Modeling and Analysis of Morphology of Injection Molding Polypropylene Parts Induced by In-Mold Annealing

Abstract

1. Introduction

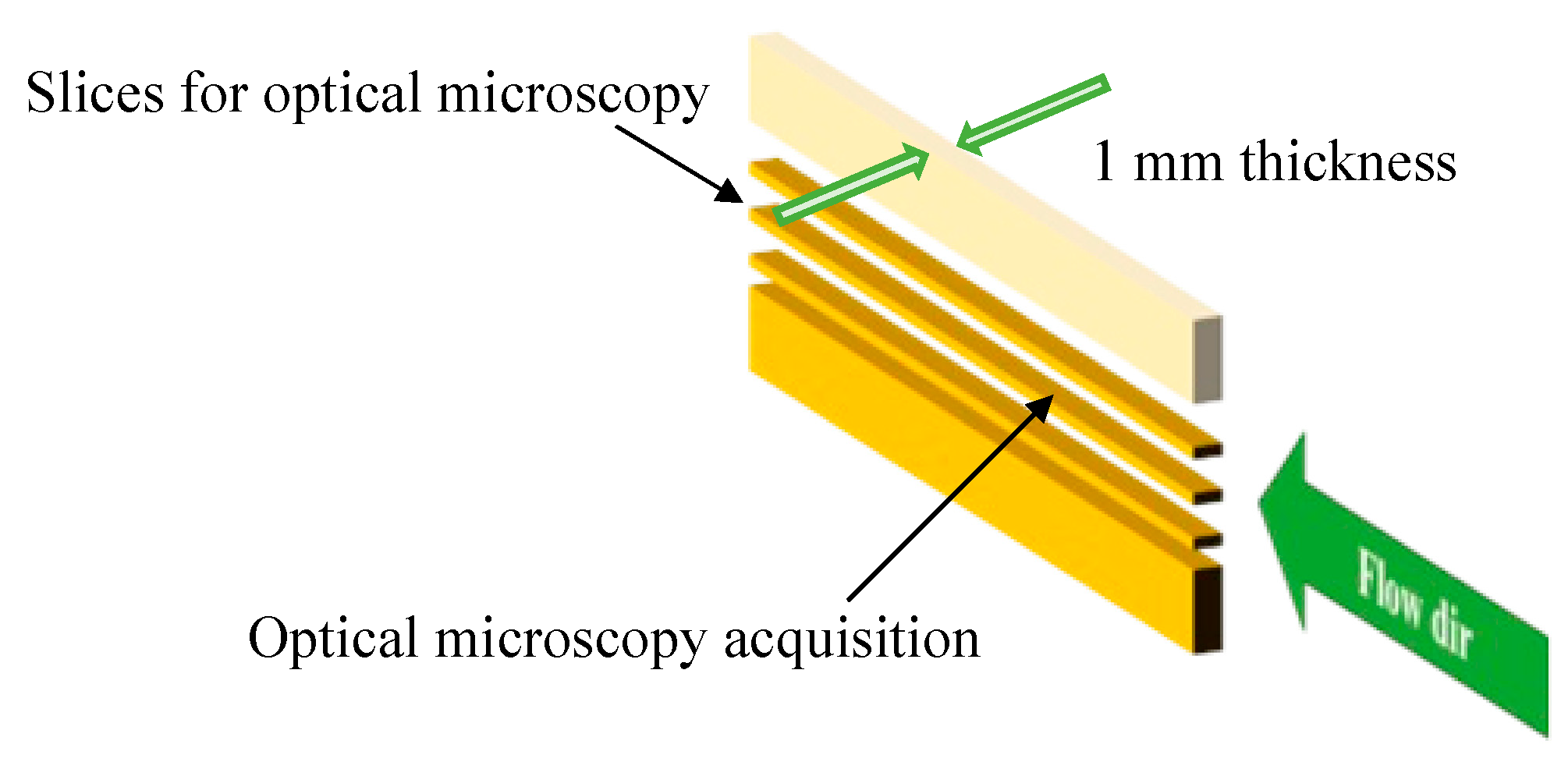

