Development of Geopolymers Based on Fly Ashes from Different Combustion Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Samples Preparation

2.2. Research Methods

2.2.1. Density

2.2.2. Chemical Composition of Precursors

2.2.3. Strength Tests

2.2.4. Microstructure

3. Results and Discussion

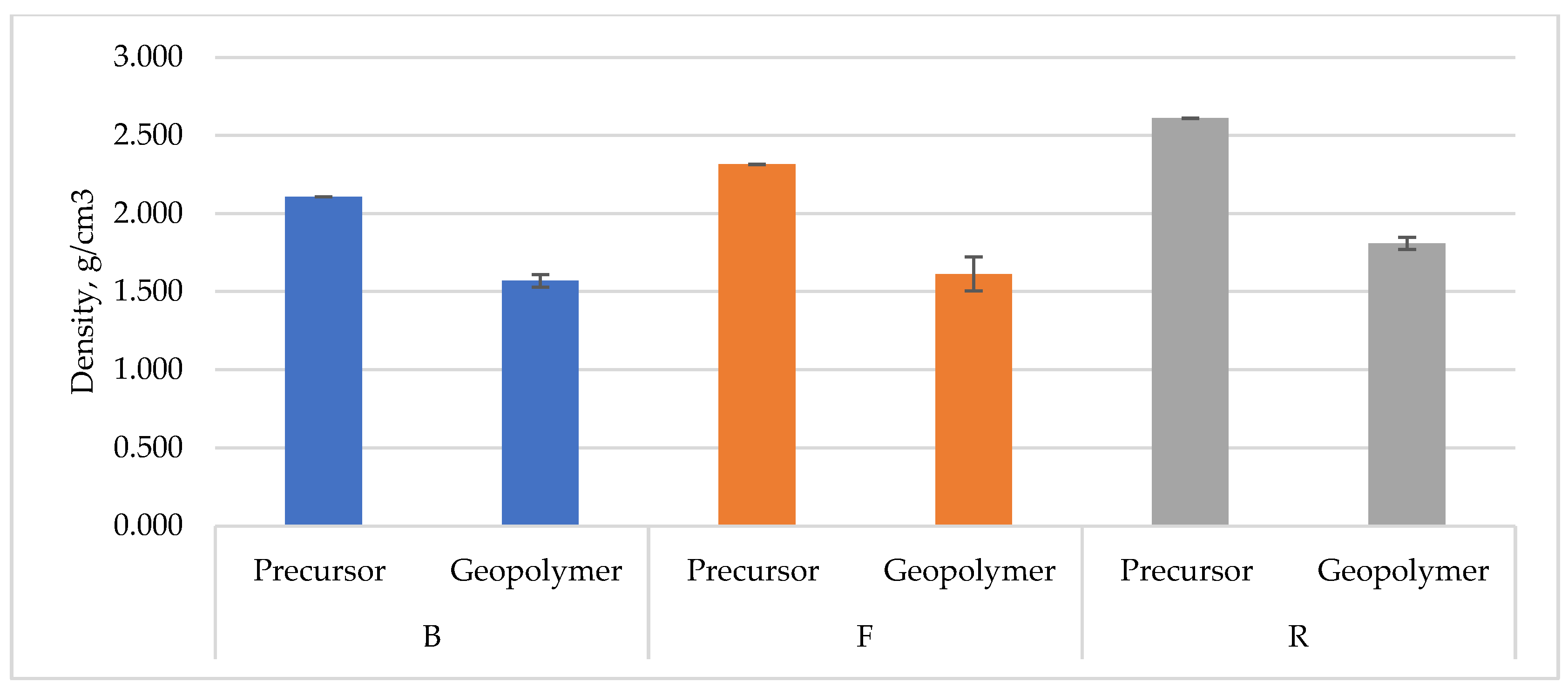

3.1. Density Results

3.2. Chemical Compositions Results

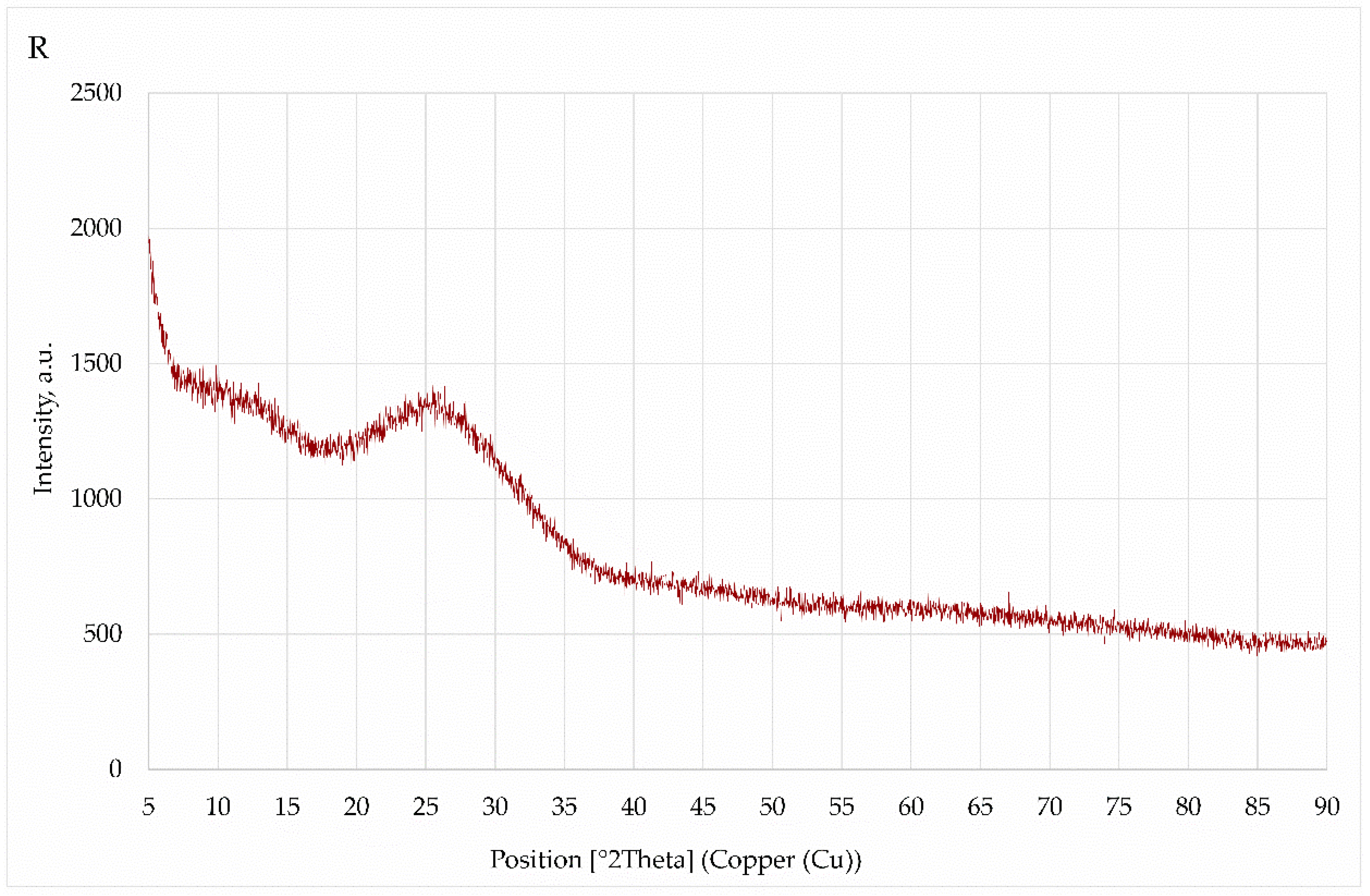

