Preparation and Performance of Leather-Finished Plywood

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

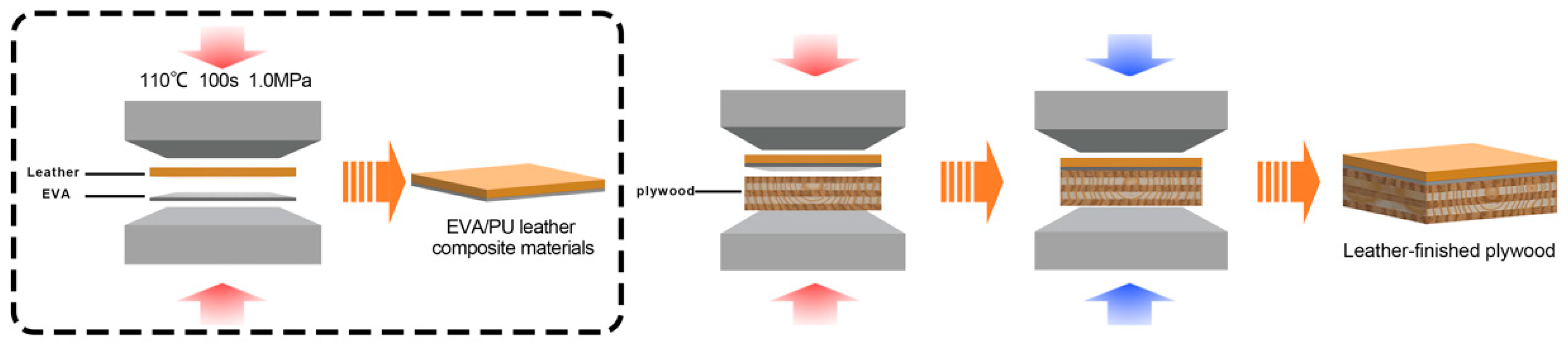

2.2. Preparation of PU-Leather-Finished Plywood

2.3. Characterization

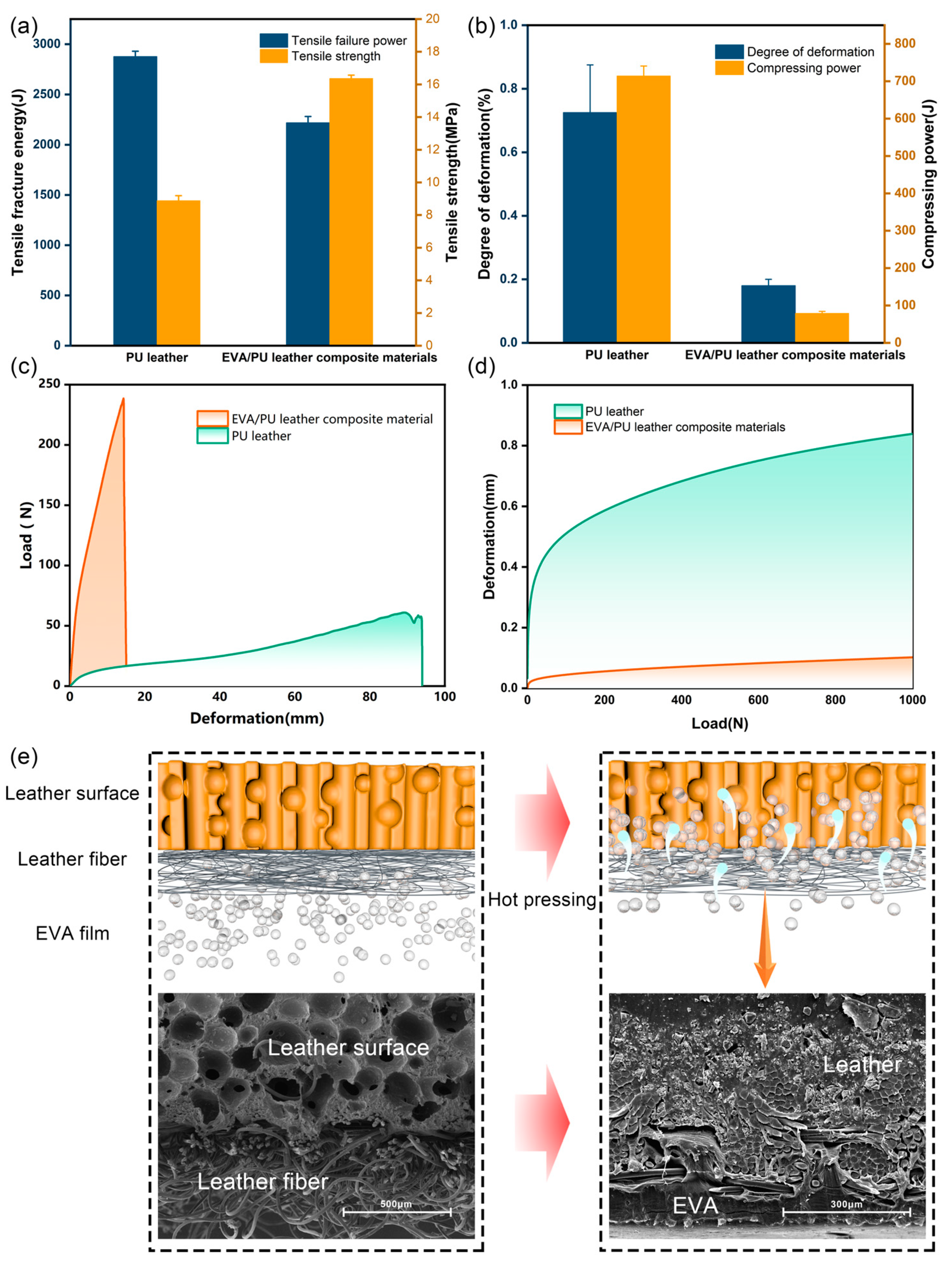

2.3.1. Decorative Leather Performance Tests

- Compression performance. First, the PU leather specimen with a specification of 35 mm × 35 mm was prepared. Second, the leather specimen was spread on the specimen table of the mechanical testing machine and loaded. During the test, the load was increased from 0 N to 1000 N. The changes in the thickness of the loaded specimen were recorded every 0.1 s. The maximum displacement was recorded when the load was 1000 N. Six specimens were selected for testing under each respective test level, and the results were averaged.

- Tensile performance. Based on the standard GB/T 16799-2018 [31] “leather for furniture” preparation specifications for 25 mm × 100 mm PU leather specimens, the displacement was controlled and varied uniformly during the test. The displacement and tensile force were recorded every 0.1 s until the specimen was damaged. The maximum load during the damage was recorded. Six specimens were selected under each test level, and the results were averaged.

2.3.2. Overlaying Performance Test

- Impregnation peel performance. Based on the standard GB/T 17657-2022 [32] “test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels” preparation specifications for 75 mm × 75 mm leather-finished plywood specimens, firstly, the specimens were impregnated in hot water (63 ± 3) °C for 3 h and then dried in an oven at (63 ± 3) °C for 3 h. The peel length of the adhesive layer between the veneer and the substrate was recorded. Six specimens were selected for testing under each respective test level, and the results were averaged.

- Surface bonding strength. Based on the standard GB/T 17657-2022 [32], specimens of leather-finished plywood with specifications of 50 mm × 50 mm were prepared. They were tested with a mechanical testing machine to determine the maximum damage load. Six specimens were selected for testing under each test level, and the results were averaged.

