Assessment of Binder Modification in Dry-Added Waste Plastic Modified Asphalt

Abstract

1. Introduction

2. Materials

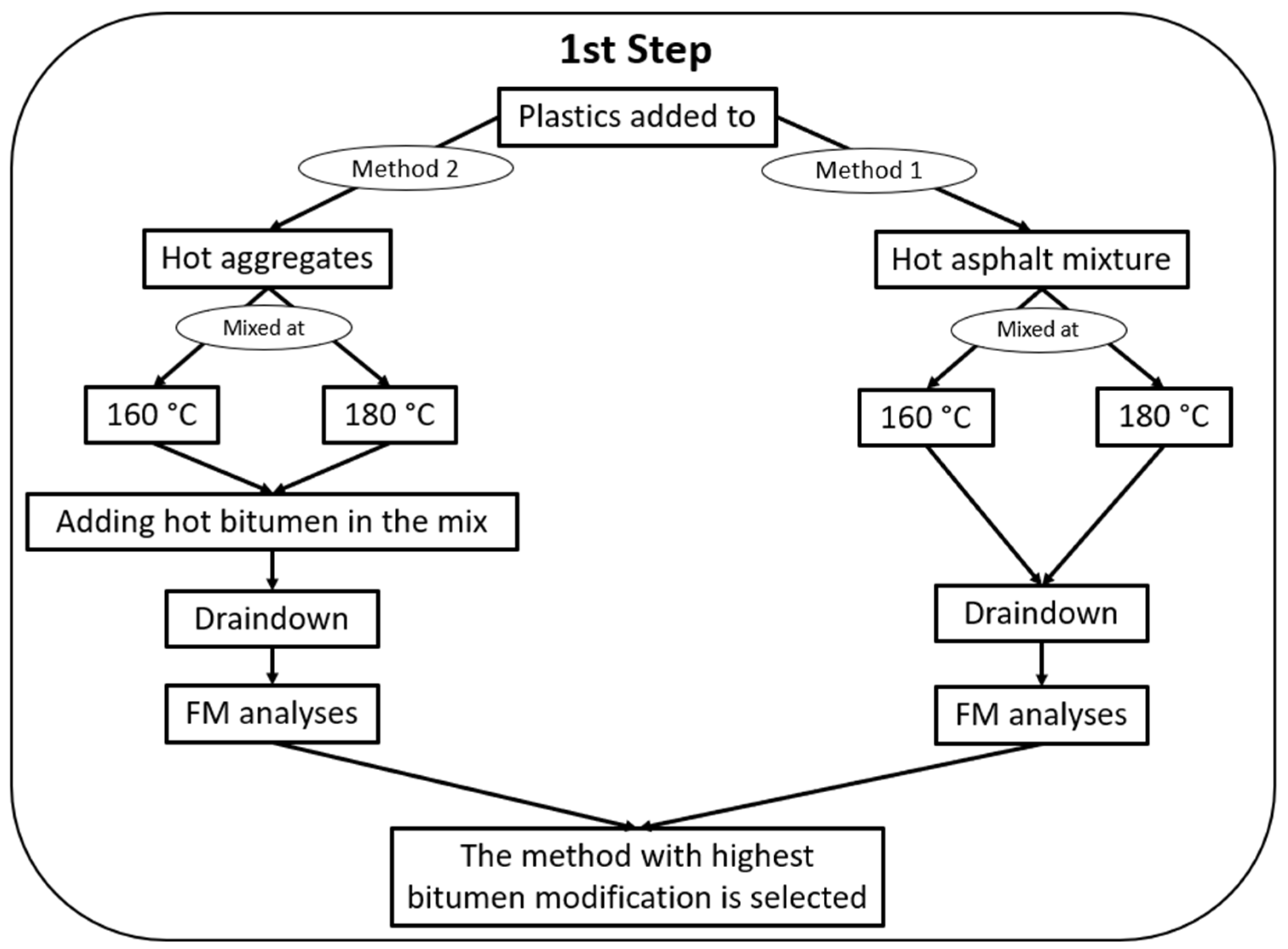

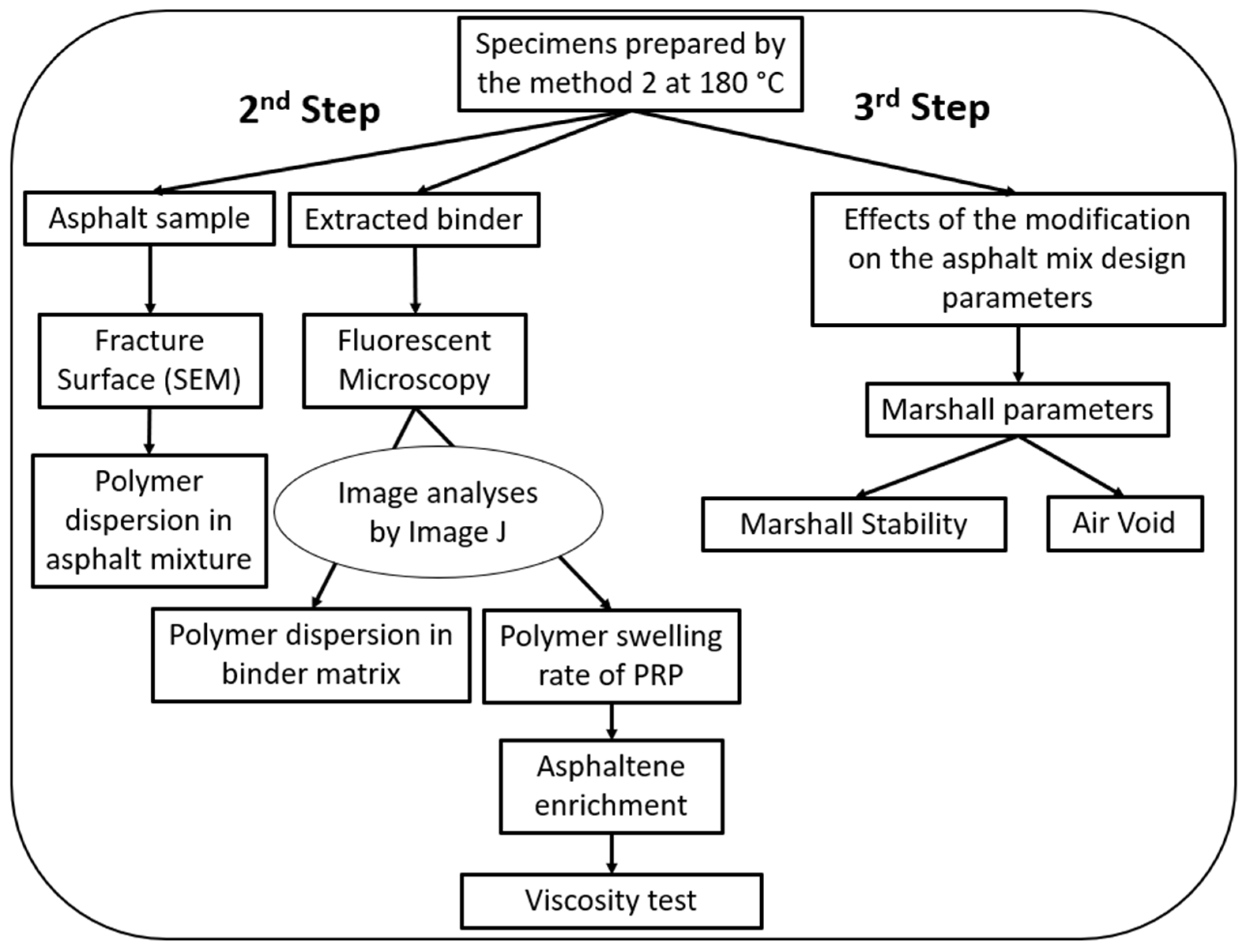

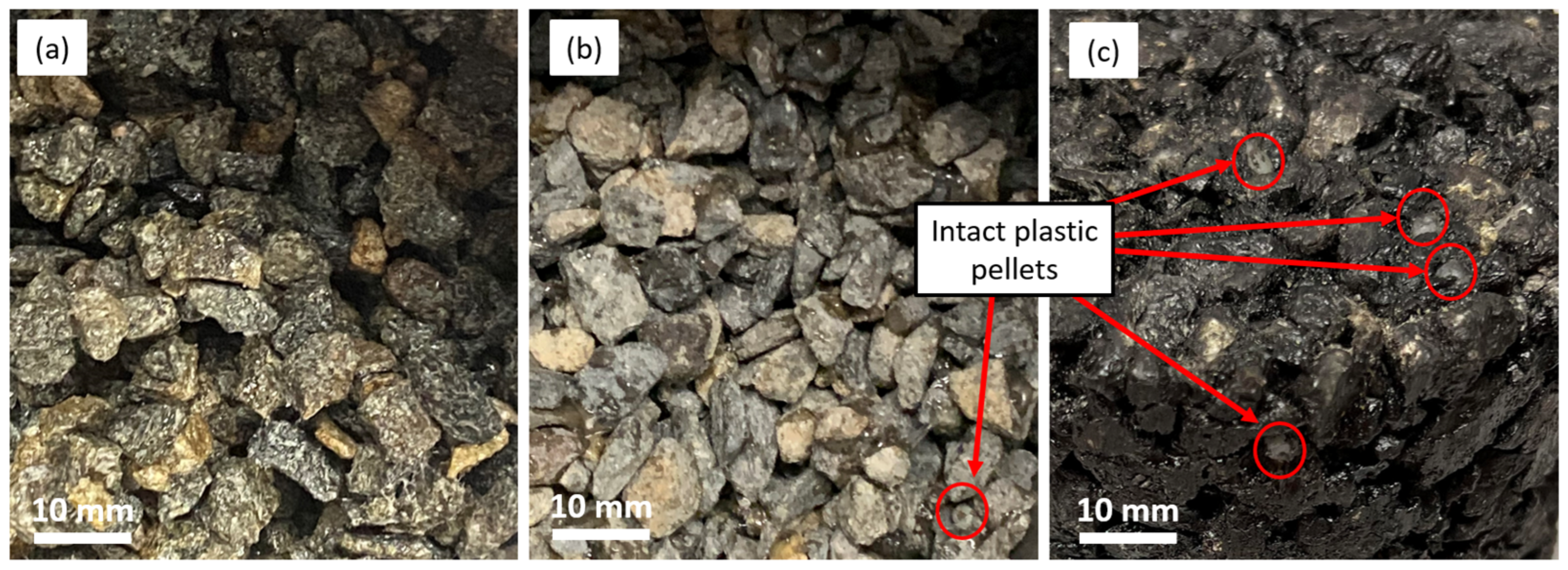

3. Research Methodology

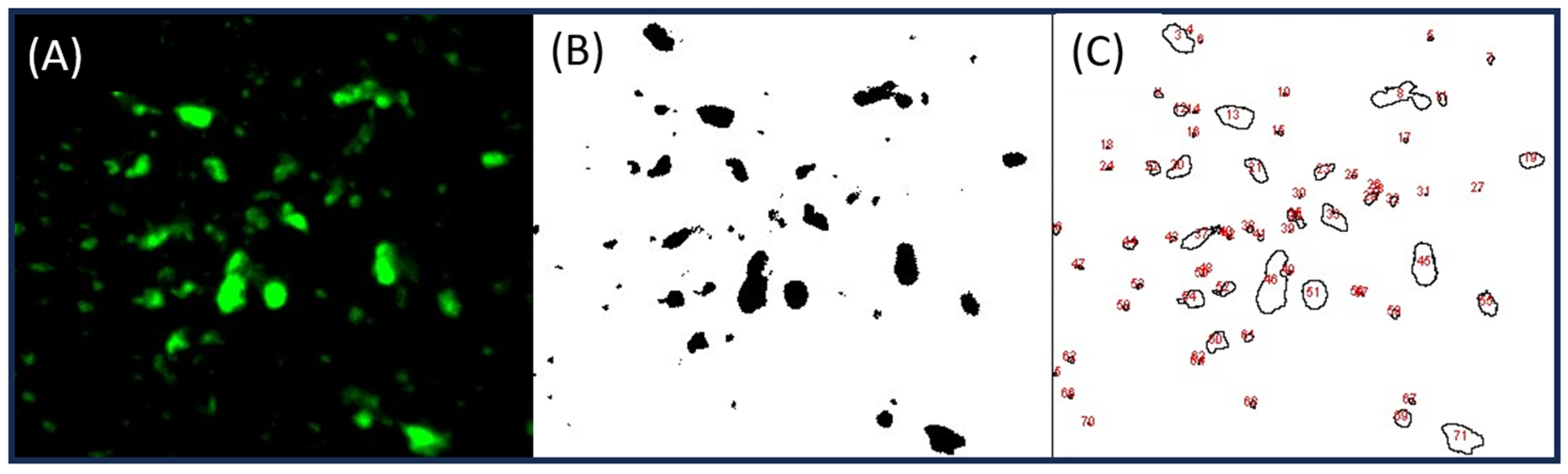

3.1. Methodology, Mixing Methods and Sample Preparation

3.2. Marshall and Draindown Tests

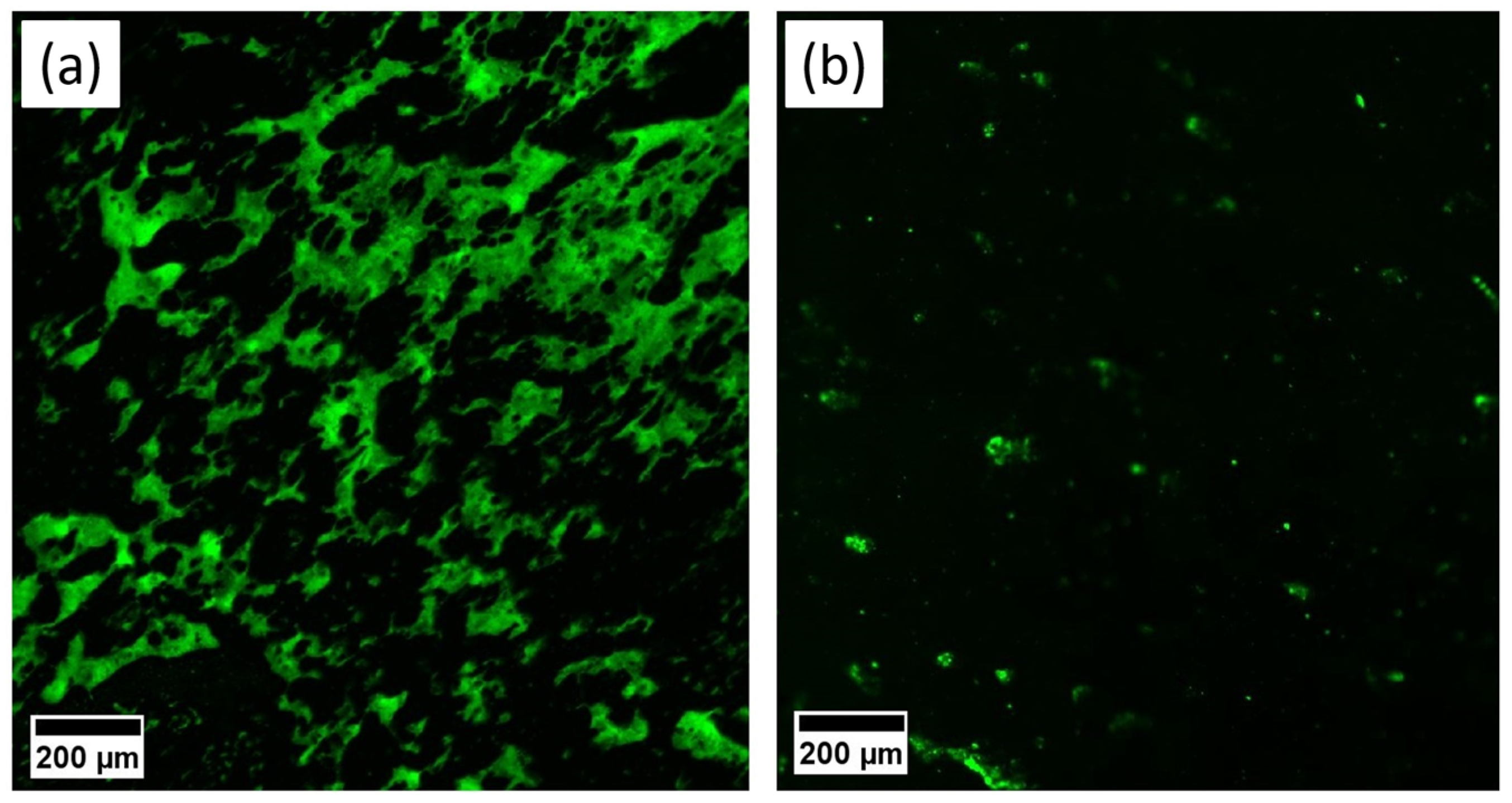

3.3. Fluorescent Microscopy

3.4. Fracture Surface Analyses Using Scanning Electron Microscope

3.5. Viscosity Test

4. Results and Discussion

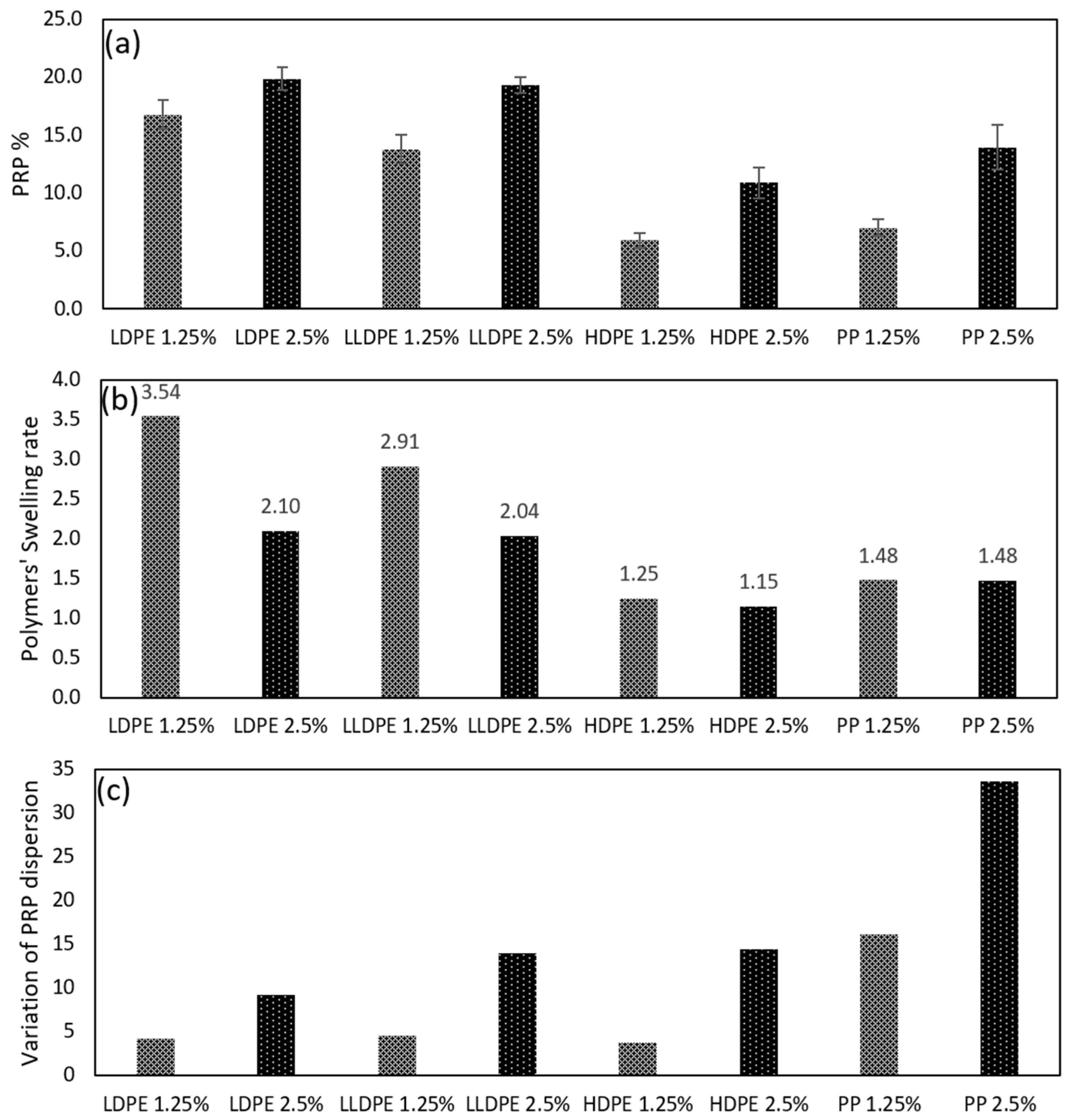

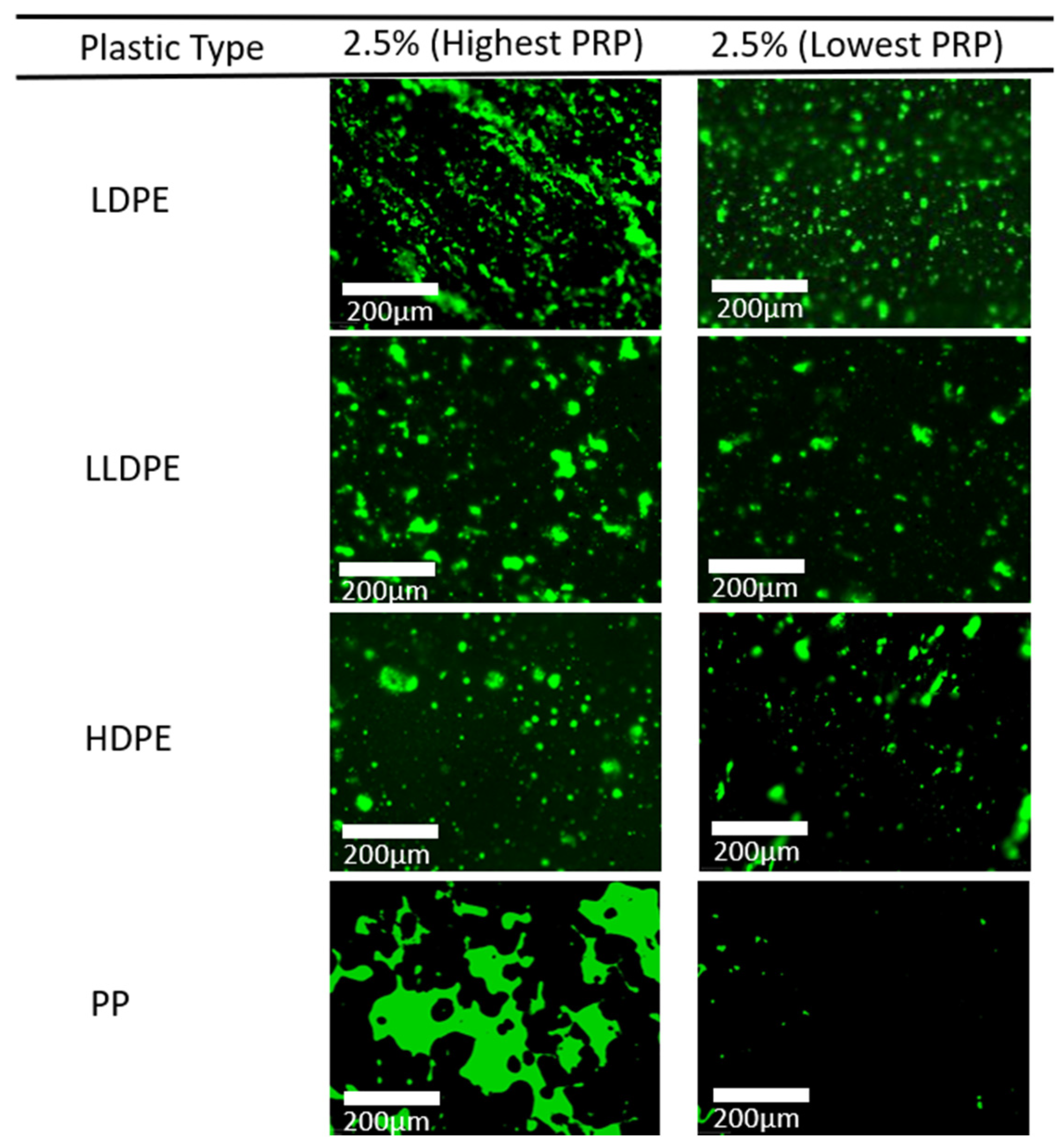

4.1. Swelling Rate and Dispersion of Plastics in the Asphalt Matrix

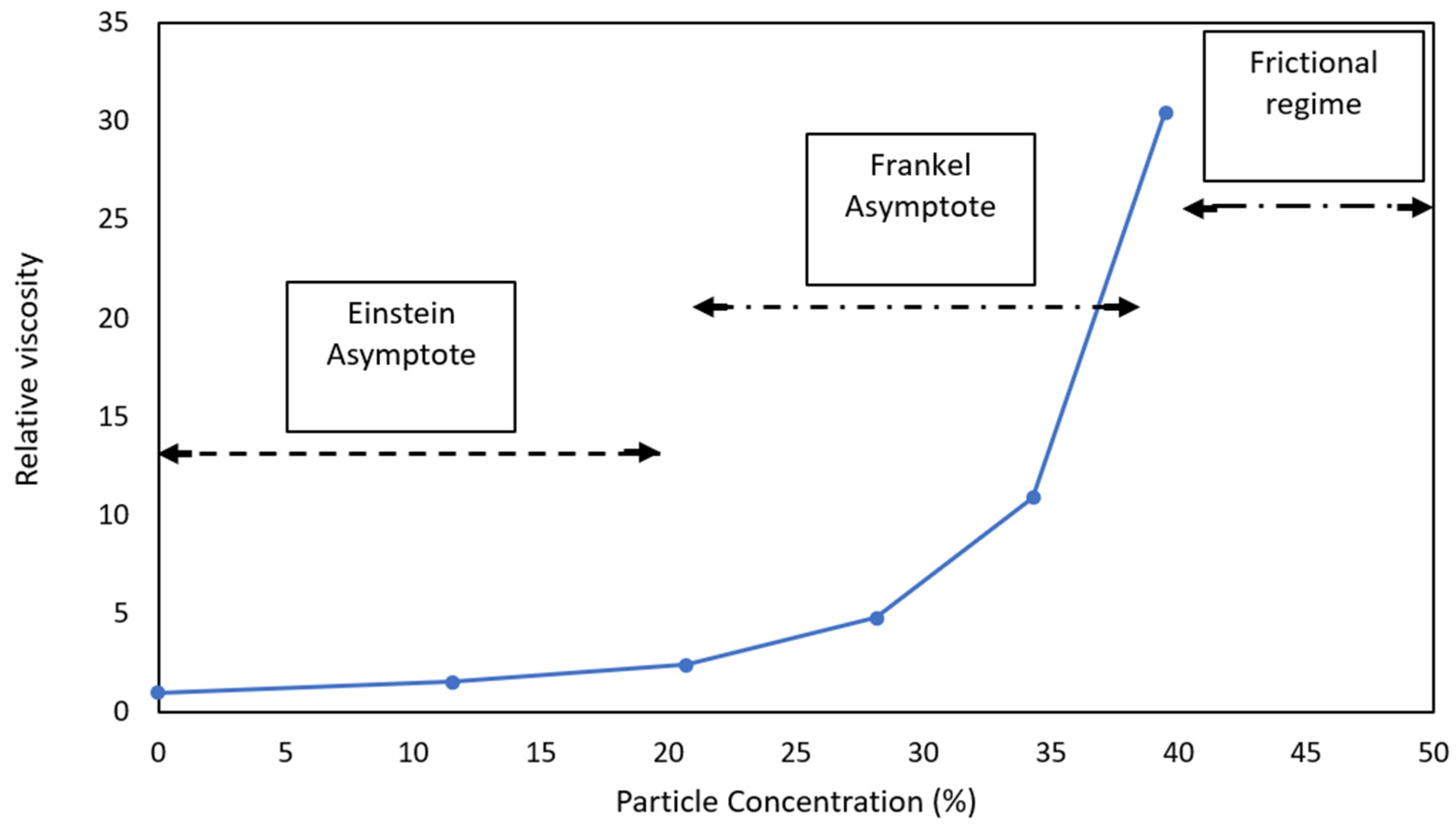

4.2. Asphaltene Enrichment and Viscosity of the Binder

4.3. Marshall Tests and Air Voids

5. Conclusions

