Effect of Surface Treatment on Stiffness and Damping Behavior of Metal-Metal and Composite-Metal Adhesive Joints

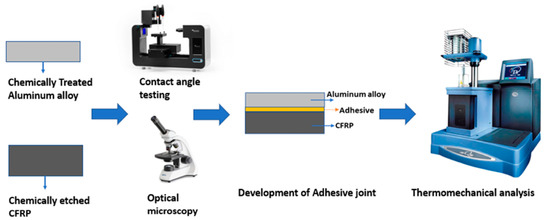

Abstract

1. Introduction

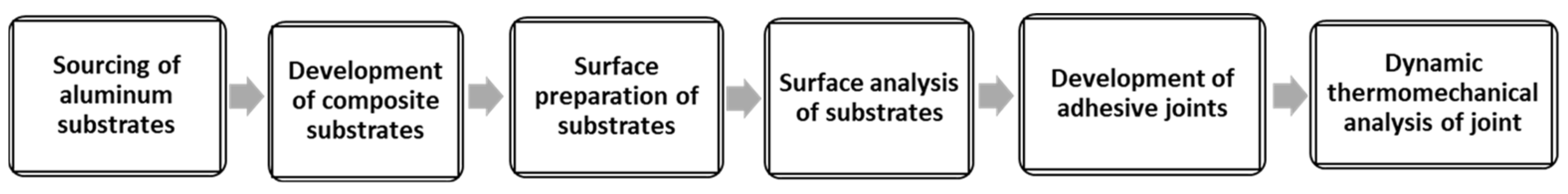

2. Materials

Surface Preparation

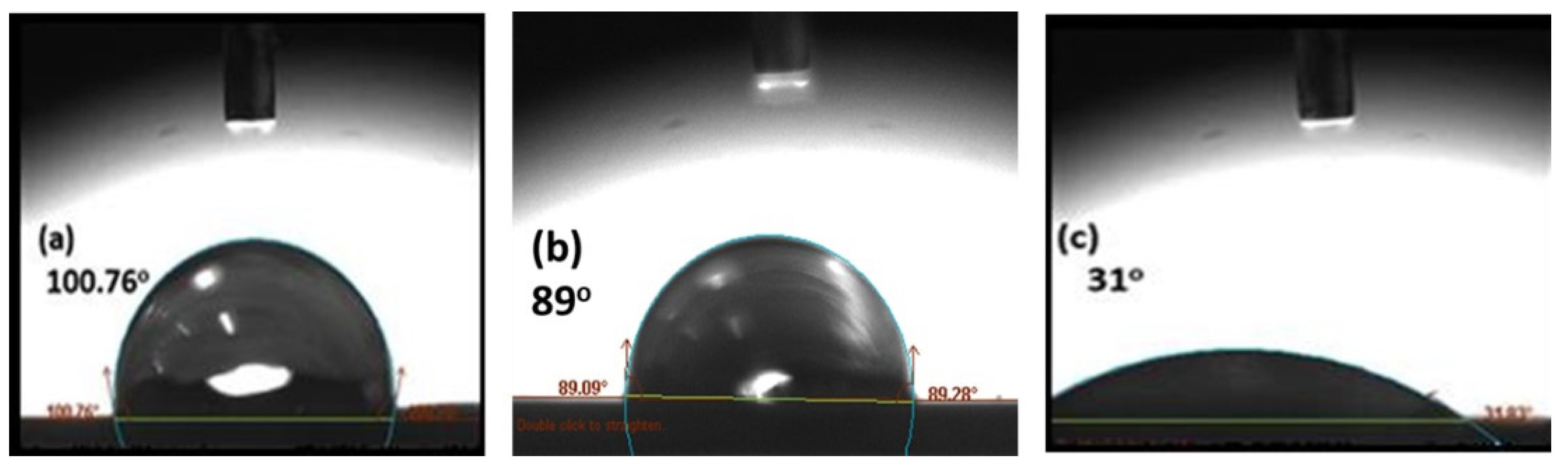

3. Adhesive Joint Fabrication

4. Discussion

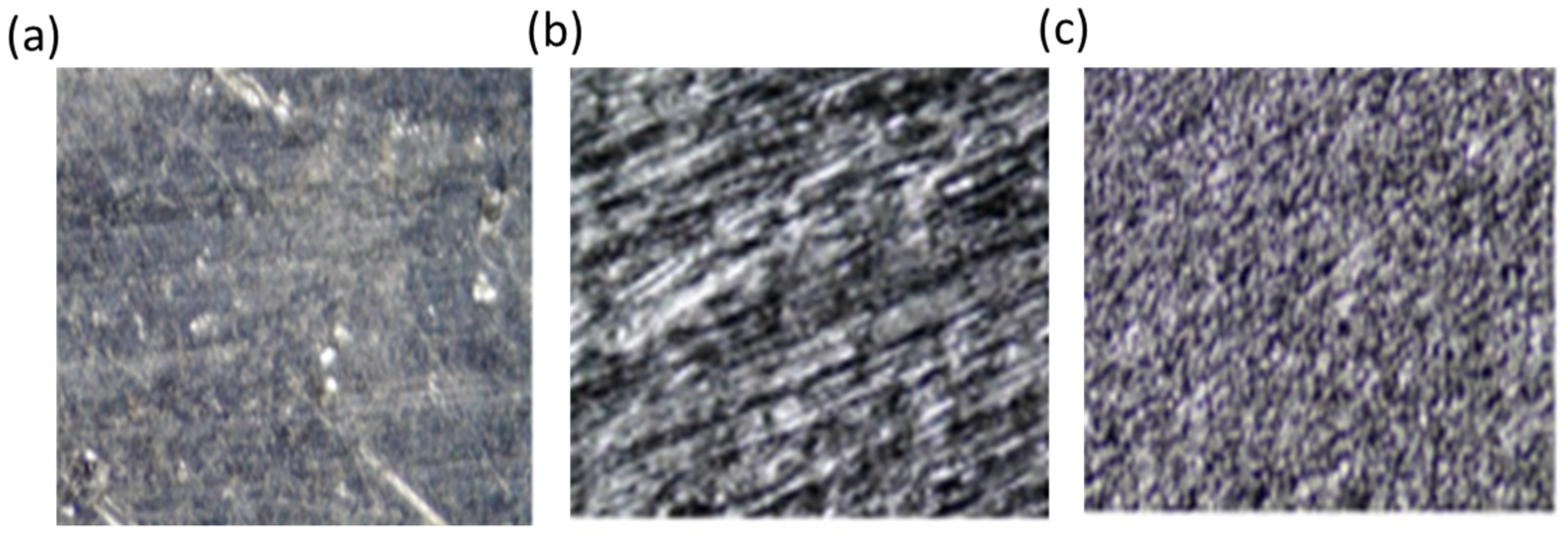

Surface Texture Analysis

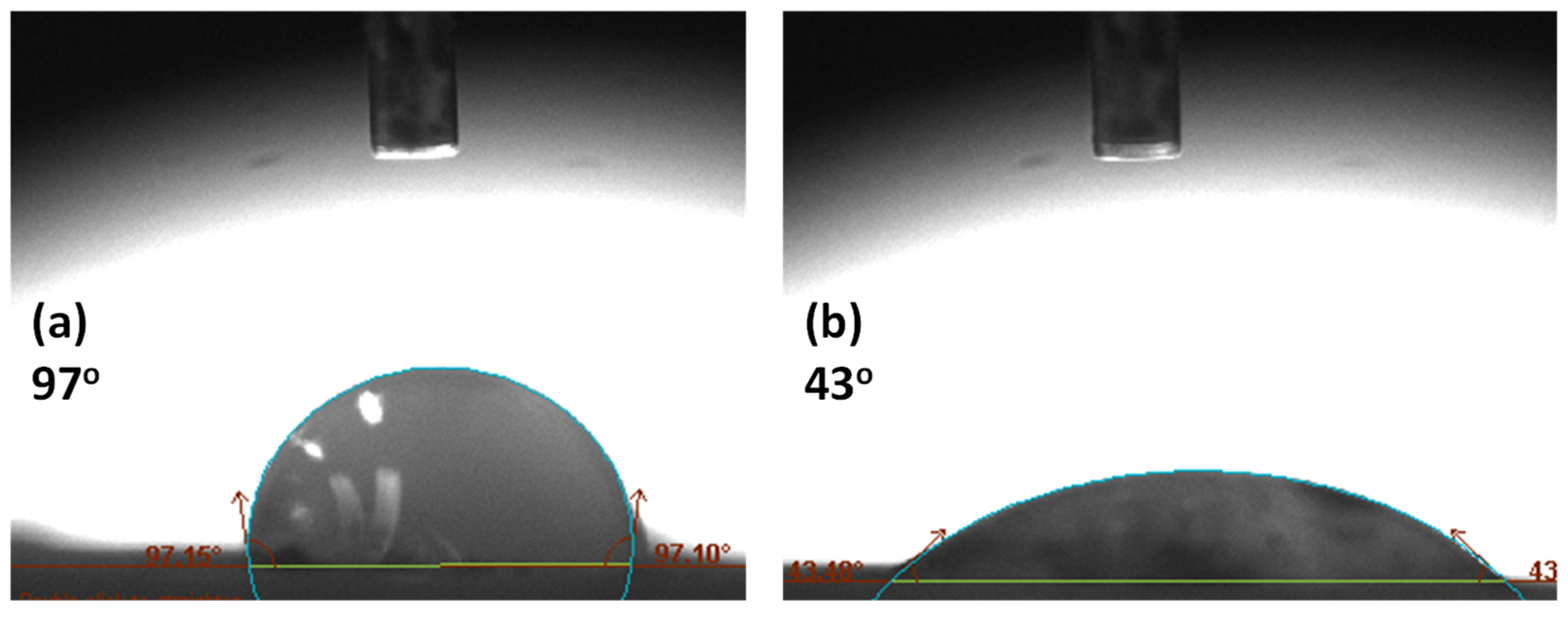

5. Wettability Performance Test

6. Effect of Surface Treatment on Mechanical Performance of Joints

7. Effect of Surface Treatment on Joint Stiffness

