Development of Raw Materials and Technology for Pulping—A Brief Review

Abstract

:1. Introduction

2. Pulping

2.1. Raw Materials for Pulping

2.2. Other Ingredients

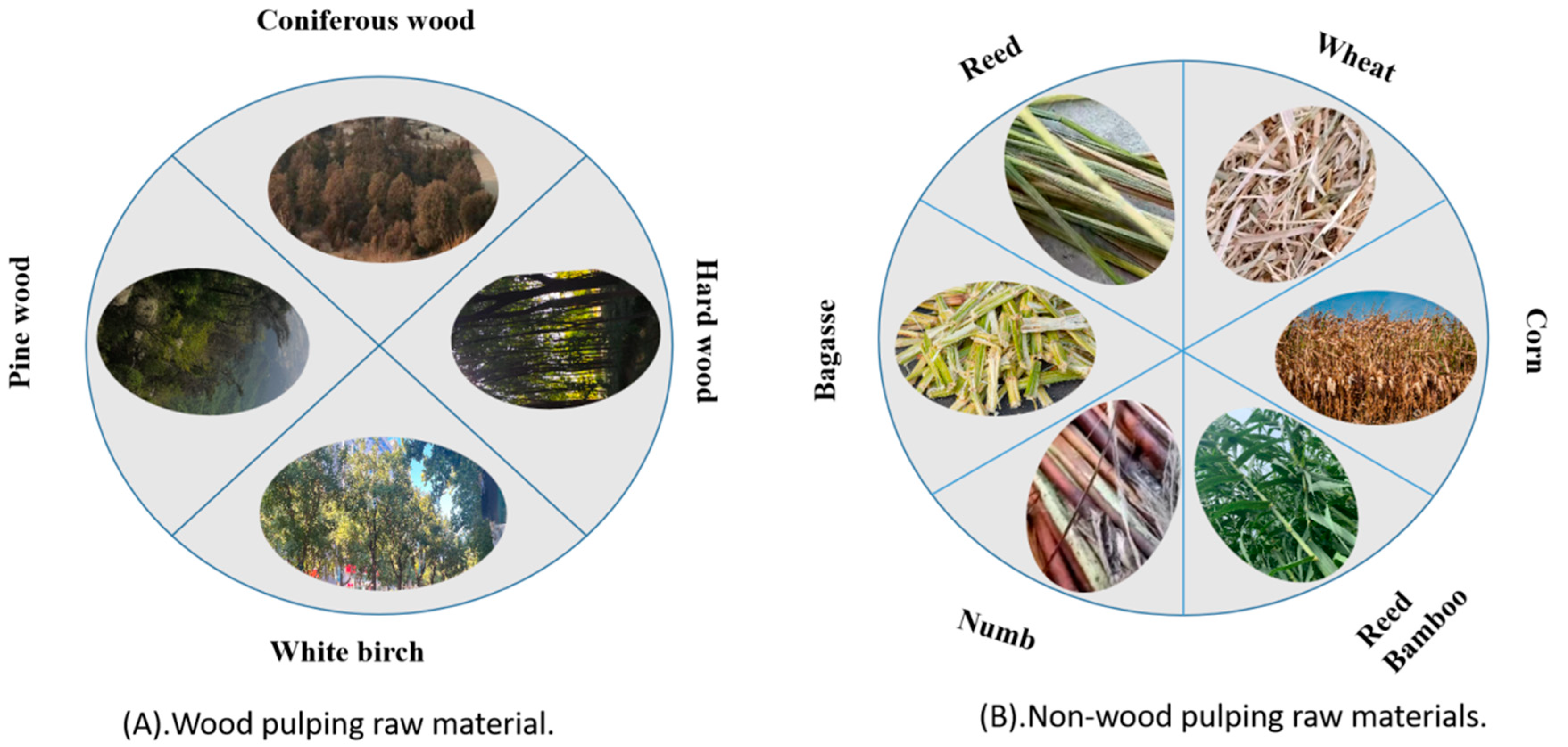

2.2.1. Wood Raw Material

2.2.2. Non-Wood Fiber Raw Materials

Corn Stalks

Wheat Straw

Bagasse

Rice Straw

Coconut Shell

Bamboo

Reeds

Hemp

Sorghum Stalks

Kenaf

Other Materials

3. Pulping Process

3.1. Traditional Pulping Process

3.2. Biopulping

3.3. Other Pulping Methods

4. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Abd El-Sayed, E.S.; El-Sakhawy, M.; El-Sakhawy, M.A.-M. Non-wood fibers as raw material for pulp and paper industry. Nord. Pulp Pap. Res. J. 2020, 35, 215–230. [Google Scholar] [CrossRef]

