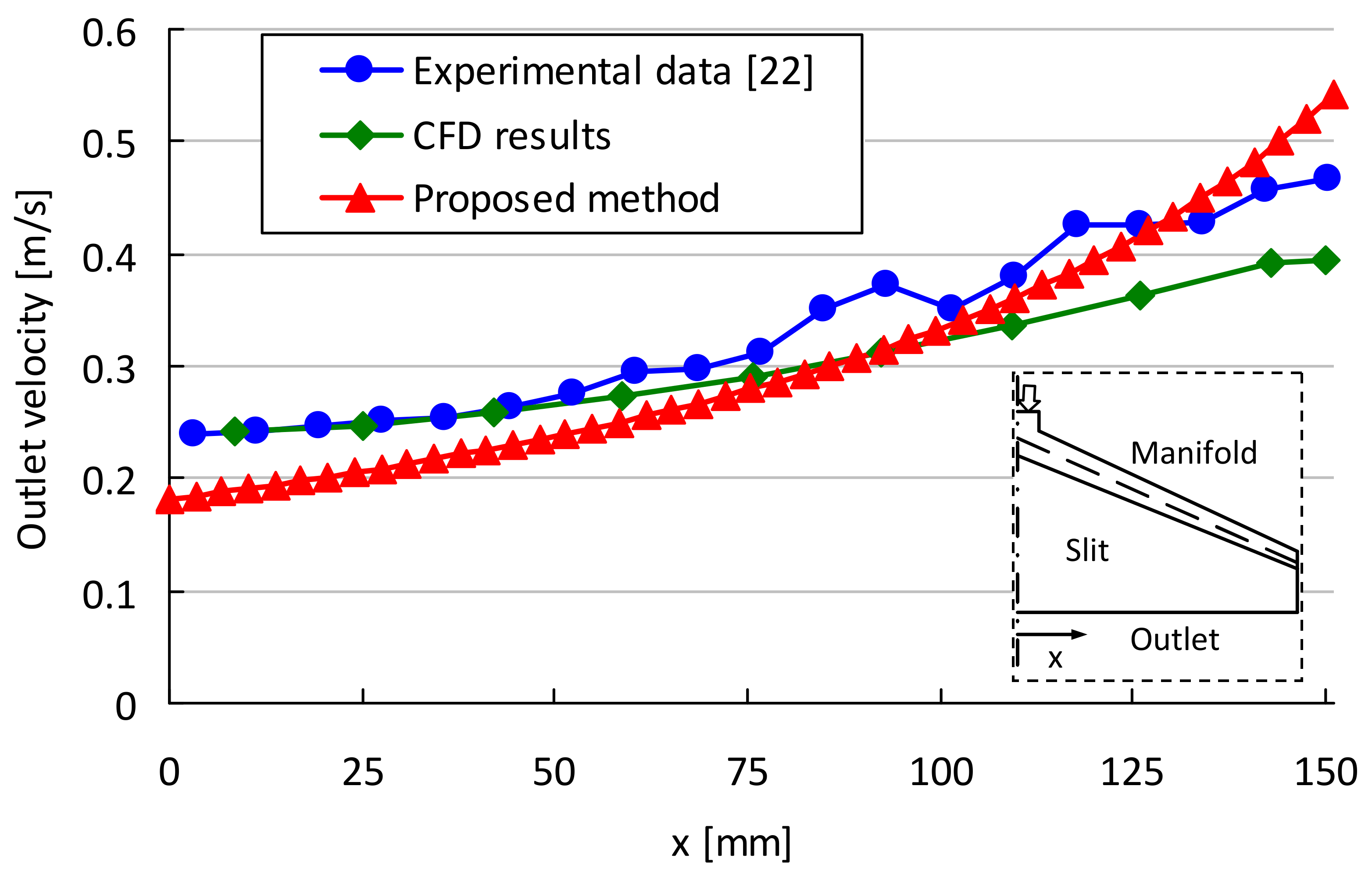

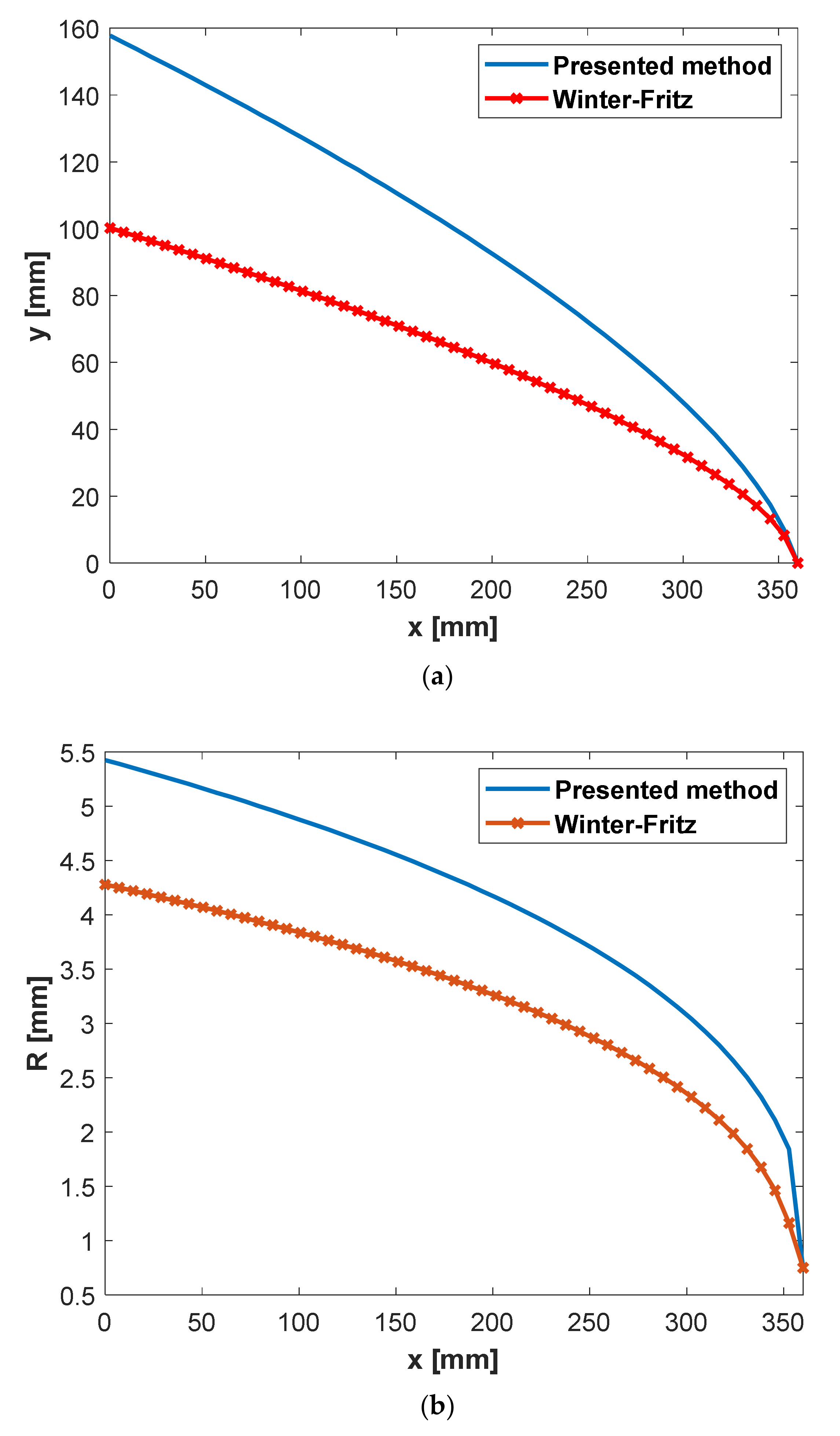

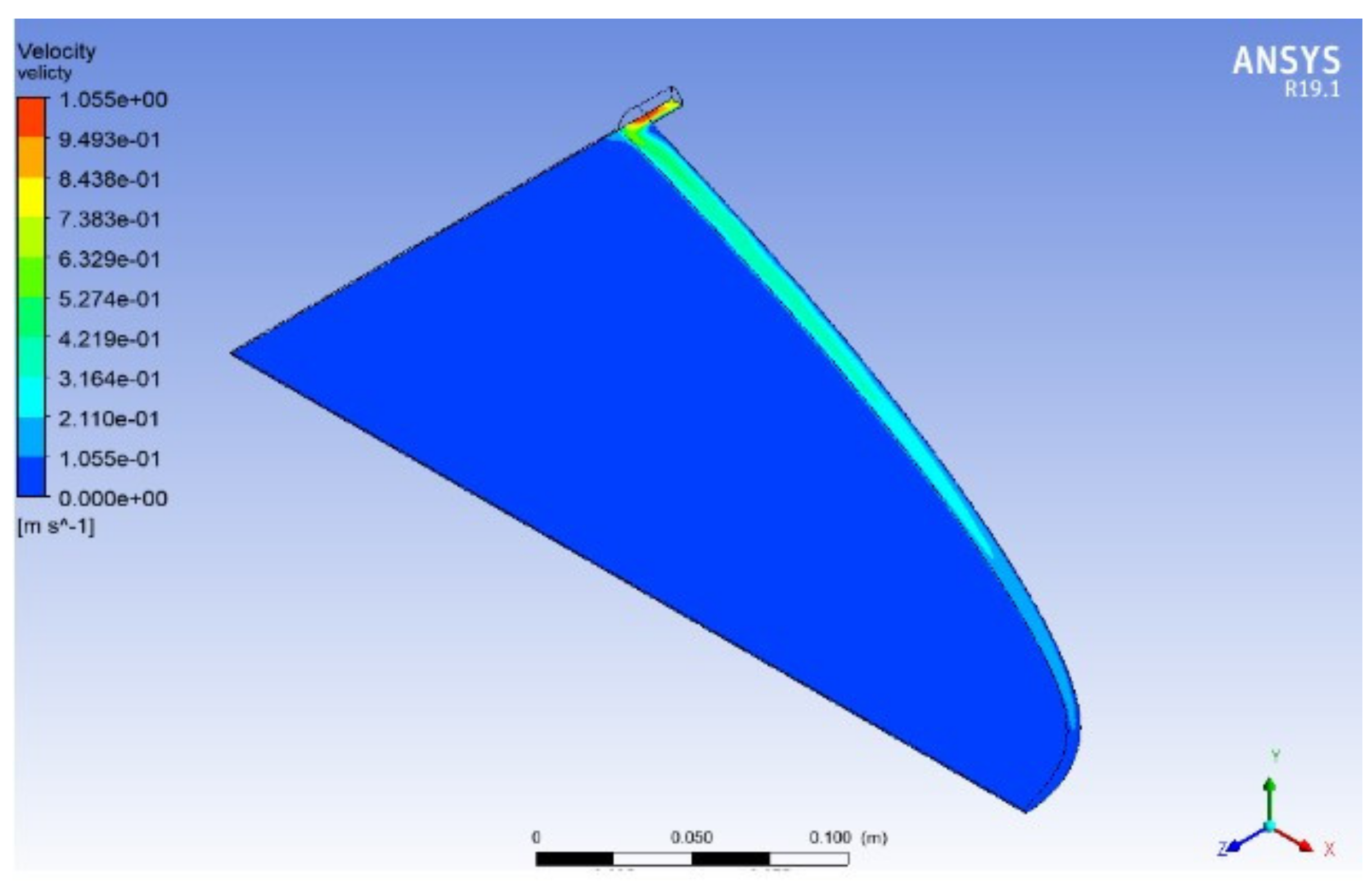

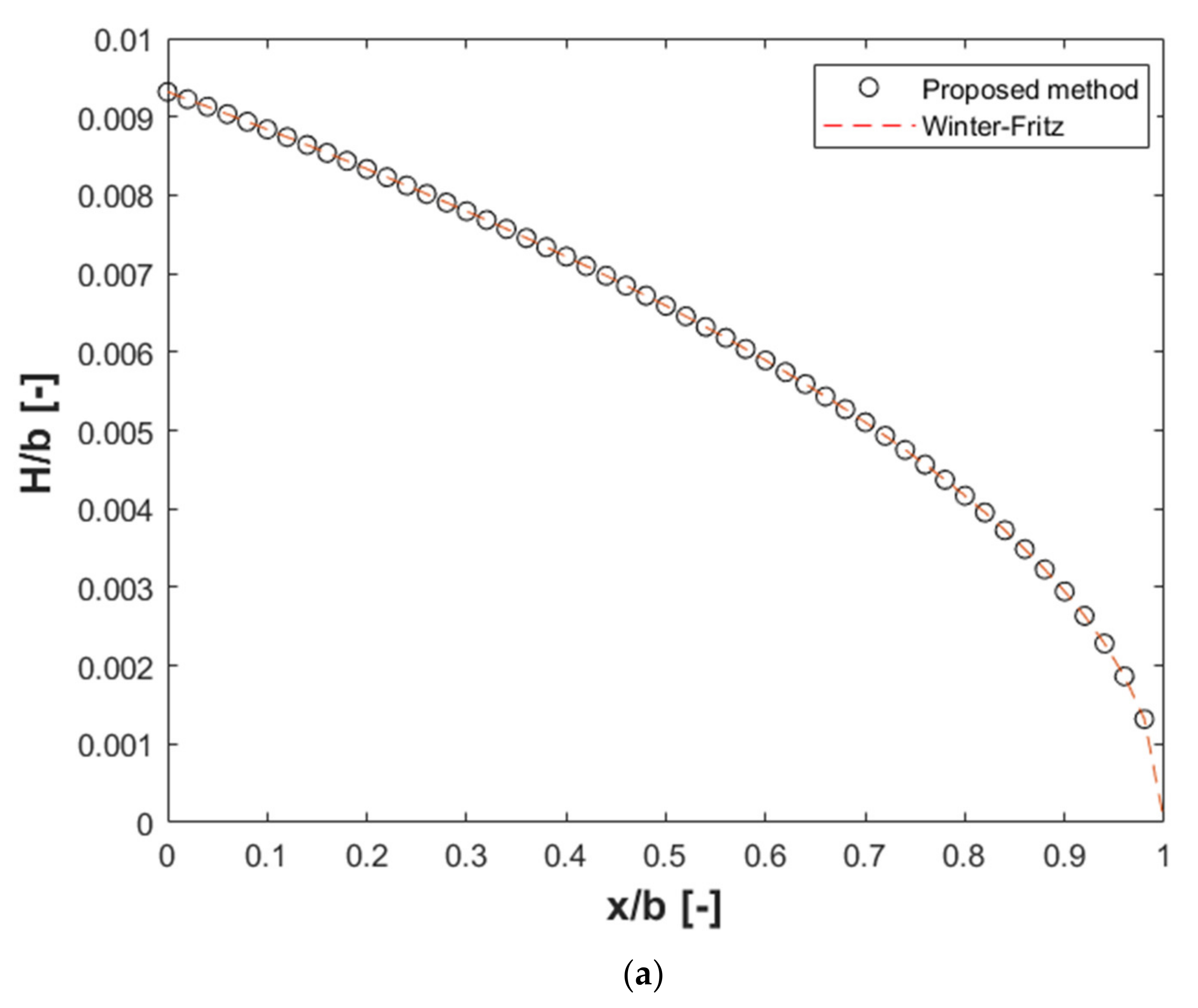

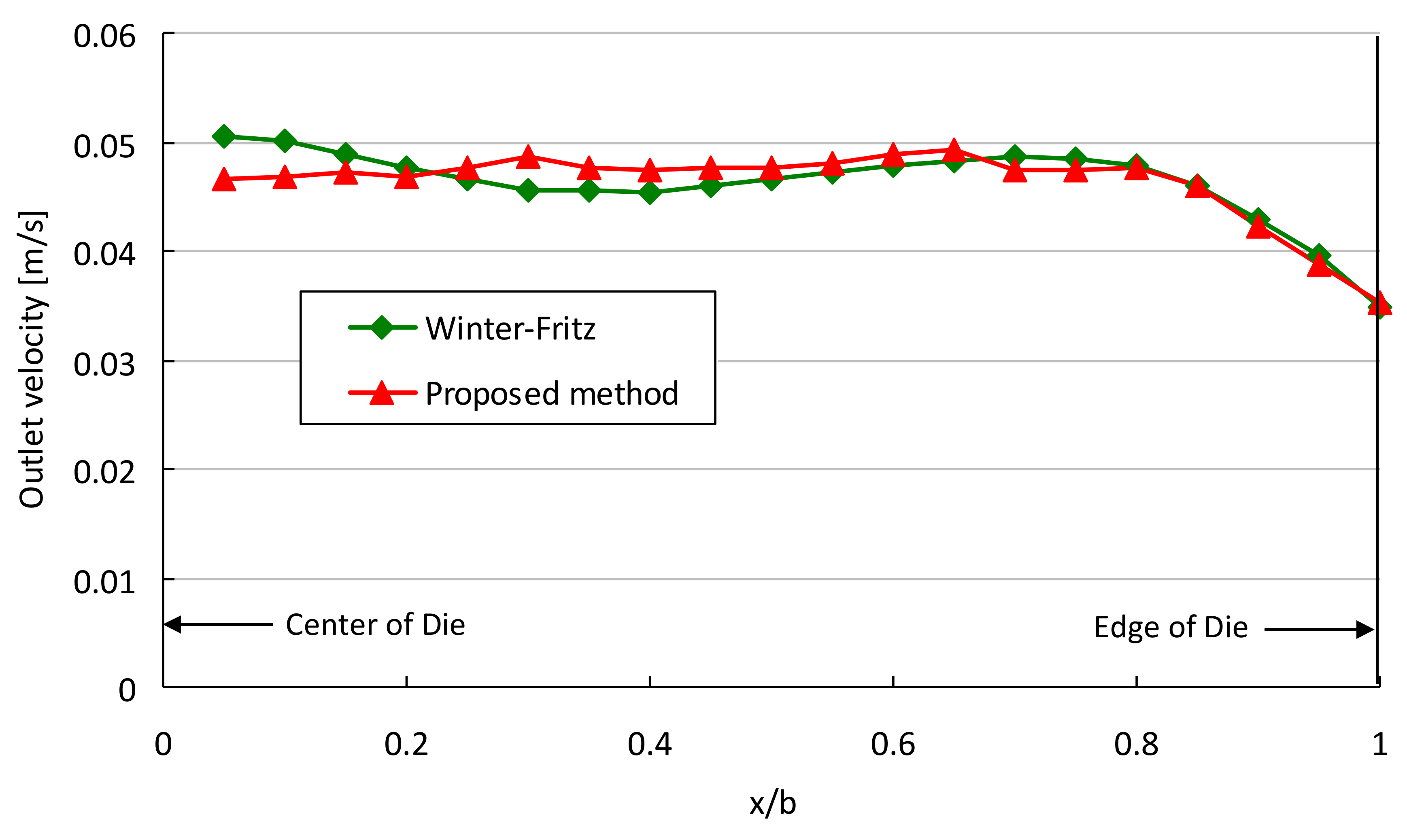

3.1. Validation

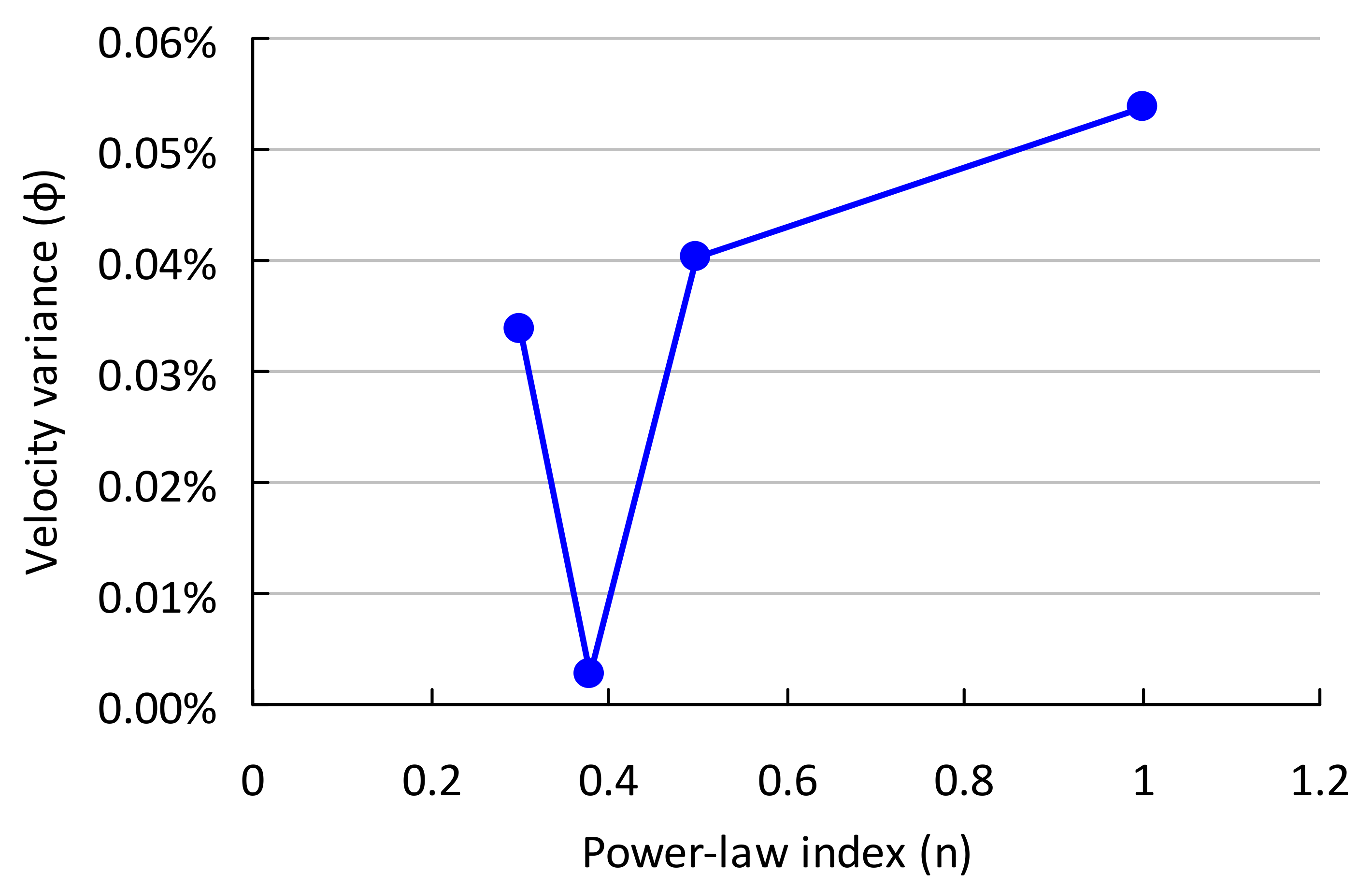

3.2. Sensitivity Analysis

3.3. Design of a Power-Law Fluid with Circular Manifold

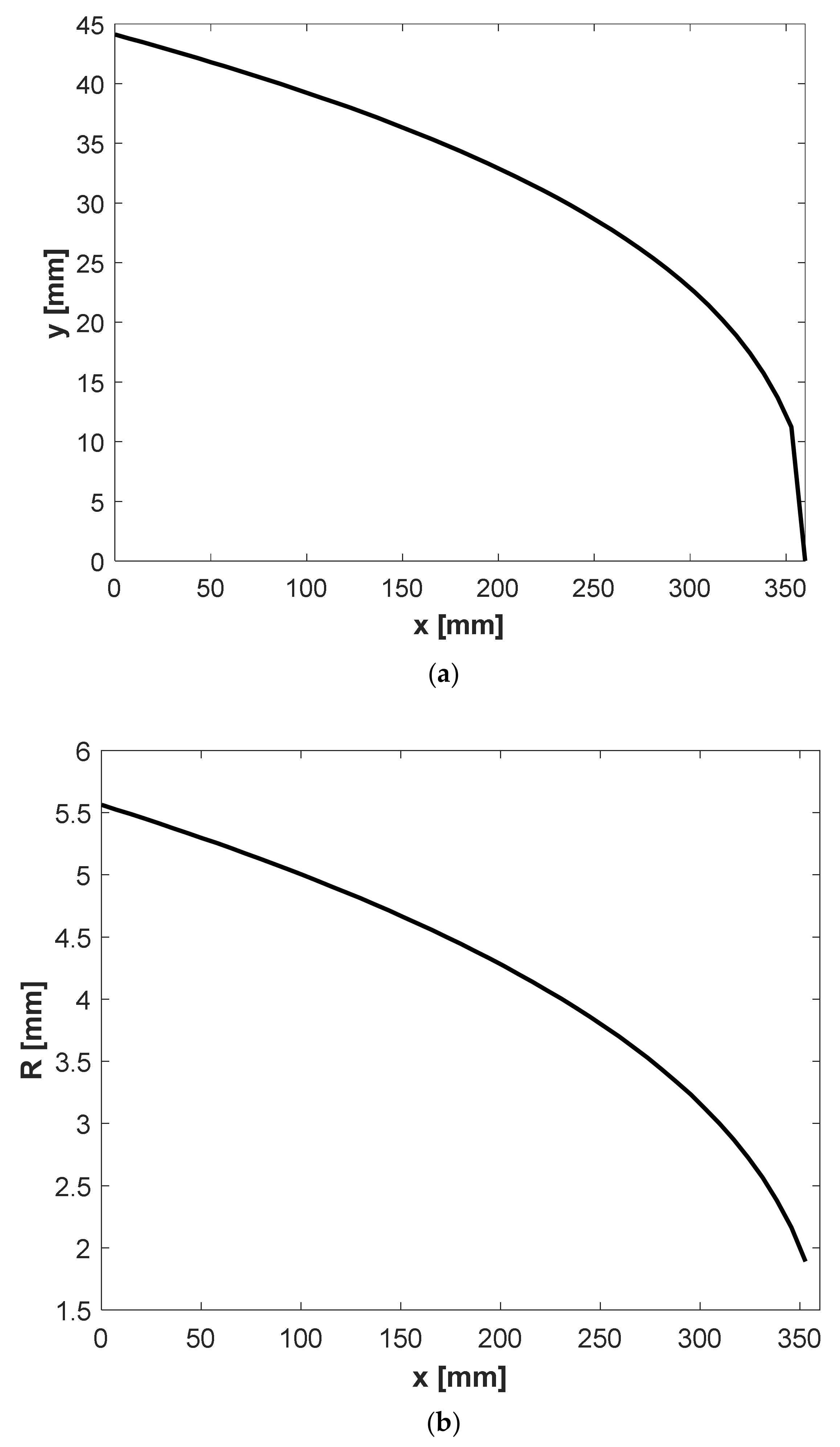

3.4. Design of a Carreau-Yasuda Fluid

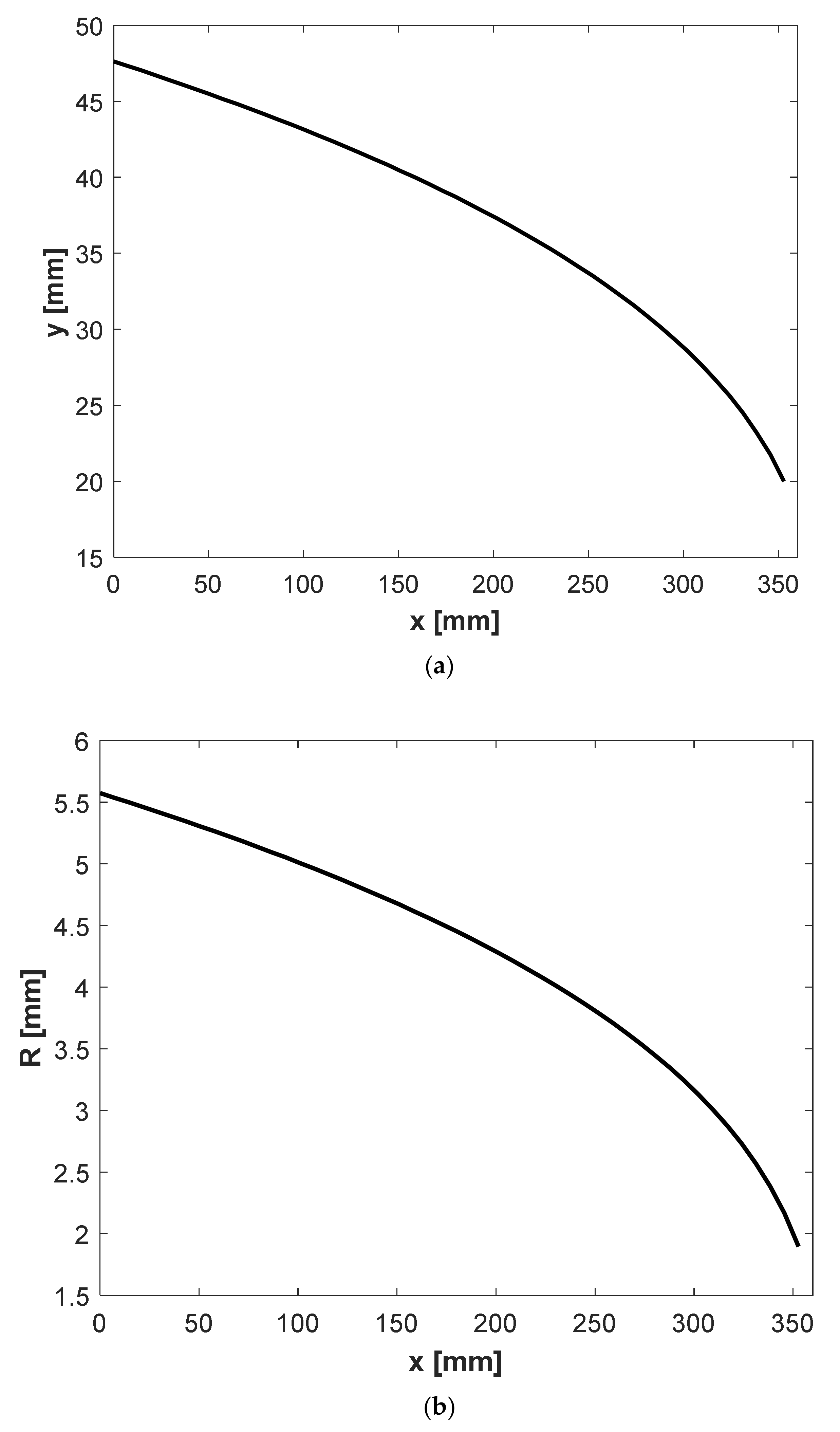

3.5. Design of a Cross Fluid

3.6. Desgin of a Power-Law Fluid with Rectangular Manifold

