Abstract

Composite materials containing natural reinforcement fibers, generally called biocomposites, have attracted the interest of both researchers and manufacturers, but the most environmentally advantageous combinations include a bio-based matrix, as well. With this in mind, a poly(lactic acid) (PLA) matrix was reinforced with natural fibers from hemp, both untreated strands (UHSs) and soda-bleached fibers (SBHFs). The preparation of the subsequent fully bio-sourced, discontinuously reinforced composites involved kinetic mixing, intensive single-screw extrusion, milling, and injection molding. Up to a fiber content of 30 wt%, the tensile modulus increased linearly with the volume fraction of the dispersed phase. Differences between SBHFs (up to 7.6 Gpa) and UHSs (up to 6.9 Gpa) were hardly significant (p = 0.1), but SBHF-reinforced composites displayed higher strain at failure. In any case, for the same fiber load (30 wt%), the Young’s modulus of PLA/hemp biocomposites was greater than that of glass fiber (GF)-reinforced polypropylene (5.7 GPa), albeit lower than that of PLA/GF (9.8 GPa). Considering all the measurements, the contribution of each phase was analyzed by applying the Hirsch model and the Tsai-Pagano model. As a concluding remark, although the intrinsic tensile modulus of SBHFs was lower than that of GF, the efficiency of those natural fibers as reinforcement (according to the rule of mixtures) was found to be higher.

1. Introduction

Bioplastic/natural fiber composites can be thought as the intersection between two sets of materials. On one side stand bioplastic composites, in which the reinforcement phase may consist of wood fiber, wood flour, glass fiber (GF), or carbon fiber, among other possibilities. They may be biodegradable or non-biodegradable. Their market size was valued at USD 30.9 billion in 2021, and is expected to grow at a compound annual growth rate (CAGR) of 10.4% [1]. On the other side, we can find the so-called biocomposites, which are reinforced with wood or other natural fibers, but their matrix may (or may not) be synthetic. Their CAGR has been projected to be as high as 16% [2]. Thence, it follows that prospects for bioplastic/natural fibers composites share some of the optimism of these two sets in which they participate.

Regarding the bioplastic matrix, one of the most popular choices is poly(lactic acid) (PLA), due to a number of reasons that have been discussed in depth elsewhere [3,4]. One of them is its high stiffness, which can be even further enhanced, as is known for other thermoplastic matrices, by fiber reinforcements. Indeed, the tensile modulus of polypropylene (PP), polycarbonate and different polyamides, for example, can be more than doubled with the incorporation of glass fiber (GF) [5,6,7]. Hence, GF-reinforced composites are usually chosen in the so-called “stiffness-limited design”. This term refers to the design of columns, panels, shafts, building blocks, or any other component or product that prioritizes avoiding or minimizing elastic deformation [8].

Despite the environmental advantages of natural fibers, mainly in terms of energy consumption and carbon footprint [9,10,11], their market share still goes far behind GF in the current composites market [12]. Determining the optimal process to incorporate natural fibers, such as those of hemp, flax, or jute, as a discontinuous reinforcement phase into thermoplastic matrices remains a pending issue. Various compatibilizers and chemical modifications have been suggested to promote dispersion [13]. Strategies for improving dispersion and/or interfacial compatibility often involve either reactions on the surface of the fibers [14,15] or the use of maleic anhydride-grafted thermoplastics [16,17]. Nonetheless, this practice does not comply with the principles of green chemistry [18]. Well-known and relatively clean processes, such as soda pulping and total chlorine bleaching, have been shown to enhance the tensile strength of PLA/hemp composites [19], but at the expense of significant material losses.

Strands and fabrics from hemp, both untreated and after undergoing different chemical processes, have already been incorporated into PLA matrices [15,20,21]. Song et al.’s [20] biocomposites [3,20], comprising PLA and degummed hemp strands (cooking in alkali, 100 °C), reached tensile strength improvements of up to 39% over the initial bioplastic. We hypothesize that bleached soda-anthraquinone hemp fibers (BSHFs) with a high content of fines would attain better interaction after extensive blending processes. This is expected from the fact that they possess even less lignin and more surface area for intermolecular interactions [22].

This work analyzes the stiffness of PLA composites reinforced with untreated hemp strands (UHSs) and with soda-bleached hemp fibers (SBHFs). In both cases, the reinforcement phase was discontinuous, and the same methods of compounding and molding were implied. The research question addressed in this work was “Does the biocomposite benefit from delignification and subsequent disintegration of the middle lamellae of natural fibers?” Compatibilizers, binders, and derivatizing agents were avoided. We describe the production of specimens for tensile tests using kinetic mixing, extrusion (twice), and injection molding. Then, the stiffness of PLA/SBHF materials is compared to that of PLA/UHS and unreinforced PLA. To draw conclusions on their potential applications, the fully green composites proposed here are also compared to conventional GF-reinforced PP.

2. Materials and Methods

2.1. Materials

The PLA matrix of the biocomposites described here was Ingeo™ Biopolymer 3251D from NatureWorks (Plymouth, MN, USA). Agrofibra S.L. (Puigreig, Spain) kindly provided untreated hemp strands (UHSs). Total chlorine-free bleached soda pulp from hemp strands, with an ISO brightness value of 89.5%, was supplied by Celesa (Tortosa, Spain).

Basic chemical characterizations of both UHSs and SBHFs were carried out according to TAPPI standards for lignocellulosic materials (T 204, T 211, T 249, T 429, T 222, UM 250) [23]. Additionally, their crystallinity index was estimated by applying Segal’s method [24] on X-ray diffraction patterns attained by means of an X’Pert MPD X-ray diffractometer from Philips (Philips Ibérica, Valencia, Spain) with auto-divergent slits and Cu-Kα radiation (45 kV, 40 mA).