- Martins, G.S.; Yuliarto, M.; Antes, R.; Sabki; Prasetyo, A.; Unda, F.; Mansfield, S.D.; Hodge, G.R.; Acosta, J.J. Wood and Pulping Properties Variation of Acacia crassicarpa A.Cunn. ex Benth. and Sampling Strategies for Accurate Phenotyping. Forests 2020, 11, 1043. [Google Scholar] [CrossRef]

- Pokhrel, D.; Viraraghavan, T. Treatment of pulp and paper mill wastewater—A review. Sci. Total Environ. 2004, 333, 37–58. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Miscanthus × giganteus stalks as a potential non-wood raw material for the pulp and paper industry. Influence of pulping and beating conditions on the fibre and paper properties. Ind. Crops Prod. 2019, 141, 111744. [Google Scholar] [CrossRef]

- H, W.R. A Text-book of Paper-making. Nature 1889, 40, 414. [Google Scholar] [CrossRef]

- Sandberg, C.; Hill, J.; Jackson, M. On the development of the refiner mechanical pulping process—A review. Nord. Pulp Pap. Res. J. 2020, 35, 1–17. [Google Scholar] [CrossRef]

- Vidaurre, G.B.; Pereira, M.; Boschetti, W.T.N.; Patt, R.; Colodette, J.L.; Vital, B.R.; de Almeida, M.N.F. NSSC pulping of fast growing trees. Nord. Pulp Pap. Res. J. 2018, 33, 404–413. [Google Scholar] [CrossRef]

- Fardim, P.; Durán, N. Surface Chemistry of Eucalyptus Wood Pulp Fibres: Effects of Chemical Pulping. Holzforschung 2002, 56, 615–622. [Google Scholar] [CrossRef]

- Taher-Ghahremani, F.; Omidvari, M. Providing an evaluation model of Green Productivity in paper-making industries. Int. J. Environ. Sci. Technol. 2017, 15, 333–340. [Google Scholar] [CrossRef]

- Sundholm, J. History of mechanical pulping. In Mechanical Pulping; Sundholm, J., Ed.; Fapet Oy: Jyväskylä, Finland, 1999. [Google Scholar]

- Rubin, E.M. Genomics of cellulosic biofuels. Nature 2008, 454, 841–845. [Google Scholar] [CrossRef]

- Musekiwa, P.; Moyo, L.B.; Mamvura, T.A.; Danha, G.; Simate, G.S.; Hlabangana, N. Optimization of pulp production from groundnut shells using chemical pulping at low temperatures. Heliyon 2020, 6, e04184. [Google Scholar] [CrossRef]

- Dimmel, D.R.; MacKay, J.J.; Courchene, C.E.; Kadla, J.F.; Scott, J.T.; O’Malley, D.M.; McKeand, S.E. Pulping and Bleaching of Partially Cad-Deficient Wood. J. Wood Chem. Technol. 2002, 22, 235–248. [Google Scholar] [CrossRef]

- Xue, L.; Han, H.; Fan, H.; Li, P.; Wang, T.; Xiao, J.; Wang, R.; Wang, J. Construction and Application of Low Cellulase-producing Bacillus licheniformis Strains for Bio-pulping of Bamboo. Biotechnol. Bioprocess Eng. 2019, 24, 810–817. [Google Scholar] [CrossRef]

- Sharma, N.; Tripathi, S.K.; Bhardwaj, N.K. Utilization of sarkanda for making pulp and paper using elemental chlorine free and total chlorine free bleaching processes. Ind. Crops Prod. 2020, 149, 112316. [Google Scholar] [CrossRef]

- Amode, N.S.; Jeetah, P. Paper Production from Mauritian Hemp Fibres. Waste Biomass Valorization 2020, 12, 1781–1802. [Google Scholar] [CrossRef]

- Mandeep; Kumar Gupta, G.; Shukla, P. Insights into the resources generation from pulp and paper industry wastes: Challenges, perspectives and innovations. Bioresour. Technol. 2020, 297, 122496. [Google Scholar] [CrossRef]

- Khiari, R.; Mhenni, M.F.; Belgacem, M.N.; Mauret, E. Chemical composition and pulping of date palm rachis and Posidonia oceanica--a comparison with other wood and non-wood fibre sources. Bioresour. Technol. 2010, 101, 775–780. [Google Scholar] [CrossRef]