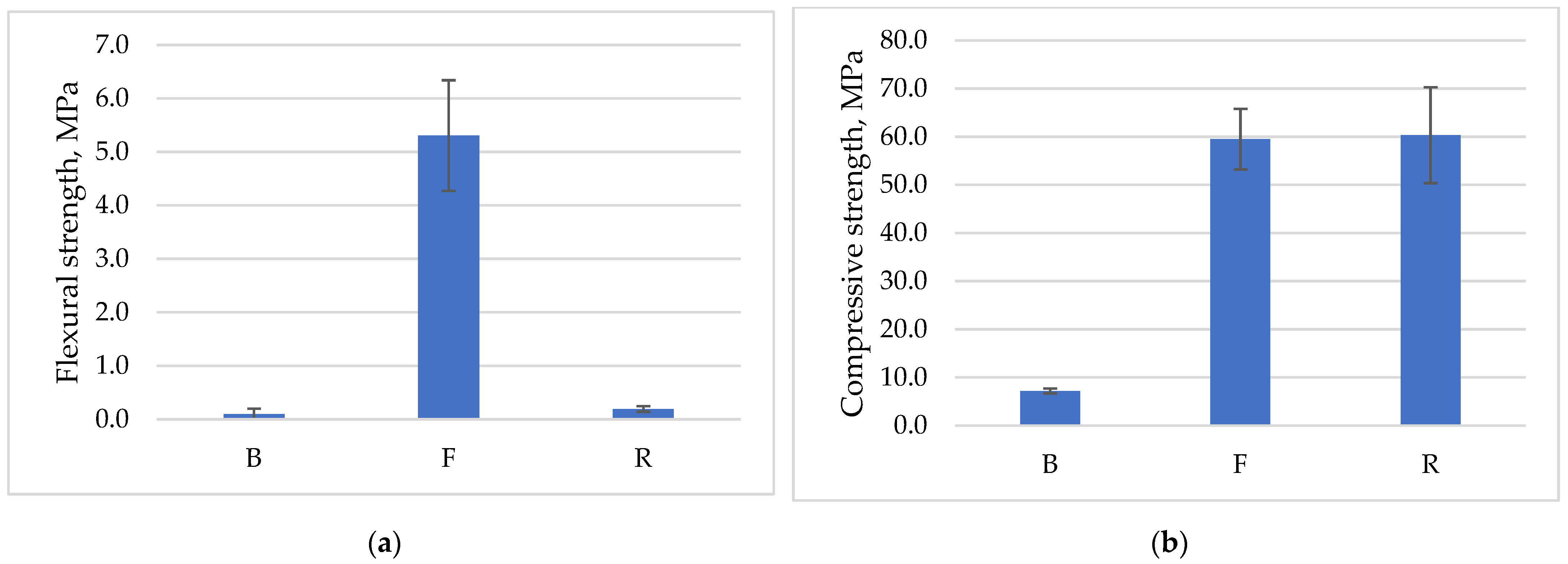

3.3. Mechanical Properties and Structure Observations

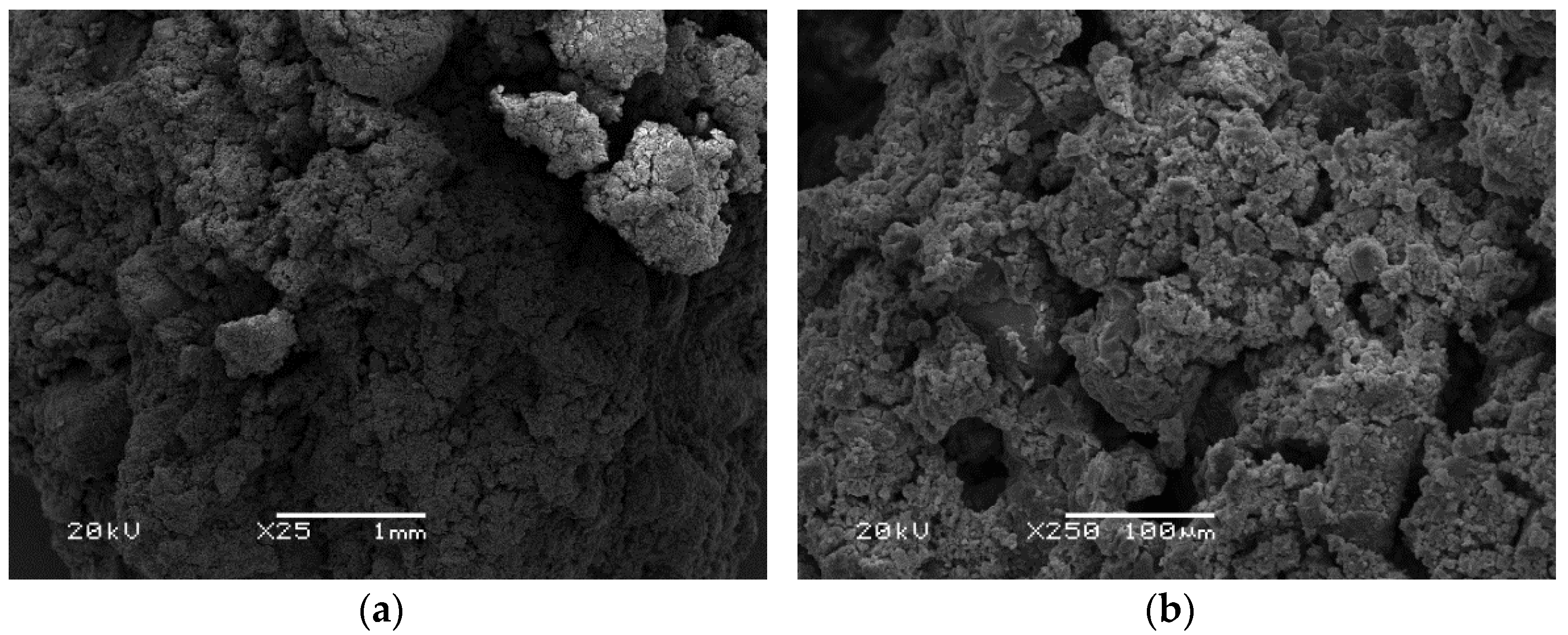

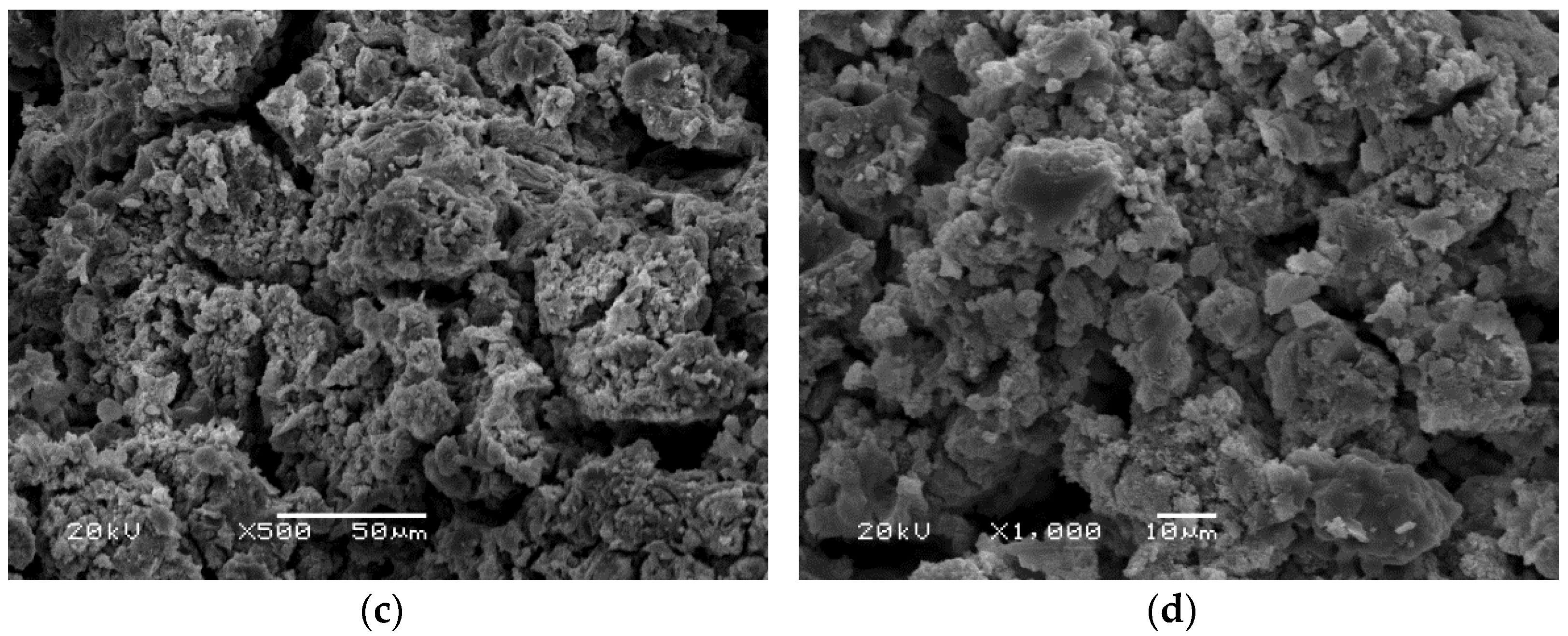

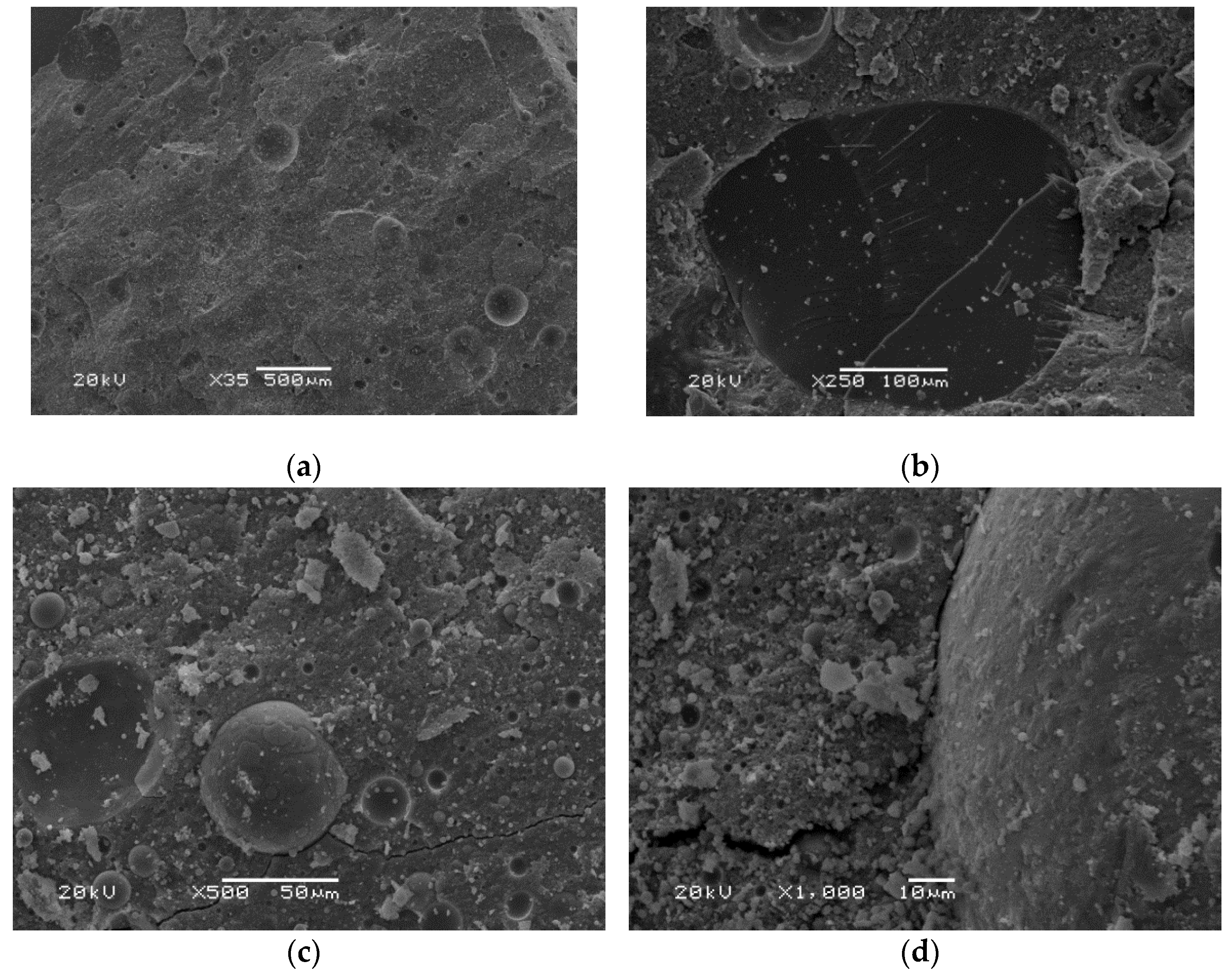

3.4. Microscopic Observations

4. Conclusions

- Mechanical tests showed that materials made from fly ash obtained from the Skawina Power Plant had better strength properties compared to other materials analyzed.