8. Effect of Surface Treatment on Damping Behavior of Joints

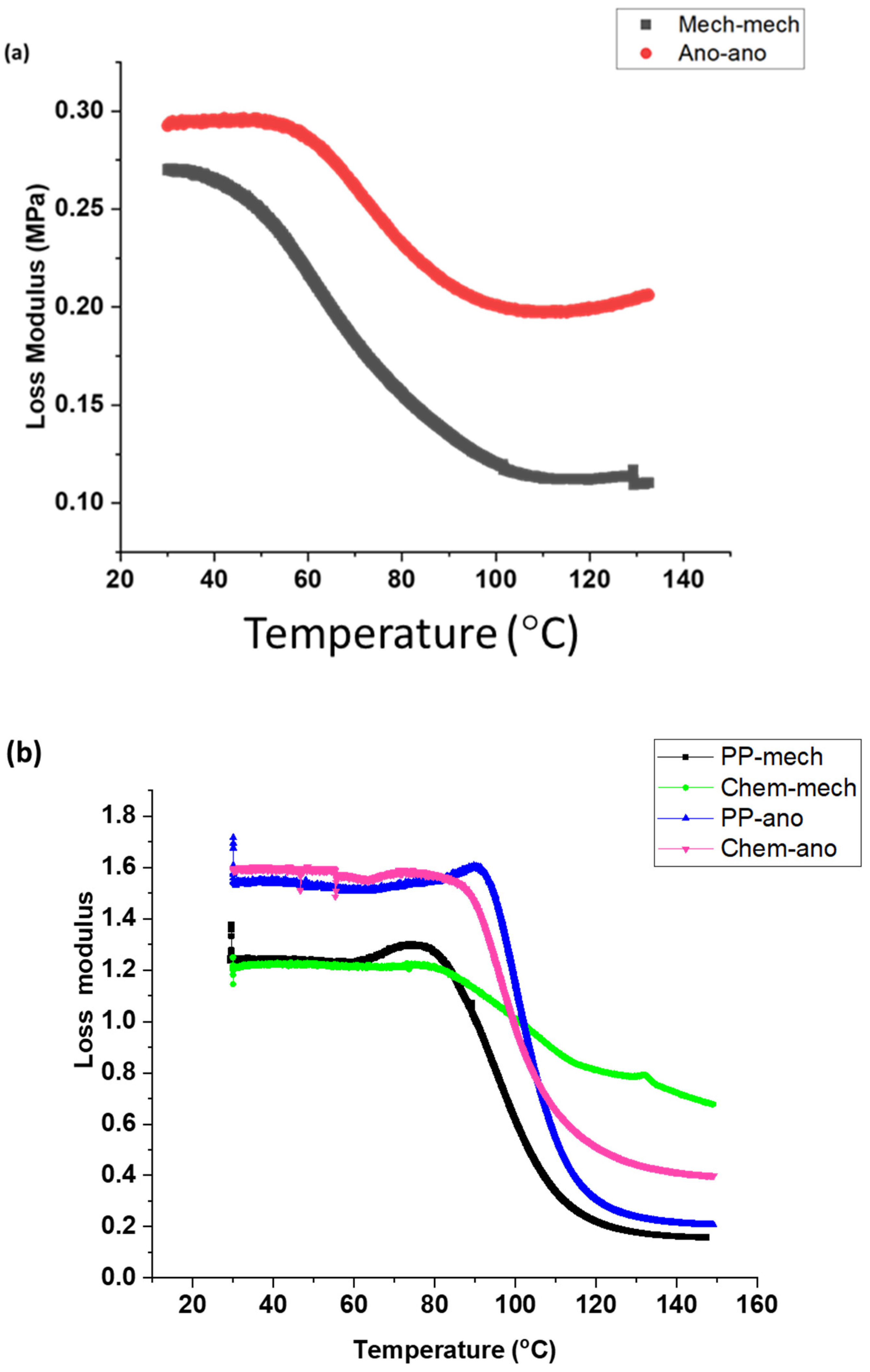

8.1. Loss Modulus

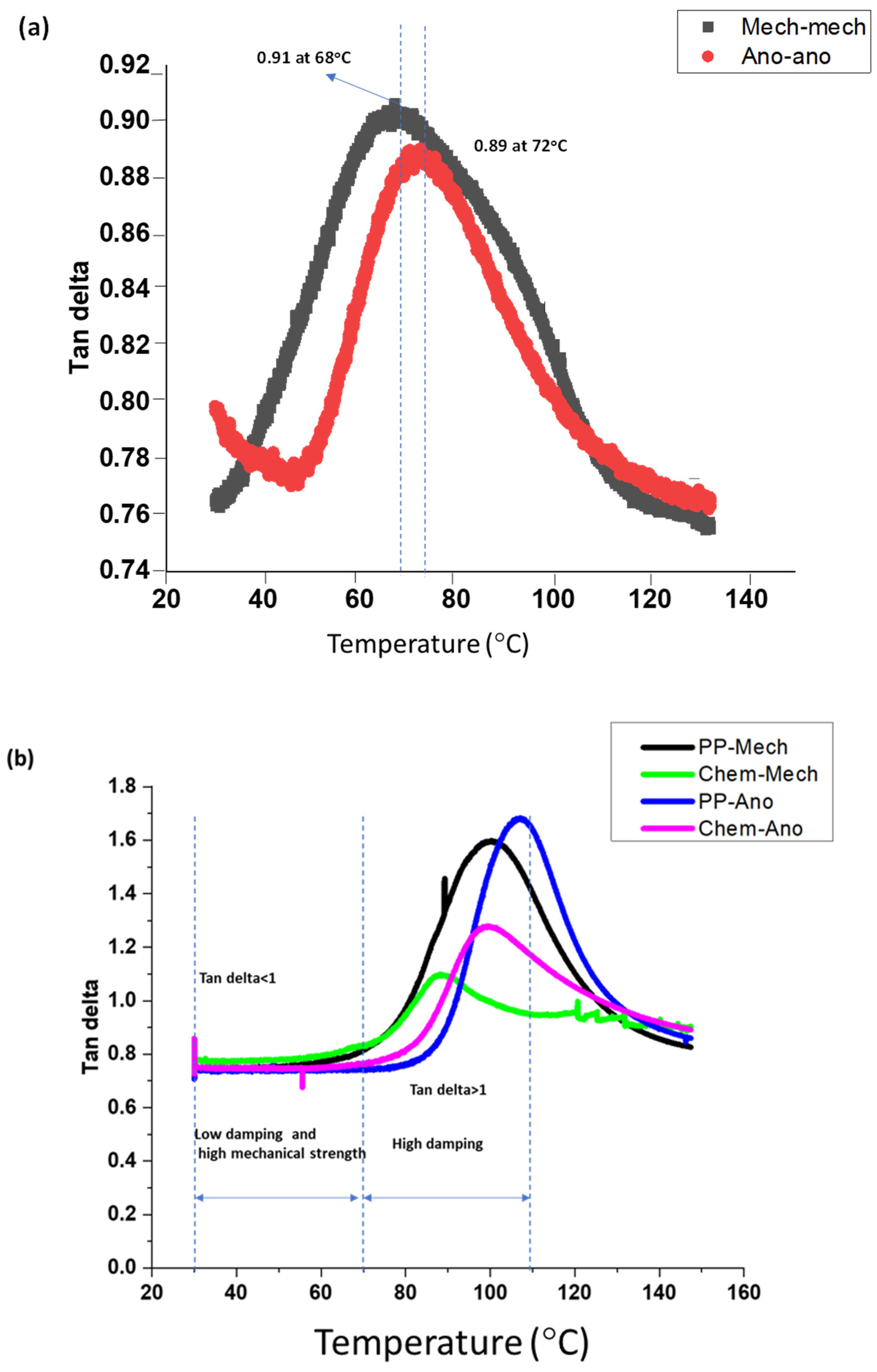

8.2. Tan Delta

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Du, G.; Li, Z.; Ran, X.; Zhou, X.; Li, T.; Gao, W.; Li, J.; Lei, H.; Yang, L. Superstrong Adhesive of Isocyanate-Free Polyurea with a Branched Structure. ACS Appl. Polym. Mater. 2021, 3, 1638–1651. [Google Scholar] [CrossRef]

- Rehman, M.M.; Shaker, K.; Nawab, Y. Effect of PEEK Particles on Physiomechanical Behavior of Carbon/Epoxy Composite. Int. J. Polym. Sci. 