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| a | Ratio of manifold width to half die thickness (W/b) |

| b | Half die thickness [m] |

| B | Parameter in Winter–Fritz equation |

| fp | Shape factor in Winter–Fritz model |

| g | Parameter in Winter–Fritz equation |

| H | Manifold height [m] |

| hs | Slit height [m] |

| I | Identity tensor |

| Ic | Definite integral definition for circular duct in Equation (22) [Pa3 s−1] |

| Ipp | Definite integral definition for parallel plates Equation (19) [Pa2 s−1] |

| k | Power-law consistency factor |

| m | Cross model parameter |

| n | Power-law index |

| N | Number of manifold and slit segments |

| Q0 | Flow rate in entry [m3/s] |

| Qm | Flow rate in the manifold [m3/s] |

| Qs | Flow rate in the slit [m3/s] |

| R | Radius of manifold [m] |

| v | Velocity [m/s] |

| φ | Velocity variance |

| W | Width of channel [m] |

| x | Coordinate along die [m] |

| y | Distance between manifold and die outlet [m] |

| ΔPm | Incremental pressure drops in manifold [Pa] |

| ΔPs | Incremental pressure drops in slit [Pa] |

| µ | Apparent viscosity [Pa s] |

| µ0 | Rheological parameter in Cross and Carreau–Yasuda models [Pa s] |