2. Materials and Methods

3. The Crystallization Model

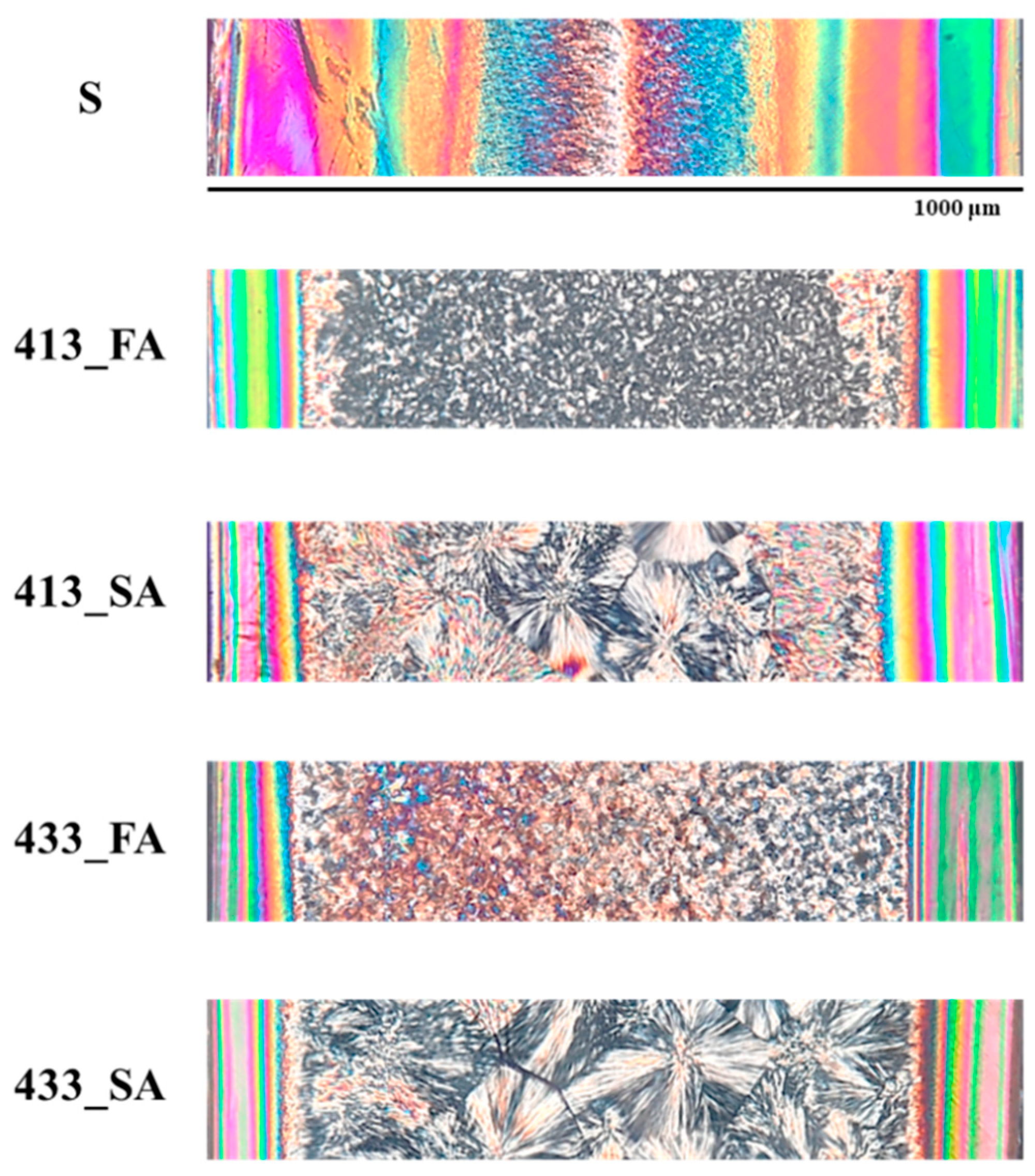

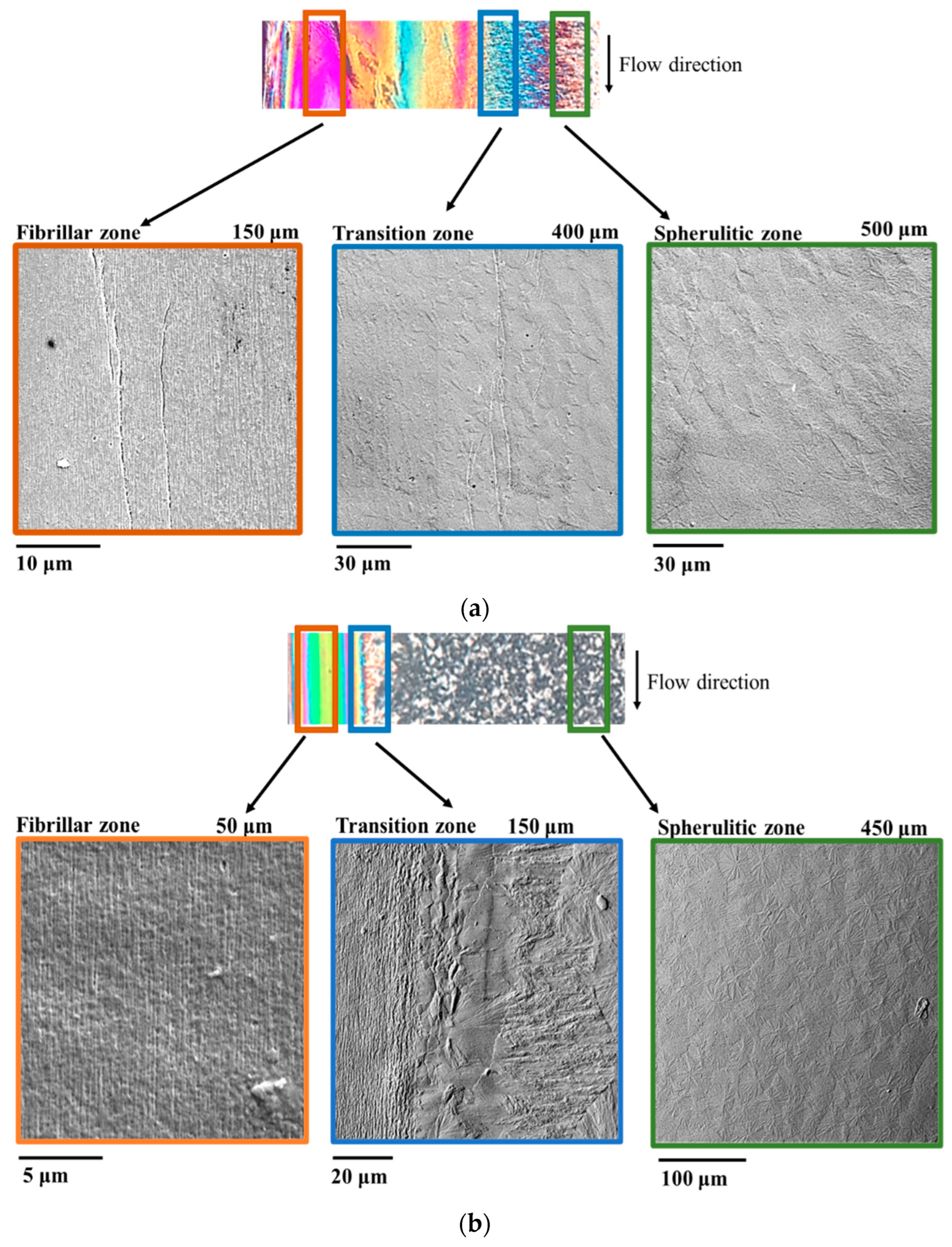

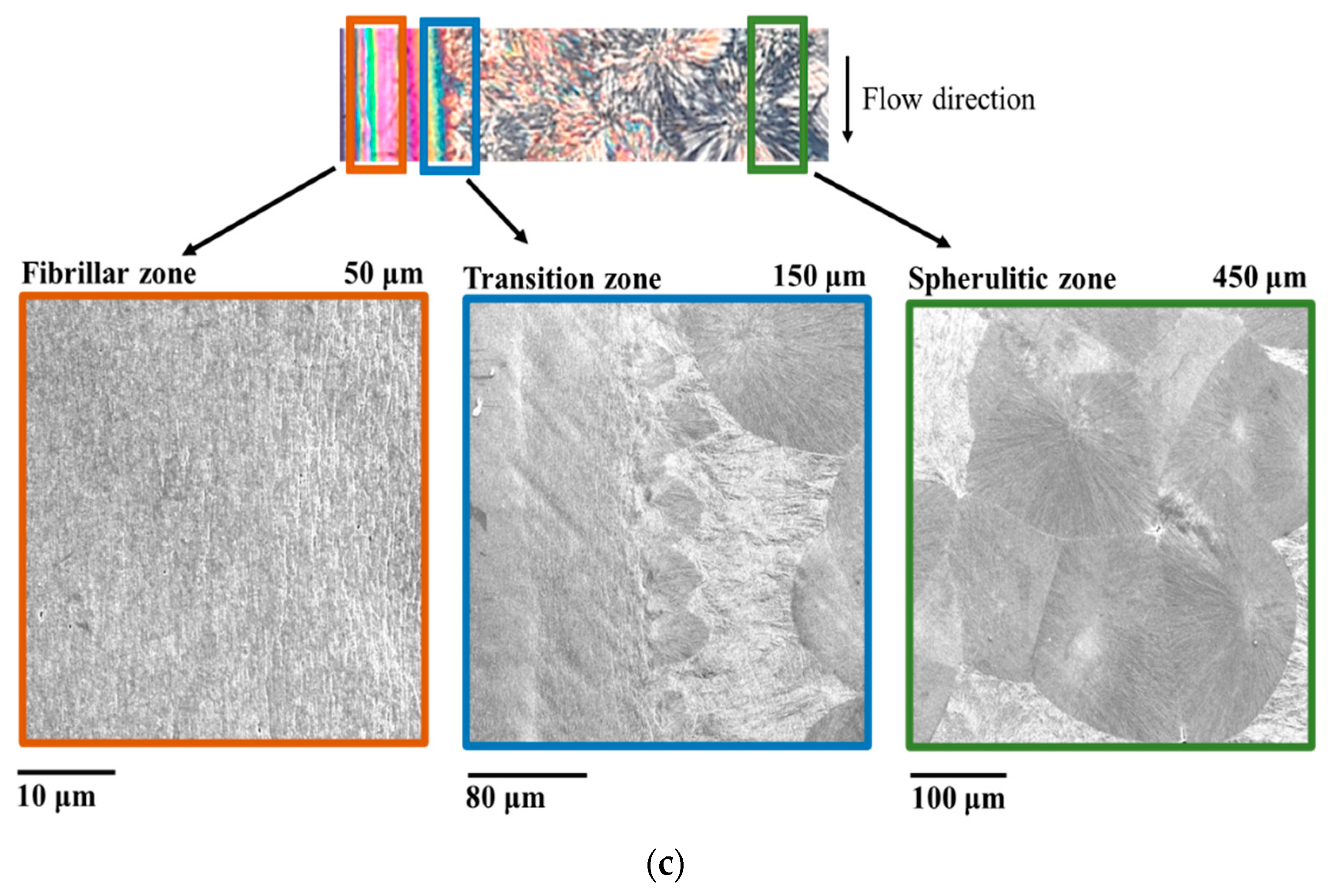