- Tripathi, S.K.; Alam, I.; Bhardwaj, N.K. Effect of bark content in mixed hardwood chips on pulp and papermaking properties. Nord. Pulp Pap. Res. J. 2020, 35, 325–331. [Google Scholar] [CrossRef]

- Khristova, P.; Kordsachia, O.; Patt, R.; Dafaalla, S. Alkaline pulping of some eucalypts from Sudan. Bioresour. Technol. 2006, 97, 535–544. [Google Scholar] [CrossRef]

- dos Santos Muguet, M.C.; Ruuttunen, K.; Jääskeläinen, A.-S.; Colodette, J.L.; Vuorinen, T. Thermomechanical pulping of novel Brazilian Eucalyptus hybrids. Holzforschung 2013, 67, 489–495. [Google Scholar] [CrossRef]

- Yi, T.; Zhao, H.; Mo, Q.; Pan, D.; Liu, Y.; Huang, L.; Xu, H.; Hu, B.; Song, H. From Cellulose to Cellulose Nanofibrils-A Comprehensive Review of the Preparation and Modification of Cellulose Nanofibrils. Materials 2020, 13, 5062. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.C.; Murthy, Z.V.P. Study of cellulosic fibres morphological features and their modifications using hemicelluloses. Cellulose 2017, 24, 3119–3130. [Google Scholar] [CrossRef]

- Du, H.; Parit, M.; Wu, M.; Che, X.; Wang, Y.; Zhang, M.; Wang, R.; Zhang, X.; Jiang, Z.; Li, B. Sustainable valorization of paper mill sludge into cellulose nanofibrils and cellulose nanopaper. J. Hazard. Mater. 2020, 400, 123106. [Google Scholar] [CrossRef]

- Henschen, J.; Li, D.; Ek, M. Preparation of cellulose nanomaterials via cellulose oxalates. Carbohydr. Polym. 2019, 213, 208–216. [Google Scholar] [CrossRef] [PubMed]

- da Costa Correia, V.; Santos, S.F.; Soares Teixeira, R.; Savastano Junior, H. Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr. Build. Mater. 2018, 160, 376–384. [Google Scholar] [CrossRef]

- Xia, F.; Liu, H.; Lu, J.; Lv, Y.; Zhai, S.; An, Q.; Cheng, Y.; Wang, H. An integrated biorefinery process to produce butanol and pulp from corn straw. Ind. Crops Prod. 2019, 140, 111648. [Google Scholar] [CrossRef]

- Zhang, S.; Xiao, J.; Wang, G.; Chen, G. Enzymatic hydrolysis of lignin by ligninolytic enzymes and analysis of the hydrolyzed lignin products. Bioresour. Technol. 2020, 304, 122975. [Google Scholar] [CrossRef]

- Andrade Alves, J.A.; Lisboa Dos Santos, M.D.; Morais, C.C.; Ramirez Ascheri, J.L.; Signini, R.; Dos Santos, D.M.; Cavalcante Bastos, S.M.; Ramirez Ascheri, D.P. Sorghum straw: Pulping and bleaching process optimization and synthesis of cellulose acetate. Int. J. Biol. Macromol. 2019, 135, 877–886. [Google Scholar] [CrossRef]

- Rodriguez, A.; Moral, A.; Serrano, L.; Labidi, J.; Jimenez, L. Rice straw pulp obtained by using various methods. Bioresour. Technol. 2008, 99, 2881–2886. [Google Scholar] [CrossRef]

- Belle, J.; Odermatt, J. Initial wet web strength of paper. Cellulose 2016, 23, 2249–2272. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- Sharma, N.; Bhardwaj, N.K.; Singh, R.B.P. Environmental issues of pulp bleaching and prospects of peracetic acid pulp bleaching: A review. J. Clean. Prod. 2020, 256, 120338. [Google Scholar] [CrossRef]

- Fearon, O.; Kuitunen, S.; Ruuttunen, K.; Alopaeus, V.; Vuorinen, T. Detailed Modeling of Kraft Pulping Chemistry. Delignification. Ind. Eng. Chem. Res. 2020, 59, 12977–12985. [Google Scholar] [CrossRef]

- Gao, X.; Li, M.; Zhang, H.; Tang, X.; Chen, K. Fabrication of regenerated cellulose films by DMAc dissolution using parenchyma cells via low-temperature pulping from Yunnan-endemic bamboos. Ind. Crops Prod. 2021, 160, 113116. [Google Scholar] [CrossRef]