- The ultrafine fly ash, in which the bending strength was low, can be also useful material for geopolymers preparation, but it requires some reinforcement. This kind of reinforcement could be, for example, glass fiber, to improve the bending properties.

- Studies conducted with incineration waste indicate that this specific type of ash is not suitable for the production of alkali-activated materials under the conditions presented. There were not enough strong bonds in this type of material, resulting in an extremely developed material structure that was very brittle and did not meet the minimum strength requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehta, P. Reducing the environmental impact of concrete. Concr. Int. 2001, 23, 61–66. [Google Scholar]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Kalinowska-Wichrowska, K.; Pawluczuk, E.; Bołtryk, M.; Nietupski, A. Geopolymer Concrete with Lightweight Artificial Aggregates. Materials 2022, 15, 3012. [Google Scholar] [CrossRef]

- Baziak, A.; Pławecka, K.; Hager, I.; Castel, A.; Korniejenko, K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials 2021, 14, 5741. [Google Scholar] [CrossRef] [PubMed]

- Ercoli, R.; Laskowska, D.; Nguyen, V.V.; Le, V.S.; Louda, P.; Łoś, P.; Ciemnicka, J.; Prałat, K.; Renzulli, A.; Paris, E.; et al. Mechanical and Thermal Properties of Geopolymer Foams (GFs) Doped with By-Products of the Secondary Aluminum Industry. Polymers 2022, 14, 703. [Google Scholar] [CrossRef]

- Petrus, H.T.B.M.; Olvianas, M.; Shafiyurrahman, M.F.; Pratama, I.G.A.A.N.; Jenie, S.N.A.; Astuti, W.; Nurpratama, M.I.; Ekaputri, J.J.; Anggara, F. Circular Economy of Coal Fly Ash and Silica Geothermal for Green Geopolymer: Characteristic and Kinetic Study. Gels 2022, 8, 233. [Google Scholar] [CrossRef]

- Nguyen, V.V.; Le, V.S.; Louda, P.; Szczypiński, M.M.; Ercoli, R.; Růžek, V.; Łoś, P.; Prałat, K.; Plaskota, P.; Pacyniak, T.; et al. Low-Density Geopolymer Composites for the Construction Industry. Polymers 2022, 14, 304. [Google Scholar] [CrossRef]

- El Hafid, K.; Hajjaji, M.; El Hafid, H. Influence of NaOH concentration on microstructure and properties of cured alkali-activated calcined clay. J. Build. Eng. 2017, 11, 158–165. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Geopolymer Institute: Saint-Quentin, France, 2015; p. 644. [Google Scholar]

- Figiela, B.; Šimonová, H.; Korniejenko, K. State-of-the-Art, Challenges and Emerging trends: Geopolymer Composite Reinforced by Dispersed Steel Fibers. Rev. Adv. Mater. Sci. 2022. [Google Scholar] [CrossRef]

- Yang, T.; Han, W.; Wang, X.; Wu, D. Surface decoration of polyimide fiber with carbon nanotubes and its application for mechanical enhancement of phosphoric acid-based geopolymers. Appl. Surf. Sci. 2017, 416, 200–212. [Google Scholar] [CrossRef]

- Le, V.S.; Louda, P.; Tran, H.N.; Nguyen, P.D.; Bakalova, T.; Buczkowska, K.E.; Dufkova, I. Study on Temperature-Dependent Properties and Fire Resistance of Metakaolin-Based Geopolymer Foams. Polymers 2020, 12, 2994. [Google Scholar] [CrossRef] [PubMed]

- Luukkonen, T.; Sarkkinen, M.; Kemppainen, K.; Rämö, J.; Lassi, U. Metakaolin geopolymer characterization and application for ammonium removal from model solutions and landfill leachate. Appl. Clay Sci. 2016, 119, 266–276. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Yan, F. Synthesis and mechanical properties of metakaolinite-based geopolymer. Colloids Surf. A—Physicochem. Eng. Asp. 2005, 268, 1–6. [Google Scholar] [CrossRef]

- Duxon, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; Van Deventer, J.S. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A—Hysicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Sitarz, M.; Hager, I.; Choińska, M. Evolution of mechanical properties with time of fly-ash-based geopolymer mortars under the effect of granulated ground blast furnace slag addition. Energies 2020, 13, 1135. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Assi, L.N.; Ghahari, S.A.; Deaver, E.; Leaphart, D.; Ziehl, P. Improvement of the early and final compressive strength of fly ash-based geopolymer concrete at ambient conditions. Constr. Build. Mater. 2016, 123, 806–813. [Google Scholar] [CrossRef]