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- He, X.; Zhang, Y. Numerical Studies on Mechanical Behavior of Adhesive Joints. Adv. Mater. Sci. Eng. 2015, 2015, 1–13. [Google Scholar] [CrossRef]

- Adin, M.Ş.; Kılıçkap, E. Strength of double-reinforced adhesive joints. Mater. Test. 2021, 63, 176–181. [Google Scholar] [CrossRef]

- Gao, X.; Umair, M.; Nawab, Y.; Latif, Z.; Ahmad, S.; Siddique, A.; Yang, H. Mode I Fatigue of Fibre Reinforced Polymeric Composites: A Review. Polymers 2022, 14, 4558. [Google Scholar] [CrossRef] [PubMed]

- Nasreen, A.; Shaker, K.; Nawab, Y. Effect of Surface Treatments on Metal–Composite Adhesive Bonding for High-Performance Structures: An Overview. Compos. Interfaces 2021, 28, 1221–1256. [Google Scholar] [CrossRef]

- Yuan, J.; Du, G.; Yang, H.; Liu, S.; Wu, Y.; Ni, K.; Ran, X.; Gao, W.; Yang, L.; Li, J. Functionalization of cellulose with amine group and cross-linked with branched epoxy to construct high-performance wood adhesive. Int. J. Biol. Macromol. 2022, 222, 2719–2728. [Google Scholar] [CrossRef]

- Jiang, S.; Niu, H.; Wang, S.; Qian, Z.; Du, G.; Zhou, X.; Shen, Y.; Yang, Z.; Li, T. Novel and high-performance tannin-polyamine adhesive: New insight into phenol-amine chemistry. Ind. Crops Prod. 2023, 192, 116129. [Google Scholar] [CrossRef]

- Ke, L.; Li, C.; Luo, N.; He, J.; Jiao, Y.; Liu, Y. Enhanced Comprehensive Performance of Bonding Interface between CFRP and Steel by a Novel Film Adhesive. Compos. Struct. 2019, 229, 111393. [Google Scholar] [CrossRef]

- Sperandio, C.; Laachachi, A.; Ruch, D.; Poilâne, C.; Bourson, P.; Salvestrini, J.-P.; Ahzi, S. Use of Functionalized Nanosilica to Improve Thermo-Mechanical Properties of Epoxy Adhesive Joint Bonding Aluminium Substrates. J. Nanosci. Nanotechnol. 2010, 10, 2844–2849. [Google Scholar] [CrossRef]

- Krogh, L.; Schawe, J.E.K.; Possart, W. Dynamic Mechanical Properties of Very Thin Adhesive Joints. J. Appl. Polym. Sci. 2015, 132, 1–7. [Google Scholar] [CrossRef]