4. Results and Discussion

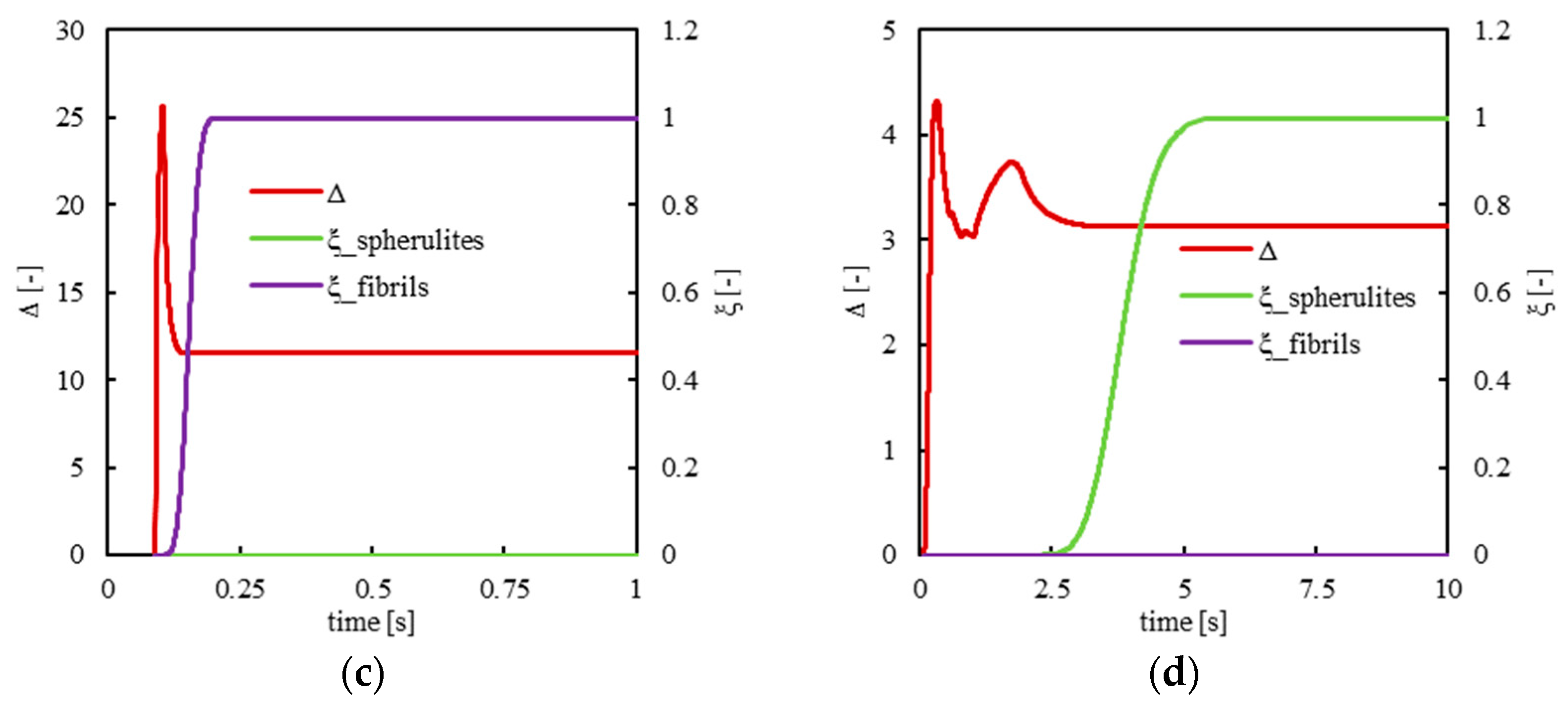

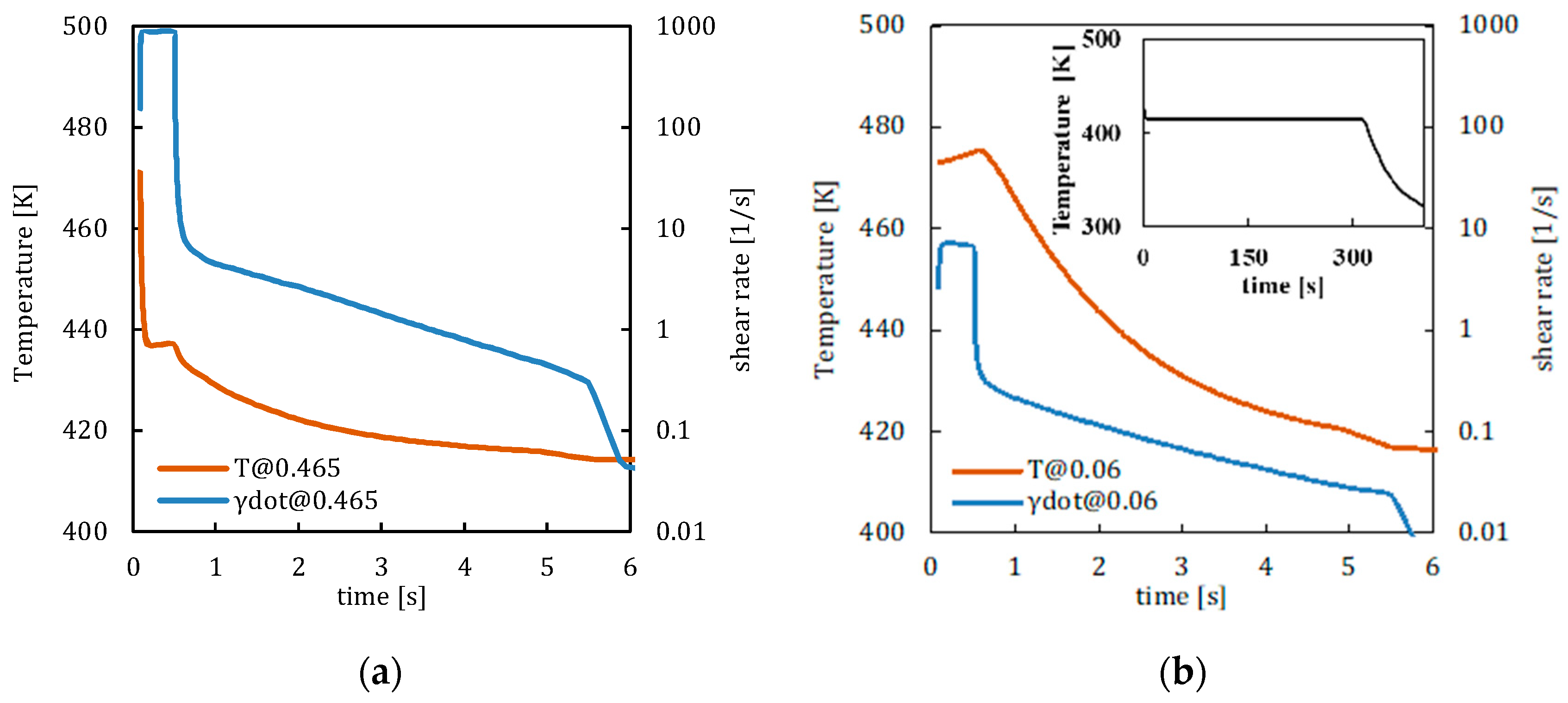

Morphology Prediction

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Zhang, W.; Liang, B. The influences of multiple factors for flexural performance of polypropylene: Crystallization, crystal evolution, nanoparticles. J. Mater. Sci. 2021, 56, 15667–15683. [Google Scholar] [CrossRef]

- Selezneva, M.; Swolfs, Y.; Katalagarianakis, A.; Ichikawa, T.; Hirano, N.; Taketa, I.; Karaki, T.; Verpoest, I.; Gorbatikh, L. The brittle-to-ductile transition in tensile and impact behavior of hybrid carbon fibre/self-reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2018, 109, 20–30. [Google Scholar] [CrossRef]