- →

- The influence of dry-added plastics in an asphalt mixture varies depending on the method of introduction. However, the most effective approach is to initially mix plastics with hot aggregates at 180 °C (coat the aggregates) before introducing bitumen. This method ensures full integration of plastics into the binder matrix.

- →

- Higher plastic inclusion results in a lower swelling rate.

- →

- Improved dispersion of PRP throughout the binder was noted at a lower plastic inclusion level (1.25% by the total volume of the mixture).

- →

- The highest swelling rate, reaching 3.5, was observed in LDPE, attributed to its elevated amorphous content. Optimal dispersion of PRP within the matrix is likewise achieved with LDPE.

- →

- HDPE exhibits the lowest swelling rate.

- →

- The most heterogeneous matrix was obtained with the inclusion of dry-added polypropylene. This can be attributed to the elevated crystallinity of PP and its notably high melting point.

- →

- For dry-added modification, it is recommended to include plastic less than 2.5% by volume of the mixture.

- →

- Stability values and air void content vary among samples modified with different plastics, with polyethylene-modified samples exhibiting superior workability and compactibility compared to polypropylene-modified samples.

- →

- This study also suggests that using plastics to replace both bitumen and filler not only improves cost efficiency and reduces the carbon footprint but also enhances the overall performance of the asphalt mixture.

- →

- Incorporating 2.5% plastics impacts asphalt mixture design, resulting in excessive AV, which can be addressed by reducing the filler content of the mixture.

- →