- Su, H.; Du, G.; Yang, H.; Wu, Y.; Liu, S.; Ni, K.; Ran, X.; Li, J.; Gao, W.; Yang, L. Novel ultrastrong wood bonding interface through chemical covalent crosslinking of aldehyde-amine. Ind. Crops Prod. 2022, 189, 115800. [Google Scholar] [CrossRef]

- Damm, J.; Ummenhofer, T.; Albiez, M. Influence of damping properties of adhesively bonded joints on the dynamic behaviour of steel structures: Numerical investigations. J. Adhes. 2022, 98, 934–962. [Google Scholar] [CrossRef]

- Nasreen, A.; Bangash, M.K.; Shaker, K.; Nawab, Y. Effect of Surface Treatment on the Performance of Composite-Composite and Composite-Metal Adhesive Joints. Polym. Compos. 2022, 43, 6320–6331. [Google Scholar] [CrossRef]

- Amuthakkannan, P.; Manikandan, V. Free Vibration and Dynamic Mechanical Properties of Basalt Fiber Reinforced Polymer Composites. Indian J. Eng. Mater. Sci. 2018, 25, 265–270. [Google Scholar]

- Causse, N.; Quiroga Cortes, L.; Dantras, E.; Tonon, C.; Chevalier, M.; Combes, H.; Guigue, P.; Lacabanne, C. New Bonded Assembly Configuration for Dynamic Mechanical Analysis of Adhesives. Int. J. Adhes. Adhes. 2013, 46, 1–6. [Google Scholar] [CrossRef]

- Casalegno, V.; Salvo, M.; Rizzo, S.; Goglio, L.; Damiano, O.; Ferraris, M. Joining of Carbon Fiber Reinforced Polymer to Al-Si Alloy for Space Applications. Int. J. Adhes. Adhes. 2018, 82, 146–152. [Google Scholar] [CrossRef]

- Ahmad, H.S.; Hussain, T.; Nawab, Y.; Salamat, S. Effect of Different Dielectric and Magnetic Nanoparticles on the Electrical, Mechanical, and Thermal Properties of Unidirectional Carbon Fiber-Reinforced Composites. Int. J. Polym. Sci. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Liu, S.; Wu, Y.; Du, G.; Yang, H.; Ni, K.; Su, H.; Ran, X.; Zhou, X.; Gao, W.; Yang, L. H2O2-mediated tannin bio-based wood adhesive inspired by starfish structure and phenol-amine synergy. Ind. Crops Prod. 2022, 188, 115714. [Google Scholar] [CrossRef]

- Shen, Y.; Tan, J.; Fernandes, L.; Qu, Z.; Li, Y. Dynamic mechanical analysis on delaminated flax fiber reinforced composites. Materials 2019, 12, 2559. [Google Scholar] [CrossRef]

- Onic, L.; Bucur, V.; Ansell, M.P.; Pizzi, A.; Deglise, X.; Merlin, A. Dynamic Thermomechanical Analysis as a Control Technique for Thermoset Bonding of Wood Joints. Int. J. Adhes. Adhes. 1998, 18, 89–94. [Google Scholar] [CrossRef]

- Kirmann, J.; Roizard, X.; Pagetti, J.; Halut, J. Effects of the Alkaline Permanganate Etching of Epoxy on the Peel Adhesion of Electrolessly Plated Copper on a Fibre-Reinforced Epoxy Composite. J. Adhes. Sci. Technol. 1998, 12, 383–397. [Google Scholar] [CrossRef]

- Young, G.L. Micro-Roughening of Epoxy and Cyanate Ester Laminates as a Precursor to Electroless Plating. Plat. Surf. Finish 2004, 91, 26–30. [Google Scholar]

- Digby, R.P.; Packham, D.E. Pretreatment of Aluminium: Topography, Surface Chemistry and Adhesive Bond Durability. Int. J. Adhes. Adhes. 1995, 15, 61–71. [Google Scholar] [CrossRef]

- Kanerva, M.; Saarela, O. The Peel Ply Surface Treatment for Adhesive Bonding of Composites: A Review. Int. J. Adhes. Adhes. 2013, 43, 60–69. [Google Scholar] [CrossRef]