- Feng, Z.; Alén, R. Soda-AQ pulping of reed canary grass. Ind. Crops Prod. 2001, 14, 31–39. [Google Scholar] [CrossRef]

- Liu, H.; Pang, B.; Zhou, J.; Han, Y.; Lu, J.; Li, H.; Wang, H. Comparative study of pretreated corn stover for sugar production using cotton pulping black liquor (CPBL) instead of sodium hydroxide. Ind. Crops Prod. 2016, 84, 97–103. [Google Scholar] [CrossRef]

- Gupta, R.; Lee, Y.Y. Pretreatment of corn stover and hybrid poplar by sodium hydroxide and hydrogen peroxide. Biotechnol. Prog. 2010, 26, 1180–1186. [Google Scholar] [CrossRef]

- He, Z.-X.; Shen, W.-X.; Li, Q.-b.; Xu, S.-C.; Zhao, B.; Long, R.-Y.; Chen, H. Investigating external and internal pressures on corporate environmental behavior in papermaking enterprises of China. J. Clean. Prod. 2018, 172, 1193–1211. [Google Scholar] [CrossRef]

- Yusuf, S.; Syamani, F.A.; Fatriasari, W.; Subyakto. Review on Bamboo Utilization as Biocomposites, Pulp and Bioenergy. IOP Conf. Ser. Earth Environ. Sci. 2018, 141, 12039. [Google Scholar] [CrossRef]

- Jahan, M.S.; Haris, F.; Rahman, M.M.; Samaddar, P.R.; Sutradhar, S. Potassium hydroxide pulping of rice straw in biorefinery initiatives. Bioresour. Technol. 2016, 219, 445–450. [Google Scholar] [CrossRef]

- Ahlawat, S.; Mandhan, R.P.; Dhiman, S.S.; Kumar, R.; Sharma, J. Potential application of alkaline pectinase from Bacillus subtilis SS in pulp and paper industry. Appl. Biochem. Biotechnol. 2008, 149, 287–293. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Wen, Y.; Kapu, N.S.; Beatson, R.; Mark Martinez, D. A biorefinery scheme to fractionate bamboo into high-grade dissolving pulp and ethanol. Biotechnol. Biofuels. 2017, 10, 38. [Google Scholar] [CrossRef] [PubMed]

- Lipiäinen, S.; Kuparinen, K.; Vakkilainen, E. Effect of polysulfide pulping process on the energy balance of softwood and hardwood kraft pulp mills. Nord. Pulp Pap. Res. J. 2021, 36, 570–581. [Google Scholar] [CrossRef]

- Jámbor, A.; Török, Á. The Economics of Arundo donax—A Systematic Literature Review. Sustainability 2019, 11, 4225. [Google Scholar] [CrossRef]

- Pakkanen, H.; Alén, R. Alkali consumption of aliphatic carboxylic acids during alkaline pulping of wood and nonwood feedstocks. Holzforschung 2013, 67, 643–650. [Google Scholar] [CrossRef]

- Yue, F.; Chen, K.L.; Lu, F. Low Temperature Soda-Oxygen Pulping of Bagasse. Molecules 2016, 21, 85. [Google Scholar] [CrossRef]

- Singh, P.; Dubey, P.; Younis, K.; Yousuf, O. A review on the valorization of coconut shell waste. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Ferdous, T.; Quaiyyum, M.A.; Bashar, S.; Jahan, M.S. Anatomical, morphological and chemical characteristics of kaun straw (Seetaria-ltalika). Nord. Pulp Pap. Res. J. 2020, 35, 288–298. [Google Scholar] [CrossRef]

- Li, H.; Sun, H.; He, Z. Achnatherum inebrians straw as a potential raw material for pulp and paper production. J. Clean. Prod. 2015, 101, 193–196. [Google Scholar] [CrossRef]

- Mboowa, D. A review of the traditional pulping methods and the recent improvements in the pulping processes. Biomass Convers. Biorefinery 2021, 35, 219–229. [Google Scholar] [CrossRef]

- Mboowa, D.; Khatri, V.; Saddler, J.N. The use of fluorescent protein-tagged carbohydrate-binding modules to evaluate the influence of drying on cellulose accessibility and enzymatic hydrolysis. RSC Adv. 2020, 10, 27152–27160. [Google Scholar] [CrossRef] [PubMed]