- It is recommended to model the impact of plastic incorporation and subsequent filler substitution in future studies to guarantee the optimal mix design.

- →

- Further investigation is suggested to understand the effects of the modification on critical asphalt properties, especially air voids and rutting performance.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- British Plastics Federation. Plastics Applications. 2022. Available online: https://www.bpf.co.uk/plastipedia/applications/Default.aspx (accessed on 23 June 2022).

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of waste plastics to liquid fuel. A suitable method for plastic waste management and manufacture of value added products-A world prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Garside, M. Production of Plastics Worldwide from 1950 to 2019 (in Million Metric Tons), Statista 2018–2019. 2021. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 21 January 2021).

- Haji Seyed Javadi, N.; Heydari, S.; Hajimohammadi, A. Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging. Polymers 2024, 16, 1669. [Google Scholar] [CrossRef] [PubMed]

- Heydari, S.; Hajimohammadi, A.; Javadi, N.H.S.; Khalili, N. The use of plastic waste in asphalt: A critical review on asphalt mix design and Marshall properties. Constr. Build. Mater. 2021, 309, 125185. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Tapkin, S.; Çevik, A.; Uşar, Ü. Accumulated strain prediction of polypropylene modified marshall specimens in repeated creep test using artificial neural networks. Expert. Syst. Appl. 2009, 36, 11186–11197. [Google Scholar] [CrossRef]

- Costa, L.M.B.; Peralta, J.; Oliveira, J.R.M.; Silva, H.M.R.D. A new life for cross-linked plastic waste as aggregates and binder modifier for asphalt mixtures. Appl. Sci. 2017, 7, 603. [Google Scholar] [CrossRef]