2.2. Preparation of Biocomposites

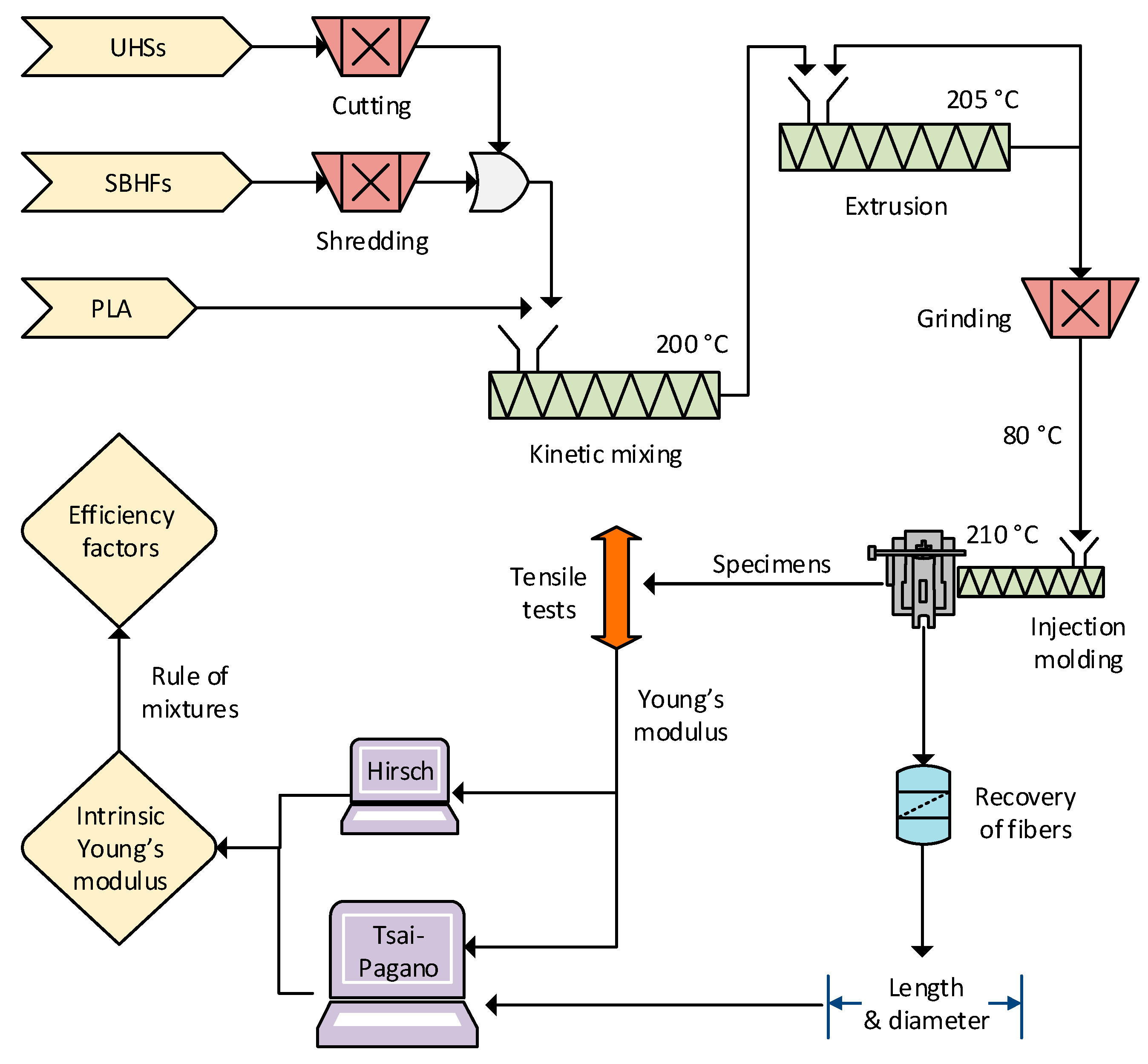

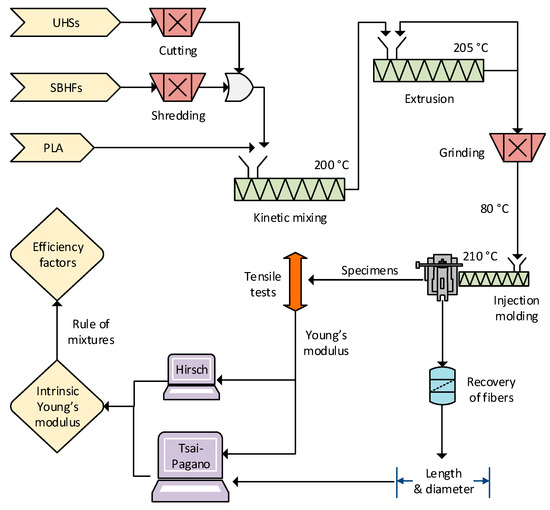

To produce the composites, PLA was mixed with 10 wt%, 20 wt%, and 30 wt% of either UHSs or BSHFs. The procedure is summarily schematized in Figure 1. For combinations, UHSs were cut down to lengths of 3.0 ± 0.3 mm, while SBHF dry pulp boards underwent fractionation using a paper shredder. In both cases, fibers were dispersed in the matrix using a Gelimat™ G5S kinetic mixer (Dusatec, Ramsey, NJ, USA). We set the angular speed at 2500 rpm, the discharge temperature at 200 °C, and the mixing time at 3 min. Then, the combined material was passed twice through a single-screw extruder, Eurotecno 3035 D (Eurotecno, Sant Fost de Camcentelles, Spain), with the screw rotating at 40 rpm. The temperature increased from 180 °C (hopper) to 205 °C (die). Finally, the extrudate was granulated in a hammer mill and stored at 80 °C for 24 h.

Figure 1.

Simplified diagram of the experimental procedure and the calculation methodology.

We obtained dog-bone specimens (type I, ASTM D790) for tensile tests by means of an injection molding machine from Arburg (Lossburg, Germany), 220 M 350-90U [25]. The processing temperature increased from 170 °C (hopper) to 210 °C (nozzle). The injection pressure ranged from 50 MPa to 80 MPa, depending on the fiber load.

2.3. Characterization of Biocomposites

Specimens were conditioned under standard conditions of temperature and humidity [26]. After 24 h, we performed tensile tests at 2 mm/min on up to ten samples, according to ASTM D3039 [25]. The tests were performed using a Universal Testing Machine, Instron 1122 (Barcelona, Spain), equipped with a 5 kN load cell and an extensometer. Additional experiments were performed with UHSs, following the ASTM standard D3379-75(1989)e1 for high-modulus single-filament materials [27].

The reinforcement fibers were recovered from the composites by the dissolution of the matrix in dichloromethane. Recovered fibers were suspended in water and had their dimensions measured using a MorFi Compact analyzer from Techpap (Gières, France), equipped with the software MorFi v9.2.