- Paananen, M.; Sixta, H. High-alkali low-temperature polysulfide pulping (HALT) of Scots pine. Bioresour. Technol. 2015, 193, 97–102. [Google Scholar] [CrossRef] [PubMed]

- Jahan, M.S.; Rahman, M.M.; Ni, Y. Alternative initiatives for non-wood chemical pulping and integration with the biorefinery concept: A review. Biofuels Bioprod. Biorefining 2020, 15, 100–118. [Google Scholar] [CrossRef]

- Popy, R.S.; Nayeem, J.; Arafat, K.M.Y.; Rahman, M.M.; Jahan, M.S. Mild potassium hydroxide pulping of straw. Curr. Res. Green Sustain. Chem. 2020, 3, 100015. [Google Scholar] [CrossRef]

- Sahin, H.T.; Young, R.A. Auto-catalyzed acetic acid pulping of jute. Ind. Crops Prod. 2008, 28, 24–28. [Google Scholar] [CrossRef]

- Pydimalla, M.; Muthyala, B.R.; Adusumalli, R.B. Influence of Temperature on Kraft Pulping of Whole Bagasse and Depithed Bagasse. Sugar Tech. 2019, 21, 1003–1015. [Google Scholar] [CrossRef]

- Singh, M.; Pant, M.; Godiyal, R.D.; Kumar Sharma, A. MCDM approach for selection of raw material in pulp and papermaking industry. Mater. Manuf. Process. 2020, 35, 241–249. [Google Scholar] [CrossRef]

- Stier, J.C. Technological substitution in the United States pulp and paper industry: The sulfate pulping process. Technol. Forecast. Soc. Chang. 1983, 23, 237–245. [Google Scholar] [CrossRef]

- Varghese, L.M.; Agrawal, S.; Nagpal, R.; Mishra, O.P.; Bhardwaj, N.K.; Mahajan, R. Eco-friendly pulping of wheat straw using crude xylano-pectinolytic concoction for manufacturing good quality paper. Env. Sci. Pollut. Res. Int. 2020, 27, 34574–34582. [Google Scholar] [CrossRef]

- Wang, X.; Xie, J.; Zhang, H.; Zhang, W.; An, S.; Chen, S.; Luo, C. Determining the lignin distribution in plant fiber cell walls based on chemical and biological methods. Cellulose 2019, 26, 4241–4252. [Google Scholar] [CrossRef]

- Xu, H.; Chen, K.; Zhang, L.; Wu, Y. Synchronous Silicon Removal and Viscosity Reduction in the Soda-Oxygen Pulping of Wheat Straw. Res. Sq. 2021. [Google Scholar] [CrossRef]

- Ashori, A.; Raverty, W.D.; Vanderhoek, N.; Ward, J.V. Surface topography of kenaf (Hibiscus cannabinus) sized papers. Bioresour. Technol. 2008, 99, 404–410. [Google Scholar] [CrossRef] [PubMed]

- Karakus, S.; Roy, D.N.; Goel, K. Chemical and Soda Pulping Properties of Kenaf as a Function of Growth. J. Wood Chem. Technol. 2001, 21, 157–167. [Google Scholar] [CrossRef]

- Yaghoubi, K.; Pazouki, M.; Shojaosadati, S.A. Variable optimization for biopulping of agricultural residues by Ceriporiopsis subvermispora. Bioresour. Technol. 2008, 99, 4321–4328. [Google Scholar] [CrossRef] [PubMed]

- Jia, M.; Sun, M.; Li, X.; Xu, X.; Wang, Y.; Shi, L.; Hu, H. A new era of straw-based pulping? Evidence from a carbon metabolism perspective. J. Clean. Prod. 2018, 193, 327–337. [Google Scholar] [CrossRef]

- Zhou, H.; Han, S.; Shen, K.; Zhao, M.; Huang, C.; Fang, G.; Wu, Y.; Huang, H.; He, Z. A novel clean bio-pulping process for rice straw based on aerobic fermentation coupled with mechanical refining. Environ. Technol. Innov. 2023, 31, 103146. [Google Scholar] [CrossRef]

- Li, F.; Zhao, Y.; Xue, L.; Ma, F.; Dai, S.Y.; Xie, S. Microbial lignin valorization through depolymerization to aromatics conversion. Trends. Biotechnol. 2022, 40, 1469–1487. [Google Scholar] [CrossRef]

- Clark, J.D.A. Pulp technology and treatment for paper. In Pulp Technology and Treatment for Paper; Miller Freeman Publications, Inc.: San Francisco, CA, USA, 1985. [Google Scholar]