- Ahmad, S.R.; Xue, C.; Young, R.J. The mechanisms of reinforcement of polypropylene by graphene nanoplatelets. Mater. Sci. Eng. B 2017, 216, 2–9. [Google Scholar] [CrossRef]

- Maiti, P.; Hikosaka, M.; Yamada, K.; Toda, A.; Gu, F. Lamellar Thickening in Isotactic Polypropylene with High Tacticity Crystallized at High Temperature. Macromolecules 2000, 33, 9069–9075. [Google Scholar] [CrossRef]

- Kolstad, J.J. Crystallization kinetics of poly(L-lactide-co-meso-lactide). J. Appl. Polym. Sci. 1996, 62, 1079–1091. [Google Scholar] [CrossRef]

- Bai, H.; Deng, H.; Zhang, Q.; Wang, K.; Fu, Q.; Zhang, Z.; Men, Y. Effect of annealing on the microstructure and mechanical properties of polypropylene with oriented shish-kebab structure. Polym. Int. 2012, 61, 252–258. [Google Scholar] [CrossRef]

- Boruvka, M.; Cermak, C.; Behalek, L.; Brdlik, P. Effect of In-Mold Annealing on the Properties of Asymmetric Poly(l-lactide)/Poly(d-lactide) Blends Incorporated with Nanohydroxyapatite. Polymers 2021, 13, 2835. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Yang, B.; Han, W.; Li, H.; Kang, Z.; Lin, J. Tailoring the thermal and mechanical properties of injection-molded poly (lactic acid) parts through annealing. J. Appl. Polym. Sci. 2021, 138, 49648. [Google Scholar] [CrossRef]

- Pantani, R.; Coccorullo, I.; Speranza, V.; Titomanlio, G. Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog. Polym. Sci. 2005, 30, 1185–1222. [Google Scholar] [CrossRef]

- Liao, T.; Zhao, X.; Yang, X.; Coates, P.; Whiteside, B.; Barker, D.; Thompson, G.; Lai, Y.; Jiang, Z.; Men, Y. In situ synchrotron small angle X-ray scattering investigation of structural formation of polyethylene upon micro-injection molding. Polymer 2021, 215, 123390. [Google Scholar] [CrossRef]

- Na, B.; Tian, N.; Lv, R.; Zou, S.; Xu, W.; Fu, Q. Annealing-Induced Oriented Crystallization and Its Influence on the Mechanical Responses in the Melt-Spun Monofilament of Poly (L-lactide). Macromolecules 2010, 43, 1156–1158. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Titomanlio, G.; Pantani, R. Effect of rapid mold heating on the structure and performance of injection-molded polypropylene. Polymers 2020, 12, 341. [Google Scholar] [CrossRef] [PubMed]

- Pantani, R.; Speranza, V.; Titomanlio, G. Evolution of iPP Relaxation Spectrum during Crystallization. Macromol. Theory Simul. 2014, 23, 300–306. [Google Scholar] [CrossRef]

- Pantani, R.; Speranza, V.; Titomanlio, G. Effect of flow-induced crystallization on the distribution of spherulite dimensions along cross section of injection molded parts. Eur. Polym. J. 2017, 97, 220–229. [Google Scholar] [CrossRef]

- Pantani, R.; Speranza, V.; Titomanlio, G. Simultaneous morphological and rheological measurements on polypropylene: Effect of crystallinity on viscoelastic parameters. J. Rheol. 2015, 59, 377–390. [Google Scholar] [CrossRef]

- White, H.M.; Bassett, D.C. On Row Structures, Secondary Nucleation and Continuity in Alpha- Polypropylene. Polymer 1998, 39, 3211–3219. [Google Scholar] [CrossRef]

- Liparoti, S.; Sorrentino, A.; Speranza, V. Micromechanical Characterization of Complex Polypropylene Morphologies by HarmoniX AFM. Int. J. Polym. Sci. 2017, 2017, 9037127. [Google Scholar] [CrossRef]