2.4. Modeling and Calculation

There are many empirical or semi-empirical models used to predict the tensile properties of fiber-reinforced composites, commonly based on the rule of mixtures [28]. Indeed, the Young’s modulus of composites (EtC) often follows a linear trend with the volume fraction of fibers (VF), at least until a certain level of fiber load [16,29]:

where Etm is the modulus of the matrix, EtF is the intrinsic Young’s modulus of fibers, and ηe is an efficiency factor, which can be expressed as the product of an orientation efficiency factor (ηo) and a length efficiency factor (ηl). The latter can be estimated from the Cox–Krenchel model [30,31]. In general, the higher the aspect ratio of fibers, the higher the length efficiency factor. At the same time, the product ηe × EtF is the contribution of the reinforcement and is used to obtain a fiber tensile modulus factor (FTMF), which corresponds to the slope of EtC − (1 − VF) × Etm against VF. EtF can be estimated from the Hirsch model [32]:

EtC = ηe × EtF × VF + (1 − VF) × Etm

EtC = β [EtF × VF + Etm × (1 − VF)] + (1 − β) × EtF × Etm/[Etm × VF + EtF (1 − VF)]

In Equation (2), the parameter β accounts for the capability of matrix-to-fiber stress transfer. A value of 0.4 usually yields satisfactory predictions [33,34]. Whereas this approach does not consider fiber morphology, the length (lF) and diameter (dF) of the recovered fibers are input variables for the Halpin and Tsai equations with the Tsai and Pagano solution [35,36]:

3. Results and Discussion

3.1. Stiffness of PLA/UHS and PLA/SBHF

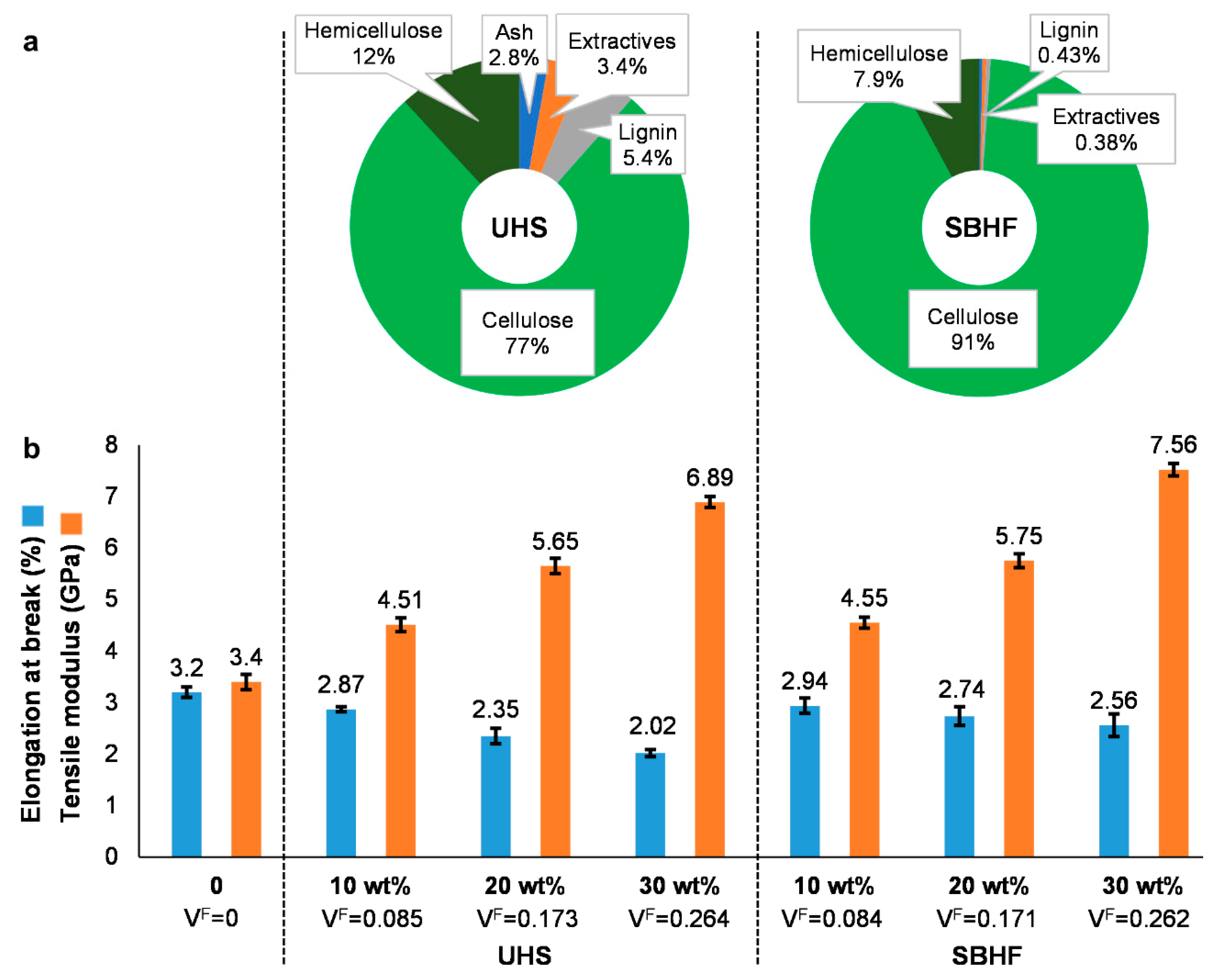

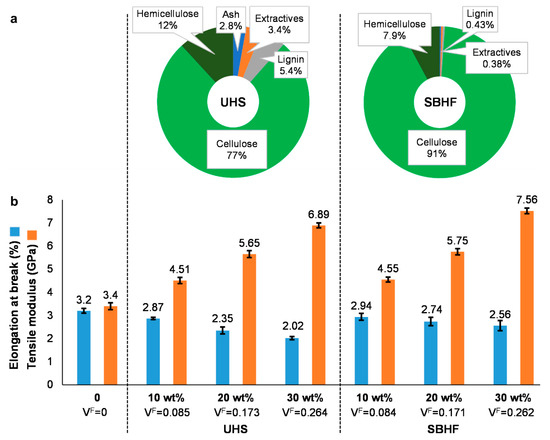

Soda pulping processes are known to be rather unselective, but the subsequent bleaching stage allowed for a more selective removal of lignin [37]. As shown in Figure 2a, the fractions of lignin and extractives were diminished by one order of magnitude. The density of the reinforcement phase was slightly decreased, from 1.50 g/cm3 to 1.48 g/cm3. This difference was taken into account for the calculation of the volume fraction, but it is probably negligible in terms of the contribution to stiffness.

Figure 2.

Experimental data (a) of the composition analysis and (b) of the tensile tests, encompassing Young’s modulus and strain at break (εtC), of PLA/UHS and PLA/SBHF biocomposites.