- Afrifah, K.A.; Osei, L.; Ofosu, S. Suitability of Four Varieties of Cocos Nucifera Husk in Ghana for Pulp and Paper Production. J. Nat. Fibers 2021, 19, 4654–4661. [Google Scholar] [CrossRef]

- Kose, R.; Yamaguchi, K.; Okayama, T. Preparation of fine fiber sheets from recycled pulp fibers using aqueous counter collision. Cellulose 2016, 23, 1393–1399. [Google Scholar] [CrossRef]

- Jahan, M.S.; Mostafizur Rahman, J.N.M.; Islam, M.; Quaiyyum, M.A. Chemical characteristics of ribbon retted jute and its effect on pulping and papermaking properties. Ind. Crops Prod. 2016, 84, 116–120. [Google Scholar] [CrossRef]

- Bajpai, P. Application of enzymes in the pulp and paper industry. Biotechnol. Prog. 1999, 15, 147–157. [Google Scholar] [CrossRef]

- Saleh, T.M.; El-Ashmawy, A.E. Alkaline pulping of mixed reed and bagasse. J. Chem. Technol. Biotechnol. 1978, 28, 721–726. [Google Scholar] [CrossRef]

- Nagpal, R.; Bhardwaj, N.K.; Mishra, O.P.; Mahajan, R. Cleaner bio-pulping approach for the production of better strength rice straw paper. J. Clean. Prod. 2021, 318, 128539. [Google Scholar] [CrossRef]

- Lin, X.; Wu, Z.; Zhang, C.; Liu, S.; Nie, S. Enzymatic pulping of lignocellulosic biomass. Ind. Crops Prod. 2018, 120, 16–24. [Google Scholar] [CrossRef]

- Pérez, E.; Abad-Fernández, N.; Lourençon, T.; Balakshin, M.; Sixta, H.; Cocero, M.J. Base-catalysed depolymerization of lignins in supercritical water: Influence of lignin nature and valorisation of pulping and biorefinery by-products. Biomass Bioenergy 2022, 163, 106536. [Google Scholar] [CrossRef]

- Hernandez-Hernandez, H.M.; Chanona-Perez, J.J.; Vega, A.; Ligero, P.; Farrera-Rebollo, R.R.; Mendoza-Perez, J.A.; Calderon-Dominguez, G.; Vera, N.G. Spectroscopic and Microscopic Study of Peroxyformic Pulping of Agave Waste. Microsc. Microanal. 2016, 22, 1084–1097. [Google Scholar] [CrossRef]

- Malik, S.; Rana, V.; Joshi, G.; Gupta, P.K.; Sharma, A. Valorization of Wheat Straw for the Paper Industry: Pre-extraction of Reducing Sugars and Its Effect on Pulping and Papermaking Properties. ACS Omega 2020, 5, 30704–30715. [Google Scholar] [CrossRef]

| Raw Materials | Cellulose (%) | Hemicellulose (%) | Lignin (%) |

|---|---|---|---|

| Hardwood | 43–47 | 25–35 | 16–24 |

| Coniferous Wood | 42–50 | 24–34 | 15–22 |

| Bagasse | 40 | 30 | 30 |

| Corn stalk | 37 | 25 | 35 |

| Wheat | 43.7 | 23 | 22.3 |

| Rice | 43 | 25 | 16 |

| Cizhu | 46 | 32 | 12 |

| Reed Bamboo | 48 | 26 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Xu, Y.; Yin, L.; Liang, X.; Wang, R.; Liu, K. Development of Raw Materials and Technology for Pulping—A Brief Review. Polymers 2023, 15, 4465. https://doi.org/10.3390/polym15224465

Li P, Xu Y, Yin L, Liang X, Wang R, Liu K. Development of Raw Materials and Technology for Pulping—A Brief Review. Polymers. 2023; 15(22):4465. https://doi.org/10.3390/polym15224465

Chicago/Turabian StyleLi, Piwu, Yanpeng Xu, Liang Yin, Xiaoli Liang, Ruiming Wang, and Kaiquan Liu. 2023. "Development of Raw Materials and Technology for Pulping—A Brief Review" Polymers 15, no. 22: 4465. https://doi.org/10.3390/polym15224465

APA StyleLi, P., Xu, Y., Yin, L., Liang, X., Wang, R., & Liu, K. (2023). Development of Raw Materials and Technology for Pulping—A Brief Review. Polymers, 15(22), 4465. https://doi.org/10.3390/polym15224465