- De Santis, F.; Pantani, R. Thermodynamic properties and crystallization kinetics of isotactic polypropylene under pressure. In Proceedings of the PPS-33: The 33rd International Conference of the Polymer Processing Society, Cancun, Mexico, 10–14 December 2017; Octavio Manero and Fausto Calderas. AIP Publishing: New York, NY, USA, 2019; p. 150001. [Google Scholar] [CrossRef]

- Sorrentino, A.; Pantani, R. Determination of the effect of pressure on viscosity of an isotactic polypropylene. Polym. Bull. 2013, 70, 2005–2014. [Google Scholar] [CrossRef]

- Speranza, V.; Liparoti, S.; Pantani, R. Prediction of Morphology Distribution within Injection Molded Parts Obtained with Fast Cavity Heating Cycles: Effect of Packing Pressure. Macromol. Mater. Eng. 2022, 2200436. [Google Scholar] [CrossRef]

- Speranza, V.; Liparoti, S.; Volpe, V.; Titomanlio, G.; Pantani, R. Modelling of morphology development towards spherulites and shish-kebabs: Application to isothermal flow-induced crystallization experiments on isotactic polypropylene. Polymer 2020, 196, 122459. [Google Scholar] [CrossRef]

- Pantani, R.; Coccorullo, I.; Volpe, V.; Titomanlio, G. Shear-Induced Nucleation and Growth in Isotactic Polypropylene. Macromolecules 2010, 43, 9030–9038. [Google Scholar] [CrossRef]

- De Santis, F.; Pantani, R.; Titomanlio, G. Effect of shear flow on spherulitic growth and nucleation rates of polypropylene. Polymer 2016, 90, 102–110. [Google Scholar] [CrossRef]

- Speranza, V.; Liparoti, S.; Pantani, R.; Titomanlio, G. Hierarchical structure of iPP during injection molding process with fast mold temperature evolution. Materials 2018, 12, 424. [Google Scholar] [CrossRef] [PubMed]

| Sample Name | Tmold (K) | tfa (min) | Tsa (K) | tsa (min) |

|---|---|---|---|---|

| S | 298 | - | - | - |

| 413_FA | 413 | 5 | - | |

| 413_SA | 413 | 5 | 403 | 120 |

| 433_FA | 433 | 5 | - | - |

| 433_SA | 433 | 5 | 403 | 120 |

| Case | Rexp (μm) | RMF (μm) | Rcalc (μm) |

|---|---|---|---|

| S | 7.5 ± 2 | 1 | 2 |

| 413_FA | 17 ± 2 | 7 | 11 |

| 433_FA | 17 ± 2 | 7 | 10 |

| 413_SA | 70 ± 5 | 74 | 90 |

| 433_SA | 75 ± 10 | 74 | 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salomone, R.; Speranza, V.; Liparoti, S.; Titomanlio, G.; Pantani, R. Modeling and Analysis of Morphology of Injection Molding Polypropylene Parts Induced by In-Mold Annealing. Polymers 2022, 14, 5245. https://doi.org/10.3390/polym14235245

Salomone R, Speranza V, Liparoti S, Titomanlio G, Pantani R. Modeling and Analysis of Morphology of Injection Molding Polypropylene Parts Induced by In-Mold Annealing. Polymers. 2022; 14(23):5245. https://doi.org/10.3390/polym14235245

Chicago/Turabian StyleSalomone, Rita, Vito Speranza, Sara Liparoti, Giuseppe Titomanlio, and Roberto Pantani. 2022. "Modeling and Analysis of Morphology of Injection Molding Polypropylene Parts Induced by In-Mold Annealing" Polymers 14, no. 23: 5245. https://doi.org/10.3390/polym14235245

APA StyleSalomone, R., Speranza, V., Liparoti, S., Titomanlio, G., & Pantani, R. (2022). Modeling and Analysis of Morphology of Injection Molding Polypropylene Parts Induced by In-Mold Annealing. Polymers, 14(23), 5245. https://doi.org/10.3390/polym14235245