UHSs and SBHFs approximately doubled the Young’s modulus of PLA, but the difference between both kinds of fibers was hardly significant (Figure 2b). A one-way ANOVA test at a 95% confidence rate did not allow the null hypothesis (p = 0.10) to be discarded. However, these similar enhancements of stiffness came along with unequal effects on the strain at failure, since PLA/SBHF composites were consistently able to withstand more plastic deformation than PLA/UHS. The strain at failure for PLA/UHS (30%) was identical to that found by Zouari et al. [38]. In all cases, the enhancement of stiffness came at the expense of lower ductility, but this detriment was less prejudicial for the composite material in the case of the fibers that underwent chemical pulping and bleaching.

On one hand, the removal of amorphous components (lignin, some hemicellulose macromolecules, and extractives) is generally expected to impart greater intrinsic stiffness [39]. On the other, given that the original strands were already rich in cellulose (77%), the extent of the enhancement attained by delignification was rather low. Also in this context, the crystallinity index of SBHFs was only slightly higher than that of UHSs (0.87 and 0.79, respectively). It is known that the degree of supramolecular order exerts a significant effect on the tensile properties of cellulosic materials [40], but that of hemp strands was initially elevated. Furthermore, the possible gains attained by removing amorphous components were plausibly hampered by the depolymerization of cellulose during alkaline pulping and bleaching [41]. In the same sense, these treatments damaged the surface of fiber hemps to the point of generating a high amount of fines (47%), which may contribute to the tensile strength of the material [19,42], but made no significant contribution to stiffness.

In a previous work with jute [43], whose initial lignin content was as high as 13%, the Young’s modulus significantly increased by decreasing the lignin content to roughly 8%, but further delignifying had negligible effects on stiffness. In the case of hemp, whose lignin content without chemical treatments lies below that amount (as long as the hemp core is removed), the importance of delignification is arguable. Furthermore, a major drawback of chemical pulping is the low material efficiency. In fact, the total yield of pulping and bleaching was 45%, meaning that 55% of the initial hemp weight was solubilized. The material that was lost this way included not only lignin (11% of the solubilized fraction), ashes (6%) and extractives (7%), but also hemicellulose (17%) and hydrolyzed cellulose (59%). Hence, the loss of cellulose was as high as 32% over the initial weight of hemp, which puts the convenience of pulping and bleaching for stiffness-limited design under question. Nonetheless, they have been proven to be of utmost relevance to enhance the tensile strength, for which the quality of the interphase has a significant influence [19].

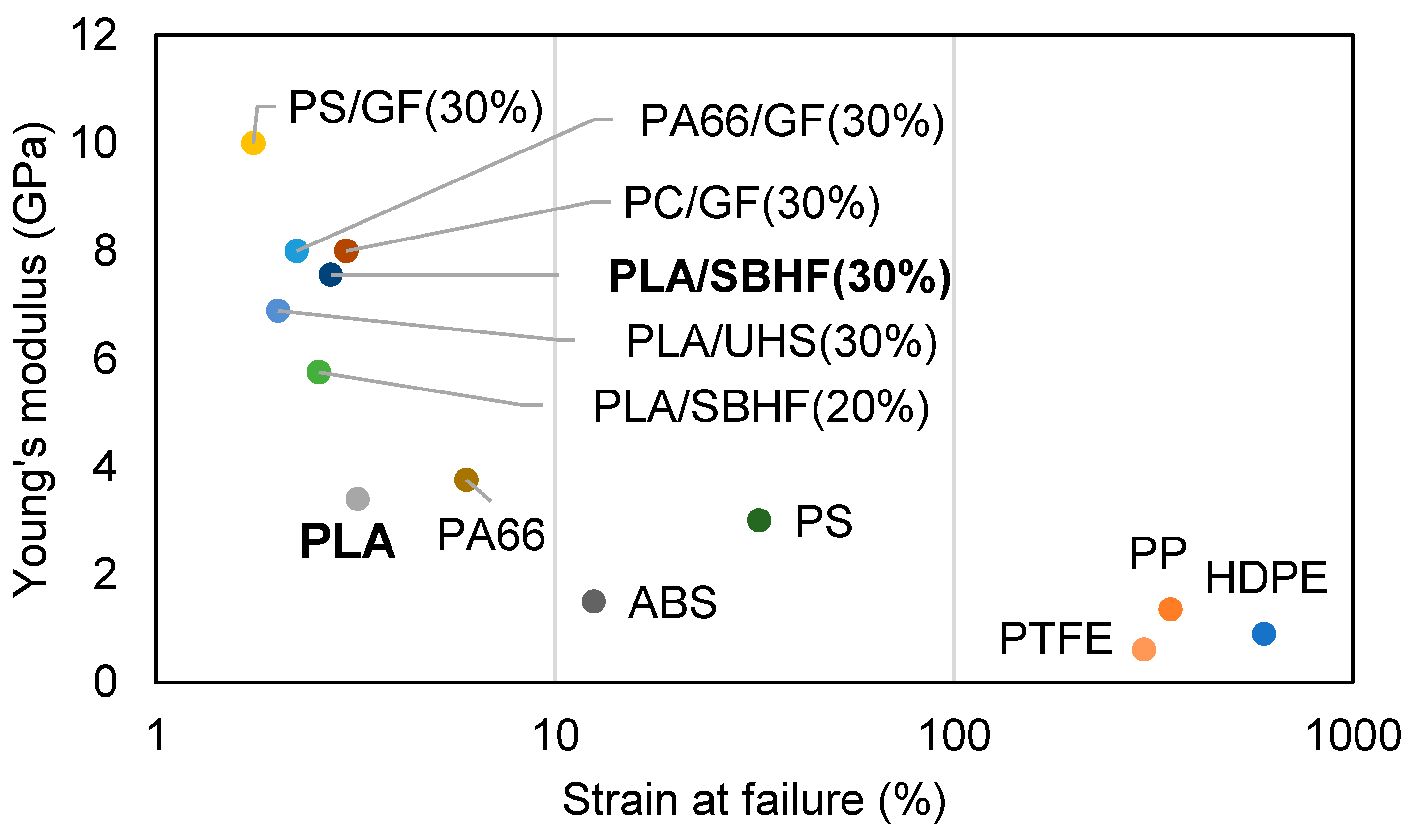

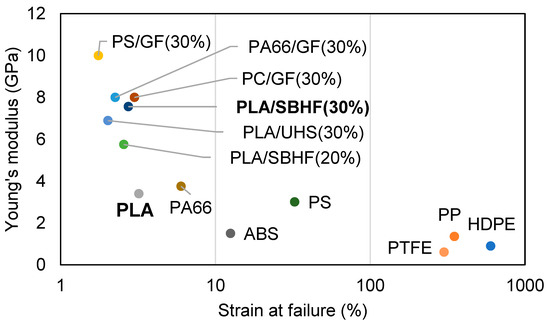

3.2. Empirical Assessment of the Constituents

As a matrix, PLA is deemed a relatively stiff thermoplastic material, with a Young’s modulus of 3.4 GPa. For comparison purposes, it could be mentioned that the moduli of PP, high-density polyethylene (HDPE), polybutylene, poly(vinyl chloride), and acrylonitrile butadiene styrene (ABS) lie around 1.5 GPa, 0.8 GPa, 0.4 GPa, 2.8 GPa, and 2.3 GPa, respectively [44]. Figure 3 locates PLA and PLA/hemp composites in comparison with popular thermoplastic materials and GF-reinforced composites in which they constitute the matrix [45,46]. It should be noted that the indicative values displayed may belong to a broad range of possible values. In any case, the region at the right (high strain at failure) includes plausible choices for ductility design, while the upper region (high modulus of elasticity) includes materials for stiffness design.