- Kaur, K.; Singh, J.; Kaur, M. Compressive strength of rice husk ash based geopolymer: The effect of alkaline activator. Constr. Build. Mater. 2018, 169, 188–192. [Google Scholar] [CrossRef]

- Detphan, S.; Chindaprasirt, P. Preparation of fly ash and rice husk ash geopolymer. Int. J. Miner. Metall. Mater. 2009, 16, 720–726. [Google Scholar]

- Cheng, T.W.; Chiu, J.P. Fire-resistant geopolymer produced by granulated blast furnace slag. Miner. Eng. 2003, 16, 205–210. [Google Scholar] [CrossRef]

- Nguyen, H.; Carvelli, V.; Adesanya, E.; Kinnunen, P.; Illikainen, M. High performance cementitious composite from alkali-activated ladle slag reinforced with polypropylene fibers. Cem. Concr. Compos. 2018, 90, 150–160. [Google Scholar] [CrossRef]

- Aziz, I.H.; Al Bakri Abdullah, M.M.; Salleh, M.A.A.M.; Yoriya, S.; Razak, R.A.; Mohamed, R.; Baltatu, M.S. The investigation of ground granulated blast furnace slag geopolymer at high temperature by using electron backscatter diffraction analysis. Arch. Metall. Mater. 2022, 67, 227–231. [Google Scholar] [CrossRef]

- Thokchom, S.; Ghosh, P.; Ghosh, S. Performance of fly ash based geopolymer mortars in sulphate solution. J. Eng. Sci. Technol. 2010, 3, 31–38. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Zhang, Z.; Ou, Z. Durability of alkali-activated materials in aggressive environments: A review on recent studies. Constr. Build. Mater. 2017, 15, 598–613. [Google Scholar] [CrossRef]

- Rangan, B.V. Geopolymer concrete for environmental protection. Indian Concr. J. 2014, 88, 41–59. [Google Scholar]

- Rickard, W.D.; Vickers, L.; Van Riessen, A. Performance of fibre reinforced, low density metakaoline geopolymers under simulated fire conditions. Appl. Clay Sci. 2013, 73, 71–77. [Google Scholar] [CrossRef]

- Duxon, P.; Fernansez-Jimenez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S. Geopolymer technology: The current state of the art. J. Mater. Sci. 2006, 42, 2917–2933. [Google Scholar] [CrossRef]

- Liu, Z.; Cai, C.S.; Peng, H.; Fan, F. Experimental study of the geopolymeric recycled aggregate concrete. J. Mater. Civ. Eng. 2016, 28, 04016077. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Suksiripattanapong, C.; Chinkulkijniwat, A.; Arulrajah, A.; Disfani, M.M. Calcium carbide residue: Alkaline activator for clay–fly ash geopolymer. Constr. Build. Mater. 2014, 69, 285–294. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Z.; Xu, G.; Peng, H.; Cai, C.S. Mechanical and thermal properties of fly ash based geopolymers. Constr. Build. Mater. 2018, 160, 66–81. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Duxon, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; Van Deventer, J.S. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. A—Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Li, Z. Preparation and microstructure of K-PSDS geopolymeric binder. Colloids Surf. A—Hysicochem. Eng. Asp. 2007, 302, 473–482. [Google Scholar]

- Grela, A.; Łach, M.; Bajda, T.; Mikuła, J.; Hebda, M. Characterization of the products obtained from alkaline conversion of tuff and metakaolin. J. Therm. Anal. Calorim. 2018, 133, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.; Nie, Q.; Huang, B.; Shu, X.; He, Q. Mechanical and microstructural characterization of geopolymers derived from red mud and fly ashes. J. Clean. Prod. 2018, 186, 799–806. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Chindaprasirt, P.; Jaturapitakkul, C.; Chalee, W.; Rattanasak, U. Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag. 2009, 29, 539–543. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Lo, F.C.; Lo, S.L.; Lee, M.G. Effect of partially replacing ordinary Portland cement with municipal solid waste incinerator ashes and rice husk ashes on pervious concrete quality. Environ. Sci. Pollut. Res. 2020, 27, 23742–23760. [Google Scholar] [CrossRef]

- Yakubu, Y.; Zhou, J.; Shu, Z.; Zhang, Y.; Wang, W.; Mbululo, Y. Potential application of pre-treated municipal solid waste incineration fly ash as cement supplement. Environ. Sci. Pollut. Res. 2018, 25, 16167–16176. [Google Scholar] [CrossRef]

- Yang, Z.; Tian, S.; Liu, L.; Wang, X.; Zhang, Z. Application of washed MSWI fly ash in cement composites: Long-term environmental impacts. Environ. Sci. Pollut. Res. 2018, 25, 12127–12138. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Shen, X.; Tan, G.; Tanner, J.E. Compressive strength and hydration characteristics of high-volume fly ash concrete prepared from fly ash. J. Therm. Anal. Calorim. 2019, 136, 565–580. [Google Scholar] [CrossRef]

- Praveenkumar, T.R.; Vijayalakshmi, M.M. Microstructural properties of nano-rice husk ash concrete. Nanotechnol. Environ. Eng. 2019, 4, 4–9. [Google Scholar] [CrossRef]