- Ma, F.; Dai, J.; Fu, Z.; Liu, J.; Dong, W.; Huang, Z. A New type of crumb rubber asphalt mixture: A dry process design and performance evaluation. Appl. Sci. 2020, 10, 372. [Google Scholar] [CrossRef]

- Chin, C.; Damen, P. Viability of Using Recycled Plastics in Asphalt and Sprayed Sealing Applications; Austroads, Ltd.: Sydney, Australia, 2019. [Google Scholar]

- Gawande, A.; Zamre, G.S.; Renge, V.C.; Bharsakale, G.R.; Tayde, S. Utilization of waste plastic in asphalting of roads. Sci. Rev. Chem. Commun. 2012, 2, 147–157. [Google Scholar]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Yu, R.; Fang, C.; Liu, P.; Liu, X.; Li, Y. Storage stability and rheological properties of asphalt modified with waste packaging polyethylene and organic montmorillonite. Appl. Clay Sci. 2015, 104, 1–7. [Google Scholar] [CrossRef]

- Cao, W. Study on properties of recycled tire rubber modified asphalt mixtures using dry process. Constr. Build. Mater. 2007, 21, 1011–1015. [Google Scholar] [CrossRef]

- Zoorob, S.E.; Suparma, L.B. Laboratory design and investigation of the properties of continuously graded asphaltic concrete containing recycled plastics aggregate replacement (plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Developing laboratory fatigue and resilient modulus models for modified asphalt mixes with waste plastic bottles (PET). Constr. Build. Mater. 2014, 68, 259–267. [Google Scholar] [CrossRef]

- Fernandes, S.; Costa, L.; Silva, H.; Oliveira, J. Effect of incorporating different waste materials in bitumen. Cienc. Tecnol. Mater. 2017, 29, e204–e209. [Google Scholar] [CrossRef]

- Jafar, J.J. Utilisation of waste plastic in bituminous mix for improved performance of roads. KSCE J. Civ. Eng. 2016, 20, 243–249. [Google Scholar] [CrossRef]

- Khurshid, M.B.; Qureshi, N.A.; Hussain, A.; Iqbal, M.J. Enhancement of hot mix asphalt (HMA) properties using waste polymers. Arab. J. Sci. Eng. 2019, 44, 8239–8248. [Google Scholar] [CrossRef]

- Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Indacoechea-Vega, I. Comparative analysis of the performance of asphalt concretes modified by dry way with polymeric waste. Constr. Build. Mater. 2016, 112, 1133–1140. [Google Scholar] [CrossRef]

- Almeida, A.; Capitão, S.; Bandeira, R.; Fonseca, M.; Picado-Santos, L. Performance of AC mixtures containing flakes of LDPE plastic film collected from urban waste considering ageing. Constr. Build. Mater. 2020, 232, 117253. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, E.; Wong, Y.C.; Horpibulsuk, S. Recycled plastic granules and demolition wastes as construction materials: Resilient moduli and strength characteristics. Constr. Build. Mater. 2017, 147, 639–647. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Ahmadinia, E. Performance evaluation of utilization of waste Polyethylene Terephthalate (PET) in stone mastic asphalt. Constr. Build. Mater. 2012, 36, 984–989. [Google Scholar] [CrossRef]

- Jeong, K.D.; Lee, S.J.; Kim, K.W. Laboratory evaluation of flexible pavement materials containing waste polyethylene (WPE) film. Constr. Build. Mater. 2011, 25, 1890–1894. [Google Scholar] [CrossRef]

- Suaryana, N.; Nirwan, E.; Ronny, Y. Plastic bag waste on hotmixture asphalt as modifier. Key Eng. Mater. 2018, 789, 20–25. [Google Scholar] [CrossRef]

- Tiwari, V.; Rao, Y.R.M. Study of plastic waste mixed bituminous concrete using dry process for road construction. J. Civ. Eng. 2019, 13, 105–112. [Google Scholar] [CrossRef]

- Nejad, F.M.; Arabani, M.; Hamedi, G.H.; Azarhoosh, A.R. Influence of using polymeric aggregate treatment on moisture damage in hot mix asphalt. Constr. Build. Mater. 2013, 47, 1523–1527. [Google Scholar] [CrossRef]

- Vasudevan, R.; Sekar, A.R.C.; Sundarakannan, B.; Velkennedy, R. A technique to dispose waste plastics in an ecofriendly way—Application in construction of flexible pavements. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Sarang, G.; Lekha, B.M.; Krishna, G.; Shankar, A.U.R. Comparison of Stone Matrix Asphalt mixtures with polymer-modified bitumen and shredded waste plastics. Road Mater. Pavement Des. 2016, 17, 933–945. [Google Scholar] [CrossRef]

- Laminated Plastics. Polyethylene Technical Data Sheet. 2018. Available online: https://www.smithmetal.com/pdf/plastics/polyethylene.pdf (accessed on 11 November 2023).

- ACT Recycling. Product Data Sheet—DGB20 & DGS20—Crushed Aggregate. 2023. Available online: https://actrecycling.com.au/ (accessed on 11 November 2023).

- State Asphalt NSW. 2023. Available online: http://www.stateasphalts.com.au/ (accessed on 11 November 2023).

- Closedloop. 2024. Available online: https://closedloop.com.au/ (accessed on 10 February 2024).

- Hordin, T. 7 Types of Plastic That Are Most Common. 2021. Available online: https://plasticoceans.org/7-types-of-plastic/ (accessed on 10 February 2024).

- IC-QA-3253; Transport for NSW, QA Specification Bitumen for Pavements. NSW Government: Sydney, Australia, 2020.

- IC-QA-R121; QA Specification R121 Stone Mastic Asphalt, Transport for NSW (TfNSW). NSW Government: Sydney, Australia, 2020.

- Mikhailenko, P.; Ataeian, P.; Baaj, H. Extraction and recovery of asphalt binder: A literature review. Int. J. Pavement Res. Technol. 2020, 13, 20–31. [Google Scholar] [CrossRef]

- Transport Roads & Maritime Services. Test Method T648 Static Binder Drainage Test. 2012. Available online: https://standards.transport.nsw.gov.au/_entity/annotation/68e9941c-e4a5-ed11-aad0-000d3ae019e0 (accessed on 11 November 2023).