Figure 3.

Typical stiffness and ductility of some of the most popular thermoplastic materials and their composites [44,45,46], including the biocomposites presented in this work. PS: polystyrene. PC: polycarbonate. PA66: polyamide 6,6. PTFE: polytetrafluoroethylene.

Regarding reinforcement fibers, it is unusual for those of natural origin to match GF (much less carbon fiber). Hence, with a choice of materials depending on a stiffness-limited design in mind, natural fibers should reinforce an already stiff matrix. Tensile tests on single UHSs revealed a Young’s modulus of 25 ± 9 GPa (95% confidence). The uncertainty of the measurement arises from the heterogeneity of the material and from the limitations of the method. It should be noted that these experiments were performed with UHSs, following the ASTM standard D3379-75(1989)e1 (withdrawn). Moreover, this kind of direct measurements could not be applied to SBHFs, whose length is generally <1 mm. For these reasons, the contribution of reinforcement fibers to stiffness is better estimated using micromechanical models, such as those of Hirsch (Equation (2)) or Tsai-Pagano (Equation (3)). Commonly, values estimated from these models are higher than experimental results [34], but also more reliable when it comes to predict the mechanical properties of similar composites.

3.3. Micromechanics of the Tensile Modulus

Table 1 presents the average length (weighted in length), the mean diameter, and the intrinsic tensile modulus and reinforcement efficiency factors of PLA/SBHF composites. Since their EtC did not differ significantly from that of PLA/UHS, the latter’s micromechanical parameters are qualitatively similar.

Table 1.

Intrinsic Young’s modulus of SBHFs and efficiency, as calculated from the Hirsch [32] and the Tsai-Pagano models [35].

While Equation (3) considers the influence of the aspect ratio, the intrinsic Young’s moduli, as calculated by Equation (2), differed by less than 10% from the former. Hence, with fewer inputs, the Hirsch model provided a satisfactory estimation. This estimation of EtF can be extrapolated to predict the contribution of SBHFs in other composite materials, i.e., in matrices other than PLA. For instance, using a value of 30 GPa for EtF and a value of 0.5 for ηe would predict an increase in the Young’s modulus of bleached hemp-reinforced polyamides, applying the rule of mixtures (Equation (1)), from 3.4 to 7.0 GPa. In a previous work, the axial tensile modulus of said composite was measured as 6.7 ± 0.2 GPa [47]. In other words, the prediction of the Young’s modulus by the Hirsch model yielded an overestimation of only 5% with respect to the experimental results, or of 1.5–0.77% taking into account the lower and higher limits of the tolerance interval.

The mean efficiency factor was found to be 0.530 according to the Hirsch model, or 0.561 with the Tsai–Pagano model. The intrinsic Young’s modulus showed a mean value of 32.5 GPa (Hirsch) or 30.7 GPa (Tsai-Pagano). The product of both parameters, FTMF, was 17.4 GPa, and it quantifies the contribution of the reinforcement phase. As expected, these intrinsic Young’s moduli, slightly over 30 GPa according to both models, were lower than that of GF, 71.6 GPa [33]. They lie within the range reported in the literature for hemp fibers, roughly between 17 and 45 GPa [48]. However, hemp strands, either untreated or after a delignifying treatment, were more efficient as a reinforcement phase than GF (ηe = 0.243).

As mentioned above, the efficiency factor can be expressed as a product of two contributions; that of the fiber length (Cox-Krenchel), and that of orientation. Table 2 shows their values estimated for each level of fiber load. From the mean orientation efficiency factor, 0.649 (if EtF is calculated from the Tsai-Pagano model), the average angle of reinforcement fibers with the axis can be estimated as 43.2°. In the hypothetical case of fibers that were perfectly aligned in the axial direction, the orientation efficiency factor would be 1. The accomplishment of such a hypothesis is highly unlikely with injection molding, especially if using a discontinuous reinforcement phase, but composites with well-aligned mats have been reported to be produced by stacking and hot pressing [49]. If this axial orientation were attained with SBHFs, reaching ηo values close to 1, the modified rule of mixtures would predict Young’s moduli as high as 9.4 GPa.

Table 2.

Breakdown of the efficiency factor in length and orientation, and average orientation angle of reinforcement fibers.