- Abousnina, R.; Manalo, A.; Ferdous, W.; Lokuge, W.; Benabed, B.; Saif Al-Jabri, K. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Constr. Build. Mater. 2020, 252, 119155. [Google Scholar] [CrossRef]

- Łach, M.; Mierzwiński, D.; Korniejenko, K.; Mikuła, J.; Hebda, M. Geopolymers as a material suitable for immobilization of fly ash from municipal waste incineration plants. J. Air Waste Manag. Assoc. 2018, 68, 1190–1197. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.A.; Ferdous, W.; Saha, A.K.; Alyousef, R. 3D-printed concrete: Applications, performance, and challenges. J. Sustain. Cem. Mater. 2020, 9, 127–164. [Google Scholar] [CrossRef]

- Lin, W.T. Reactive ultra-fine fly ash as an additive for cement-based materials. Mater. Today Commun. 2020, 25, 101466. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Farhana, Z.F.; Kamarudin, H.; Rahmat, A.; Bakri, A.M.M. A study on relationship between porosity and compressive strength for geopolymer paste. Key Eng. Mater. 2014, 594–595, 1112–1116. [Google Scholar] [CrossRef]

- Mindess, S. Relation Between the Compressive Strength and Porosity of Autoclaved Calcium Silicate Hydrates. J. Am. Ceram. Soc. 1970, 53, 621–624. [Google Scholar] [CrossRef]

- Luna-Galiano, Y.; Fernández-Pereira, C.; Izquierdo, M. Contributions to the study of porosity in fly ash-based geopolymers. Relationship between degree of reaction, porosity and compressive strength. Mater. Constr. 2016, 66, 324. [Google Scholar]

- Lloyd, R.R.; Provis, J.L.; Smeaton, K.J.; Van Deventer, J.S.J. Spatial distribution of pores in fly ash-based inorganic polymer gels visualised by Wood’s metal intrusion. Microporous Mesoporous Mater. 2009, 126, 32–39. [Google Scholar] [CrossRef]

- Škvára, F.; Kopecký, L.; Němeček, J.; Bittnar, Z. Microstructure of geopolymer materials based on fly ash. Ceram-Silik. 2006, 50, 208–215. [Google Scholar]

- Korniejenko, K.; Kejzlar, P.; Louda, P. The Influence of the Material Structure on the Mechanical Properties of Geopolymer Composites Reinforced with Short Fibers Obtained with Additive Technologies. Int. J. Mol. Sci. 2022, 23, 2023. [Google Scholar] [CrossRef] [PubMed]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Rattanasak, U.; Pankhet, K.; Chindaprasirt, P. Effect of chemical admixtures on properties of high-calcium fly ash geopolymer. Int. J. Miner. Metall. Mater. 2011, 18, 364–369. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Chindaprasirt, P.; Sata, V.; Pangdaeng, S.; Sinsiri, T. Properties of high calcium fly ash geopolymer pastes with Portland cement as an additive. Int. J. Miner. Metall. Mater. 2013, 20, 214–220. [Google Scholar] [CrossRef]

- Nikolić, V.; Komljenović, M.; Baščarević, Z.; Marjanović, N.; Miladinović, Z.; Petrović, R. The influence of fly ash characteristics and reaction conditions on strength and structure of geopolymers. Constr. Build. Mater. 2015, 94, 361–370. [Google Scholar] [CrossRef]

- Kumar, S.; Mucsi, G.; Kristály, F.; Pekker, P. Mechanical activation of fly ash and its influence on micro and nano-structural behaviour of resulting geopolymers. Adv. Powder Technol. 2017, 28, 805–813. [Google Scholar] [CrossRef]

- Korniejenko, K.; Halyag, N.P.; Mucsi, G. Fly ash as a raw material for geopolymerisation-chemical composition and physical properties. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012002. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Marczyk, J.; Ziejewska, C.; Halyag, N.P.; Mucsi, G. Fly ash as a raw material for geopolymerisation-mineralogical composition and morphology. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012006. [Google Scholar] [CrossRef] [Green Version]

- Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. Do geopolymers actually contain nanocrystalline zeolites? A reexamination of existing results. Chem. Mater. 2005, 17, 3075–3085. [Google Scholar] [CrossRef]

- Jaarsveld, J.G.S.; Van Deventer, J.S.J.; Van Lukey, G.C. The characterization of source materials in fly ash-based geopolymers. Fuel Energy Abstr. 2004, 45, 23. [Google Scholar]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef] [Green Version]

- Ban, C.C.; Ken, P.W.; Ramli, M. Mechanical and Durability Performance of Novel Self-activating Geopolymer Mortars. Procedia Eng. 2017, 171, 564–571. [Google Scholar] [CrossRef]

- Wongsa, A.; Boonserm, K.; Waisurasingha, C.; Sata, V.; Chindaprasirt, P. Use of municipal solid waste incinerator (MSWI) bottom ash in high calcium fly ash geopolymer matrix. J. Clean. Prod. 2017, 148, 49–59. [Google Scholar] [CrossRef]

- Lee, W.K. Solid-Gel Interactions in Geopolymers. Chem. Eng. 2002. [Google Scholar]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548. [Google Scholar] [CrossRef]