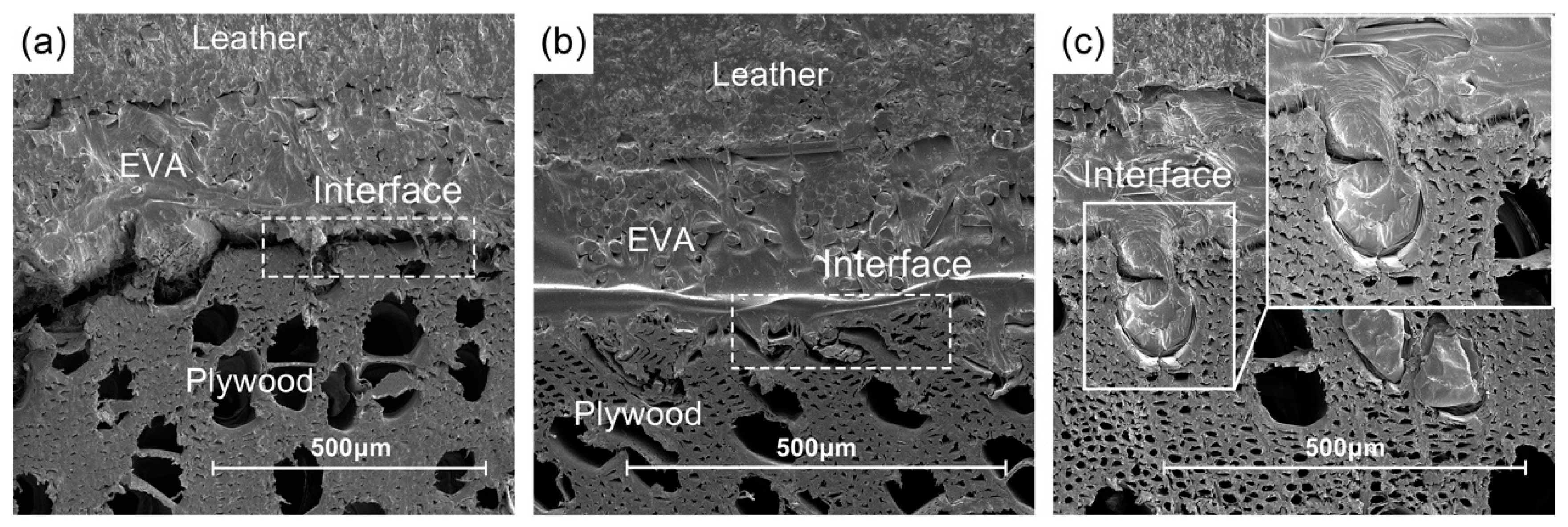

- Microscopic morphology of the gluing interface. The leather-finished plywood specimens were cut to a size of 5 mm × 3 mm. After gold spraying of the cross-section, the gluing interface between the decorative leather, the EVA film interlayer and the plywood substrate was analyzed via environmental scanning electron microscopy (ESEM).

3. Results and Discussion

3.1. Analysis of Tactile Properties of PU Leather

3.1.1. Compression Performance of PU Leather

3.1.2. Tensile Properties of PU Leather

3.1.3. Effect of EVA Compound on the Tactile Sensation of Leather

3.2. Performance Analysis of Leather-Finished Plywood

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lihra, T.; Buehlmann, U.; Graf, R. Customer preferences for customized household furniture. J. For. Econ. 2012, 18, 94–112. [Google Scholar] [CrossRef]

- Wang, L.; He, J.; Xu, S. The application of industry 4.0 in customized furniture manufacturing industry. MATEC Web Conf. 2017, 100, 03022. [Google Scholar] [CrossRef]

- Mikulskienė, B.; Moskvina, J. Peculiar properties of the pricing process in customized furniture manufacturing enterprises. J. Revenue Pricing Manag. 2020, 19, 411–420. [Google Scholar] [CrossRef]

- Xiong, X.; Li, R.; Bai, H. Research status and development trend of intelligent furniture in China. J. For. Eng. 2021, 6, 21–28. [Google Scholar]

- Wu, Z.; Zong, F.; Zhang, F.; Wang, J.; Zhu, Z.; Guo, X.; Cao, P. Investigation of the customized furniture industry’s production management systems. J. Eng. Res. 2023, 11, 164–175. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, Z. Rolling and pressing composite technology of plastic film and decorative veneer based on response surface optimization method. J. For. Eng. 2019, 4, 31–37. [Google Scholar]

- Wang, R.; Lye, B. Analysis and Consideration of Wooden Household Surface Decoration Industry in China. China Wood-Based Panels 2019, 26, 10–14. [Google Scholar]

- Peng, X.; Zhang, Z. Research of polypropylene (PP) decorative board surface painting used for wood product decoration and the paint film adhesion improvement by plasma. J. Adhes. Sci. 2020, 34, 246–262. [Google Scholar] [CrossRef]

- Peng, X.; Lyu, B.; Wang, C.; Zhao, L.; Zhang, Z. New Products and Technologies of Decorative Surfaces for Wood Products. Chin. J. Wood Sci. Technol. 2021, 35, 6–11. [Google Scholar]

- Cui, H. Development of New Decorative Paper Products and Requirements for Performance of Base Paper. China Wood-Based Panels 2022, 29, 6–9. [Google Scholar]

- Yang, J.; Shen, Y. Research Actuality and Application Prospect of Melamine-formaldehyde Resin and the Derivatives. Chem. Ind. Times 2004, 12, 12–15. [Google Scholar]

- Kandelbauer, A.; Petek, P.; Medved, S.; Pizzi, A.; Teischinger, A. On the performance of a melamine-urea-formaldehyde resin for decorative paper coatings. Eur. J. Wood Wood Prod. 2010, 68, 63–75. [Google Scholar] [CrossRef]

- Xu, J. Significant breakthroughs in aldehyde-free impregnated adhesive film paper technologies and products. China Wood-Based Panels 2021, 28, 48. [Google Scholar]