- Lesueur, D.; Gérard, J.-F.; Claudy, P.; Létoffé, J.-M.; Martin, D.; Planche, J.-P. Polymer modified asphalts as viscoelastic emulsions. J. Rheol. 1998, 42, 1059–1074. [Google Scholar] [CrossRef]

- Lu, X.; Soenen, H.; Sjövall, P.; Pipintakos, G. Analysis of asphaltenes and maltenes before and after long-term aging of bitumen. Fuel 2021, 304, 121426. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Schaur, A.; Unterberger, S.; Lackner, R. Impact of molecular structure of SBS on thermomechanical properties of polymer modified bitumen. Eur. Polym. J. 2017, 96, 256–265. [Google Scholar] [CrossRef]

- Fang, C.; Yu, R.; Li, Y.; Zhang, M.; Hu, J.; Zhang, M. Preparation and characterization of an asphalt-modifying agent with waste packaging polyethylene and organic montmorillonite. Polym. Test. 2013, 32, 953–960. [Google Scholar] [CrossRef]

- Yousefi, A.A. Polyethylene Dispersions in Bitumen: The Effects of the Polymer Structural Parameters. J. Appl. Polym. Sci. 2003, 90, 3183–3190. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- ASTM D 6927; Standard Test Method for Marshall Stability and Flow of Bituminous Mixtures. ASTM Standards: West Conshohocken, PA, USA, 2007; pp. 1–44.

- Brovelli, A.; Crispino, M.; Pais, J.; Pereira, P. Using polymers to improve the rutting resistance of asphalt concrete. Constr. Build. Mater. 2015, 77, 117–123. [Google Scholar] [CrossRef]

- Punith, V.S.; Veeraragavan, A. Behavior of asphalt concrete mixtures with reclaimed polyethylene as additive. J. Mater. Civ. Eng. 2007, 19, 500–507. [Google Scholar] [CrossRef]

- Geraldin, J.; Makmur, A. Experimental Study on the Effects of Reclaimed Asphalt Pavement towards Marshall Parameters on Asphalt Course-Wearing Course. IOP Conf. Ser. Earth Environ. Sci. 2020, 498, 012025. [Google Scholar] [CrossRef]

- Hinislioglu, S.; Agar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Yilmaz, M. Effect of polyester resin additive on the properties of asphalt binders and mixtures. Constr. Build. Mater. 2008, 22, 481–486. [Google Scholar] [CrossRef]

- Specification No. 245; Asphaltic Concrete. NSW Government: Sydney, Australia, 2002.

- AS/NZS 2891.5; Methods of Sampling and Testing Asphalt—Method 5: Compaction of Asphalt by Marshall Method and Determination of Stability and Flow Marshall Procedure. NSW Government: Sydney, Australia, 2015.

- Celauro, C.; Saroufim, E.; Mistretta, M.C.; La Mantia, F.P. Influence of short-term aging on mechanical properties and morphology of polymer-modified bitumen with recycled plastics from waste materials. Polymers 2020, 12, 1985. [Google Scholar] [CrossRef] [PubMed]

- Sengoz, B.; Isikyakar, G. Evaluation of the properties and microstructure of SBS and EVA polymer modified bitumen. Constr. Build. Mater. 2008, 22, 1897–1905. [Google Scholar] [CrossRef]

- Zhu, J.; Lu, X.; Kringos, N. Experimental investigation on storage stability and phase separation behaviour of polymer-modified bitumen. Int. J. Pavement Eng. 2018, 19, 832–841. [Google Scholar] [CrossRef]

- Haji, N.; Javadi, S.; Hajimohammadi, A.; Heydari, S.; Jeremy, J.; Ng, K.C.; Kypreos, J.E.; Khalili, N. Investigating the applicability of Storage Stability Test for Waste Plastic Modified Bitumen: Morphological Analyses. Constr. Build. Mater. 2024; in press. [Google Scholar]

- Sapuan, S.M.; Ismail, H.; Zainudin, E.S. Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Woodhead Publishing: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Tian, X.; Zhang, R.; Yang, Z.; Chu, Y.; Xu, Y.; Zhang, Q. Multiscale study on the effect of nano-organic montmorillonite on the performance of rubber asphalt. J. Nanomater. 2018, 2018, 9638603. [Google Scholar] [CrossRef]

- Murakami, Y. The mechanism of fatigue failure in the very high cycle fatigue (VHCF) life regime of N> 107 cycles. Met. Fatigue 2019, 341–406. [Google Scholar] [CrossRef]

- Lewis, P.R.; Weidmann, G.W. Catastrophic failure of a polypropylene tank Part I: Primary investigation. In Failure Analysis Case Studies II; Elsevier: Amsterdam, The Netherlands, 2001; pp. 79–96. [Google Scholar] [CrossRef]

- Fu, T.; Wei, J.H.; Bao, H.; Liang, J. Multiscale Study on the Modification Mechanism of Red Mud Modified Asphalt. Adv. Mater. Sci. Eng. 2020, 2020, 2150215. [Google Scholar] [CrossRef]

- Castorena, C.; Pape, S.; Mooney, C. Blending measurements in mixtures with reclaimed asphalt. Transp. Res. Rec. 2016, 2574, 57–63. [Google Scholar] [CrossRef]

- Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Characterization of unaged asphalt binder modified with carbon nano particles. Int. J. Pavement Res. Technol. 2011, 4, 281–286. [Google Scholar] [CrossRef]

- Yao, H.; Dai, Q.; You, Z.; Ye, M.; Yap, Y.K. Rheological properties, low-temperature cracking resistance, and optical performance of exfoliated graphite nanoplatelets modified asphalt binder. Constr. Build. Mater. 2016, 113, 988–996. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Gravina, R.; Giustozzi, F. Recycled plastic as bitumen modifier: The role of recycled linear low-density polyethylene in the modification of physical, chemical and rheological properties of bitumen. J. Clean. Prod. 2020, 266, 121988. [Google Scholar] [CrossRef]

- Heydari, S.; Hajimohammadi, A.; Javadi, N.H.S.; Ng, J.J.K.C.; Kypreos, J.E.; Khalili, N. Modified asphalt by coffee cup Fibres: An optimum mix design using response surface method. Constr. Build. Mater. 2023, 401, 133005. [Google Scholar] [CrossRef]

- AS 2341.3-1993; Methods of Testing Bitumen and Related Roadmaking Products Method 3: Determination of Kinematic Viscosity by Flow through a Capillary Tube. NSW Government: Sydney, Australia, 1993; pp. 2–3.