- Alehyen, S.; Achouri, M.E.L.; Taibi, M. Characterization, microstructure and properties of fly ash-based geopolymer. J. Mater. Environ. Sci. 2017, 8, 1783–1796. [Google Scholar]

| Index | D10 [µm] | D50 [µm] | D90 [µm] | Mean Size [µm] |

|---|---|---|---|---|

| F | 2.040 | 10.235 | 23.167 | 12.167 |

| R | 0.7922 | 1.8683 | 4.266 | 2.418 |

| B | 1.9866 | 11.924 | 28.063 | 14.513 |

| Index | Description | Mix Proportion |

|---|---|---|

| B | Geopolymer based on the precursor of the municipal waste incineration plant (Białystok, Poland) | 4 kg of precursor + 10 M sodium hydroxide solution + water glass (1200 mL in total) |

| F | Geopolymer based on the precursor of the Power Plant in Skawina (Skawina, Poland) | |

| R | Geopolymer based on precursor from the Power Plant in China (TRIAXIS Corporation). |

| Precursor | F | R | B | |||

|---|---|---|---|---|---|---|

| Compound Formula | Conc, % | Compound Formula | Conc, % | Compound Formula | Conc, % | |

| 1 | Na2O | 1.714 | Na2O | 1.950 | Na2O | 3.277 |

| 2 | MgO | 1.636 | MgO | 1.214 | MgO | 0.438 |

| 3 | Al2O3 | 25.499 | Al2O3 | 16.639 | Al2O3 | 1.273 |

| 4 | SiO2 | 50.897 | SiO2 | 50.914 | SiO2 | 3.994 |

| 5 | P2O5 | 0.469 | P2O5 | 2.013 | P2O5 | 0.387 |

| 6 | SO3 | 1.276 | SO3 | 0.238 | SO3 | 10.672 |

| 7 | K2O | 3.007 | K2O | 3.532 | K2O | 4.350 |

| 8 | CaO | 5.306 | CaO | 15.435 | CaO | 43.323 |

| 9 | TiO2 | 1.456 | TiO2 | 1.602 | TiO2 | 0.719 |

| 10 | Cr2O3 | 0.030 | Cr2O3 | 0.025 | Cr2O3 | 0.037 |

| 11 | MnO | 0.111 | MnO | 0.078 | MnO | 0.065 |

| 12 | Fe2O3 | 8.001 | Fe2O3 | 5.509 | Fe2O3 | 1.060 |

| 13 | NiO | 0.017 | Co3O4 | 0.015 | CuO | 0.082 |

| 14 | CuO | 0.024 | NiO | 0.024 | ZnO | 2.872 |

| 15 | ZnO | 0.036 | CuO | 0.054 | SrO | 0.051 |

| 16 | Rb2O | 0.023 | ZnO | 0.112 | ZrO2 | 0.023 |

| 17 | SrO | 0.078 | Ga2O3 | 0.039 | CdO | 0.029 |

| 18 | ZrO2 | 0.043 | SeO2 | 0.015 | SnO2 | 0.085 |

| 19 | BaO | 0.091 | Rb2O | 0.024 | SbO2 | 0.064 |

| 20 | CeO2 | 0.032 | SrO | 0.236 | BaO | 0.073 |

| 21 | PbO | 0.024 | Y2O3 | 0.015 | PbO | 0.420 |

| 22 | Cl | 0.230 | ZrO2 | 0.096 | Cl | 26.477 |

| 23 | BaO | 0.048 | Br | 0.215 | ||

| 24 | PbO | 0.083 | I | 0.014 | ||

| 25 | Cl | 0.088 | ||||

| Sample ID | Identified Phases | Chemical Formula | Amount of Phase |

|---|---|---|---|

| B | Calcite (Calcium Carbonate) | CaCO3 | 43.0 |

| Chlorocalcite | CaCl3K | 35.0 | |

| Anhydrite | CaSO4 | 14.4 | |

| Quartz | SiO2 | 7.5 | |

| Kaolinite | Al2Si2O5(OH)4 | 0.1 |

| Sample ID | Identified Phases | Chemical Formula | Amount of Phase |

|---|---|---|---|

| F | Quartz | SiO2 | 47.8 |

| Mullite | Al6Si2O13 | 48.4 | |

| Hematite | Fe2O3 | 1.6 | |

| Alite | Ca3SiO5 | 2.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pławecka, K.; Bazan, P.; Lin, W.-T.; Korniejenko, K.; Sitarz, M.; Nykiel, M. Development of Geopolymers Based on Fly Ashes from Different Combustion Processes. Polymers 2022, 14, 1954. https://doi.org/10.3390/polym14101954

Pławecka K, Bazan P, Lin W-T, Korniejenko K, Sitarz M, Nykiel M. Development of Geopolymers Based on Fly Ashes from Different Combustion Processes. Polymers. 2022; 14(10):1954. https://doi.org/10.3390/polym14101954

Chicago/Turabian StylePławecka, Kinga, Patrycja Bazan, Wei-Ting Lin, Kinga Korniejenko, Maciej Sitarz, and Marek Nykiel. 2022. "Development of Geopolymers Based on Fly Ashes from Different Combustion Processes" Polymers 14, no. 10: 1954. https://doi.org/10.3390/polym14101954