- Xu, J.; Ling, L.; Ru, L. Research Status Review of Formaldehyde-Free Decorative Paper for Wood-Based Panels. Chin. J. Wood Sci. Technol. 2021, 35, 1–5. [Google Scholar]

- Badila, M.; Kohlmayr, M.; Zikulnig-Rusch, E.M.; Dolezel-Horwath, E.; Kandelbauer, A. Improving the Cleanability of Melamine-Formaldehyde-Based Decorative Laminates. J. Appl. Polym. Sci. 2014, 131, 40964. [Google Scholar] [CrossRef]

- Antunes, A.; Henriques, A.; Lima, F.; Ferra, J.; Martins, J.; Carvalho, L.; Magalhães, F.D. Postformable and Self-Healing Finish Foil Based on Polyurethane-Impregnated Paper. Ind. Eng. Chem. Res. 2016, 55, 12376–12386. [Google Scholar] [CrossRef]

- Wang, R. Study on the Modification of Melamine Formaldehyde Resin by Three (2-hydroxyethyl) Isocyanurate for Impregnated Resin Paper; Chinese Academy of Forestry: Beijing, China, 2018. [Google Scholar]

- Cheng, F.; Zhang, Y.; Fan, S.; Ji, M.; Wang, K. Preparation and properties of impregnated paper with waterborne acrylic modified by nano Al(OH)3 and cellulose nanocrystalline. J. For. Eng. 2018, 3, 93–97. [Google Scholar]

- Zhang, L. Leather in household product design……. West Leather 2010, 32, 41–43. [Google Scholar]

- Zhang, H. Application of cultural and creative elements in leather material furniture. China Leather 2023, 52, 99–103+109. [Google Scholar]

- Lu, Y.; Gui, C.; Chen, J.; Zou, Y.; Fang, L. Effect of scoring pretreatment on the properties of polyurethane leather finished plywood. J. For. Eng. 2024, 9, 40–46. [Google Scholar]

- Guan, X. Leather and Furniture; LuXun Academy of Fine Arts: Shenyang, China, 2014. [Google Scholar]

- Liu, M.; Wu, Z. Application of Decorative Technoloay in Modern Leather Product Design. China Leather 2011, 40, 116–118. [Google Scholar]

- Huang, H. Application of leather stitching technology in furniture design. China Leather 2016, 45, 26–28+34. [Google Scholar]

- Sylvie, G.; George, T. Leather Laminated Decorative Panel. U.S. Patent 8262827, 11 September 2012. [Google Scholar]

- Liu, Y. Preparation Technology and Mechanism of Laminating Wood Veneer with Wood Plastic Composites; Northeast Forestry University: Harbin, China, 2019. [Google Scholar]

- Savini, G.; Oréfice, R.L. Super ductility in HDPE/EVA blends triggered by synthetic amorphous nanotalc. J. Polym. Res. 2021, 28, 1–17. [Google Scholar] [CrossRef]

- Guo, L.; Wang, W.; Wang, Q. Study on Veneer Overlaid of Wood-Flour/HDPE Composites. J. Southwest For. Univ. 2014, 34, 95–98+110. [Google Scholar]

- Fang, L.; Xiong, X.; Zou, Y.; Wu, Z.; Mo, X.; Li, R.; Wang, X. A Kind of Dry-Glue Formaldehyde-Free Thin Wood Veneer Decorative Board and Method for Producing the Same. CN206839789U, 5 January 2018. [Google Scholar]

- Zhang, X.; Fang, L.; Wu, Z.; Zhao, J. Preparation and properties of EVA film reinforced decorative veneer. J. For. Eng. 2022, 7, 58–63. [Google Scholar]

- GB/T 16799-2018; Furniture Leather. State Administration for Market Regulation; Standardization Administration: Beijing, China, 2018.

- GB/T 17657-2022; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. State Administration for Market Regulation; Standardization Administration: Beijing, China, 2022.

- Lin, W. Perceptual Dimensions and Evaluation of Tactile Textures; Donghua University: Shanghai, China, 2008. [Google Scholar]

- Zhang, M. Analysis and Research on the Testing Method of Leather Tactile Characteristic Parameters; Shanxi University of Science and Technology: Xi’an, China, 2016. [Google Scholar]

- Dong, J.; Zhang, S.; Zhang, X.; Qian, D. Expressing Leather Organoleptic Characteristic by Mechanic Parameters. Leather Sci. Eng. 2008, 18, 41–44. [Google Scholar]

- Ding, S.; Chen, X.; Hu, L. Study on the Relevance of Physical Property Parameters of Chrome-tanned Goat Shoe Upper Leather. China Leather 2006, 15, 11–14. [Google Scholar]