| µ∞ | Rheological parameter in Cross and Carreau–Yasuda models [Pa s] |

| γm | Shear rate in manifold [1/s] |

| γs | Shear rate in slit [1/s] |

| γw | Shear rate at wall [1/s] |

| ζ | Coordinate in direction of manifold [m] |

| λ | Rheological parameter in Cross and Carreau–Yasuda models [s] |

| τ | Shear stress [Pa] |

| τw | Shear stress at wall [Pa] |

| φ | Velocity variance [m2/s2] |

| dPm | Differential pressure drops in manifold [Pa] |

| dPs | Differential pressure drops in slit [Pa] |

References

- Hopmann, C.; Michaeli, W. Extrusion Dies for Plastics and Rubber: Design and Engineering Computations; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2016. [Google Scholar]

- Reid, J.; Campanella, O.; Corvalan, C.; Okos, M. The influence of power-law rheology on flow distribution in coathanger manifolds. Polym. Eng. Sci. 2003, 43, 693–703. [Google Scholar] [CrossRef]

- Winter, H.; Fritz, H. Design of dies for the extrusion of sheets and annular parisons: The distribution problem. Polym. Eng. Sci. 1986, 26, 543–553. [Google Scholar] [CrossRef]

- Awe, T.J.; Eligindi, M.; Langer, R. Internal Design of Uniform Shear Rate Dies. Morehead Electron. J. Appl. Math. 2005. [Google Scholar]

- Igali, D.; Perveen, A.; Zhang, D.; Wei, D. Shear Rate Coat-Hanger Die Using Casson Viscosity Model. Processes 2020, 8, 1524. [Google Scholar] [CrossRef]

- Han, W.; Wang, X. Multi-objective optimization of the coat-hanger die for melt-blowing process. Fibers Polym. 2012, 13, 626–631. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, J.; Xia, C.; Zhou, W. A finite piece method for simulating polymer melt flows in extrusion sheet dies. J. Appl. Polym. Sci. 2012, 123, 3189–3198. [Google Scholar] [CrossRef]

- Smith, D.E.; Wang, Q. Optimization-based design of polymer sheeting dies using generalized Newtonian fluid models. Polym. Eng. Sci. 2005, 45, 953–965. [Google Scholar] [CrossRef]

- Smith, D.E. Design sensitivity analysis and optimization for polymer sheet extrusion and mold filling processes. Int. J. Numer. Methods Eng. 2003, 57, 1381–1411. [Google Scholar] [CrossRef]

- Nadhir, L.; Fabrice, S.; Stephan, P. Design and optimization of three-dimensional extrusion dies, using constraint optimization algorithm. Finite Elem. Anal. Des. 2009, 45, 333–340. [Google Scholar]