- Boerio, F.J.; Roby, B.; Dillingham, R.G.; Bossi, R.H.; Crane, R.L. Effect of Grit-Blasting on the Surface Energy of Graphite/Epoxy Composites. J. Adhes. 2006, 82, 19–37. [Google Scholar] [CrossRef]

- Adin, H.; Adin, M.Ş. Effect of particles on tensile and bending properties of jute epoxy composites. Mater. Test 2022, 64, 401–411. [Google Scholar] [CrossRef]

- Rana, A.K.; Mitra, B.C.; Banerjee, A.N. Short Jute Fiber-Reinforced Polypropylene Composites: Dynamic Mechanical Study. J. Appl. Polym. Sci. 1999, 71, 531–539. [Google Scholar] [CrossRef]

| Brand Name | Physical Appearance | Lap Shear Strength | Temperature Resistance |

|---|---|---|---|

| Aremco 2310 | Paste | 33 MPa | −55 °C–165 °C |

| LY 564 | Film | 9 MPa | 25 °C–150 °C |

| Redux 312 | Film | 27 MPa | 25 °C–100 °C |

| Epibond 100 | Paste | 22.8 MPa | 25 °C–150 °C |

| AF163-2 | Film | 39 MPa | −55 °C–121 °C |

| Technical Name | Thickness (mm) | Tensile Strength in Longitudinal Direction (MPa) | Tensile Modulus Longitudinal Direction (GPa) |

|---|---|---|---|

| G-CFRP | 2 | 415 | 57 |

| Al 7075-T6 | 0.6 | 575 | 71 |

| Aremco 2310 | 0.6 | 33 | - |

| Serial No. | Type of Joint | Bonded Samples Coding | Surface Treatment | Actual Samples |

|---|---|---|---|---|

| 1 | Metal-metal | Mech-mech | Mechanical treatment on both metal substrates |  |

| 2 | Metal-metal | Ano-ano | Mechanical and anodizing treatment on both metal substrates |  |

| 3 | Composite-metal | PP-mech | Peel ply treatment on composite and mechanical treatment on metal |  |

| 4 | Composite-metal | PP-ano | Peel ply treatment on composite and anodizing on metal |  |

| 5 | Composite-metal | Chem-mech | Peel ply and chemical etching on composite and mechanical treatment on metal |  |

| 6 | Composite-metal | Chem-ano | Peel ply and chemical etching on composite and anodizing on metal |  |

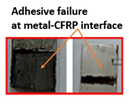

| Type of Joint | Type of Surface Treatment | Tensile Strength (MPa) | Impact Strength (KJ/m2) | Failure Surfaces after Tensile Test | Failure Surfaces after Impact Test |

|---|---|---|---|---|---|

| Mech-mech | Mechanical | 11.5 | 119 |  |  |

| Ano-ano | Anodizing | 12.6 | 224 |  |  |

| Mech-pp | Mechanical-peel ply | 8.41 | 50 |  |  |

| Ano-pp | Anodizing-peel ply | 9.83 | 95 |  |  |

| Mech-chem | Mechanical-chemical | 11.7 | 102 |  |  |

| Ano-chem | Anodizing-chemical | 12.5 | 147 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasreen, A.; Bangash, M.K.; Shaker, K.; Nawab, Y. Effect of Surface Treatment on Stiffness and Damping Behavior of Metal-Metal and Composite-Metal Adhesive Joints. Polymers 2023, 15, 435. https://doi.org/10.3390/polym15020435

Nasreen A, Bangash MK, Shaker K, Nawab Y. Effect of Surface Treatment on Stiffness and Damping Behavior of Metal-Metal and Composite-Metal Adhesive Joints. Polymers. 2023; 15(2):435. https://doi.org/10.3390/polym15020435

Chicago/Turabian StyleNasreen, Adeela, Muhammad Kashif Bangash, Khubab Shaker, and Yasir Nawab. 2023. "Effect of Surface Treatment on Stiffness and Damping Behavior of Metal-Metal and Composite-Metal Adhesive Joints" Polymers 15, no. 2: 435. https://doi.org/10.3390/polym15020435

APA StyleNasreen, A., Bangash, M. K., Shaker, K., & Nawab, Y. (2023). Effect of Surface Treatment on Stiffness and Damping Behavior of Metal-Metal and Composite-Metal Adhesive Joints. Polymers, 15(2), 435. https://doi.org/10.3390/polym15020435