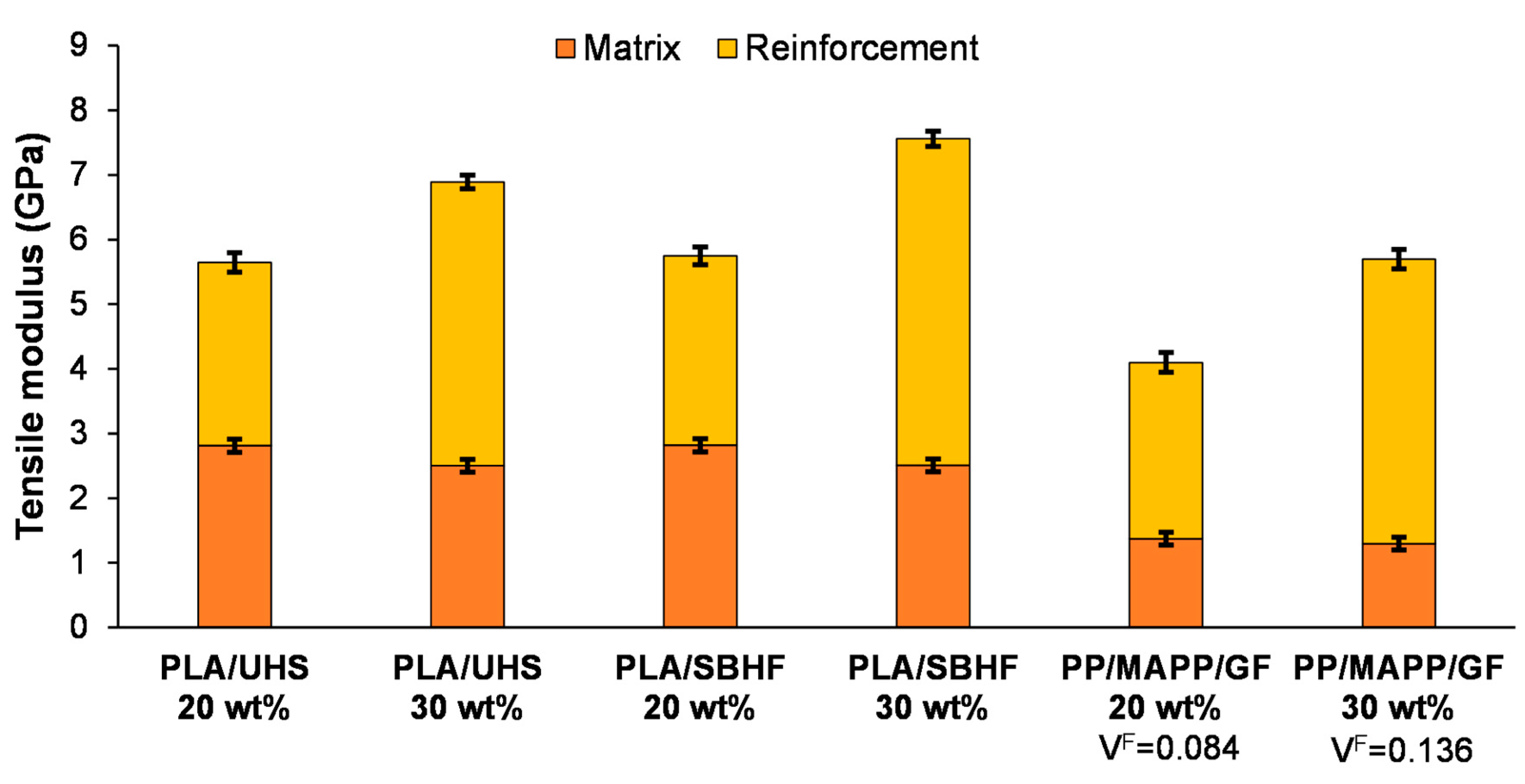

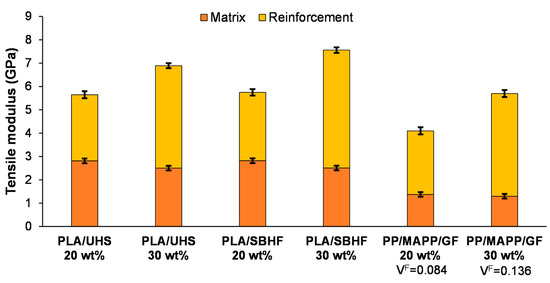

3.4. Comparison of PLA/Hemp and More Conventional Options

Figure 4 shows the contributions of the composite constituents, namely matrix and reinforcement fibers, to the Young’s modulus of PLA/UHS, PLA/SBHF, and PP/GF with maleic anhydride–grafted polypropylene (MAPP). Two levels of fiber load were selected for this comparison: 20 wt% and 30 wt%. Overall, due to the higher stiffness of the matrix (PLA vs. PP) [50,51], the tensile modulus of PLA/hemp was significantly higher than that of a more conventional PP/GF composite.

Figure 4.

Comparison between PLA/SBHF and PP/GF in terms of stiffness, highlighting the contribution of the matrix and that of the reinforcement fibers.

As a drawback, PLA/hemp composites (minimum εtC = 2.0%) were more brittle than PP/GF (minimum εtC = 4.4%). Additionally, PLA/UHS composites were shown to withstand less tensile load (roughly 56 MPa) than PP/GF, as delignification was required to match the tensile strength of the latter (78 MPa for the same fiber load) [19]. Unlike stiffness, these two properties, i.e., ductility and tensile strength, were enhanced by alkaline pulping and bleaching, possibly due to the improvement of the fiber/matrix interfacial compatibility [52], which does not exert a capital effect when it comes to the Young’s modulus. Moreover, compatibility reasons aside, delignification allowed fibers to withstand more plastic deformation, since cellulose–lignin interfaces are zones of preferential fracture, as discovered in molecular dynamics studies [53].

An inescapable question is how PLA/hemp composites compare to PLA/GF composites; same matrix, stiffer reinforcement fibers. The latter kind of material should not be included within the umbrella term of biocomposites, given the energy-intensive manufacturing process of GF, and that it hampers the biodegradation of PLA. In fact, commercially available composites of this nature have recently been disappearing from the catalogue of some major manufacturers [54]. That said, the extraordinary stiffness of PLA/GF composites is undoubted. With a fiber load of 30 wt%, their tensile modulus has been found to be 9.8 GPa [55]. Interpolating for 20 wt%, the expected value is 7.7 GPa, which stands close to the stiffness found for Wang et al.’s silanized GF (20 wt%)-reinforced PLA (7.8 GPa) [56]. Nonetheless, although the intrinsic Young’s modulus of GF more than doubles that of hemp fibers [33], the increase in the composite’s stiffness that SBHFs impart is approximately 70% of the enhancement provided by GF. This means that the efficiency of SBHFs as a reinforcement for PLA is higher than that of GF.

All notions considered, PLA/UHS or PLA/SBHF composites are solid candidates for nearly the whole spectrum of applications of GF-reinforced thermoplastics with a stiffness-focused design. Nonetheless, the brittleness of PLA-based composites may limit their applications in aerospace parts, home appliances, or any other material meant to withstand plastic deformation before breaking down.

4. Conclusions

UHSs and SBHFs of up to 30 wt% (i.e., a volume fraction of 0.26) were dispersed in a PLA matrix, yielding fully bio-sourced composites with enhanced stiffness. PLA/hemp composites were found to be stiffer than some conventional reinforced materials, namely, PP/GF, although less stiff than, e.g., PLA/GF or PA66/GF. Remarkably, PLA/UHS biocomposites were more brittle (εtC as low as 2.0%) than PLA/SBHF, but both were significantly more brittle than PP/GF. With tensile moduli around 7 GPa for both PLA/UHS and PLA/SBHF, the loss of material experienced during pulping and bleaching (55%) made these processes unworthy of consideration in terms of stiffness-limited design. The values estimated for the intrinsic Young’s modulus (around 30 GPa) and the efficiency factor (roughly 0.5) can be used to predict the contribution of hemp strands to other thermoplastic matrices.