- Kubantseva, N.; Hartel, R.W.; Swearingen, P.A. Factors affecting solubility of calcium lactate in aqueous solutions. J. Dairy. Sci. 2004, 87, 863–867. [Google Scholar] [CrossRef] [PubMed]

- Dong, F.; Zhao, W.; Zhang, Y.; Wei, J.; Fan, W.; Yu, Y.; Wang, Z. Influence of SBS and asphalt on SBS dispersion and the performance of modified asphalt. Constr. Build. Mater. 2014, 62, 1–7. [Google Scholar] [CrossRef]

- Polińska, M.; Rozanski, A.; Galeski, A.; Bojda, J. The Modulus of the Amorphous Phase of Semicrystalline Polymers. Macromolecules 2021, 54, 9113–9123. [Google Scholar] [CrossRef]

- Einstein, A. New determination of molecular dimensions. Ann. Phys 1906, 19, 289–306. [Google Scholar] [CrossRef]

- Hesami, E.; Jelagin, D.; Kringos, N.; Birgisson, B. An empirical framework for determining asphalt mastic viscosity as a function of mineral filler concentration. Constr. Build. Mater. 2012, 35, 23–29. [Google Scholar] [CrossRef]

- Zeng, M.; Wu, C. Effects of Type and Content of Mineral Filler on Viscosity of Asphalt Mastic and Mixing and Compaction Temperatures. J. Transp. Res. Board 1974, 2051, 31–40. [Google Scholar] [CrossRef]

- Holý, M.; Remišová, E. Analysis of influence of bitumen composition on the properties represented by empirical and viscosity test. Transp. Res. Procedia 2019, 40, 34–41. [Google Scholar] [CrossRef]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

| Plastics | Plastic Shape | Aggregates Grading | Role in Mix Design | Reference |

|---|---|---|---|---|

| LDPE | Pellets | Constant | Aggregate | [15] |

| PET | Crushed | Variable | Aggregate | [16] |

| PE | flakes | Variable | Aggregate | [17] |

| Plastic | 1–4 mm | Variable | Aggregate | [18] |

| LDPE, HDPE | Shredded | Constant | Bitumen modifier | [19] |

| PE, PP | 1–6.3 mm | Constant | Filler | [20] |

| LDPE | Flakes | Constant | Not mentioned | [21] |

| LDPE, HDPE | Granules | Constant | Not mentioned | [22] |

| PET | Crushed | Constant | Not mentioned | [23] |

| PET | Crushed | Constant | Not mentioned | [24] |

| PET | Crushed | Constant | Not mentioned | [25] |

| PE | Shredded | Constant | Not mentioned | [26] |

| LDPE | Shredded | Constant | Coated aggregates | [27] |

| LDPE, HDPE | Shredded | Constant | Coated aggregates | [28] |

| PE | NM | Constant | Coated aggregates | [29] |

| Plastic | Shredded | Constant | Coated aggregates | [30] |

| Plastic | Shredded | Constant | Additive | [31] |

| Plastics | MFR (g/10 min) | Density (g/cm3) | Melting Point (°C) | Crystallinity (%) |

|---|---|---|---|---|

| LDPE | 21 | 0.917 | 106 | 20 |

| LLDPE | 1 | 0.921 | 121 | 50 |

| PP | 30 | 0.9 | 165 | 65 |

| HDPE | 20 | 0.956 | 127 | 70 |

| Sample Labels | Mixing Method | Plastics (%) | Bitumen C170 (%) | Aggregates SMA10 (%) | Mixing Temperature (°C) | |

|---|---|---|---|---|---|---|

| PP | PE | |||||

| a-160 | Method 1 | 1.25 | 1.25 | 12.65 | 84.85 | 160 |

| a-180 | Method 1 | 1.25 | 1.25 | 12.65 | 84.85 | 180 |

| b-160 | Method 2 | 1.25 | 1.25 | 12.65 | 84.85 | 160 |

| b-180 | Method 2 | 1.25 | 1.25 | 12.65 | 84.85 | 180 |

| Run | Label | Plastic Type | Plastic Content (%) | Plastics/(Bitumen + Filler + Plastics) (%) |

|---|---|---|---|---|

| 1 | LDPE 1.25% | LDPE | 1.25 | 4.74 |

| 2 | LDPE 2.5% | LDPE | 2.5 | 9.47 |

| 3 | LLDPE 1.25% | LLDPE | 1.25 | 4.74 |

| 4 | LLDPE 2.5% | LLDPE | 2.5 | 9.47 |

| 5 | HDPE 1.25% | HDPE | 1.25 | 4.74 |

| 6 | HDPE 2.5% | HDPE | 2.5 | 9.47 |

| 7 | PP 1.25% | PP | 1.25 | 4.74 |

| 8 | PP 2.5% | PP | 2.5 | 9.47 |

| 9 | Control | - | 0 | 0 |

| Run | Label | Plastic Type | Plastic Content (%) | Amendment on Asphalt Mixture | Plastics/(Bitumen + Filler + Plastics) (%) |

|---|---|---|---|---|---|

| 1 | Control | - | 0 | Plastics replacing bitumen | 0 |

| 2 | LDPE 2.5% | LDPE | 2.5 | Plastics replacing bitumen | 9.47 |

| 3 | LLDPE 2.5% | LLDPE | 2.5 | Plastics replacing bitumen | 9.47 |

| 4 | HDPE 2.5% | HDPE | 2.5 | Plastics replacing bitumen | 9.47 |

| 5 | PP 2.5% | PP | 2.5 | Plastics replacing bitumen | 9.47 |

| 6 | A-LDPE 2.5% | LDPE | 2.5 | Plastics replacing filler and bitumen | 9.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heydari, S.; Haji Seyed Javadi, N.; Bayat, H.; Hajimohammadi, A. Assessment of Binder Modification in Dry-Added Waste Plastic Modified Asphalt. Polymers 2024, 16, 1987. https://doi.org/10.3390/polym16141987

Heydari S, Haji Seyed Javadi N, Bayat H, Hajimohammadi A. Assessment of Binder Modification in Dry-Added Waste Plastic Modified Asphalt. Polymers. 2024; 16(14):1987. https://doi.org/10.3390/polym16141987

Chicago/Turabian StyleHeydari, Soheil, Nioushasadat Haji Seyed Javadi, Hamid Bayat, and Ailar Hajimohammadi. 2024. "Assessment of Binder Modification in Dry-Added Waste Plastic Modified Asphalt" Polymers 16, no. 14: 1987. https://doi.org/10.3390/polym16141987

APA StyleHeydari, S., Haji Seyed Javadi, N., Bayat, H., & Hajimohammadi, A. (2024). Assessment of Binder Modification in Dry-Added Waste Plastic Modified Asphalt. Polymers, 16(14), 1987. https://doi.org/10.3390/polym16141987