- Meng, F. Creep Properties of Leather under Tensile, Bending, Compression and Overstretch Deformation; Zhengzhou University: Zhengzhou, China, 2009. [Google Scholar]

- Peng, X.; Zhang, Z. Preparation and Application of Plastic Film Reinforced Pliable Decorative Veneer. J. Wood Sci. Technol. 2022, 36, 1–5+12. [Google Scholar]

- GB/T 15104-2021; Decorative Veneered Wood-Based Panel. State Administration for Market Regulation; Standardization Administration: Beijing, China, 2021.

| Levels | Factors | ||

|---|---|---|---|

| Temperature (°C) | Time (s) | Pressure (MPa) | |

| −1 | 95 | 50 | 0.5 |

| 0 | 110 | 150 | 1.0 |

| 1 | 125 | 250 | 1.5 |

| Run | Level | Impregnation Peeling Properties/mm | Surface Bonding Strength/MPa | ||

|---|---|---|---|---|---|

| A | B | C | |||

| 1 | 0 | 0 | 0 | 0 | 1.67 |

| 2 | 0 | 0 | 0 | 0 | 1.69 |

| 3 | 1 | −1 | 0 | 0 | 1.56 |

| 4 | 0 | 0 | 0 | 0 | 1.75 |

| 5 | −1 | 1 | 0 | 0 | 1.14 |

| 6 | −1 | 0 | 1 | 0 | 1.16 |

| 7 | 1 | 0 | −1 | 1.03 | 1.21 |

| 8 | 0 | 1 | −1 | 0 | 1.31 |

| 9 | 0 | 0 | 0 | 0 | 1.65 |

| 10 | 1 | 0 | 1 | 0 | 1.83 |

| 11 | 1 | 1 | 0 | 0 | 1.79 |

| 12 | 0 | 1 | 1 | 0 | 1.59 |

| 13 | −1 | −1 | 0 | 0 | 0.99 |

| 14 | 0 | −1 | −1 | 0 | 1.05 |

| 15 | 0 | 0 | 0 | 0 | 1.70 |

| 16 | −1 | 0 | −1 | 4.25 | 0.98 |

| 17 | 0 | −1 | 1 | 0 | 1.29 |

| Source | Sum of Squares | df | Mean Squares | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 1.4284 | 9 | 0.1587 | 34.36 | 0.0001 | ** |

| A | 0.5618 | 1 | 0.5618 | 121.63 | <0.0001 | ** |

| B | 0.1105 | 1 | 0.1105 | 23.91 | 0.0018 | ** |

| C | 0.2178 | 1 | 0.2178 | 47.16 | 0.0002 | ** |

| AB | 0.0016 | 1 | 0.0016 | 0.35 | 0.5746 | - |

| AC | 0.0484 | 1 | 0.0484 | 10.48 | 0.0143 | * |

| BC | 0.0004 | 1 | 0.0004 | 0.09 | 0.7771 | - |

| A2 | 0.1195 | 1 | 0.1195 | 25.88 | 0.0014 | ** |

| B2 | 0.0992 | 1 | 0.0992 | 21.48 | 0.0024 | ** |

| C2 | 0.2198 | 1 | 0.2198 | 47.60 | 0.0002 | ** |

| Residual | 0.0323 | 7 | 0.0046 | |||

| Std. Dev. | 0.0267 | 3 | 0.0089 | 6.26 | 0.0544 | |

| C.V. % | 4.74 | |||||

| Adjusted R2 | 0.9779 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Yuan, Z.; Lu, Y.; Liu, X.; Chen, C.; Fang, L. Preparation and Performance of Leather-Finished Plywood. Polymers 2024, 16, 2587. https://doi.org/10.3390/polym16182587

Zou Y, Yuan Z, Lu Y, Liu X, Chen C, Fang L. Preparation and Performance of Leather-Finished Plywood. Polymers. 2024; 16(18):2587. https://doi.org/10.3390/polym16182587

Chicago/Turabian StyleZou, Yuanyuan, Ziyi Yuan, Yuxin Lu, Xiaoqian Liu, Chuxuan Chen, and Lu Fang. 2024. "Preparation and Performance of Leather-Finished Plywood" Polymers 16, no. 18: 2587. https://doi.org/10.3390/polym16182587

APA StyleZou, Y., Yuan, Z., Lu, Y., Liu, X., Chen, C., & Fang, L. (2024). Preparation and Performance of Leather-Finished Plywood. Polymers, 16(18), 2587. https://doi.org/10.3390/polym16182587