Author Contributions

Conceptualization, P.M.; methodology, M.D.-A., Q.T. and R.J.A.; software, F.X.E. and J.L.; validation, M.D.-A. and P.M.; formal analysis, Q.T.; investigation, G.A.B. and Q.T.; resources, M.D.-A. and P.M.; data curation, R.J.A. and G.A.B.; writing—original draft preparation, R.J.A.; writing—review and editing, Q.T., F.X.E. and G.A.B.; visualization, P.M.; supervision, M.D.-A. and P.M.; project administration, P.M.; funding acquisition, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

Marc Delgado-Aguilar and Quim Tarrés are Serra Húnter Fellows.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

All data are explicit in the manuscript or else available on request.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Precedence Research. Bioplastic Composites Market (By Type: Biodegradable, Non-Biodegradable; By Fiber Type: Wood Fiber Composites, Non-Wood Fiber Composites. Available online: https://www.precedenceresearch.com/bioplastic-composites-market (accessed on 15 November 2022).

- Markets and Markets. Biocomposites Market by Fiber Type (Wood-Fiber and Non-Wood-Fiber), Polymer Type (Synthetic and Natural), Product. Available online: https://www.marketsandmarkets.com/Market-Reports/biocomposite-market-258097936.html (accessed on 15 November 2022).

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Patel, M.; Schwendemann, D.; Zaccone, M.; Geng, S.; Maspoch, M.L.; Oksman, K. Effect of Chitin Nanocrystals on Crystallization and Properties of Poly(lactic acid)-Based Nanocomposites. Polymers 2020, 12, 726. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Lee, J.; Kim, H.; Jang, H.; Nam, J.; Kim, K.; Suhr, J. Semi-Empirical Investigation of the Interfacial Shear Strength of Short Fiber Polymer Composites. Polym. Test. 2019, 74, 99–103. [Google Scholar] [CrossRef]

- Teixeira, D.; Giovanela, M.; Gonella, L.B.; Crespo, J.S. Influence of Flow Restriction on the Microstructure and Mechanical Properties of Long Glass Fiber-Reinforced Polyamide 6.6 Composites for Automotive Applications. Mater. Des. 2013, 47, 287–294. [Google Scholar] [CrossRef]

- Chen, T.; Mansfield, C.D.; Ju, L.; Baird, D.G. The Influence of Mechanical Recycling on the Properties of Thermotropic Liquid Crystalline Polymer and Long Glass Fiber Reinforced Polypropylene. Compos. Part B Eng. 2020, 200, 108316. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural Reuse of Wind Turbine Blades through Segmentation. Compos. Part C Open Access 2021, 5, 100137. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are Natural Fiber Composites Environmentally Superior to Glass Fiber Reinforced Composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Ong, M. Comparison of Structural Performance and Environmental Impact of Epoxy Composites Modified by Glass and Flax Fabrics. J. Compos. Sci. 2022, 6, 284. [Google Scholar] [CrossRef]

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905. [Google Scholar] [CrossRef]

- Research and Markets. Composites Market by Fiber Type (Glass Fiber Composites, Carbon Fiber Composites, Natural Fiber Composites), Resin Type (Thermoset Composites, Thermoplastic Composites), Manufacturing Process, End-Use Industry and Region—Global Forecast to 2026. Available online: https://www.researchandmarkets.com/reports/5130343/composites-market-by-fiber-type-glass-fiber (accessed on 7 December 2022).

- Alao, P.F.; Marrot, L.; Kallakas, H.; Just, A.; Poltimäe, T.; Kers, J. Effect of Hemp Fiber Surface Treatment on the Moisture/Water Resistance and Reaction to Fire of Reinforced PLA Composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Ke, K.; Yang, M.-B.; Yang, W. Recent Progress on Chemical Modification of Cellulose for High Mechanical-Performance Poly(lactic acid)/Cellulose Composite: A Review. Compos. Commun. 2021, 23, 100548. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of Fibre Treatments on Interfacial Shear Strength of Hemp Fibre Reinforced Polylactide and Unsaturated Polyester Composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1189–1196. [Google Scholar] [CrossRef]

- López, J.P.; Boufi, S.; El Mansouri, N.E.; Mutjé, P.; Vilaseca, F. PP Composites Based on Mechanical Pulp, Deinked Newspaper and Jute Strands: A Comparative Study. Compos. Part B Eng. 2012, 43, 3453–3461. [Google Scholar] [CrossRef]

- Dong, Y.; Bhattacharyya, D. Investigation on the Competing Effects of Clay Dispersion and Matrix Plasticisation for Polypropylene/Clay Nanocomposites. Part II: Crystalline Structure and Thermo-Mechanical Behaviour. J. Mater. Sci. 2012, 47, 4127–4137. [Google Scholar] [CrossRef]

- Schaub, T. Efficient Industrial Organic Synthesis and the Principles of Green Chemistry. Chem.–A Eur. J. 2021, 27, 1865–1869. [Google Scholar] [CrossRef]

- Aguado, R.J.; Espinach, F.X.; Julián, F.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P. Tensile Strength of Poly(lactic acid)/Bleached Short Hemp Fiber Fully Green Composites as Replacement for Polypropylene/Glass Fiber. Polymers 2023, 15, 146. [Google Scholar] [CrossRef]

- Song, Y.; Liu, J.; Chen, S.; Zheng, Y.; Ruan, S.; Bin, Y. Mechanical Properties of Poly (Lactic Acid)/Hemp Fiber Composites Prepared with a Novel Method. J. Polym. Environ. 2013, 21, 1117–1127. [Google Scholar] [CrossRef]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and Thermal Behavior of Woven Hemp Fiber Reinforced Poly(lactic acid) Composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Vilaseca, F.; Mutjé, P.; Delgado-Aguilar, M. Influence of Lignin Content on the Intrinsic Modulus of Natural Fibers and on the Stiffness of Composite Materials. Int. J. Biol. Macromol. 2020, 155, 81–90. [Google Scholar] [CrossRef]

- TAPPI. TAPPI Standards, Technical Information Papers, and Useful Methods; Technical Association of the Pulp & Paper Industry: New York, NY, USA, 2020. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- ASTM D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: Conshohocken, PA, USA, 2008.

- ASTM D618-21; Standard Practice for Conditioning Plastics for Testing. ASTM International: Conshohocken, PA, USA, 2021.

- ASTM D3379-75(1989)E1; Standard Test Method for Tensile Strength and Young’s Modulus for High-Modulus Single-Filament Materials (Withdrawn 1998). ASTM International: Conshohocken, PA, USA, 1989.