- Lebaal, N.; Puissant, S.; Schmidt, F. Application of a response surface method to the optimal design of the wall temperature profiles in extrusion die. Int. J. Mater. Form. 2010, 3, 47–58. [Google Scholar] [CrossRef]

- Lebaal, N.; Puissant, S.; Schmidt, F. Rheological parameters identification using in situ experimental data of a flat die extrusion. J. Mater. Process. Technol. 2005, 164, 1524–1529. [Google Scholar] [CrossRef] [Green Version]

- Razeghiyadaki, A.; Zhang, D.; Wei, D.; Perveen, A. Optimization of Polymer Extrusion Die Based on Response Surface Method. Processes 2020, 8, 1043. [Google Scholar] [CrossRef]

- Oh, K.W.; Lee, K.; Ahn, B.; Furlani, E.P. Design of pressure-driven microfluidic networks using electric circuit analogy. Lab A Chip 2012, 12, 515–545. [Google Scholar] [CrossRef]

- Yilmaz, O.; Kirkkopru, K. Inverse Design and Flow Distribution Analysis of Carreau Type Fluid Flow through Coat-Hanger Die. Fibers Polym. 2020, 21, 204–215. [Google Scholar] [CrossRef]

- Michaeli, W.; Kaul, S.; Wolff, T. Computer-aided optimization of extrusion dies. J. Polym. Eng. 2001, 21, 225–238. [Google Scholar] [CrossRef]

- Liu, T.J.; Liu, L.D.; Tsou, J.D. A unified lubrication approach for the design of a coat-hanger die. Polym. Eng. Sci. 1994, 34, 541–550. [Google Scholar] [CrossRef]

- Dealy, J.M.; Wissbrun, K.F. Melt Rheology and Its Role in Plastics Processing: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Rudolph, N.; Osswald, T.A. Polymer Rheology: Fundamentals and Applications; Carl Hanser Verlag GmbH Co KG: Berlin, Germany, 2014. [Google Scholar]

- Chhabra, R.P.; Richardson, J.F. Non-Newtonian Flow and Applied Rheology: Engineering Applications; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Amangeldi, M.; Wei, D.; Perveen, A.; Zhang, D. Numerical Modeling of Thermal Flows in Entrance Channels for Polymer Extrusion: A Parametric Study. Processes 2020, 8, 1256. [Google Scholar] [CrossRef]

- Meng, K.; Wang, X.; Chen, Q. Fluid flow in coat-hanger die of melt blowing process: Comparison of numerical simulations and experimental measurements. Text. Res. J. 2011, 81, 1686–1693. [Google Scholar] [CrossRef]

- Kozicki, W.; Chou, C.; Tiu, C. Non-Newtonian flow in ducts of arbitrary cross-sectional shape. Chem. Eng. Sci. 1966, 21, 665–679. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Xiao, B.; Liu, Y.; Chen, H.; Chen, X.; Long, G. A Novel Fractal Solution for Laminar Flow Resistance in Roughened Cylindrical Microchannels. Fractals 2020, 28, 2050097–2050968. [Google Scholar] [CrossRef]

- Sochi, T. Analytical solutions for the flow of Carreau and Cross fluids in circular pipes and thin slits. Rheol. Acta 2015, 54, 745–756. [Google Scholar] [CrossRef] [Green Version]

| Rheology Model | Equation | Parameters |

|---|---|---|

| Power-law | k = 8.125 × 103 Pa sn n = 0.38 | |

| Carreau–Yasuda | µ0 = 1326 Pa sn µ∞ = 0 λ = 0.12 s n = 0.35 | |

| Cross | µ0 = 564.4 Pa sn µ∞ = 0 λ = 0.017 s m = 0.749 |

| Parameter | Value |

|---|---|

| Flow rate in the entry of the die, Q0 | 5 × 10−5 m3/s |

| Land height, hs | 1.5 mm |

| Total die width at exit, b | 360 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razeghiyadaki, A.; Wei, D.; Perveen, A.; Zhang, D. A Multi-Rheology Design Method of Sheeting Polymer Extrusion Dies Based on Flow Network and the Winter–Fritz Design Equation. Polymers 2021, 13, 1924. https://doi.org/10.3390/polym13121924

Razeghiyadaki A, Wei D, Perveen A, Zhang D. A Multi-Rheology Design Method of Sheeting Polymer Extrusion Dies Based on Flow Network and the Winter–Fritz Design Equation. Polymers. 2021; 13(12):1924. https://doi.org/10.3390/polym13121924

Chicago/Turabian StyleRazeghiyadaki, Amin, Dongming Wei, Asma Perveen, and Dichuan Zhang. 2021. "A Multi-Rheology Design Method of Sheeting Polymer Extrusion Dies Based on Flow Network and the Winter–Fritz Design Equation" Polymers 13, no. 12: 1924. https://doi.org/10.3390/polym13121924

APA StyleRazeghiyadaki, A., Wei, D., Perveen, A., & Zhang, D. (2021). A Multi-Rheology Design Method of Sheeting Polymer Extrusion Dies Based on Flow Network and the Winter–Fritz Design Equation. Polymers, 13(12), 1924. https://doi.org/10.3390/polym13121924