- Tham, M.W.; Fazita, M.R.N.; Abdul Khalil, H.P.S.; Mahmud Zuhudi, N.Z.; Jaafar, M.; Rizal, S.; Haafiz, M.K.M. Tensile Properties Prediction of Natural Fibre Composites Using Rule of Mixtures: A Review. J. Reinf. Plast. Compos. 2018, 38, 211–248. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Zhao, Z.; He, Y.; Dong, P.; Ma, Y.; Huang, J. A Theoretical Model for the Tensile Modulus of Polymer/CNT Nanocomposites over a Wide Temperature Range. Compos. Commun. 2021, 28, 100971. [Google Scholar] [CrossRef]

- Krenchel, H. Fibre Reinforcement: Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Yan, J.; Demirci, E.; Gleadall, A. Are Classical Fibre Composite Models Appropriate for Material Extrusion Additive Manufacturing? A Thorough Evaluation of Analytical Models. Addit. Manuf. 2023, 62, 103371. [Google Scholar] [CrossRef]

- Hirsch, T.J. Modulus of Elasticity Iof Concrete Affected by Elastic Moduli of Cement Paste Matrix and Aggregate. ACI J. Proc. 1962, 59, 427–452. [Google Scholar] [CrossRef]

- López, J.P.; Mutjé, P.; Pèlach, M.À.; El Mansouri, N.-E.; Boufi, S.; Vilaseca, F. Analysis of the Tensile Modulus of Polypropylene Composites Reinforced with Stone Groundwood Fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of Tensile and Flexural Modulus in Hemp Strands/Polypropylene Composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- Halpin, J.C.; Pagano, N.J. The Laminate Approximation for Randomly Oriented Fibrous Composites. J. Compos. Mater. 1969, 3, 720–724. [Google Scholar] [CrossRef]

- Halpin, J.C. Effects of Environmental Factors on Composite Materials. Available online: https://apps.dtic.mil/sti/citations/ADA306357 (accessed on 17 April 2023).

- Laine, J.; Stenius, P.; Carlsson, G.; Strom, G. The Effect of ECF and TCF Bleaching on the Surface Chemical Composition of Kraft Pulp as Determined by ESCA. Nord. Pulp Pap. Res. J. 1996, 11, 201–210. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Ganesh, S.; Keerthiveettil Ramakrishnan, S.; Palani, V.; Sundaram, M.; Sankaranarayanan, N.; Ganesan, S.P. Investigation on the Mechanical Properties of Ramie/Kenaf Fibers under Various Parameters Using GRA and TOPSIS Methods. Polym. Compos. 2022, 43, 130–143. [Google Scholar] [CrossRef]

- Šturcová, A.; Davies, G.R.; Eichhorn, S.J. Elastic Modulus and Stress-Transfer Properties of Tunicate Cellulose Whiskers. Biomacromolecules 2005, 6, 1055–1061. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.G.; Ferreira, P.J.; Figueiredo, M.M. Cellulose Depolymerisation and Paper Properties in E. globulus Kraft Pulps. Cellulose 2000, 7, 359–368. [Google Scholar] [CrossRef]

- Ham, C.H.; Youn, H.J.; Lee, H.L. Influence of Fiber Composition and Drying Conditions on the Bending Stiffness of Paper. BioResources 2020, 15, 9197–9211. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Oliver-Ortega, H.; Alberto Méndez, J.; Camps, J.; Espinach, F.X.; Mutjé, P. The Role of Lignin on the Mechanical Performance of Polylactic Acid and Jute Composites. Int. J. Biol. Macromol. 2018, 116, 299–304. [Google Scholar] [CrossRef] [PubMed]

- The Engineering Toolbox Thermoplastics—Physical Properties. Available online: https://www.engineeringtoolbox.com/physical-properties-thermoplastics-d_808.html (accessed on 25 June 2023).

- Omnexus Modulus of Elasticity. Available online: https://omnexus.specialchem.com/polymer-properties/properties/young-modulus (accessed on 26 June 2023).

- Omnexus Elongation at Break. Available online: https://omnexus.specialchem.com/polymer-properties/properties/elongation-at-break (accessed on 26 June 2023).

- Alonso-Montemayor, F.J.; Tarrés, Q.; Oliver-Ortega, H.; Espinach, F.X.; Narro-Céspedes, R.I.; Castañeda-Facio, A.O.; Delgado-Aguilar, M. Enhancing the Mechanical Performance of Bleached Hemp Fibers Reinforced Polyamide 6 Composites: A Competitive Alternative to Commodity Composites. Polymers 2020, 12, 1041. [Google Scholar] [CrossRef]

- Duval, A.; Bourmaud, A.; Augier, L.; Baley, C. Influence of the Sampling Area of the Stem on the Mechanical Properties of Hemp Fibers. Mater. Lett. 2011, 65, 797–800. [Google Scholar] [CrossRef]

- Sunny, T.; Pickering, K.L. Improving Polypropylene Matrix Composites Reinforced with Aligned Hemp Fibre Mats Using High Fibre Contents. Materials 2022, 15, 5587. [Google Scholar] [CrossRef]

- Sangeetha, V.H.; Deka, H.; Varghese, T.O.; Nayak, S.K. State of the Art and Future Prospectives of Poly(lactic acid) Based Blends and Composites. Polym. Compos. 2018, 39, 81–101. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Markó, G.; Alpár, T. Thermomechanical Characteristics of Flax-Woven-Fabric-Reinforced Poly(lactic acid) and Polypropylene Biocomposites. Green Mater. 2022, 10, 1–10. [Google Scholar] [CrossRef]

- Feng, L.; Li, K.; Xue, B.; Fu, Q.; Zhang, L. Optimizing Matrix and Fiber/Matrix Interface to Achieve Combination of Strength, Ductility and Toughness in Carbon Nanotube-Reinforced Carbon/Carbon Composites. Mater. Des. 2017, 113, 9–16. [Google Scholar] [CrossRef]

- Mazumder, S.; Zhang, N. Cellulose–Hemicellulose–Lignin Interaction in the Secondary Cell Wall of Coconut Endocarp. Biomimetics 2023, 8, 188. [Google Scholar] [CrossRef] [PubMed]

- RTP Company Glass Fiber Reinforced PLA Bioplastic. Available online: https://web.archive.org/web/20171215074618/ (accessed on 16 November 2022).

- Jaszkiewicz, A.; Bledzki, A.K.; Franciszczak, P. Improving the Mechanical Performance of PLA Composites with Natural, Man-Made Cellulose and Glass Fibers—A Comparison to PP Counterparts. Polymery 2013, 58, 435–443. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass Fiber Reinforced PLA Composite with Enhanced Mechanical Properties, Thermal Behavior, and Foaming Ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).